Abstract

The effects of carbon dioxide, sodium chloride, and sodium nitrite on type B botulinum neurotoxin (BoNT/B) gene (cntB) expression in nonproteolytic Clostridium botulinum were investigated in a tryptone-peptone-yeast extract (TPY) medium. Various concentrations of these selected food preservatives were studied by using a complete factorial design in order to quantitatively study interaction effects, as well as main effects, on the following responses: lag phase duration (LPD), growth rate, relative cntB expression, and extracellular BoNT/B production. Multiple linear regression was used to set up six statistical models to quantify and predict these responses. All combinations of NaCl and NaNO2 in the growth medium resulted in a prolonged lag phase duration and in a reduction in the specific growth rate. In contrast, the relative BoNT/B gene expression was unchanged, as determined by the cntB-specific quantitative reverse transcription-PCR method. This was confirmed when we measured the extracellular BoNT/B concentration by an enzyme-linked immunosorbent assay. CO2 was found to have a major effect on gene expression when the cntB mRNA levels were monitored in the mid-exponential, late exponential, and late stationary growth phases. The expression of cntB relative to the expression of the 16S rRNA gene was stimulated by an elevated CO2 concentration; the cntB mRNA level was fivefold greater in a 70% CO2 atmosphere than in a 10% CO2 atmosphere. These findings were also confirmed when we analyzed the extracellular BoNT/B concentration; we found that the concentrations were 27 ng · ml−1 · unit of optical density−1 in the 10% CO2 atmosphere and 126 ng · ml−1 · unit of optical density−1 in the 70% CO2 atmosphere.

In recent years, nonproteolytic strains of Clostridium botulinum have become a subject for concern due to the development of novel food products having alternative formulations and produced by different processing techniques (e.g., refrigerated processed foods with extended durability) (26). These food products are usually pasteurized at temperatures that destroy vegetative bacteria but do not kill spores, are packed under an anaerobic atmosphere, and are then stored at refrigerated temperatures. These characteristics are favorable for spore germination, outgrowth, and subsequent neurotoxin formation in the food if nonproteolytic C. botulinum is present, as this bacterium has been reported to multiply and produce type B, E, or F botulinum neurotoxins (BoNTs) at temperatures as low as 3.0°C (11). To ensure food safety in these refrigerated food products, additional control measures must be employed; these measures include adjustment of the pH and addition of sodium chloride and other food preservatives to prevent growth and formation of neurotoxin by C. botulinum.

In previous studies on C. botulinum workers have focused mainly on the germination and outgrowth of spores in both microbiological growth medium and different foods (10, 18, 22, 27). However, little is known about the environmental factors that regulate BoNT gene (cnt) expression in C. botulinum. Nutritional conditions affect BoNT formation in C. botulinum, and it has been reported that nitrogen sources, such as tryptophan and arginine, repress BoNT production (16, 25), whereas casein induces synthesis of the toxin (6, 16). The botR gene encoding a 22-kDa protein has been localized in the cnt gene cluster of all serotypes except serotype E (4, 12, 13, 29). Furthermore, the protein encoded by this gene, BotR, has been recognized as a positive regulator of the cntB gene in C. botulinum type A (21). BotR is related to other regulatory proteins, such as TetR of Clostridium tetani (20) and TxeR of Clostridium difficile (23).

To better understand regulation of cnt gene expression in C. botulinum, it is necessary to identify the environmental factors in different foods that induce or repress neurotoxin production. A quantitative reverse transcription-PCR (qRT-PCR) method was recently developed for relative quantification of type B cnt (cntB) expression (19). The results obtained showed that the maximum cntB mRNA accumulation occurred as the bacteria entered the early stationary growth phase. Furthermore, it was found that exposure to air had no effect on cntB expression, whereas a sodium nitrite concentration of 45 ppm suppressed cntB expression.

In the present study, the effects of selected food preservatives on cntB expression in a nonproteolytic C. botulinum Eklund type B strain were investigated by using the cntB-specific qRT-PCR method (19). Various concentrations of carbon dioxide, sodium chloride, and sodium nitrite were studied in a factorial-design experiment in order to quantitatively study interaction effects, as well as main effects, on the following responses: lag phase duration (LPD), growth rate, relative cntB expression, and neurotoxin production. Fifty-four independent growth experiments were performed with a tryptone-peptone-yeast extract (TPY) medium, and the cntB expression was measured three times during the growth cycle: in the mid-exponential, late exponential, and late stationary growth phases. BoNT/B production was quantified by an enzyme-linked immunosorbent assay (ELISA). Multiple linear regression was used to set up six models to quantify and predict the responses.

(cntB, the designation for the C. botulinum type B neurotoxin gene, was recommended by the ASM Publications Board Nomenclature Committee.)

MATERIALS AND METHODS

Bacterial strain and culture conditions.

The nonproteolytic strain C. botulinum Eklund 2B was used throughout this study and was maintained as described previously (5). Overnight cultures were prepared in TPY broth (17) and incubated anaerobically for 18 to 20 h at 30°C until the optical density at 620 nm (OD620) was 1.2 ± 0.1. TPY broth contained tryptone (50 g/liter; Oxoid Ltd., Basingstoke, United Kingdom), proteose peptone (5 g/liter; Oxoid Ltd.), yeast extract (20 g/liter; Oxoid Ltd.), and sodium thioglycolate (1 g/liter; Merck, Darmstadt, Germany). Anaerobic conditions were created by boiling the medium for 10 min before sterilization (121°C for 15 min). After sterilization the medium was incubated for 24 to 36 h before use in an anaerobic workstation (AW 800 TG; Electrotek, AddVise, Stockholm, Sweden). The atmosphere in the workstation contained nitrogen, carbon dioxide, and hydrogen (80:10:10).

