Abstract

Studies were conducted to extend the shelf life of sorghum based fermented milk beverage (referred to SSL) developed at our Institute. In the first approach preservatives namely nisin (N) @ 400RU/ml, MicroGARD (M) @ (1%), potassium sorbate (PS) @ (0.15%) were added to the beverage before packaging and in the second approach thermization (65 °C/5 min) of the packaged samples containing above mentioned preservatives was adopted. The shelf life was assessed on the basis of sensory, physico-chemical and microbiological parameters. Total plate count and lactic acid bacterial count increased till 7th day of storage and afterwards decreased significantly (p < 0.01). Yeasts and molds count increased significantly (p < 0.01) throughout the storage period and the rate of increase was lowest in samples containing PS. Samples containing PS, N and M were found sensorily acceptable up to 35, 28 and 21 days, respectively. Though the thermization treatment helped in improving the microbiological and chemical quality of the beverage, the sensory and physical quality was adversely affected. Addition of PS without thermization was found to be the best preservation technique for enhancing the shelf life of SSL at refrigeration conditions.

Keywords: Salted Sorghum Lassi, Preservatives, Thermization

Introduction

The market for fermented milk products is growing at a faster rate throughout the world. In India, around 9% of the total milk produced is converted into fermented milk products with an annual growth rate of more than 20% (Singh 2007). Cereals are one of the economical and nutritious food sources in the human diet. They contain good amount of carbohydrates, proteins, minerals, vitamins and antioxidants (Das et al. 2011), and recommended in the diets of individuals suffering from metabolic disorders (Vaidya and Sheth 2011). Rabadi is a cereal based fermented milk beverage popular in rural parts of the Northern states of India. Normally underutilized cereals such as sorghum, pearl millet and barley are used for the manufacture of rabadi. It is generally prepared by mixing cereal flour with buttermilk and allowing it to ferment for 4–6 h in the sun. The product is then diluted with water, boiled, salted and cooled before consumption (Dhankher and Chauhan 1987; Modha and Pal 2011). Being a cereal based lactic fermented milk product, rabadi not only provides both the milk and cereal nutrients in a palatable and easily digestible form but also supplies the fiber, a valuable food ingredient from the cereals (Gupta and Nagar 2010).

Though fermented milk products are better preserved, we cannot expect the freshness of these products for longer times as these are prone to deterioration by spoilage organisms, mainly, yeasts and molds. Several workers have tried to extend the shelf life of fermented milks using different preservation treatments viz. thermization (a mild heat treatment i.e. below pasteurization temperature which varies from 50 °C for 30 min to 70 °C for 14 s) (Sarkar et al. 1992a, b; Behare and Prajapati 2007), pasteurization (Guldas and Atamer 1995), addition of chemical and bio-preservatives (Al-Zoreky et al. 1991; Var et al. 2004; von Staszewskia and Jagusa 2008), effective packaging (Patidar and Prajapati 1998), gas flushing (Rosenthal et al. 1991), high pressure technology (Reps et al. 2001; Jankowska et al. 2003; Walker et al. 2006), irradiation (Mainville et al. 2001) and the combination of two or more of these treatments (Hurdle technology) (Lacroix and Lahance 1990). The conventional process of rabadi yields a product with poor and unpredictable sensory and microbiological attributes with limited shelf life. A new technology has been developed for the commercial manufacture of rabadi-like fermented milk beverage using sorghum malt and milk, referred to as salted sorghum lassi (SSL) at National Dairy Research Institute, Karnal. The product had a shelf life of 7 days at refrigeration temperature (6 ± 1 °C), but this short shelf life is not sufficient for its commercial marketing. Moreover the existing cold chain conditions in India would not permit adequate shelf life to SSL to meet the growing demands of the urban consumers. Therefore, the present study was undertaken to enhance the shelf life of SSL using different preservatives either singly or in combination with thermization.

