Abstract

Silk presents a rare combination of desirable properties for sustained drug delivery, including aqueous-based purification and processing options without chemical cross-linkers, compatibility with common sterilization methods, controllable and surface-mediated biodegradation into non-inflammatory by-products, biocompatibility, utility in drug stabilization, and robust mechanical properties. A versatile silk-based toolkit is currently available for sustained drug delivery formulations of small molecule through macromolecular drugs, with a promise to mitigate several drawbacks associated with other degradable sustained delivery technologies in the market. Silk-based formulations utilize silk’s well-defined nano- through microscale structural hierarchy, stimuli-responsive self-assembly pathways and crystal polymorphism, as well as sequence and genetic modification options towards targeted pharmaceutical outcomes. Furthermore, by manipulating the interactions between silk and drug molecules, near-zero order sustained release may be achieved through diffusion- and degradation-based release mechanisms. Because of these desirable properties, there has been increasing industrial interest in silk-based drug delivery systems currently at various stages of the developmental pipeline from pre-clinical to FDA-approved products. Here, we discuss the unique aspects of silk technology as a sustained drug delivery platform and highlight the current state of the art in silk-based drug delivery. We also offer a potential early development pathway for silk-based sustained delivery products.

Keywords: Silk, Processing, Biocompatibility, Biodegradation, Drugs, Biologics, Mechanisms

1. Introduction

In sustained drug delivery, the goal is to extend the inter-dose duration for chronic use medications while maintaining nearly constant plasma drug concentrations within the target therapeutic range. Sustained release formulations offer many potential clinical benefits including reduced side effects for therapeutics with low toxic thresholds, improved patient compliance for frequent, difficult, and/or invasive administrations, and decreased costs for third-party payers. The majority of sustained drug delivery formulations on the market or in development are based on synthetic polymers such as polylactide-co-glycolide acid (PLGA) due to their desirable pharmacokinetics and controllable hydrolytic degradation profiles [1]. While they are generally considered safe by the U.S. Food and Drug Administration (FDA), their inherent properties and processing requirements (e.g., acidic polymer degradation products, aqueous/organic solvent interfaces, and processing in organic solvents [2–5]) restrict their use in certain sustained delivery areas, such as protein therapeutics, where these issues may impact product stability. Naturally derived proteins, such as collagen, gelatin, albumin, elastin and milk proteins offer an interesting alternative to PLGA-based systems and are currently under investigation for their potential use in sustained drug delivery [6]. These protein-based materials mitigate some of the drug instability and toxicity concerns related to PLGA but also tend to have relatively rapid dissolution rates in aqueous media, higher batch-to-batch variability, and concerns with sourcing. Thus, any natural protein-based product must offer tunable sustained release kinetics and enhanced product stability, all from a reliably sourced and well-characterized starting material.

To that end, a considerable amount of work has been dedicated to silk protein-based materials for drug delivery applications [7–10]. Silk fibroin offers a unique combination of beneficial properties for drug delivery (Table 1), including controllable biodegradation into noninflammatory by-products [11–15], biocompatibility [12, 15–23], aqueous-based ambient purification [24] and processing options [25], compatibility with sterilization methods [26–29], utility in drug stabilization [30, 31], and robust mechanical properties (Table 1). Furthermore, silk offers a versatile toolkit for various drug delivery applications including not only varied material formats from injectable particles [32–34], bioadhesives [35, 36] and hydrogels [18, 37–39] to reservoirs and scaffold implants [15, 40, 41], but also formulation control points from genetic and sequence modifications [42–44] and bioconjugates [45] to silk material composition and crystallinity [46–48]. By properly matching the physicochemical properties of the target drug with those of the silk format, near-zero order sustained release may be achieved as a function of diffusion- and degradation-based release mechanisms. Because of these desirable properties, industrial interest in silk-based drug delivery systems has grown rapidly, with not only FDA-approved products such as silk sutures (Surusil®, Suru; Sofsilk™, Covidien) and silk scaffolds (Seri® Surgical Scaffold, Allergan), but also amongst companies at various stages of development, such as Ekteino Laboratories (silk-based sustained drug delivery), AMSilk (high performance materials from spider silk), Vaxess (vaccine stabilization), Banner Pharmacaps (silk-based drug delivery platforms), and Immuno-Biological Laboratories (recombinant human proteins made using transgenic silkworms).

Table 1.

The unique combination of desirable properties of silk for sustained drug delivery. Key distinctions versus synthetic polymer systems (e.g., PLGA) are highlighted in bold.

| Structure | Predominantly hydrophobic, block copolymeric and modifiable sequence |

| Self-assembly into β-sheet rich supramolecular structures | |

| Strong intra-/intermolecular physical interactions | |

| Stimuli-responsive crystal polymorphism | |

| High and tunable molecular weight | |

| Processing | Aqueous-based ambient purification and processing capabilities |

| Versatile material forms | |

| Suitability with common sterilization techniques | |

| Physicochemical properties | Controllable network density, hydration resistance and swelling |

| Controllable surface charge through sequence modifications | |

| High thermal stability | |

| Robust mechanical properties | |

| Tunable aqueous solubility | |

| Biological properties | Low inflammatory/cytotoxic/immunogenic potential |

| Enzymatic, surface mediated biodegradation | |

| Slow, controllable biodegradation rates | |

| Non-toxic, neutral biodegradation products (amino acids and peptides) | |

| Pharmacological properties | Tunable release rates via diffusion- and biodegradation-controlled release |

| Encapsulation of poorly soluble drugs | |

| Drug stabilization | |

In this review, we discuss the unique aspects of silk technology as a sustained drug delivery platform. First, we concentrate on the rare structural features and processing capabilities of silk, highlighting its desirable physicochemical and biological properties. Then, we describe the current state of the art in silk-based drug delivery, and offer a potential early development pathway for a silk-based product.

2. Desirable properties of silk for sustained drug delivery

2.1. Silk structure and self-assembly

In nature, the largest producer of silk is the domestic silkworm Bombyx mori (B. mori). Silk fibroin is the structural protein component produced in the posterior region of the B. mori gland. Due to its well-characterized structural hierarchy and its dominating hydrophobic and block copolymer features, along with its stimuli-responsive self-assembly pathway in aqueous solution, silk fibroin displays unique physicochemical and biological properties desirable for sustained drug delivery applications [49–58] (Figure 1). In essence, silk fibroin is a high molecular weight (≈ 2.3 MDa [59]) protein complex consisting of heavy (Fib-H, MCalculated = 391.6 kDa [60], MExperimental ≈ 350 kDa [57]) and light (Fib-L, MC = 27.7 kDa [60], ME = 26 kDa [56]) chains held together with a disulfide bond at the C-terminus [55], physically encapsulating a glycoprotein (Fibrohexamerin or p25, MC = 25.2 kDa [60]) at a molar ratio of 6:6:1 (Fib-H, Fib-L, p25) [50]. The fibroin heavy chain is the major structural component of the protein complex and is essentially an amphiphilic, alternating block copolymer. This copolymer consists of 12 long hydrophobic “crystallizable” domains and 11 almost identical, less repetitive and more hydrophilic “amorphous” domains, with hydrophilic C- and N-terminal domains all contributing to give the molecule an overall anionic (pIfibroin≈4) character in neutral solution. The crystallizable domains provide a major control point for silk formulations, primarily consisting of 66-residue sub-domains, rich in a low-complexity, dipeptide motif of GX (G: Glycine and over 90% of X residues are either alanine, serine, tyrosine or valine in decreasing frequency) and GAAS tetrapeptides. By manipulating the crystal form and content of these domains, the physical properties of a silk-based formulation may be tuned to achieve the desired release kinetics and biodegradation profile.

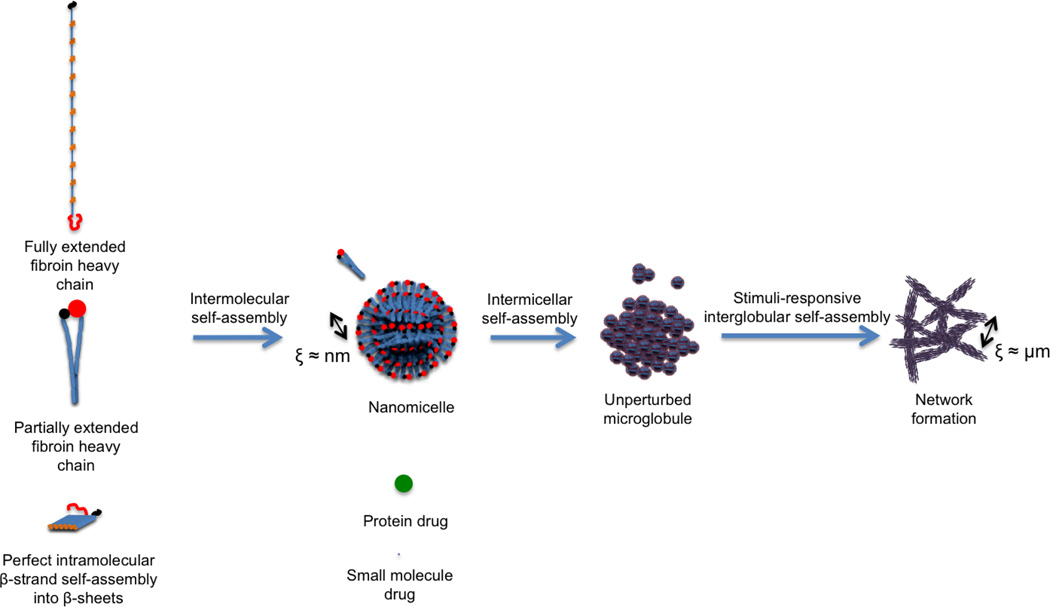

Figure 1.

