Abstract

Background

Prolonged standing has been hypothesized as a vital contributor to discomfort and muscle fatigue in the workplace. The objective of this study was to develop a decision support system that could provide systematic analysis and solutions to minimize the discomfort and muscle fatigue associated with prolonged standing.

Methods

The integration of object-oriented programming and a Model Oriented Simultaneous Engineering System were used to design the architecture of the decision support system.

Results

Validation of the decision support system was carried out in two manufacturing companies. The validation process showed that the decision support system produced reliable results.

Conclusion

The decision support system is a reliable advisory tool for providing analysis and solutions to problems related to the discomfort and muscle fatigue associated with prolonged standing. Further testing of the decision support system is suggested before it is used commercially.

Keywords: decision support system, discomfort, ergonomics, fatigue, prolonged standing

1. Introduction

Many industrial workplaces require workers to perform their jobs in a standing position. One of the advantages of standing is that it can provide a large degree of freedom to workers when manipulating materials and tools at their workstation. In addition, a standing position is practical and effective when workers are operating large machines and work pieces, reaching out for materials and tools, and pushing and pulling excessive loads. For instance, a worker who works at a conventional surface grinding machine requires a large degree of freedom to push and pull the machine table when grinding the surface of the work piece. This type of job is almost impossible to perform in a sitting position, so standing is the best option. A standing working position also encourages workers to be more productive and consequently contributes to higher productivity.

However, when workers spend long periods of time standing, they may experience discomfort and muscle fatigue at the end of the working day. In the long term they may experience occupational injuries such as work-related musculoskeletal disorders, chronic venous insufficiency, and carotid atherosclerosis [1]. A worker is considered to be exposed to prolonged standing if he or she spends over 50% of their total working hours during a full work shift in a standing position [2]. Working in a standing position for an extended period of time has been recognized in industry as contributing to a decrease in workers' performance. This decrease may be a result of occupational injuries, a decrease in productivity, and an increase in treatment and medical costs. Prolonged standing can lead to subjective discomfort in workers. When workers perform jobs in a prolonged standing position, static contraction occurs, particularly in their back and legs, resulting in discomfort and muscle fatigue [3]. Employers may also be affected due to the loss of revenue in the form of productivity, workers' compensation, and health treatment costs [4]. For example, a pain in the lower back due to prolonged standing can affect the ability of a worker to perform a job involving flexion or extension postures. This may, in turn, affect the productivity of the worker. In addition, workers who suffer from occupational injuries must be referred to clinical experts for health treatment, which involves substantial amounts of consultancy and treatment costs.

Many ergonomics simulation systems have been introduced to improve the productivity, comfort, and safety of workers in manufacturing workplaces [5,6] and numerous assessment tools have been suggested to assess and analyze the risk factors associated with prolonged standing. For example, the Rapid Entire Body Assessment (REBA) [7] and the Guidelines on Occupational Safety and Health for Standing at Work [8] can be applied to analyze and minimize postural stress due to standing jobs. However, almost all existing methods are only available as pen and paper forms and do not provide a comprehensive assessment of prolonged standing. The methods are time consuming, difficult to retrieve electronically, require manual data processing, and may suffer from human errors when performing calculations. In addition, the existing assessment methods are seen as individual, isolated tools, hence it is difficult to perform multiple assessments concurrently [9]. Innovative best practice and the underlying measurement science for assessing and analyzing the risk factors associated with prolonged standing and documenting the results of the computations do not yet exist. As a consequence, the authorized institutions and industry practitioners who are concerned with occupational safety and health do not have a reliable measurement tool with which to assess and analyze the risk factors associated with jobs involving prolonged standing in the workplace. This includes the proposition of solutions to minimize the level of risk.

To counter these limitations, this study aimed to develop a decision support system to assess, analyze, and propose solutions for minimizing the discomfort and muscle fatigue associated with prolonged standing in industrial workplaces. Six risk factors related to prolonged standing (working posture, muscle activity, duration of standing, holding time, whole-body vibration, and indoor air quality) [10] were considered as the basis to develop knowledge for the decision support system. These risk factors are related to humans, machines, and the environment in the workplace. All the risk factors were analyzed individually to determine their risk levels. The risk levels of each risk factor were then assigned with multipliers to represent their severity for discomfort and fatigue. A strain index was developed through multiplicative interactions between the assigned multipliers. The decision support system developed in this way proposes alternative solutions to minimizing the risk levels corresponding to the strain index. In the decision support system developed, an Ergonomic Workstation model and a Decision Support System for Prolonged Standing (DSSfPS) model were designed to function as data capturing and analysis models, respectively.

2. Materials and methods

2.1. Stage 1: knowledge acquisition

The first stage in developing the decision support system was knowledge acquisition. In a decision support system, knowledge can be considered as the “brain” to process the input data and information supplied to the system. The knowledge can be obtained by extracting, structuring, and organizing knowledge from one or more sources [11]. In this study, knowledge acquisition was performed to determine the risk factors that contribute significantly to the discomfort and muscle fatigue associated with jobs involving prolonged standing. The ergonomics evaluation tools used to analyze the risk factors were also obtained at this stage. This was carried out by obtaining information from reliable sources such as published literature, onsite observations in industry, interviews with management staff and production workers, guidelines and standards from authorized organizations, and expert opinion.

