Abstract

We have added force and displacement measurement capabilities in the transmission electron microscope (TEM) for in situ quantitative tensile experimentation on nanoscale specimens. Employing the technique, we measured the stress–strain response of several nanoscale free-standing aluminum and gold films subjected to several loading and unloading cycles. We observed low elastic modulus, nonlinear elasticity, lack of work hardening, and macroscopically brittle nature in these metals when their average grain size is 50 nm or less. Direct in situ TEM observation of the absence of dislocations in these films even at high stresses points to a grain-boundary-based mechanism as a dominant contributing factor in nanoscale metal deformation. When grain size is larger, the same metals regain their macroscopic behavior. Addition of quantitative capability makes the TEM a versatile tool for new fundamental investigations on materials and structures at the nanoscale.

Nanomechanical behavior of materials has gained considerable attention because of the ever-shrinking dimensions of thin-film materials in microelectronics, data storage, and microelectromechanical sensors/actuators, and also the advancements in bulk nanostructured materials. Mechanical properties of materials are influenced by their length-scales. For example, yield stress of polycrystalline metals increases with a decrease in grain size [Hall–Petch behavior (1, 2)], and strain-gradient-dependent strengthening (3–6) occurs when the specimen size is reduced to the micrometer scale. Dislocations have been attributed to cause both of these behaviors as long as the grain size or the thickness is >100 nm. At smaller length-scales, strain-gradient-dependent strengthening disappears (7) and reverse Hall–Petch behavior is observed (8–13). Another less understood size effect observed at nanoscale is the reduction of Young's modulus, which has been attributed to specimen density (13) and grain boundary compliance (14, 15). Models that attempt to explain the nanoscale size effect are of two basic types: (i) models describing nanocrystalline materials as two-phase composites with grain interiors and boundaries, where the mechanical properties are averaged by simple “rule of mixtures” (16, 17); and (ii) models considering dislocation motion (10, 18, 19), grain boundary sliding (20, 21), and diffusion (12, 22) as competing deformation mechanisms. Although the literature has compelling evidence of these size-effects, the underlying deformation mechanisms are not yet well understood (23).

Experimental Methods

Direct experimental observations of the deformation mechanisms mentioned above while the materials behavior is measured quantitatively is difficult at the nanoscale even with the recent novel existing approaches (24–28). We overcome the difficulty by developing microinstrumentation that combines quantitative tensile testing of thin films with the qualitative capabilities of the transmission electron microscope (TEM) so that one can simultaneously measure the stress–strain states in solids and observe the deformation mechanisms during materials testing. Although the TEM has so far been a major analytical instrument in materials research (29), nonuniformity in specimen cross-section and space restrictions for the accommodation of force and displacement sensors have limited its application to qualitative in situ straining without simultaneous measurement of stress–strain response (30–32). Our experimental setup consists of a free-standing tensile sample with uniform width and thickness, cofabricated with a microtensile stage with force and displacement sensors. They are made by microelectromechanical systems (MEMS) fabrication technology based on lithography. Cofabrication and the specific flexure design of the stage ensure alignment between the loading and the specimen directions, and minimize the setup size.

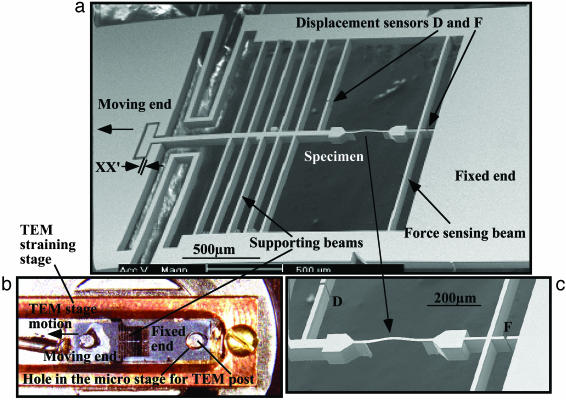

Fig. 1 shows the microtensile test stage with a 100-nm-thick aluminum specimen bonded to a force sensor beam at one end, and to a set of supporting beams at the other end. The beams are made of single-crystal silicon (27). Quasistatic displacements are imposed on one end of the stage and are then transmitted to the force sensor beam through the free-standing specimen. The displacement sensors (in the form of two marker gaps, F and D) read the specimen elongation. The force on the specimen is given by the spring constant and the displacement (marker F) of the force sensor beam. The spring constant is calibrated with a nanoindenter after the tensile experiment is completed. The supporting flexural beam assembly prevents misalignment of the specimen. A finite element analysis of the stage shows that it suppresses any misalignment error in loading by six orders of magnitude (27). The clearance (XX′) between the fixed and moving parts allows spring-loading of the stage on a TEM straining stage and prevents any prestress on the specimen.

