Abstract

Stevia is a natural sweetener obtained from the leaf of Stevia rebaudiana plant. Its refined extract powder is 130–300 times sweeter than sucrose. Besides, it prevents diabetes, decreases weight, prevents tooth decay, increases digestion etc. Dietetic kulfi was produced, in which 50, 60 and 70% sugar was replaced with 0.05, 0.06 and 0.07% refined stevia extract powder respectively. At higher levels of sugar replacement there was a significant decrease in specific gravity, melting rate, carbohydrate percentage and total calorie content and a significant increase in freezing point, hardness and fat, protein, ash and moisture percentage. Kulfi prepared by replacing half the sugar content with stevia was adjudged on par with the control in sensory characteristics. Above 50% sugar replacement resulted in bitterness, lack of brownish appearance and presence of icy texture.

Keywords: Stevia, Kulfi, Sugar replacement

Introduction

Kulfi, an Indian traditional frozen dairy product, has the composition almost similar to that of ice cream. Sugar is an important ingredient of kulfi. It is the most widely used sweetener in the food industry. The pleasant sweet taste, low cost and high energy value make it the most desirable food sweetener. But it cannot be used by people suffering from diabetes.

Stevia, a natural sweetener obtained from the leaf of Stevia rebaudiana plant, is 130–300 times sweeter than sucrose. It is heat stable up to 200°C. It contains different sweetening compounds like stevioside, a principal diterpene glycosides having sweetness of 250–300 times than that of sucrose. Rebaudioside-A is another sweet constituent, which is ~400 times sweeter than sugar. The other sweet constituents are rebaudioside-B, rebaudioside-C, rebaudioside-D, rebaudioside-E and dulcoside. These compounds differ from each other only with respect to their glucose side chain (Geuns 2003). Besides its sweetness properties, stevia prevents diabetes, decreases weight, prevents tooth decay, increases digestion etc (Rao and Giri 2009). Stevia has been introduced as a sweetener in number of countries i.e., Brazil, Argentina, Korea, Mexico, US, Indonesia, Tanzania and Canada (Kolb et al. 2001).

Stevia had received government approval in over 20 countries. In Latin America, stevia has been used for centuries for its sweet taste and medicinal properties. The Japan Ministry of Health and Welfare and the Korean Ministry of Health approved stevia for food applications more than 30 years ago. In China, stevia has been approved as a ‘Food additive’ by the National Health Inspection Authority. In Australia, stevia has been listed under the Australian Register of the Therapeutic Goods (ARTG). In America, stevia has been approved as ‘a dietary supplement’ by the US Food and Drug Administration (USFDA) in 1994.

Due to bitter after taste stevia cannot replace 100% sugar in kulfi. Complete replacement of sugar with stevia may develop some undesirable physicochemical properties in kulfi. So the objective of this study was to optimize the level of sugar replacement with stevia in kulfi without affecting physicochemical and sensory properties of the product.

Materials and methods

Ingredients

Fresh cow milk was taken from Students’ Experimental Dairy Plant, Dairy Science College, Bangalore, for preparation of kulfi in this investigation. Fresh cream (40% fat and 6% SNF) which was obtained after separating the fresh whole milk and ‘Sagar’ brand skim milk powder were used for standardization of milk (fat 5%, SNF 8.5%). Good quality cane sugar was purchased from the local market. Refined stevia extract powder (containing 91.1% stevioside) was obtained from Kuber Botanicals, Hubli. ‘Aloch’ brand Sodium alginate, used as stabilizer, was purchased from local market.

Production of reduced sugar kulfi

Standardized milk (5% fat, 8.5% SNF) was condensed to half of its original volume in an open pan (Salooja and Balachandran 1982; Rao and Shiv Prakash 2004). Then at 65°C, 0.3% sodium alginate and different levels of sugar like -6.5% (50% sugar reduction), 5.2% (60% sugar reduction) and 3.9% (70% sugar reduction) and different levels of stevia like - 0.05, 0.06, 0.07% were added respectively for different batches by weight of concentrated milk and mixed thoroughly. Trials with different dairy products showed that 1 g stevia is equivalent to 130 g sugar on the basis of sweetness. Accordingly, the levels of stevia required for different extents of sugar replacement were calculated and used. The mix after cooling to room temperature was filled into moulds and hardened at -20°C for 8 h. The products thus prepared were subjected to analysis for different physical and sensory attributes in comparison with control kulfi (13% sugar and no stevia).

