Abstract

Objective

The aim of this article was to assess how intraoral biodegradation influenced the surface characteristics and friction levels of metallic brackets used during 12 and 24 months of orthodontic treatment and also to compare the static friction generated in these brackets with four different methods of the ligation of orthodontic wires.

Material and Methods

Seventy premolar brackets as received from the manufacturer and 224 brackets that were used in previous orthodontic treatments were evaluated in this experiment. The surface morphology and the composition of the deposits found in the brackets were evaluated with rugosimetry, scanning electron microscopy, and energy dispersive X-ray spectroscopy. Friction was analyzed by applying tensile tests simulating sliding mechanics with a 0.019x0.025" steel wire. The static friction levels produced by the following ligation methods were evaluated: loosely attached steel ligature around all four bracket wings, steel ligature attached to only two wings, conventional elastomeric ligation around all 4 bracket wings, and non-conventional Slide® elastomeric ligature.

Results

The results demonstrated the presence of biodegradation effects such as corrosion pits, plastic deformation, cracks, and material deposits. The main chemical elements found on these deposits were Carbon and Oxygen. The maximum friction produced by each ligation method changed according to the time of intraoral use. The steel ligature loosely attached to all four bracket wings produced the lowest friction levels in the new brackets. The conventional elastic ligatures generated the highest friction levels. The metallic brackets underwent significant degradation during orthodontic treatment, showing an increase in surface roughness and the deposit of chemical elements on the surface.

Conclusion

The levels of static friction decreased with use. The non-conventional elastic ligatures were the best alternative to reduce friction.

Keywords: Orthodontic brackets, Friction, Biodegradation

INTRODUCTION

Orthodontic tooth movement (OTM) efficiency is influenced by both biological and mechanical variables, and friction is one of the most studied due to its complexity and importance. OTM occurs when the orthodontic forces applied to the teeth are higher than the static friction22. Some physical variables interfere in the friction magnitude, such as the type of bracket and wire material14, the angle of insertion of the wires2, the surface characteristics11, geometry and dimensions of these materials22, as well as the type of ligature12 and method of ligating the wire to the brackets13. It is impossible to fully eliminate friction in sliding mechanics. Therefore, orthodontists must understand the factors that influence friction and how they can effectively control them, according to the demands of the different stages of treatment22.

In recent years, the so-called low friction systems22, such as self-ligating brackets22, have been gaining ever-greater space in the orthodontic product market18, despite their higher costs22. Other attempts to reduce friction have also been suggested, such as modifications on the surface and geometry of the bracket slot3,5,22, coating the external layer of specific orthodontic wires19, the use of loosely tied steel ligature wires13, or elastic ligatures with new designs24.

A very important aspect directly related to friction that has not been adequately studied is the mid and long-term changes that take place in orthodontic materials after their intraoral use. The few studies available in the literature have reported signs of corrosion, structural wear, plastic deformation, and deposition of biofilm after the use of stainless steel brackets and wires in orthodontic treatments20. These findings were considered co-responsible for the increased friction levels registered after their biodegradation in the oral cavity15,16,21,23.

In addition to the limited number of studies that have evaluated the biodegradation of orthodontic materials22, none have analyzed if different methods of ligating the wire to the brackets may reduce some of the negative effects generated from exposure of these materials to the oral environment. Thus, the aim of the present study was to: (1) evaluate how the biodegradation influenced the surface characteristics and friction levels of metallic brackets used during 12 and 24 months of orthodontic treatment; (2) compare the static friction generated in these brackets with four ligation methods for orthodontic wires; and (3) test the hypothesis that brackets as received from the manufacturer present lower friction levels than those that were used for 12 or 24 months and that different methods of ligation produce different amounts of friction.

MATERIAL AND METHODS

Sample and groups

The present study evaluated the static friction of metallic brackets as received from the manufacturer and after their intraoral use during 12 or 24 months of orthodontic treatment in a private office. The sample consisted of stainless steel premolar brackets (edgewise Standard 0.022x0.028", Morelli Ortodontia, Sorocaba, SP, Brazil). After completing the intraoral exposure time, the brackets were carefully removed with debonding orthodontic pliers especially designed to apply force only to the bracket base to avoid slot and wing deformation. Immediately after debonding, all brackets were cleaned with a dental water jet, placed in an ultrasound device for 5 minutes, and maintained in closed recipients until they were tested. Before friction evaluation, the brackets were brushed with an electric toothbrush (model 3744, Oral-B/Braun, Queimados, RJ, Brazil) with a round head for 10 seconds, without placing pressure onto the slot.

A total of 294 brackets were tested, 224 were used in the orthodontic treatment of 25 patients from a private practice (average age of 31 years and 6 months) and 70 were new, tested as received from the manufacturer. During orthodontic treatment, stainless steel and nickel-titanium wires were used, which were tied to the brackets with elastomeric and/or steel ligatures.