Fig. 1.

(a) Scanning electron micrograph of the microstage showing the freestanding aluminum thin-film specimen being attached to the force sensor beam at one end and to supporting beams at the other. Markers D and F, read displacements at both ends of the specimen. The left end of the microstage is pulled by a piezo actuator of a TEM straining stage. Deflection of the sensor beam (read by marker F), multiplied by its spring constant, gives the force on the specimen. The difference between the two markers' (D and F) gaps gives the elongation of the specimen. The gap XX′ prevents accidental straining of the sample during mounting of the microstage on to the TEM straining stage. The TEM straining stage has to move and deform the microstage to close the gap XX′ before loading the sample. (b) Microtensile test stage on a TEM straining stage. (c) Zoomed view of the specimen and the two displacement sensors D and F. There is no substrate under the specimen so that the TEM beam can go through the sample for microstructural inspection.

Results and Discussions

All of the films tested in this paper are dc sputtered [1 × 10-6 torr (1 torr = 133 Pa) base pressure, 2.7 mtorr Argon pressure, 300 W, room temperature], 99.99% pure, and deposited on bare silicon substrate. The films are subjected to compressive residual stress. Hence, the free-standing specimen buckles (Fig. 1) and relieves most of the stress. Because the critical buckling load is small, the compressive stress in the specimen after buckling is negligible compared to the tensile stress applied during testing.

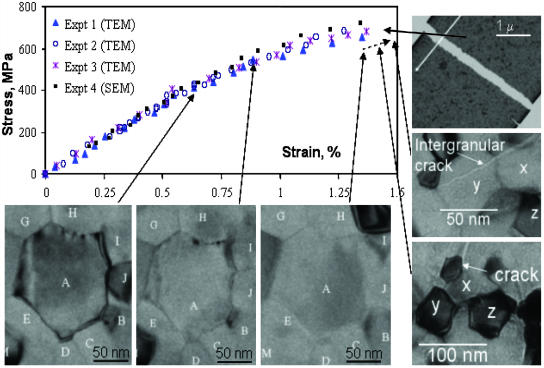

The microinstrument is first used to apply tensile stress on 100-nm-thick free-standing aluminum films in situ in a Philips CM200 TEM at 160 kV. The average grain size of the films was 50 nm. The experiments were performed quasistatically, and microstructures were visually monitored continually with digital image acquisition. TEM images were recorded as single frames after each increment of strain of the sample. No video camera was used for recording. Fig. 2 shows the stress–strain diagram for three specimens tested in TEM and one in scanning electron microscope to highlight the consistency of the experimental results. Also shown are TEM images of a sample at different levels of stress and strain, and during failure. The top right TEM image shows the film after failure with a crack normal to the loading direction. Elastic modulus for the four samples is found to be 68 GPa, which is close to the bulk value of 70 GPa. The films had 〈111〉 texture.

Fig. 2.

Quantitative, in situ TEM test results for 100-nm-thick freestanding aluminum films. Three TEM test results are shown along with a scanning electron microscope test result to demonstrate experimental consistency. (Insets) Microstructures corresponding to the different stress–strain states for experiment 1 (triangle data markers). The rightmost Insets show crack growth through the grains and between the grains. The top right Inset shows the film after fracture.

The TEM images show neither any dislocation activity within the grains nor any generation even at high stress. However, one cannot rule out the possibility that dislocations might have moved from one grain boundary to another through small grains at high speeds and were not captured in the recorded frames. Gradual, and not sudden, change of contrast was observed in some grains (grain A, Fig. 2) over many strain increments, perhaps induced by grain rotation and or global tilting of the film (30, 31). The specimens behaved as macroscopically brittle and failed at ≈680 MPa with a crack initiating from the edge and advancing both through the grain boundaries and grain interiors. No dislocation activities were observed ahead of the crack tip (TEM image in Fig. 2). It is worth noting that ex situ TEM studies of 200-nm-thick aluminum films reveal significant dislocation activities within grains of dimension 150 nm and higher, whereas no such activity was observed in films with thickness of 100 nm and lower and with average grain size of 50 nm and lower. No void or intergranular crack was observed in any of the films except during failure. Earlier in situ straining experiments (32) in TEM on 10-nm-grained gold films also show lack of dislocation activity and negligible change in grain size, although grain rotation was observed, and deformation was attributed to the grain boundary sliding and rotation. Note that in the study described in ref. 32, applied stress on the specimen was not measured, and local strain was estimated from TEM images. In the work described in ref. 33, specimens of nanocrystalline n-Ni from the tip of a microhardness indent were studied under TEM and no dislocations were found. Here the average grain size was 28 nm.

