Abstract

In view of the wider consumption of bakery products, they could be good choice for the delivery of functionality. The present study attempts to develop a functional formulation of bread by incorporation of shatavari (Asparagus racemosus Willd.), which is an important medicinal plant of India. Central composite rotatable design (CCRD) was used for experiments in which yeast and shatavari powder were taken as variables. Response surface methodology (RSM) was used to optimize the bread formulations on the basis of hardness, adhesiveness, springiness, chewiness and cohesiveness as responses. Qualitative tests were performed for assessing the presence of phytochemicals in shatavari bread. Sensory attributes of the shatavari bread were evaluated using descriptive analysis technique. The optimum acceptable level for shatavari and yeast in bread was found to be 3.5 % and 4.96 %, respectively. All the phytochemicals such as alkaloid, steroid, terpenoid and saponin present in original herbs were also present in bread. However flavonoids were not found in the bread when analysed qualitatively and using TLC.

Keywords: Bread, Shatavari, Sensory attributes, Response surface methodology, Thin layer chromatography

Introduction

Asparagus racemosus Willd. is an important medicinal plant of the Liliaceae family. It is a climbing plant which grows in low forests throughout India. Mostly the roots of this plant are used for medicinal purposes under popular local name as ‘Shatavari or Shatavar’. The roots of this plant contain steroidal saponins, the active constituents of shatavari, identified as Shatavarins I, II, III and IV (Ashajyothi et al. 2009). The roots are fleshy, whitish-brown in colour and slightly sweet in taste. The healing qualities of shatavari roots are useful for several types of ailments. Healing effect of the roots on the female reproductive system are well known. The plant is also found effective against certain other body ailments like nervous disorders, dyspepsia, throat infections, tuberculosis, cough bronchitis and for general debility and is therefore useful for both men and women (Bopana and Saxena 2007; Velavan et al. 2007). It also acts as a nutritive tonic and good source of folic acid that is vital for the growth of featus. Shatavai roots and their different extracts have shown demulcent, aphrodisiac, antiseptic, anti-cancer and antioxidant activity (Velavan et al. 2007; Hayes et al. 2008). Long term administration of powder or extracts of shatavari roots did not show any toxicity in animals (Goel et al. 2006).

Today consumers are becoming increasingly aware of the relationship between the diet and health. The knowledge of nutrition among the general population has led to the development of foods, meeting specific nutritional requirements for better immunity and health. One way to deliver a specific health benefit in a familiar manner is the incorporation of beneficial ingredients into existing food products. Thus, a conventional food could be transformed into a functional food with altered nutritional characteristics, but with unchanged sensory attributes. Bakery products could be considered to have a great potential to deliver functionality as they are widely consumed throughout the world. Worldwide demand for bakery products is increasing at the rate of 10.07 % per annum (Kamaljit et al. 2010). Among bakery products, bread is one of the most widely consumed foods in existence and is the one which has shown the most dynamic growth pattern in terms of volume over the last few years (Collar et al. 2007).

Given low profits on basic breads, many bakeries are working to differentiate and add value to their products. In Europe, breads and cakes with herbal incorporation like carrot pomace are available in the market (Upadhyay et al. 2008; Vassallo et al. 2009). Pearl millet incorporation in cake was studied by Singh et al. (2006) for fibre and functional benefits. The present study is an attempt to incorporate a popular Indian herb, shatavari, into the conventional bread recipe for added health benefits.

Materials and methods

Bread ingredients including wheat flour, sugar, salt, vegetable fat were purchased from the local market of Varanasi (Uttar Pradesh), India. Skimmed milk powder (SMP), dry-yeast (Make: Saf Yeast Co. Pvt. Ltd. India) and improver (Trade Name: Dough Bake, Make: Hindustan Organic Corporation, New Delhi, India) were purchased from a local bakery of Varanasi. Dried shatavari roots were purchased from a local herb dealer. Shatavari roots were broken into small pieces and exposed to 60 °C for 2 h before converting them into powder in a domestic mixer. Shatavari root powder (SRP) obtained as described above was passed through a 60 mesh screen and stored in air-tight containers for further use and analysis.

Base recipe and baking conditions

The procedure reported by Artan et al. (2010) was adopted for producing SRP incorporated bread with slight modification. Bread mix was prepared by adding 4.5 g sugar, 1.5 g salt, 2 g fat, 1 g improver, 1.5 g SMP in 100 g wheat flour. Varying quantities of SRP and yeast, per 100 g of the mix, were added. Few preliminary trials were performed to arrive at the central point values of SRP and yeast in the Central Composite Rotational Design (CCRD) used for the study. Dough was prepared manually by adding 57 ml of water per 100 g of the final mix and rested for 2 h for proper fermentation and knocked back for 2 to 3 times during fermentation. Dough (150 g) was placed in aluminium mould (15 × 7 × 6 cm3, internal measures) and proofing was done at 35 °C and 80 % relative humidity for 60 min. Baking was carried in an electrically heated baking oven (Make: Bent India Ltd., New Delhi; India, Temperature accuracy ±2 °C) at 200 °C for 25 min and prepared bread samples were allowed to cool at room temperature.

Experimental design

Response surface methodology (RSM) using CCRD (Myers 1971) was used in the experimental design by DESIGN EXPERT Software Version 8 (Stat-Ease, Inc USA). SRP (A) and yeast powder (B) incorporated per 100 g of the bread mix were taken as two independent variables for the experiments. A total of 13 experimental trials (T1 to T13) were carried out. SRP (A) and yeast powder (B) having levels of 3.5 % and 4 %, respectively, were taken as centre point of RSM design, on the basis of preliminary trials. Textural parameters viz. springiness, cohesiveness, adhesiveness, chewiness, and hardness were recorded as responses to study as a function of the independent variables. These values were recorded as an average of three observations. The experimental design is shown in Table 1 with the observed textural responses.