The effective correlation lengths (ξ) in self-assembled silk fibroin structure for diffusion-controlled drug release (adapted from [51])

In aqueous solution, this unique crystallizable sub-domain sequence forms β-strands and 3-strand β-sheetsextending over 20 nm and stabilized by inter-strand hydrogen bonding [58] (Figure 1).. Intramolecular fibroin self-assembly then proceeds by lateral and facial packing of β-sheets via folding around amorphous domains, leading to strong physical interactions such as dense hydrogen bonding and increased hydrophobic interactions. These large, hydrophobic domains are responsible for the robust mechanical properties of silk fibroin that also translate into desirable characteristics for sustained delivery, such as slow biodegradation rates in the absence of chemical crosslinking. Subsequent intermolecular fibroin heavy chain self-assembly results in the formation of micellar structures where the hydrophobic crystallizable domains are encapsulated inside a hydrophilic shell consisting of the “amorphous” domains and C- and N-terminal domains. The morphology of these nano-micelles is essentially spherical due to the relatively small surface area of the hydrophilic shell to the overall volume of fibroin heavy chain molecules. The manipulation of the self-assembly of these nano-micelles offers another control point for formulation development.

Intermicellar self-assembly is largely controllable and is strongly stimuli responsive in aqueous solution without the use of harsh chemicals, an important distinction from synthetic polymers. In unperturbed aqueous conditions similar to that in the B. mori silk glands, fibroin nano-micelles can self-assemble into spherical microglobular superstructures enabling high aqueous solubility of hydrophobic domains via a hydrophilic shell and interspersed hydrophobic-hydrophilic core structures [51] (Figure 1). With external stimuli, such as changes in solution conditions (e.g., fibroin concentration, pH, ionic strength, temperature), protonation or charge screening of hydrophilic domains leads to essentially permanent, physical intermicellar and interglobular crosslinks, and an overall increase in β-sheet content and formation of silk networks [51]. β-sheet crosslink formation can also be triggered by application of mechanical (e.g., shear) [38, 39] or electromagnetic fields [36, 61], presumably due to chain extension and alignment of fibroin micelles and globules, and resulting enhanced physical permanent crosslinking. The stimuli-responsiveness of the silk self-assembly pathway enables the control of effective correlation lengths in the network and facilitates diffusion-controlled release of drug molecules varying in size from small molecules to protein drugs [7–10]. This is all achieved without toxic organic solvents or cross-linkers, thus preserving the stability of any potential protein therapeutic.

As a consequence of these stimuli-responsive self assembly mechanisms, the silk fibroin heavy chain displays crystalline polymorphism with predominantly three crystal forms, silk I, II and III [53, 62]. Silk I is the meta-stable, pre-spinning crystal form of silk fibroin in the middle region of the silk gland, primarily consisting of intra- and intermolecular bonding of a repeated type II, β-turn structure [62], and possibly helical structural elements forming a less extended chain confirmation than silk II [63]. Silk II is the crystal form of the spun silk fibroin fiber, mainly consisting of antiparallel β-sheets [53] with distorted β-sheets and distorted β-turns [62], while silk III is a 3-fold extended helix that forms at air-water interfaces [64]. High-order conformation of aqueous regenerated fibroin solutions and fibroin material formats relevant to sustained drug delivery generally contain a mixture of β-sheets, β-turns, helices and random coils. The structural differences in crystallizable and amorphous domains due to crystal polymorphism can result in differences in enzymatic biodegradation rates. Therefore, controlling the overall supramolecular structure is critical to fine tune silk biodegradation, especially when targeting biodegradation-controlled release.

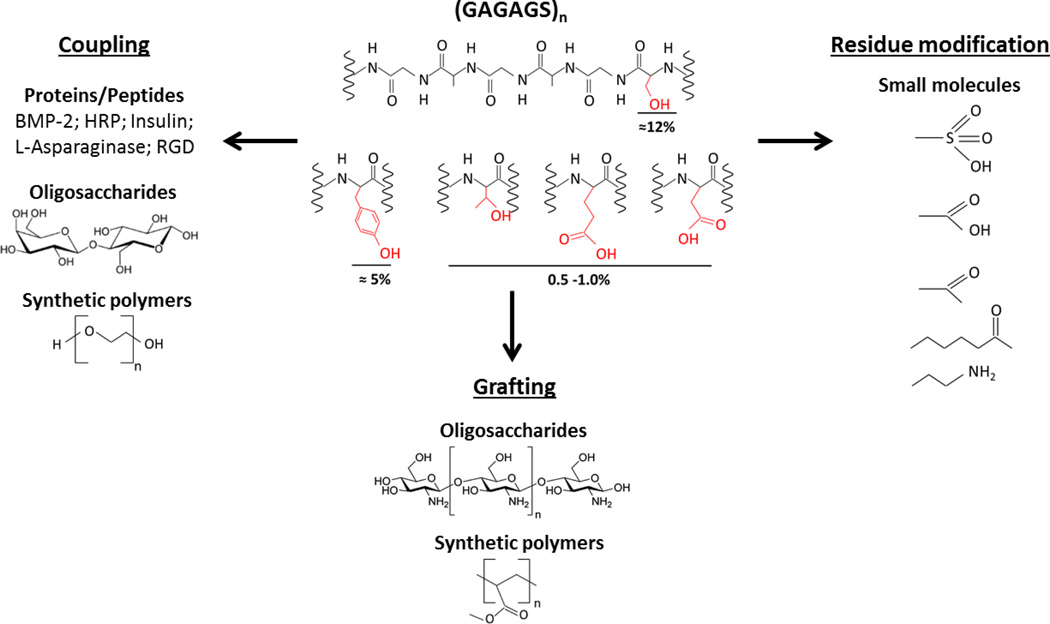

Additional versatility of the silk platform for sustained drug delivery stems from possible chemical modifications, utilizing the reactive residues in silk sequence as reviewed elsewhere [42]. A number of chemical modification approaches, including coupling, side chain modifications and grafting, together with various functional groups and biomacromolecules covalently fused to silk are summarized in Figure 2. Overall, by systematically controlling fibroin primary structure, self-assembly kinetics in aqueous solution, the crystal polymorphism, and the resulting physicochemical properties of silk-based formulations in solution through the solid state can be tuned to achieve a desired pharmacological outcome.

Figure 2.

Selected chemical modification approaches and molecules covalently bound to silk fibroin [42]. GAGAGS is the basic silk fibroin heavy chain repeat. The percentage values represent approximate molar density of reactive residues in silk fibroin heavy chain sequence. BMP-2: Bone Morphogenetic Protein, HRP: Horseradish Peroxidase, RGD: Arginylglycylaspartic acid.

2.2. Aqueous silk fibroin purification

The main goal in silk fibroin purification is to remove the surface coating layer of B. mori silk fibers, eliminating potential immunogenic proteins or glycoproteins, as well as possible contamination on the fiber surface [16, 65, 66].

Sericin proteins are key impurities in fibroin purification as they may trigger an immunogenic response in vivo. Sericin proteins are secreted in the middle region of the silk gland of B. mori and form an adhesive coating around fibroin. They constitute the majority of the native B. mori fiber surface layer and up to 30% of the total fiber mass. The main components of sericin proteins are those produced in the anterior (Ser-A, ME≈250 kDa), middle (Ser-M, ME≈450 kDa), and posterior (Ser-P, ME≈150 kDa) regions of the middle silk gland [67], with a total of 5 to ≥12 proteins, possibly including minor sericin components, fragments of major sericin components, or non-silk related B. mori polypeptides/glycoproteins, also being identified as sericins [68, 69]. In contrast to fibroin, sericin protein sequences generally contain a higher density of serine and a lower density of glycine residues, as well as a higher density of polar and/or charged groups (such as those in aspartic acid/asparagine and less commonly glutamic acid/glutamine side chains). This results in the overall more hydrophilic and ionic nature of sericin proteins in comparison to fibroin [67, 68].