A factorial design was used to study the effects of carbon dioxide (CO2), sodium chloride (NaCl), and sodium nitrite (NaNO2) on the LPD, the specific growth rate, the relative cntB expression, and the extracellular BoNT/B concentration. Various amounts of NaCl (final concentrations, 0, 1.25, and 2.5% [wt/vol]; Merck) and NaNO2 (final concentrations, 0, 37.5, and 75 ppm; Sigma Chemical Co., St Louis, Mo.) were added before sterilization to TPY-C basal medium, which was TPY medium supplemented with 0.4% (wt/vol) glucose (BDH Laboratory Supplies, Poole, United Kingdom), 0.1% (wt/vol) maltose (ICN Biochemicals Inc., Aurora, Ill.), 0.1% (wt/vol) cellobiose (Sigma Chemical Co.), and 0.1% (wt/vol) soluble starch (Merck) (24). Three modified atmospheres with different levels of CO2 were tested; these atmospheres contained 10, 35, and 70% (vol/vol) CO2. The concentration of H2 was maintained at 10% (vol/vol) in all three gas mixtures. Nine flasks containing TPY-C medium and the various concentrations of NaCl and NaNO2 were flushed with each of the three gas mixtures. Before flushing of the medium, the gas was passed through a sterile filter with a pore size of 0.2 μm. The gas was flushed through the medium for 10 min at a constant rate of 0.25 liter/min by using a gas distributor and a magnetic stirrer. After flushing, the medium was equilibrated for 24 to 36 h at 30°C in an anaerobic workstation with the same atmosphere. The remaining oxygen in the medium was measured with an oxygen sensor (Inpro 6000; Mettler Toledo, Steinbach, Germany) after equilibration in the anaerobic workstation to ensure that it was anaerobic. The initial pH was 7.0 for all flasks, indicating that it was not influenced by the CO2.

The factorial design resulted in 27 different medium combinations (Table 1). Each flask containing 237.5 ml of TPY-C broth was inoculated with 12.5 ml of an overnight culture of C. botulinum Eklund 2B and incubated under the conditions described above. Growth was monitored by measuring the OD620 with an Hitachi UV-1500 spectrophotometer (Hitachi Instruments Inc.). The duration of each growth experiment was 10 days. The pH was measured each time that samples were withdrawn for measurement of OD620. Samples used for extraction of total RNA were withdrawn three times during growth: in the middle of the exponential growth phase, in the early stationary growth phase, and in the late stationary growth phase. The growth experiment was performed twice with each of the 27 medium combinations. The specific growth rate was calculated by linear regression of the natural logarithm of the OD620 versus time (in hours) for the first OD620 measurements that gave a linear relationship between the two variables. The LPD and the maximum OD620 values were determined by using the Baranyi growth model (1) and R software, version 1.6.1 Rfit; (http://umr5558-sud-str3.univ-lyon1.fr/Rfit/) (3).

TABLE 1.

Experimental design and results obtained when we studied the interaction effects of NaCl, NaNO2, and CO2 on the LPD, specific growth rate, and the maximum optical density

| Expt | Exptl design

|

LPD (h)a | Specific growth rate (h−1)a | OD620a | ||

|---|---|---|---|---|---|---|

| NaCl concn (%, wt/vol) | NaNO2 concn (ppm) | CO2 concn (%) | ||||

| 1 | 0 | 0 | 10 | 3.0, 3.5 | 1.14, 1.12 | 4.4, 4.4 |

| 2 | 0 | 37.5 | 10 | 19.5, 19.5 | 0.73, 0.69 | 2.7, 2.7 |

| 3 | 0 | 75 | 10 | 24.5, 24.5 | 0.61, 0.61 | 2.9, 2.9 |

| 4 | 1.25 | 0 | 10 | 4.5, 4.5 | 0.81, 0.79 | 4.5, 3.8 |

| 5 | 1.25 | 37.5 | 10 | 17.0, 17.0 | 0.75, 0.69 | 2.7, 2.6 |

| 6 | 1.25 | 75 | 10 | 24.4, 24.6 | 0.38, 0.36 | 2.9, 2.9 |

| 7 | 2.5 | 0 | 10 | 23.0, 28.0 | 0.42, 0.53 | 2.8, 1.6 |

| 8 | 2.5 | 37.5 | 10 | NGb | NG | NG |

| 9 | 2.5 | 75 | 10 | NG | NG | NG |

| 10 | 0 | 0 | 35 | 3.5, 4.5 | 0.87, 0.80 | 4.5, 4.3 |

| 11 | 0 | 37.5 | 35 | 16.0, 17.0 | 0.87, 0.85 | 3.1, 3.1 |

| 12 | 0 | 75 | 35 | 26.5, 18.0 | 0.75, 0.56 | 3.5, 3.5 |

| 13 | 1.25 | 0 | 35 | 5.5c | 0.67c | 3.9c |

| 14 | 1.25 | 37.5 | 35 | 15.5, 18.0 | 0.68, 0.69 | 3.0, 2.9 |

| 15 | 1.25 | 75 | 35 | 18.0, 18.0 | 0.62, 0.58 | 2.9, 2.7 |

| 16 | 2.5 | 0 | 35 | 26.5c | 0.41c | 1.9c |

| 17 | 2.5 | 37.5 | 35 | NG | NG | NG |

| 18 | 2.5 | 75 | 35 | NG | NG | NG |

| 19 | 0 | 0 | 70 | 6.5c | 0.66c | 4.0c |

| 20 | 0 | 37.5 | 70 | 37.0c | 0.48c | 3.1c |

| 21 | 0 | 75 | 70 | 69.0c | 0.49c | 2.4c |

| 22 | 1.25 | 0 | 70 | 6.5, 5.0 | 0.66, 0.66 | 2.7, 2.5 |

| 23 | 1.25 | 37.5 | 70 | 32.0, 32.0 | 0.39, 0.43 | 2.6, 2.5 |

| 24 | 1.25 | 75 | 70 | 62.5, 63.5 | 0.29, 0.42 | 2.3, 2.5 |

| 25 | 2.5 | 0 | 70 | 32.0, 35.5 | 0.09, 0.12 | 2.6, 2.4 |

| 26 | 2.5 | 37.5 | 70 | NG | NG | NG |

| 27 | 2.5 | 75 | 70 | NG | NG | NG |

Data obtained from two experiments unless indicated otherwise.

