Abstract

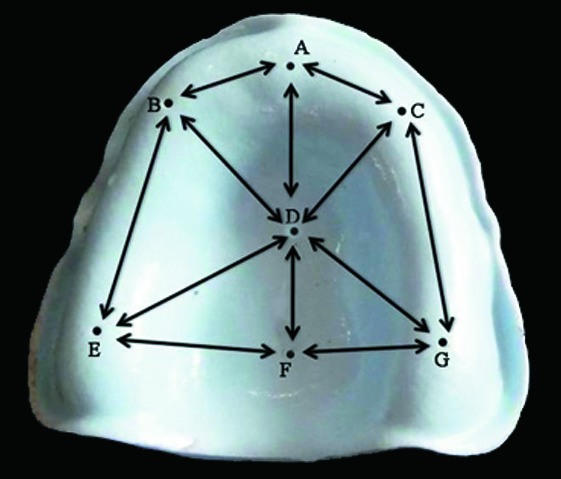

Background: The aim of this study is to evaluate the dimensional accuracy of heat polymerized PMMA denture base clamped by the conventional method and by R.S technique and cured by a different curing cycle. Materials & Methods: In this study, a total of 40 standardized maxillary record bases were fabricated with seven reference points: Point A - Incisive papilla, Point B & C - Canine region on either side, Point E & G - Midpoint of tuberosities on either side, Point F- Midpoint of the line joining the two tuberosities, Point D- Midpoint between the line joining A and F. Group A: Ten maxillary record bases were fabricated by conventional clamping method and cured by long curing cycle. Group A1: Ten maxillary record bases were fabricated by R.S tension clamping method and cured by long curing cycle. Group B: Ten maxillary record bases were fabricated by conventional clamping method and cured by short curing cycle. Group B1: Ten maxillary record bases were fabricated by R.S tension clamping method and cured by short curing cycle. The distances between the reference points i.e. A-B, A-C, A-D, D-F, B-E, C-G, E-F, F-G, B-D, D-G, CD, D-E of all three thermoplastic denture base plates were measured and recorded with the help of a travelling microscope and were used for comparison with the measured and recorded readings of processed acrylic denture bases. The data obtained was analyzed by using the One Way Analysis of Variance. Results: The overall results of the in vitro study indicate that among all the PMMA bases cured by the two clamping systems and the different curing cycle, group A` was the most dimensionally stable, followed by control group A, then followed by B` and B was most unstable. Conclusion: The study concluded that the denture bases fabricated by the R.S Technique using the long curing cycle would produce the most dimensionally stable PMMA denture bases. How to cite the article: Babu MR, Rao CS, Ahmed ST, Bharat JS, Rao NV, Vinod V. A comparative evaluation of the dimensional accuracy of heat polymerised PMMA denture base cured by different curing cycles and clamped by R S technique and conventional method – An In-vitro study. J Int Oral Health 2014;6(2):68-75.

Key words: : Long-curing cycle, R S Technique, short curing cycle

Introduction

Polymethylmethacrylate (PMMA) has excellent aesthetic properties, adequate strength, low water sorption, low solubility, lack of toxicity and could be constructed by simple moulding and processing technique and therefore PMMA has been the material of choice. 1 Lack of dimensional accuracy to a small degree of dimensional change in denture base, has been accepted as one of its prime disadvantages. This dimensional change in the denture base can be influenced by polymerization shrinkage, the resin flasking method and time–temperature correlation during the polymerization procedure. 2 , 3

During the flasking procedure, the flask is placed in traditional clamps after final pressing in the hydraulic press. This condition may lead to release of residual internal stresses from the resin dough before polymerization. This release of residual internal stress along with polymerization shrinkage, thermal contraction during flask cooling and strain accompanying stress release during deflasking may cause diminished adaptation of the PMMA base to the tissues. 4

Firtell DN et al who studied the distortion in posterior peripheral seal area related to processing temperature and concluded that the greatest effect of linear shrinkage on a maxillary denture is usually on the posterior palatal area, resulting in space between the palatal portion of the cast

and the processed denture. 5

Conventional method of PMMA resin flasking leads to the release of residual internal stresses from the acrylic resin dough before polymerization. 6

Rafael and Saide introduced an improved processing technique (New-Press Technique) with the help of R.S. tension plate clamping, which proved to decrease the magnitude of this gap. 7

Earlier studies, 7 measured the adaptability of the bases with the cast, only in the posterior palatal region and the fact being that the dimensional changes are seen throughout in the denture base, a study only in one area would not justify the results. The dimensional accuracy of the denture bases processed by different clamping methods, different curing cycles and in different areas and in different directions has not been extensively studied.