Reviews of published papers were carried out using hard-copy publications, such as magazines, journals, and guidelines, as well as online databases. The main purpose of the literature review was to determine the risk factors that contribute significantly to the discomfort and muscle fatigue associated with jobs involving prolonged standing. Literature reviews are also useful in identifying ergonomics evaluation tools and control measures that can be applied to assess, analyze, and minimize discomfort and muscle fatigue. The identified risk factors, methods, and control measures were compiled for consideration in the decision support system.

A series of onsite observations was conducted in three metal-stamping companies in Malaysia. The main purpose of the onsite observations was to identify the risk factors that are present in standing workstations. A video camcorder was used to record these risk factors. The video camcorder was set close to the workstation to record posture, movements, and job cycles while the workers were performing their jobs. The process of video recording took about 30 minutes to ensure that all the risk factors, working practices, and job processes in the workstation were recorded completely. The advantage of video recording is that the recorded information is easy to replay, stop, or pause so that the postures, movements, and job cycles in the workstation can be monitored. In addition, the risk factors captured by video recording can be considered as knowledge for the decision support system.

In addition to the onsite observations, interview sessions with management staff and production workers were carried out to acquire the personal background and job activities of the workers, the discomfort and fatigue experienced by the workers while performing their jobs in a prolonged standing position, any history of pain and treatment taken, and suggestions to improve the standing workstations. The Prolonged Standing Questionnaire [12] was applied during the interview sessions. Through the interview sessions, we were able to acquire useful information that could not be obtained during the onsite observations, such as the solutions applied by the management staff and production workers to minimize the discomfort and muscle fatigue associated with prolonged standing.

Authorized organizations such as the International Organization for Standardization and Department of Safety and Health of Malaysia are good sources from which to acquire information on prolonged standing in workplaces. These institutions have published regulations and guidelines on standing in the workplace. The Guidelines on Occupational Safety and Health for Standing at Work [8], the Code of Practice on Indoor Air Quality [13], and standards of comfort levels due to acceleration values of whole-body vibration [14] were referred to in order to establish the knowledge base of the decision support system.

Experts, including ergonomic practitioners, medical doctors, physiotherapists, safety and health engineers, and academics, were significant contributors in developing the knowledge of the decision support system. Their opinions and advice were gathered through discussions in seminars and conferences. One of the outcomes from the discussion was the selection of ergonomics evaluation tools to be applied in the decision support system.

All the risk factors related to the discomfort and muscle fatigue associated with prolonged standing which were compiled from these sources were categorized into three domains, namely: human, machine, and environment. Each risk factor from these domains was equipped with ergonomics evaluation tools to analyze and quantify the risk levels. For example, the risk factor associated with an awkward working posture has been identified as a vital contributor to discomfort and fatigue. This is categorized under the human domain and the REBA [7] was applied to analyze the working posture used when a worker performs a job in a prolonged standing position. The process to integrate the risk factors and ergonomics evaluation tools was performed in the second stage.

2.2. Stage 2: knowledge integration

The second stage continued with an integration of all the knowledge obtained through these sources. All the risk factors that contribute significantly to the discomfort and muscle fatigue associated with prolonged standing were matched with ergonomics evaluation tools to quantify the risk levels. Based on the risk factors, the Prolonged Standing Strain Index (PSSI) was developed. Details of the development of the PSSI can be found in Isa and Abdul [10].

2.3. Stage 3: Ergonomic Workstation model and the DSSfPS model

This study used the Model Oriented Simultaneous Engineering System (MOSES) architecture [9,15] to develop the decision support system. The decision support system has two main models, namely, the Ergonomic Workstation model and the DSSfPS model. The Ergonomic Workstation model captures data and information on the workplace, worker, working posture, muscle activity, standing duration, holding time, whole-body vibration, and indoor air quality in the workplace.

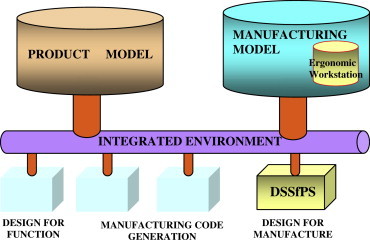

The DSSfPS model, on the other hand, consists of knowledge and established ergonomics evaluation tools to analyze data about risk factors that are captured by the Ergonomic Workstation model. The DSSfPS model is functioned to quantify the risk levels of each risk factor and to compute the PSSI value. The DSSfPS model will suggest alternative solutions with respect to the PSSI value to minimize discomfort and fatigue while performing jobs at a standing workstation. A working memory in the DSSfPS model is used to save all the results from the analysis. Both the Ergonomic Workstation model and the DSSfPS model are well fitted under the Manufacturing model of the MOSES architecture (Fig. 1).

Fig. 1.

An integrated environment between the Ergonomic Workstation model and the Decision Support System for Prolonged Standing (DSSfPS) model within Model Oriented Simultaneous Engineering System architecture.

The Ergonomic Workstation model is represented by a workstation, the place at which a worker performs jobs. The data and information captured by the Ergonomic Workstation model are then supplied to the DSSfPS model for further analysis. The users (e.g., ergonomics experts) can apply the outcomes of the analysis to modify the design of the workstation to minimize the discomfort and muscle fatigue associated with jobs involving prolonged standing. The communication between the two models in the decision support system is achieved when information and data captured by the Ergonomics Workstation model are supplied to the DSSfPS model through an integrated computer environment.