NG, no growth.

Data obtained from a single experiment.

Analysis of cntB expression and BoNT/B production.

For extraction of total RNA a modified method for extraction of total RNA from Bacillus spp. with acidic phenol was used (30). Ten milliliters of the suspension was removed from each flask after shaking and chilled on ice, and the cells were harvested by centrifugation at 4°C and 10,400 × g for 10 min and resuspended in ice-cold TES buffer (50 mM Tris [ICN Biochemicals Inc.], 5 mM EDTA [Sigma Chemical Co.], 50 mM NaCl [Sigma Chemical Co.]; pH 7.5). Total RNA was recovered by the method described in the accompanying paper (19). Before reverse transcription, contaminating DNA was degraded by treatment with DNase (Promega Co., Madison, Wis.). Total RNA concentrations were determined with a RiboGreen RNA quantification kit (Molecular Probes, Inc., Leiden, The Netherlands). The concentrations were determined by measuring the fluorescence at 525 nm with a TD-700 fluorometer (Turner Designs, Sunnyvale, Calif.). The RNA was stored at −80°C before analysis.

The cntB-specific qRT-PCR method used in this study is described in the accompanying paper (19). To quantify the transcript levels of cntB, the same amount of total RNA (0.5 μg) from each growth phase culture was used in the reverse transcription reaction. PCR amplification was carried out with a Lightcycler instrument (Roche Diagnostics GmbH, Mannheim, Germany). The crossing point for each transcript was determined by using the second derivative maximum mathematical model in the Lightcycler software, version 3.5 (Roche Molecular Biochemicals). Specific primers were used in two separate PCR assays; one of the primers was specific for cntB, and the other was specific for rrn encoding the 16S rRNA. The two fluorogenic probes, one for cntB and one for rrn, contained a reporter dye (6-carboxyfluorescein) covalently attached at the 5′ end and an internal quencher dye (Dark Quencher) attached to a deoxyuridine nucleotide (19). In order to check for amplification of any contaminating genomic DNA, a negative control was added to the PCR analysis. The negative control contained DNase-treated RNA, which was added to the PCR mixture without being reverse transcribed.

Relative quantification was based on the mRNA level of cntB compared with the level of the reference gene, rrn, as described by Pfaffl (28). The relative expression (RE) was calculated from the amplification efficiencies of the cntB assay (EcntB) and the 16S rRNA gene assay (Errn) and the crossing point deviation (ΔCp) of the unknown sample compared with a calibrator sample, as follows: RE = (1 + EcntB)ΔCpcntB(calibrator-unknown sample)/(1 + Errn)ΔCprrn(calibrator-unknown sample).

The extracellular BoNT/B concentration was determined by an ELISA with polyclonal antibodies specific for the type B BoNT from rabbits (Metabiologics, Inc., Madison, Wis.), as described in the accompanying paper (19). Samples were collected at the same time as the samples used for RNA extraction in the late stationary growth phase. BoNT/B standards were included on each plate at the following concentrations: 1, 0.9, 0.8, 0.7, 0.6, 0.5, 0.4, and 0.3 ng/ml. Casein buffer was included as a negative control on each plate. Samples from both growth experiments for each medium combination were analyzed by ELISA, and an average value and standard deviation were calculated. For each sample the extracellular toxin concentration was correlated with the total cell mass by dividing the concentration by the maximum OD620 value.

Statistical analysis.

We constructed six regression models in order to obtain a quantitative description of how the explaining variables CO2, NaCl, and NaNO2 are related to six outcome variables: LPD, growth rate, relative expression of cntB in the three different growth phases, and the extracellular BoNT/B concentration. For all six outcome variables, we used all linear, quadratic, and second-order interaction terms; i.e., we supposed that the outcome, except for independent and normally distributed statistical errors, was b0 + b1 · [CO2] + b2 · [NaCl] + b3 · [NaNO2] + b11 · [CO2] + b22 · [NaCl] + b33 · [NaNO2] + b12 · [CO2] · [NaCl] + b13 · [CO2] · [NaNO2] + b23 · [NaCl] · [NaNO2], and from this starting point the best-fit model with all bs significant was selected (7). We ended up with a smaller model (some bs were zero) when insignificant terms were removed. Note how the coefficients were constructed; the covariates were numbered 1, 2, and 3, and the coefficient before covariate 1 times covariate 2 was designated b12, for example. To make estimates of the coefficients easier to compare, all values for CO2, NaCl, and NaNO2 were divided by the largest values before they were put into the regression; i.e., the values for NaCl were divided by 2.5, the values for NaNO2 were divided by 75, and the values for CO2 were divided by 70. For the analysis of relative expression and the extracellular BoNT/B concentration, the logarithm of the value was used as the dependent variable, since this brought the data closer to the assumption of normal distribution and of equal variance of the error terms.

RESULTS

Effect on LPD and growth rate.