The purpose of this study was to investigate the dimensional accuracy of denture bases processed with the conventional heat-polymerizing acrylic resin and the R.S technique (Rafael and Saide) by means of different curing cycles in different areas and different directions.

Materials and Methods

The materials and methods used in this study have been described in the following order:

Heat polymerizing acrylic resin, Dental products of India Ltd.,

Metallic Edentulous maxillary cast made up of Aluminum ( Figure 3 )

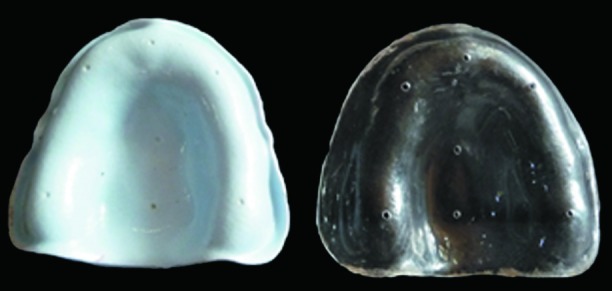

Thermoplastic sheet 5" x 5", 4mm thickness (ULTRADENT) for making standard denture base plate ( Figure 1 )

Transparent thermoplastic sheet 5" x 5", 4mm thick for making transfer template ( Figure 2 )

Petroleum jelly

Figure 3: Metallic Edentulous Mould.

Figure 1: Thermoplastic Sheet.

Figure 2: Transparent Thermoplastic Sheet.

Fabrication of Thermoplastic Denture Base Plate

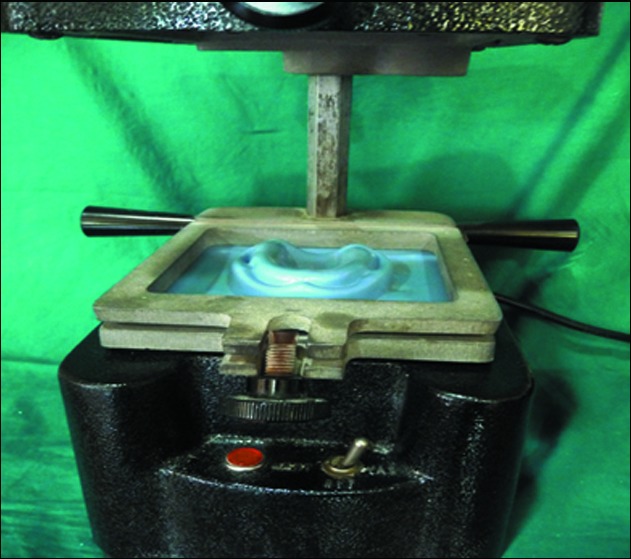

A 4 mm thick thermoplastic sheet was vacuum pressed over the metallic edentulous maxillary cast ( Figure 4 ). One

Figure 4: Vaccum pressed Thermoplastic Sheet.

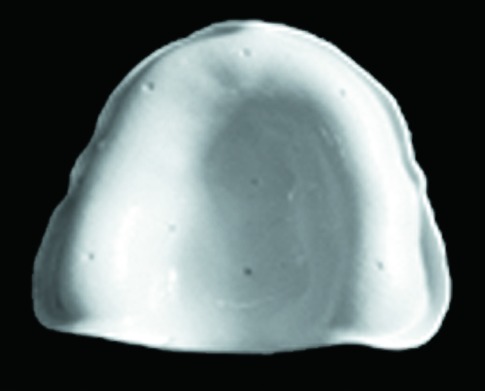

thermoplastic denture base plate (SP1) was fabricated. ( Figure 5 )

Figure 5: Thermoplastic Denture Baseplate.

Fabrication of Thermoplastic Transfer Template

A 2-mm thick transparent thermoplastic sheet was vacuum pressed over the thermoplastic denture base plate placed over the metallic edentulous maxillary cast ( Figure 6 ).

Figure 6: Transparent Transfer Plate.

