Significance

Previous research has demonstrated that proximity to unconventional gas development is associated with elevated concentrations of methane in groundwater aquifers in Pennsylvania. To date, the mechanism of this migration is poorly understood. Our study, which looks at more than 41,000 conventional and unconventional oil and gas wells, helps to explain one possible mechanism of methane migration: compromised structural integrity of casing and cement in oil and gas wells. Additionally, methane, being the primary constituent of natural gas, is a strong greenhouse gas. The identification of mechanisms through which methane may migrate to the atmosphere as fugitive emissions is important to understand the climate dimensions of oil and gas development.

Keywords: shale oil and gas, casing integrity, cement integrity, onshore wells, wellbore integrity

Abstract

Casing and cement impairment in oil and gas wells can lead to methane migration into the atmosphere and/or into underground sources of drinking water. An analysis of 75,505 compliance reports for 41,381 conventional and unconventional oil and gas wells in Pennsylvania drilled from January 1, 2000–December 31, 2012, was performed with the objective of determining complete and accurate statistics of casing and cement impairment. Statewide data show a sixfold higher incidence of cement and/or casing issues for shale gas wells relative to conventional wells. The Cox proportional hazards model was used to estimate risk of impairment based on existing data. The model identified both temporal and geographic differences in risk. For post-2009 drilled wells, risk of a cement/casing impairment is 1.57-fold [95% confidence interval (CI) (1.45, 1.67); P < 0.0001] higher in an unconventional gas well relative to a conventional well drilled within the same time period. Temporal differences between well types were also observed and may reflect more thorough inspections and greater emphasis on finding well leaks, more detailed note taking in the available inspection reports, or real changes in rates of structural integrity loss due to rushed development or other unknown factors. Unconventional gas wells in northeastern (NE) Pennsylvania are at a 2.7-fold higher risk relative to the conventional wells in the same area. The predicted cumulative risk for all wells (unconventional and conventional) in the NE region is 8.5-fold [95% CI (7.16, 10.18); P < 0.0001] greater than that of wells drilled in the rest of the state.

Oil and natural gas production has increased substantially in the United States in recent years, predominantly due to innovations such as high-volume hydraulic fracturing and directional drilling in shale formations (1). Concurrent with this increase, concerns have mounted regarding effects of this oil and gas development process on groundwater quality, human health, public safety, and the climate, due, in part, to subsurface migration of methane and other associated hydrocarbon gases and volatile organic compounds. Economic development of gas and oil from shale formations requires a high well density, at least one well per 80 surface acres, over large continuous areas of a play. Osborn et al. (2) and Jackson et al. (3) identified a positive relationship between the concentration of thermogenic methane in private water wells in Pennsylvania and the proximity of those water wells to the nearest unconventional (i.e., Marcellus shale) gas production well. These studies also identified three possible mechanisms for explaining this relationship, and concluded that the most likely of these is subsurface migration from leaking gas wells. Other researchers have observed thermogenic and other subsurface-sourced methane in atmospheric concentrations high above background levels near conventional and unconventional gas development (4–6), suggesting that leaking wells may also contribute to fugitive methane and other associated gas emissions, with clear climatic and air quality consequences (7).

Leaking oil and gas wells have long been recognized as a potential mechanism of subsurface migration of thermogenic and biogenic methane, as well as heavier n-alkanes, to the surface (7–11). A leaking well, in this context, is one in which zonal isolation along the wellbore is compromised due to a structural integrity failure of one or more of the cement and/or casing barriers. Such loss of integrity can lead to direct emissions to the atmosphere through one or more leaking annuli and/or subsurface migration of fluids (gas and/or liquid) to groundwater, surface waters, or the atmosphere. Cement barriers may fail at any time over the life of a well for a number of reasons, including hydrostatic imbalances caused by inappropriate cement density, inadequately cleaned bore holes, premature gelation of the cement, excessive fluid loss in the cement, high permeability in the cement slurry, cement shrinkage, radial cracking due to pressure fluctuations in the casings, poor interfacial bonding, and normal deterioration with age (12). Casing may fail due to failed casing joints, casing collapse, and corrosion (13). Loss of zonal isolation creates pressure differentials between the formations intersected by the wellbore and the open barrier(s). The pressure gradient thus created allows for the flow of gases or other formation fluids between geological zones (i.e., interzonal migration) and possibly to the surface (14–16), where it might manifest as sustained casing pressure (SCP) or sustained casing vent flow.

Annuli are often vented, as noted in inspection records, and may contribute to fugitive emissions from the well site. Low-pressure leaks may continue to be periodically bled off and monitored, although recent studies warn that bleeding pressure to zero may actually lead to gas migration (17). High-risk (e.g., rapid repressuring of the annulus following bleed down) leaks must be structurally remedied (i.e., cement squeeze, gel squeeze, use of packers, topping off cement). State regulations (Pennsylvania code 25 §78.86) mandate that wells with leaks that cannot be vented or adequately repaired be permanently plugged, which may reduce but not eliminate the interzonal flow of gases and liquids. Leaks that continue undetected or inadequately remedied may lead to the contamination of shallow aquifers, accumulation of explosive gases within and around residences and other structures, and emission of methane and other associated gases to the atmosphere.