The programming architecture of the Ergonomic Workstation model and the DSSfPS model was developed using object-oriented programming (OOP). The Java programming language and the open source database db4o (Oracle, Redwood Shores, California, USA) were used as the programming language and the database engine, respectively. OOP is a programming paradigm that uses interactions of class and attribute (sometimes called objects) to design computer programs. The advantage of using OOP is that any required modifications to the information architecture can be carried out easily. For example, if a system developer wishes to modify the information architecture for certain reasons, he or she can manipulate the respective class without interfering with other classes.

2.4. Development of the Ergonomic Workstation model

The information model of the Ergonomic Workstation was designed by considering workers in their actual workplaces. A workplace is usually represented by the hierarchy of company, department, and workstation. In the workstation, it consists of at least a human (worker), a machine, and a working environment. When a worker is performing jobs in a standing position, his or her workstation is considered as a critical point at which ergonomics principles should be taken into account to minimize discomfort and muscle fatigue.

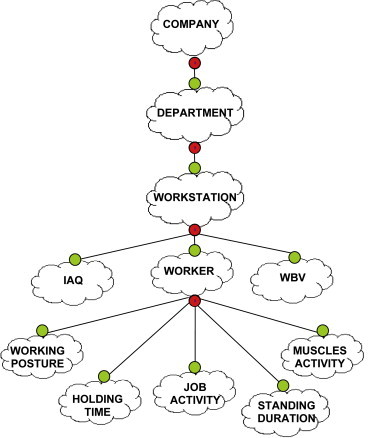

In the Ergonomic Workstation information model, the relationship of each human–machine–environment constituent in a workstation built their own classes, represented by the clouds in the information structure (Fig. 2). In the information structure, the primary class of the Ergonomic Workstation is COMPANY. DEPARTMENT is then assigned as a subclass of COMPANY. Consecutively, the WORKSTATION class is created as a subclass of DEPARTMENT. To represent machine and environment constituents, whole-body vibration and indoor air quality classes were created, respectively. The WORKER class consists of five subclasses, representing job activity, working posture, muscle activity, standing duration, and holding time. Except for job activity, all classes represent factors that need to be assessed and analyzed when a worker is performing jobs in a prolonged standing position. Although no ergonomics evaluation is carried out for the job activity, its information is useful in deciding further analysis. For example, if a worker is exposed to an activity of jobs associated with “standing with forward bending,” ergonomics evaluation associated with working posture assessment will be carried out.

Fig. 2.

Information structure in the Ergonomic Workstation model to represent the human–machine–environment in a workstation. IAQ = indoor air quality; WBV = whole-body vibration.

All information on the workplace, worker's profile, and data about risk factors are saved in the Ergonomic Workstation model. The data and information are manipulated by the DSSfPS model for further analysis.

2.5. Development of the DSSfPS model

The DSSfPS model is used to analyze the risk factors, quantify the risk level of standing, and to obtain alternative solutions to improve the workstation design. The DSSfPS model plays an important part in providing alternative solutions to design an ergonomic standing workstation, therefore its knowledge development should be given a high priority to ensure that the system can achieve the desired performance.

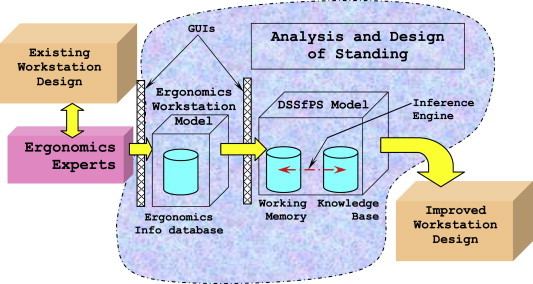

Fig. 3 shows that the DSSfPS model has three main mechanisms: a working memory, a knowledge base, and an inference engine. In addition, graphical user interfaces (GUIs) are provided in the system to facilitate communication between the decision support system and the users. The relationship between the working memory and knowledge base in the DSSfPS model is clearly shown in Fig. 4.

Fig. 3.

Decision Support System for Prolonged Standing (DSSfPS) model and its mechanisms. GUIs = graphical user interfaces.

Fig. 4.

Structure of knowledge base and working memory in the Decision Support System for Prolonged Standing model (DSSfPS). IAQ = indoor air quality; PSSI = Prolonged Standing Strain Index; WBV = whole-body vibration.

2.6. Working memory of the DSSfPS model

The DSSfPS model is equipped with eight working memories. Generally, the working memories function to temporarily store the data and results of analysis. Table 1 summarizes the functions of each working memory.

Table 1.

Working memories of the decision support system for prolonged standing model and their functions

| Working memory | Function |

|---|---|

| Worker Memory | Compiles data and information on the workplace profile (company name, worker's department, worker's workstation) and the worker's profile (name, employee number, age, and job activity) |

| Posture Memory | Saves data, information, and results of working posture analysis |

| Muscle Memory | Saves data, information, and results of muscle activity analysis |

| Standing Memory | Saves data and results of standing duration analysis |

| Holding Memory | Saves data and results of holding time analysis |

| WBV Memory | Saves data and results of whole-body vibration analysis |

| IAQ Memory | Saves data and results of indoor air quality analysis |

| PSSI Memory | Saves results of PSSI and recommendations |

IAQ, indoor air quality; PSSI, prolonged standing strain index; WBV, whole body vibration.

