Abstract

Objective:

The aim of this study was to assess the surface of yttrium-stabilized tetragonal zirconia (Y-TZP) after surface treatment with lasers and airborne-particle abrasion.

Materials and Methods:

First, 77 samples of presintered zirconia blocks measuring 10 × 10 × 2 mm were made, sintered and polished. Then, they were randomly divided into 11 groups (n=7) and received surface treatments namely, Er:YAG laser irradiation with output power of 1.5, 2 and 2.5 W, Nd:YAG laser with output power of 1.5, 2 and 2.5 W, CO2 laser with output power of 3, 4 and 5 W, AL2O3 airborne-particle abrasion (50μ) and no treatment (controls). Following treatment, the parameters of surface roughness such as Ra, Rku and Rsk were evaluated using a digital profilometer and surface examination was done by SEM.

Results:

According to ANOVA and Tukey’s test, the mean surface roughness (Ra) after Nd:YAG laser irradiation at 2 and 2.5 W was significantly higher than other groups. Roughness increased with increasing output power of Nd:YAG and CO2 lasers. Treated surfaces by Er:YAG laser and air abrasion showed similar surface roughness. SEM micrographs showed small microcracks in specimens irradiated with Nd:YAG and CO2 lasers.

Conclusion:

Nd:YAG laser created a rough surface on the zirconia ceramic with many microcracks; therefore, its use is not recommended. Air abrasion method can be used with Er:YAG laser irradiation for the treatment of zirconia ceramic.

Keywords: Zirconia, Laser Treatment, Air Abrasion, Scanning Electron Microscopy

INTRODUCTION

In recent years, cosmetic dentistry has progressed [1]. New advances in dental ceramics have led to the use of yttrium-stabilized tetragonal zirconia polycrystals (Y-TZP) as a substitute for fixed PFM dental restorations [2]. Zirconia has shown several important features that make it suitable for dental applications, including: ideal mechanical properties, good biocompatibility, high strength and esthetics [3–5]. Although mechanical properties are very important, clinical success depends on the strength and durability of the bond of resin cement to ceramic substrates and teeth to prevent marginal discoloration, recurrent caries and failure [6].

One problem in this respect is the low capacity of resin bonding to zirconia ceramic; which is related to glass-free composition of zirconia [7]. Different surface treatments have been recommended in order to increase surface roughness and obtain better mechanical bond strength. Airborne particle abrasion has been proposed to facilitate the micromechanical retention between the Y-TZP ceramics and resin cements. This method increases the surface roughness and bonding area and changes the superficial energy and wettability [3]. Air abrasion may cause flaws and defects that may act as initiators of cracks and compromise the mechanical properties and long-term durability of restorations [8–10].

Laser irradiation is another technique to increase surface roughness and improve adhesion between ceramics and resin cements. CO2 laser is one of the most common and effective electromagnetic wave sources in the infrared spectrum. Because the CO2 laser emission wavelength is absorbed by the ceramics, this device is suitable for ceramic surface treatment [11, 12]. One study stated that zirconia ceramic is the selective material for irradiation by Nd:YAG laser due to toughness and low thermal conductivity [13]. Er:YAG laser is a solid state laser that uses suspended Er +3 ions in a Yttrium-Aluminum-Garnet (YAG) crystalline matrix to provide electrons for excitation. Er:YAG lasing occurs in 2.94 μm wavelength that is well absorbed by hydroxyapatite and water [14].

Of course, the control of the laser settings (power, pulse and duration) is very important in order to prevent damage to the zirconia surface. All the above procedures emphasize increasing the surface area to strengthen bonding and durability of the restorations. Although several surface treatments have been proposed, selection of the most appropriate method is still a challenge. The objective of this study was to characterize the surface morphology and roughness of zirconia surface after different laser irradiations including Nd:YAG, CO2 and Er:YAG and compare them with air-particle abrasion.

Our hypothesis was that different surface treatments have obvious effects on the patterns of surface roughness. Another hypothesis was that airborne particle abrasion might be replaced with laser irradiation.

MATERIALS AND METHODS

First, 77 blocks of presintered zirconia (ICE Zirkon, Zirkonzahn GmbH, Bruneck, Italy) measuring 10 × 10 × 2 mm were made using a diamond blade mounted in Mecatome T201 cutting saw machine (PRESI. Grenoble. France). All samples were sintered according to the instructions of the manufacturer, and then embedded in acrylic resin in the metal molds. Next, the upper surface was polished with 800, 1000 and 1200 grit silicon carbide disks under running water. The samples were ultrasonically cleaned with distilled water for 6 min. Then, the specimens were randomly divided into 11 groups (n=7) and received the following surface treatments:

▪ Er: YAG laser with output power of 1.5 W(4.39 J/cm2)

▪ Er: YAG laser with output power of 2 W(5.85 J/cm2)

▪ Er: YAG laser with output power of 2.5 W(7.32 J/cm2)

▪ Nd: YAG laser with output power of 1.5 W(111.96 J/cm2)

▪ Nd: YAG laser with output power of 2 W(149.28 J/cm2)

▪ Nd: YAG laser with output power of 2.5 W(186.6 J/cm2)