Materials and methods

Fresh buffalo milk and mesophilic mixed strain dahi culture NCDC-167 (Lactococcus lactis ssp. lactis and Lactococcus lactis ssp. var diacetylactis) were obtained from Experimental Dairy and National Collection of Dairy Cultures (NCDC), respectively of the National Dairy Research Institute, Karnal. Sorghum, common salt, cumin and black pepper were procured from the local market. Pectin was obtained from Central Drug House Pvt. Ltd, New Delhi. Nisin and MicroGARD 100 were provided by Danisco India Pvt. Ltd., Gurgaon, Haryana as complimentary samples.

Beverage preparation

Buffalo milk standardized to 4% fat was preheated to 40 °C, added with 24 hr germinated sorghum flour (4.7% of milk), heated to 90 °C for 5 min and then immediately cooled to 37 °C, added with starter culture (NCDC-167) (3%) followed by incubation at 37 °C for 8–10 h to obtain curd with desirable acidity (0.9–1.0% lactic acid). Water at an amount of 69% of curd was heated to 60 °C to dissolve pectin (added @ 0.3% of SSL) followed by addition of salt, black pepper and cumin at a concentration of 0.8, 0.05 and 0.25% of SSL, respectively. It was then heated to 80 °C followed by immediate cooling to 30 °C and was added to the curd obtained above by proper mixing to obtain SSL, and stored at refrigeration temperature (6 ± 1 °C) during the study.

Preservative treatments

SSL was added with preservatives viz. potassium sorbate (0.15%) (P), nisin (400 RU/ml) (N) and MicroGARD (0.1%) (M). The levels of addition of preservatives and temperature-time combination for thermization was based on earlier studies (Olasupo et al. 1996; Hassan et al. 1994; Khurana and Kanawjia 2006; Sherif et al. 1994; Sahil and Sandine 1990) related to shelf-life enhancement of fermented milk beverages having similar composition/characteristics as that of SSL. All the SSL samples were packaged in LDPE pouches (film thickness 70 μm) of 200 ml quantity using sachet filling machine.

Thermization treatment

All the SSL samples with above mentioned preservatives and without preservatives were divided into two batches and one batch was subjected to thermization in water bath at 65 °C for 5 min.

Physico-chemical analysis

The fat and total solids content of milk, moisture content and acidity of SSL was estimated as per the procedure described in IS: SP: 18, part XI (1981). The fat content of SSL was determined by Mojonnier method (Anon 1959) with slight modifications. pH was measured using digital pH meter (LABINDIA) with combined glass electrode. The protein and ash contents of SSL were estimated as per AOAC (1995) method. The total free fatty acid content of the SSL samples was estimated using the method described by Deeth and FitzGerald (1976). The extent of proteolysis in SSL samples during storage was determined according to the method described by Hull (1947). The viscosity was determined at 25 °C using 2-2 system of a coaxial cylinder viscometer (Contrives Rheomat 108 ER) at a shear rate of 100 s−1. Wheying off and sedimentation was measured by keeping 10 ml of beverage in a 15 ml graduated tube with cap in the refrigerator (6 ± 1 °C) for 24 h, measuring the amount of sediment and whey and expressed as ml of sediment and per cent wheying off, respectively.

Microbiological analysis

Microbiological analysis of the SSL was done for standard plate count (SPC), coliform, lactic acid bacteria and yeast and mold counts as per the method of Marshall (1993).

Sensory evaluation

The SSL samples were evaluated for their sensory characteristics viz. flavour, colour and appearance, consistency, sedimentation and overall acceptability using a 9 point hedonic scale (Stone et al. 1974). The sensory evaluation of all the SSL samples was carried out till they got spoiled or became unfit for consumption.

Statistical analysis

The statistical analysis of the data obtained was carried out using Least Square ANOVA in Unix System V Release 42 Ver-I software. The comparison of the mean values was done by Duncan’s multiple range test. Experiments were carried out in triplicates and all the data presented was average of three replicates.