2.7. Knowledge base of the DSSfPS model

The knowledge base of the DSSfPS model serves as a shell to contain rule sets for the ergonomic evaluation tools such as the Posture Rule, Muscle Rule, Holding Rule, Standing Rule, Whole Body Vibration Rule, and Indoor Air Quality Rule. In addition, the PSSI Rule is also embedded in the knowledge base. The rule sets consist of a list of if statements and a list of then conditions to process any input data and provide a set of alternative solutions to minimize the discomfort and muscle fatigue associated with prolonged standing. The development of the rule sets involved two stages. The first stage consisted of assigning each ergonomics evaluation tool to a class. The formulation of rules to reach the final results was performed in the second stage.

In the first stage, the ergonomics knowledge was assigned to several classes to accommodate the following rule sets:

-

1.

Posture Rule – rules for working posture analysis;

-

2.

Muscle Rule – rules for muscle activity analysis;

-

3.

Holding Rule – rules for holding duration analysis;

-

4.

Standing Rule – rules for standing time analysis;

-

5.

Whole Body Vibration Rule – rules for whole-body vibration exposure analysis;

-

6.

IAQ Rule –rules for indoor air quality analysis.

In the second stage, the rule set for the PSSI Rule was developed. The PSSI Rule has several rules that are used to perform PSSI calculations and to obtain recommendations to minimize discomfort and muscle fatigue based on the PSSI value. The development of the PSSI Rule began with assigning the results of risk factor analysis (in terms of risk levels) to multipliers to represent their severity for discomfort and fatigue. A PSSI value is obtained through multiplicative interactions between these multipliers. Potential solutions to minimize the risk levels were then recommended based on the PSSI value. Table 2 summarizes the knowledge base of the DSSfPS model, which includes the risk factors or knowledge, knowledge description, numbers of rules, questions, and alternative answers.

Table 2.

Summary of knowledge base of decision support system for prolonged standing model

| Knowledge | Knowledge description | No. of rule | No. of question | No. of optional answer |

|---|---|---|---|---|

| Working posture |

|

299 | 16 | 53 |

| Muscle activity |

|

455 | 21 | 84 |

| Holding time |

|

10 | 2 | 10 |

| Standing duration |

|

3 | 1 | 3 |

| Whole-body vibration |

|

166 | 3 | 200 |

| Indoor air quality |

|

11 | 5 | — |

| Prolonged Standing Strain Index |

|

25 | 6 | 22 |

| Total | 969 | 54 | 372 | |

2.8. Inference engine of the DSSfPS model

In the DSSfPS model, an inference engine is used to obtain the results (risk levels, PSSI value, and recommendations) by matching the rule sets in the knowledge base and the data available in the working memory. The method applied to design the inference mechanism is forward chaining. Forward chaining works by processing the data first and then using the rules in the knowledge base to draw new conclusions from these data [16,17]. This study applied forward chaining because it operates via a top-down approach, which takes the data available in the working memory and then generates results based on the satisfied conditions of the rules in the knowledge base. In the DSSfPS model, the inference engine performs the following functions:

-

1.

supplies background information for the worker, such as the workplace profile, personal details, job activities, and data about risk factors captured by the Ergonomic Workstation model to the working memory of the DSSfPS model;

-

2.

searches rule sets in the knowledge base and matches these with data from the working memory to obtain results (risk levels, PSSI value, and recommendations);

-

3.

retrieves updated working memory database to display the outcomes of the analysis.

The inference engine of the DSSfPS model works in three stages: between the GUIs and the working memory; between the working memory and the knowledge base; and at the working memory to display the outcomes of analysis.

2.9. GUIs

In the decision support system, the GUIs are used as the communication medium between the user, the Ergonomic Workstation model, and the DSSfPS model. The GUIs were designed using facilities available in NetBeans IDE 6.8 (Oracle Corporation). The user provides information from the actual industrial workstation, such as information about the workplace, the worker's profile, and data about the risk factors, to the database in the Ergonomic Workstation model through the GUIs. In the decision support system, ten GUIs have been designed to perform various functions.

A main menu GUI was designed to enable a user to populate a database in the Ergonomic Workstation model. When the program is executed, the main menu GUI will appear. In the main menu GUI, there are several menus:

-

1.

the File menu – to exit from the decision support system;

-

2.

the Manage Database menu – to create databases;

-

3.

the Populate Database menu – to provide data and information about the risk factors to be analyzed;

-

4.

the Display Information menu – to preview data and results of analysis; and

-

5.

the Help menu – to guide the user about the basic operation of the decision support system.

2.10. Integrating the Ergonomic Workstation model and the DSSfPS model

Both the Ergonomic Workstation model and the DSSfPS model have to be integrated in a decision support system to enable prospective users to analyze jobs in their workplaces involving standing. To use the decision support system, a user should create a database for the Ergonomic Workstation model and a working memory for the DSSfPS model. The user should then supply information about the workplace, worker, and data for the risk factors from the actual workplace and store them in the database in the Ergonomic Workstation model. The inference engine retrieves the data and information from the Ergonomic Workstation database and sends them to the database in the working memory. The inference engine then examines and matches the rules embedded in the knowledge base of the DSSfPS model with the data and information from the working memory to generate the results. The results obtained are saved in the working memory. The inference engine retrieves the saved results in the working memory for display purposes.