These differences in overall charge and hydrophobicity of fibroin and sericin proteins present several options for aqueous-based fibroin purification (degumming or desericinization). For example, selective dissolution/hydrolysis of sericins can be conducted at temperatures between ambient to 100°C, in alkali (e.g., sodium carbonate), acids (e.g. citric acid), or high concentration denaturant solutions (e.g. urea), and/or proteases [52]. The most commonly used degumming method in silk fibroin-based sustained delivery literature is alkali-heat degumming (Figure 3). This process involves boiling silkworm silk cocoons in an aqueous, 0.02 M Na2CO3 solution and results in an essentially instantaneous (≈ 5 min) dissolution and partial hydrolysis of sericin proteins as well as a degumming time-dependent, partial hydrolysis of fibroin for a controllable molecular weight distribution [24]. Once purified, fibroin can be dissolved in a number of aqueous, chaotropic high concentration salts (e.g., ≥9 M LiBr, ≥50°C or ≥10 M LiSCN, ≥25°C) or ternary systems containing alcohols (e.g., CaCl2–water-ethanol, ≥70°C). Subsequent desalting of high-salt fibroin solutions is generally carried out by dialysis to obtain an aqueous regenerated fibroin solution, though chromatographic desalting protocols have also been proposed [70].

Figure 3.

Aqueous silk fibroin purification and example biomaterial processing options for sustained drug delivery. Transdermal microneedles image reprinted with permission from John Wiley & Sons, Inc. (Tsioris, et al. Advanced Functional Materials, 22 (2011) 330–335).

From a physical stability viewpoint, it should be noted that in aqueous solution, fibroin molecules gradually self-assemble into hydrogel networks rich in silk II, β-sheet content in an external stimuli-responsive manner [39]. In ambient, neutral solution conditions and without perturbations, fibroin self-assembly and hydrogelation kinetics are rather slow, providing a controllable timeframe for sustained delivery formulation processing. For example, complete hydrogelation duration of alkali-heat purified fibroin at 2–8°C can be tuned between less than 24 hours to over 30 days, simply by varying the fibroin concentration. Furthermore, the physical stability of aqueous fibroin solutions, i.e., the kinetics of fibroin self-assembly and hydrogelation, may depend on fibroin molecular weight distribution, storage conditions (e.g., solution ionic strength, pH, and temperature) [37], as well as the presence of mechanical [38, 39] or electromagnetic stimuli [35, 36].

The resulting aqueous fibroin solution is typically used as the starting material for processing into materials suitable for drug delivery such as injectable nano/microspheres [32, 33, 71], hydrogels [17, 18, 38, 39] and bioadhesives [35, 36], and implantable scaffolds [15], films, tubes [72] and rods, and transdermal microneedles [73] as reviewed elsewhere [25] (Figure 3).

2.3. Compatibility of silk with common sterilization methods

To eliminate sources of bacterial or viral contamination, sterilization is a critical step in the manufacture of sustained delivery products. However, several common sterilization methods are not compatible with most biodegradable synthetic polymers (e.g., PLGA) or protein-based (e.g., collagen) matrices, primarily due to their low thermal stability and hydrolytic degradation mechanisms [74, 75]. For example, high temperature methods including autoclaving (high steam pressure at 120–135°C) or dry heat sterilization (160–190°C) result in PLGA deformation and degradation, or melting and softening, respectively [74]. Similarly, collagen scaffolds undergo denaturation with autoclaving, and partial denaturation and cross-linking with dry heat sterilization [75]. Physical sterilization methods, such as gamma or beta irradiation could also result in instability and deterioration of PLGA, and cross-linking and/or chain scission of both PLGA and collagen-based matrices [74, 75]. Ethylene oxide terminal sterilization may be suitable for several synthetic polymers and biopolymers, but this process is lengthy and produces toxic residues. On the other hand, disinfection in 70% aqueous ethanol generally does not adequately eliminate hydrophilic viruses and bacterial spores [76]. These limitations associated with sterilization of the polymeric matrix material may create significant hurdles for a pharmaceutical product, including increased manufacturing costs.

Silk-based biomaterials are generally compatible with most common sterilization methods, presumably due to their extraordinary mechanical properties and high thermal stability (glass transition temperature, Tg ≅ 190–200°C; decomposition temperature, Td ≅ 220–300°C for side chains, and ≥300°C for the peptide backbone [27]). For example, self-assembled silk fibers consisting of recombinant spider silk analogs retained their predominantly β-sheet structure, nano-scale morphology, and mechanical properties (tensile modulus) after autoclaving, with no signs of hydrolysis [28]. Similarly, the bulk morphology, topography, crystallinity and cytocompatibility of porous silk fibroin scaffolds were minimally affected by common sterilization methods, including autoclaving (121°C, high pressure steam, 15 min), dry heat (180°C, 30 min) ethylene oxide (55°C, 4 h) or exposure to disinfecting agents (70% aqueous ethanol or an antibiotic-antimycotic solution) [77]. Generally, an increase in the stiffness and strength values of silk fibroin scaffolds were observed in compression due to autoclave sterilization [27, 77]. In addition, no detrimental effects of autoclaving were observed on the gross morphology, micro-scale porosity, or mechanical properties of the silk fibroin scaffolds [27]. A thorough physicochemical characterization of possible effects of autoclaving on silk fibroin scaffold structure indicated a slight increase in silk II, β-sheet content and crystal size, an overall reduction in amorphous domain mobility, and higher thermal stability for autoclaved scaffolds compared to non-sterile scaffolds. It was proposed that the changes in supramolecular organization in amorphous domains induced by autoclave sterilization could slow down protease diffusion rates in the silk fibroin matrix and/or hinder enzyme adhesion, effectively reducing enzymatic degradation rates. For sterilization of regenerated silk fibroin solutions and hydrogels, gamma irradiation induced random coil to silk II, beta-sheet transition in solution state and reduced the silk fibroin hydrogelation duration, while autoclaving led to less significant molecular conformational changes and slower hydrogelation kinetics than those after gamma irradiation [29]. Neither solution sterilization method had a detectable effect on the final molecular conformation of self-assembled silk fibroin hydrogels, which was rich in silk II, β-sheet content. In a thin film format, gamma-irradiation (in air or nitrogen) did not significantly alter the optical or tensile properties of silk fibroin, or adhesion of cells to the silk fibroin film [26]. On the other hand, autoclaving resulted in an increase in silk fibroin film tensile modulus and strength, in a similar fashion to the effect of autoclaving on the mechanical properties of silk fibroin scaffolds [27, 77]. Overall, the potential effects of the sterilization protocol on silk fibroin final material properties and subsequent pharmacological performance should be considered when identifying suitable sterilization methods. From a manufacturing perspective, the general suitability of common sterilization treatments for silk-based biomaterials renders them a desirable sustained drug delivery matrix.

2.4. Silk biocompatibility

Cytocompatibility and low inflammatory potential of silk

The majority of reports over the past 15 years suggest a desirable biocompatibility profile for alkali-heat purified silk fibroin-based materials due to their cytocompatibility and relatively lower or similar immunogenic potential compared to other common degradable polymers, such as collagen and PLGA. For example, in vitro cultures of various cell types, including fibroblasts, keratinocytes, hepatocytes, osteoblasts, epithelial, endothelial, glial, and mesenchymal stem cells (MSCs) indicated desirable cytocompatibility profiles for various silk fibroin formats (see for example [78–80]). The inflammatory potential of silk fibroin and fibroin-RGD films cast from hexafluoroisopropanol (HFIP) solution and treated with methanol to enhance silk II, β-sheet crystallinity was investigated using human mesenchymal stem cells (hMSCs) [20]. Transient pro-inflammatory (IL-1β) and inflammatory (COX-2) gene expression in response to stimulation with fibroin films was at similar levels to those for collagen or PLA polymer matrices. Furthermore, higher cell proliferation rates were observed for fibroin films as compared to collagen or PLA, highlighting the relatively low immunogenic potential and high cytocompatibility of silk fibroin. Different components of B. mori silk were isolated to determine their individual inflammatory potential including (1) B. mori silk fibers including sericin-rich surface coating layer, (2) alkali-heat regenerated fibroin fibers, (3) alkali-heat degumming supernatant rich in sericins, (4) regenerated fibroin fibers incubated in the alkali-heat degumming supernatant, and (5) insoluble fibroin particles obtained by chymotrypsin proteolysis of degummed fibroin [21]. The results indicated that stimulation of macrophages with none of the individual silkworm silk components produced elevated levels of pro-inflammatory TNF either in short (1-day) or long-term (7-day) cultures. Further studies investigated possible in vitro complement activation by silk fibroin films (prepared by casting a film of alkali-heat regenerated fibroin solution in LiBr, followed by methanol treatment to induce silk II, β-sheet structure) [22]. The silk fibroin films interacted with the humoral inflammatory system in a similar manner as the synthetic polymers, such as polystyrene and poly(2-hydroxyethylmethacrylate) films. Specifically, C3 complement bound strongly to silk fibroin films, presumably due to the nano-scale heterogeneity of silk fibroin surface crystallinity, but without C3 complement activation. Silk fibroin also induced a lower degree of activation and adhesion of immune-competent peripheral blood mononuclear cells (PBMCs) after treatment with plasma proteins as compared to synthetic model polymers.

