Abstract

Objective

To determine how mechanical stability changes in the lower lateral cartilage (LLC) after varying degrees of cephalic resection in a porcine cartilage nasal tip model.

Methods

Alar cartilage was harvested from fresh porcine crania (n=14) and sectioned to precisely emulate a human LLC in size and dimension. Flexural mechanical analysis was performed both before and after cephalic trims of 0 (control), 4, and 6 mm. Cantilever deformation tests were performed on the LLC models at 3 locations (4, 6, and 8 mm from the midline), and the integrated reaction force was measured. An equivalent elastic modulus of the crura was calculated assuming that the geometry of the LLC model approximated a modified single cantilever beam. A 3-dimensional finite element model was used to model the stress distribution of the prescribed loading conditions for each of the 3 types of LLC widths.

Results

A statistically significant decrease (P=.02) in the equivalent elastic modulus of the LLC model was noted at the most lateral point at 8 mm and only when 4 mm of the strut remained (P=05). The finite element model revealed that the greatest internal stresses was at the tip of the nose when tissue was flexed 8 mm from the midline.

Conclusion

Our results provide the mechanical basis for suggested clinical guidelines stating that a residual strut of less than 6 mm can lead to suboptimal cosmetic results owing to poor structural support of the overlying skin soft-tissue envelope by an overly resected LLC.

Refinement of a broad nasal tip is one of the most challenging aspects of the rhinoplasty operation. In addressing this issue, a conservative cephalic trim of lower lateral cartilages (LLCs) is often advocated along with dome-binding sutures and other approaches. This procedure is commonly undertaken to address bulbous deformity of the nasal tip in the horizontal dimension, and it may allow an arched cartilage to bend without buckling. However, overresection of the LLCs to narrow the tip in individuals with thick skin is a common mistake, with profound functional and aesthetic consequences.1,2 Common deformities include external valve dysfunction, alar retraction, and bossa formation.1,2

Preservation of a substantial complete strip of cartilage is critical to avoid these complications.3 The exact width of this residual strip has not been well defined, and minimum widths of 5 to 7 mm have been advocated, which are figures that have been empirically derived over time. The mechanical basis of this guideline has not been previously established; therefore, the focus of this study was to investigate the mechanics governing the cephalic trim maneuver using a previously described porcine cartilage model for nasal tip rhinoplasty. A 3-dimensional (3D) finite element model (FEM) for LLCs was also used to demonstrate the stress distribution in our cartilage model before and after the cephalic trim maneuver.

Methods

Nasal cartilage tissue was dissected from 7 freshly euthanized, nonpreserved, nonfrozen porcine crania. Alar cartilages (N=14) were harvested and carved and sectioned to emulate the dimensions of human LLC according to a previously described method.4 Briefly, the cephalic orientation was marked at a 45° angle, and the anteroposterior dimensions of the crura were marked according to previous human cadaveric measurements. Cartilaginous incisions were then made along the marked regions, and the specimens were sharply sculpted to a 1-mm thickness. The length of each LLC was set at 15 mm, and the width averaged 10 mm, with a range of 6 mm at the intermediate crus to 12 mm at the widest region of the lateral crus. To prevent desiccation, the cartilage was maintained in a buffered saline solution during the preparation of the experiment and hydrated with a moist wick during the course of the experiment. Two LLC constructs were secured to one another with sutures and mounted on a mechanical testing apparatus (ElectroForce 3300 Series; Bose Corp) (Figure 1). A custom-made metallic clamp was used to secure and stabilize the specimen onto the apparatus. Once the specimen was secured, a blunt-tipped actuator was used to depress the lateral crura at various distances from the midline (4, 6, and 8 mm). Measurements were taken with the testing apparatus. The reaction force and displacement measurements were recorded to a text file and then imported into Matlab (MathWorks) for data analysis. The elastic modulus of the crura was calculated assuming that the geometry of the LLC model approximated a rectangular cantilever beam (Figure 2).