Although not every instance of loss of zonal isolation will lead to such events, the incidence rate of cement/casing impairments and failures can provide some insight into the scale of current and future problems. However, the structural integrity failure rate of oil and gas well barriers continues to be a subject of debate. The rates most commonly cited (from 2 to >50%) are based upon industry reporting for offshore wells in the Gulf of Mexico (13, 14) and Canadian onshore (mostly conventional) wells (16). Watson and Bachu (16) note that wells drilled during periods of rapid development activity and/or wellbores deviated from vertical (e.g., horizontal wellbores) may be more prone to casing vent flow and/or gas migration away from the wellhead.

Due to the lack of publicly available structural integrity monitoring records for onshore wells from industry, more recent studies have used data from state well inspection records to estimate the proportion of unconventional wells drilled that develop cement and/or casing structural integrity issues. For instance, Considine et al. (18) analyzed Pennsylvania Department of Environmental Protection (PADEP) notice of violation (NOV) records for 2008–2011 and found that between 1% and 2% of wells had one or more potential structural integrity issues during that time period. Vidic et al. (19), using the 2008–2013 data from the PADEP database, found that 3.4% of all monitored unconventional wells drilled to date in Pennsylvania might have structural integrity failures based on NOVs related to cement/casing integrity. However, neither study adequately accounts for non-NOV indicators of cement/casing integrity impairment or temporal or spatial dimensions of such impairments.

Earlier work found that the NOV count alone does not account for all incidences of cement/casing failure (20). State regulatory agencies and the oil and gas industry monitor many of the wells showing signs of SCP or other indicators of cement and/or casing impairment. Remedial action is often attempted once or many times on a monitored well, but a NOV is not issued by the agency. Additionally, violation codes are sometimes entered incorrectly as non-cement/casing issues and later corrected in violation comments. By not accounting for these, previous assessments based on PADEP inspection records (18, 19) may underestimate the actual proportion of wells with cement and/or casing problems in Pennsylvania.

Failure to account for temporal dimensions of the data may also skew results. Previous studies on cement/casing impairment have noted that wells drilled during boom periods may be more susceptible to loss of zonal isolation because operators might cut corners in an attempt to increase the number of wells drilled over a short period (16). The increased risk of zonal isolation problems as wells age and the increased probability of identifying these issues with more inspections may also create a time lag between the date that drilling of the well commences (i.e., the spud date) and the entry of a cement/casing issue in the inspection records. This time lag is due to the fact that wells drilled in recent years have not been subject to the same duration of analysis or number of inspections as older wells. Thus, inspection records on newer wells are incomplete relative to those of older wells.

Here, we offer an in-depth analysis of the complete inspection records, including NOVs, observations and corrections noted in the inspector comments, for 32,678 oil and gas production wells drilled in Pennsylvania between 2000 and 2012. We use a time-dependent risk analysis model to assess the cumulative risk of cement/casing problems for wells based on the historical occurrence of cementing/casing impairment events.

Results and Discussion

Comparison of state inspection and well spud reports (where the “spud” date is the start date of drilling) indicates a loss of well integrity in 1.9% of the oil and gas production wells spudded between 2000 and 2012. This value agrees well with some previous estimates in the literature; however, this superficial indication comes with important caveats and is an incomplete assessment. The data suggest large differences in structural integrity issues between well types, with unconventional wells showing a sixfold higher incidence of cement and/or casing issues relative to conventional wells statewide (Table 1 and SI Appendix, Table S14). Even within the unconventional well category, a wide range (1.49–9.84%) of incident rates is observed among wells spudded during different time periods and in different regions. Unconventional wells spudded before 2009 in the northeastern (NE) counties of the state are associated with the highest occurrence of loss of structural integrity (9.84%). It can be argued that this subcategory reflects a small number of observed cases (61 wells) and the earliest industry experience in the Marcellus play, and thus should not be used as an indication of current practices. However, unconventional wells spudded in the NE region since 2009 (2,714 wells) show a similarly high rate of occurrence (9.18%).

Table 1.

Percentage of wells showing loss of structural integrity by temporal (pre- and post-2009 spuds), geographic (non-NE and NE counties), and well type (conventional and unconventional) categories

| Non-NE counties | NE counties | |||

| Wells spudded | Conventional | Unconventional | Conventional | Unconventional |

| Pre-2009 | 0.73% | 1.49% | 5.21% | 9.84% |

| Post-2009 | 2.08% | 1.88% | 2.27% | 9.14% |

Statewide, rate of loss of structural integrity for conventional and unconventional wells spudded between 2000–2012 are 1.0% and 6.2%, respectively (weighted average = 1.9%).