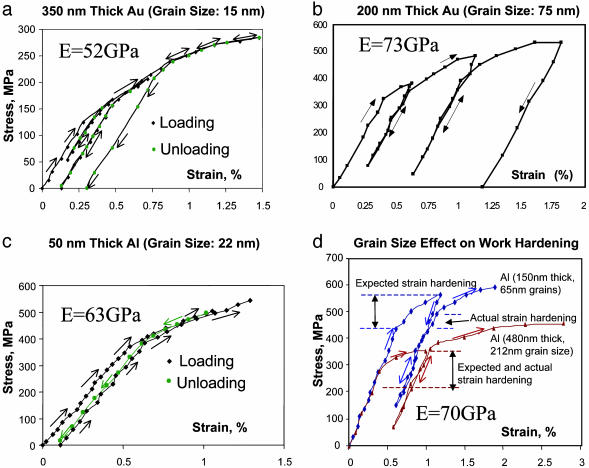

To reveal the relative importance of grain size and thickness on the mechanical behavior of thin metal films, ideally, one needs to test such films with fixed thickness but with varying average grain size, and with fixed average grain size but with varying thickness. Although it is difficult, if not impossible, to sputter deposit thin metal films with such control on grain size and thickness, we deposit gold films with small thickness (200 nm) and large (75 nm) grains, and with large thickness (350 nm) and small (15 nm) grains. Both the films had 〈111〉 texture. We tested these films under uniaxial loading with the microinstrument. We find that the Young's modulus of the small-grained (15 nm) film is 52 GPa, whereas the modulus for the larger (75 nm)-grained sample is 73 GPa, closer to the modulus F: (80 GPa under isostrain condition, 87 GPa under isostress condition) of bulk polycrystalline gold with 〈111〉 texture. The small-grained sample with larger thickness shows nonlinear elasticity upon unloading with small permanent deformation (Fig. 3a), whereas the larger-grained sample with smaller thickness showed macroscopic plasticity (Fig. 3b). These observations suggest that grain size is the critical dimension (8) that determines the mechanical behavior of metals, at least when the grains are much smaller (2–3 times) than the film thickness, unless the thickness is so small that both the surface energy and its strain dependence play a major role in determining the overall stress–strain response (34).

Fig. 3.

(a) Low elastic modulus and nonlinear elastic response with small plastic deformation in small-grained but thick gold film. (b) As the grain size of gold is increased while the film thickness is decreased, bulk gold behavior is approached (elastic modulus of bulk gold with 〈111〉 texture is 80–87 GPa, depending on isostrain and isostress condition). (c) Low elastic modulus and nonlinear elastic response in small-grained Al. (d) Reduced permanent strain hardening in 65-nm-grain-sized aluminum (150-nm-thick film), but macroscopic strain hardening in 212-nm-grained-sized (480-nm-thick film) samples. Resolutions in stress measurements are as follows: 2.4 MPa for 350-nm-thick Au, 5 MPa for 50-nm-thick Al, 9 MPa for 150-nm-thick Al and 200-nm-thick Au, and 8 MPa for 485-nm-thick Al. Resolution in strain measurement for all of the tests is 0.05%.

To explore the size effect in aluminum, we measure the stress–strain response of several aluminum specimens with thicknesses 50, 150, and 480 nm, with the corresponding average grain sizes of 22, 65, and 212 nm, respectively (Fig. 3 c and d). All of the specimens had 〈111〉 texture. We find that the elastic modulus of the smallest-grained (22 nm) sample is 63 GPa, whereas it is 70 GPa, the bulk value, for the larger-grained samples. Note that 50-nm-grained Al (Fig. 2) has an elastic modulus of 68 GPa. Thus, elastic modulus of gold decreases much more with grain size than it does for aluminum. The results for aluminum and gold films suggest that at small grain size (50 nm or smaller for Al) (i) elastic modulus decreases with decreasing grain size. (ii) Upon unloading, the metals behave nearly as nonlinear elastic, i.e., they almost follow the loading stress–strain path, with a small permanent deformation. Note that this nonlinear elastic response occurs at much smaller strains than that expected from single-crystal whiskers [nonlinearity starts at ≈3% strain (35)]. (iii) Upon reloading, metals show negligible strain hardening, i.e., the increase of “yield stress” (stress at the onset of nonlinearity) is negligible compared to the corresponding increase for macroscopic metals. As grain size is increased [even when thickness is decreased (Fig. 3b)], metals regain macroscopic elastic modulus, plastic behavior with large permanent deformation, and strain hardening.

