Abstract

Kunda, an indigenous heat desiccated sweet product prepared from milk and added sugar, has a shelf-life of a few days under market conditions. In this study, effect of preservatives viz. potassium sorbate and nisin on the shelf-life of kunda stored at 30° and 5 °C was investigated. During storage, several changes took place in physico-chemical and sensory characteristics, the changes being faster at 30° than at 5 °C. There was little effect of preservatives per se on the quality of kunda, but changes were slower in kunda preserved with nisin. Kunda packaged in LDPE pouches or tin cans and stored at 30° and 5 °C, irrespective of the presence or absence of preservatives, was stable for 42 and 90 days respectively. Increase in osmotic pressure due to high levels of sugar in kunda might be responsible for containing the growth of microbes in the product.

Keywords: Kunda, Shelf-life, Preservative, Nisin, Potassium sorbate

Introduction

Kunda is a heat desiccated indigenous dairy product popular as a sweetmeat in northern Karnataka region. According to an estimate 4.0 tonnes of kunda is sold or consumed in northern Karnataka. Most of kunda marketed is being manufactured by small scale sweetmeat makers and sold in packaged (LDPE, bags or butter paper lined cardboard boxes) or loose form with varying compositions (Kulkarni et al. 2001). People of the region relish the typical and lingering taste of kunda, but the quality of the product depends on the skills of the manufacturer and is greatly influenced by the type of milk, fat content of milk, extent of desiccation, initial raw material used, amount of sugar etc. Hence, the product prepared by some manufacturers is more popular than that made by others. According to a report (Anonymous 2006), there were 300 manufacturing units spread across northern region of Karnataka, but in southern parts of the state, the product is not well known. The reason for the popularity of this product remaining limited to northern Karnataka could be attributed to its short shelf-life. It stays well for about four days at ambient temperature, and later develops a mild sour taste. The spoilage begins with visible growth of yeasts and molds. Thus, if the market for kunda has to expand to the southern regions, its shelf-life has to be extended to an acceptable limit. So far, studies carried out have been confined to characterization (Kulkarni et al. 2001). standardization of the method of manufacture (Mahalingaiah et al. 2000) and mechanization of manufacturing process (Menon et al. 2004). However, till date no study on the shelf-life enhancement of kunda has been reported. Attempts have been therefore made in this study to improve the shelf-life of kunda by using appropriate preservatives.

Materials and methods

Preparation of kunda

Kunda was prepared from standardised cow milk as per the standardised method reported by Mahalingaiah et al. (2000).

Fresh cow milk was procured from dairy farm of National Dairy Research Institute, Bangalore, and analyzed for its fat and solids not fat (SNF) (BIS 1981) It was preheated, filtered and standardised to 5.0% fat and 8.5% SNF by using cream. Milk was taken into a clean, sterilized khoa kettle and steam let into the jacket. Subsequently it was brought to boil and heating continued with continuous stirring till desiccation stage to obtain khoa. Cane sugar at the rate of 9.0% (w/w) on milk was added at pat formation stage. The contents were heated to dissolve sugar with scraping and vigorous mixing. Potable water was added at the rate of about 10 to 15% of khoa (w/w) to make slurry. The slurry was heated with continuous scraping and desiccated to ‘pat’ stage. Then subsequent lot of water was added to make slurry again and further desiccation was continued to ‘pat’ stage. These steps were continued till a typical brown coloured kunda was developed.

Use of preservatives

Preservatives viz. potassium sorbate and nisin were tried to extend the shelf-life of kunda. The preservative @ 2000 ppm was dissolved in a little quantity of sterilized distilled water and added to kunda when the product was still hot (about 85°–90 °C). Then the product was mixed thoroughly and packaged in LDPE pouches of 200 g capacity. The pouches were sealed by impulse sealing machine.

Storage

Kunda packed in LDPE pouches was stored at 5o and 30 °C and the samples were drawn at regular intervals of 15 days at 5 °C and 7 days at 30 °C. The kunda was analysed for various physico-chemical, microbiological and sensory parameters.