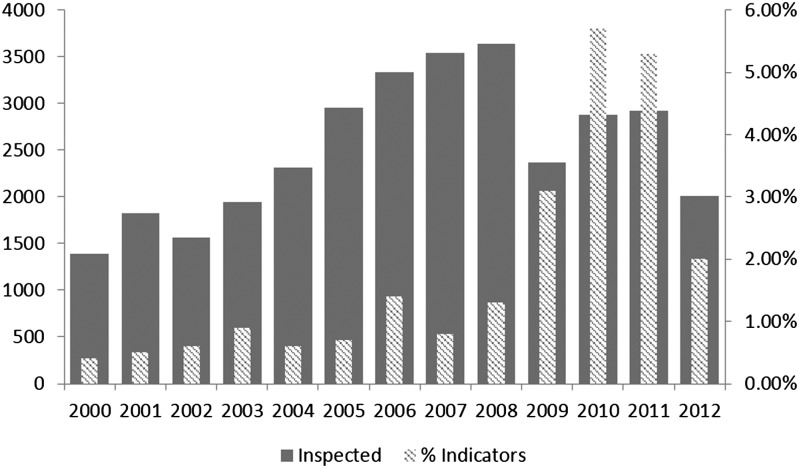

As already noted, direct comparison of rates of loss of well integrity in young wells to those of much older wells is misleading. Assuming an increased risk of cement/casing issues as the materials (cement/casing) age, it must follow that the risk of structural integrity loss and likelihood of state inspectors identifying a cement/casing problem will increase through time as a well accumulates additional inspections. Thus, a well spudded 3 y ago, which will ideally have a 3-y record of inspections from which to draw observations, is more likely to have an indicator of cement/casing integrity loss noted in the inspection record than a similar well spudded only 1 y ago and associated with just one-third of the observation time. The effects of this temporal dependency can be seen in Fig. 1. Annual trends for wells spudded in 2010 and 2011 show rates of incidence similar to the cumulative unconventional rate reported in Table 1 (unconventional wells make up 57.5% and 66.3% of spuds in 2010 and 2011, respectively). However, wells spudded in 2012 and subject to an observation period ≤1 y appear to have a much lower incidence of cement/casing issues. This raises an important question: Are wells spudded in 2012 more sound than those spudded in previous years, or is the apparent decline in indicators in state inspection reports an artifact of an incomplete inspection history?

Fig. 1.

Annual trends of indicators for wells spudded in the state of Pennsylvania, 2000–2012. The percentage of spuds with integrity issues reflects the number of unique wells spudded in a given year for which an indicator was found at any time within the inspection record (13 y). The rates of incidence noted in the inspection records for pre-2009 spuds hover around 1% for the several years before spiking in 2010. These trends may represent differences in state emphasis on locating leaking wells following widely publicized contamination events or actual increases in loss of structural integrity.

Note that incomplete inspection records may also occur in older wells that have not been regularly inspected through time. Inspection records for modeled wells indicate an average of 2.75 inspections per well statewide, despite nearly 71.6% of wells being >3 y old. Moreover, PADEP records indicate that of the more than 41,000 oil and gas production wells spudded between 2000 and 2013, 24% of conventional and 4% of unconventional well spuds have never received facility-level inspections or the relevant inspections are not included in the PADEP online database (8,703 wells in total). It should be noted that these wells might have received inspections under the client- or site-level category, which generally are carried out as part of large-scale contamination/gas migration investigations, but these types of inspections are not included in our analysis because the details of such inspections often do not include a full listing of wells of interest. Assuming that the individual wells observed in these larger scale investigations did, in fact, receive facility-level inspections and are included in our analysis, we would expect a negligible impact from excluding client- and site-level investigations because the individual well inspections would have likely been flagged by at least one of the indicators before a large-scale contamination event. The impact of wells investigated in the client- and site-level inspections but not receiving a facility-level inspection (i.e., not included in this analysis) may be significant but cannot be assessed with the data available. Not all wells inspected in large-scale contamination investigations are found to be leaking and, although the count of impairment events from such wells could increase, the rate of impairment (the number of events per wells inspected) might not.

Hazard analysis captures such temporal dependencies through the nonparametric baseline hazard rates and hazard ratios of the inspection count variable, thus allowing us to predict what the incidence rate for wells might be if they were to acquire comparable observation times and inspection counts. Results from hazard modeling of temporal and geographic strata are given next.

Hazard Model: Temporal Strata.

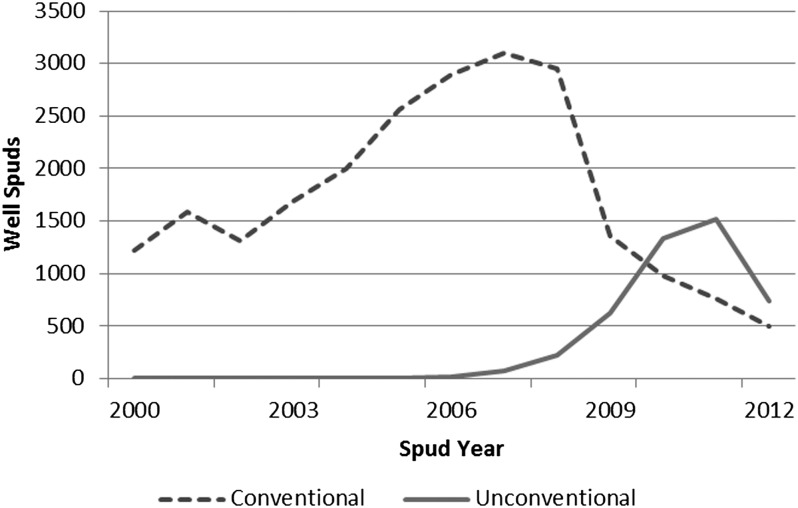

Wells spudded before 2009 make up almost 72% of the total wells modeled but just 31% of the total count of unique wells with documented cement/casing indicator events from the 2000–2012 modeled dataset. Unconventional wells make up 16.8% of the wells in this stratum. The first unconventional well in the modeled dataset has a 2002 spud date; however, unconventional drilling activity remained relatively low until 2009 (Fig. 2). Pre-2009 unconventional wells show a modest but statistically insignificant increase in hazard [1.07-fold greater risk relative to pre-2009 conventional wells, 95% confidence interval (CI) (0.18, 1.52); Table 2]. However, in the post-2009 stratum, risk of a cement/casing event is 1.58-fold [95% CI (1.45, 1.67); P < 0.0001] higher in an unconventional well relative to a conventional well spudded within the same time period (Table 2).

Fig. 2.

Conventional and unconventional spud counts: 2000–2012 (Source: PADEP, 2013).