Results and discussion

Effect of preservative treatments on the sensory quality

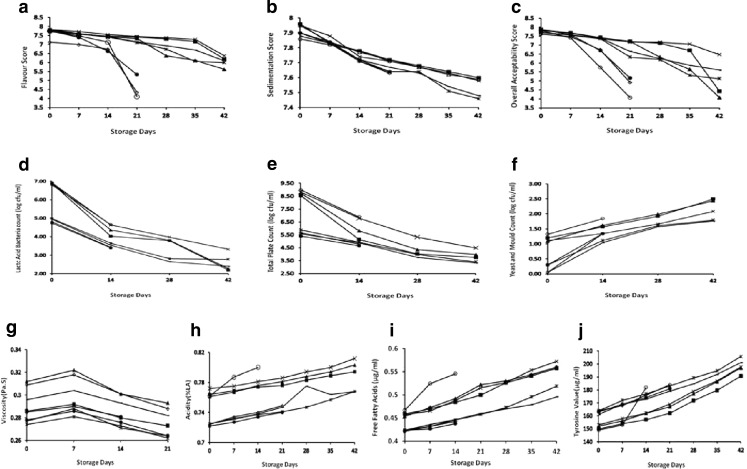

The sensory scores of all the SSL samples gradually decreased throughout the storage period. The sensory scores of all the SSL samples differed significantly (p < 0.01) between storage intervals and treatments (Table 1). The rate of decline in the sensory scores of control (C) was more when compared with the treated samples. This may be due to faster growth of microorganisms leading to quicker spoilage of the control sample during storage. The rate of decrease in flavour score of samples added with nisin (N) and MicroGARD (M) was less up to 21st day when compared with potassium sorbate added sample (PS), after that up to 42nd day, the flavour score of N and M decreased at a higher rate than PS (Fig. 1a). This could be due to the fact that, in fermented milks, bacterial growth predominates in the earlier stages followed by growth of yeasts and molds at higher acidity (Walker 1977; Main 1984). As nisin and MicroGARD are more effective against bacteria they might have prevented bacterial growth in the earlier stages of fermentation and therefore obtained better flavour scores than the samples containing PS. After reaching certain acidity where the yeast and molds outweighs the growth of bacteria, nisin and MicroGARD are not effective as that of potassium sorbate in preventing the growth of yeasts and molds and hence the rate of decrease in sensory score of PS containing product was less when compared to that containing N and M.

Table 1.

Least square anova for changes in sensory quality, physico-chemical characteristics and microbiological counts of salted sorghum lassi subjected to different preservation treatments

| Sensory attributes | Mean Sum of Squares | |

|---|---|---|

| Treatments | Storage period | |

| Flavour | 3.76** | 9.86** |

| Sedimentation | 0.02** | 0.34** |

| Overall Acceptability | 3.68** | 18.79** |

| Physico-chemical characteristics | ||

| Viscosity (Pa.S at D:100 s−1) | – | 0.00067** |

| Acidity (% LA) | 0.008** | 0.004** |

| Free fatty acids (μg/ml) | 0.015** | 0.02** |

| Tyrosine (μg/ml) | 785.95** | 3805.92** |

| Microbiological counts | ||

| Total plate count (log cfu/ml) | 9.46** | 42.94** |

| Lactic acid bacterial count (log cfu/ml) | 3.97** | 38.02** |

| Yeasts and Molds count (log cfu/ml) | 0.75** | 4.36** |

** Significant at 1% level (p < 0.01); D is shear rate

Fig. 1.

Changes in quality of salted sorghum lassi subjected to different preservation treatments during storage at 6 ± 1 °C (n = 3)  Control

Control  Nisin

Nisin  MicroGARD

MicroGARD  Potassium sorbate

Potassium sorbate  Control + Thermization

Control + Thermization  Nisin + Thermization

Nisin + Thermization  MicroGARD + Thermization

MicroGARD + Thermization  Potassium sorbate + Thermization

Potassium sorbate + Thermization

Whey separation in cultured products might be attributed to dehydration of proteins on heating (Rasic and Kurmann 1978). Because of added pectin, all the SSL samples attained good consistency (low sedimentation) which might be due to the increase in viscosity of the serum phase and in the volume fraction of dispersed materials (van Hooydonk et al. 1982). Khurana and Kanawjia (2006) reported that pectin could be successfully applied in fruit lassi to prevent whey separation during storage. Towler (1984) reported that pectin was effective in preventing sedimentation in the fermented beverage base. Thermized samples had low scores for sedimentation than other samples (Fig. 1b). Ramana and Tiwari (1999) reported that addition of stabilizers viz. carboxy methyl cellulose and pectin reduced the quantity of whey separated in heat treated lassi during storage at 4 ± 1 °C and they also reported that lassi heated above 60 °C was criticised for coarse mouthfeel, whey separation and thin consistency.