▪ CO2 laser with output power of 3 W(2.29 J/cm2)

▪ CO2 laser with output power of 4 W(3.05 J/cm2)

▪ CO2 laser with output power of 5 W(3.82 J/cm2)

▪ Air abrasion with 50μ Al2O3 particles, perpendicular to the surface, from a distance of 10 mm for a period of 10 sec at 2.8 bar pressure

▪ Controls (no treatment)

The Er:YAG laser (Smart 2940D, Deka laser, Florence, Italy) was used with a wavelength of 2940 nm, frequency of 10 Hz and pulse duration of 230μsec (very short pulse). The spot size was 1 mm and the handpiece was used at a distance of 4 mm (focusing distance of the handpiece) above the surface (noncontact mode) for 10 sec accompanied by water and air spray. The Nd:YAG laser (Fidelis, Fotona, Slovenia) was used at a wavelength of 1064 nm, frequency of 10Hz and pulse duration of 100 μsec (very short pulse). Total surfaces of the block were scanned with 320μ fiber about 1mm above the surface for 1 min. The CO2 laser (Smart US20D, Deka laser, Florence, Italy) was used at a wavelength of 10600 nm, in continuous mode, 1mm above the surface for 1min. All laser treatments were done in scanning mode.

Evaluation of surface roughness:

Surface roughness was assessed by profilometry (T-8000, Hommelwerke, JENOPTIK, Germany). The diamond tip of the device with a speed of 0.15 mm/s and load of 4 N was passed through the surface of the samples. The average surface roughness (Ra-micron) and other parameters such as Rku and Rsk in treated surfaces were determined. Surface roughness (Ra), a quantitative calculation of the relative roughness of a linear profile or area, was expressed as a single numeric parameter (Ra).

Ra provides limited information and does not show a definite profile. Ra does not make a distinction between the grooves and prominences and provides no information about the three-dimensional structure. Rsk or skewness, the symmetry measure of the profile about the mean line, was characterized as positive or negative.

The next parameter Rku or kurtosis was the sharpness measure of the surface profile and took the value 3 for the normal distribution [15].All parameters were analyzed using one-way ANOVA and post-hoc multiple comparisons by Tukey’s test.

P-value <0.05 was considered statistically significant. Leven’s test confirmed the equality of variances (P value >0.05).

SEM:

To evaluate the surface morphology, the same samples used for profilometry were coated with gold-palladium (Quorum Technologies Polaron SC7620, Newhaven, East Sussex, UK) and observed under SEM (JSM-6610 LV Scanning electron microscope, JEOL USA) with 50X, 500X and 5000X magnifications and 15 kV voltage.

RESULTS

Mean surface roughness: (Table 1)

Table 1.

The mean± SD of Ra, Rsk and Rku after different surface treatments of Y-TZP (The same letters in the same column indicate no significant differences according to one-way ANOVA)

| Parameter | Ra(mic) | Rsk | Rku |

|---|---|---|---|

|

| |||

| Treatment | |||

| Er:YAG 1.5 W | 0.46±0.19 a | −0.32±0.03 a | 3.89±0.81 a |

| Er:YAG 2 W | 0.53±0.04 a | −0.50±0.09 a | 3.65±0.81 a |

| Er:YAG 2.5 W | 0.21±0.005 a | −0.99±0.05 a | 4.82±1.31 a |

| Nd:YAG 1.5 W | 2.7±0.16 b | 0.95±0.1 b | 5.15±0.98 a |

| Nd:YAG 2 W | 6.62±0.41 c | 0.18±0.05 b | 3.56±0.58 a |

| Nd:YAG 2.5 w | 7.39±0.28 c | 0.21±0.02 b | 3.38±1.00 a |

| CO2 3W | 0.63±0.07 a | 0.07±0.02 b | 3.38±0.72 a |

| CO2 4W | 1.19±0.38 b | 0.37±0.04 b | 3.64±0.76 a |

| CO2 5W | 1.5±0.38 | 0.95±0.1 b | 3.09±0.36 a |

| A.A | 0.58±0.05 a | −0.36±0.05 a | 3.10±0.30 a |

| Control | 0.23±0.07 a | −0.52±0.07 a | 3.75±0.66 a |

The ANOVA showed that the surface roughness (Ra) was significantly different between groups (P <0.001).

Ra in Nd:YAG group with output power of 2 and 2.5 W was higher than other groups (P <0.05) .After that, CO2 laser with output power of 4 and 5W and Nd: YAG laser with power of 1.5W showed higher Ra values; however, there was no significant difference between these groups. The lowest surface roughness (Ra) was in the control group (Table 1).

There was no significant difference between groups in the Rku values (P >0.05). All of them showed Rku over 3, expressing more pointed peaks and valleys in the rough profile. Rsk values were positive in the samples treated with 1.5, 2 and 2.5W Nd: YAG and 3, 4 and 5 W CO2 lasers; indicating the sharp prominences and depressions of the surface. But the remaining groups showed negative Rsk values that indicated a plateau like surface.