Biocompatibility of silk implants

Long-term, in vivo biocompatibility of model silk fibroin-based systems, including fibroin films and porous scaffolds were investigated in small animal models (Table 2). For example, silk fibroin and fibroin-RGD films seeded with autologous rat mesenchymal stem cells and implanted intramuscularly in Lewis rats demonstrated low inflammatory potential [20]. Histological and immunohistochemical evaluation of the silk explants 6 weeks post-implantation revealed the presence of circumferentially oriented fibroblasts, few blood vessels, macrophages at the implant-host interface, and the absence of giant cells. In comparison to collagen or PLA films, the inflammatory tissue reaction was less pronounced around the fibroin films. In another study, porous, 3D fibroin scaffolds prepared from aqueous or organic solvents at different fibroin concentrations and pore size distribution and pore inter-connectivity were implanted subcutaneously or intramuscularly in nude or Lewis rats [15]. Gross observations, histological and immunohistochemical evaluations, and real time-PCR analyses were conducted at 2, 8, 26, and 52 weeks to investigate acute and long-term immunogenic potential and biodegradation of porous silk fibroin scaffolds. All scaffolds were well tolerated throughout the study with no reported abnormalities. Early responses to both aqueous-based and organic solvent-based fibroin scaffolds were similar; macrophages and giant cells were observed at the administration site after 2 and 8 weeks, respectively resulting in gradual enzymatic biodegradation of silk fibroin scaffolds. Inflammatory gene (IL-4, IL-13, IL-6, TNF-α, and IFN-γ) expression levels generally remained low (and even lower for aqueous-based scaffolds than that for organic solvent-based scaffolds) and local throughout the study with only a slight, transient increase in IFN-γ levels between 2 and 8 weeks. Overall immune response to fibroin scaffolds was described as low to mild, and local and transient, consistent with previous biocompatibility data on fibroin scaffolds and films [20, 81, 82].

Table 2.

Key in vivo studies on silk fibroin biocompatibility and biodegradation

| Silk Biomaterial | Model | Biocompatibility | Biodegradation | References |

|---|---|---|---|---|

| Films | Rat, I.M. implant | Less pronounced inflammatory reactions around fibroin than collagen or PLA | Not reported | [20] |

| Fibroin-RGD yarns | Rat, I.M. and S.C. implants; Goat, knee implant | No hypersensitivity reactions; Low immune responses to both silk and collagen controls | Complete biodegradation expected in 18 to 36 months | [12] |

| Porous scaffolds (6–10 wt% silk) | Rat, I.M. and S.C. implants | All scaffolds well tolerated; Mild, local and transient immune responses | Complete biodegradation in ≤6 months to ≥12 months depending on silk concentration, pore size, and interconnectivity | [15] |

| Ethanol induced hydrogels; Fibroin-RGD microgels (4–6 wt% silk) | Rat, S.C implant; Guinea pig, I.D. injection | 23-RGD modification improved fibroin biocompatibility; Similar host response to fibroin-RGD and collagen controls | Similar biodegradation of fibroin-RGD and collagen controls; 75% of all sites had residual material after 92 days | [17] |

| Acidic hydrogels (2 wt% silk) | Rabbit, knee implant | No inflammatory reactions; Fibroin hydrogels promoted bone remodeling | Partial biodegradation in 12 weeks | [18] |

| Sonicated hydrogels (1–2 wt%) | Rat, knee implant | Not reported | Complete biodegradation in 12 weeks | [11] |

I.M. = Intramuscular; S.C. = Subcutaneous; I.D. = Intradermal

Silk injectable hydrogels and micro-gel suspensions

In addition to implantable systems, the biocompatibility of injectable fibroin systems such as hydrogels and micro-gels has also been investigated (Table 2). As an example, the biocompatibility of acidic fibroin hydrogels (2 wt% fibroin, pH < 3.8) was studied in a rabbit critical sized distal femur defect model over 12 weeks and compared to that of PLGA [18]. Bone remodeling was quantified using trabecular bone volume, thickness, number, and separation, and rates of mineral deposition and bone formation. Silk fibroin hydrogels did not elicit a tissue inflammatory reaction and promoted bone remodeling and maturation. Interestingly, regrown bone of fibroin hydrogel treated defects were more similar to native bone than that for PLGA-treated defects, demonstrating a good biocompatibility profile for acidic fibroin hydrogels in rabbits and their potential in promoting bone remodeling. Similarly, biocompatibility of ethanol-induced, fibroin-based hydrogels was assessed in vivo [17]. Fibroin hydrogels and fibroin hydrogels covalently functionalized with a 23-residue peptide containing a cell-binding sequence (fibroin-23RGD) were subcutaneously implanted in male Lewis rats in a 57-day study. All fibroin hydrogels were completely penetrated with host tissue within 57 days, with minimal visible residual material. Histological examination indicated a low-grade but persistent, fibrotic type inflammatory response to fibroin hydrogels and a less robust inflammatory response to fibroin-23RGD hydrogels, indicating that the RGD functionalization could improve biocompatibility through enhanced cell binding and permeability in fibroin hydrogels. This approach was further validated in intradermal injections of fibroin-23RGD hydrogel particle (or microgel) suspensions in comparison to commercial, collagen-based products, such as Zyplast™ (Allergan, CA) and Hylaform™ (Allergan, CA) using a Hartley guinea pig model over 92 days. For all groups, 75% of administration sites had residual test material at termination, indicating comparable long-term, in vivo biodegradation rates for fibroin and chemically cross-linked, collagen-based products. Overall, fibroin-23RGD hydrogel was found to be biocompatible, exhibiting similar chronic cellular responses to that for collagen-based products, typically a mild fibrotic reaction with populations of fibroblasts, lymphocytes, macrophages, multi-nucleated giant cells and eosinophils, with abundant deposition of collagen in and around the implant site and no ulcerations.

Biological testing of an FDA-approved silk-based product

While comparison data between silk and other relevant polymer systems is encouraging, general preclinical biological testing of a candidate biodegradable polymeric delivery vehicle may require a more comprehensive series of toxicity assays. These may include cytotoxicity, intradermal and systemic injections, pyrogenicity testing, allergic sensitization, biodegradation, and biocompatibility assays to demonstrate safety in small and large animal models. One silk fibroin-based product that has passed regulatory scrutiny, Seri® Surgical Scaffold (Allergan, MA), is a resorbable matrix of fibroin yarns functionalized with RGD cell-binding domains that is currently approved by the FDA for anterior cruciate ligament repair. Though the FDA may regulate fibroin-based drug delivery systems differently (e.g., drug vs. device), the thorough pre-clinical biological testing conducted on Seri® Surgical Scaffold may be relevant to the development of potential fibroin-based drug products. In terms of biocompatibility, Seri® Surgical Scaffold passed all ISO standard biocompatibility testing, demonstrating non-toxicity, non-pyrogenicity, and non-allergenicity, and overall biocompatibility of the device [12]. Furthermore, Seri® Surgical Scaffold demonstrated greater cellular infiltration than silk sutures in an intramuscular rat model over 30 days, with a fibroin biodegradation mechanism involving epithelioid macrophages associated with granulomatous inflammatory response within the yarns, through secretion of proteases or possible engulfing of fibroin yarns by macrophages. In terms of immunogenicity, total average plasma IgE concentration was essentially constant at baseline levels for 6 months following subcutaneous implantation of Seri® Surgical Scaffold in rats, indicating the absence of a hypersensitivity reaction and low immune response. Safety of Seri® Surgical Scaffold was also demonstrated in a large animal (goat knee) model, with no signs of acute inflammation, swelling, or scar formation, and active bone remodeling and joint stability over 12 months. Conversely, a positive immunogenic control containing silk scaffold processing impurities showed deleterious responses, such as synovitis and extensive inflammation within the joint.

Common silk processing impurities and contaminants

As reports on the biocompatibility and low inflammatory potential of silk fibroin have multiplied, the majority of early reports on the immunogenic responses to native, virgin silk fibers may be attributed to impurities [66] and/or contaminants on native silkworm silk fiber surface or in the production waste. For silk fiber surface contaminants, studies on the possible immunogenic potential of the sericin-rich, alkali-heat degumming supernatant of B. mori fibers showed insignificant macrophage activation [21] and low-level activation of pro-inflammatory and inflammatory mediators [83, 84], generally insufficient to cause inflammatory response or prevent cellular proliferation. Furthermore, B. mori silk degumming supernatants containing predominantly partially hydrolyzed (for alkali-heat, acid-heat, heat-pressure degumming) or native sericins (urea degumming) were not toxic to mouse fibroblast cells at concentrations below 40 ug/ml, while cell viability and collagen production at higher concentrations depended on the degree of sericin hydrolysis (e.g., changes in molecular weight, overall surface charge and aggregation state, and amino acid composition).

In addition to sericin impurities, native B. mori silk fibers may also contain potentially immunogenic impurities of non-silk origin, such as silkworm excretory products or dust [85]. These contaminants are the result of improper storage or handling and/or processing additives depending on silk sourcing [86]. Clearly, this may lead to differences in the impurity and contaminant profile of material obtained in different research labs due to potential differences in sourcing, storage and handling protocols during purification and processing. Therefore, thorough physicochemical and biological characterization and documentation of identity and purity of test articles is critical to address potential effects of impurities, additives and/or contaminants on the immunogenic potential.