Samples containing N, PS and M were judged acceptable for consumption till 35, 28 and 21 days of storage, respectively (Fig. 1c). These findings are also in good agreement with the findings of Olasupo et al. (1996) who reported that nono, a Nigerian fermented milk product had acceptable sensory scores till 25th day of its storage when added with nisin at 400 RU/ml. Khurana and Kanawjia (2006) reported that mango lassi added with 750 ppm nisin had acceptable sensory scores till 30th day of storage. Sherif et al. (1994) found that potassium sorbate when added to yoghurt @ 0.15% yielded a product with appreciable sensory quality up to 23 days at refrigeration temperature. Thermized samples obtained lesser overall acceptability scores than the non-thermized samples. Similar findings were obtained by Ramana and Tiwari (1999) and Behare and Prajapati (2007) who reported that the sensory quality of lassi, subjected to heat treatment at or above 65 °C for 5 min, gradually decreased during the refrigerated storage and the rate of decrease in sensory score was lesser in control. Among heat treated samples, nisin + thermized sample (NT) and MicroGARD 100 + thermized sample (MT) obtained lower scores throughout the study and were rejected earlier than the other samples. The main reason for the lower acceptability of thermized samples was deterioration of flavour due to the degradation of preservative compounds upon heating in the acidic environment.

Effect of preservative treatments on the physico-chemical characteristics

It can be seen from Table 1 that the physico-chemical characteristics of all the SSL samples differed significantly (p < 0.01) between storage intervals and treatments. The acidity (Fig. 1h), free fatty acids content (Fig. 1i) and tyrosine values (Fig. 1j) of all the SSL samples were increased with the advancement of the storage period. The rate of increase was more in sample C than the other samples. These findings are in accordance with the findings of Sherif et al. (1994), Olasupo et al. (1996) and Khurana and Kanawjia (2006) who observed a similar trend for mango lassi, nono and yoghurt, respectively at refrigerated storage. Hassan et al. (1994) reported a slow rate of increase in free fatty acids (FFA) value for potassium sorbate added acidophilus milk during its storage at refrigeration temperature.

The rate of increase in acidity and FFA value for all thermized samples was lesser when compared to non-thermized samples throughout the storage period. Ramana and Tiwari (1999), Kumar et al. (2003a, b) and Behare and Prajapati (2007) observed no significant increase during storage in the acidity and FFA value of lassi subjected to heat treatment of more than 65 °C. This might be due to the heat shock given to microorganisms which slowed down rate of metabolic and enzymatic activity by the microorganisms.

Thermized samples obtained higher values for tyrosine content than the other samples. Ramana and Tiwari (1999) reported that the high tyrosine values may be due to the destruction of microbial cells during heat treatment of lassi causing release of metabolites into the product.

The presence of pectin had a significant role in increasing the viscosity of all the samples. The viscosities of all the samples were increased from 0 to 7th day of storage and then decreased gradually (Fig. 1g). This increase in viscosity may be due to the reaction between pectin and water molecules leading to enhanced gel structure reinforcement (Oliveira et al. 2001). The subsequent decline in viscosity after 7 days may be due to action of spoilage microorganisms which led to breakdown of casein network. Similar trend was observed by Khurana and Kanawjia (2006) for mango lassi. Samples added with M obtained higher viscosities than the remaining samples. This may be due to the increase in total solids concentration as M was added at higher concentration (1%) than the other preservatives. The maximum viscosity value of 0.322 Pa.s was found in case of sample containing M on its 7th day of storage. Practically no wheying off was observed in any of the SSL samples as the pectin and starch might have prevented the wheying off by combining with free water.