Results of SEM:

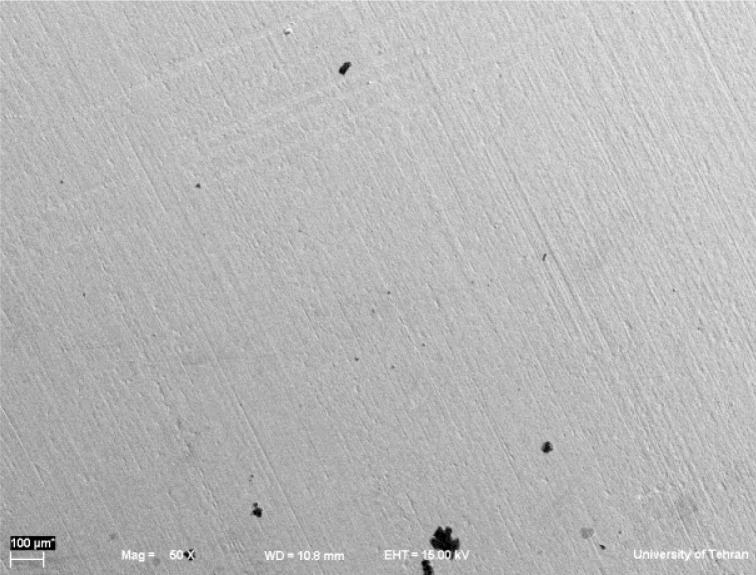

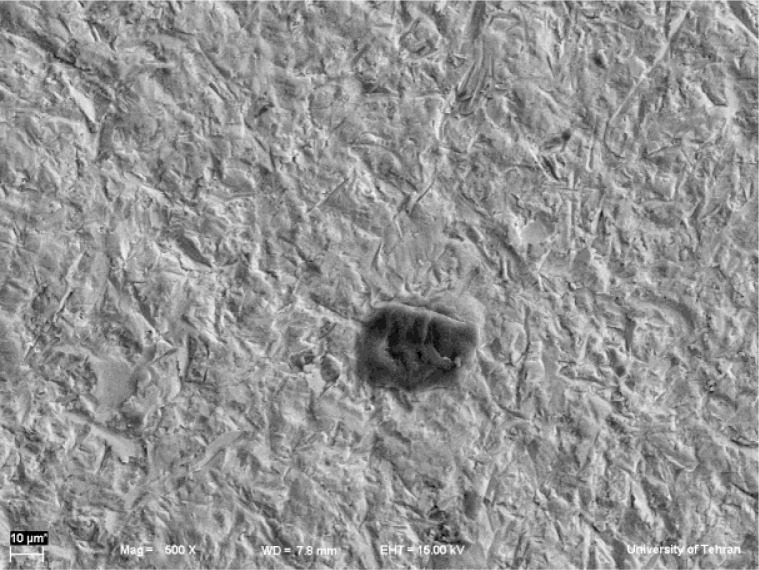

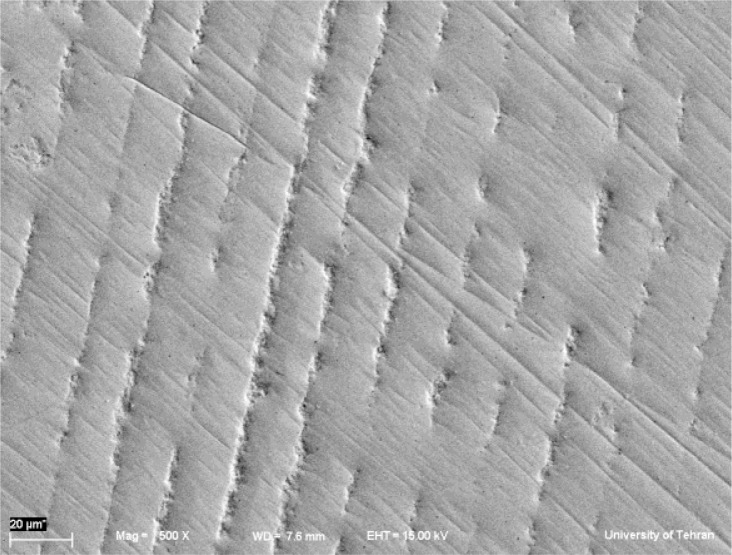

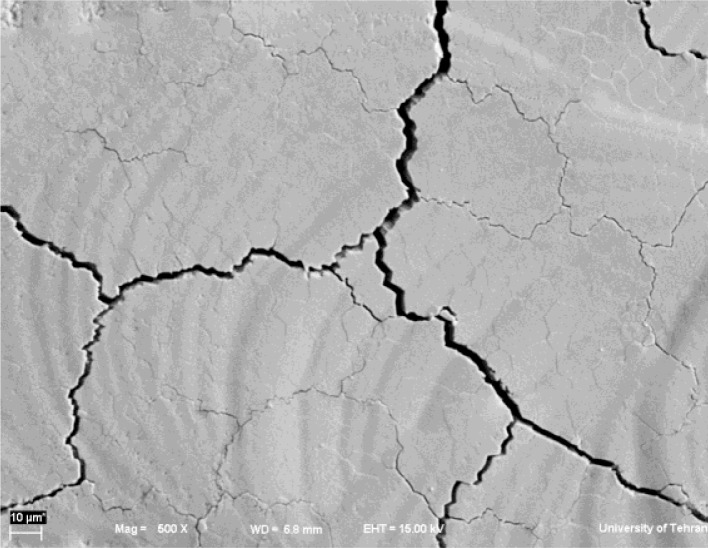

In SEM images, non-treated surfaces of YTZP showed grooves and irregularities due to the polishing process (Figure 1). Treated Surfaces by AL2O3 air-particle abrasion (50μ) indicated roughness, grooves and irregularities, uniformly throughout the surface (Figure 2).