Various concentrations of carbon dioxide (10, 35, and 70% [vol/vol]), sodium chloride (0, 1.25, and 2.5% [wt/vol]), and sodium nitrite (0, 37.5, and 75 ppm) were added to TPY-C medium. C. botulinum Eklund 2B was able to grow in 21 of the 27 factorial-designed medium combinations (Table 1). The following model was used to quantitatively describe the interaction effects on LPD: LPD = b0i + b13i · [CO2] · [NaNO2] + b22i · [NaCl]2 + error (see Table 2 for the b values). The errors in the different measurements were assumed to be independent Gaussian-distributed random variables with mean zero and constant variance. In the model, significant effects on the LPD were found for the quadratic term for NaCl and the interaction between NaNO2 and CO2 (Table 2). However, the effect of the interaction (50) (Table 2) was about twice that of the effect of NaCl (21) (Table 2). The LPD was extended with increasing concentrations of NaNO2 and CO2. At 10 and 35% CO2 the LPD was the same order of magnitude, whereas at 70% CO2 and 75 ppm NaNO2 the LPD was almost three times longer (69.0 h at 70% CO2 compared with 24.5 h at 10% CO2).

TABLE 2.

Effects on LPD and growth rate of C. botulinum Eklund 2Ba

| Dependent variable | Coefficient | Effect | 95% confidence interval |

|---|---|---|---|

| LPD | b0i | 5.6 | 1.4, 9.7 |

| b13i | 50 | 40, 58 | |

| b22i | 21 | 12, 29 | |

| Specific growth rate | b0ii | 1.0 | 0.9, 1.1 |

| b3ii | −0.4 | −0.6, −0.3 | |

| b12ii | 0.3 | 0.1, 0.5 | |

| b22ii | −0.5 | −0.6, −0.4 | |

| b11ii | −0.4 | −0.5, −0.3 |

The effect of CO2 is indicated by 1, the effect of NaCl is indicated by 2, and the effect of NaNO2 is indicated by 3, so that b3 is the effect of [NaNO2], b11 is the effect of [CO2]2, b22 is the effect of [NaCl]2, b13 is the effect of [CO2]· [NaNO2], and b12 is the effect of [CO2]·[NaCl]. The level when all the effects were zero is indicated by b0.

In the statistical analysis of the effect on the specific growth rate (μ) the following model was used:

μ = b0ii + b3ii · [NaNO2] + b13ii · [CO2] · [NaNO2] + b22ii · [NaCl]2 + b11ii · [CO2]2 + error. All of the preservatives investigated decreased the growth rate. However, the effects could not simply be added due to the positive interaction between NaNO2 and CO2. The growth rate decreased (negative effect in Table 2) with increasing salt concentration, and the most significant effect was observed at 2.5% NaCl (Table 1). Furthermore, the maximum OD620 value decreased as the NaCl concentration increased. For NaNO2, the same trend was observed; there was slower growth and a reduction in the maximum OD620 value as the NaNO2 concentration increased at both 10 and 70% CO2. These results agree with what was previously determined about the effects of NaCl and NaNO2 on growth (16). However, at 35% CO2 there was instead a small increase in both the growth rate and the OD620. The highest CO2 concentration, 70%, was found to inhibit growth in all medium combinations compared with the growth in the other gas mixtures.

Effect on cntB expression.

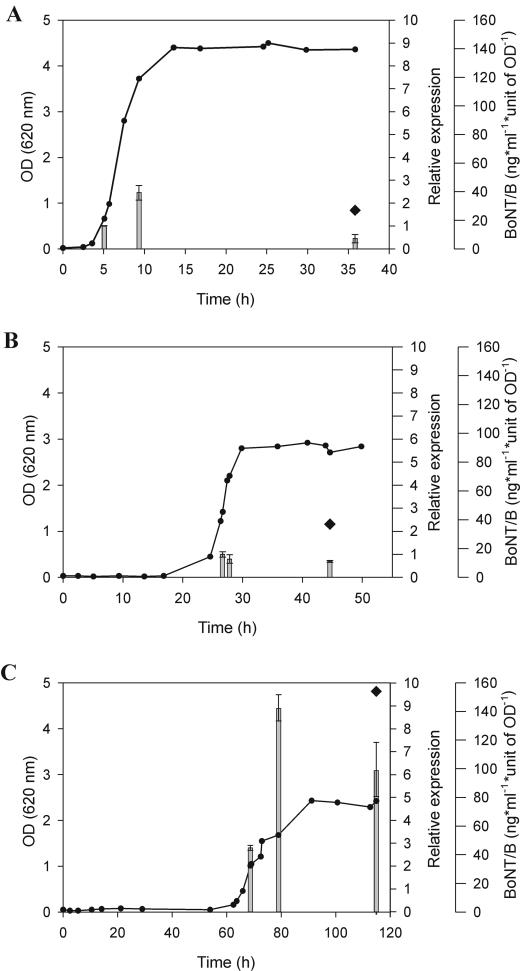

cntB expression was monitored three times during growth: in the middle of the exponential phase, in the late exponential phase, and in the late stationary phase (Table 3 and Fig. 1). The level of expression of the reference gene was found to be constant in all growth phases and media, as shown by stable crossing point values (data not shown). In the statistical analysis of the effect on cntB expression, the three growth phases were analyzed individually, resulting in the following three models: for the mid-exponential phase, log(RE) = b0iii + b11iii · [CO2]2 + b2iii · [NaCl] + error; for the late exponential phase, log(RE) = b0iv + b3iv · [NaNO2] + b11iv · [CO2]2 + b33iv · [NaNO2]2 + error; and for the late stationary phase, log(RE) = b0v + b1v · [CO2] + b2v · [NaCl] + error. In general, most combinations resulted in maximum cntB expression in the late exponential growth phase. Statistical analysis showed that NaCl had a significant effect on cntB transcription in the middle of the exponential growth phase and in the late stationary growth phase (Table 4). This was most obvious when the growth medium had been supplemented with 2.5% NaCl in the presence of both 10 and 35% CO2. In these cases the cntB mRNA level continued to increase after the late exponential phase and reached a maximum in the late stationary growth phase. In the presence of 70% CO2 the maximum cntB mRNA level was again observed in the late exponential phase, but the level was much higher than the previous level (Fig. 1C).