Fabrication of RS Tension Plates

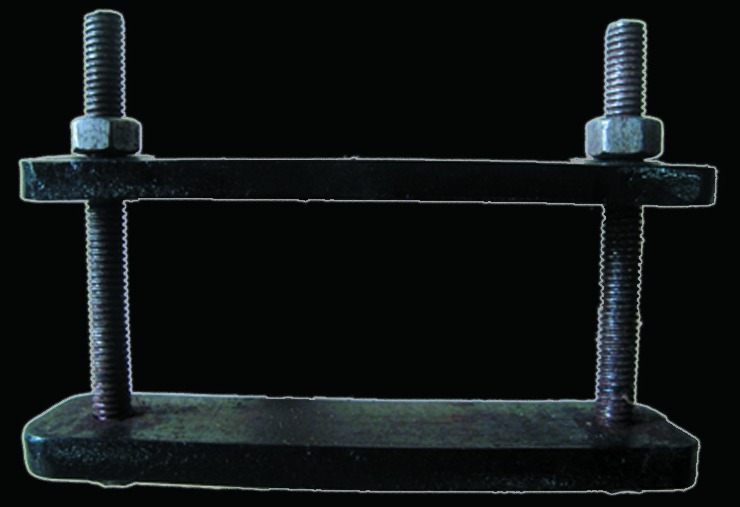

The assembly consisted of 2 iron plates, each of dimensions 150 x 40 x 8 mm with two screws (9 mm dia)

soldered into the centre of each end of one plate ( Figure 7 ), and was named the lower plate. Two corresponding holes (10 mm dia) were drilled on another plate which

Figure 7: R.S. Tension Plate Assembly.

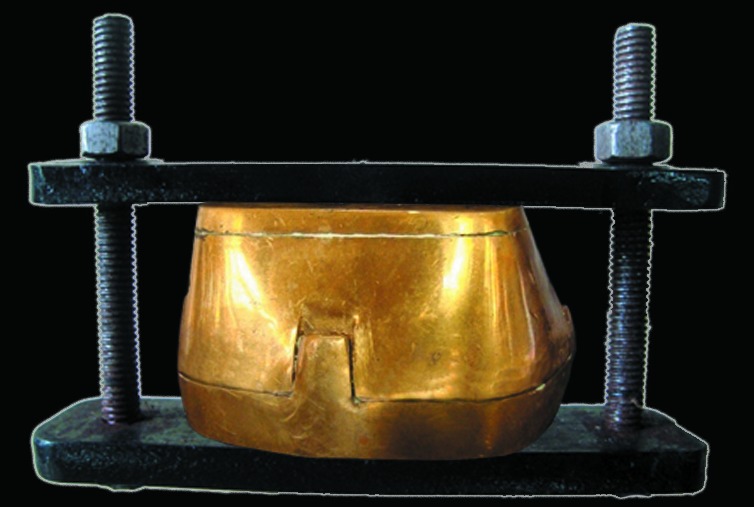

formed the upper plate. During the definitive flask closure in the hydraulic bench press, the screws of the lower plate were fit into the holes of the upper plate and after obtaining an adequate pressure of 1200lbs, the screw nuts were strongly fastened ( Figure 8 ).

Figure 8: R.S. Tension Plate Assembly with Flask.

Marking of Points on the Thermoplastic denture base plate and Transfer Template

Seven reference points were marked on the thermoplastic denture base plate SP1 ( Figure 9 ) with the help of 0.5mm tip permanent marking pen.

Figure 9: Reference Points on SP1.

Point A: Incisive papilla.

Point B & C: Canine region on either side.

Point E & G: Midpoint of tuberosity on either side.

Point F: Midpoint of the line joining the two tuberosity.

Point D: Midpoint between the line joining A and F.

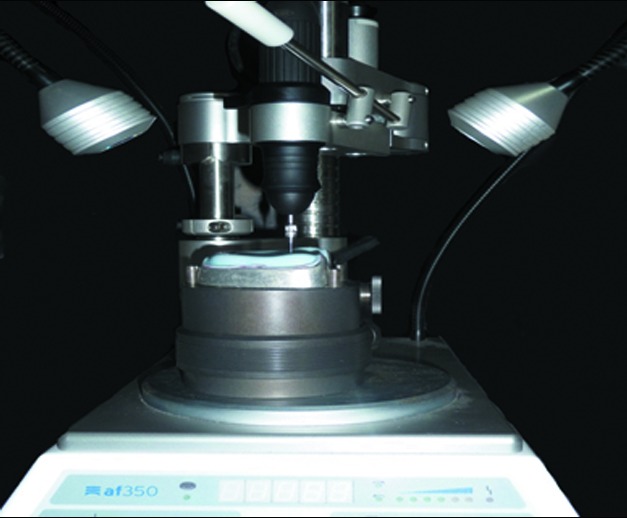

The transparent thermoplastic transfer template was placed over the marked thermoplastic denture base plate and both were together kept on the metallic maxillary edentulous cast ( Figure 10 ). The whole assembly was placed on the adjusting table of the milling machine (GIRRBACH, GERMANY) and was made parallel to the platform of the milling machine. Holes were drilled on to the transparent transfer template and the thermoplastic base plate SP1 with the help of 0.5mm round diamond point ( Figure 11 ).

Figure 10: Milling Machine.