Fig 1.

SEM micrographs (magnification 500X) of non-treated Y-TZP surfaces (magnification 60X)

Fig 2.

SEM micrographs of air abraded Y-TZP surfaces (magnification 500X)

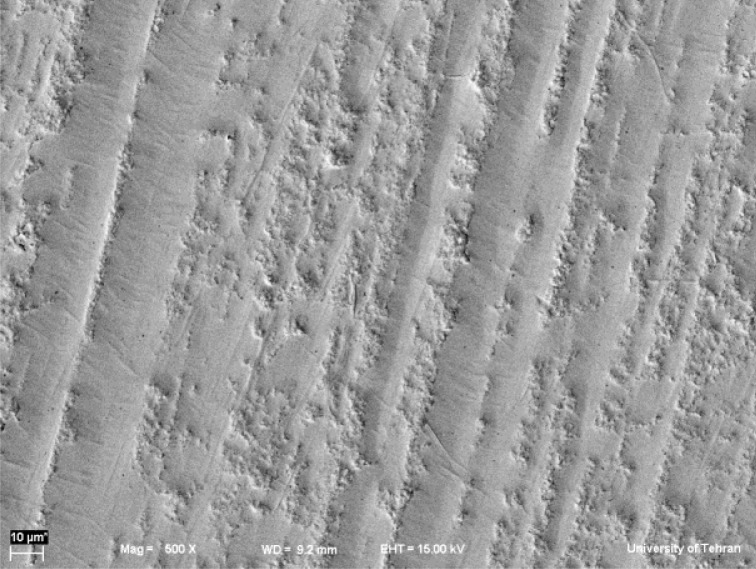

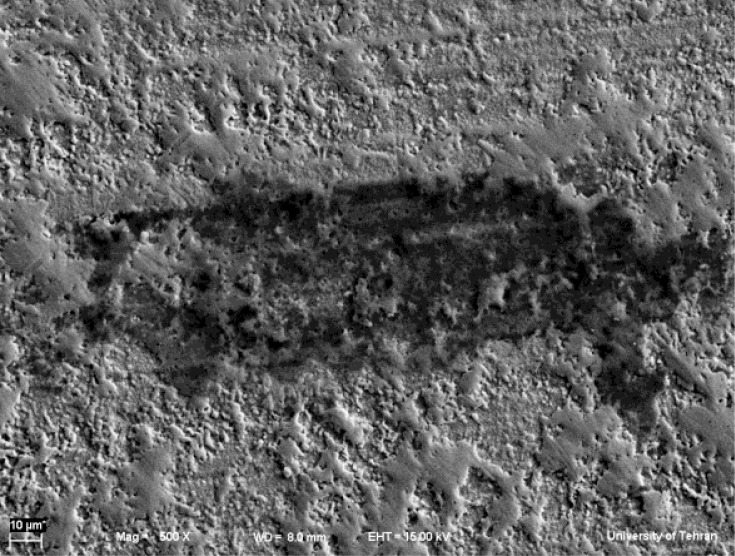

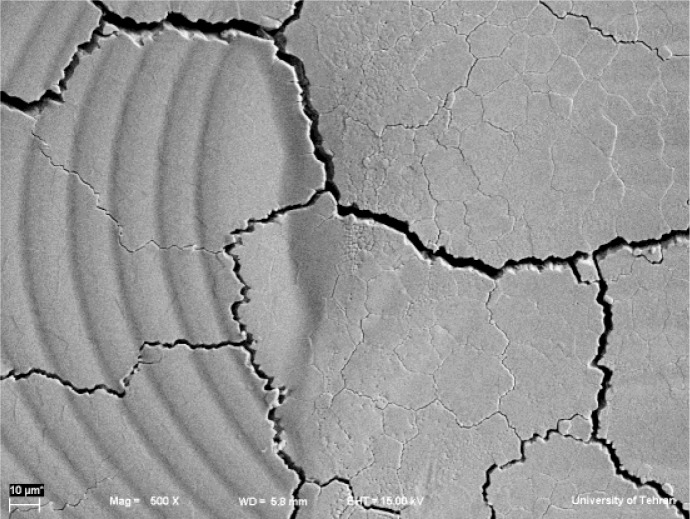

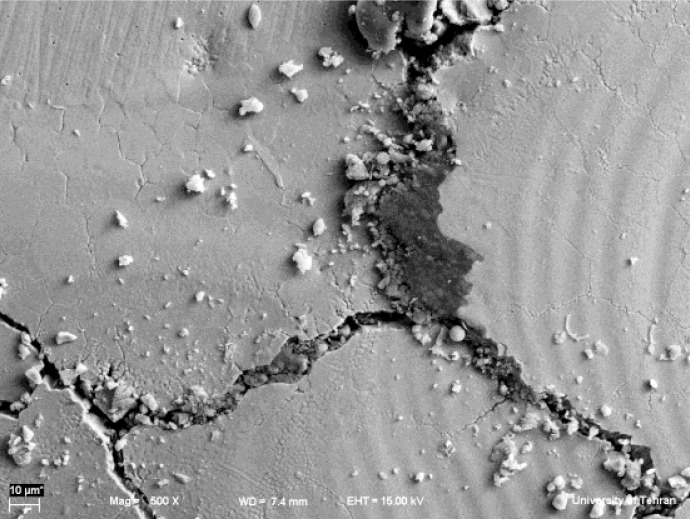

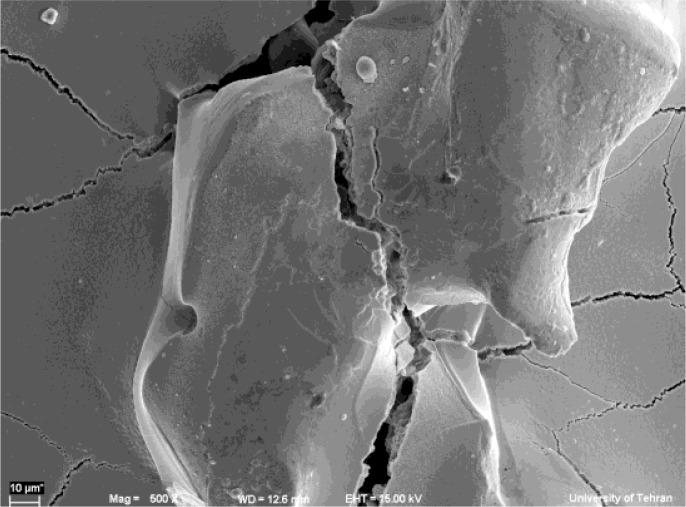

The Er: YAG laser with power of 1.5W created a rough surface with irregularities (Figure 3a). Surface roughness increased by enhancing output power to 2W; also, the surface became more uniform (Figure 3b). The Er:YAG laser irradiation at power of 2.5W reduced surface roughness and depth of irregularities (Figure 3c). Treated surfaces by CO2 laser with power of 3W showed several fine and wide crack lines (Figure 4a). In addition, the circular shape prominences could be seen over the surface produced by the motion of laser irradiation. With increasing power, the rate of irregularities and surface roughness increased (Figures 4b and 4c). Treating samples by Nd: YAG laser at a power