It is suggested (36–38) that nanocrystalline materials exhibit anelastic relaxation behavior at low temperatures, which may result in the lower values of the Young's modulus (Enanocrystal = σ/(εelastic + εanelastic) < Ebulk = σ/εelastic). To explore anelasticity as a possible mechanism for reduced modulus of nanograined samples, we carried out uniaxial tension experiments on aluminum films with average grain size of 60 nm at varying temperatures (up to 160°C) and strain rates. We find that the elastic modulus is consistent with that found in scanning electron microscopy and TEM, and that there is negligible dependence of modulus on temperature and strain rate as long as the temperature is <80°C and strains are small. Thus, anelasticity does not appear to be a dominant mechanism for reducing elastic modulus at room temperatures.

We believe that a single mechanism can explain both reduced Young's modulus and nonlinear elasticity of small nanograined sputter deposited metals at room temperatures as follows: grain boundary region is elastically softer than grain interior, and it becomes increasingly softer with increasing tensile strain.

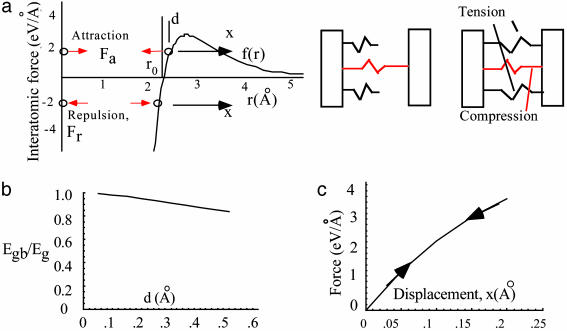

At small grain size, grain boundary regions occupy a significant part of the bulk (39–42). The structure of the grain boundary region is not yet fully understood. Direct experimental observation of grain boundary by using a high-resolution TEM (HRTEM) are available for limited cases in the literature. Krakow et al. (43) studied  tilt boundary prepared from gold bicrystals and found that the lattice spacing on either side of the interfacial plane is dilated by 45%, and the dilation is totally localized in a slab of three atomic planes occupying ≈0.3 nm. A similar conclusion was drawn from a theoretical study on grain boundary (44). Siegel and Thomas (40) studied grain boundary structure of cluster consolidated nanophase Pd by using a HRTEM. They found that the lattice fringes end abruptly near the grain boundary, and any disorder of atoms in the grain boundary, if present, is limited to within 0.4 nm, again consistent with ref. 44. The authors concluded that the grain boundaries of the nanophase metal are not different from large-grained boundaries, i.e., the boundaries are not influenced by the close proximity of other boundaries. However, HRTEM studies on electrodeposited nanocrystalline Ni–1 wt % P (45), and electrodeposited palladium and titanium films (46) found evidence of amorphous region at some boundaries and at triple junctions of nanograins. Although there are some controversies on the structure of grain boundaries in the literature, the following are generally accepted: grain boundaries, irrespective of the grain size, host various defects such as dislocations, partial dislocations, steps, disordered regions [may appear at a regular spacing along the interface (41)], lattice dilatations, and distortions. Such defects allow for accommodation of the misfit between the two meeting grains (41). The width of the grain boundary region and its structure depends on various factors such as the orientations of the adjoining grains and the processing history of the metal. The atoms within the grain boundary regions have higher energies than those within the grains, but the boundary atoms collectively maintain force equilibrium. Thus, some atom pairs have interatomic spacing larger than equilibrium spacing. These atoms attract one another, resulting in a tensile region. Some other pairs have spacing smaller than the equilibrium spacing. These atoms repel each other giving rise to a compressive region. Such tension–compression ensures overall equilibrium. To illustrate, consider the two pairs of aluminum atoms in Fig. 4a. The spacing for one pair is r0 + d, where r0 is the equilibrium distance between aluminum atoms and d > 0 is the measure of deviation from the granular lattice spacing. These atoms are subjected to attractive force, Fa, which can be computed from the interatomic potential of aluminum (47). The spacing between the atoms of the second pair is r0 - dr, where dr = dr(d) is such that the repulsive force between the atoms Fr = Fa, and the arrangement is in equilibrium. The arrangement is analogous to a three spring system with two short and one long spring, put together at self equilibrium between two plates. The shorter springs are in tension and the longer one is in compression, but the spring-plate system is in equilibrium. The stiffness or the spring constant of the two atomic pair system of the grain boundary can be compared to that of their granular counterpart with interatomic spacing of r0 as Egb/Eg = (f′(r0 + d) + f′(r0 - dc))/2f′(r0), where f(r) is the interatomic force for aluminum (47) and the prime denotes derivative with respect to interatomic distance. The ratio is thus a measure of the modulus, Egb, of the grain boundary region with respect to its granular counterpart, Eg (Fig. 4b), and is found to be less than unity for any d > 0 for aluminum. Thus, grain boundary region at self equilibrium must be more compliant than its granular counterpart, because the loss of stiffness due to the pair with atomic spacing r0 + d is not fully compensated by the increase of stiffness due to the pair with spacing r0 - dc. It is thus not surprising that amorphous materials have consistently lower elastic modulus than their crystalline counterpart. The actual modulus of the grain boundary will depend on the number of atoms under attraction and repulsion and their distribution, which depends on the processing of the film. It is likely that there are more atoms with r > r0 than there are with r < r0, because the attractive force due to many atoms can be equilibrated by only a few in compression because of the steeper interatomic force distance relation in the r < r0 region. The net effect is the higher compliance of the grain boundary than that predicted by the two pair system. Note that the two atomic pair system is different from the three spring analogue if the springs are linear, in which case the combined spring constant of the system is the sum of the three individual constants, i.e., the system spring constant does not change because of residual stress in the linear springs.

