Abstract

The study was carried out on the harvesting and handling methods of okra with the objective to maintain the best quality of pods from harvesting to end consumer especially for export marketing. For that purpose okra cv. ‘Punjab-8’ pods were harvested with minimum handling (least injuries to the pubescence on the ridges of pod) and normal handling (no safety taken to prevent injuries on pods). Pods were precooled at 15 ± 1ºC, 90–95% RH; jumble packed in the CFB boxes of 2.0 Kg capacity and than stored at 8 ± 1ºC, 90–95% RH. The quality parameters of okra namely texture, chlorophyll content, physiological loss in weight, rotting percentage and general appearance were studied. The pods harvested with minimum handling and field packaging can retain their green colour, crisp texture (maximum force to puncture pod = 500.2 g) with minimum rotting (3.0%) and physiological loss in weight (15.8%) and good appearance upto 13 days of cold storage whereas normal handled pods can be stored upto 5 days at 8 ± 1ºC, 90–95% RH and thereafter lost their general appearance on the 7th day of storage and were discarded. Therefore, in order to maintain high quality of okra from harvesting to the final destination (consumer), the okra pods should be harvested with minimum handling followed by field packaging in CFB boxes.

Keywords: Chlorophyll, Colour, Okra, Quality, Texture

Okra (Abelmoschus esculentus (L.) Moench) is one of the important vegetable crop grown throughout the tropical and subtropical parts of the world. It is valued in India and other countries for its delicious and nutritious edible green pods. Due to its high respiration rate (Hardenburg et al. 1986, Scholz et al. 1961), it has been grouped under highly perishable crops (Kedar 1992). Okra has a vast potential as one of the foreign exchange earning crop and accounts for about 60% of the India’s export of fresh vegetables excluding potato, onion, garlic etc. (Jasol 1988). For export purpose, the quality criterion is that the okra pods should be green, tender, 4–5 ridged and about 6–8 cm in length (Singh and Pandey 1993). In India, okra is generally harvested without any safety to prevent bruising and after harvesting it is dumped at one place. In the whole operation from harvesting to consumption, it has been handled by growers, packagers, transporters, storehouse operators and distributors which results mechanical injuries to the ridges of pods and finally these pods become blacken on ridges and calyx disc, resulting in value deletion and unsaleability in quality conscious markets (Anonymous 2004). To reduce the post harvest losses in okra, it should be least handled. In the recent past, some of our country’s okra export consignments have been rejected at the destination because of blackning of ridges, shriveling of pods and development of moulds. Therefore, to maintain their high quality from harvesting to the entire supply chain and to predict the acceptability of the final product, it is important to study the exact cause of blackning of pods. In India, study on this aspect has not been practiced. Therefore, the present study is conducted to find out the effect of harvesting and handling methods on the post-harvest quality of fresh okra during cold storage and to develop a postharvest protocol of okra for export marketing.

Materials and methods

The experiment was conducted at Punjab Horticultural Postharvest Technology Centre, Punjab Agricultural University, Ludhiana, to study the effect of harvesting and handling methods on the post harvest quality of fresh okra during cold storage. The representative quantity of fresh okra cv ‘Punjab-8’ was procured from the farmers field near Ludhiana. The experiment consists of two treatments on the handling methods and each treatment was replicated thrice using completely randomized design. The handling methods include normal handling and minimum handling at the time of harvesting. In minimum handling method, pods were harvested by holding it from the tip and cutting the stem end by using clipper and by wearing cotton gloves and simultaneously field packing in CFB boxes of 2.0 kg capacity. In normal handling, pods were harvested with bare hands, collected in gunny bags of 20 kg capacity and then transferred to CFB boxes of 2.0 kg capacity. Both minimum and normal handled okra pods were first pre-cooled at 15 ± 1 °C, 90–95% RH and thereafter stored in walk-in-cool chamber maintained at 8 ± 1 °C, 90–95% RH.