Analyses

Samples of kunda were drawn at regular intervals and analyzed for physico-chemical (moisture, water activity, acidity and browning index), microbiological (bacterial, yeast and mold and coliform counts) and sensory properties. Packets containing kunda were cut open and the contents were transferred to a mortar and ground thoroughly with a pestle to obtain a uniformly mixed sample, which was then used for analyses of physico-chemical properties. For microbiological analyses, the sealed sachets containing kunda were opened under sterile conditions (BIS 1980a).

Physico-chemical characteristics

Moisture content and acidity were determined as per methods given in BIS (1981) and BIS (1980b), respectively. Browning index determination was carried out by enzymatic method using Pronase enzyme (Sigma-Aldrich) as described by Gothwal and Bhavadasan (1992), and the results were expressed as optical density (OD) per gm. Water activity of kunda was measured by using Rotronic Hygroskop (BT-RS1, Switzerland) at a calibrated temperature of 25 °C as per the method of Fontana and Campbell (2004).

Microbiological characteristics

Bacterial counts (SPC) were estimated by plating suitable buffer dilutions using nutrient agar and incubating the petri plates at 30 °C for 48 h (BIS 1980a), yeast and mold counts were estimated using MEA agar with incubation at 25 °C for 72 h (BIS 1980a) and coliform counts using violet red blue Agar and incubation at 30 °C for 24–48 h (BIS 1980a). The counts were expressed as colony forming units (cfu) per gram of kunda.

Sensory evaluation

Kunda packed in LDPE pouches was transferred to a well cleaned glass plates, tempered to ambient temperature and served to a panel of expert judges chosen from the faculty of National Dairy Research Institute and Karnataka Veterinary Animal and Fisheries Sciences University, Bangalore in a sensory evaluation laboratory. The panelists were asked to evaluate the sensory quality in terms of colour and appearance, body and texture, flavour and overall acceptance using a 9-point Hedonic scale, in which a score of 1 indicated ‘dislike extremely’ and a score of 9 indicated ‘like extremely’ (Amerine et al. 1965).

Statistical analysis

The various physico-chemical, microbiological and sensory evaluation data were subjected to 2 × 3 × 7 factorial design analysis and the statistical significance of effect of various treatments and their interactions were determined by SPSS package (Version 11.0).

Results and discussion

Effect of preservatives on physico-chemical and microbiological characteristics of Kunda during storage