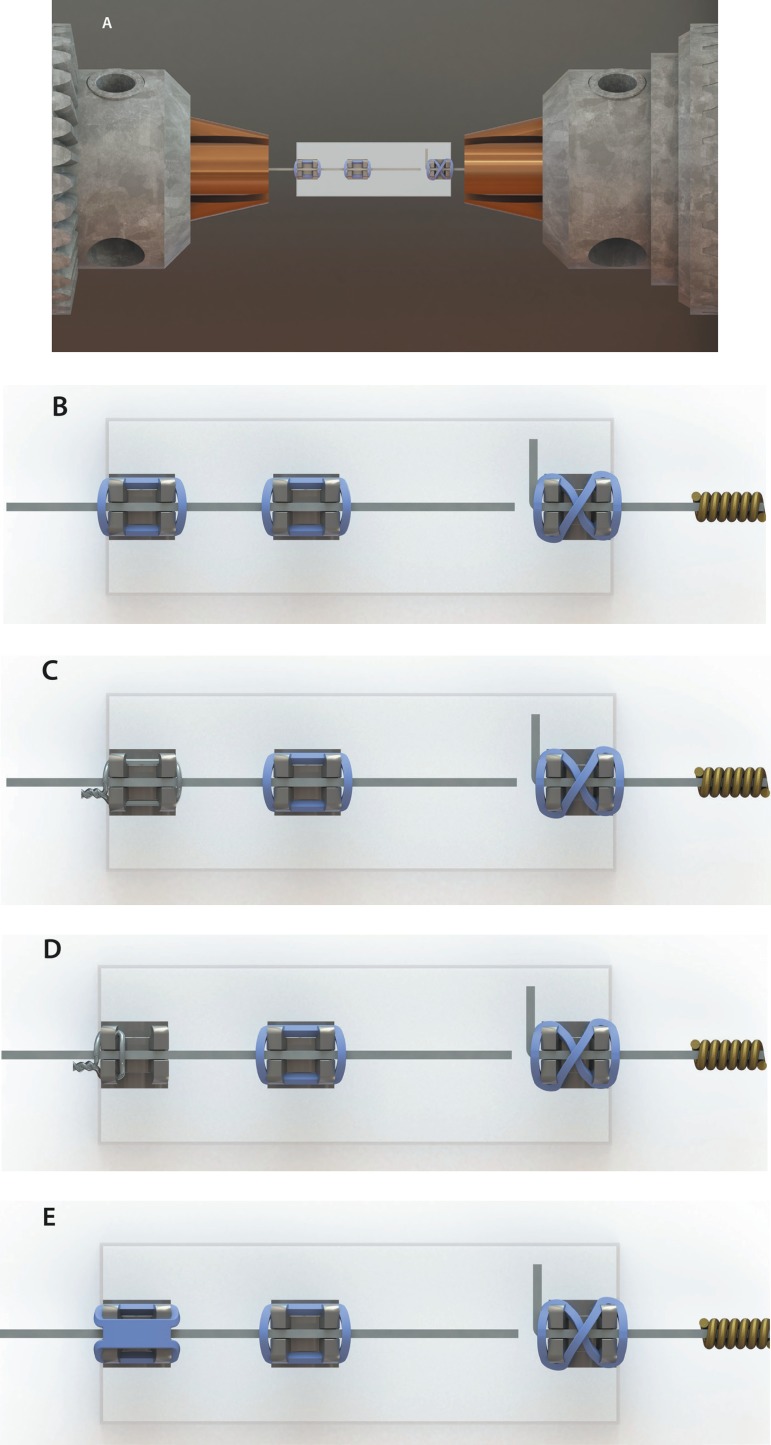

Friction was evaluated by simulating sliding mechanics with a 0.019x0.025" stainless steel orthodontic wire (Morelli Ortodontia, Sorocaba, SP, Brazil). Four types of ligation were tested: (1) conventional gray elastic ligatures (Morelli Ortodontia, Sorocaba, SP, Brazil); (2) 0.010" steel ligatures (Morelli Ortodontia, Sorocaba, SP, Brazil) tied around all four bracket wings; (3) steel ligatures tied only to the two bracket wings closest to the load-cell; (4) low friction gray elastic ligatures (Slide®, Leone Orthodontics and Implantology, Florence, Italy) (Figure 1).

Figure 1.

Graphic representation of the device developed to attach the samples to the universal testing machine presenting all brackets aligned and ready for testing and illustration of the methods of ligation tested. (A) Overall view of the apparatus; (B) Elastic ligature tied to the 4 bracket wings; (C) Steel ligature tied to all 4 bracket wings; (D) Steel ligature tied to 2 bracket wings; and (E) Ligation with Slide® elastic ligature

The new brackets (control group), ligatures, and wires were used as received from the manufacturer. Thus, they were removed from their original packaging and immediately submitted to the tests. Four test groups with seven new brackets each, of the same brand, model, and ligation method, were used as controls. According to the combinations of bracket and types of ligations tested, 12 groups were formed, as shown in Figure 2.

Figure 2.

Distribution of brackets and types of wire ligation evaluated

| Groups | Time of use (month) | Type of ligation |

|---|---|---|

| 0-LE | 0 | Elastomeric ligatures |

| 0-LM | 0 | Metallic ligatures 4/4 * |

| 0-2/4LM | 0 | Metallic ligatures 2/4 ** |

| 0-LS | 0 | Slide® |

| 12-LE | 12 | Elastomeric ligatures |

| 12-LM | 12 | Metallic ligatures 4/4 * |

| 12-2/4LM | 12 | Metallic ligatures 2/4 ** |

| 12-LS | 12 | Slide® |

| 24-LE | 24 | Elastomeric ligatures |

| 24-LM | 24 | Metallic ligatures 4/4 * |

| 24-2/4LM | 24 | Metallic ligatures 2/4 ** |

| 24-LS | 24 | Slide® |

Metallic ligation tied to 4 bracket tie-wings

Metallic ligature tied to only 2 and 4 bracket tie-wings

Scanning Electron Microscopy (SEM) analysis

SEM was performed with a JSM-5310 microscope (JEOL, Tokyo, Japan) from the Center for Development of Nuclear Technology (CDTN/ CNeN). It was used to obtain the images of the brackets surface and analyze the possible damages generated after the exposure to oral cavity during the orthodontic treatment. Twelve orthodontic brackets were randomly selected for this analysis, 4 as received from the manufacturer (Group 0), 4 from the 12-month treatment samples (Group 12), and 4 from the 24-month treatment specimens (Group 24).