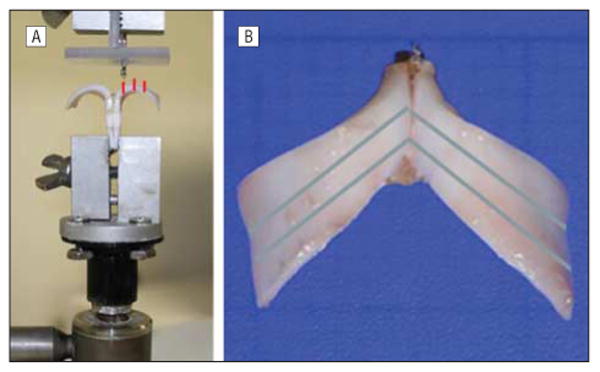

Figure 1.

Frontal (A) and axial (B) views of the mounted cartilage model. A, Frontal view of the cartilage model with a mechanical testing apparatus (ElectroForce Probe; Bose Corp) positioned 4 mm from the midline. The red lines indicate the 3 positions of the probe that were tested (4, 6, and 8 mm from the midline). B, Axial view of the cartilage model with the blue lines indicating incision lines for successive cephalic trims, with respective residual struts of approximately 6 mm after the first trim and 4 mm after the second trim.

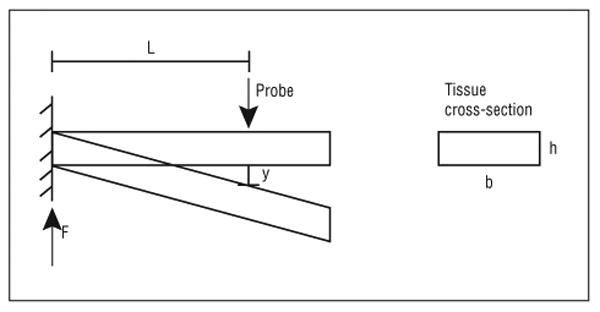

Figure 2.

Stress strain graph calculated based on cantilever model approximation of the mechanical behavior of the lower lateral crura. The elastic modulus is calculated as follows: E=4FL3/ybh3, where F indicates the reaction force; L, the distance from the fulcrum, where the probe displaces the tissue; y, displacement; b, the width of the tissue; and h, the tissue thickness.

The same specimen underwent 2 successive cephalic trims. Each cephalic trim was made along a line parallel to the plane of the cephalic orientation of the LLC (set at approximately 45°) such that after the first trim a residual strip of 6 mm remained and after the second trim a residual strip of 4 mm remained (Figure 1). Measurements and mechanical testing as described above were repeated after each consecutive cephalic trim.

Statistical Testing

A 1-way analysis of variance was performed using Matlab on the 3 groups of cephalic trims (no trim, 4-mm trim, and 6-mm trim) to see whether the means of each group were different. If the analysis of variance showed a statistical difference (P< .05), a t test was performed to see which cephalic trims were significant (P< .05).

Fem Modeling and Simulation

A 3D FEM of the LLC fabricated in this study was created in 3ds Max (Autodesk). Three different types of models were created, one for each of the 3 types of the LLC widths. The 3D models were then imported into COMSOL Multiphysics to visualize the stress distributions along the crura where the prescribed loading conditions were applied. The mechanical properties used for the simulation had a Young modulus of 5 MPa and a Poisson ratio of 0.33. The model was assumed to be isotropic; the boundaries of the medial crura were held fixed; and all other parts of the tissue were free to move. To simulate the study, the lateral crura were depressed 2 mm downward on both sides, at 4, 6, and 8 mm away from the midline.

Results

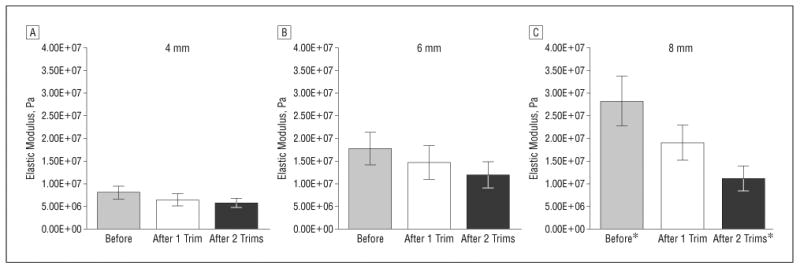

Figure 3 shows the average elastic modulus of the LLC models at various points along the length of the lateral crura before and after 2 successive cephalic trims. Analysis of variance testing was performed to determine the statistical difference in the elastic modulus of the un-trimmed LLC model after each successive trim. Statistical significance was reached only with measurements obtained at the point 8 mm lateral to the midline (P=.02).