Effect of preservative treatments on the microbiological characteristics of SSL

The total plate count (TPC) (Fig. 1e) and lactic acid bacterial (LAB) (Fig. 1d) count for all the eight samples decreased throughout the storage period. The rate of decrease in TPC and LAB count was lesser for control than the remaining samples. It can be seen from Table 1 that the microbiological characteristics of all the SSL samples differed significantly (p < 0.01) between storage intervals and treatments. Sherif et al. (1994), Olasupo et al. (1996) and Khurana and Kanawjia (2006) found gradual decrease in TPC and LAB count for nono added with nisin, mango lassi added with MicroGARD and yoghurt added with potassium sorbate, respectively. The TPC and LAB count of all the non-thermized samples decreased by more than 2 log cycles in first 14 days and for thermized samples they decreased by more than one log cycle and after that there was a gradual decrease in the lactic count of all the samples which may be ascribed to the outgrowth of these bacteria by yeast and molds in the presence of highly acidic environment. There was a reduction in the bacterial counts of thermized samples which may be ascribed to the lethal effect caused by the heat treatment.

The rate of increase of yeast and mold count for samples containing PS was less compared to control and samples containing N and M. Nisin and MicroGARD did not show inhibitory effect on yeast and molds and their number increased throughout the storage in samples containing nisin and MicroGARD. The results were in good agreement with results observed by Khurana and Kanawjia (2006). Sherif et al. (1994) reported that potassium sorbate added at a concentration of 0.15% to yoghurt inhibited the growth of yeast and molds effectively. Thermized samples had shown very low counts of yeast and molds and the rate of increase was also very less when compared with non-thermized samples (Fig. 1f) and similar trend was observed by Ramana and Tiwari (1999) and Behare and Prajapati (2007) for lassi and Chander et al. (1992) for dahi. There were no coliforms found in any of the samples throughout the storage period. Absence of coliforms in all the SSL samples indicates hygienic practices followed during product manufacture.

Conclusion

Incorporation of cereal flours into milk to develop fermented beverages adds value to milk and also confers health benefits to consumers. However, for effective marketing it is imperative that such beverages should posses adequate shelf-life. The sensory attributes, physico-chemical characteristics and microbial counts of all the samples were significantly differed by the applied storage treatments and storage period. On the basis of above findings it was concluded that nisin, MicroGARD and potassium sorbate can be used to preserve salted sorghum lassi (SSL) for about 3 weeks at refrigeration temperature (6 ± 1 °C). Addition of potassium sorbate without thermization was found the best preservation treatment for the preservation of SSL at refrigeration temperature (6 ± 1 °C).

Acknowledgement

First author is thankful to Indian Council of Agricultural Research (ICAR), New Delhi for providing financial assistance in the form of junior research fellowship (JRF) and to the Director, National Dairy Research Institute (NDRI), Karnal for providing necessary facilities to carry out this work. The first author is also thankful to Dr. P. Narender Raju, Scientist, NDRI, Karnal for his help in preparing this manuscript and Dr. Rashiya Banu for her help in statistical analysis.

References

- Al-Zoreky N, Ayres JW, Sandine WE. Antimicrobial activity of MicroGARD against food spoilage and pathogenic microorganisms. J Dairy Sci. 1991;74(3):758–763. doi: 10.3168/jds.S0022-0302(91)78222-2. [DOI] [PubMed] [Google Scholar]

- Methods of analysis of milk and its products. 3. Washington: Milk Industry Foundation; 1959. [Google Scholar]

- Official methods of analysis. 11. Washington: Association of Official Analytical Chemists; 1995. [Google Scholar]

- Behare PV, Prajapati JB. Thermization as a method for enhancing the shelf life of cultured buttermilk. Indian J Dairy Sci. 2007;60(2):86–93. [Google Scholar]

- Chander H, Batish VK, Mohan M, Chand R, Singh RS. Effect of heat treatment on bacterial quality of dahi-An Indian fermented dairy product. Cult Dairy Prod J. 1992;27(2):8–9. [Google Scholar]