For each sample, 5 photographic images were taken, in the following order: (1) 15x magnification at a 90° angle; (2) 15x at 45°; (3) 50x at 90°; (4) between 100x; and (5) 350x of the slot region near the tie-wings.

Semi-quantitative analysis through Energy Dispersive X-ray Spectroscopy

Chemical analyses of micro-regions in the brackets used for 12 or 24 months, and in the deposits found in their surface were performed using energy Dispersive X-ray Spectroscopy (EDS) in a Genesis Spectrum machine (eDAX, Mahwah, NJ, USA), attached to the SEM. Deposits present on the bracket base, tie-wings, and in a area free of impurities were analyzed to identify the composition of the bracket.

Bracket surface roughness analysis

Surface roughness was measured on 5 brackets of each group to verify possible differences on the effects of their exposure to the oral environment. The images were obtained with 2,000x of vertical magnification and 100x horizontally. Magnifications of 2,000x or 5,000x and a cut-off of 0.25 mm were used to obtain Ra values. The values of the five largest distances between the highest peak and the lowest valley in each of the five sample lengths (R1, R2, R3, R 4, and R 5 ), as well as the average of these values (Rtm) were also registered. The images were obtained at 1 mm from the central region of the brackets slots. Five measurements were performed for each bracket, resulting in a total of 75 analyses of R a and R tm.

Evaluation of the friction levels

The static friction was evaluated with an AN8032 testing machine (Analógica Instrumentação e Controle Ltda., Belo Horizonte, MG, Brazil) at room temperature, in a dry environment and using the tensile test in a straight line. The load cell had a maximum capacity of 222.4 N and the machine was operated at 0.075 mm/seg. Each trial had its initial (500 μm) and final (1,400 μm) positions set by the machine.

In order to perform the friction tests, the brackets were positioned on an acrylic plate that remained in a horizontal position and was hooked to the lower claw of the universal testing machine, while the wire was hooked to the upper claw and pulled to slide through the bracket slots (Figure 1). This positioning was carefully set to allow the test to be performed through the long axis of the machine.

The load cell registered the levels of force necessary to move the wire through the brackets for 9 mm. However, only the measurements registered along the first 7 mm were taken into consideration because this distance is equivalent to the average space available when premolars are extracted in an orthodontic treatment. The data was transmitted to a computer connected to the machine, which plotted a graph with XY coordinates. The X-axis registered the displacement of the wire in mm, while the Y-axis registered the friction in Newtons at the bracket/wire interface.

The same operator prepared the specimens and performed all tests of this study. During the preparation of the brackets, the operator carefully standardized the insertion of the elastic ligatures, stretching them with Mathieu tweezers (Quinelato, São Paulo, SP, Brazil) to the minimum needed to place them around the bracket wings. The nonconventional Slide® elastic ligatures were inserted according to the manufacturer's instructions.

Statistical procedures

The Kolmogorov-Smirnov normality test showed that the data presented normal distribution. The two-way analysis of variance (two-way ANOVA) followed by the Bonferroni's post hoc test was used to compare static friction registered with the different types of ligation and various duration of intraoral use of the brackets.

The one-way analysis of variance (One-way ANOVA) followed by the Tukey post hoc test was used to compare the surface roughness (Ra ) and the largest distance between peaks and valleys (R tm ) between different times of intraoral exposure.

The level of significance was set at 5% for all tests that were performed with the GraphPad Prism®software (GraphPad Software, San Diego, CA, USA).

RESULTS

Friction evaluation

The descriptive analyses of the mean static friction values, registered for all combinations of time of exposure to the oral environment and wire ligation methods, are presented in Figure 2. Table 1 shows the comparison of the static friction levels registered among all groups and the comparison of static friction levels produced with the different wire ligation methods at each time interval, according to the two-way ANOVA followed by the Bonferroni's post hoc test.

Table 1.