2.11. Validation of the decision support system

A validation process was conducted to ensure that the knowledge of the developed decision support system was able to perform its functionality with an acceptable level of accuracy. To achieve this, a validation process was performed through a technical validation using two real case studies [18]. According to the technical validation, the results generated by the decision support system should be consistent with the results of conventional methods when assessing and analyzing a similar case study [19].

The validation process was carried out through two onsite observations at a metal-stamping company in Shah Alam, Malaysia and a footwear manufacturer in Petaling Jaya, Malaysia. To validate the knowledge of the developed decision support system, 26 workers (13 from each company) were selected as samples for study. Data and information about the workplace, workstation, worker, and risk factors were acquired directly from the companies. Data on risk factors, including working posture, muscle activity, standing duration, and holding time were observed under three conditions: high, medium, and low risk levels. Data on risk factors associated with whole-body vibration were measured using a vibration accelerometer (QUEST Technologies, Oconomowoc, Wisconsin, USA) at the standing workstation. In addition, the amounts of carbon dioxide and carbon monoxide surrounding the workstation were measured using an Indoor Air Quality Probe IQ-410 (Gray Wolf, Shelton, Connecticut, USA) [20]. In the decision support system, all the data and information were supplied to the Ergonomic Workstation model; the DSSfPS model then analyzed them to generate the results. The data and information were analyzed on an individual basis. Therefore all the workers had their own data and information about the workplace, workstation, worker, and risk factors. Similarly, the data about risk factors were analyzed through a conventional method; for example, data about working posture and muscle activity were analyzed using the REBA worksheet [7] and Rodgers Muscle Fatigue Analysis worksheet [21], respectively.

A comparison was then performed between the results generated by the decision support system and the conventional method to determine the validity of knowledge in the developed decision support system. Tables 3–8 present the results of this comparison of knowledge for the six risk factors (working posture, muscle activity, duration, holding time, whole-body vibration, and indoor air quality). The result of the validation for the PSSI is given in Table 9. Based on this comparison, it is clear that the decision support system developed is able to generate results comparable with conventional methods. In other words, the results from both the decision support system and the conventional method showed good agreement for all analyzed risk factors.

Table 3.

Validation of knowledge for working posture

| Data and information | Results (decision support system) | Results (conventional method) |

|---|---|---|

| Trunk: 0–20° flexion Neck: more than 20° flexion Legs: unstable posture Upper arms: 20–45° flexion Lower arms: less than 60° flexion Wrists: more than 15° flexion Load: less than 5 kg Coupling: fair (hand-hold is acceptable) Activity: repeated small range action |

Medium risk | Medium risk |

| Trunk: 0–20° flexion Neck: 0–20° flexion and twisting Legs: bilateral weight-bearing Upper arms: 45–90° flexion Lower arms: 60–100° flexion Wrists: more than 15° flexion Load: less than 5 kg Coupling: fair (hand-hold acceptable) Activity: repeated small range actions |

Medium risk | Medium risk |

| Trunk: upright Neck: 0–20° flexion Legs: bilateral weight-bearing Upper arms: 20° extension to 20° flexion Lower arms: 60–100° flexion Wrists: 0–15° flexion Load: less than 5 kg Coupling: good (well-fitted handle) Activity: body parts are static |

Low risk | Low risk |

Table 4.

Validation of knowledge for muscle activity

| Data and information | Results (decision support system) | Results (conventional method) |

|---|---|---|

| Neck effort level: moderate – head forward about 20° Neck effort duration: 6–20 s Neck effort frequency: 1–5/min Shoulder effort level: light, arm slightly extended Shoulder effort duration: <6 s Shoulder effort frequency: 1–5/min Back effort level: moderate bending forward Back effort duration: 6–20 s Back effort frequency: 1–5/min Arm/elbow effort level: moderate–moderate force of lifting Arm/elbow effort duration: 6–20 s Arm/elbow effort frequency: 1–5/min Wrist/hand/finger effort: moderate grip with moderate force Wrist/hand/finger effort duration: 6–20 s Wrist/hand/finger effort frequency: 1–5/min Leg/knee effort level: moderate bending forward Leg/knee effort duration: 6–20 s Leg/knee effort frequency: 1–5/min Ankle/foot/toe effort level: moderate bending forward Ankle/foot/toe effort duration: 6–20 s Ankle/foot/toe frequency: 1–5/min |

Medium risk | Medium risk |

| Trunk: 0–20° flexion Neck: 0–20° flexion and twisting Legs: bilateral weight-bearing Upper arms: 45–90° flexion Lower arms: 60–100° flexion Wrists: more than 15° flexion Load: less than 5 kg Coupling: fair (hand-hold acceptable) Activity: repeated small range actions |

||

| Neck effort : light – head turned partly to side and slightly forward Neck effort duration: less than 6 s Neck effort frequency: less than 1/min Shoulder effort level: light – arm slightly extended Shoulder effort duration: less than 6 s Shoulder effort frequency: less than 1/min Back effort level: moderate bending forward Back effort duration: less than 6 s Back effort frequency: less than 1/min Arm/elbow effort level: light–light lifting Arm/elbow effort duration: less than 6 s Arm/elbow effort frequency: less than 1/min Wrist/hand/finger effort level: light–light forces Wrist/hand/finger effort duration: less than 6 s Wrist/hand/finger effort frequency: less than 1/min Leg/knees effort level: light – standing without bending Leg/knee effort duration: less than 6 s Leg/knee effort frequency: less than 1/min Ankle/foot/toe effort level: light – standing without bending Ankle/foot/toe effort duration: less than 6 s |

Low risk | Low risk |

Table 5.