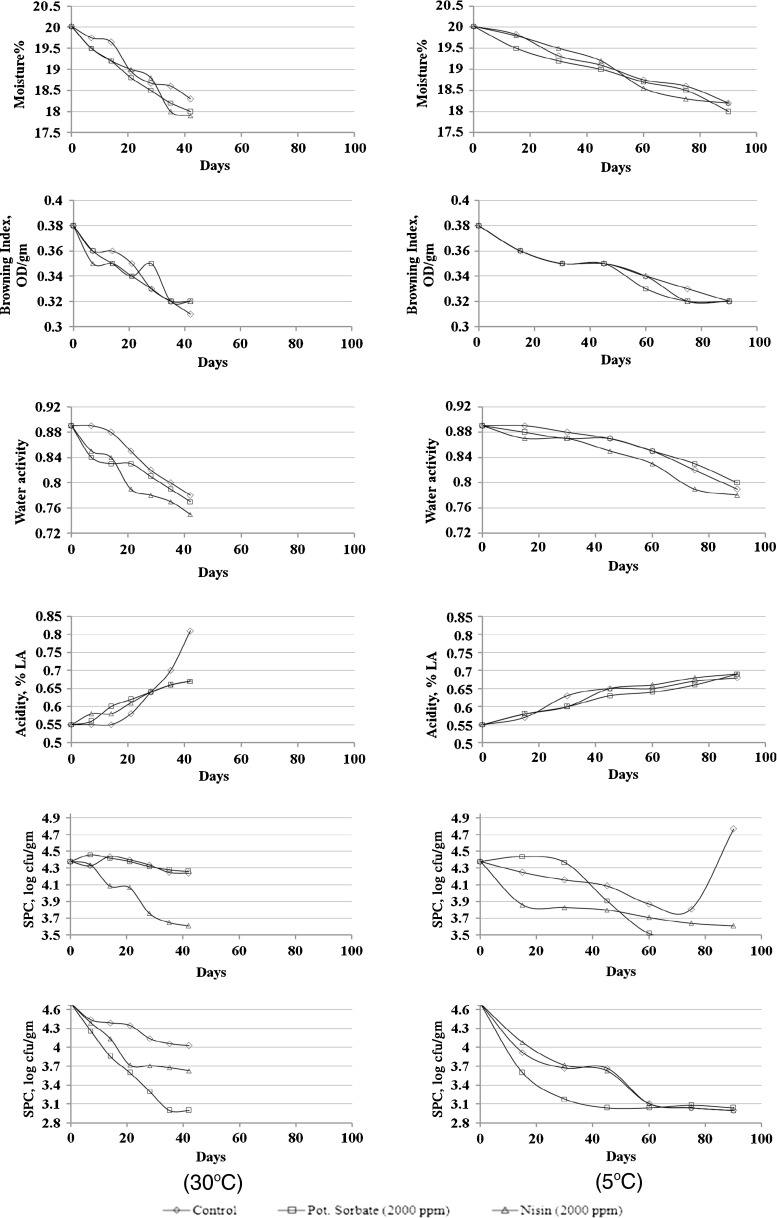

The results on physico-chemical and microbiological changes of kunda occurring during storage are presented in Fig. 1. These changes varied with temperature of storage. Moisture content of kunda decreased gradually as the storage progressed at both the temperatures of storage (Fig. 1), but the extent of moisture loss was different among various kunda samples. Statistical analysis indicated a significant difference among the treatments, namely, storage durations, preservatives and storage temperatures (Table 1). Similarly, the water activity of kunda also decreased with storage period as could be observed from Fig. 1 (P < 0.05). However, no temperature effect was observed on the change in aw (Table 1). This could be attributed to measurement of aw of the samples at a fixed instrument calibrated temperature. Also, the losses observed in moisture contents because of difference in storage temperatures were not to that extent as to result in significant changes in aw. This is because of sigmoidal relationship between moisture content and water activity (Sawhney et al. 1997; Rao 2000). Regarding browning index (BI), it decreased during storage at both the temperatures (Fig. 1). This decrease in browning during storage was found to be significant (P < 0.05) (Table 1). However, the changes due to temperature of storage were non-significant. Probably for the same reason, there was no difference in change in acidity between the preservatives. The decrease in browning index during the storage could be attributed indirectly to decrease in moisture and water activity. It is known that at intermediate moisture range, lower the moisture, lower is the browning rate (Rao 2000). However, Navajeevan and Rao (2005) observed an increase in browning index in retort sterilized kunda stored 37° and 55 °C for about 3 weeks. The acidity development could be attributed to production of acids like formic, acetic, lactic and other organic acids and free fatty acids as reported by O’Brien (1997). Maillard reaction produces many organic acids, so that there is increase in acidity (Goyal and Srinivasan 1988, 1989). In the present study also, there was increase in acidity in all the samples during storage at both the temperatures of 30° and 5 °C. However, this could be attributed to disappearance of basic amino groups. Similar result was also reported by Navajeevan and Rao (2005) in kunda. Increase in titrable acidity was also observed during storage of khoa (Kalra et al. 1973). Champak Palit and Dharam Pal (2005) reported that the rate of increase in acidity was slower in burfi samples with potassium sorbate as preservative, irrespective of packaging conditions and attributed the same to slower microbial activity.

Fig. 1.

Changes in physico-chemical and microbiological characteristics of kunda added with different preservatives and stored at 30o and 5 °C (LA—Lactic acid; SPC—Standard Plate Count; YMC—Yeast and Mold Count; cfu—Colony forming units) (n=3)

Table 1.

ANOVA for changes in physico-chemical and microbiological characteristics of kunda during storage at 5o and 30 °C

| Source | df | Moisture | Browning Index | Water activity | Acidity | SPC | YMC | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MSS | F-value | MSS | F-value | MSS | F-value | MSS | F-value | MSS | F-value | MSS | F-value | ||

| Storage durations (D) | 6 | 8.550 | 392.0* | 0.009 | 10.3* | 0.020 | 3.1* | 0.056 | 488.4* | 621.323 | 264.4* | 4793.864 | 195.7* |

| Preservatives (P) | 2 | 0.285 | 13.1* | 0.001 | 1.3NS | 0.021 | 3.3* | 0.0002 | 1.9NS | 699.427 | 297.7* | 761.095 | 31.1* |