- Das A, Raychaudhuri U, Chakraborty R (2011) Cereal based functional food of Indian subcontinent: a review. J Food Sci Technol. doi:10.1007/s13197-011-0474-1 [DOI] [PMC free article] [PubMed]

- Deeth HC, FitzGerald CH. Lipolysis in dairy products: a review. Aust J Dairy Technol. 1976;31(2):53–64. [Google Scholar]

- Dhankher N, Chauhan BM. Technical note: preparation, acceptability and B vitamin content of rabadi - a fermented pearl millet food. Int J Food Sci Technol. 1987;22(2):173–176. doi: 10.1111/j.1365-2621.1987.tb00474.x. [DOI] [Google Scholar]

- Guldas M, Atamer M. Effect of pasteurization norm and storage temperature on the quality of long life yoghurt. GIDA. 1995;20(5):313–319. [Google Scholar]

- Gupta V, Nagar R. Effect of cooking, fermentation, dehulling and utensils on antioxidants present in pearl millet rabadi – a traditional fermented food. J Food Sci Technol. 2010;47(1):73–76. doi: 10.1007/s13197-010-0018-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hassan MNA, Mehriz AM, Hefny AA, Aziz AHH. Effect of some fungicides on the keeping quality of sour acidophilus milk. Egypt J Dairy Sci. 1994;22(1):155–166. [Google Scholar]

- Hull ME. Studies on milk proteins II. Colorimetric determination of the partial hydrolysis of the proteins in milk. J Dairy Sci. 1947;30:881–884. doi: 10.3168/jds.S0022-0302(47)92412-0. [DOI] [Google Scholar]

- Handbook of food analysis (Part XI): dairy products. New Delhi: Bureau of Indian Standards; 1981. [Google Scholar]

- Jankowska A, Reps A, Proszek A, Krasowska M (2003) Applying high pressure to yoghurt preservation. Proceedings of the 17th forum Applied Biotechnology, Parts I and II, 18–19 September, 2003, Universitet Gent, Gent, Belgium, pp. 477–480

- Khurana HK, Kanawjia SK (2006) Extension of shelf-life of mango lassi using biopreservatives. XXXV Dairy Ind. Confererence, November 23–25, Collate, India, DPP No. 02

- Kumar A, Solanky MJ, Chauhan AK. Storage related lipolytic changes in lassi. Indian J Dairy Sci. 2003;56(1):20–22. [Google Scholar]

- Kumar A, Solanky MJ, Pinto S, Chauhan AK. Storage related proteolytic changes in lassi. Indian J Dairy Sci. 2003;56(6):394–396. [Google Scholar]

- Lacroix C, Lahance O. Effects of various humectants and aw on proteolysis, yeast and mould growth and shelf life during cold storage of yoghurt. Can Inst Food Sci Technol J. 1990;23(2–3):101–108. doi: 10.1016/S0315-5463(90)70211-8. [DOI] [Google Scholar]

- Main MA. The occurrence and growth of yeasts in refrigerated fruit juices, dairy products and frozen fruits and vegetables. Diss Abstr Int B. 1984;44(8):2374. [Google Scholar]

- Mainville I, Montpetit D, Durand N, Farnworth ER. Deactivating the bacteria and yeast in kefir using heat treatment, irradiation and high pressure. Int Dairy J. 2001;11(1):45–49. doi: 10.1016/S0958-6946(01)00038-3. [DOI] [Google Scholar]

- Marshall RT. Standard methods for the examination of dairy products. Washington: American Public Health Association; 1993. [Google Scholar]

- Modha H, Pal D. Optimization of Rabadi-like fermented milk beverage using pearl millet. J Food Sci Technol. 2011;48(2):190–196. doi: 10.1007/s13197-010-0146-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Olasupo NA, Akinsanya SM, Oladele OF, Azeez MK. Evaluation of nisin for the preservation of nono-a Nigerian fermented milk product. J Food Proc Pres. 1996;20:71–78. doi: 10.1111/j.1745-4549.1996.tb00341.x. [DOI] [Google Scholar]