of 1.5W created surface microcracks, prominences and porosities; moreover, some areas were partially melted (Figure 5a). Nd:YAG laser irradiation at 2 and 2.5W power increased these changes (Figures 5b and 5c).

Fig 3a.

SEM micrographs of Y-TZP surfaces after Er:YAG laser irradiation (at 1.5W) (magnification 500X)

Fig 3b.

SEM micrographs of Y-TZP surfaces after Er:YAG laser irradiation (at 2W) (magnification 500X)

Fig 3c.

SEM micrographs of Y-TZP surfaces after Er:YAG laser irradiation (at 2.5W) (magnification 500X)

Fig 4a.

SEM micrographs of Y-TZP surfaces after CO2 laser irradiation at 3W (magnification 500X)

Fig 4b.

SEM micrographs of Y-TZP surfaces after CO2 laser irradiation at 4W (magnification 500X)

Fig 4c.

SEM micrographs of Y-TZP surfaces after CO2 laser irradiation at 5W (magnification 500X)

Fig 5a.

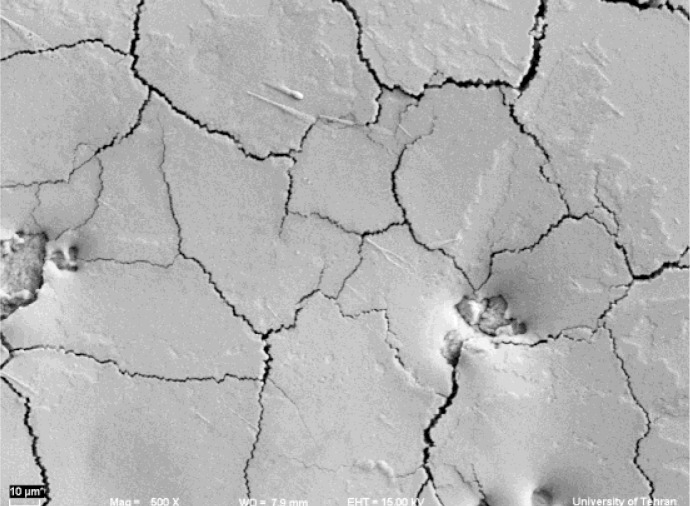

SEM micrographs of Y-TZP surfaces after Nd:YAG laser irradiation at 1.5W (magnification 500X)

Fig 5b:

SEM micrographs of Y-TZP surfaces after Nd:YAG laser irradiation at 2W (magnification 500X)