| Storage temperatures (T) | 1 | 0.192 | 8.8* | 0.001 | 1.3NS | 0.003 | 0.4NS | 0.004 | 37.0* | 2449.078 | 1042.3* | 380.643 | 15.5* |

| DxP | 12 | 0.060 | 2.7* | 0.001 | 1.2NS | 0.005 | 0.8NS | 0.002 | 17.2* | 61.846 | 26.3* | 221.039 | 9.0* |

| DxT | 6 | 0.035 | 1.6NS | 0.001 | 1.1NS | 0.010 | 1.6NS | 0.003 | 21.9* | 88.873 | 37.8* | 371.539 | 15.2* |

| PxT | 2 | 0.138 | 6.3* | 0.002 | 1.9NS | 0.007 | 1.1NS | 0.002 | 19.4* | 119.529 | 50.9* | 84.750 | 3.5* |

| DxPxT | 12 | 0.053 | 2.4* | 0.001 | 1.1NS | 0.007 | 1.0NS | 0.002 | 19.3* | 94.312 | 40.1* | 109.091 | 4.5* |

| Error | 84 | 0.022 | – | 0.001 | – | 0.006 | – | 0.0001 | – | 2.350 | – | 24.491 | – |

| Total | 125 | – | – | – | – | – | – | – | – | – | – | – | – |

* Significant at P < 0.05; NS—Not Significant

Microbiological changes were observed in kunda during storage (Fig. 2). The total bacterial count in general decreased during storage. The lowest mean value of 3.98 log cfu/gm in case of nisin added sample compared to 4.14 in samples with potassium sorbate and 4.26 in control show that the decrease in the SPC was more in nisin added kunda (P < 0.05). Temperature also had a significant effect on the decrease in the counts (Table 1). In general, counts at 5 °C were lower than those at 30 °C. Also, the decrease in the SPC was slightly more in preservative containing samples. The decrease in SPC was due to increased osmotic pressure and decreased water activity. When bacterial cells are exposed to high osmotic pressure and high ionic strength environment (low aw), water flows out of the cells to maintain equilibrium increasing the ionic strength inside the cells. Thus, the metabolic activity was reduced and stopped at some level (Rao 2000). Prajapati et al. (1986) observed that during storage, addition of 40 and 50% sugar in khoa practically prevented the bacterial and fungal growth. Kalra et al. (1973) reported that khoa samples containing nisin failed to show the presence of any bacteria. Champak Palit and Dharam Pal (2005) recorded that potassium sorbate containing and vacuum packaged samples did not show any symptoms of spoilage up to 60 days at 30 °C. Similar findings are also reported by Rajarajan et al. (2006), who reported that potassium sorbate at 0.3% showed decreased yeast and mold counts during storage at 30 °C and 5 °C. In the present study, kunda samples stored at 30 °C had significantly higher yeast and mold counts than those stored at 5 °C. It was observed that all the interaction effects were significant for change in microbial counts.