Figure 3.

Average elastic modulus after cephalic trims at 4-, 6-, and 8-mm measuring points (N=14). Asterisks indicate statistically significant difference (P=.02); error bars, standard error.

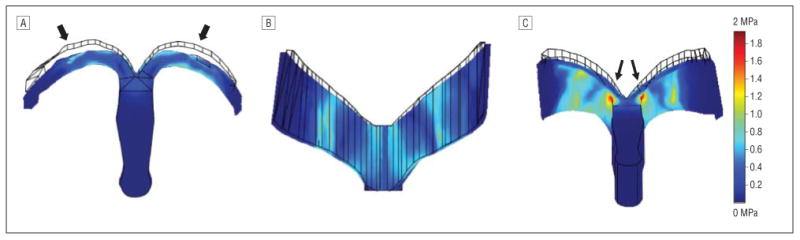

Figure 4 shows the 3D FEM of the LLC depicting the stress distribution along the lateral crus as a function of the location force vector. This model demonstrated the greatest degree of direct load bearing and force distribution along the lateral crura when vertical force was applied via a probe in a superior to inferior direction 8 mm from midline of the nose (when compared with the 2-, 4-, or 6-mm positions).

Figure 4.

Subdomain plot of Von Mises stresses when depressed 8 mm from the midline. Wire-frame plot indicates the original position. A, Frontal view of the lower lateral cartilage (after cephalic trim). The arrows indicate the direction of displacement. B, Axial view. C, Base view. The arrows indicate the areas of maximum tissue stress.

Comment

While it is widely accepted that cephalic trim of the lateral crura should be limited such that it preserves a minimum 5- to 7-mm strut, the mechanical basis of this phenomenon has been poorly explained to date. Using an ex vivo animal model and FEM modeling, we demonstrated the mechanical consequences of an overresected lateral crus.

The ex vivo cartilaginous model of rhinoplasty used in this study is inexpensive and highly replicable. Although variation will exist in certain parameters, these models demonstrate variations that are very similar to those seen between pointy, boxy, and bulbous nasal tips in humans. The overall geometry of our models fit a human type III boxy nasal tip, as described by Rohrich and Adams,5 making it a useful educational and research model for performing requisite procedures to manage this condition. The major drawbacks of this model are its ex vivo nature and the lack of a soft-tissue envelope, which is important for creating pockets for cartilage grafts and for observing the tissue healing response. Although broad concepts derived from this study would be applicable in clinical settings, the specific quantitative data may not be of direct clinical consequence as a result of these limitations. However, we believe that isolating the cartilaginous framework of the nasal tip is advantageous in simplifying tip mechanics research.

To examine what the true stress distribution in loaded LLC cartilage might look like, we also developed an FEM model to investigate the deformation of lateral crura under various physiologic loading conditions. The FEM gives us a powerful tool for accurate evaluation of complex mechanical problems, such as emulation of the behavior of nasal cartilages under external loads.6-8 Although numerical models allow accurate assessment of the behavior of a geometrically complex structure, such as the nasal tip, they still harbor some limitations that warrant the concurrent use of a physical model for the purposes of the study. The limitations of numerical techniques are as follows: (1) modeling complex structures remains a challenge; (2) the material properties of most biologic materials are unknown (and generally nonlinear and anisotropic); and (3) simple and intuitive software packages aimed at the end user are not yet available; therefore, the complexity of the analytical model is limited.

Using this model, we determined that deformation forces from soft-tissue contracture are greatest as we move laterally across the lateral crura. Mechanical assessment of lateral crural trim in an ex vivo porcine model of nasal tip demonstrated a significant decrease in the elastic modulus of a lateral crural model at the most lateral point of measurement when the strut width was reduced beyond 6 mm. Moreover, when at least a 6-mm residual strut was maintained (after just 1 cephalic trim), there was no statistically significant decline in the elastic modulus (P=.44). These results attribute the adverse consequence of an overresected lateral crus to diminishing mechanical stability of the lateral aspect of the lateral crura. The commonly associated adverse outcomes of alar retraction and alar pinching appear to be a direct consequence of the loss of structural support of the soft tissues along the lateral-most aspect of the LLCs. The weakened lateral crura are thus unable to resist the forces of contracture from postoperative scar tissue, leading to cosmetic deformity.