Figure 11: Markings on SP1 & Transfer Template.

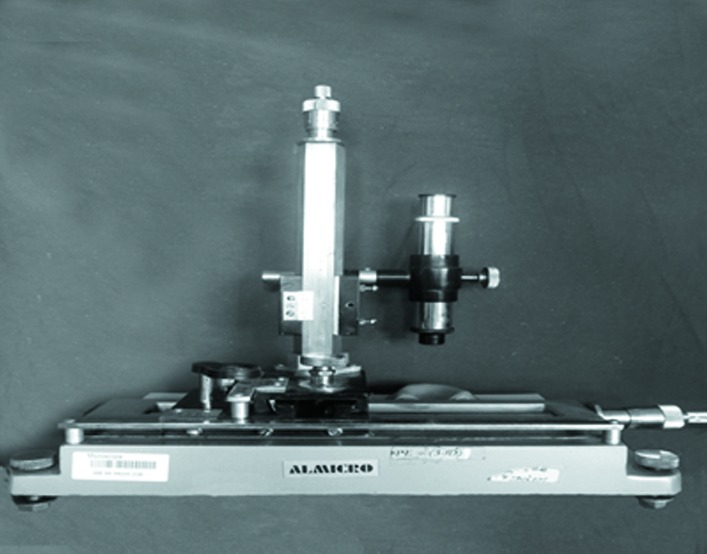

The distances between the reference points i.e. A-B, A-C, A-D, D-F, B-E, C-G, E-F, F-G, B-D, D-G, C-D, D-E of all three thermoplastic denture base plates were measured and recorded with the help of a travelling microscope and were used for comparison later with the processed acrylic denture bases.( Figure 12 )

Figure 12: Travelling Microscope.

Method of Fabrication of Acrylic Denture Bases

Group A - Ten standardized maxillary denture bases were fabricated by conventional clamping method cured by long-curing cycle (74 o C for 8 hours) 8

Group A 1 - Ten standardized maxillary record bases were fabricated by RS Tension 7 method / New-Press Technique cured by long curing cycle 7

Group B - Ten standardized maxillary denture bases were fabricated by conventional clamping method cured by short-curing cycle 8

Group B 1 - Ten standardized maxillary record bases were fabricated by RS Tension 7 method Technique cured by short curing cycle 7

Measuring the Denture Bases

The processed denture bases(A,A`) and (B,B`) were stored in distilled water for seven days and then the distances between the following points (A-B, A-C, A-D, D-F, B-E, C-G, E-F, F-G, B-D, D-G, C-D, D-E) were measured and recorded using a travelling microscope.

Statistical Analysis of the Data

All the 40 denture bases were measured, readings were recorded, and data was tabulated. These readings were compared with the standard denture base plate readings i.e. A and A 1 , B AND B 1 with SP1and analyzed with the help of ONE WAY ANOVA TEST.

Results

Table 1: Average Readings of thermoplastic base plates SP1.

| A-B | A-C | A-D | D-F | B-E | C-G | E-F | F-G | B-D | D-G | C-D | D-E | |

| SP1 | 15.40 | 15.95 | 23.00 | 15.70 | 29.10 | 29.70 | 23.55 | 24.56 | 23.13 | 29.05 | 21.86 | 27.74 |

| 15.39 | 15.93 | 22.98 | 15.68 | 29.08 | 29.68 | 23.54 | 24.59 | 23.12 | 29.04 | 21.88 | 27.75 | |

| 15.40 | 15.95 | 22.97 | 15.67 | 29.10 | 29.70 | 23.55 | 24.58 | 23.13 | 29.05 | 21.88 | 27.74 | |

| 15.38 | 15.94 | 23.00 | 15.70 | 29.06 | 29.69 | 23.53 | 24.59 | 23.14 | 29.03 | 21.87 | 27.73 | |

| 15.40 | 15.95 | 23.00 | 15.70 | 29.10 | 29.70 | 23.55 | 24.57 | 23.13 | 29.05 | 21.88 | 27.72 |

Table 2: Average Readings of processed acrylic denture bases A A1.