tilt boundary prepared from gold bicrystals and found that the lattice spacing on either side of the interfacial plane is dilated by 45%, and the dilation is totally localized in a slab of three atomic planes occupying ≈0.3 nm. A similar conclusion was drawn from a theoretical study on grain boundary (44). Siegel and Thomas (40) studied grain boundary structure of cluster consolidated nanophase Pd by using a HRTEM. They found that the lattice fringes end abruptly near the grain boundary, and any disorder of atoms in the grain boundary, if present, is limited to within 0.4 nm, again consistent with ref. 44. The authors concluded that the grain boundaries of the nanophase metal are not different from large-grained boundaries, i.e., the boundaries are not influenced by the close proximity of other boundaries. However, HRTEM studies on electrodeposited nanocrystalline Ni–1 wt % P (45), and electrodeposited palladium and titanium films (46) found evidence of amorphous region at some boundaries and at triple junctions of nanograins. Although there are some controversies on the structure of grain boundaries in the literature, the following are generally accepted: grain boundaries, irrespective of the grain size, host various defects such as dislocations, partial dislocations, steps, disordered regions [may appear at a regular spacing along the interface (41)], lattice dilatations, and distortions. Such defects allow for accommodation of the misfit between the two meeting grains (41). The width of the grain boundary region and its structure depends on various factors such as the orientations of the adjoining grains and the processing history of the metal. The atoms within the grain boundary regions have higher energies than those within the grains, but the boundary atoms collectively maintain force equilibrium. Thus, some atom pairs have interatomic spacing larger than equilibrium spacing. These atoms attract one another, resulting in a tensile region. Some other pairs have spacing smaller than the equilibrium spacing. These atoms repel each other giving rise to a compressive region. Such tension–compression ensures overall equilibrium. To illustrate, consider the two pairs of aluminum atoms in Fig. 4a. The spacing for one pair is r0 + d, where r0 is the equilibrium distance between aluminum atoms and d > 0 is the measure of deviation from the granular lattice spacing. These atoms are subjected to attractive force, Fa, which can be computed from the interatomic potential of aluminum (47). The spacing between the atoms of the second pair is r0 - dr, where dr = dr(d) is such that the repulsive force between the atoms Fr = Fa, and the arrangement is in equilibrium. The arrangement is analogous to a three spring system with two short and one long spring, put together at self equilibrium between two plates. The shorter springs are in tension and the longer one is in compression, but the spring-plate system is in equilibrium. The stiffness or the spring constant of the two atomic pair system of the grain boundary can be compared to that of their granular counterpart with interatomic spacing of r0 as Egb/Eg = (f′(r0 + d) + f′(r0 - dc))/2f′(r0), where f(r) is the interatomic force for aluminum (47) and the prime denotes derivative with respect to interatomic distance. The ratio is thus a measure of the modulus, Egb, of the grain boundary region with respect to its granular counterpart, Eg (Fig. 4b), and is found to be less than unity for any d > 0 for aluminum. Thus, grain boundary region at self equilibrium must be more compliant than its granular counterpart, because the loss of stiffness due to the pair with atomic spacing r0 + d is not fully compensated by the increase of stiffness due to the pair with spacing r0 - dc. It is thus not surprising that amorphous materials have consistently lower elastic modulus than their crystalline counterpart. The actual modulus of the grain boundary will depend on the number of atoms under attraction and repulsion and their distribution, which depends on the processing of the film. It is likely that there are more atoms with r > r0 than there are with r < r0, because the attractive force due to many atoms can be equilibrated by only a few in compression because of the steeper interatomic force distance relation in the r < r0 region. The net effect is the higher compliance of the grain boundary than that predicted by the two pair system. Note that the two atomic pair system is different from the three spring analogue if the springs are linear, in which case the combined spring constant of the system is the sum of the three individual constants, i.e., the system spring constant does not change because of residual stress in the linear springs.