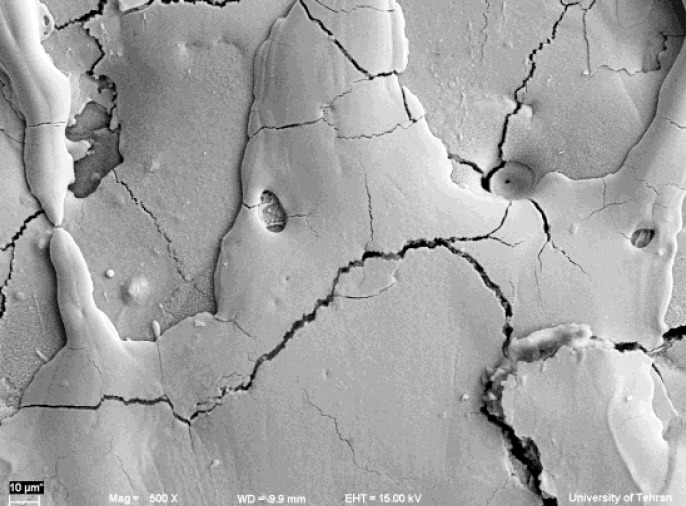

Fig 5c.

SEM micrographs of Y-TZP surfaces after Nd:YAG laser irradiation at 2.5W (magnification 500X)

DISCUSSION

The aim of this study was to evaluate the surface roughness and morphology of Y-TZP samples treated with different powers of various lasers (CO2, Er:YAG and Nd:YAG) and compare them with Al2O3 air-particle abrasion. Sandblasting with aluminum oxide particles is a general practice that increases resin bond strength due to creating surface roughness and undercuts. However, this method can initiate phase transition and change the mechanical properties [13,16]. Air abrasion creates flaws and roughness on the surface due to phase transformation by the higher impact energy of particles. In addition, airborne particle abrasion of restorations has the potential to remove significant amounts of substrates; therefore, it can affect clinical adaptation and may have negative impact on the retention of restorations [17–19].

Air abrasion showed increased surface roughness (Ra) compared to the control group. SEM images of the control group were almost smooth except for some scratch-like lines and small pits that were created by the polishing sandpaper.

In this study, SEM micrographs showed that the application of air abrasion with AL2O3 particles leads to apparent retentive pits and scratches; although, there was no significant difference in Ra between treated surfaces with air-particle abrasion and Er: YAG laser.

In this study, the specimens irradiated with CO2 laser showed significant superficial changes in SEM observations. The high temperature due to CO2 laser irradiation effectively facilitates localized surface melting and creates micro-cracks on the surface. Increased Ra values of treated Y-TZP by CO2 laser in the present study confirm SEM observations. Different reasons are expressed for the formation of these cracks after CO2 laser irradiation [20].

According to Großmann et al, superficial emission of atoms, ions and electrons occurs during the temperature rise in the ceramic surface as the result of the absorption of laser beam.

Due to the photoionization produced by the irradiation, physical plasma is created and its formation is accompanied by extremely high pressure and temperature variations in the ranges of 10,000–50,000 k.

This can cause a lot of physical stress during the rehardening of the ceramic surface. In addition, two different phases are formed: one with a crystalline structure and another with an amorphous structure; each with a different thermal expansion coefficient.

Once the material starts to harden, regions of internal mechanical stress are created between the two phases leading to the formation of micro-cracks [20, 21]. Stubinger also reported that the main part of the absorbed energy was used during melting and only a small portion was spent for heating the mass of material.

This feature causes rapid cooling of the molten layer as soon as irradiation is removed and as a result, cracks are formed [22].

Nd: YAG laser irradiation is recommended to change the ceramic surface due to the formation of a glazed superficial layer [23].

In the present study, results of SEM micrographs and ANOVA confirmed that the treated samples with Nd:YAG laser had higher Ra than the other groups and indicated uniform surface cracks and molten regions. Like the CO2 laser process, increasing temperature during the laser irradiation can also cause thermal melting of the ceramic surface. Surface expands during melting and immediately contracts during solidification. This stress due to temperature can cause superficial cracks. Another challenge is that Nd:YAG laser treated surfaces are characterized by a carbonized layer with silver pigments [24]. This feature can prevent the use of Nd: YAG laser in the esthetic zones. Cavalcanti et al. evaluated the surface roughness of Y-TZP ceramics (Cercon, Procera) after different treatments.

They used different parameters of Er:YAG laser (200, 400 and 600 mJ) and expressed that the lower energy intensity (200mJ) could be a potential method for the surface treatment of zirconia. They also concluded that the higher intensities of laser are not suitable for treatment due to severe damage to the ceramic surface [25]. In our study, one-way ANOVA showed no significant difference between Er: YAG laser irradiation and air abrasion groups. However, in SEM micrographs, treated samples with Er:YAG at 2.5W showed reduction in the amount of irregularities and undercuts due to homogenous ablation of the surface.