TABLE 3.

Interaction effects of NaCl, NaNO2, and CO2 on the relative expression of the type B neurotoxin gene and the extracellular neurotoxin concentration

| Expt | Exptl design

|

Relative expression of type B neurotoxin genea

|

Extracellular neurotoxin concn (ng · ml−1 · unit of OD620−1)a | ||||

|---|---|---|---|---|---|---|---|

| CO2 concn (%, vol/vol) | NaCl concn (%, wt/vol) | NaNO2 concn (ppm) | Mid-exponential phase | Late exponential phase | Late stationary phase | ||

| 1 | 10 | 0 | 0 | 1.0, 1.0 | 2.9, 2.0 | 0.2, 0.7 | 25.7, 27.7 |

| 2 | 10 | 0 | 37.5 | 0.6, 0.4 | 0.4, 0.6 | 0.4, 0.3 | 28.9, 32.6 |

| 3 | 10 | 0 | 75 | 0.4, 0.4 | 0.9, 0.5 | 0.3, 0.4 | 21.7, 38.3 |

| 4 | 10 | 1.25 | 0 | 0.7, 0.9 | 1.0, 1.2 | 0.7, 1.0 | 20.9, 43.7 |

| 5 | 10 | 1.25 | 37.5 | 1.1, 0.8 | 0.8, 1.3 | 0.9, 1.0 | 40.4, 71.2 |

| 6 | 10 | 1.25 | 75 | 1.1, 0.9 | 0.8, 0.8 | 0.8, 0.6 | 35.2, 55.2 |

| 7 | 10 | 2.5 | 0 | 1.5, 1.3 | 1.3, 1.4 | 1.5, 1.8 | 37.9, 63.8 |

| 8 | 10 | 2.5 | 37.5 | NGb | NG | NG | NG |

| 9 | 10 | 2.5 | 75 | NG | NG | NG | NG |

| 10 | 35 | 0 | 0 | 0.8, 0.8 | 2.5, 1.2 | 0.4, 0.5 | 27.8, 47.9 |

| 11 | 35 | 0 | 37.5 | 0.6, 0.5 | 1.3, 0.9 | 1.0, 0.7 | 37.7, 53.9 |

| 12 | 35 | 0 | 75 | 0.6, 0.6 | 1.4, 0.8 | 0.8, 0.6 | 19.1, 30.9 |

| 13 | 35 | 1.25 | 0 | 1.2c | 2.7c | 0.8c | 27.9c |

| 14 | 35 | 1.25 | 37.5 | 1.0, 2.1 | 1.4, 1.4 | 2.3, 1.8 | 30.0, 44 |

| 15 | 35 | 1.25 | 75 | NG | 1.4, 1.6 | 1.1, 1.6 | 34.1, 54.8 |

| 16 | 35 | 2.5 | 0 | 2.2c | 2.7c | 3.3c | 64.2c |

| 17 | 35 | 2.5 | 37.5 | NG | NG | NG | NG |

| 18 | 35 | 2.5 | 75 | NG | NG | NG | NG |

| 19 | 70 | 0 | 0 | 6.6c | 12.3c | 2.0c | 126.2c |

| 20 | 70 | 0 | 37.5 | 2.4c | 9.0c | 1.0c | 104.2c |

| 21 | 70 | 0 | 75 | 3.9c | 5.4c | 1.6c | 87.5c |

| 22 | 70 | 1.25 | 0 | 4.2, 4.2 | 9.4, 12.0 | 3.0, 4.6 | 100.7, 180.0 |

| 23 | 70 | 1.25 | 37.5 | 1.3, 0.6 | 3.0, 4.7 | 3.7, 2.5 | 100.4, 152.4 |

| 24 | 70 | 1.25 | 75 | 2.6, 2.9 | 9.7, 8.1 | 4.5, 7.8 | 122.6, 182.0 |

| 25 | 70 | 2.5 | 0 | 6.3, 6.1 | 8.1, 10.1 | 4.0, 2.8 | 68.8, 120.8 |

| 26 | 70 | 2.5 | 37.5 | NG | NG | NG | NG |

| 27 | 70 | 2.5 | 75 | NG | NG | NG | NG |

Data obtained from two experiments unless indicated otherwise.

NG, no growth.

Data obtained from a single experiment.

FIG. 1.

Effects of carbon dioxide, sodium chloride, and sodium nitrite on LPD, growth, relative cntB expression, and extracellular BoNT/B formation in C. botulinum Eklund 2B. The concentrations of the different preservatives were as follows: 10% carbon dioxide, 0% sodium chloride, and 0 ppm of sodium nitrite (A); 10% carbon dioxide, 1.25% sodium chloride, and 75 ppm of sodium nitrite (B); and 70% carbon dioxide, 1.25% sodium chloride, and 75 ppm of sodium nitrite (C). •, growth curve as determined by measurement of OD620; bars, relative expression of cntB; ⧫, concentration of extracellular BoNT/B. The values are averages and standard deviations based on two independent growth experiments.

TABLE 4.

Effects on relative neurotoxin expression during growth of C. botulinum Eklund 2Ba

| Phase | Coefficient | Effect | 95% confidence interval |

|---|---|---|---|

| Mid-exponential | b0iii | −0.6 | −0.8, −0.4 |

| b2iii | 0.9 | 0.5, 1.2 | |

| b11iii | 1.6 | 1.3, 1.9 | |

| Late exponential | b0iv | 0.3 | 0.1, 0.5 |

| b3iv | −2.1 | −3.2, −1.2 | |

| b11iv | 2.1 | 1.8, 2.4 | |

| b33iv | 1.6 | 0.6, 2.6 | |

| Late stationary | b0v | −1.2 | −1.4, −0.9 |

| b1v | 1.5 | 1.2, 1.9 | |

| b2v | 1.4 | 1.1, 1.7 |

The effect of CO2 is indicated by 1, the effect of NaCl is indicated by 2, and the effect of NaNO2 is indicated by 3, so that b1 is the effect of [CO2], b11 is the effect of [CO2], b2 is the effect of [NaCl], b3 is the effect of [NaNO2], and b33 is the effect of [NaNO2]2. The level when all the effects were zero is indicated by b0.