Table 2.

Statewide data: Effects of model covariates for pre- and post-2009 well spuds

| Pre-2009 spuds | Wells spudded 2009–2012 | |||||

| Covariate | HR | 95% CI | HR | 95% CI | ||

| Well type | 1.07 | 0.18 | 1.52 | 1.58 | 1.45 | 1.67 |

| Inspection count | 1.177 | 1.154 | 1.201 | 1.059 | 1.048 | 1.069 |

The hazard ratio (HR) reflects the multiplicative change in risk at any time due to a change in the covariate. A change in well type reflects the change from conventional to unconventional. A change in inspection count reflects a single (+1) increase to the total inspection count for a well.

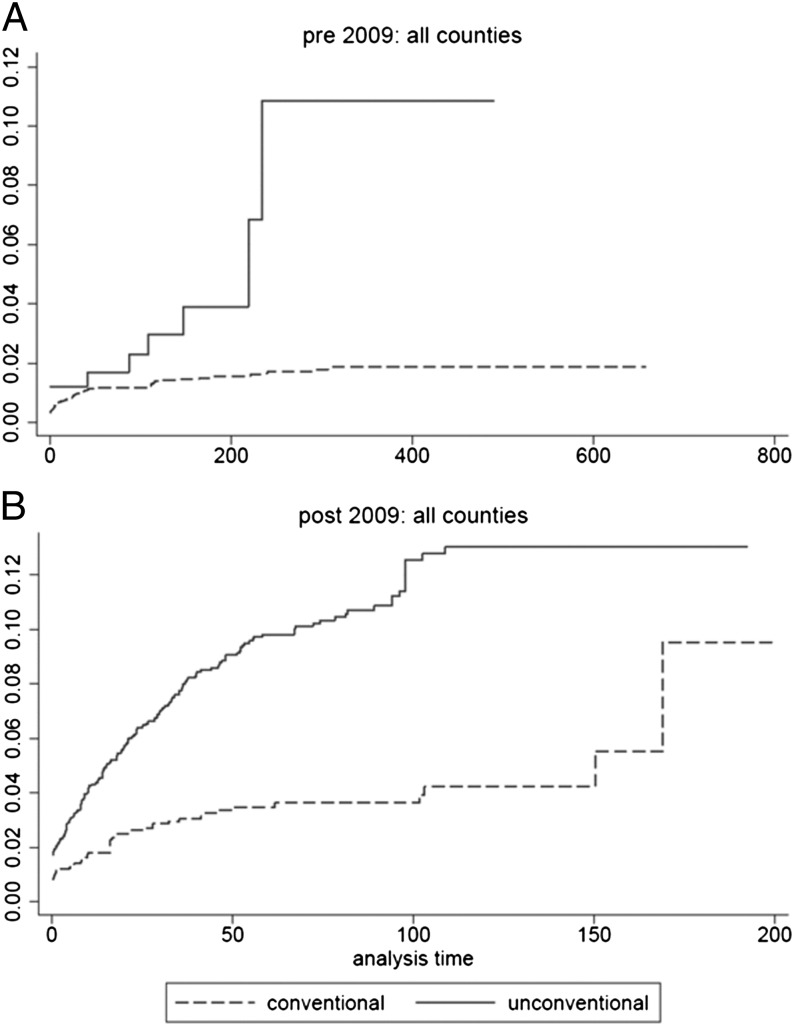

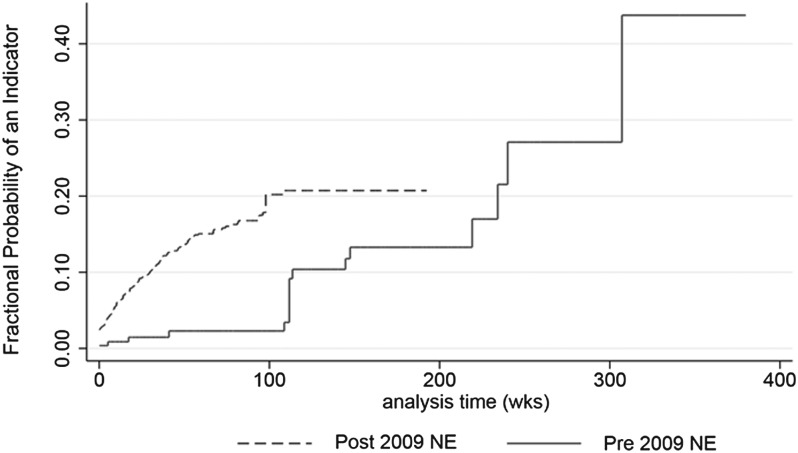

Fig. 3 shows estimated cumulative hazards for conventional and unconventional wells across the state for pre- and post-2009 strata, respectively. These figures are plotted in the units of the Nelson–Aalen estimator of the cumulative hazard function (i.e., the definite integral, from zero up to the indexed time, of the hazard function). These plots are used for visually examining differences in distributions in time-to-event data and are interpreted here as the fractional probability that a well will be identified as having a cement and/or casing problem at time t, assuming that the event has not occurred before time t. Wells spudded after January 1, 2009, show significantly higher (P < 0.0001) predicted hazards across comparable analysis times, regardless of well type, relative to pre-2009 well spuds [4.58 hazard ratio, 95% CI (3.84–5.47)].

Fig. 3.

Nelson–Aalen cumulative hazard for pre-2009 (A) and post-2009 (B) spuds by well type. The vertical axis is the fractional probability of an event occurring at a given analysis time.