- Oliveira JD, Silva DA, de Paula RCM, Feitosa JPA, Paula HCB. Composition and effect of salt on rheological and gelation properties of Enterolobium contortisiliquum gum exudate. Int J Biol Macromol. 2001;29:35–44. doi: 10.1016/S0141-8130(01)00151-9. [DOI] [PubMed] [Google Scholar]

- Patidar SK, Prajapati JB. Standardization and evaluation of lassi prepared using Lactobacillus acidophilus and Streptococcus thermophilus. J Food Sci Tech. 1998;35(5):428–431. [Google Scholar]

- Ramana BLV, Tiwari BD. Effect of processing variables on sensory and physico-chemical qualities of heat treated lassi. Indian J Dairy Sci. 1999;52(5):272–278. [Google Scholar]

- Rasic JL, Kurmann JA. Yoghurt: Scientific grounds, technology, manufacture and preparations. Copenhagen: Technical Dairy Publishing House; 1978. p. 466. [Google Scholar]

- Reps A, Warminska-Radyko I, Krzyzewska A, Tomasik J. Effect of high pressure on Streptococcus salivarius subsp. thermophilus. Milchwissenschaft. 2001;56:131–133. [Google Scholar]

- Rosenthal IB, Rosen BS, Popel G. Preservation of fresh cheeses in a CO2 enriched atmosphere. Milchwissenschaft. 1991;46:706–708. [Google Scholar]

- Sahil MA, Sandine WE. Inhibitory effect of MicroGARD™ on yoghurt and cottage cheese spoilage organisms. J Dairy Sci. 1990;73:887–893. doi: 10.3168/jds.S0022-0302(90)78744-9. [DOI] [Google Scholar]

- Sarkar SP, Dave JM, Sannabhadti SS. Effect of thermization of Misti Dahi on Shelf life and Beta-D-galactosidase activity. Indian J Dairy Sci. 1992;45(3):135–139. [Google Scholar]

- Sarkar SP, Dave JM, Sannabhadti SS. A note on the effect of thermization of misti dahi on the acid producers count. Indian J Dairy Sci. 1992;45(3):131–134. [Google Scholar]

- Sherif SA, Hegazi NA, Kandeel AA. Prolongation of yoghurt shelf life using some preservatives. Ann Agr Sci-Moshtohor. 1994;32(1):331–339. [Google Scholar]

- Singh R. Characteristics and technology of traditional cultured Indian milk products. Bull IDF. 2007;415:11–20. [Google Scholar]

- Stone H, Sidel J, Oliver S, Woosley A, Singleton RC. Sensory evaluation by quantitative descriptive analysis. Food Technol. 1974;28(11):24–34. [Google Scholar]

- Towler C. Sedimentation in a cultured milk beverage. NZ J Dairy Sci Technol. 1984;19:205–211. [Google Scholar]

- Vaidya RH, Sheth MK. Processing and storage of Indian cereal and cereal products alters its resistant starch content. J Food Sci Technol. 2011;48(5):622–627. doi: 10.1007/s13197-010-0151-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- van Hooydonk ACM, Smalbrink L, Hagedoorn HG, Reitsma JCE. Manufacture of drinking yoghurt [part 2: the effect of product composition] Zuivelzicht. 1982;74(40):901–904. [Google Scholar]

- Var I, Sahan N, Kabak B, Golge O. The effects of Natamycin on the shelf life of yoghurt. Arch Leb. 2004;55:7–9. [Google Scholar]

- von Staszewskia M, Jagusa RJ. Natural antimicrobials: effect of MicroGARD™ and nisin against Listeria innocua in liquid cheese whey. Int Dairy J. 2008;18(3):255–259. [Google Scholar]

- Walker HW. Spoilage of food by yeasts. Food Technol. 1977;31:57–61. [Google Scholar]

- Walker MK, Farkas DF, Loveridge V, Meunier-Goddik L. Fruit yogurt processed with high pressure. Int J Food Sci Technol. 2006;41:464–467. [Google Scholar]