| A-B | A-C | A-D | D-F | B-E | C-G | E-F | F-G | B-D | D-G | C-D | D-E | ||

| A | 15.36 | 15.86 | 22.96 | 15.64 | 29.02 | 29.58 | 23.44 | 24.48 | 23.00 | 28.92 | 21.74 | 27.52 | |

| 15.36 | 15.84 | 22.96 | 15.62 | 29.00 | 29.58 | 23.43 | 24.48 | 23.08 | 28.94 | 21.74 | 27.54 | ||

| 15.36 | 15.85 | 22.98 | 15.62 | 29.00 | 29.60 | 23.44 | 24.50 | 23.08 | 28.92 | 21.73 | 27.56 | ||

| 15.38 | 15.84 | 22.96 | 15.62 | 28.98 | 29.61 | 23.44 | 24.52 | 23.10 | 28.90 | 21.72 | 27.54 | ||

| 15.36 | 15.85 | 23.00 | 15.64 | 29.00 | 29.62 | 23.44 | 24.48 | 23.10 | 28.94 | 21.74 | 27.54 | ||

| 15.36 | 15.86 | 22.96 | 15.64 | 29.02 | 29.58 | 23.44 | 24.48 | 23.00 | 28.92 | 21.74 | 27.52 | ||

| 15.36 | 15.84 | 22.96 | 15.62 | 29.00 | 29.58 | 23.43 | 24.48 | 23.08 | 28.94 | 21.74 | 27.54 | ||

| 15.36 | 15.85 | 22.98 | 15.62 | 29.00 | 29.60 | 23.44 | 24.50 | 23.08 | 28.92 | 21.73 | 27.56 | ||

| 15.38 | 15.84 | 22.96 | 15.62 | 28.98 | 29.61 | 23.44 | 24.52 | 23.10 | 28.90 | 21.72 | 27.54 | ||

| 15.36 | 15.85 | 23.00 | 15.64 | 29.00 | 29.62 | 23.44 | 24.48 | 23.10 | 28.94 | 21.74 | 27.54 | ||

| A1 | 15.36 | 15.86 | 23.00 | 15.64 | 29.00 | 29.64 | 23.44 | 24.50 | 23.10 | 28.92 | 21.74 | 27.62 | |

| 15.38 | 15.86 | 22.96 | 15.63 | 29.02 | 29.61 | 23.45 | 24.50 | 23.08 | 28.94 | 21.78 | 27.64 | ||

| 15.38 | 15.86 | 23.00 | 15.64 | 29.00 | 29.62 | 23.44 | 24.51 | 23.10 | 28.96 | 21.78 | 27.68 | ||

| 15.40 | 15.86 | 23.00 | 15.62 | 29.01 | 29.64 | 23.46 | 24.52 | 23.10 | 28.94 | 21.74 | 27.68 | ||

| 15.38 | 15.86 | 23.00 | 15.64 | 29.02 | 29.64 | 23.40 | 24.52 | 23.10 | 28.94 | 21.76 | 27.68 | ||

| 15.36 | 15.86 | 23.00 | 15.64 | 29.00 | 29.64 | 23.44 | 24.50 | 23.10 | 28.92 | 21.74 | 27.62 | ||

| 15.38 | 15.86 | 22.96 | 15.63 | 29.02 | 29.61 | 23.45 | 24.50 | 23.08 | 28.94 | 21.78 | 27.64 | ||

| 15.38 | 15.86 | 23.00 | 15.64 | 29.00 | 29.62 | 23.44 | 24.51 | 23.10 | 28.96 | 21.78 | 27.68 | ||

| 15.40 | 15.86 | 23.00 | 15.62 | 29.01 | 29.64 | 23.46 | 24.52 | 23.10 | 28.94 | 21.74 | 27.68 | ||

| 15.38 | 15.86 | 23.00 | 15.64 | 29.02 | 29.64 | 23.40 | 24.52 | 23.10 | 28.94 | 21.76 | 27.68 | ||

Table 3: Average Readings of processed acrylic denture bases B B1.

| A-B | A-C | A-D | D-F | B-E | C-G | E-F | F-G | B-D | D-G | C-D | D-E | |

| B | 15.32 | 15.90 | 22.94 | 15.58 | 28.98 | 29.55 | 23.42 | 24.44 | 23.02 | 28.91 | 21.71 | 27.46 |

| 15.34 | 15.90 | 22.94 | 15.58 | 29.00 | 29.56 | 23.41 | 24.45 | 23.05 | 28.92 | 21.68 | 27.46 | |

| 15.34 | 15.90 | 22.94 | 15.56 | 28.96 | 29.55 | 23.42 | 24.44 | 23.04 | 28.90 | 21.69 | 27.45 | |

| 15.36 | 15.92 | 22.96 | 15.58 | 28.98 | 29.54 | 23.42 | 24.46 | 23.05 | 28.92 | 21.72 | 27.48 | |

| 15.34 | 15.92 | 22.96 | 15.58 | 28.94 | 29.54 | 23.41 | 24.46 | 23.05 | 28.94 | 21.74 | 27.48 | |

| 15.32 | 15.90 | 22.94 | 15.58 | 28.98 | 29.55 | 23.42 | 24.44 | 23.02 | 28.91 | 21.71 | 27.46 | |