Analytical methods

Fat content in milk was determined by Gerber method and in cream and kulfi by Rose-Gottlieb method (IS: Part XI, 1981). The milk solids not fat content of milk was determined according to the method outlined in IS: 10083 (1982). Total nitrogen content of kulfi was estimated by Microkjeldahl method (IS: 5194, 1969). Percentage of protein was obtained by multiplying total nitrogen by a factor of 6.38. Lactose content was estimated by Lane-Eynon method as per IS: Part XI (1981). By adding sugar content to lactose content, total carbohydrate content of kulfi was calculated. Ash content was estimated by incinerating the sample at 550°C in a muffle furnace as per IS: Part XI (1981). Moisture content in kulfi was determined gravimetrically (IS: Part XI, 1981).

Specific gravity of kulfi mix was estimated at 30°C by using a standard specific gravity bottle of 50 ml capacity, taking distilled water as the standard liquid. The melting rate of the kulfi was observed by drawing 50 g of the sample on to a wire net placed on a funnel over a beaker immediately after removal from the hardening chamber. The time taken by the sample for complete melt down and dripping into the beaker at room temperature was noted. The melting rate was expressed as ml/15 min. Penetration value was determined using penetrometer (AIMIL, Associated Instrument Manufactures Pvt. Ltd., Bangalore) to assess hardness of kulfi. Penetration value was determined as soon as kulfi was drawn from the moulds after hardening. The distance in millimeters travelled by the cone in 5 s into the sample at room temperature (30°C) was noted. For each sample, readings were recorded at 3 different spots and the mean value was noted. The freezing point of the kulfi mix was determined by using cryoscope (Cryostar I, Advanced Milk Instruments Manufacturer, USA). Calorific value of carbohydrate, fat and protein are assumed as 3.87, 8.79 and 4.27 cal/g respectively during estimation of calorie content of kulfi (Arbuckle 1986).

|

Judging and analyzing of quality

Kulfi samples were judged by a panel of six judges with a 9-point hedonic-scale score card. Scoring system for the characteristics was provided with standard descriptive phrases to help the judges to arrive at a decision. Judges were supplied with 4 to 5 coded samples of 30 g each as per IS: 6273 (1971).

Statistical analysis

All experiments were in triplicate. Mean scores obtained for the experimental samples were compared with those of the control samples and the results were analyzed statistically for test of significance according to Sundararaj et al. (1972). Significance was tested by employing analysis of variance (ANOVA) and comparison between means was made by critical difference (CD) value.

Results and discussion

Physical properties of kulfi mix/kulfi

The data on the physical properties of kulfi mix/kulfi are shown in Table 1.

Table 1.

Effect of different levels of sugar replacement with stevia on the physical properties of kulfi mix/kulfi

| Levels of sugar reduction (%) | Levels of stevia addition (%) | Specific gravity | Freezing point (°C) | Melting rate (ml/15 min) | Penetration value (mm/5 s) |

|---|---|---|---|---|---|

| 0 (Control) | 0.00 | 1.098 | -2.6863 | 18.1 | 47.0 |

| 50 | 0.05 | 1.086 | -2.5359 | 14.8 | 28.3 |

| 60 | 0.06 | 1.080 | -2.5178 | 12.4 | 24.5 |

| 70 | 0.07 | 1.076 | -2.5012 | 12.2 | 24.2 |

| CD | 0.003 | 0.057 | 0.5 | 0.1 | |

*All values indicated are mean of 3 replications

*Significant at 0.05 level (P < 0.05)

*CD = critical difference

Specific gravity

The specific gravity of control kulfi mix recorded was 1.098, as against 1.086, 1.080 and 1.076 for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. The specific gravity of control sample was significantly higher than that of all treated kulfi mix samples. Among the treated samples, as the level of stevia increased from 0.05 to 0.07%, significant decrease in specific gravity was noticed. This is mainly due to the reduction in the level of sugar with increased levels of stevia. Further, as the percentage of total solids decreased due to reduction in sugar level, specific gravity also decreased. Salem and Massoud (2003) reported that increased level of replacement of sugar with stevia in fibre fortified frozen yoghurt decreased the specific gravity of the product.