Validation of knowledge for standing duration

| Data and information | Results (decision support system) | Results (conventional method) |

|---|---|---|

| More than 1 h continuous standing or more than 4 h total standing | Medium risk | Medium risk |

| More than 1 h continuous standing and more than 4 h total standing | High risk | High risk |

Table 6.

Validation of knowledge for holding time

| Data and information | Results (decision support system) | Results (conventional method) |

|---|---|---|

| Shoulder height: 50% Arm reach distance: 25% |

Low risk | Low risk |

| Shoulder height: 50% Arm reach distance: 50% |

Low risk | Low risk |

| Shoulder height: 75% Arm reach distance: 25% |

Low risk | Low risk |

| Shoulder height: 75% Arm reach distance: 50% |

Low risk | Low risk |

| Shoulder height: 100% Arm reach distance: 25% |

Medium risk | Medium risk |

| Shoulder height: 100% Arm reach distance: 50% |

Low risk | Low risk |

| Shoulder height: 50% Arm reach distance: 75% |

Medium risk | Medium risk |

| Shoulder height: 75% Arm reach distance: 75% |

Medium risk | Medium risk |

| Shoulder height:100% Arm reach distance: 75% |

Medium risk | Medium risk |

Table 7.

Validation of knowledge for whole-body vibration

| Data and information | Results (decision support system) | Results (conventional method) |

|---|---|---|

| Acceleration 0.100–0.214 m/s2 | Comfort | Comfort |

| Acceleration 0.315–0.369 m/s2 | Little discomfort | Little discomfort |

| Acceleration 0.374–0.382 m/s2 | Some discomfort | Some discomfort |

Table 8.

Validation of knowledge for indoor air quality

| Data and information | Results (decision support system | Results (conventional method) |

|---|---|---|

| Carbon dioxide: 4045 ppm | Safe | Safe |

| Carbon monoxide: 1.67 ppm | Safe | Safe |

Table 9.

Validation for prolonged standing strain index

| Risk factors | Risk level | Rating criterion | Multiplier | Results (manual analysis) | Results (decision support system analysis) |

|---|---|---|---|---|---|

| Working posture | Low | Safe | 2 | 2 × 1 × 244 × 1 × 3 × 1 = 1464 | |

| Muscle activity | Low | Little fatigue | 1 | 1,464 | |

| Standing duration | High | Unsafe | 244 | ||

| Holding time | Low | Comfort | 1 | ||

| Whole-body vibration | Little discomfort | Little discomfort | 3 | ||

| Indoor air quality | Safe | Safe | 1 |

3. Discussion

Decision support systems have been recognized as efficient decision-making tools in many applications. For example, in medical care, a decision support system that provides an explicit point of decision-making to clinicians has achieved clinician compliance rates of 90–95% [22]. This study has developed a decision support system that consists of an Ergonomic Workstation model and a DSSfPS model. Both models were designed using OOP. We found that OOP is a versatile and flexible system, especially when designing programming architecture because any modifications and improvements on the models related to their classes and attributes can be easily carried out. In other words, if the programming architecture needs to be modified, the relevant class can be manipulated without interfering with the other classes. This advantage enables the programming architecture to be easily reorganized, with resulting savings of time. In addition, designing a relationship between a work system and its components using OOP is particularly useful for making the designed system easily understood [23].

In terms of the development of the knowledge base, this study established information about risk factors by surveying published work and performing onsite observations at industrial workplaces. This combination of a literature review and onsite observations has been shown to be an effective way to establish a comprehensive knowledge base. As a result, information about risk factors related to the human–machine–environment has been established. This study applied reliable sources such as established ergonomics evaluation tools, guidelines, and standard for data analysis and decision-making to each corresponding risk factor. Other decision support systems for application in ergonomics have based the acquisition of knowledge solely on literature reviews [24].

In the knowledge base, the current study developed the rule sets utilizing an if–then production rule to execute the knowledge. The if–then production rule is preferred because the data and information to be analyzed by the developed decision support system requires straightforward manipulations. In the development of many rule sets, the fuzzy rule is widely used [25–29]; however, the fuzzy rule is not suitable in the current study because its decision-making is not always a matter of black and white – it often involves grey areas [30].

The working memory is a vital component in a decision support system as it is used to store the data and information supplied by the users. In developed decision support system, data and information about the workplace, workers, and risk factors captured by the Ergonomic Workstation model and the results of analysis performed by the DSSfPS model are saved in a working memory. When the decision support system is used to perform many assessments, the amount of data in the working memory increases and there is a possibility of a conflict of data. This may lead to data manipulation errors. To avoid this, the working memory has to be cleared. To clear the working memory, it should be initialized. This study created a function to initialize the working memory of the DSSfPS model by deleting old data. Interestingly, the deletion process in the working memory of the DSSfPS model does not affect the data and information about the workplace, workers, and risk factors saved in the Ergonomic Workstation model. The program code deletes the results of previous assessments in the working memory of the DSSfPS model; however, the data and information about workplace, workers, and risk factors are still available in the Ergonomic Workstation model. The advantage of this system is that the data and information stored in the Ergonomic Workstation model could be retrieved when further assessments are required.