The observations on quality characters like physiological loss in weight, rotting percentage, texture, chlorophyll content and general appearance were recorded on alternate days after 1 day of initial storage. The physiological loss in weight (PLW) of pods was calculated on the initial weight basis and expressed in percent. The texture of pods was measured with the help of Texture Analyzer (Model TA-HDi make, stable Microsystems, UK) using 2 mm cylindrical stainless steel probe and results expressed in gram force. The rotting of pods were calculated by weighing the number of rotted pods on each sampling date and expressed in percent. The overall sensory quality of pods was determined by panel of 10 judges using 9 point hedonic scale (Amerine et al. 1965). The chlorophyll content of pods was estimated as described by Rangana (1977). The colour of Okra pods was measured with Colour Difference Meter (Model: Mini Scan XE Plus, Make: Hunter Lab, USA) and expressed as L,a,b Hunter Colour values (Hunter 1975)

Results and discussion

Physiological loss in weight

The physiological loss in weight (PLW) of okra pods increased during storage, irrespective of the handling methods (Table 1). Pods harvested with maximum handling recorded minimum PLW (15.8%) after 13 days of storage whereas in normal handling method, PLW after 7 days of storage was 12.0%. The probable reason for higher weight loss in the later may be due to higher incidence of injuries on the hairs and surface bruise of pods during harvesting, collection and packing in gunny bags, resulting in excessive moisture loss. The effect of harvesting method in reducing the PLW has also been reported by Dhall et al. (2008) and Uppal et al. (2002).

Table 1.

The effect of handling methods on the Physiological loss in weight (PLW), rotting and general appearance of okra cv. ‘Punjab-8’ during cold storage (8 ± 1 °C, 90–95% RH)

| Storage period, days | PLW (%) | Rotting (%) | Sensory quality | |||

|---|---|---|---|---|---|---|

| I | II | I | II | I | II | |

| 1 | 3.4 | 5.0 | NIL | NIL | 9.0 | 9.0 |

| 3 | 4.9 | 7.1 | NIL | NIL | 8.4 | 7.1 |

| 5 | 7.5 | 9.0 | NIL | NIL | 7.6 | 6.2 |

| 7 | 9.7 | 12.0 | NIL | NIL | 7.2 | 5.0 |

| 9 | 11.9 | 15.2a | NIL | 8.5a | 7.0 | 3.1a |

| 11 | 14.1 | – | NIL | – | 6.8 | – |

| 13 | 15.8 | – | NIL | – | 6.5 | – |

| 15 | 17.6 | – | 3.0 | – | 5.2 | – |

| 18 | 20.1a | – | 16.0a | – | 3.2a | – |

| CD (0.05) | 0.64 | 0.52 | – | – | 0.72 | 0.91 |

aExperiment discontinued

I = Minimum handling II = Normal handling

Rotting

The data on rotting of pods revealed that pods harvested with normal method turned complete black and rotten after 9 days of storage as compared to no rotting till 13 days of storage and only 3% rotting after 15 days of storage in case of minimal handling method (Table 1). The normal method of harvesting resulted in development of dark brown streaks on ridges and other bruised parts on 5th days of storage, making them non-salable. However, no fungal pathogen could be detected from the discoloured parts, even upto 7th day of storage.

Overall sensory quality

The sensory quality of pods decreased at a slower rate in minimum handled treatment as compared to normal handling method during cold storage (Table 1). The overall sensory quality score was highest (6.5) upto 13 days for minimum handled pods whereas pods harvested with normal method recorded the overall sensory score of 6.2 after 5 days of storage. It clearly indicated that overall quality of minimum handled and normal handled pods were acceptable for 13 and 5 days respectively. Thereafter there is loss in the sensory quality due to development of fungus on the injured portion of pods.