Mean and standard deviations of the static friction during sliding tests. Comparison between different types of ligation and duration of intraoral bracket use

| Type of ligation | Force (N) | |||

|---|---|---|---|---|

| New | 12 months | 24 months | P value * | |

| Metallic ligatures 2/4 | 2.64±0.43 | 1.72±0.35 | 1.91±0.47 | n.s. 3 /p<0.05 1,2 |

| Metallic ligatures 4/4 | 1.98±0.26 | 1.95±0.26 | 2.42±0.36 | n.s. 1,2,3 |

| Elastomeric | 4.31±0.27 | 3.70±0.29 | 4.18±0.59 | n.s. 2,3 /p<0.05 1 |

| Slide® | 2.74±0.35 | 1.67±0.19 | 1.51±0.16 | n.s. 3/p<0.05 1,2 |

| P value * | n.s. 6 | n.s. 4,6,8 | n.s. 6 | |

| p<0.05 4,5,7,8,9 | p<0.05 5,7,9 | p<0.05 4,5,7,8,9 |

P values were obtained by two way analysis of variance (one way ANOVA) followed by the Bonferroni's post hoc test

n.s.=not significant (p>0.05)

New versus 12 months

New versus 24 months

12 months versus 24 months

2/4 versus 4/4

2/4 versus Elastomeric

2/4 versus Slide®

4/4 versus Elastomeric

4/4 versus Slide®

Elastomeric versus Slide®

Bracket surface roughness analysis

Even tough the brackets as received from the manufacturer presented the lowest surface roughness (Ra) mean values, no statistically difference was observed when the new, the 12- and the 24-month brackets were compared (Table 2). The largest distance between the peaks and valleys on the slot surface (Rtm) was higher in the 24-month brackets when compared to the new and to the 12-month brackets (Table 2).

Table 2.

Mean and standard deviation of surface roughness (Ra) and of the largest distance between peaks and valleys (Rtm) found on the brackets' surfaces

| Condition | ||||

|---|---|---|---|---|

| New | 12 months | 24 months | P value * | |

| Ra | 0.79±0.15 | 0.85±0.36 | 1.17±0.39 | n.s. 1,2,3 |

| Rtm | 2.04±0.33 | 2.66±1.23 | 4.29±1.07 | p<0.05 2,3 /n.s. 1 |

P values were obtained by one way analysis of variance (one way ANOVA) followed by the Tukey post hoc test

n.s.=not significant (p>0.05)

New versus 12 months

New versus 24 months

12 months versus 24 months

SEM analysis

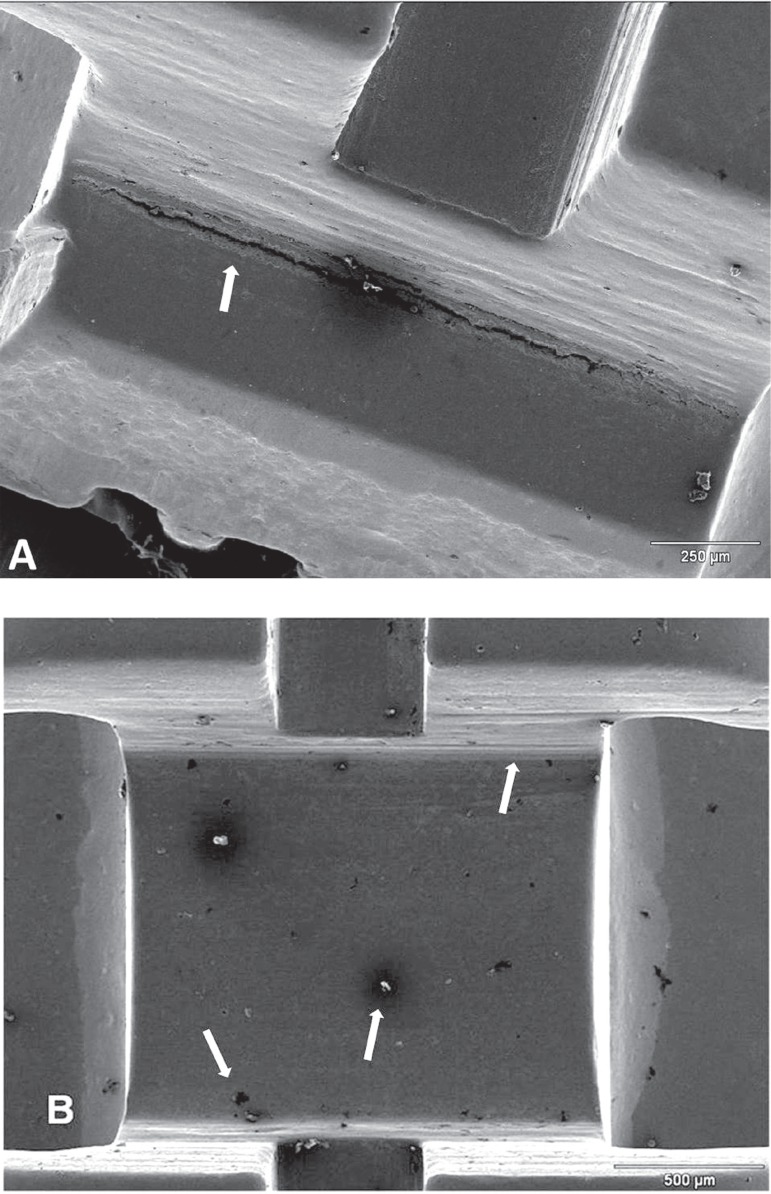

The SEM evaluation of the brackets as received from the manufacturer showed presence of machining marks and some corrosion pits. Some of these pits were filled with impurities that appeared as shiny white spots in the SEM images (Figure 3A). There were also clefts of different sizes on the external surface of the bracket wings base (Figure 3B).

Figure 3.