| 15.34 | 15.90 | 22.94 | 15.58 | 29.00 | 29.56 | 23.41 | 24.45 | 23.05 | 28.92 | 21.68 | 27.46 | |

| 15.34 | 15.90 | 22.94 | 15.56 | 28.96 | 29.55 | 23.42 | 24.44 | 23.04 | 28.90 | 21.69 | 27.45 | |

| 15.36 | 15.92 | 22.96 | 15.58 | 28.98 | 29.54 | 23.42 | 24.46 | 23.05 | 28.92 | 21.72 | 27.48 | |

| 15.34 | 15.92 | 22.96 | 15.58 | 28.94 | 29.54 | 23.41 | 24.46 | 23.05 | 28.94 | 21.74 | 27.48 | |

| B1 | 15.36 | 15.90 | 22.96 | 15.62 | 28.98 | 29.60 | 23.42 | 24.46 | 23.00 | 28.90 | 21.70 | 27.48 |

| 15.38 | 15.92 | 22.94 | 15.62 | 29.00 | 29.58 | 23.44 | 24.48 | 23.04 | 28.94 | 21.72 | 27.50 | |

| 15.36 | 15.92 | 22.94 | 15.64 | 28.98 | 29.61 | 23.45 | 24.44 | 23.04 | 28.92 | 21.72 | 27.52 | |

| 15.36 | 15.92 | 22.94 | 15.66 | 29.01 | 29.58 | 23.44 | 24.46 | 23.05 | 28.94 | 21.73 | 27.52 | |

| 15.36 | 15.92 | 22.94 | 15.64 | 28.98 | 29.60 | 23.44 | 24.46 | 23.02 | 28.92 | 21.72 | 27.48 | |

| 15.36 | 15.90 | 22.96 | 15.62 | 28.98 | 29.60 | 23.42 | 24.46 | 23.00 | 28.90 | 21.70 | 27.48 | |

| 15.38 | 15.92 | 22.94 | 15.62 | 29.00 | 29.58 | 23.44 | 24.48 | 23.04 | 28.94 | 21.72 | 27.50 | |

| 15.36 | 15.92 | 22.94 | 15.64 | 28.98 | 29.61 | 23.45 | 24.44 | 23.04 | 28.92 | 21.72 | 27.52 | |

| 15.36 | 15.92 | 22.94 | 15.66 | 29.01 | 29.58 | 23.44 | 24.46 | 23.05 | 28.94 | 21.73 | 27.52 | |

| 15.38 | 15.92 | 22.94 | 15.64 | 28.98 | 29.60 | 23.44 | 24.46 | 23.02 | 28.92 | 21.72 | 27.48 | |

Discussion

PMMA resins have been used for more than half a century because of its excellent aesthetics and physical properties. The ease with which polymethylmethacrylate resins are processed has made them the material of choice in complete denture fabrication.

When PMMA resin is mixed at recommended polymer :monomer ratio; density of the mass changes from 0.94g/cm 3 to 1.19g/cm 3 .This change in density results in volumetric shrinkage of 7% and a corresponding linear shrinkage of 2%. The greater the linear shrinkage the greater the discrepancy observed in the initial fit of the denture. In a study Dixon et al 9 reviewed the properties of denture base polymers and concluded that linear shrinkage generally, is observed to be less than 1%.

Conventional method of PMMA resin flasking may lead to the release of residual internal stresses from the acrylic resin dough before polymerization. The release of residual internal stress along with polymerization shrinkage, thermal contraction during flask cooling and strain

accompanying stress release during deflasking may cause diminished adaptation of the denture to the tissues. 6

Rafael and Saide introduced the New Press technique that decreased the magnitude of the gap between the denture base and the tissue surface. This system inhibited the premature release of the residual internal stresses from the acrylic resin dough before polymerization shrinkage. 7

Therefore, polymerization shrinkage, flask clamping method and time temperature correlation play a critical role in decreasing the probability of unfavourable dimensional changes in acrylic based denture base resins. This study was done to evaluate the dimensional accuracy of heat polymerized acrylic resin denture bases clamped by conventional method and by New Press technique and

cured by long curing cycle so as to assess the curing cycle and the clamping best suited to achieve optimum adaptation of the denture base to the soft tissue.