It is unclear whether these temporal differences reflect more thorough inspections and greater emphasis on finding well leaks, more detailed note taking in the available inspection reports, or real changes in rates of structural integrity loss. The percentage of wells inspected in the first year has risen, from an average of 76% in pre-2009 spuds to 88.7% in the post-2009 spuds (SI Appendix, Table S3), and this may partially account for the increase in documented cement/casing problems. Additionally, more than one-half (53.2%) of the nonevent wells (i.e., no indicator of loss of structural integrity found) lack inspector comments and other information necessary to determine whether a cement/casing issue ever occurred. These wells, by default, are modeled as nonevents. The majority of such wells (73%) were spudded before 2009. This lack of data for older wells may result in an underestimation of events in the pre-2009 stratum. As such, results from our modeling should be considered conservative.

Note that the full analysis time for the statewide dataset is 676 wk (13 y). Naturally, more recently spudded wells will have a shorter analysis time (1–208 wk for wells spudded since 2009). However, inspection records indicate that 52.9% of pre-2009 spuds have a <2-y inspection record, with an average of 2.4 inspections per well across the entire time period (SI Appendix, Table S4). This suggests that the majority of these active, older wells are no longer being inspected. Continued annual inspections may increase the predicted cumulative risk of structural integrity issues for these wells beyond what is reported here, indicating, again, that results from our analysis are conservative. Each additional inspection in the pre-2009 stratum increases the risk of identifying a cement or casing problem by 17.7% [1.18 hazard ratio, 95% CI (1.15, 1.20); Table 3] relative to the hazards shown in Fig. 3. The effect of increased inspections on younger wells (post-2009 spuds) is smaller but statistically significant [1.06 hazard ratio, 95% CI (1.05–1.07); Table 3].

Table 3.

NE counties data: Effects of model covariates

| Covariate | HR | 95% CI | |

| Well type | 2.657 | 1.428 | 4.946 |

| Inspection count | 1.065 | 1.047 | 1.083 |

| Temporal stratum | 1.580 | 1.152 | 2.167 |

The HR reflects the multiplicative change in risk at any time due to a change in the covariate. A change in well type reflects the change from conventional to unconventional. A change in inspection count reflects a single (+1) increase to the total inspection count for a well.

Hazard Model: Geographic Strata.

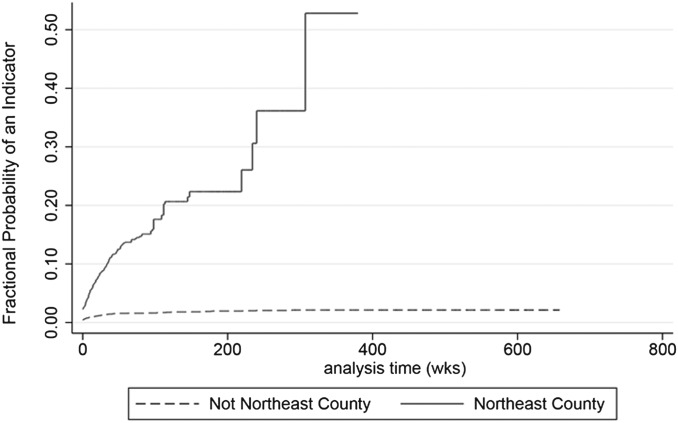

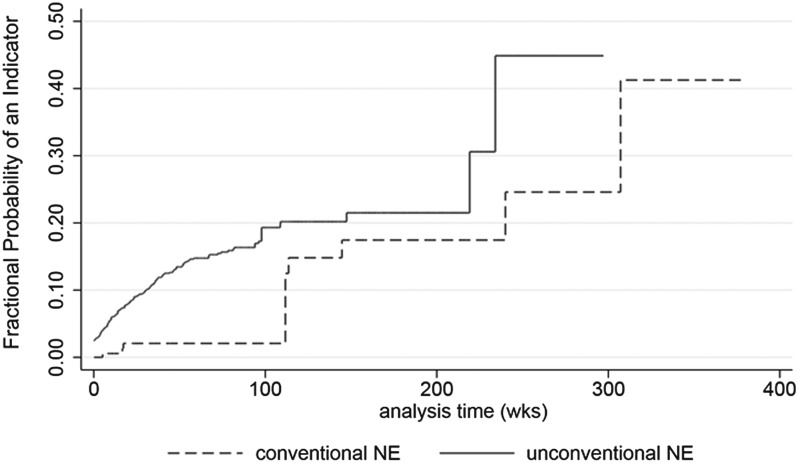

The NE counties of the state (Bradford, Cameron, Clinton, Lycoming, Potter, Sullivan, Susquehanna, Tioga, Wayne, and Wyoming) make up just 11% of the total wells spudded (3,030 wells) but 54.7% of the state’s unconventional wells and 88.8% of the cement/casing events in unconventional wells. There are 266 total structural integrity indicator events in the NE region, or ∼52% of events statewide. The predicted cumulative hazard for all wells (unconventional and conventional) in the NE region is 8.5-fold [95% CI (7.16, 10.18)] greater than that of wells drilled in the rest of the state (Table 3). The log-rank test for this regional difference is extremely significant (P < 0.0001).

As with the statewide data, effects of covariates in the NE counties indicate significant increases in the risk of finding an indicator in the inspection records. Unconventional wells in the NE region are at a 2.7-fold higher risk relative to the region’s conventional wells [95% CI (1.43, 4.95); Table 3]. Additional inspections in these counties have a similar effect on risk as that found for post-2009 spuds statewide [1.06 hazard ratio, 95% CI (1.05, 1.08); Table 3].