Cleft found on the external surface of the base of the tie-wing on a new bracket with 75x magnification (A). Marks of machining, corrosion cavities (which appear as dark spots), some filled with impurities; 15x magnification (B)

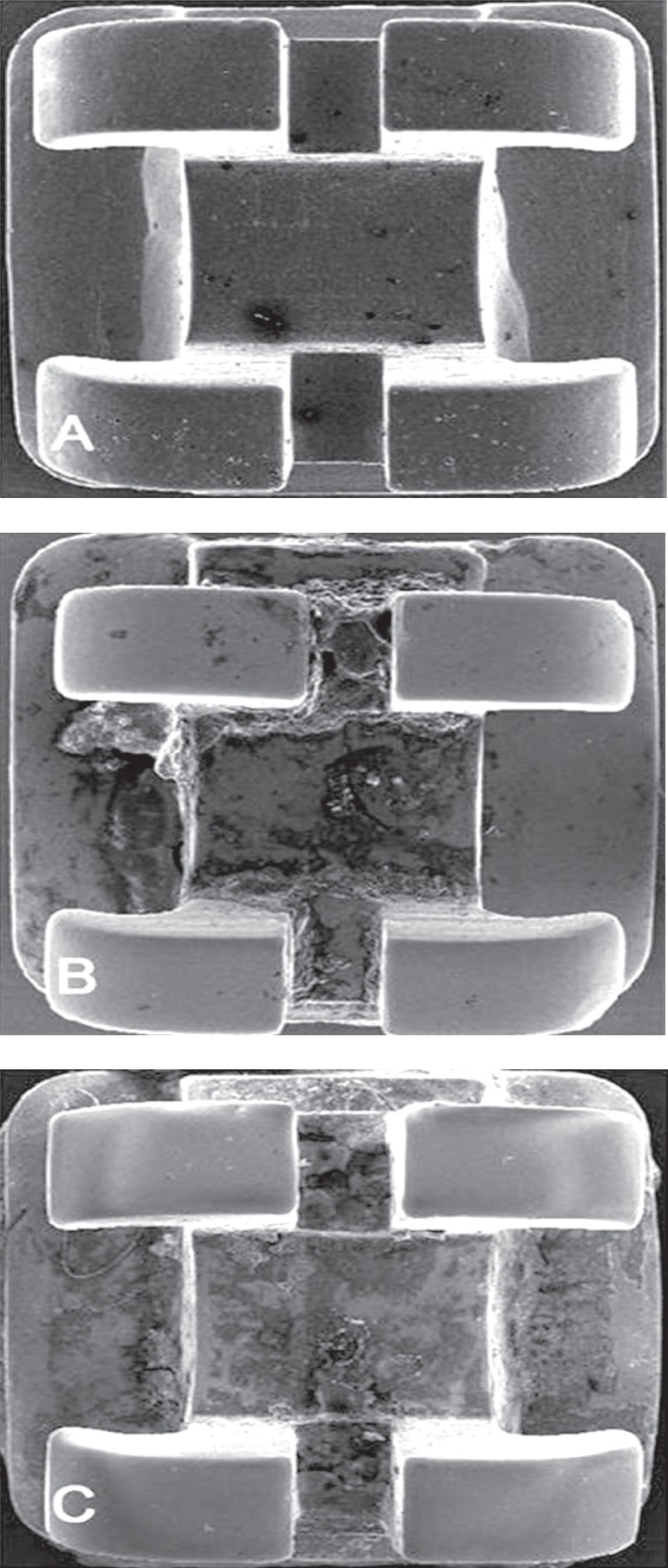

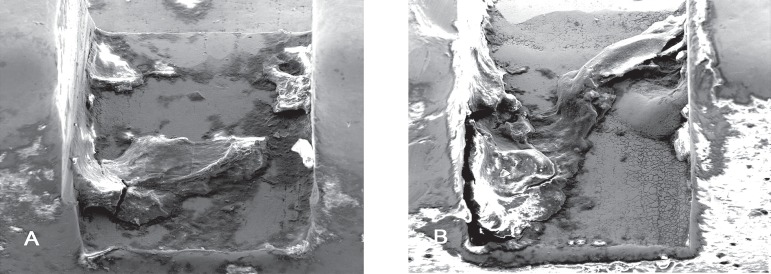

The SEM qualitative evaluation of the brackets used for 12 and 24 months revealed important differences in relation to the evaluation of the brackets as received from the manufacturer. These changes were signs of corrosion and wear, plastic deformation, presence of clefts, cracks, and grooves. Furthermore, the used brackets presented biofilm deposits and accumulations of materials of various sizes on their surface (Figure 4). Figure 5 illustrates the bracket slots after 12 and 24 months of orthodontic treatment.

Figure 4.

Changes stemming from use and consequent exposure to the intraoral medium. New bracket (A), after 12 months of use (B), and after 24 months of use (C), all with 15x magnification

Figure 5.

Biofilm deposit over the bracket slot after exposure to the intraoral medium for 12 (A) and 24 (B) months; 150x magnification

Semi-quantitative analysis through Energy Dispersive X-ray Spectroscopy

Semi-quantitative EDS chemical analysis of the deposits found on the slot surfaces of the orthodontic brackets that were used for 12 or 24 months are shown in Tables 2 and 3, respectively. Carbon and oxygen were the elements detected in the highest concentrations. However, signs of sodium, phosphorus, potassium, calcium, iron, lead, and aluminum could also be identified. In some areas, the accumulations of deposits actually masked the original topography of the brackets' surfaces.

Table 3.