Fig. 4.

(a) Interatomic force between two aluminum atoms from Morse potential (47). Two pairs of atoms representing grain boundary are shown. The atoms of one pair are farther apart from equilibrium distance by d, a measure of distortion from the crystalline arrangement. These atoms attract each by a force Fa. The atoms of the other pair are closer to one another than the equilibrium distance such that they repel each other by a force Fr = Fa. The atomic pair system is analogous to a three-spring system brought together to equilibrium by two free plates. Here, the short springs are in tension and the longer spring is in compression. (b) The combined spring constant of the two atomic pair system compared to a system where the atoms of both the pairs are at an equilibrium distance, r0, apart is shown as a function of d. Their ratio is a measure of the elastic modulus of the grain boundary compared to grain interior, Egb/Eg. (c) The net force needed to increase the gap between the atoms of both the pairs by a distance x is shown. The system behaves as a softening nonlinear spring.

If the two atomic pair system is now strained under tension (along x, Fig. 4a), the interatomic spacing increases for both the pairs and the right atoms of the pairs ride along the force–distance curve, both with decreasing slopes, although the slope decreases faster for the atoms initially under attraction. Consequently, the system behaves as a softening nonlinear spring that, upon unloading, returns along the loading path. Thus, with increasing tensile strain, the compliance of the grain boundary increases, the boundary shares an increasingly larger part of the total strain compared to its granular counterpart, and the metal shows increasing softening. Grain boundary may accommodate the large strain by various processes such as rotation (32), widening, and shearing. Upon unloading, both the grain boundary region and the grains follow the loading path, and the metal behaves as nonlinear elastic. Thus, for metals with nanograins where grain boundaries are abundant but dislocations are rare (32, 33, 41, 42) even at high stresses as evidenced in our in situ TEM studies, deformation mechanism is primarily contributed by the boundaries. At small strains, they contribute to reduced elastic modulus of the metal. With increasing strain, they behave as softening springs and the metal behaves as a nonlinear elastic material. The metal is macroscopically brittle with high fracture stress and low ductility. The small plastic permanent deformation is probably contributed by “secondary” irreversible mechanisms such as dislocation slip in a few larger grains in the polycrystalline metal, and by grain boundary sliding.

When the average grain size is increased, many grains begin to accommodate dislocations that allow higher ductility and plastic deformation, but as observed in the 65-nm-grain-sized aluminum sample in Fig. 3d (film thickness 150 nm), there may be reduced permanent strain hardening than that expected for large-grained metals. Here, the dislocation density is low, and dislocation forests, which cause permanent strain hardening in bulk metal samples, may not yet exist. However, for larger grains, higher dislocation density (Fig. 3d) results in the typical qualitative behavior of bulk aluminum such as strain hardening as observed in a 480-nm-thick aluminum sample with a 212-nm average grain size. There is thus a transition of the deformation mechanism: at small grain size, dislocation slip ceases to operate and deformation is contributed by grain boundary mechanisms, whereas as grain size increases, dislocation dynamics overwhelms the grain boundary mechanisms. At the transition size, where there are not enough grain boundaries to assist in deformation but the grain size is small enough so that dislocation dynamics is energetically unfavorable, metal may show highest strength (42). For aluminum, this critical grain size seems to be ≈50 nm from our experimental observations, close to 20–30 nm predicted by theory (42). It is interesting to note that aluminum exhibits strain-gradient-induced strengthening when grain size is >50 nm but ceases to show the gradient effect below 50 nm. The characteristic length scale, l, that quantifies the strain gradient strengthening increases from zero and takes a steady value of ≈4 μm as the grain size increases from 50 nm to ≈100 nm (7). Strain-gradient strengthening has been attributed to geometrically necessary dislocations (6, 48). As grains become smaller than the critical size when dislocations cannot exist within the grains, strain-gradient-induced strengthening disappears, and it is not surprising that l vanishes.