Figs. 4–6 reveal increased cumulative hazards for wells in the NE counties relative to other areas of the state, as well as increased cumulative hazards associated with unconventional wells (P < 0.001) and post-2009 spudded wells (P = 0.005) in the region. These figures, like Fig. 3, are plotted in units of the cumulative hazard function. Overall, NE wells show a risk of an identified integrity issue within the first 3 to 4 y (156–208 wk) of operation of ∼20% (Fig. 4). The cumulative hazard for unconventional wells in the region is predicted to increase upward of 40% by year 7 of the analysis (364 wk; Figs. 5 and 6).

Fig. 4.

Nelson–Aalen cumulative hazard: NE vs. non-NE counties for combined conventional and unconventional wells. The vertical axis is the fractional probability of an event occurring at a given analysis time.

Fig. 6.

Nelson–Aalen cumulative hazard for NE counties by temporal strata. The vertical axis is the fractional probability of an event occurring at a given analysis time.

Fig. 5.

Nelson–Aalen cumulative hazard for NE counties by well type. The vertical axis is the fractional probability of an event occurring at a given analysis time.

Conclusion

Pennsylvania state inspection records show compromised cement and/or casing integrity in 0.7–9.1% of the active oil and gas wells drilled since 2000, with a 1.6- to 2.7-fold higher risk in unconventional wells spudded since 2009 relative to conventional well types. Hazard modeling suggests that the cumulative loss of structural integrity in wells across the state may actually be slightly higher than this, and upward of 12% for unconventional wells drilled since January 2009. This wide range of estimates is influenced by significantly higher rates of impairment in wells spudded in the NE counties of the state (average of 12.5%, range: 2.2–50%), with predicted cumulative hazards exceeding 40% (Figs. 5 and 6).

These results, particularly in light of numerous contamination complaints and explosions (21–23) nationally in areas with high concentrations of unconventional oil and gas development and the increased awareness of the role of methane in anthropogenic climate change (24), should be cause for concern. A recent investigative report of water contamination cases confirmed PADEP determination letters and enforcement orders indicating that at least 90 private water supplies across the state were damaged due to subsurface gas migration between 2008 and 2012 (25). The NE region of Pennsylvania, in particular, has experienced several widely publicized methane migration cases related to loss of structural integrity of wells, including the Dimock, Susquehanna County [Commonwealth of Pennsylvania Department of Environmental Protection (DEP) Consent Order to Cabot Oil & Gas, December 15, 2010] and Towanda, Bradford County (Commonwealth of Pennsylvania DEP Consent Order to Chesapeake Appalachia LLC, May 16, 2011) groundwater contamination cases. PADEP records cite unconventional wells spudded between 2009 and 2010 in both of these cases. Incidence rates inferred from direct comparison of indicator counts and the number of wells inspected in these townships as of December 31, 2012, are 21.2% and 15.4%, respectively; however, hazard modeling predicts a cumulative 7-y hazard for similar wells in the region twofold higher (Figs. 5 and 6; t = 364).

Our aim in this study was to quantify the rate of barrier impairment in a population of modern on-shore oil and gas wells, and in doing so, we have noted significant temporal and spatial differences in risk of impairment. It is beyond the scope of this paper to explain these spatial and temporal differences. Various biasing effects might influence these differences and are the focus of our continuing study of this problem. Moreover, results presented here represent a snapshot in time of an evolving situation. This study presents the state of structural integrity loss in oil and gas wells over a 13-y period in the state of Pennsylvania as inferred from publicly available data, while also presenting a risk assessment model of future performance. It should be a priority to update and validate this model with well monitoring and evaluation data reported to the PADEP from the industry as they are collected. Finally, although this study discusses one possible primary mechanism of methane migration to groundwater aquifers and fugitive emissions to the atmosphere, more studies are needed to investigate the association between the structural integrity loss in oil and gas wells and the incidence of these unwanted events.

Methods

Database.

The database created here is based upon spud reports from the PADEP Office of Oil and Gas Management website for conventional and unconventional gas, oil, combined gas and oil, and coal-bed methane wells spudded from January 1, 2000–December 31, 2012 (www.depweb.state.pa.us/portal/server.pt/community/oil_and_gas_reports/20297). Spud reports provide data on well characteristics, including American Petroleum Institute (API) well identification, spud date, well type, production type, and well location (county, municipality, and geographic coordinate information). We exclude storage, injection, and undetermined purpose wells to focus exclusively on oil and gas production wells.

Compliance Reports.

The compliance reports for oil and gas well inspections carried out over the same time period (www.depweb.state.pa.us/portal/server.pt/community/oil_and_gas_compliance_report/20299) are then cross-referenced with the well inventory by matching API identification codes. PADEP compliance reports provide data on inspection category (i.e., site, client, facility), inspection type (e.g., administrative review, drilling, routine), inspection date, violations issued, and comments noted by PADEP inspection staff regarding the inspection and/or violation(s) issued. We exclude client and site inspection categories, because these inspections generally reflect multiwell, large-scale compliance assessments and rarely identify individual wells. We also do not include construction (i.e., site clearing), asbestos program, Chapter 94, joint external/internal, Nuclear Regulatory Commission, and road-spreading inspection types. Construction inspections occur before well spudding, and thus are not relevant to well integrity. The remaining excluded inspection types are also considered not relevant to the study question. Excluded inspections accounted for <0.5% of total inspections carried out over the 2000–2012 time frame.