In this study, a total of 40 standardized maxillary record bases were fabricated with seven reference points. Twenty maxillary record bases were fabricated by conventional clamping method, out of which 10 Acrylic denture bases were cured by long curing cycle (Group A) by

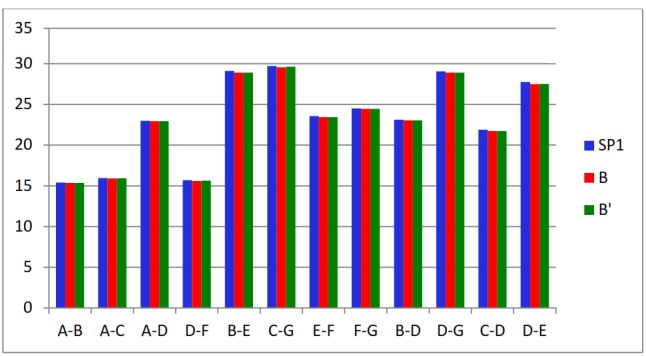

conventional clamping technique and 10 Acrylic denture bases were cured by long curing cycle(Group A') by New Press method.8Twenty maxillary record bases were fabricated by conventional clamping method, out of which 10 Acrylic denture bases were cured by short curing cycle (Group B) ( Graph 2 ) by conventional clamping technique and 10 Acrylic denture bases were cured by Short curing cycle (Group B') by New Press method. 8

Graph 2: Comparison of SP1, B, B1.

The distances between the reference points i.e. A-B, A-C, A-D, D-F, B-E, C-G, E-F, F-G, B-D, D-G, C-D, D-E of all three thermoplastic denture base plates were measured and recorded with the help of travelling microscope and were used for comparison with the measured and recorded readings of processed acrylic denture bases. The data obtained was analyzed by using the One Way Analysis of Variance.

The comparative results of thermoplastic denture base plate SP1(control) and denture bases cured by long curing cycle and short curing cycle using conventional method and New press method i.e. A and A 1 ,B and B 1 respectively, using One Way ANOVA showed that the p value (<0.0005) was highly significant in all the 12 distances i.e. A-B, A-C, A-D,D-F, B-E, C-G, E-F, F-G, B-D, D-G, C-D, D-E between the two groups. It was concluded that the denture bases fabricated by New Press method were dimensionally more stable when compared to those fabricated by conventional method. This is in accordance with the previous study done by Consani RLX Domitti SS, Consani S et al 6 who studied the effect of New Press system on the dimensional stability of denture bases. They suggested that New Press system is able to produce a more accurate denture base, minimizing the inaccuracies associated with the conventional clamping technique.

The clamping method (New Press / conventional method) had the least impact on the dimensions of the denture bases cured by long curing cycle with only 3 distances showing significant changes.

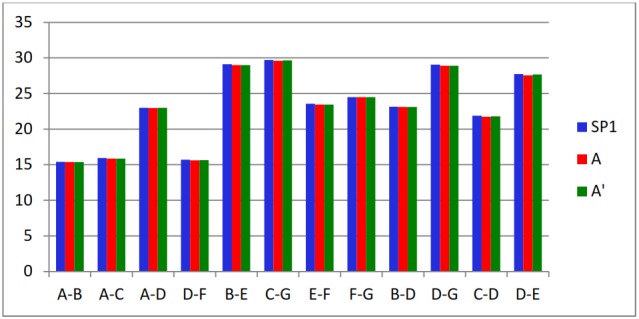

The mean value of the total of all the distances between the points, of standard denture base plate SP1 was 23.219mm.When compared to this, the similar mean value of Group A 1 was 23.159mm ( Graph 1 ) which shows that there was an overall shrinkage of 0.060 mm. This was the least among the groups, proving that the denture bases fabricated by the New Press method and long curing cycle demonstrated least shrinkage. The Group A showed a mean value of 23.134, which showed 0.085mm shrinkage. This shows that the denture bases fabricated by long curing cycle were the most dimensionally stable followed by the denture bases fabricated by short curing cycle and the denture bases fabricated by fast curing cycle being the least stable. This is because the long curing cycle is a wellcontrolled process which prevents the effects of uncontrolled rise in temperature, boiling of the monomer, denture base porosity and associated polymerization shrinkage, when compared to the other cycle. This is in accordance with the study done by Honorez P et al 10 who studied the effects of three processing cycles on some physical and chemical properties of heat cure acrylic resins and concluded that long curing cycle had resulted in low residual monomer content thereby indicating low polymerization shrinkage when compared to other two curing cycles.

Graph 1: Comparison of SP1, A, A1.

On overall analysis of data it was concluded that distance A-D(anterior slope of the palate) was the most dimensionally stable distance and distances E-F and F-G (posterior palatal area) were least dimensionally stable distances in all the groups. The reason for A-D being most

dimensionally stable could be the presence of rugae which would impede the linear shrinkage due to better adaptability of the acrylic denture base to the underlying cast surface and the reason for E-F and F-G being least dimensionally stable is the large unsupported posterior palatal area. This is in accordance with the previous study done by Firtell D Net al 5 who studied the distortion in posterior peripheral seal area related to processing temperature and concluded that the greatest effect of linear shrinkage on a maxillary denture is usually on the posterior palatal area, resulting in space between the palatal portion of the cast and the processed denture.