To provide an unbiased comparison of the relative immunogenic potential of different polymer systems, processing should be conducted in a similar lab environment and ideally at a similar scale, with known identity and purity profiles. One comparison of the potential innate and adaptive immune responses to fibroin films and scaffolds, sericin films, and a commercial collagen-based sponge (Ultrafoam™) indicated a decreasing order of monocyte activation (innate response) from bacterial LPS (positive control) > sericin films > fibroin scaffolds > fibroin films > Ultrafoam™, with no adaptive response detected in any of the groups [87]. Despite this result, no information on the quantification of purity and/or impurity or contamination profile for either of the fibroin test articles was provided to ensure their successful sterilization or decontamination (e.g., depyrogenation). On the other hand, one would expect such characterization, documentation and process controls to be in place for the commercial product comparator used in this study. In this sense, this study does not provide an unbiased comparison between immunogenic potential of different proteins, as the test articles were not prepared under identical or similar conditions and process controls. Furthermore, all of the fibroin materials used in the biocompatibility assays reportedly had similar mass and specific surface area values due to the possible dependence of immunogenic potential on these parameters, while the specific surface area of the collagen-based product was not reported. To investigate a possible link between monocyte activation by fibroin test articles and their potential pyrogenic contamination, the authors added 10 µg/ml Polymyxin B (PMB, a cationic peptide antibiotic that blocks biological effects of pyrogens through binding to their toxic, anionic lipid A components), similar to a previous report [21]. This treatment inhibited activation in the bacterial LPS positive control group, but not that in the fibroin scaffold group, a result that the authors attributed to a monocyte activation pathway for fibroin scaffolds that does not involve potential pyrogenic contamination. It should be noted, however, that PMB could also bind to anionic fibroin scaffold formats due to potentially attractive electrostatic and hydrophobic interactions, decreasing the effective PMB concentration in culture. Furthermore, no data was provided on the possible effects of PMB addition on monocyte response to fibroin films, rendering it difficult to draw any conclusions regarding the innate response to fibroin test articles in this report.

2.5. Silk biodegradation

The unique physicochemistry of silk, including a predominantly hydrophobic structure, strong intramolecular and intermolecular physical interactions, and crystal polymorphism enable tunable and slow silk fibroin biodegradation kinetics in the absence of potentially toxic chemical crosslinkers. Fibroin hydrolysis is predominantly attributed to the action of proteolytic enzymes naturally secreted in the body, including part of the foreign body response cascade [12, 15]. Several potential proteolytic cleavage sites exist in both the amorphous and crystalline domains of fibroin [13], leading to gradual fibroin biodegradation into soluble amino acids and peptide fragments [88] through a proteolysis pathway that may involve non-toxic, supramolecular intermediates [89] and/or tightly-packed aggregates [14]. Fibroin biodegradation time, defined as the time to complete loss of structural integrity and loss of mass of the test article in vivo can be fine-tuned per application from <3 months for injectable sonicated hydrogels containing ≤2 wt% silk fibroin in a rat femoral defect model [11], to <6 months to over 12 months depending on fibroin concentration and pore size distribution and connectivity for porous scaffolds with ≤10 wt% silk fibroin in a subcutaneous rat model [15], or an estimated 18–36 months for hydrophilic silk fibroin yarns in a goat knee model [12], covering a desirable timeframe for long-term, sustained delivery applications (Table 2).

Accelerated biodegradation models have been developed in vitro to study the critical physicochemical parameters controlling silk fibroin biodegradation. Protease XIV, a mixture of serine proteases ranging in apparent molecular weight from 16 to 27 kDa is commonly used for accelerated in vitro silk fibroin degradation studies, mainly due to its low cleavage site selectivity and resulting high in vitro silk fibroin degradation rates. For example, protease XIV-mediated degradation of fibroin yarns led to a predictable, gradual reduction in molecular mass of fibroin heavy and light chains, and overall size and mass, and deterioration of mechanical properties [90]. In terms of controlling the rates of silk fibroin degradation, high-order structural aspects of fibroin formats such as the total silk crystal content (e.g., silk I and silk II), relative fraction of each crystal polymorph [47], and the degree of crystal order (relative concentration of intramolecular to intermolecular silk II) [14] may play an important role. For example, silk fibroin films rich in silk I, helical content degraded at significantly faster rates in vitro compared to films rich in silk II, β-sheet crystal content [47]. Furthermore, in vitro enzymatic degradation rates for wet-milled, spray-dried silk fibroin microparticles (<10 µm size) was approximately three times faster than that for silk fibroin fibers at a similar overall crystal content, presumably due to a relative reduction in intermolecular silk II, β-sheet content and high specific area (surface area/volume) values for microparticles [14]. In addition to silk crystal structure, molecular weight also appears to influence silk fibroin biodegradation. For example, faster silk in vitro enzymatic degradation rates induced by increasing the alkali-heat degumming time were attributed to the reduction in the average molecular weight [91]. This hypothesis could be further supported by the quantitation of fibroin molecular weight distribution as well as the isolation of possible effects of average molecular weight and polydispersity and the possible changes in fibroin primary structure with varied durations of alkali-heat degumming. The biodegradation rates are further impacted by silk concentration as increasing the silk fibroin concentration reduced in vitro enzymatic degradation rates for sonication-induced hydrogels [38]. This mirrors the effect of fibroin protein concentration on the in vivo biodegradation rates observed for porous fibroin scaffolds [15]. Overall, silk fibroin proteolysis can be tuned through silk fibroin purification and processing, with resulting differences in structure and morphology controlling the biodegradation rates for any given silk format.

Biodegradation heterogeneity vs. drug stability and pharmacokinetics

The enzymatic nature of silk biodegradation presents additional potential advantages in sustained delivery of low stability drugs and/or applications requiring zero-order pharmacokinetics. Generally, macro-scale homogeneity of a polymer biodegradation process may depend on the relative rate of diffusion (D) of the hydrolyzing agent in the polymer matrix to the rate of polymer hydrolysis (H). In case of a hydrophilic, highly porous network, D >> H would lead to homogenous or bulk biodegradation, while H >> D for a non-porous, hydrophobic system would lead to heterogeneous biodegradation confined predominantly to the surface of the matrix. For example, bulk hydrolysis commonly observed for PLGA polymers results in prolonged exposure of the therapeutic compound to undesirable acidic PLGA polymer hydrolysis products, while the surface erosion commonly observed for silk fibroin could enable diffusion of biodegradation products away from the active site, reducing the loss in drug stability, activity and/or safety. For example, in vitro proteolytic degradation of fibroin yarns was essentially confined to the yarn surface leading to a reduction in fiber diameter and visible surface particulate debris that correlated well with a reduction of overall mass, indicating the heterogeneous, surface mediated biodegradation of silk fibroin [90]. From a pharmacokinetic perspective, generally heterogeneous biodegradation characteristics of predominantly hydrophobic, silk-based dosage forms may also provide zero-order sustained release of drugs as discussed further in section 3.2. The biodegradation rates may be further impacted by the cellular interpenetration and enzymatic diffusion rates in silk fibroin networks. For example, cellular and protease diffusion rates may be higher for self-assembled, highly hydrated, low fibroin concentration hydrogel networks, or porous fibroin scaffolds [15] as compared to high solid density, hydrophobic fibroin yarns or films, potentially leading to more homogeneous silk fibroin matrix biodegradation. Even though determining specific silk fibroin biodegradation pathways is important for fibroin-based product development, one would not expect a correlation between the macro-scale homogeneity of fibroin biodegradation and the suitability of fibroin formulations for a specific drug delivery application since the eventual biodegradation products of silk fibroin are essentially neutral amino acids, not acidic byproducts as with PLGA hydrolysis.

2.6. Which silk to use?

Generally, formulation scientists considering silk protein-based vehicles for sustained delivery have two options: naturally-derived, regenerated silk fibroin or genetically engineered, synthetic silk analogs. Silk sourcing may be one of the most critical parameters for sustained delivery applications, with potential effects on the identity, purity, and physicochemical characteristics of a potential silk product and subsequently its biological response and the pharmacological outcome. Silk fibroin is available in large quantities in Nature, and can be readily purified in aqueous-based, non-toxic solvents with relatively low energy input and potentially low manufacture costs. Silk fibroin structure, physicochemical properties and long-term biological response can be controlled through fibroin purification, its stimuli-responsive self-assembly and processing, providing a viable platform for sustained delivery applications. On the other hand, synthetic silk analogs may provide higher levels of control over silk molecular structure and purity as compared to silk fibroin, while potentially requiring higher cost of goods. Therefore, the utility of synthetic silk analogs in sustained delivery may depend on whether they can provide more reproducible and/or desirable pharmaceutical outcomes than those achievable using naturally derived silk fibroin.

3. Current state of the art in sustained drug delivery using silk

3.1. Drug delivery applications of silk technology

Silk has been utilized as a vehicle to deliver a wide range of bioactive molecules including genes [43, 92–95], small molecules [34, 96–99], and biological drugs [33, 100–103]. For each class of molecules, various silk technologies (Figure 3) have been applied for the delivery and controlled release of therapeutic drugs [7–10]. The combination of silk material platforms, processing conditions, and drug compounds used in prior work, and ultimately drug release kinetics and mechanisms, are instructive for any future drug delivery application.