Carbon dioxide had a significant effect on cntB expression in all three growth phases. Overall, the cntB mRNA level increased as the CO2 concentration increased, and the highest levels were detected with the 70% CO2 atmosphere. In the three cases in which the medium was not supplemented with any NaCl or NaNO2 and only the effect of CO2 was monitored, the largest difference in expression was observed in the late exponential growth phase, and there was a fivefold increase between 10 and 70% CO2. This was confirmed by measuring the extracellular BoNT/B concentration by the ELISA in the late stationary growth phase. Nitrite, when studied alone (experiments 1 to 3, 10 to 12, and 19 to 21 in Table 3) had an inhibitory effect on cntB expression, especially in the exponential phases. However, the impact was strong enough to be visible in the statistical analyses only during the late exponential phase (Table 4).

Effect on BoNT/B production.

The following model was used for statistical evaluation of BoNT/B production: BoNT/B = b0vi + b11vi · [CO2]2 + error. Table 5 shows the values. A higher concentration of the toxin was detected at an elevated CO2 concentration, and the highest concentrations were detected with the 70% CO2 atmosphere. In the presence of 10% CO2 when the medium was not supplemented with NaCl or NaNO2, the BoNT/B concentration was 27 ng · ml−1 · unit of OD620−1. The corresponding value in the presence of 70% CO2 was 126 ng · ml−1 · unit of OD620−1; thus, there was a fivefold increase in the level of extracellular toxin.

TABLE 5.

Effects on extracellular BoNT/B concentration of C. botulinum Eklund 2Ba

| Coefficient | Effect | 95% confidence interval |

|---|---|---|

| b0vi | 29 | 18, 40 |

| b11vi | 90 | 70, 110 |

The effect of CO2 is indicated by 1, the effect of NaCl is indicated by 2, and the effect of NaNO2 is indicated by 3, so that b11 is the effect of [CO2]2. The level when all the effects were zero is indicated by b0.

DISCUSSION

In this investigation, we studied the effects of three food preservatives that are commonly used to control C. botulinum in foods (carbon dioxide, sodium chloride, and sodium nitrite) on the cntB expression of the nonproteolytic strain C. botulinum Eklund 2B. Six statistical models were constructed to quantify and predict the interaction effects of these selected food preservatives on LPD, growth rate, relative cntB expression, and neurotoxin production.

The growth of C. botulinum and cntB expression were influenced by addition of CO2, NaCl, and NaNO2 to TPY-C medium, both when the compounds were added individually and when they were added in combination. The stimulating effect of CO2 on cntB expression could clearly be seen at all stages of growth. NaCl also appeared to have a stimulating effect, at least in the mid-exponential and late stationary phases. The impact of CO2 was also seen in BoNT/B production (Table 5). The positive effect on toxin production was clear, unlike the effects of the other factors. The differences between the effects on toxin expression and toxin production can be explained by the role that factors other than the growth environment play in neurotoxin formation. For the most part the amount of neurotoxin formed can be predicted from the relative expression ratio in the late exponential phase. Including the other growth phases does not improve the analysis significantly (data not shown).

The combination consisting of 2.5% NaCl and 37.5 or 75 ppm of NaNO2 totally inhibited growth in either of the CO2 atmospheres investigated. Furthermore, we found that addition of NaNO2 repressed the expression of cntB, which is in agreement with findings described in the accompanying paper (19). However, BoNT/B production was unchanged, which may be explained by cell death in the culture and release of BoNT/B into the culture fluid. Addition of NaCl stimulated cntB expression, both in the middle of the exponential growth phase and in the late stationary growth phase. As a result of the higher gene expression, the concentration of BoNT/B was higher (51 ng · ml−1 · unit of OD620−1) than the concentration in the medium with no NaCl (27 ng · ml−1 · unit of OD620−1). At the same time, we found that NaCl extended the LPD and reduced the specific growth rate. This may indicate that cntB expression is induced when the bacteria are in a saline environment. NaCl is one of the most commonly used and important food preservatives for control of C. botulinum as it lowers the water activity in foods (15). In general, nonproteolytic strains of C. botulinum can be totally inhibited by 5% (wt/vol) salt under otherwise optimal growth conditions (15). However, foods containing high concentrations of salt are not especially popular among consumers. Therefore, a combination of NaCl and NaNO2 is often used to reduce the amount of NaCl needed to inhibit C. botulinum.

When 1.25% NaCl and 75 ppm NaNO2 were combined in the growth medium (Fig. 1), we found that the gene expression was still pronounced in all three growth phases and that the extracellular BoNT/B concentration was still unchanged (45 ng · ml−1 · unit of OD620−1). This combination of NaCl and NaNO2 was also found to increase the LPD sixfold compared with the LPD obtained with the medium to which no preservatives were added. The increase in the LPD was probably an effect of the NaNO2 added to the medium, as the LPD was the same order of magnitude as the LPD observed when NaNO2 alone was used. The growth rate seemed to be influenced more by the increasing NaCl concentration. Thus, the concentration of the extracellular BoNT/B remained unchanged, regardless of the inhibition of the growth of C. botulinum.