EDS semi-quantitative chemical analysis on the deposits found in an orthodontic bracket slot used for 12 or 24 months

| 12 months | 24 months | ||||

|---|---|---|---|---|---|

| Element | weight % | atomic % | Element | weight % | atomic % |

| C | 62.7 | 78.3 | C | 53.4 | 63.4 |

| O | 13.8 | 13 | O | 37.5 | 33.5 |

| Na | 2.2 | 1.5 | F | 0.5 | 0.4 |

| Mg | 0.4 | 0.2 | Na | 0.5 | 0.3 |

| Si | 0.3 | 0.2 | Al | 0.4 | 0.2 |

| P | 2.5 | 1.2 | Si | 0.2 | 0.1 |

| S | 1.3 | 0.6 | P | 0.5 | 0.2 |

| Cl | 0.5 | 0.2 | S | 0.2 | 0.1 |

| K | 5.4 | 2.1 | Cl | 0.2 | 0.1 |

| Ca | 1.1 | 0.4 | K | 0.9 | 0.3 |

| Cr | 0.9 | 0.3 | Cr | 1.6 | 0.4 |

| Fe | 2.6 | 0.7 | Fe | 4.2 | 1.1 |

| Cu | 6.3 | 1.5 | |||

| Total | 100 | 100 | Total | 100 | 100 |

DISCUSSION

The physical properties of orthodontic materials as received from the manufacturer have been widely studied over the years16. However, the knowledge about the clinical performance of orthodontic materials over the duration of treatment, thus after they are exposed to the oral environment is also very important. Variations in temperature and pH as registered intraorally22 may cause the biodegradation of these materials, changing some of their properties22, which may compromise their clinical performance9.

The combined action of these biological factors can significantly alter the integrity of the orthodontic materials surface, especially metallic brackets8,9. However, the extension of these changes and how they actually affect the clinical performance of these materials remain unclear. Thus, the purpose of this study was to evaluate physical and chemical changes on metallic brackets surfaces after different intervals of clinical use. The present study also analyzed the static friction generated on these biodegraded brackets with 4 different wire ligation methods. Furthermore, the surface roughness of the brackets was also evaluated. SEM and EDS were the methods of evaluation used to quantify the chemical elements present in the biofilm generated during the intraoral use of the materials tested.

Friction evaluation

The comparison of static friction among the brackets as received from the manufacturer combined to different methods of wire ligation showed that loose ligation with steel ligatures around the four bracket wings presented the lowest mean friction values, while the maximum friction was registered when the brackets had the wire ligated with conventional elastic ligatures. These findings are compatible with what has previously been reported in the literature4. However, our results differ from others regarding the use of the non-conventional Slide®elastic ligatures. In the present study, no significant differences were identified between ligation with metallic ligatures on two bracket wings and the Slide®ligatures. Conversely, Chen, et al.6 (2010) found the lowest friction values using Slide® also combined with stainless steel brackets and wires.

The comparison of the maximum friction generated among the new brackets and brackets used over a 12-month period revealed a reduction for all different methods of wire ligation, except for loose ligation with steel ligatures around the four bracket wings. The comparison of the maximum friction generated among the new brackets and brackets used over a 24-month period revealed a reduction for all different methods of wire ligation, except for loose ligation with steel ligatures around the four bracket wings and for elastomeric ligatures. These results are in accordance with previously reported results21 and are partially in agreement with the findings from the evaluation of friction levels produced with three bracket models after an average period of intraoral use of 41 months. The Mini Standard edgewise bracket (American Orthodontics, Sheboygan, WI, USA) presented a reduction of 3.10% in friction levels, while the Kirium edgewise brackets (3M/Abzil, Sumaré, SP, Brazil) and the Nuedge Roth Prescription brackets (TP Orthodontics, LaPorte, IN, USA) presented a significant increase in relation to those observed with brackets as received from the manufacturer9.

All friction tests of this study were performed under dry conditions. The effects of lubricating agents such as artificial saliva in the results of friction tests are controversial. Some studies suggest the use of a lubrication medium because it would better simulated the intraoral conditions1, whereas others attained controversial results10.

The use of brackets exposed to the oral environment for 12 or 24 months positively contributes to the external validity of our results, since it resembled and evaluated some of the challenges that any orthodontist may face upon dealing with materials that age in the oral cavity during treatment. Another precaution taken to increase the reliability of our results was the development of a mechanism that eliminated any tipping between the wire and the brackets attached to the lower portion of the load cell4, preventing the existence of binding effect which would be a significant confounder, increasing the friction levels11. Moreover, the conventional elastomeric ligatures were inserted prior to performing the tests in each group. This alternative was chosen to standardize any possible alteration of the ligature's modules of elasticity, an effect which has previously been described1.

However, all the limitations that involve in vitro studies must be taken into consideration when attempting to apply the present study's results to a clinical reality. Factors such as second and third order sloping, the binding effect between the wire and the bracket, the presence of masticatory forces, and the thin biofilm were not reproduced9. Nevertheless, the present study presents evidence of the effects caused by the clinical use of metallic brackets and represents an improvement in understanding how biodegradation may compromise the clinical performance of orthodontic metallic brackets.

Bracket surface roughness analysis

The analysis of Rtm demonstrated the lower surface roughness values in the brackets as received from the manufacturer. The group of brackets after 24 hours of intraoral use presented the highest Rtm values, when compared to both other groups. These results are in accordance with reports in the literature that evaluated surface roughness changes on metallic orthodontic wires after use in the oral environment. The authors concluded such exposure caused an increase in the variety, type, and number of surface irregularities1, and our results support these findings.