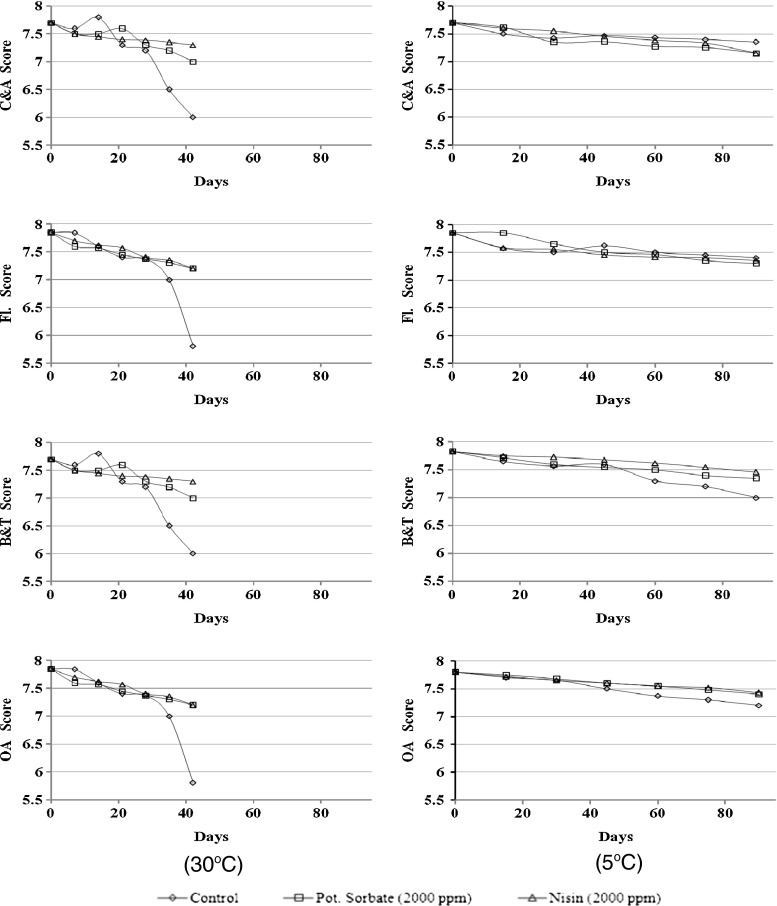

Fig. 2.

Changes in sensory scores of kunda added with different preservatives and stored at 30o and 5 °C (C&A—Colour and Appearance; Fl.—Flavour; B&T—Body and Texture; OA—Overall Acceptance) (n=3)

Effect of preservatives on sensory characteristics of kunda during storage

Sensory scores of kunda decreased with increase in storage temperature. The changes in the sensory scores of colour and appearance, flavour, body and texture and overall acceptance are depicted in Fig. 2. There was decrease in colour and appearance score during storage which could be attributed to dull appearance caused by moisture loss. The flavour scores decreased more in control than kunda containing preservatives. However, the samples possessed acceptable flavour and no off flavour was detected. The limit for this at 30 °C storage was 28 days, beyond which sensory scores were below 7.0 for control product indicating onset of spoilage. During storage at 5 °C, no off flavours were observed till storage period of 90 days. Preservative containing kunda however scored higher than control indicating a significant effect of preservatives. However, there was no difference in the scores between nisin and potassium sorbate containing products. This was also reflected in microbial counts of the preservative containing samples, which decreased to a great extent during storage. The body and textural acceptance decreased as the product turned slightly hard because of moisture loss. The mean overall acceptance scores of nisin and potassium sorbate containing kunda were 7.6 compared to 7.3 of control indicating that preservative containing product was more acceptable (P < 0.05) (Table 2). At 5 °C, all the kunda samples with or without preservatives kept well till the end of storage of 90 days, the scores being above ‘like moderately’ range. The effect of preservative probably would have been evident had the samples been stored beyond 90 days. All the interaction effects of storage period, temperature and preservatives were statistically significant (P < 0.05). Rajarajan et al. (2006) found that natamycin (0.05%) treated samples of khoa showed lesser degree of proteolysis and lipolysis when compared to potassium sorbate (0.3%). These samples were acceptable up to 12 days at 30 °C and up to 40 days at 5 °C.

Table 2.

ANOVA for changes in sensory characteristics of kunda during storage at 5o and 30 °C

| Source | df | Colour & appearance | Flavour | Body & texture | Overall acceptance | ||||

|---|---|---|---|---|---|---|---|---|---|

| MSS | F-value | MSS | F-value | MSS | F-value | MSS | F-value | ||

| Storage durations (D) | 6 | 0.939 | 43.5* | 1.358 | 82.7* | 1.618 | 84.5* | 1.053 | 79.0* |

| Preservatives (P) | 2 | 0.320 | 14.8* | 0.315 | 19.2* | 0.392 | 20.4* | 0.651 | 48.8* |

| Storage temperatures (T) | 1 | 0.471 | 21.8* | 0.267 | 16.3* | 3.271 | 170.7* | 1.201 | 90.1* |

| DxP | 12 | 0.084 | 3.9* | 0.121 | 7.4* | 0.132 | 6.9* | 0.158 | 11.9* |

| DxT | 6 | 0.193 | 8.9* | 0.301 | 18.3* | 0.260 | 13.6* | 0.141 | 10.6* |

| PxT | 2 | 0.400 | 18.5* | 0.276 | 16.8* | 0.345 | 18.0* | 0.232 | 17.4* |

| DxPxT | 12 | 0.176 | 8.1* | 0.158 | 9.6* | 0.044 | 2.3* | 0.094 | 7.07* |

| Error | 84 | 0.022 | – | 0.016 | – | 0.019 | – | 0.013 | – |

| Total | 125 | – | – | – | – | – | – | – | – |

* Significant at P < 0.05

Conclusion

It was concluded that the shelf-life of kunda packed in LDPE was 28 days at 30 °C which was enhanced to 42 days by nisin and potassium sorbate added @ 2000 ppm. At 5 °C, all the kunda samples with or preservative kept well till the end of storage period of 90 days.