It can be concluded that the denture bases fabricated by the New Press method using the long curing cycle would produce the most dimensionally stable denture bases.

Limitations of the study

The present study has certain limitations in spite of following a standard and uniform protocol for preparing, curing and finishing of all test specimens, which are enlisted below.

The homogeneity of mix, presence of internal porosity and the release of stresses during finishing procedures could not be controlled.

The measurements were made with a travelling microscope manually; hence there may be errors while recording the distances.

Conclusion

Within the limits of the present study and on the basis of results obtained, it may be concluded that:

In all the fabricated denture bases, the distance E-F and F-G i.e. the posterior palatal seal area was the least dimensionally stable region.

In all the fabricated denture bases, the distance A-D i.e. the anterior slope of the palate was the most dimensionally stable region.

The denture bases fabricated by New Press method and long curing cycle were dimensionally more stable when compared to those fabricated by conventional method.

Footnotes

Source of Support: Nil

Conflict of Interest: None

Contributor Information

Mandava Ramesh Babu, Department of Conservative dentistry & Endodontics, Drs. Sudha & Nageswara Rao Siddhartha Institute of Dental Sciences, Chinnoutupalli, Andhra Pradesh, India.

C Satyanageswar Rao, Department of Prosthodontics, Hi-Tech Dental College, Bhubaneswar, Orissa, India.

Syed Tauqheer Ahmed, Department of Prosthodontics, Oxford Dental College & Hospital, Bangalore, Karnataka, India.

J S V Bharat, Department of Prosthodontics, Lenora Institute of Dental Sciences, Rajanagaram, Rajamundry, Andhra Pradesh, India.

N Venugopal Rao, Department of Prosthodontics, Career Post Graduate Institute of Dental Sciences & Hospital, Lucknow, Uttar Pradesh, India.

V Vinod, Department of Prosthodontics, Oxford Dental College & Hospital, Bangalore, Karnataka, India.

References

- 1.FA Rueggeberg. From vulcanite to vinyl, a history of resins in restorative dentistry. J Prosthet Dent. 2002;87:364–379. doi: 10.1067/mpr.2002.123400. [DOI] [PubMed] [Google Scholar]

- 2.FA Peyton. History of resins in dentistry. Dent Clin North Am. 1975;19:211–222. [PubMed] [Google Scholar]

- 3.RG Craig, JM Powers. Restorative Dental Materials, 11th edn. St. Louis, USA: Mosby CV Co. 2002:636–689. [Google Scholar]

- 4.SK Lechner, GA Thomas. Changes caused by processing complete denture. J Prosthet Dent. 1951;1:551–559. [Google Scholar]

- 5.DN Firtell, AJ Green, JM Elahi. Posterior peripheral seal distortion related to processing temperature. J Prosthet Dent. 1981;45(6):598–601. doi: 10.1016/0022-3913(81)90418-2. [DOI] [PubMed] [Google Scholar]

- 6.RL Consani, SS Domitti, S Consani. Effect of a new tension system, used in acrylic resin flasking, on the dimensional stability of denture bases. J Prosthet Dent. 2002;88(3):285–289. doi: 10.1067/mpr.2002.128447. [DOI] [PubMed] [Google Scholar]

- 7.V Jerelimov, RG Jagger, PJ Milward. Effect of curing cycle on acrylic denture base glass transition temperature. J Dent. 1991;19(4):245–248. doi: 10.1016/0300-5712(91)90128-l. [DOI] [PubMed] [Google Scholar]

- 8.ET Mainieri, ME Boone, RH Potter. Tooth movement and dimensional change of denture base materials using two investment methods. 1980;J Prosthet Dent44(4):368–373. doi: 10.1016/0022-3913(80)90091-8. [DOI] [PubMed] [Google Scholar]

- 9.DL Dixon, LC Breeding, KG Ekstrand. Linear dimensional variability of three denture base resins after processing and in water storage. J Prosthet Dent. 1992;68(1):196–200. doi: 10.1016/0022-3913(92)90304-s. [DOI] [PubMed] [Google Scholar]

- 10.P Honorez, A Catalan, U Anganes. The effect of three processing cycles on some physical and chemical properties of heat-cured acrylic resins. J Prosthet Dent. 1989;61(4):510–517. doi: 10.1016/0022-3913(89)90025-5. [DOI] [PubMed] [Google Scholar]