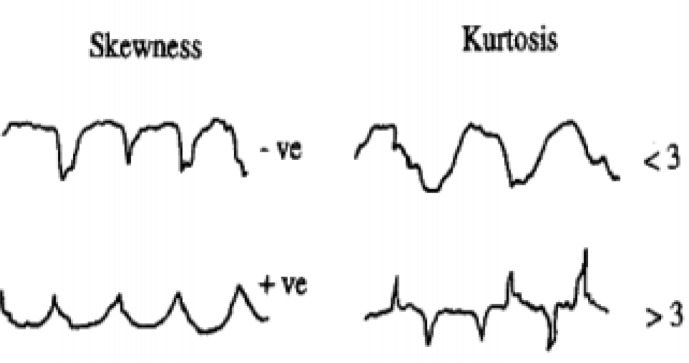

Rsk or skewness is the symmetry measure of the profile about the mean line and is characterized as positive or negative. Negative skewness indicates a plateau like profile and positive skewness confirms the peaks (Figure 6). Rsk values were positive in treated samples with Nd:YAG and CO2 lasers; indicating prominences on the surfaces. But the other groups showed negative Rsk numbers. A plateau-like profile is indicated by a negative skewness value. As the levels of Rsk approach zero, we encounter more normal distribution of peak and plateau-like areas [15].

Fig 6.

Schematic design of kurtosis and skewness values

The next parameter was Rku or kurtosis. This is a measure of the sharpness of the surface profile and takes the value 3 for the normal distribution. Rku >3 indicates that the surface is dominated by sharp peaks (spiky); whereas, the peaks are bumpy if Rku is lower than 3 (Figure 6). The differences in Rku between groups were not statistically significant (P >0.005) and all of them showed Rku >3; indicating sharp prominences and depressions [15]. All the above-mentioned processes rely on increasing the surface area for bonding and creating a stronger and more durable restoration. However, the range of changes on the surface of ceramics depends greatly upon the energy intensity of laser irradiation and type of ceramic.

We concluded that the different surface treatments have significant effects on the patterns of surface roughness. Therefore, the first hypothesis is accepted. Also, we found that Er:YAG laser could be a suitable alternative for airborne particle abrasion; but, treating the zirconia surface by Nd:YAG and CO2 lasers is very destructive, generating a lot of heat that may adversely affect the adhesion and mechanical properties.

CONCLUSION

According to this study, all treated surfaces showed higher roughness than the control group.

Treated surfaces by Er: YAG laser and air abrasion showed similar surface roughness; thus, this laser can be a suitable substitute for air abrasion.

Increasing the output power of Nd:YAG and CO2 lasers increased the roughness; but it did not apply to Er: YAG laser.

Nd:YAG and CO2 lasers were destructive on the zirconia surfaces since they created extensive cracks and high temperatures.

Acknowledgments

The authors gratefully thank Dr. Mohammad Javad Kharazi Fard for his help in statistical analysis. This research was supported by a grant from the Laser Research Center of Dentistry, Tehran University of Medical Sciences, Tehran, Iran.

REFERENCES

- 1.Fischer J, Grohmann P, Stawarczyk B. Effect of zirconia surface treatments on the shear strength of zirconia/veneering ceramics composites. Dent Mater J. 2008 May;27(3):448–54. doi: 10.4012/dmj.27.448. [DOI] [PubMed] [Google Scholar]

- 2.Della Bona A, Donassollo TA, Demarco FF, Barrett AA, Mecholsky JJ., Jr Characterization and surface treatment effects on topography of a glass-infiltrated alumina/zirconia reinforced ceramic. Dent Mater. 2007 Jun;23(6):769–75. doi: 10.1016/j.dental.2006.06.043. Epub 2006 Nov 16. [DOI] [PubMed] [Google Scholar]

- 3.Xie ZG, Meng XF, Xu LN, Yoshida K, Luo XP, Gu N. Effect of air abrasion and dye on the surface element ratio and resin bond of zirconia ceramic. Biomed Mater. 2011 Dec;6(6):065004. doi: 10.1088/1748-6041/6/6/065004. Epub 2011 Oct 14. [DOI] [PubMed] [Google Scholar]

- 4.Sailer I, Gottnerb J, Kanelb S, Hammerle CH. Randomized controlled clinical trial of zirconia-ceramic and metal-ceramic posterior fixed dental prostheses: A 3-year follow up. Int J Prosthodont. 2009 Nov-Dec;22(6):553–60. [PubMed] [Google Scholar]

- 5.Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008 Mar;24(3):299–307. doi: 10.1016/j.dental.2007.05.007. Epub 2007 Jul 19. [DOI] [PubMed] [Google Scholar]

- 6.Lee TH, Shim JS, Han CH, Kim SJ. Influence of cement thickness on resin-zirconia microtensile bond strength. J Adv Prosthodont. 2011 Sep;3(3):119–25. doi: 10.4047/jap.2011.3.3.119. Epub 2011 Sep 25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: Where are we now? Dent Mater. 2011 Jan;27(1):71–82. doi: 10.1016/j.dental.2010.10.022. Epub 2010 Nov 20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Akin H, Tugut F, Akin GE, Guney U, Mutaf B. Effect of Er:YAG laser application on the shear bond strength and microleakage between resin cements and Y-TZP ceramics. Laser med sci. 2012;27:333–8. doi: 10.1007/s10103-011-0883-4. [DOI] [PubMed] [Google Scholar]