Freezing point

The freezing point of control kulfi mix recorded was -2.6863°C as against, -2.5359°C, -2.5178°C and -2.5012°C for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. The freezing point of control sample was significantly lower than that of all treated samples. However, level of stevia did not have a significant effect on the freezing point of kulfi mix. Freezing point depends on number of soluble molecule present in the solution. So 50% reduction of sugar level in the kulfi mix increases freezing point significantly. According to Savita et al. (2004) only 36.5% stevia constituents are soluble. Also addition of stevia in small levels may not affect freezing point to a great extent in the sugar reduced stevia added kulfi.

Melting rate

The melting rate (ml/15 min) of control kulfi recorded was 18.1, as against 14.8, 12.4 and 12.2 for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. The melting rate of control sample was significantly higher than that of all treated kulfi samples. As the level of stevia increased from 0.05 to 0.06%, melting rate decreased significantly. However, as the level of stevia increased from 0.06 to 0.07%, significant effect on melting rate was not noticed. The melting rate decreased due to reduction in sugar level and increased moisture content of kulfi. So at higher levels of sugar replacement, increase in free moisture content and subsequent increase in large ice crystal formation might be the reason for decreased melting rate in the kulfi samples. Salama (2004) also reported that in ice cream mix, whenever levels of sugar replacement (20, 40 and 60%) increased by stevia addition, there was reduction in the melting rate.

Penetration value

The penetration value (mm/5 s) of control kulfi recorded was 47.0, as against 28.3, 24.5 and 24.2 for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. The penetration value of control sample was significantly higher than that of all treated kulfi samples. As the level of stevia increased from 0.05 to 0.06%, there was significant decrease of penetration value. However, as the level of stevia increased from 0.06 to 0.07%, no significant effect on penetration value was noticed. The lower penetration values observed in the treated samples could be mainly due to decrease in total solids and increased ice crystal formation which resulted in a hard body that resisted penetration.

Composition of kulfi

Due to lower levels of sugar, there was decrease of total weight of kulfi when stevia was added. So the fat, protein, ash and moisture percentage increased proportionally in these samples. Carbohydrate percentage reduced significantly with increased levels of sugar replacement (Table 2).

Table 2.

Composition of different levels of sugar reduced and different levels of stevia added kulfi

| Levels of sugar reduction (%) | Levels of stevia addition (%) | Constituents (%) | ||||

|---|---|---|---|---|---|---|

| Fat | Protein | Carbohydrate | Ash | Moisture | ||

| 0 (Control) | 0.00 | 10.0 | 6.4 | 22.8 | 0.99 | 59.8 |

| 50 | 0.05 | 10.7 | 6.9 | 16.4 | 1.06 | 64.9 |

| 60 | 0.06 | 10.9 | 7.0 | 15.2 | 1.07 | 66.0 |

| 70 | 0.07 | 11.0 | 7.1 | 13.9 | 1.09 | 67.0 |

| CD | 0.3 | 0.3 | 1.0 | 0.04 | 0.9 | |

*All values indicated are mean of 3 replications

*Significant at 0.05 level (P < 0.05)