We note that Shen et al. (15) used nanoindentation technique to measure elastic modulus of polycrystalline Fe, Ni, Cu, and Cu-Ni alloys prepared by mechanical milling. The range of grain size was 17–27 nm for Cu, Ni, and Cu-Ni alloys, and 7–80 nm for Fe. Elastic modulus of Cu, Ni, and Cu-Ni alloys was found to be similar to their bulk polycrystalline counterpart. Modulus decreased with grain size for Fe, although the decrease was only ≈5% when the grain size was 7 nm. These results may, at first look, appear contradictory to the experimental findings and the arguments presented in this paper for Al and Au. Here, we attributed to grain boundaries (when no flaws or voids could be detected by TEM) of nanocrystalline aluminum and gold for the reduction of their elastic modulus and their nonlinear elastic response. However, the structure of the grain boundary region, and hence its influence on mechanical properties, depends on the processing of the metal. Thus, it is not surprising that mechanical behavior of nanocrystalline metals show varying degrees of sensitivity to grain size depending on the metal and its processing conditions.

As exemplified in this study, addition of quantitative capability complements the qualitative prowess of the TEM. Potential application of similar quantitative testing in TEM includes characterization of ceramics, semiconductors, polymers, biomaterials, nanotubes, nanorods, and wires, and other novel nanostructures and composites for their stress-dependent mechanical and electronic properties and stress-assisted evolution of microstructures. The significance of the developed technique is even more profound because it opens up new possibilities for all science and engineering disciplines where TEM is used.

Acknowledgments

The devices were fabricated in the MicroMiniature Systems Lab of the Mechanical and Industrial Engineering Department at the University of Illinois at Urbana–Champaign and tested in the Imaging Technology Group Lab of the Beckman Institute at the University of Illinois at Urbana–Champaign. We thank Professors William Nix (Stanford University) and John Hutchinson (Harvard University) for their valuable comments on the work and on the manuscript. This work was supported by National Science Foundation Career Award ECS 97-34368 (to M.T.A.S.).

This paper was submitted directly (Track II) to the PNAS office.

Abbreviation: TEM, transmission electron microscope (microscopy).

References

- 1.Hall, E. O. (1951) Proc. Phys. Soc. London Sect. B 64, 747-753. [Google Scholar]

- 2.Petch, N. J. (1953) J. Iron Steel Inst. 174, 25-28. [Google Scholar]

- 3.Fleck, N. A., Muller, G. M., Ashby, M. F. & Hutchinson, J. W. (1994) Acta Metall. Mater. 42, 475-487. [Google Scholar]

- 4.Ma, Q. & Clarke, D. R. (1995) J. Mater. Res. 10, 853-863. [Google Scholar]

- 5.Stölken, J. S. & Evans, A. G. (1998) Acta Mater. 46, 5109-5115. [Google Scholar]

- 6.Gao, H., Huang, Y., Nix, W. D. & Hutchinson, J. W. (1999) J. Mech. Phys. Solids 47, 1239-1263. [Google Scholar]

- 7.Haque, M. A. & Saif, M. T. A. (2003) Acta Mater. 51, 3053-3061. [Google Scholar]

- 8.Artz, E. (1998) Acta Mater. 46, 5611-5626. [Google Scholar]

- 9.Gleiter, H. (2000) Acta Mater. 48, 1-29. [Google Scholar]

- 10.Gutkin, M. Y., Ovidko, I. A. & Pande, C. S. (2001) Rev. Adv. Mater. Sci. 2, 80-102. [Google Scholar]

- 11.Hahn, H. & Padmanabhan, K. A. (1997) Philos. Mag. B 76, 559-571. [Google Scholar]

- 12.Masumura, R. A., Hazzledine, P. M. & Pande, C. S. (1998) Acta Mater. 46, 4527-4534. [Google Scholar]

- 13.Sanders, P. G., Eastman, J. A. & Weertman, J. R. (1997) Acta Mater. 45, 4019-4025. [Google Scholar]

- 14.Huang, H. & Spaepen, F. (2000) Acta Mater. 48, 3261-3269. [Google Scholar]

- 15.Shen, T. D., Koch, C. C., Tsui, T. Y. & Pharr, G. M. (1995) J. Mater. Res. 10, 2892-2896. [Google Scholar]

- 16.Kim, H. S. & Bush, M. B. (1999) Nanostruct. Mater. 11, 361-367. [Google Scholar]

- 17.Kim, H. S., Esterin, Y. & Bush, M. B. (2000) Acta Mater. 48, 493-504. [Google Scholar]

- 18.Freund, L. B., Arzt, E., Kraft, O. & Phillips, R. (2002) MRS Bull. 27, 30-37. [Google Scholar]