Scanning electron microscopy analysis

In the present study, the new brackets presented marks of machining in the form of parallel lines, various corrosion cavities (pits) (some filled with impurities), clefts of various sizes on the external surface of the base of the bracket tie-wings, in addition to containing an accentuated curvature in relation to the axis of the bracket slots. These findings are in accordance with prior reports that evaluated the surface of stainless steel brackets as received from the manufacturer and those after exposure to the oral environment or artificial saliva1. Therefore, the results of the present study showed that the manufacturing processes of the metallic brackets are not perfect and may produce brackets presenting grooves and marks in the bracket slot, which could compromise the ideal fitting of the orthodontic wire within the slot walls1.

In the comparative evaluation between the new brackets and those used for 12 and 24 months, changes stemming from use could be observed, such as signs of corrosion, wear, plastic deformation, clefts, cracks, and grooves. These findings are in accordance with previous reports that have also evaluated the performance of orthodontic materials after their exposure to the oral environment or to different mediums that simulated in vivo conditions7,13,16,17,23,24. Furthermore, the used brackets presented biofilm deposits and accumulations of a wide range of materials of various sizes, with results similar to those previously described in the literature9, and that were also present in orthodontic wires10 and components of extra-oral devices9. However, a variation in the biofilm levels could be observed among brackets with the same time of use, which reinforces the influence of individual variation and of methods of personal hygiene9.

The signs of wear and corrosion observed in the bracket slots, slightly below the bracket tie-wings, are compatible with galvanic corrosion which occurs when two materials made of different metals are used to construct an orthodontic bracket9,16. Finally, the signs of plastic deformation after clinical use, found in the region corresponding to the end of the bracket tie-wings, were also registered in previous investigations9.

Semi-quantitative analysis through Energy Dispersive X-ray Spectroscopy

The semi-quantitative chemical analysis of the bracket wing top after 12 months of intraoral use revealed the presence of Fe (70.2%), Cr (19.5%), Mo (0.8%), and Ni (8.8%) (Table 3). These values correspond to those used in the manufacturing of ABNT 316 steel. These results were expected and are coherent, since this alloy is commonly used to manufacture orthodontic brackets1.

The EDS analysis of metallic brackets after 12 and 24 months of intraoral use detected deposits of C, O, Na, P, S, K, and Ca. There were also traces of Cl and Si, as well as small quantities of Fe and Cr. The presence of some of these chemical elements (C, O, Ca, P, S, and K) as products of the biodegradation of orthodontic brackets has been previously reported in the literature9. Other studies also found biofilm deposits with the presence of the same elements in NiTi orthodontic wires12 and in extra-oral devices after their clinical use12, indicating similar findings but in different proportions than those found in the present study.

The EDS analysis of deposits found on the base of the used brackets identified similar results to those observed in the slot region of the brackets, except for the presence of relatively large quantities of Cu and Ag in the brackets used for 12 months and of Al in the brackets used for 24 months. However, it was impossible to determine the origin of these elements.

Clinical application

The results of this investigation have significant clinical application because they showed that different types of wire ligation generate different levels of friction even after the biodegradation of orthodontic brackets in the oral environment. Based on these findings, the orthodontist may use a type of wire ligation to generate less friction at the early stages of the orthodontic treatment and implement a different ligation protocol at the finishing stages, when higher levels of friction are desired.

CONCLUSIONS

Based on the results of the present study, the conclusions are as follows:

The largest distance between peaks and valleys (Rtm) of metallic brackets increased after 24 months of exposure in the oral environment;

The maximum friction levels produced during the sliding mechanics decreased with use;

The ligation method that presented the lowest friction levels for new brackets was the steel ligature loosely attached around all four bracket wings;

The assays using brackets after 12 or 24 months of exposure to the oral environment presented the lowest static friction levels;

For all assays, the wire ligation using conventional elastic ligatures presented the highest static friction levels.

The hypothesis that different types of wire ligation generates different levels of static friction was confirmed.

REFERENCES

- 1.Alcock JP, Barbour ME, Sandy JR, Ireland AJ. Nanoindentation of orthodontic archwires: the effect of decontamination and clinical use on hardness, elastic modulus and surface roughness. Dent Mater. 2009;25:1039–1043. doi: 10.1016/j.dental.2009.03.003. [DOI] [PubMed] [Google Scholar]

- 2.Articolo LC, Kusy RP. Influence of angulation on the resistance to sliding in fixed appliances. Am J Orthod Dentofacial Orthop. 1999;115:39–51. doi: 10.1016/S0889-5406(99)70314-8. [DOI] [PubMed] [Google Scholar]

- 3.Baccetti T, Franchi L, Camporesi M, Defraia E, Barbato E. Forces produced by different nonconventional bracket or ligature systems during alignment of apically displaced teeth. Angle Orthod. 2009;79:533–539. doi: 10.2319/050508-249.1. [DOI] [PubMed] [Google Scholar]

- 4.Burrow SJ. Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop. 2009;135:442–447. doi: 10.1016/j.ajodo.2008.09.023. [DOI] [PubMed] [Google Scholar]