Indicators Search.

Inspector comments indicate barrier remediation and/or ongoing monitoring of annular gas or pressure (indicators of impaired structural integrity) for numerous wells that were not issued an NOV. To ensure that we captured these wells, we filtered both the “Inspection_Comment” and “Violation_Comment” fields for the most common keywords associated with failure of primary cement/casing or common remediation measures. Keywords used in the filtering and their relevancy to impaired primary cementing and casings are presented in SI Appendix, Table S6. Keyword filter results are then human-read thoroughly to confirm an indication of impaired well integrity and to separate filter results that do not indicate an integrity issue (e.g., gas meter readings = 0, nonremediation perforations, “no visible bubbling”). A detailed discussion of the indicators and their temporal and geographic distributions is provided in SI Appendix.

Violation codes provide a more direct indication of a potential well impairment. PADEP violation codes relevant to cement and casing integrity are listed in SI Appendix, Table S7. The compliance reports indicate multiple misentries in the original violation code noted by an inspector, which are later corrected in the “Violation_Comment” field. We assume that wells with any one of the violations or a combination of violations listed in SI Appendix, Table S7 and entered in either the “Violation_Code” or “Violation_Comment” field in inspection reports are indicative of a well with impaired cement and/or casing. We note that not all violations will result in groundwater contamination events. The relative importance of key violation codes and the temporal and geographic distributions of total violation counts are discussed in detail in SI Appendix.

Hazard Analysis.

The Cox proportional hazards model (26) is a semiparametric model that uses a multivariate regression technique to model the instantaneous probability of observing an event (i.e., occurrence of a cement/casing indicator in the inspection record) at time t, given that an observed case (i.e., a well) has survived to time t (i.e., has not experienced an inspection where a cement/casing indicator was found) as a function of predictive covariates (well type and total number of inspections received). All wells enter observation at t = 0, regardless of spud date, and observation continues until the last known date of inspection or the occurrence of a cement/casing indicator in a well’s inspection history. Addition details and definitions of key model terms and concepts are provided in SI Appendix.

Time of analysis of a well, as the dependent variable in the statistical model, cannot be a null or a negative value. Wells showing no record of inspection (8,703 wells) have null t values, and are therefore removed from the model dataset. We also found 5,223 wells, 100 of which were associated with comment or violation indicators, where the time since spud to first inspection was negative. Because construction/site clearing inspections were removed from the database in previous steps, we assume that either the spud dates or inspection dates for these wells were entered incorrectly; these data are also removed from the dataset. The impact of removing these inspections from the modeled dataset is negligible, because the overall impairment rate (1.9%) for these wells mirrors that of the statewide data. The resulting modeled statewide dataset contains 27,455 wells that are associated with 75,505 inspections.

Multiple inspections per unique well number are mined to return only a single set of entries per well: well characteristics (i.e., county, well type, spud date), event status (a binary code assigned to each well stating whether an indicator was found at any point in the life of the well: Y = 1, N = 0), date of first inspection, date of first mention of indicator if found, date of last inspection (for nonevent wells), and total number of inspections carried out.

An assumption of the Cox proportional hazards model is that the hazard ratio is constant over time. The validation of this assumption for the various models, using the Grambsch and Therneau test (27), is presented in SI Appendix, Table S1. The proportional hazards test for individual covariates passed for well type (P = 0.06) and inspection counts (P = 0.09) in the full dataset. The proportional hazards model assumption also holds for the pre/post-2009 analyses. Well type (i.e., unconventional, conventional) and inspection counts (i.e., number of times a well is inspected during the analysis time) are used as covariates in these models.

Temporal and geographic (i.e., county) strata are run in separate analyses. Interannual log-rank statistics were used to assess whether any groups of well spuds were statistically significantly different in terms of their predicted failure risk. We stratified the data accordingly to allow for separate regressions of temporal period (before January 1, 2009, and after that date). We also stratified the data by region to assess the relative geographic distributions [the NE counties (Bradford, Cameron, Clinton, Lycoming, Potter, Sullivan, Susquehanna, Tioga, Wayne, and Wyoming) compared with the rest of the state] of wells with indications of cement/casing problems. Log-rank tests (28) were used to assess geographic variation.

As robustness checks to the Cox proportional hazards model, parametric Weibull and Gompertz regression models (28) were also fit to the full data and the temporal and geographic strata, and the magnitude substantive conclusions did not change.

Supplementary Material

Footnotes

The authors declare no conflict of interest.

This article is a PNAS Direct Submission.

See Commentary on page 10902.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1323422111/-/DCSupplemental.

References

- 1.Intek, Inc. 2011. Review of emerging resources: U.S. shale gas and shale oil plays. Report prepared for U.S. Department of Energy (Energy Information Administration, Washington), July 2011.