Gene delivery

For gene delivery, recombinant silk analogs or silk-like polymers are commonly used to deliver plasmid DNA or adenoviral vectors (Table 3). These silk-based block copolymers are typically utilized for this application due to their ability to be functionalized, an important advantage over other gene delivery vehicles such as liposomes and synthetic polymers [8]. As an example, genetic engineering approaches have been used to form block copolymers of spider silk consensus repeats and poly(L-lysine) domains to form ionic complexes that deliver plasmid DNA [43, 104]. These gene carriers may then be functionalized with cell penetrating and cell membrane destabilizing peptides to enhance transfection efficiency [105] or bioengineered as complexes to home specifically to targets such as tumor cells using tumor-homing peptide [95]. Additional functionality may also be gained by producing silk variants such as silk-elastin-like polymers to achieve fine control over the material properties and biodegradation rates of a given formulation. As an example, these polymers have been used to form hydrogels for the controlled delivery of plasmid DNA [92, 106, 107] and adenoviral vectors [92, 108–114], among other model drugs and macromolecules [93, 94]. This approach has been particularly effective for adenoviral gene therapy for cancer treatment as silk-elastin-like protein polymer hydrogels loaded with adenovirus demonstrated greater reduction in tumor volume as compared to control injections of adenovirus in saline solution in a mouse model [113, 114]. In addition to their efficacy, silk-elastin-like protein polymers offer several advantages over other synthetic and natural polymer delivery systems including control of monomer structure at the genetic level and aqueous compatibility for adenoviral viability [114]. In addition, from a processing and delivery perspective, these polymers may be engineered to form thermosensitive hydrogels (liquid at room temperature and hydrogel at body temperature), an attractive feature for any injectable system application [94, 108, 115].

Table 3.

Silk-based formulation approaches for sustained delivery of genes

| Formulation | Gene Delivery | Construct Size (kbp) |

Sustained Release Duration (days) |

References |

|---|---|---|---|---|

| Spider silk consensus repeat/poly(L-lysine) ionic complexes | Plasmid DNA | |||

| pDNA-GFP | 7.65 | ---- | [43. 105] | |

| pDNA-Luc | 7.04 | ---- | [95, 104, 105] | |

| Silk-elastin-like polymer hydrogels | pDNA (pUC18) | 2.60 | 281 | [92] |

| pDNA (pRL-CMV) | 4.08 | 281 | [92] | |

| 282 | ||||

| pDNA (pRL-CMV-Luc) | 4.08 | 281 | [107] | |

| pDNA (pCFB-EGSH-Luc) | 8.50 | 281 | [92] | |

| pDNA (pFB-ERV) | 11.0 | 281 | [92] | |

| Adenovirus | ||||

| Ad-CMV-GFP | 281 | [92] | ||

| Ad-GFP | 281 | [110] | ||

| 282 | ||||

| Ad-CMV-LacZ | 281 | [108, 110, 113] | ||

| 212 | ||||

| Ad-CMV-Luc | 15–212 | [108, 112, 113] | ||

| Ad-Luc-HSVtk | 28–502 | [109,111] | ||

| Ad-Tk | 142 | [113] | ||

| Ad-Luc-Tk | 332 | [114] | ||

| 3D porous scaffold | Ad-BMP7 | 211 | [124] | |

pDNA = Plasmid DNA; Ad = Adenovirus; GFP = green fluorescent protein; Luc = luciferase reporter gene; CMV = cytomegalovirus promoter gene; LacZ = beta galactosidase reporter gene; HSVtk = herpes simplex virus thymidine kinase gene; Tk = thymidine kinase gene; BMP7 = bone morphogenic protein 7;

= in vitro release data;

= in vivo release data

Small molecule drug delivery

For small molecular weight drugs, proof of concept approaches to silk-based drug delivery have primarily focused on film coatings and reservoir systems (Table 4). By controlling the number and thickness of coating layers, as well as silk crystallinity and corresponding film solubility and swelling, a barrier to diffusion is established, and subsequent release rates of the drugs are regulated [10]. One basic approach is to dip coat (as in layer-by-layer assembly) small molecule drug pellets (e.g., approximately 1 cm in diameter) with silk fibroin solution followed by controlled drying and film treatment to manipulate the fibroin crystal form. This has been done using theophylline [116] and adenosine [96], with release profiles lasting from a few hours to 10+ days, respectively, depending on the thickness of the silk film coating, cross-linking with polyethylene glycol, and/or film treatment conditions to control crystallinity. Release rates were primarily a function of coating thickness and crystallinity, with zero order release sustained for up to 17 days [96]. Further control may be achieved by incorporating protease inhibitors into the reservoirs to control local degradation rates [117]. Other reservoir-type approaches include silk fibroin-coated liposomes (300–400 nm), where the introduction of silk fibroin enhanced retention time and improved efficacy for the anti-cancer agent emodin [97, 118]. In addition to reservoir coatings, small molecule drugs may be directly incorporated homogeneously into silk nanolayer coatings for controlled drug delivery [98]. By coating with multiple silk capping layers, and by increasing the silk II, β-sheet crystal content, the initial burst of the model compound rhodamine was suppressed and the duration of release was prolonged up to 30 days [98]. This approach was further validated by incorporating antiproliferative and antithrombotic small molecule drugs, paclitaxel and clopidogrel, into layer-by-layer silk coatings for vascular stents [119]. Pharmacodynamic activity of the coatings was confirmed in vitro as the proliferation of human coronary artery smooth muscle cells and human aortic endothelial cells was inhibited over 28 days, indicating concomitant sustained release over that time [119]. In each of these studies, manipulation of the barrier to diffusion through silk fibroin film thickness, crystal form, and crystal content was critical to control the release profile. Additional manipulation of the silk fibroin diffusive barrier may be achieved by increasing the alkali-heat degumming time during silk fibroin purification [91]. For example, it was hypothesized that the lower average fibroin molecular weight due to prolonged alkali-heat degumming led to a less organized and more permeable fibroin film structure, resulting in faster small molecule drug diffusion [91]. An investigation of specific fibroin physicochemical properties that depend on alkali-heat degumming time may further support this argument, potentially allowing for fine tuning of diffusion-based mechanisms of small molecule release.

Table 4.

Silk-based formulation approaches for sustained delivery of small molecule drugs

| Formulation | Small Molecule Drug | Molecular Weight (Da) |

pKa [168,169] |

logP [168,169] |

Sustained Release Duration (days) |

References |

|---|---|---|---|---|---|---|

| Implants | ||||||

| Tablets | Theophylline | 180 | 8.8 | 0.0 | <11 | [116] |

| Adenosine | 267 | 3.6, 12.4 | −1.1 | 10–171 | [96, 117] | |

| Films/coatings | Penicillin | 356 | 2.8 | 1.8 | 11 | [99] |

| Ampicillin | 371 | 2.5, 7.3 | 1.4 | 11 | [99] | |

| Clopidogrel | 420 | 5.3 | 3.8 | 281 | [119] | |

| Cefazolin | 455 | 3.6 | −0.6 | 31 | [99] | |

| Indigo carmine | 466 | 141 | [91] | |||

| Gentamicin | 478 | −3.1 | 51 | [99] | ||

| Rhodamine B | 479 | 351 | [98] | |||

| Rifampicin | 823 | 1.7 | 4.2 | 3–141 | [91, 99] | |

| Paclitaxel | 854 | 3.0 | 281 | [119] | ||

| Reactive red 120 | 1470 | 71 | [91] | |||

| 3D porous scaffolds (+/− microspheres) | Adenosine | 267 | 3.6, 12.4 | −1.1 | 141 | [120] |

| 202 | ||||||

| Erythromycin | 734 | 8.9 | 3.1 | 311 | [99] | |

| Rifampicin | 823 | 1.7 | 4.2 | 91 | [99] | |

| Injectables | ||||||

| Microcapsules | Emodin | 270 | 4–61 | [97, 118] | ||

| Microspheres/nanospheres | Salicylic acid | 138 | 3.0, 13.6 | 2.3 | 11 | [34] |

| Propranolol HCl | 296 | 9.5 | −0.5 | 281 | [34] | |

| Rhodamine B | 479 | 141 | [33] | |||

| Hydrogels (silk-only or composites, +/− microspheres) | Penicillin | 356 | 2.8 | 1.8 | 2–41 | [99] |

| Prednisone | 358 | 1.5 | <11 | [137] | ||

| Prednisolone | 360 | 1.6 | <11 | [137] | ||

| Cortisone | 360 | <11 | [137] | |||

| Hydrocortisone | 363 | 1.6 | 1–21 | [137] | ||

| Ampicillin | 371 | 2.5, 7.3 | 1.4 | 3–41 | [99] | |

| 12 | ||||||

| 6α-methylprednisolone | 375 | 1.8 | 21 | [137] | ||

| Dexamethasone | 393 | 1.8 | 21 | [137] | ||

| Buprenorphine HCl | 504 | 8.3 | 5.0 | <11 | [122] | |

| Transdermal | ||||||

| Microneedles | Tetracycline | 444 | 3.3 | −1.4 | <11 | [73] |

= in vitro data;