*CD = critical difference

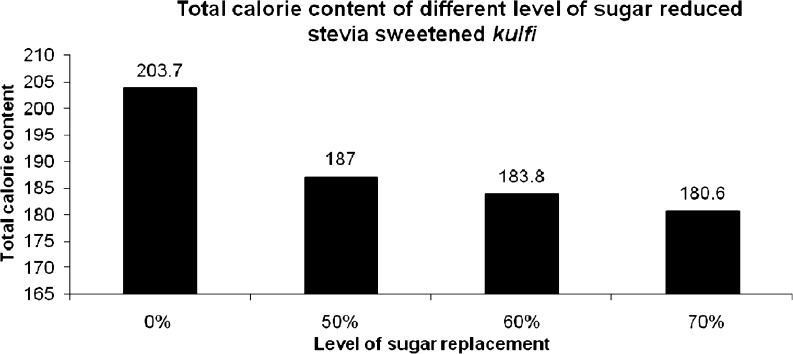

The calorific value (cal/100 g) of control kulfi recorded was 203.7, as against 187.0, 183.8 and 180.6 for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively (Figure 1). It may be observed from the results that calorific value of all treated kulfi samples was lower than that of control kulfi. This is due to decreased level of sugar which was a major contributor to calorie level in kulfi. Among three treated kulfi samples, as the percentage of sugar reduction increased, the calorie level of kulfi decreased. This is again due to increased replacement of sugar with non caloric stevia. Salem and Massoud (2003) found that replacing sucrose with stevia reduced the caloric value of the frozen yoghurt by about 33.86% when 75% sucrose was replaced with stevia.

Fig. 1.

Total calorie content of different level of sugar reduced stevia sweetened kulfi. Each observation is a mean of three replicate experiments (n = 3)

Sensory properties

Kulfi samples were evaluated for sensory properties and the scores are depicted in Table 3.

Table 3.

Effect of different levels of sugar reduction and different levels of stevia addition on sensory characteristics of kulfi

| Levels of sugar reduction (%) | Levels of stevia addition (%) | Color and appearance | Body and texture | Flavor | Sweetness | Overall acceptability |

|---|---|---|---|---|---|---|

| 0(Control) | 0.00 | 8.0 | 8.5 | 8.0 | 8.0 | 8.2 |

| 50 | 0.05 | 7.0 | 8.2 | 7.6 | 7.9 | 7.8 |

| 60 | 0.06 | 6.9 | 8.0 | 4 | 7.9 | 7.0 |

| 70 | 0.07 | 6.7 | 8.0 | 3.5 | 7.8 | 6.0 |

| CD | 0.5 | 0.4 | 0.45 | 0.4 | 0.45 | |

*All values indicated are mean of 3 replications

*Significant at 0.05 level (P < 0.05)

*CD = critical difference

Color and appearance

The color and appearance score awarded for control kulfi was 8, as against 7, 6.9 and 6.7 for the samples subjected to 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. The color and appearance score of control sample was significantly higher than that of all the three treated kulfi samples. However, among the treated kulfi samples, increased level of stevia addition had no significant effect on color and appearance score. The lower color and appearance score for treated kulfi was mainly due to lack of desirable brownish appearance. This could be mainly due to reduction in the sucrose level, which is required for development of desirable brown color in kulfi through caramelisatoin. Reduction in quantity of sugar in stevia added kulfi resulted in development of only a mild brown color.

Body and texture

The body and texture score awarded for control kulfi was 8.5, as against 8.2, 8 and 8 for the samples subjected to 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. Between control and 0.05% stevia added kulfi there was no significant difference in body and texture score but the samples with 0.06 and 0.07% stevia differed significantly with control in the scores. However, the scores did not differ significantly among the three treated kulfi samples prepared with different levels of stevia. At higher level of sugar replacement (60 and 70%) the lower body and texture scores could be due to formation of larger proportion of ice crystals.

Flavor

The flavor score of control kulfi awarded was 8.0, as against 7.6, 4.0 and 3.5 for 50, 60 and 70% sugar reduction, through 0.05, 0.06 and 0.07% stevia addition respectively. Between control and 0.05% stevia added kulfi there was no significant difference on flavor score. However, at higher level of stevia addition, flavor score significantly decreased compared to control sample. Among the treated samples, there was significant decrease in flavor score. Reduction in sugar level by 60 and 70% resulted in increased addition of stevia which increased bitterness in the product as opined by the sensory panelists.