Texture

The texture of the pods, generally, decreased with increase in storage period (Table 2). However, the rate of softening of pods was slower in minimum handled method as compared to normal handled method. In normal handled method, pods retained their optimum texture (600.5 g force) upto 5 days of storage though with black spots/patches and thereafter on 7th day, pods turned soft, shriveled, lost their general appearance and were discarded. On the other hand, minimally handled pods maintained their texture and crispness upto 13 days of storage (500.2 g force). Softening of fruits is caused either by breakdown of insoluble proto-pectin into soluble pectin or by cellular disintegration leading to increased membrane permeability (Solomos and Letties 1973). The loss of texture in normal handled pods at a faster pace might be due to excessive injuries on the pod surface which cause high respiration rate, high moisture loss, shrivelling and browning which ultimately resulted in softening of pods. Similar trend in change of texture was also reported by Dhall et al. (2008) and Uppal et al. (2002).

Table 2.

The effect of handling methods on texture, chlorophyll content and colour of okra cv. ‘Punjab-8’ during cold storage (8 ± 1 °C, 90–95% RH)

| Storage period, days | Texture (g force) | Chlorophyll content (mg/g) | Hunter colour values | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| I | II | |||||||||

| I | II | I | II | L | a | b | L | a | b | |

| 1 | 672.5 | 652.2 | 2.9 | 2.8 | 54.3 | −15.9 | 28.9 | 55.3 | −15.6 | 27.8 |

| 3 | 646.2 | 628.2 | 2.7 | 2.5 | 52.2 | −13.6 | 26.2 | 40.1 | −8.9 | 18.9 |

| 5 | 620.4 | 600.5 | 2.4 | 2.1 | 48.3 | −11.0 | 22.2 | 32.4 | −6.9 | 15.8 |

| 7 | 580.5 | 552.8 | 2.4 | 1.7 | 46.5 | −10.8 | 20.6 | 30.0 | −5.7 | 13.9 |

| 9 | 550.8 | 540.6a | 2.2 | 0.6a | 45.5 | −9.8 | 18.2 | 28.2a | −4.0 | 12.1 |

| 11 | 518.4 | – | 2.1 | – | 44.8 | −9.0 | 16.7 | – | – | – |

| 13 | 500.2 | – | 1.9 | – | 44.6 | −8.7 | 14.5 | – | – | – |

| 15 | 430.2 | – | 1.6 | – | 40.0 | −7.9 | 13.0 | – | – | – |

| 18 | 418.4a | – | 1.5 | – | 38.6a | −5.4 | 12.5 | |||

CD (0.05) 40 30 0.32 0.24

aExperiment discontinued

I = Minimum handling II = Normal handling

Chlorophyll content

The loss of green colour of okra pods during storage was determined by the chlorophyll content which declined during storage (Table 2). However, the rate of degradation of chlorophyll was at faster pace in normal harvesting method compared to the minimum handled method. The okra pods which were harvested with normal method retained 0.6 mg/g chlorophyll content upto 9th day as compared to 1.5 mg/g chlorophyll content upto 18th day retained by minimum handling method. The loss of green colour is probably caused first by injury of fine hairs on the ridges/disc of pod thereby, resulting in collapse of intercellular spaces and this whole process finally lead to blackening areas.

Colour

The decrease in the green colour value (-a) during storage was rapid in normal handled pods and gradual in minimum handled pods. In both the treatments there is decrease in the whiteness value (L) but the rapid decrease in the L value (55.3–32.4) in just 5 days in normal handled pods clearly indicated that there was development of black colour on the pods surface. This might be due to injuries on the surface of pods which get blacken during storage period. On the other hand, in normal handled pods, the blackness value increased at a very slow rate as observed from the L value which decreased from 54.3 to 44.6 in 13 days after storage. The b value of pods also decreased in both the treatments which indicated that there is decreased in the yellowness of the pods with increase in storage period.