= in vivo data

Similar control mechanisms may be applied to other silk-based technologies (e.g., microspheres, hydrogels, or combination approaches) to tune the release of small molecules. As an example, silk fibroin microsphere formulations of salicylic acid and propranolol hydrochloride demonstrated approximately first order release kinetics and lower initial burst and sustained release rates at higher concentrations of silk fibroin, with overall release lasting from 1 to 30 days [34]. Silk fibroin microspheres may also be incorporated as part of a fibroin scaffold as a combination approach. For example, adenosine-loaded silk fibroin microspheres were homogenously encapsulated within a porous 3D silk scaffold which in turn was coated with alternating nanolayers of silk fibroin and silk-fibroin-drug films to create additional diffusion barriers. The pharmacodynamic effect of these scaffolds was evaluated in a rat model of kindling epileptogenesis, demonstrating a dose dependent retardation of kindling seizures [120]. Future work on fibroin-based combination formulations should concentrate on reducing system complexity and overall size to avoid issues with reproducibility or invasiveness and enhance the viability of any future implant product. More recent work has focused on incorporation of antibiotics into various silk fibroin-based formats, including films, coatings, microspheres, and hydrogels [99]. For antibiotics with high aqueous solubility (penicillin, ampicillin, cefazolin, gentamicin), release durations were relatively short (1 to 5 days) across all formats (films, nanofilm-coated scaffolds, hydrogels, microsphere-loaded gels), yet still preserved antibiotic efficacy as demonstrated through in vitro and in vivo testing of bacterial growth. For antibiotics with lower aqueous solubility (rifampicin, erythromycin), longer release durations were achieved (9 and 31 days for rifampicin- and erythromycin-loaded silk sponges, respectively), demonstrating the important role of hydrophobic interactions between the silk and drug in controlling release in a non-diffusion-based mechanism [99]. Further utility of silk fibroin-based small molecule drug delivery was demonstrated using other material formats, such as tetracycline or methylene blue-loaded silk microneedles [73, 121]. As with silk fibroin films, small molecule diffusivity in silk hydrogels can be controlled effectively via varying molecular weight and/or use of other excipients, as demonstrated in buprenorphine-loaded silk protein polymer hydrogels [122], presumably via mechanisms including hydrogel mesh size distribution and intermolecular interactions between the drug and silk matrix.

Biological drug delivery

For biological drug delivery from silk fibroin-based vehicles, significant research has focused on the delivery of growth factors for tissue engineering applications or the delivery of model drugs for proof-of-principle drug delivery applications (Table 5). As with small molecules, the intermolecular interactions between the biological drug and silk fibroin matrix are critical for controlling diffusion-based and more complex release mechanisms. In the most basic silk-based biological drug delivery formulations, adsorption may be used to load preformed, unmodified silk scaffolds with a growth factor of interest by soaking them in a growth factor solution. As an example, this method has been used to load silk fibroin films and electrospun mats with epidermal growth factor (EGF) for wound healing applications [123]. Growth factor adsorption has also been used to form osteoconductive matrices by coating 3D silk scaffolds with bone morphogenic protein-2 (BMP-2) [81, 100] or BMP-7 adenovirus [124]. In these cases, surface adsorption of the compound of interest is needed to enhance the biological interactions at the cell-biomaterial interface. For sustained drug delivery, however, bulk-loading of formulations by directly mixing the growth factor and silk fibroin solutions prior to formation of the delivery vehicle has generally been the preferred approach, with the exception of lysozyme-coated silk particles [125]. Examples of the solution state loading approach include dextran-, lysozyme-, or horseradish peroxidase (HRP)-loaded silk films [126]; BMP-loaded silk microspheres [127] or electrospun scaffolds [128]; EGF-loaded silk films or electrospun mats [123, 129]; neurotrophin-loaded silk films, tubes [130, 131], or hydrogels [132]; or azoalbumin-loaded [98] or heparin-loaded [119] layer-by-layer silk film coatings. This method of pre-mixing silk and drug before formation has similarly been applied to deliver insulin-like growth factor I (IGF-I) from silk microspheres [34] and 3D scaffolds [101]. Despite differences in material format, these formulations demonstrate the critical role of treatment conditions to induce β-sheet formation and control diffusive pathways, with methanol or water vapor exposure reducing initial burst release and extended release out to 49 and 29 days, respectively [34, 101]. Similar control of crystalline content of horseradish peroxidase (HRP)-loaded silk fibroin microspheres through methanol or salt treatment had a significant effect on release kinetics [32]. As with small molecule delivery, precise control of silk fibroin crystallinity using different processing conditions (e.g., methanol, water annealing, or salt treatment) is critical to manipulate diffusion barriers to achieve target sustained release rates from silk-based formats for a given application.

Table 5.

Silk-based formulation approaches for sustained delivery of biological drugs

| Formulation | Biological Drug | Molecular Weight (kDa) |

Sustained Release Duration (days) |

References |

|---|---|---|---|---|

| Implants | ||||

| Films/coatings (silk-only or composites) | Inulin | 3.9 | 281 | [140] |

| Dextran | 4–40 | 281 | [126] | |

| EGF | 6 | 122 | [123] | |

| NGF | 13.5 | 221 | [130] | |

| Lysozyme | 14.3 | 231 | [126] | |

| Heparin | 15 | 281 | [119] | |

| FGF-2 | 17 | 61 | [44] | |

| HRP | 44 | 231 | [126] | |

| BSA | 66 | 281 | [140] | |

| Azoalbumin | 66.4 | 30–351 | [91, 98] | |

| Electrospun fibers/mats/tubes/scaffolds | EGF | 6 | 71, 122 | [123, 129] |

| NGF | 13.5 | 281 | [131] | |

| GDNF | 15 | 281 | [131] | |

| BMP-2 | 26 | Not reported | [128] | |

| Tubes/conduits (+/− microspheres) | NGF | 13.5 | 221 | [130] |

| GDNF | 15 | ≈422 | [136] | |

| 3D porous scaffolds (silk-only or composites, +/− microspheres) | Inulin | 3.9 | 35 | [142] |

| IGF-1 | 7.6 | 29–491 | [101, 103, 143] | |

| BMP-2 | 26 | ≈7–351, ≈14–282 | [100, 103] | |

| BSA | 66 | 351 | [142] | |

| Lyogels | Anti-TGFβ IgG1 | 150 | 38–1601 | [41, 102] |

| Injectables | ||||

| Bioconjugate solutions | Insulin | 5.8 | ≈21, ≈12 | [45] |

| Microspheres/nanospheres (silk-only or composite) | Insulin | 5.8 | <<11 | [135] |

| IGF-1 | 7.6 | 14–491 | [34, 103] | |

| Dextran | 10 | 141 | [33] | |

| Lysozyme | 14.3 | 281 | [125] | |

| BMP-(2,9,14) | 24–27 | 141 | [103, 127] | |

| HRP | 44 | 15–321 | [32, 139] | |

| BSA | 66 | 14–161 | [33, 139] | |

| Hydrogels (silk-only or composites) | Inulin | 3.9 | 451 | [141] |

| Dextran | 4–250 | 1–41 | [137] | |

| NT-3 | 27.2 | 251 | [132] | |

| VEGF | 38.2 | 421 | [137] | |

| Anti-TGFβ IgG1 | 150 | 261 | [102] | |

| Transdermal | ||||

| Microneedles | HRP | 44 | 21 | [73] |

EGF = epidermal growth factor; NGF = nerve growth factor; FGF = fibroblast growth factor; HRP = horseradish peroxidase; BSA = bovine serum albumin; GDNF = glial cell line-derived neurotrophic factor; BMP = bone morphogenic protein; IGF = insulin-like growth factor; NT-3 = neurotrophin-3; VEGF = vascular endothelial growth factor;

= in vitro data;

= in vivo data

Additional points of control include format dimensions and intermolecular interactions between the silk fibroin and drug compound of interest. As an example, development of silk micro- and nanospheres using a silk/polyvinyl alcohol (PVA)-based emulsion approach yielded particles with improved control over size and shape [33]. The homogeneity of drug distribution within fibroin spheres, loading efficiency, and the release kinetics of model drugs, e.g. tetramethylrhodamine conjugated dextran and bovine serum albumin (BSA), was a function of silk-drug interactions as dictated by hydrophobicity and surface charge, as well as drug molecular weight [33]. The role of intermolecular interactions on pharmacokinetics has also been observed with silk hydrogels and lyophilized silk hydrogels (lyogels) in the sustained delivery of monoclonal antibodies [102]. While hydrogel preparations released the antibody load relatively rapidly (over 10 days), lyogels with greater than 6.2% (w/w) initial silk fibroin content demonstrated sustained release over 38 days [102]. This release profile was primarily attributed to hydrophobic interactions between the silk fibroin matrix and the antibody as well as the density and crystalline content of the fibroin matrix [41, 102]. Generally, interactions between a target protein drug and the silk fibroin matrix, including size exclusion effects (hydrodynamic radius of the drug vs. effective correlation lengths in the silk matrix), solution state structure of the protein drug, and hydrophobic and electrostatic interactions depending on protein sequence and surface charge, may affect release mechanisms. Thus it is critical to manipulate the properties of the silk matrix to control intermolecular interactions and achieve the desired release profile as a function of a complex combination of diffusion, desorption, and degradation-based release mechanisms.