Sweetness

The sweetness score of control kulfi awarded was 8, as against 7.9, 7.9, and 7.8 for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. There was no significant difference between control and the treated samples. The scores also did not differ significantly among the treated samples.

Overall acceptability

The overall acceptability score of control kulfi awarded was 8.2, as against 7.8, 7.0 and 6 for 50, 60 and 70% sugar reduction through 0.05, 0.06 and 0.07% stevia addition respectively. Between control and 0.05% stevia added kulfi no significant difference was observed on overall acceptability score but at 0.06 and 0.07% stevia addition as the level of stevia addition increased, the overall acceptability score significantly decreased compared to control sample. Among the treated samples, as the level of stevia addition increased, there was significant decrease of overall acceptability score. Up to 50% replacement of sugar by stevia did not affect body and texture and flavour score significantly. Above 50% replacement of sugar by stevia there was a significant reduction of body and texture and flavour score. Hence judges adjudged the 50% sugar replaced kulfi on par with the control. Salama (2004) reported that replacement of sucrose by stevia sweetener up to 50% improved the physical properties and sensory characteristics of ice cream.

Conclusion

The present investigation was carried out to maximize the level of sugar replacement with stevia. Though a higher level of replacement would reduce the calorific value, use of stevia beyond 50% of sugar replacement resulted in bitterness and icy texture. However, upto 50% sugar replacement, these defects were not detectable by the sensory panelists. Therefore, upto 50% sugar can be replaced by stevia in kulfi without affecting its sensory characteristics.

References

- Arbuckle WS. Ice cream. 4. New York: AVI Pub Co Inc; 1986. pp. 10–11. [Google Scholar]

- Geuns JMC. Molecules of interest: stevioside. Phytochemistry. 2003;64:913–921. doi: 10.1016/S0031-9422(03)00426-6. [DOI] [PubMed] [Google Scholar]

- Method of test for determination of SNF in milk by the use of lactometer. New Delhi: Indian Standards Institution; 1982. [Google Scholar]

- Method of determination of nitrogen by Kjeldahl method. New Delhi: Indian Standards Institution; 1969. [Google Scholar]

- Part I, guide for sensory evaluation of foods - optimum requirements. New Delhi: Indian Standards Institution; 1971. [Google Scholar]

- Indian standards institute handbook of food analysis. New Delhi: Indian Standards Institution; 1981. [Google Scholar]

- Kolb N, Herrera JL, Ferreyrra DJ, Uliane RF. Analysis of sweet deterpene glycosides from Stevia rebaudiana: Improved HPLC method. J Agric Food Chain. 2001;49:4538–4551. doi: 10.1021/jf010475p. [DOI] [PubMed] [Google Scholar]

- Rao HGR, Giri A. Stevia - natural sweetener for dairy products. Indian Dairyman. 2009;61(11):68–73. [Google Scholar]

- Rao HGR, Shiv Prakash A. Development of pro-biotic kulfi (Indian ice cream) Indian Dairyman. 2004;56(6):57–64. [Google Scholar]

- Salama FMM. The use of some natural sweeteners in ice cream manufacture. Egypt J Dairy Sci. 2004;322:355–366. [Google Scholar]

- Salem AS, Massoud MI. Effect of using Stevia rebaudiana (Bertoni) leaves powder as natural non caloric sweetener on the physico-chemical properties of fibre fortified frozen yoghurt. Egypt J Dairy Sci. 2003;311:61–70. [Google Scholar]

- Salooja MK, Balachandran R. Studies on the production of kulfi part - I. The acceptable level of total milk solids. J Food Sci Technol. 1982;19:116–118. [Google Scholar]

- Savita SM, Sheela K, Sharan S. Stevia rebaudiana - a potential component for food industry. Trends in Carbohydrate Chem. 2004;9:9–14. [Google Scholar]

- Sundararaj N, Nagaraju S, Venkataramu MN, Jagannath MK (1972) Design and analysis of field experiments. Directorate of Research. University of Agricultural Sciences, Bangalore, India