Generally, the interaction of NaNO2 and CO2 significantly increased the LPD and reduced both the growth rate and the maximum OD620. However, in the presence of 35% CO2, growth was observed earlier and was somewhat faster than the growth in medium with 10 or 70% CO2. This was also observed when we used some of the other media containing NaNO2; e.g., 35% CO2 stimulated growth by increasing both the growth rate and the maximum OD620 compared with the growth rates and the maximum OD620 values obtained with the other CO2 concentrations. Similar findings (i.e., that CO2 can either stimulate or inhibit growth depending on the concentration in the gas atmosphere) have been reported previously for microbiological growth medium (8). Fernandez et al. (8) observed a substantial inhibitory effect on the growth of C. botulinum with 90% CO2, moderate inhibition of growth with 50% CO2, and stimulation of growth with 5% CO2. In addition to the stimulatory and inhibitory effects on vegetative growth, CO2 is also known to act as a spore germinant in C. botulinum (9). It is important to take these issues into consideration as replacing the air in the headspace in modified-atmosphere packaging with CO2 can result in a hazard rather than protection with regard to food safety

Furthermore, CO2 in the gas atmosphere was found to have the most dominant effect on cntB expression when all three growth phases were considered. Overall, expression of cntB was stimulated in the presence of elevated CO2 concentrations; the highest levels were detected in a 70% CO2 atmosphere. In some combinations a fivefold increase in relative expression was observed when we compared 10% CO2 with 70% CO2. This finding was confirmed when we analyzed the extracellular BoNT/B concentration in the late-stationary-phase cell culture fluid, in which the highest concentrations of the toxin were observed with the 70% CO2 atmosphere. The concentrations were found to be four- to fivefold higher in this atmosphere than in the presence of 10% CO2. An elevated CO2 concentration has been reported to induce the expression of genes involved in toxin production in Bacillus anthracis (2) and Vibrio cholerae (31). It was recently found that in the more closely related organism C. difficile an elevated bicarbonate concentration in peptone-yeast extract broth increased the toxin yield 10-fold (14). In our growth experiments the pH of the growth media was reduced from pH 7 to pH 5 (data not shown). As CO2 in the gas phase is more easily dissolved at a lower pH and dissociates into bicarbonate in a liquid medium, the stimulating effect that we observed on BoNT/B formation in this study could be explained by an elevated bicarbonate concentration in the TPY-C medium. In the bacterial cell an elevated concentration of bicarbonate influences several biosynthetic reactions, including biotin-dependent carboxylation. Karlsson et al. (14) suggested a possible link between carboxylation and amino acid synthesis through α-ketobutyrate, a precursor in isoleucine biosynthesis. In some anaerobic bacteria reductive carboxylation occurs during the synthesis of α-ketobutyrate from propionyl coenzyme A. In addition, it has been reported that production of BoNT is regulated by different amino acids (6, 16, 25). This may provide a possible explanation for both the increased level of cntB expression and the increased extracellular BoNT/B concentration that we observed in this study.

In conclusion, CO2 is often used to control the growth of microorganisms in ready-to-eat foods. However, our work showed that even though a high concentration of CO2 decreased the growth rate, the expression and production of toxin were greatly increased. This means that the risk of botulism may actually be increased, instead of reduced, by the use of modified-atmosphere packaging. Further studies of the interaction effects of food preservatives on neurotoxin expression and production in different foods by C. botulinum may provide new and important information concerning food safety and may help us formulate new alternative methods for food preservation.

Acknowledgments

We gratefully acknowledge Halfdan Grage for valuable discussions.

This work was supported by grants from the Swedish Foundation for Strategic Research through a national, industry-oriented program for research and postgraduate education, by LiFT—Future Technologies for Food Production, and by the Swedish Agency for Innovation Systems (VINNOVA).

REFERENCES

- 1.Baranyi, J., and T. A. Roberts. 1994. A dynamic approach to predicting bacterial growth in food. Int. J. Food Microbiol. 23:277-294. [DOI] [PubMed] [Google Scholar]

- 2.Bartkus, J. M., and S. H. Leppla. 1989. Transcriptional regulation of the protective antigen gene of Bacillus anthracis. Infect. Immun. 57:2295-2300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Baty, F., J. P. Flandrois, and M. L. Delignette-Muller. 2002. Modeling the lag time of Listeria monocytogenes from viable count enumeration and optical density data. Appl Environ Microbiol. 68:5816-5825. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Bhandari, M., K. D. Campbell, M. D. Collins, and A. K. East. 1997. Molecular characterization of the clusters of genes encoding the botulinum neurotoxin complex in Clostridium botulinum (Clostridium argentinense) type G and nonproteolytic Clostridium botulinum type B. Curr. Microbiol. 35:207-214. [DOI] [PubMed] [Google Scholar]

- 5.Dahlenborg, M., E. Borch, and P. Rådström. 2001. Development of a combined selection and enrichment PCR procedure for Clostridium botulinum types B, E, and F and its use to determine prevalence in fecal samples from slaughtered pigs. Appl. Environ. Microbiol. 67:4781-4788. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Davis, T. O., I. Henderson, J. K. Brehm, and N. P. Minton. 2000. Development of a transformation and gene reporter system for group II, non-proteolytic Clostridium botulinum type B strains. J. Mol. Microbiol. Biotechnol. 2:59-69. [PubMed] [Google Scholar]

- 7.Draper, N. R., and H. Smith. 1998. Applied regression analysis, 3rd ed. John Wiley and Sons, Inc., New York, N.Y.