- 2.Osborn SG, Vengosh A, Warner NR, Jackson RB. Methane contamination of drinking water accompanying gas-well drilling and hydraulic fracturing. Proc Natl Acad Sci USA. 2011;108(20):8172–8176. doi: 10.1073/pnas.1100682108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Jackson RB, et al. Increased stray gas abundance in a subset of drinking water wells near Marcellus shale gas extraction. Proc Natl Acad Sci USA. 2013;110(28):11250–11255. doi: 10.1073/pnas.1221635110. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Pétron G, et al. Hydrocarbon emissions characterization in the Colorado Front Range: A pilot study. J Geophys Res. 2012 10.1029/2011JD016360. [Google Scholar]

- 5.Karion A, et al. Methane emissions estimate from airborne measurements over a western United States natural gas field. Geophys Res Lett. 2013;40(16):4393–4397. [Google Scholar]

- 6.Peischl J, et al. Quantifying sources of methane using light alkanes in the Los Angeles basin, California. J Geophys Res Atmos. 2013;118(10):1–17. [Google Scholar]

- 7.Smith KR, et al. Public health benefits of strategies to reduce greenhouse-gas emissions: Health implications of short-lived greenhouse pollutants. Lancet. 2009;374(9707):2091–2103. doi: 10.1016/S0140-6736(09)61716-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Taylor SW, Lollar BS, Wassenaar LI. Bacteriogenic ethane in near-surface aquifers: Implications for leaking hydrocarbon well bores. Environ Sci Technol. 2000;34(22):4727–4732. [Google Scholar]

- 9.Szatkowski B, Whittaker S, Johnston B. Summary of Investigations 2002, Saskatchewan Geological Survey, Saskatchewan Industry and Resources, Miscellaneous Report 2002-4.1. Vol 1. Canada: Regina SK; 2002. Identifying the sources of migrating gases in surface casing vents and soils using stable carbon isotopes, Golden Lake Pool, West-central Saskatchewan; pp. 118–125. [Google Scholar]

- 10.Chilingar GV, Endres B. Environmental hazards posed by the Los Angeles Basin urban oilfields: An historical perspective of lessons learned. Environmental Geology. 2005;47(2):302–317. [Google Scholar]

- 11.Van Stempvoort D, Maathuis H, Jaworski E, Mayer B, Rich K. Oxidation of fugitive methane in ground water linked to bacterial sulfate reduction. Ground Water. 2005;43(2):187–199. doi: 10.1111/j.1745-6584.2005.0005.x. [DOI] [PubMed] [Google Scholar]

- 12.Bonnett A, Pafitis D. Getting to the root of gas migration. Oilfield Review. 1996;8(1):36–49. [Google Scholar]

- 13.Bourgoyne AT, Jr, Scott SL, Manowski W. 2000. A Review of Sustained Casing Pressure (SCP) Occurring on the OCS. Final Report to MMS, Baton Rouge LA.

- 14.Brufatto C, et al. From mud to cement—Building gas wells. Oilfield Review. 2003;15(3):62–76. [Google Scholar]

- 15.Dusseault M, Gray M, Nawrocki P. 2000. Why oilwells leak: Cement behavior and long-term consequences. Society of Petroleum Engineers Conference Paper, SPE-64733-MS, 10.2118/64733-MS.

- 16.Watson T, Bachu S. Evaluation of the potential for gas and CO2 leakage along wellbores. Society of Petroleum Engineers, Drilling and Completion. 2009;24(1):115–126. [Google Scholar]

- 17.Kinik K, Wojtanowicz AK. 2011. Identifying environmental risk of sustained casing pressure. Society of Petroleum Engineers Conference Paper, SPE-143713-MS, 10.2118/143713-MS.

- 18.Considine T, Watson R, Considine N, Martin J. Environmental Impacts During Marcellus Shale Gas Drilling: Causes, Impacts, and Remedies. Report 2012-1 Shale Resources and Society Institute. Buffalo, NY: State University of New York; 2012. [Google Scholar]

- 19.Vidic RD, Brantley SL, Vandenbossche JM, Yoxtheimer D, Abad JD. Impact of shale gas development on regional water quality. Science. 2013;340(6134):1235009. doi: 10.1126/science.1235009. [DOI] [PubMed] [Google Scholar]

- 20.Ingraffea AR. 2013. Fluid migration mechanisms due to faulty well design and/or construction: An overview and recent experiences in the Pennsylvania Marcellus play. Available at http://psehealthyenergy.org/site/view/1057. Accessed October 3, 2013.

- 21.Ohio Department of Natural Resources 2008. Report on the investigation of the natural gas invasion of aquifers in Bainbridge Township of Geauga County, Ohio. Ohio Department of Natural Resources, Division of Resources Management. September 2008.

- 22.Lustgarten A. April 26, 2009. Officials in three states pin water woes on gas drilling. ProPublica. Available at www.propublica.org/article/officials-in-three-states-pin-water-woes-on-gas-drilling-426. Accessed August 5, 2013.

- 23.Lustgarten A. January 20, 2012. Years after evidence of fracking contamination, EPA to supply drinking water to homes in Pa. Town. ProPublica. Available at http://www.propublica.org/article/years-after-evidence-of-fracking-contamination-epa-to-supply-drinking-water. Accessed August 5, 2013.

- 24.Shindell D, et al. Simultaneously mitigating near-term climate change and improving human health and food security. Science. 2012;335(6065):183–189. doi: 10.1126/science.1210026. [DOI] [PubMed] [Google Scholar]

- 25.Legere L. May 19, 2013. Sunday Times review of DEP drilling records reveals water damage, murky testing methods. The Times-Tribune. Available at http://thetimes-tribune.com/news/sunday-times-review-of-dep-drilling-records-reveals-water-damage-murky-testing-methods-1.1491547. Accessed June 28, 2013.

- 26.Cox DR. Regression models and life-tables. J R Stat Soc Series B Stat Methodol. 1972;34(2):187–220. [Google Scholar]

- 27.Grambsch PM, Therneau TM. Proportional hazards tests and diagnostics based on weighted residuals. Biometrika. 1994;81:515–526. [Google Scholar]

- 28.Kleinbaum DG, Klein M. Survival Analysis. A Self-Learning Text. New York: Springer; 2005. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.