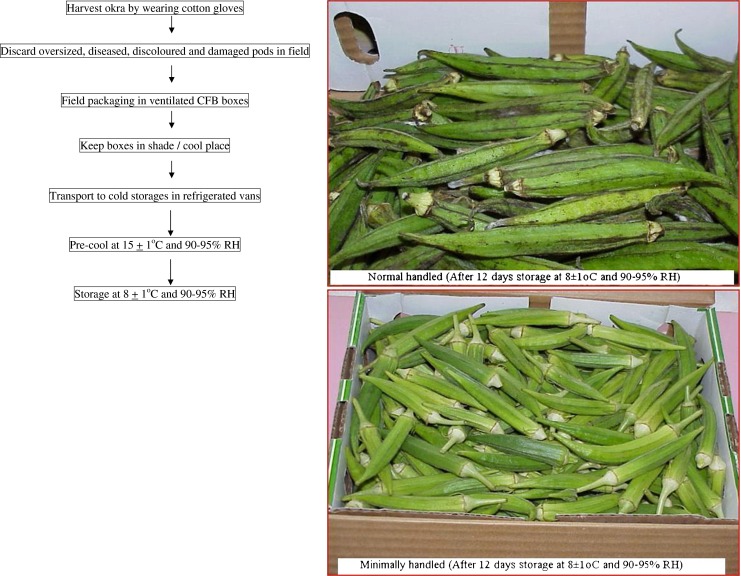

From the above study, it was observed that minimum handling of okra maintain its best possible quality upto 13 days after harvesting when it is stored at 8 ± 1 °C, 90–95% RH. Therefore the post-harvest protocol of okra from harvesting to storage were developed keeping in view its export potential, which is shown in Fig. 1.

Fig. 1.

Post-harvest protocol of okra for harvesting and storage

Conclusion

Therefore, in order to maintain high quality of okra from harvesting to the destination, the minimum handling method of picking and field packaging in CFB boxes, retains freshness, firmness and quality of okra upto 13 days at 8 ± 1 °C, 90–95% RH, without the use of postharvest chemical treatments.

References

- Amerine MA, Pangborn RM, Roessler EB. Principles of sensory evaluation of food. London: Academic; 1965. [Google Scholar]

- Annual report of punjab horticultural postharvest technology centre. Ludhiana: P.A.U; 2004. [Google Scholar]

- Dhall RK, Mahajan BVC, Sharma SR, Dhatt AS (2008) Effect of handling methods and postharvest treatment on the quality of fresh okra during storage. In : Proceeding of National Seminar on Food Safety and Quality from October 20–21, 2008 at Guru Jambheshwar University of Science and Technology, Hisar. pp 296–298

- Hardenburg RE, Watada AE, Wang CY (1986) Commercial storage of fruits, vegetables, flowers and nursery stock. USDA Handbook No. 66

- Hunter S. The measurement of appearance. New York: John Wiley and Sons; 1975. pp. 304–305. [Google Scholar]

- Jasol FS. Export prospects of horticultural produce from India. Indian Hort. 1988;34:79–85. [Google Scholar]

- Kedar AA (1992) Postharvest biology and technology- an overview. In: Postharvest technology of horticultural crops. Second Edition, UC Davis Publication No. 3311, pp 15–20

- Rangana S. Manual of analysis of fruit and vegetable products. New Delhi: Tata McGraw Hill Publishing Company Limited; 1977. pp. 80–83. [Google Scholar]

- Scholz EW, Johnson HB, Buford WR. Heat evaluation rates of some Taxes grown fruits and vegetables in Rio Grande Valley. Hort Sci. 1961;17:170–175. [Google Scholar]

- Singh K, Pandey UB. Export of vegetables- status and strategies. Veg Sci. 1993;20:93–103. [Google Scholar]

- Solomos T, Letties GG. Cellular organization and fruit ripening. Nature. 1973;245:390–391. doi: 10.1038/245390a0. [DOI] [Google Scholar]

- Uppal GS, Kamboj JS and Dhatt AS 2002. Effect of pre-packing and disinfectant and cold storage on postharvest life of Okra. In: National Workshop on newer vistas in handling and processing technology for horticultural crops, held at New Delhi on 14–15, June 2002. pp 8