- 8.Fernandez, P. S., J. Baranyi, and M. W. Peck. 2001. A predictive model of growth from spores of non-proteolytic Clostridium botulinum in the presence of different CO2 concentrations as influenced by chill temperature, pH and NaCl. Food Microbiol. 18:453-461. [Google Scholar]

- 9.Foegeding, P. M., and F. F. Busta. 1983. Effect of carbon dioxide, nitrogen and hydrogen gases on germination of Clostridium botulinum spores. J. Food Prot. 46:987-989. [DOI] [PubMed] [Google Scholar]

- 10.Gibson, A. M., R. C. L. Ellis-Brownlee, M. E. Cahill, E. A. Szabo, G. C. Fletcher, and P. J. Bremer. 2000. The effect of 100% CO2 on the growth of nonproteolytic Clostridium botulinum at chill temperatures. Int. J. Food Microbiol. 54:39-48. [DOI] [PubMed] [Google Scholar]

- 11.Graham, A. F., D. R. Mason, F. J. Maxwell, and M. W. Peck. 1997. Effect of pH and NaCl on growth from spores of non-proteolytic Clostridium botulinum at chill temperature. Lett. Appl. Microbiol. 24:95-100. [DOI] [PubMed] [Google Scholar]

- 12.Hauser, D., M. W. Eklund, P. Boquet, and M. R. Popoff. 1994. Organization of the botulinum neurotoxin C1 gene and its associated non-toxic protein genes in Clostridium botulinum C 468. Mol. Gen. Genet. 243:631-640. [DOI] [PubMed] [Google Scholar]

- 13.Henderson, I., S. M. Whelan, T. O. Davis, and N. P. Minton. 1996. Genetic characterisation of the botulinum toxin complex of Clostridium botulinum strain NCTC 2916. FEMS Microbiol. Lett. 140:151-158. [DOI] [PubMed] [Google Scholar]

- 14.Karlsson, S., L. G. Burman, and T. Akerlund. 1999. Suppression of toxin production in Clostridium difficile VPI 10463 by amino acids. Microbiology 145:1683-1693. [DOI] [PubMed] [Google Scholar]

- 15.Kim, J., and P. M. Foegeding. 1993. Principles of control, p. 121-176. In A. H. W. Hauschild and K. L. Dodds (ed.), Clostridium botulinum. Ecology and control in foods, vol. 54. Marcel Dekker, Inc., New York, N.Y.

- 16.Leyer, G. J., and E. A. Johnson. 1990. Repression of toxin production by tryptophan in Clostridium botulinum type E. Arch. Microbiol. 154:443-447. [DOI] [PubMed] [Google Scholar]

- 17.Lilly, T., S. M. Harmon, D. A. Kautter, H. M. Solomon, and R. K. Lynt. 1971. An improved medium for detection of Clostridium botulinum type E. J. Milk Food Technol. 34:492-497. [Google Scholar]

- 18.Lund, B. M., and M. W. Peck. 1994. Heat resistance and recovery of spores of non-proteolytic Clostridium botulinum in relation to refrigerated, processed foods with an extended shelf-life. Soc. Appl. Bacteriol. Symp. Ser. 23:115S-128S. [DOI] [PubMed] [Google Scholar]

- 19.Lövenklev, M., E. Holst, E. Borch, and P. Rådström. 2004. Relative neurotoxin gene expression in Clostridium botulinum type B, determined using quantitative reverse transcription-PCR. Appl. Environ. Microbiol. 70:2919-2927. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Marvaud, J. C., U. Eisel, T. Binz, H. Niemann, and M. R. Popoff. 1998. TetR is a positive regulator of the tetanus toxin gene in Clostridium tetani and is homologous to BotR. Infect. Immun. 66:5698-5702. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Marvaud, J. C., M. Gibert, K. Inoue, Y. Fujinaga, K. Oguma, and M. R. Popoff. 1998. botR/A is a positive regulator of botulinum neurotoxin and associated non-toxin protein genes in Clostridium botulinum A. Mol. Microbiol. 29:1009-1018. [DOI] [PubMed] [Google Scholar]

- 22.Meng, J., and C. A. Genigeorgis. 1993. Modeling lag phase of nonproteolytic Clostridium botulinum toxigenesis in cooked turkey and chicken breast as affected by temperature, sodium lactate, sodium chloride and spore inoculum. Int. J. Food Microbiol. 19:109-122. [DOI] [PubMed] [Google Scholar]

- 23.Moncrief, J. S., L. A. Barroso, and T. D. Wilkins. 1997. Positive regulation of Clostridium difficile toxins. Infect. Immun. 65:1105-1108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Moore, L. W. H., E. P. Cato, and W. E. C. Moore. 1977. VPI anaerobe laboratory manual. Virginia Polytechnic Institute and State University, Blacksburg.

- 25.Patterson-Curtis, S. I., and E. A. Johnson. 1989. Regulation of neurotoxin and protease formation in Clostridium botulinum Okra B and Hall A by arginine. Appl. Environ. Microbiol. 55:1544-1548. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Peck, M. W. 1997. Clostridium botulinum and the safety of refrigerated processed foods of extended durability. Trends Food Sci. Technol. 8:186-192. [Google Scholar]

- 27.Peck, M. W., B. M. Lund, D. A. Fairbairn, A. S. Kaspersson, and P. C. Undeland. 1995. Effect of heat treatment on survival of, and growth from, spores of nonproteolytic Clostridium botulinum at refrigeration temperatures. Appl. Environ. Microbiol. 61:1780-1785. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Pfaffl, M. W. 2001. A new mathematical model for relative quantification in real-time RT-PCR. Nucleic Acids Res. 29:2002-2007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Popoff, M. R., and J. C. Marvaud. 1999. The comprehensive sourcebook of bacterial protein toxins, p. 174-201. Academic Press, New York, N.Y.

- 30.Putzer, H., N. Gendron, and M. Grunberg-Manago. 1992. Co-ordinate expression of the two threonyl-tRNA synthetase genes in Bacillus subtilis: control by transcriptional antitermination involving a conserved regulatory sequence. EMBO J. 11:3117-3127. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Shimamura, T., S. Watanabe, and S. Sasaki. 1985. Enhancement of enterotoxin production by carbon dioxide in Vibrio cholerae. Infect. Immun. 49:455-456. [DOI] [PMC free article] [PubMed] [Google Scholar]