In this study, the forward chaining method was used to develop the inference engine. This method is preferred because it works through a top-down approach, which takes the data available in the working memory and then generates results based on the satisfied conditions of the rules in the knowledge base. For example, consider the rule sets in the class Posture Rule:

Rule 1: if reba_score = 1 then posture_risk_level = “Negligible”

Rule 2: if posture_risk_level = “Negligible” then PostureMultiplier = 1

Rule 3: if PostureMultiplier = 1 then

PostureRecommendation = “The posture should be maintained”

Based on the forward chaining method, we start with Rule 1 and go on downwards (Rule 3) until a rule that “fires” is found. In other words, the forward chaining method is data-driven because the initial data are processed first (reba_score, posture_risk_level, PostureMultiplier) and the rules are followed until the goal (PostureRecommendation) is achieved.

Ten GUIs are used in the decision support system for convenient data input, analysis, and display. The GUIs are predominantly used to key in data and information about the workplace, workers, and risk factors, including working posture, muscle activity, standing duration, holding time, whole-body vibration, and indoor air quality. Each kind of data and information is equipped with an individual GUI. The GUIs are of a text-based design with several facilities such as informative messages, pull-down menus, check boxes, radio buttons, and OK and Cancel buttons. No image is provided in the GUIs due to the constraint of the GUI area and the fact that it was difficult to obtain a suitable image to represent certain data and information. For example, it is difficult to attach an image of vibration at a certain frequency and acceleration in the whole-body vibration GUI because the quantities are nearly impossible to capture.

The developed decision support system underwent a final validation process. Through the validation process, it was found that the results generated by the decision support system are comparable with the conventional method. The advantages of using the decision support system are a saving of time and systematic manipulation of data.

A decision support system specifically used to analyze the risk factors and predict the risk levels due to prolonged standing at work and to propose recommendations to minimize discomfort and fatigue has been developed. This study identified working posture, muscle activity, duration of standing, holding time, whole-body vibration, and indoor air quality as the risk factors for discomfort and muscle fatigue while workers are performing jobs in a standing position. The risk levels of the risk factors can be predicted through the PSSI value. The risk factors and the PSSI value have been modeled in a decision support system to provide systematic analysis and solutions for the discomfort and muscle fatigue associated with prolonged standing. Based on the results of the validation process, this study concluded that the decision support system is reliable for assessing, analyzing, and proposing solutions to minimize the discomfort and muscle fatigue associated with prolonged standing in industrial workplaces. This study suggests further efforts such as extensive testing and the development of an attractive and user-friendly GUI to make the decision support system commercially available.

Conflicts of interest

All contributing authors declare no conflicts of interest.

Acknowledgments

The authors acknowledge the Ministry of Higher Education of Malaysia, the Faculty of Manufacturing Engineering of the Universiti Teknikal Malaysia Melaka, and the Ministry of Science, Technology and Innovation of Malaysia for funding this research under an e-Science Research Grant (grant no.: 06-01-01-SF0258), and the Faculty of Mechanical Engineering of Universiti Teknologi MARA and Research Management Institute of Universiti Teknologi MARA for providing facilities and assistance in conducting this study. Special thanks go to Miyazu (M) Sdn. Bhd. and Kulitkraf Sdn. Bhd. for facilitating the workplace surveys.

Footnotes

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

References

- 1.Isa H., Omar A.R. A review on health effects associated with prolonged standing in the industrial workplaces. Int J Res Rev Appl Sci. 2011;8:14–21. [Google Scholar]

- 2.Tomei F., Baccolo T.P., Tomao E., Palmi S., Rosati M.V. Chronic venous disorders and occupation. Am J Ind Med. 1999;36:653–665. doi: 10.1002/(sici)1097-0274(199912)36:6<653::aid-ajim8>3.0.co;2-p. [DOI] [PubMed] [Google Scholar]

- 3.Krijnen R.M.A., de Boer E.M., Ader H.J., Bruynzeel D.P. Diurnal volume changes of the lower legs in healthy males with a profession that requires standing. Skin Res Technol. 1998;4:18–23. doi: 10.1111/j.1600-0846.1998.tb00080.x. [DOI] [PubMed] [Google Scholar]

- 4.Zander J.E., King P.M., Ezenwa B.N. Influence of flooring conditions on lower leg volume following prolonged standing. Int J Ind Ergon. 2004;34:279–288. [Google Scholar]

- 5.Chaffin D.B. Human simulation for vehicle and workplace design. Hum Factors Ergon Manuf. 2007;17:475–484. [Google Scholar]

- 6.Kazmierczak K., Neumann W.P., Winkel J. A case study of serial-flow car disassembly: ergonomics, productivity and potential system performance. Hum Factors Ergon Manuf. 2007;17:331–351. [Google Scholar]

- 7.Hignett S., McAtamney L. Rapid entire body assessment (REBA) Appl Ergon. 2000;31:201–205. doi: 10.1016/s0003-6870(99)00039-3. [DOI] [PubMed] [Google Scholar]