References

- Anonymous (2006) Research and development support for process up gradation of indigenous milk products for industrial application. Net work project report. National Dairy Research Institute (Southern campus), Bangalore

- Amerine MA, Pangbom RM, Raessler B. Principles of sensory evaluation of food. New York: Academic; 1965. [Google Scholar]

- SP: 18 Hand book of food analysis Part I General methods. New Delhi: Bureau of Indian Standards; 1980a. [Google Scholar]

- IS: 4883 Indian standards specification for khoa. New Delhi: Bureau of Indian Standards; 1980b. [Google Scholar]

- SP: 18 Part XI Hand book of food analysis Part XI Dairy Products. New Delhi: Bureau of Indian Standards; 1981. [Google Scholar]

- Champak Palit, Dharam Pal Studies on mechanized production and shelf-life of burfi. Indian J Dairy Sci. 2005;58:124–125. [Google Scholar]

- Fontana AJ, Cambell CS. Water activity. In: Nollet LML, editor. Handbook of food analysis, vol.1. New York: Marcel Dekker Inc; 2004. pp. 49–50. [Google Scholar]

- Gothwal PP, Bhavadasan MK. The role of proteins in browning in milk. Indian J Dairy Sci. 1992;45(8):419–423. [Google Scholar]

- Goyal GK, Srinivasan MR. Protective role of packaging materials in refrigerated conditions on the microbiological quality of khoa. Asian J Dairy Res. 1988;7:66–72. [Google Scholar]

- Goyal GK, Srinivasan MR. Effect of packaging on the chemical quality of khoa during storage. Indian J Dairy Sci. 1989;42:165–170. [Google Scholar]

- Kalra MS, Laxminarayana H, Dudani Use of nisin for extending shelf-life of processed cheese and khoa. J Food Sci Technol. 1973;10:92–94. [Google Scholar]

- Kulkarni S, Bikash C, Ghosh BBV, Rao KJ. Kunda—desiccated dairy product of northern Karnataka. Indian Dairyman. 2001;53:65–67. [Google Scholar]

- Mahalingaiah L, Venkateshaiah BV, Rao KJ, Balasubramanyam BV, Ghosh BC, Kulkarni S (2000) Incorporation of caramelized sugar in the production of kunda. Poster paper presented at Indian convention of food scientists and technologists. Nov 22–24, Mysore

- Menon RR, Magdaline EEF, Rao KJ, Ghosh BC, Balasubramanyam BV, Chand Ram (2004) Energy conservation in the production of kunda by interaction effect of sodium citrate and caramelized sugar. Poster paper presented at Indian convention of food scientists and technologists, 12–13, December, Mysore

- Navajeevan B, Rao KJ. Physico-chemical changes in retort processed kunda. Indian J Dairy Sci. 2005;58:392–399. [Google Scholar]

- O’Brien J. Reaction chemistry of lactose: non-enzymatic degradation pathways and their significance in dairy products. In: Fox PF, editor. Advanced dairy chemistry, vol. 3. Madras: Chapman & Hall; 1997. [Google Scholar]

- Prajapati JB, Ramachandran L, Dave JM. Effect of added sugars on water activity and shelf-life of khoa. Asian J Dairy Res. 1986;5:25–29. [Google Scholar]

- Rajarajan G, Naresh Kumar C, Elango A. Effect of antifungal agents on keeping quality of khoa. Indian J Dairy Sci. 2006;59:7–9. [Google Scholar]

- Rao KJ. Water activity concepts and related aspects. Indian Dairyman. 2000;52:35–42. [Google Scholar]

- Sawhney IK, Patil GR, Kumar B, Grover S. Influence of water activity adjustment on sorption characteristics and acceptability of khoa. J Food Sci Technol. 1997;34:123–127. [Google Scholar]