- 9.Foxton RM, Cavalcanti AN, Nakajima M, Pilecki P, Sherriff M, Melo L, et al. Durability of resin cement bond to aluminium oxide and zirconia ceramics after air abrasion and laser treatment. J Prosthodont. 2011 Feb;20(2):84–92. doi: 10.1111/j.1532-849X.2010.00678.x. Epub 2011 Feb 1. [DOI] [PubMed] [Google Scholar]

- 10.Kern M, Barloi A, Yang B. Surface conditioning influences zirconia ceramic bonding. J Dent Res. 2009;88(9):817–22. doi: 10.1177/0022034509340881. [DOI] [PubMed] [Google Scholar]

- 11.Chen JR, Oka K, Kawano T, Goto T, Ichikawa T. Carbon dioxide laser application enhances the effect of silane primer on the shear bond strength between porcelain and composite resin. Dent Mater J. 2010 Nov;29(6):731–7. doi: 10.4012/dmj.2009-106. Epub 2010 Nov 19. [DOI] [PubMed] [Google Scholar]

- 12.Ural Ç, Külünk T, Külünk Ş, Kurt M. The effect of laser treatment on bonding between zirconia ceramic surface and resin cement. Acta Odontol Scand. 2010 Nov;68(6):354–9. doi: 10.3109/00016357.2010.514720. [DOI] [PubMed] [Google Scholar]

- 13.Akyil MS, Uzun IH, Bayindir F. Bond Strength of Resin Cement to Yttrium-stabilized tetragonal zirconia ceramic treated with Air abrasion, silica coating, and laser Irradiation. Photomed Laser Surg. 2010 Dec;28(6):801–8. doi: 10.1089/pho.2009.2697. [DOI] [PubMed] [Google Scholar]

- 14.Sanusi SY, Seow WK, Walsh LJ. Effects of Er:YAG Laser on Surface Morphology of Dental Restorative Materials. Journal of Physical Science. 2012;23(2):55–71. [Google Scholar]

- 15.Surface and its parameters. London: British Standards Institution; 1987. Glossary of surface roughness terms. British Standard; BS 6741-Part 1. [Google Scholar]

- 16.Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999 Nov;15(6):426–33. doi: 10.1016/s0109-5641(99)00070-6. [DOI] [PubMed] [Google Scholar]

- 17.Kern M, Thompson VP. Sandblasting and silica coating of a glass-infiltrated alumina ceramic: Volume loss, morphology, and changes in the surface composition. J Prosthet Dent. 1994;71:453–61. doi: 10.1016/0022-3913(94)90182-1. [DOI] [PubMed] [Google Scholar]

- 18.Queiroz JRC, Paulo GP, Özcan M, Nogueira L., Jr Effect of Air-borne Particle Abrasion Protocols on Surface Topography of YTZP Ceramic. Ceramica. 2012;58:253–261. [Google Scholar]

- 19.Cattani Lorente M, Scherrer SS, Richard J, Demellayer R, Amez-Droz M, Wiskott HW. Surface roughness and EDS characterization of a YTZP dental ceramic treated with the CoJet™ Sand. Dent Mater. 2010 Nov;26(11):1035–42. doi: 10.1016/j.dental.2010.06.005. [DOI] [PubMed] [Google Scholar]

- 20.Ersu B, Yuzugullu B, Yazici R, Canay S. Surface roughness and bond strengths of glass-infiltrated alumina-ceramics prepared using various surface treatments. J Dent. 2009 Nov;37(11):848–56. doi: 10.1016/j.jdent.2009.06.017. [DOI] [PubMed] [Google Scholar]

- 21.Großmann J, Emmel A, Schubert E, Bergmann HW. Generation of new surface conditions on SiC materials by excimer laser irradiation: mechanisms–properties–applications. Laser und Optoelektronik. 1994;26:34–9. [Google Scholar]

- 22.Stübinger S, Homann F, Etter C, Miskiewicz M, Wieland M, Sader R. Effect of Er:YAG, CO2 and Diode Laser Irradiation on surface properties of zirconia endosseous dental implants. Lasers Surg Med. 2008 Mar;40(3):223–8. doi: 10.1002/lsm.20614. [DOI] [PubMed] [Google Scholar]

- 23.Schmage P, Nergiz I, Herrmann W, Ozcan M. Influence of various surface-conditioning methods on the bond strength of metal brackets to ceramic surfaces. Am J Orthod Dentofacial Orthop. 2003;123:540–6. doi: 10.1067/mod.2003.S0889540602569110. [DOI] [PubMed] [Google Scholar]

- 24.Gandolfi Paranhos MP, Burnett LH, Magne P. Effect of Nd:YAG laser and CO2 laser treatment on the resin bond strength to zirconia ceramic. Quintessence Int. 2011;42:79–89. [PubMed] [Google Scholar]

- 25.Cavalcanti A, Pilecki P, Foxton R, Watson T, Tavares M, Gianinni M, et al. Evaluation of the surface roughness and morphologic features of Y-TZP ceramics after different surface treatments. Photomed Laser Surg. 2009 Jun;27(3):473–9. doi: 10.1089/pho.2008.2293. [DOI] [PubMed] [Google Scholar]