- 8.Department of Safety and Health . 2002. Ministry of Human Resources, Malaysia. Guidelines on occupational safety and health for standing at work [Internet] [cited 2013 Feb 21]. Available from: http://www.dosh.gov.my/doshv2/phocadownload/guidelines/garispanduan15.pdf. [Google Scholar]

- 9.Abdul R.O., Isa H. Modeling of an integrated workstation environment for occupational safety and health application. In: Khalid H., Hedge A., Ahram T.Z., editors. Advances in ergonomics modeling and usability evaluation. CRC Press; Boca Raton, FL: 2010. pp. 503–512. [Google Scholar]

- 10.Isa H., Abdul R.O. Development of Prolonged Standing Strain Index to quantify risk levels of standing jobs. Int J Occup Saf Ergon. 2012;18:85–96. doi: 10.1080/10803548.2012.11076917. [DOI] [PubMed] [Google Scholar]

- 11.Turban E. 2nd ed. Macmillan; New York: 1990. Decision support and expert systems. Management support systems. [Google Scholar]

- 12.Halim I., Omar A.R., Saman A.M., Othman I., Ali M.A. Development of a questionnaire for prolonged standing jobs at manufacturing industry. In: Karwowski W., Salvendy G., editors. Advances in human factors, ergonomics, and safety in manufacturing and service industries. CRC Press; Boca Raton, FL: 2010. pp. 253–261. [Google Scholar]

- 13.Department of Safety and Health . 2005. Ministry of Human Resources, Malaysia. Code of practice on indoor air quality [Internet] [cited 2012 Jan 18]. Available from: http://www.dosh.gov.my/doshv2/phocadownload/CodeOfPractice/codeofpracticeonindoorairquality.pdf. [Google Scholar]

- 14.International Organization for Standardization (ISO) ISO; Geneva: 1997. Mechanical vibration and shock – evaluation of human exposure to whole-body vibration – part 1: general requirements. Standard No. ISO 2631-1:1997. [Google Scholar]

- 15.Harding J.A., Omar A.R., Popplewell K. Applications of QFD within a concurrent engineering environment. Int J Agile Manage Syst. 1999;1:88–98. [Google Scholar]

- 16.Abraham A. Rule-based expert systems. In: Sydenham P.H., Thorn R., editors. Handbook of measuring system design. Wiley; New York: 2005. pp. 909–919. [Google Scholar]

- 17.Lee T.-Z., Wu C.-H., Wei H.-H. KBSLUA: a knowledge-based system applied in river land use assessment. Expert Syst Appl. 2008;34:889–899. [Google Scholar]

- 18.Imriyas K. An expert system for strategic control of accidents and insurers' risks in building construction project. Expert Syst Appl. 2009;36:4021–4034. [Google Scholar]

- 19.Jimenez M.L., Santamaria J.M., Barchino R., Laita L., Laita L.M., Gonzalez L.A., Asenjo A. Knowledge representation for diagnosis of care problems through an expert system: model of the auto-care deficit situations. Expert Syst Appl. 2008;34:2847–2857. [Google Scholar]

- 20.Leman A.M., Omar A.R., Yusof M.Z.M. Monitoring of welding work environment in small and medium industries (SMIs) Int J Res Rev Appl Sci. 2010;5:18–26. [Google Scholar]

- 21.Rodgers S.H. A functional job analysis technique. Occup Med. 1992;7:679–711. [PubMed] [Google Scholar]

- 22.Morris A.H. Decision support and safety of clinical environments. Qual Saf Health Care. 2002;11:69–75. doi: 10.1136/qhc.11.1.69. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Lin J. An object-oriented development method for customer knowledge management information systems. Knowl-Based Syst. 2007;20:17–36. [Google Scholar]

- 24.Kayis B., Charoenchai N. Development of a knowledge-based system for non-powered hand tools (Tool Expert): Part I – the scientific basis. Hum Factors Ergon Manuf. 2004;14:257–268. [Google Scholar]

- 25.Moynihan G.P., Fonseca D.J., Meritt T.W., Ray P.S. An object-oriented system for ergonomic risk assessment. Expert Syst. 1995;12:149–156. [Google Scholar]

- 26.Aluclu I., Dalgic A., Toprak Z.F. A fuzzy logic-based model for noise control at industrial workplaces. Appl Ergon. 2008;39:368–378. doi: 10.1016/j.apergo.2007.08.005. [DOI] [PubMed] [Google Scholar]

- 27.Akay D., Akcayol M.A., Kurt M. NEFCLASS based extraction of fuzzy rules and classification of risks of low back disorders. Expert Syst Appl. 2008;35:2107–2112. [Google Scholar]

- 28.Azadeh A., Fam I.M., Khoshnoud M., Nikafrouz M. Design and implementation of a fuzzy expert system for performance assessment of an integrated health, safety, environment (HSE) and ergonomics system: the case of a gas refinery. Inf Sci (NY) 2008;178:4280–4300. [Google Scholar]

- 29.Gurcanli G.E., Mungen U. An occupational safety risk analysis method at construction sites using fuzzy sets. Int J Ind Ergon. 2009;39:371–387. [Google Scholar]

- 30.Liao S.-H. Expert system methodologies and applications – a decade review from 1995 to 2004. Expert Syst Appl. 2005;28:93–103. [Google Scholar]