In conclusion, this study represents the first formal investigation (to our knowledge) into the mechanical basis for the preservation of a minimum width strut of lower lateral crura in rhinoplasty using both tissue and numerical models. We demonstrated that the adverse consequences of an overresected lateral crus can be attributed to loss of mechanical stability along the lateral aspect of the cartilage as the cartilage is trimmed beyond the threshold of mechanical stability, which appears to be a strut width of approximately 6 mm.

Acknowledgments

Funding/Support: This study was made possible by grant 443800/22979 from the Department of Defense.

Footnotes

Author Contributions: Dr Oliaei had full access to all the data in the study and takes responsibility for the integrity of the data and the accuracy of the data analysis. Study concept and design: Manuel, Protsenko, Chark, Wong, and Oliaei. Acquisition of data: Manuel, Hamamoto, and Oliaei. Analysis and interpretation of data: Manuel, Protsenko, Hamamoto, Wong, and Oliaei. Drafting of the manuscript: Hamamoto, Wong, and Oliaei. Critical revision of the manuscript for important intellectual content: Manuel, Protsenko, Chark, Wong, and Oliaei. Statistical analysis: Hamamoto and Oliaei. Obtained funding: Wong. Administrative, technical, and material support: Chark, Wong, and Oliaei. Study supervision: Protsenko and Wong.

Financial Disclosure: None reported.

Previous Presentation: This study was presented in part at the American Academy of Facial Plastic and Reconstructive Surgery Annual Meeting; September 10, 2011; San Francisco, California.

References

- 1.Pedroza F, Anjos GC, Patrocinio LG, Barreto JM, Cortes J, Quessep SH. Seagull wing graft: a technique for the replacement of lower lateral cartilages. Arch Facial Plast Surg. 2006;8(6):396–403. doi: 10.1001/archfaci.8.6.396. [DOI] [PubMed] [Google Scholar]

- 2.Gubisch W, Eichhorn-Sens J. Overresection of the lower lateral cartilages: a common conceptual mistake with functional and aesthetic consequences. Aesthetic Plast Surg. 2009;33(1):6–13. doi: 10.1007/s00266-008-9267-y. [DOI] [PubMed] [Google Scholar]

- 3.Constantian MB. The incompetent external nasal valve: pathophysiology and treatment in primary and secondary rhinoplasty. Plast Reconstr Surg. 1994;93(5):919–933. [PubMed] [Google Scholar]

- 4.Chark D, Oliaei S, Manuel C, Wong BJ. Porcine cartilage model for simulation of nasal tip aesthetics and mechanics. Aesthet Surg J. 2011;31(5):501–505. doi: 10.1177/1090820X11411581. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Rohrich RJ, Adams WP., Jr The boxy nasal tip: classification and management based on alar cartilage suturing techniques. Plast Reconstr Surg. 2001;107(7):1849–1868. [PubMed] [Google Scholar]

- 6.Lee SJ, Liong K, Lee HP. Deformation of nasal septum during nasal trauma. Laryngoscope. 2010;120(10):1931–1939. doi: 10.1002/lary.21072. [DOI] [PubMed] [Google Scholar]

- 7.Lee SJ, Liong K, Tse KM, Lee HP. Biomechanics of the deformity of septal L-struts. Laryngoscope. 2010;120(8):1508–1515. doi: 10.1002/lary.20976. [DOI] [PubMed] [Google Scholar]

- 8.Protsenko DE, Wong BJ. Engineering of a straighter septum: numerical model of mechanical stress relaxation in laser-heated septal cartilage. Conf Proc IEEE Eng Med Biol Soc. 2007;2007:5399–5402. doi: 10.1109/IEMBS.2007.4353563. [DOI] [PubMed] [Google Scholar]