- 19.Nieh, T. G. & Wadsworth, J. (1991) Scripta Metall. 25, 955-958. [Google Scholar]

- 20.Sciotz, J., Tolla, D. D. & Jacobsen, K. W. (1998) Nature 391, 561-563. [Google Scholar]

- 21.Heino, P. & Ristolainen, E. (2001) Philos. Mag. A. 81, 957-970. [Google Scholar]

- 22.Cai, B., Kong, Q., Liu, L. & Lu, K. (1999) Scripta Metall. 41, 755-759. [Google Scholar]

- 23.Koch, C. C. & Naryan, J. (2001) MRS Symp. Proc. 634, B5.1.1-B5.1.11. [Google Scholar]

- 24.Espinosa, H. D., Prorok, B. C. & Fischer, M. (2003) J. Mech. Phys. Solids 51, 47-67. [Google Scholar]

- 25.Chasiotis, I. & Knauss, W. G. (2002) Expt. Mech. 42, 51-57. [Google Scholar]

- 26.Sharpe, W. N., Jr., Jackson, K. M., Hemker, K. J. & Xie, Z. (2001) J. Microelectromech. Syst. 10, 317-326. [Google Scholar]

- 27.Haque, M. A. & Saif, M. T. A. (2002) Expt. Mech. 42, 123-128. [Google Scholar]

- 28.Espinosa, H. D. & Prorok, B. C. (2003) J. Mater. Sci. 38, 4125-4128. [Google Scholar]

- 29.Newbury, D. E. & Williams, D. B. (2000) Acta Mater. 48, 323-346. [Google Scholar]

- 30.Youngdahl, C. J., Hugo, R. C., Kung, H. & Weertman, J. R. (2001) MRS Symp. Proc. 634, B.1.2.1-B.1.2.6. [Google Scholar]

- 31.Hugo, R. C., Kung, H., Weertman, J. R., Mitra, R., Knapp, J. A. & Follstaedt, D. M. (2003) Acta Materialia 51, 1937-1943. [Google Scholar]

- 32.Ke, M., Hackney, S. A., Milligan, W. W. & Aifantis, E. C. (1995) Nanostruct. Mater. 5, 689-698. [Google Scholar]

- 33.Legros, M., Elliott, B. R., Rittner, M. N., Weertman, J. R. & Hemker, K. J. (2000) Philos. Mag. A 80, 1017-1026. [Google Scholar]

- 34.Spaepen, F. (2000) Acta Mater. 48, 31-42. [Google Scholar]

- 35.Honeycombe, R. W. K. (1968) The Plastic Deformation of Metals (Arnold, London).

- 36.Kalkman, A. J., Verbruggen, A. H. & Janssen, G. C. (2001) Appl. Phys. Lett. 78, 2673-2675. [Google Scholar]

- 37.Sakai, S., Tanimoto, H. & Mizubayashi, H. (1999) Acta Mater. 47, 211-217. [Google Scholar]

- 38.Baker, S. P., Vinci, R. P. & Arias, T. (2002) MRS Bull. 27, 26-29. [Google Scholar]

- 39.Fultz, B. & Frase, H. N. (2000) Hyperfine Interact. 130, 81-108. [Google Scholar]

- 40.Seigel, R. W. & Thomas, G. W. (1992) Ultramicroscopy 40, 376-384. [Google Scholar]

- 41.Van Swygenhoven, H., Farkas, D. & Caro, A. (2000) Phys. Rev. B 62, 831-838. [Google Scholar]

- 42.Yamakov, V., Wolf, D. & Phillpot, S. R. (2003) Philos. Mag. Lett. 83, 385-393. [Google Scholar]

- 43.Krakow, W., Wetzel, J. T. & Smith, D. A. (1986) Philos. Mag. A 53, 739-754. [Google Scholar]

- 44.Wolf, D. & Lutsko, J. F. (1988) Phys. Rev. Lett. 60, 1170-1173. [DOI] [PubMed] [Google Scholar]

- 45.Mehta, S. C. & Smith, D. A. (1994) MRS Symp. Proc. 351, 337-342. [Google Scholar]

- 46.Ranganathan, S., Divakar, R. & Raghunathan, V. S. (2001) Scripta Mater. 44, 1169-1174. [Google Scholar]

- 47.Voter, A. F. & Chen, S. P. (1987) MRS Symp. Proc. 82, 175-180. [Google Scholar]

- 48.Huang, Y., Gao, H., Nix, W. D. & Hutchinson, J. W. (2000) J. Mech. Phys. Sol. 48, 99-128. [Google Scholar]