Silk fibroin structure can be chemically modified to enhance silk-drug intermolecular interactions using various techniques. For example, BMP-2 immobilized on the surface of carbodiimide-coupled silk fibroin films retained biological function as indicated by the differentiation of bone marrow stromal cells [133]. A similar approach was also used to couple NeutrAvidin to silk fibroin in solution or to silk fibroin microspheres as a tool for secondary coupling of antibodies for drug delivery or cell targeting [134]. Alternatively, diazonium coupling chemistry was used to form sulfonated silk fibroin films that improved binding of fibroblast growth factor 2 (FGF-2) [44]. As another example, insulin was covalently coupled to silk fibroin in solution [45] or as nanoparticles [135] using gluteraldehyde as a cross-linking reagent. While effective, these approaches have the drawback of using harsh chemicals that may not be suitable for all biological drugs or drug delivery applications.

As with delivery of small molecule drugs, silk fibroin composite formulation approaches have also been employed for biological drug delivery. These include either all-silk composites of different formats such as glial cell line-derived neurotrophic factor (GDNF)-loaded microspheres within a silk conduit for peripheral nerve repair [136] or blends of silk fibroin with other polymers, such as silk-hyaluronan-based composite hydrogels [137] or an injectable calcium phosphate/silk fibroin/BMP-2 cement for spinal fusion [138]. In some cases, the additional polymer was used as a substrate for silk fibroin coatings as HRP and tetramethylrhodamine-conjugated BSA was delivered for 30 and 16 days, respectively, using PLGA and alginate microspheres coated with silk fibroin to control diffusion-based release [139]. Further studies on silk fibroin composite systems included silk fibroin/gelatin multi-layer films for controlled release of FITC-inulin and FITC-bovine serum albumin (FTIC-BSA) [140] and silk fibroin/polyacrylamide hydrogels for delivery of FITC-inulin [141]. In each case, release kinetics was a function of composition and introduction of a degradation-based release mechanism. More specifically, modulation of the respective ratios of silk fibroin/gelatin or silk fibroin/polyacrylamide and their corresponding polymer degradation rates was used to achieve release up to 28 and 45 days, respectively [140, 141]. The polymer composite approach presents further control of silk-based material properties such as biodegradation rate or swelling ratio, though care must be taken to maintain the biocompatibility and bioactivity of the formulation if synthetic polymers are used.

More complex systems were developed by using combinations of biological or synthetic polymers and material formats as part of silk fibroin-based formulations. These include 3D porous silk scaffolds embedded with FITC-inulin- and BSA-loaded calcium alginate or calcium alginate/silk fibroin-blended beads [142] or IGF-1-loaded PLGA microspheres [143]. These systems utilized silk fibroin scaffold matrix as a diffusion barrier, using silk fibroin concentration and crystallinity as the key parameters to limit burst and prolong release from the embedded drug-loaded microspheres. As another example, BMP-2 and IGF-1 were loaded into silk fibroin and PLGA microspheres, which were subsequently loaded into alginate gels or porous silk fibroin scaffolds to form a gradient for osteochondral tissue engineering [103]. Based on the osteogenic differentiation of human mesenchymal stem cells in the alginate gel system, silk fibroin microspheres were more efficient at delivering BMP-2 than PLGA microspheres, perhaps due to faster release from PLGA spheres or loss of bioactivity due to local acidic microenvironment caused by PLGA degradation [103]. Taken together, silk fibroin offers a versatile toolkit for various drug delivery applications. This includes not only varied material formats from injectable particles and hydrogels to implantable reservoirs and scaffolds, but also formulation control points from genetic modifications and bioconjugates to material composition and crystallinity. By properly matching the physicochemical properties of the target drug with those of the silk format, near-zero order sustained release may be achieved as a function of diffusion- and degradation-based release mechanisms.

3.2. Mechanisms and modeling

There has been a considerable amount of effort applied to determining the mechanisms of drug release from different silk-based formulations. Through a mechanistic understanding of release kinetics, critical control points in the formulation development may be elucidated to offer guidance for generating near zero-order, silk-based sustained release formulations. Based on the extensive number of applications of silk technology for drug delivery outlined above, most concluded that diffusion or a combination of diffusion, polymer swelling, and polymer degradation are the primary mechanisms governing the release of drug from silk-based formats [96, 101, 127, 144].

In order to describe drug mass transport in diffusion-controlled release, mechanistic mathematical models such as Fick’s laws of diffusion can be applied:

| (1) |

| (2) |

Here, JA is the diffusive flux of the drug, D is the diffusion coefficient, CA is the concentration of drug in the release medium, and x and t stand for position and time, respectively [145, 146]. In each of these cases, model assumptions such as a constant drug diffusion coefficient, initial drug concentration below drug solubility, and perfect sink conditions, among others, must be satisfied. Variations in this model have been derived for a variety of geometries including thin films (with negligible edge effects), spheres, and cylinders [145–147]. More complex mechanistic models consider polymer swelling, polymer/drug dissolution, chemically-controlled delivery, and/or polymer erosion/degradation [145–147], but these models have yet to be fully implemented for silk-based delivery systems.

While not based on true release mechanisms, empirical or semi-empirical mathematical models such as the Peppas power law model are useful to compare the general effects of different formulation parameters on release kinetics [146–150]. The Peppas equation is defined as:

| (3) |

where Mt and M∞ are the cumulative amount of drug released at time t and infinite time, respectively, k is constant specific to the drug delivery system, and n is the release exponent [147]. Upon fitting the initial release profile (≤60% cumulative release) to the Peppas equation, the drug release mechanism may be elucidated based on the value of the exponent, n. In the case of a thin film, if n = 0.5, the release mechanism is Fickian diffusion, and, if n =1, zero order release is observed and polymer swelling is the sole release mechanism. For values of n between 0.5 and 1, anomalous transport is attributed as the release mechanism, due to a combination of drug diffusion as well as polymer swelling and degradation [147]. This power law has similarly been applied to different geometries with different values for n corresponding to different drug release mechanisms [147, 149, 150].

Release mechanisms for small molecule drugs

For studying controlled release of small molecules from silk fibroin formulations, most research has focused on the release of compounds from silk fibroin films with varied crystalline structure. In one study, synthetic dyes were incorporated into silk fibroin films under different processing conditions (untreated, water-annealed to induce silk I crystallinity, and methanol-treated to induce silk II crystallinity) [151]. The library of dyes included different chemical structures with properties spanning a range of water solubility (logS), hydrophobicity (logP), aqueous conductivity, and net ionic charge, the parameters generally viewed to be critical in determining release kinetics from polymeric release systems [151]. In this particular study, silk fibroin films were chosen as the delivery matrix for ease of fabrication, treatment, and modeling. Dyes were tested for binding to as well as release from the silk fibroin films, and among the 12 small molecule dyes studied (with molecular weights ranging from 291 to 826 g/mol), only three dyes (eosin y sodium salt, brilliant blue R, and methyl red sodium salt) bound to silk and only one dye (brilliant blue R), the dye with the greatest molecular weight and logP among those tested, demonstrated a release mechanism other than simple diffusion [151]. In this case, mathematical modeling of the release indicated a more complex desorption and diffusion release mechanism whereas Fickian diffusion was the primary release mechanism for all other dyes. Within this data set, trends such as increasing diffusion coefficients with increasing water solubility or drug loading as well as decreasing logP or net ionic charge indicated the important role of physicochemical factors, in particular hydrophobic interactions, in determining the release rate. Electrostatic interactions also play a role in controlling release kinetics as silk fibroin, owing to its isoelectric point of ≈4, is negatively charged at neutral pH. Thus, negatively charged molecules generally released faster than positively charged molecules apparently due to electrostatic repulsion. Furthermore, controlling silk fibroin physicochemistry, such as the crystal form and content through methanol-treatment or water-annealing, reduced the effective diffusion coefficients [151]. While this study looked at short-term (less than 1 day) release profiles, similar Fickian diffusion was also observed in longer-term studies (up to 30 days) of sustained release of rhodamine from multi-layered silk fibroin coatings [98].

With additional formulation complexity, e.g. through silk-polymer composites or geometries beyond 2D films, other release mechanisms come into play. As an example, work with silk-gelatin films showed that the release of varied molecular weight compounds was essentially diffusion-controlled over the first 2–3 days, while a second, degradation-controlled phase was observed for the remainder of the 28-day study [140]. Using the Peppas power law equation, the release mechanism was defined as anomalous transport, involving a combination of drug diffusion as well as polymer swelling and degradation [140]. Similarly, application of the Peppas model to silk fibroin-coated adenosine reservoirs indicated a complex release mechanism with an increase in the exponent, n, of the Peppas equation with increasing film thickness [96]. Based on these results, silk fibroin film thickness, crystal form, and crystal content can be viewed as some of the key parameters controlling diffusion in silk fibroin reservoir systems.

Release mechanisms for biological drugs