- 5.Castro RM, Neto PS, Horta MC, Pithon MM, Oliveira DD. Comparison of static friction with self-ligating, modified slot design and conventional brackets. J Appl Oral Sci. 2013;21:314–319. doi: 10.1590/1679-775720130097. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Chen SS, Greenlee GM, Kim JE, Smith CL, Huang GJ. Systematic review of self-ligating brackets. Am J Orthod Dentofacial Orthop. 2010;137:726.e1, 726.e718. doi: 10.1016/j.ajodo.2009.11.009. [DOI] [PubMed] [Google Scholar]

- 7.Dolci GS, Menezes LM, Souza RM, Dedavid BA. Biodegradtion of orthodontics brackets: in vitro ion release. Rev Dent Press Ortodon Ortopedi Facial. 2008;13:77–84. [Google Scholar]

- 8.Doshi UH, Bhad-Patil WA. Static frictional force and surface roughness of various bracket and wire combinations. Am J Orthod Dentofacial Orthop. 2011;139:74–79. doi: 10.1016/j.ajodo.2009.02.031. [DOI] [PubMed] [Google Scholar]

- 9.Eliades T, Bourauel C. Intraoral aging of orthodontic materials: the picture we miss and its clinical relevance. Am J Orthod Dentofacial Orthop. 2005;127:403–412. doi: 10.1016/j.ajodo.2004.09.015. [DOI] [PubMed] [Google Scholar]

- 10.Eliades T, Zinelis S, Eliades G, Athanasiou AE. Characterization of as-received, retrieved, and recycled stainless steel brackets. J Orofac Orthop. 2003;64:80–87. doi: 10.1007/s00056-003-0216-8. [DOI] [PubMed] [Google Scholar]

- 11.Fidalgo TK, Pithon MM, Maciel JV, Bolognese AM. Friction between different wire bracket combinations in artificial saliva - an in vitro evaluation. J Appl Oral Sci. 2011;19:57–62. doi: 10.1590/S1678-77572011000100012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Griffiths HS, Sherriff M, Ireland AJ. Resistance to sliding with 3 types of elastomeric modules. Am J Orthod Dentofacial Orthop. 2005;127:670–675. doi: 10.1016/j.ajodo.2004.01.025. quiz 754. [DOI] [PubMed] [Google Scholar]

- 13.Hain M, Dhopatkar A, Rock P. The effect of ligation method on friction in sliding mechanics. Am J Orthod Dentofacial Orthop. 2003;123:416–422. doi: 10.1067/mod.2003.14. [DOI] [PubMed] [Google Scholar]

- 14.Kapila S, Angolkar PV, Duncanson MG, Jr, Nanda RS. Evaluation of friction between edgewise stainless steel brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990;98:117–126. doi: 10.1016/0889-5406(90)70005-W. [DOI] [PubMed] [Google Scholar]

- 15.Lima VN, Coimbra ME, Derech CD, Ruellas AC. Frictional forces in stainless steel and plastic brackets using four types of wire ligation. Dental Press J Orthod. 2010;15:82–86. [Google Scholar]

- 16.Marques IS, Araújo AM, Gurgel JA, Normando D. Debris, roughness and friction of stainless steel archwires following clinical use. Angle Orthod. 2010;80:521–527. doi: 10.2319/081109-457.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Menezes LM, Souza RM, Dolci GS, Dedavid BA. Analysis of biodegradation of orthodontic brackets using scanning electron microscopy. Dental Press J Orthod. 2010;15:48–51. [Google Scholar]

- 18.Miles PG. Self-ligating brackets in orthodontics: do they deliver what they claim? Aust Dent J. 2009;54:9–11. doi: 10.1111/j.1834-7819.2008.01081.x. [DOI] [PubMed] [Google Scholar]

- 19.Muguruma T, Iijima M, Brantley WA, Mizoguchi I. Effects of a diamond-like carbon coating on the frictional properties of orthodontic wires. Angle Orthod. 2011;81:141–148. doi: 10.2319/052110-276.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Normando D, Araújo AM, Marques Ida S, Barroso Tavares Dias CG, Miguel JA. Archwire cleaning after intraoral ageing: the effects on debris, roughness, and friction. Eur J Orthod. 2013;35:223–229. doi: 10.1093/ejo/cjr104. [DOI] [PubMed] [Google Scholar]

- 21.Pacheco MR, Oliveira DD, Smith P, Neto, Jansen WC. Evaluation of friction in self-ligating brackets subjected to sliding mechanics: an in vitro study. Dental Press J Orthod. 2011;16:107–115. [Google Scholar]

- 22.Redlich M, Mayer Y, Harari D, Lewinstein I. In vitro study of frictional forces during sliding mechanics of "reduced-friction" brackets. Am J Orthod Dentofacial Orthop. 2003;124:69–73. doi: 10.1016/s0889-5406(03)00238-5. [DOI] [PubMed] [Google Scholar]

- 23.Sathler R, Silva GR, Janson G, Castello Branco NC, Zanda M. Demystifying self-ligating brackets. Dental Press J Orthod. 2011;16:e1–e8. [Google Scholar]

- 24.Tecco S, Di Iorio D, Nucera R, Di Bisceglie B, Cordasco G, Festa F. Evaluation of the friction of self-ligating and conventional bracket systems. Eur J Dent. 2011;5:310–317. [PMC free article] [PubMed] [Google Scholar]