Table 1.

Instrumental textural quality of Shatavari root powder incorporated bread samples

| Trial | SRP (%) | Yeast (%) | Springiness | Cohesiveness | Adhesiveness(g s) | Chewiness (g) | Hardness (g) |

|---|---|---|---|---|---|---|---|

| T1* | 5.00 | 3.00 | 0.95 | 0.70 | 4068.7 | 3867.0 | 5792 |

| T 2 | 3.50 | 5.40 | 0.87 | 0.68 | 2493.0 | 2166.6 | 3645 |

| T 3 | 2.00 | 5.00 | 0.90 | 0.65 | 2023.4 | 2414.7 | 3684 |

| T 4* | 1.38 | 4.00 | 0.95 | 0.68 | 3442.0 | 3275.0 | 5072 |

| T 5* | 3.50 | 4.00 | 0.96 | 0.74 | 3677.6 | 3531.9 | 4956 |

| T 6* | 3.50 | 2.59 | 0.92 | 0.72 | 3624.2 | 3712.5 | 6779 |

| T 7* | 5.62 | 4.00 | 0.94 | 0.60 | 3471.0 | 3273.0 | 5785 |

| T 8* | 3.50 | 4.00 | 0.96 | 0.74 | 3677.6 | 3531.9 | 4956 |

| T 9* | 5.00 | 5.00 | 0.87 | 0.54 | 2910.5 | 2532.0 | 5380 |

| T 10* | 3.50 | 4.00 | 0.96 | 0.74 | 3677.6 | 3531.9 | 4956 |

| T 11* | 3.50 | 4.00 | 0.96 | 0.74 | 3677.6 | 3531.9 | 4956 |

| T 12* | 3.50 | 4.00 | 0.96 | 0.74 | 3677.6 | 3531.9 | 4956 |

| T 13* | 2.00 | 3.00 | 0.92 | 0.72 | 3245.2 | 2849.8 | 6779 |

| Average TPA for Market Bread (n = 4) (mean ± SE) | 0.94 ± 0.02 | 0.51 ± 0.06 | 2080.3 ± 31.6 | 1949.8 ± 22.7 | 4021 ± 48.2 | ||

* Non significant (P < 0.05) difference (F test) from the average texture quality of market bread samples

Statistical analysis

A second order polynomial equation was developed using the data by multiple regression procedure. This resulted in empirical models to study the combined effect of the two independent variables selected for the study. DESIGN EXPERT Software was also used for model statistics and optimization.

Texture profile analysis

The bread loaves were stored for 24 h in sealed polyethylene bag (350 μm) at 30 °C. A loaf was cut into slices of 25–27 mm thickness. Slices from the middle of the loaf were analyzed for hardness, cohesiveness, adhesiveness, springiness, and chewiness. A texture profile analyzer (TPA), TA.XT Plus (Make: Stable Micro Systems, UK) was used to perform a texture profile analysis on the crumb of baked bread. A test speed of 1.0 mm/s, return distance of 3.0 mm with contact force of 3.0 g and 40 % strain was used. An aluminium probe plate (75 mm diameter) was used for the test. Similar textural profile analysis was conducted for four market bread samples and an average was taken as control.

Sensory analysis

The quantitative descriptive analysis (QDA), method described by Curic et al. (2008) was used for the sensory profiling of SRP incorporated bread. Sensory evaluations were carried out in a uniform standard environment by an expert panel consisting of 15 members drawn from the Centre of Food Science and Technology at Banaras Hindu University, Varanasi, India. The members were asked to mark the intensity of attributes on the QDA scale, which consisted of a linear scale extended up to 15 cm, wherein 1.25 cm was anchored as low or detection threshold and 13.75 cm as high or saturation threshold. Panelists were asked to mark a vertical line on the sensory scale with the code of the sample close to the line. Maximum three samples were subjected to evaluation at a time. The panelists were explained definitions of the textural parameters given as under (Setser 1993):

Hardness: The force required to compress the material by a given amount indicating degree of force required at first bite by the molars to penetrate sample.

Cohesiveness: The strength of the internal bonds in the sample indicating masticatory analysis for degree to which mass holds together at the most extreme point during the mastication process.

Adhesiveness: The energy required to overcome attractive forces between the food and any surface it is in contact. For experimental bread it is with indicating analysis after compression between the tongue and palate to indicate degree to which the product adheres to the palate.

Springiness: It is the elastic recovery that occurs when the compressive force is removed. As sensory attribute it indicates analysis between thumb and forefinger: recovery speed and % of recovery as sample returns to original size and shape after partial compression between fingers. Degree of force used was less than that required to compress the bread beyond linear viscoelastic portion.

Chewiness: The energy required to chew a solid food into a state ready for swallowing. It indicates rubbery texture of bread during mastication.

Qualitative tests to check the presence of phytochemicals

Both alcoholic and aqueous extracts were prepared for assessing the presence of functional constituents of SRP in the experimental bread. A bread sample (50 g) was extracted with 100 ml of methanol for 5 h at 25 °C with frequent stirring and filtering through Whatman No.1 filter paper. The aqueous extract of each sample was also prepared at the same temperature by soaking 50 g sample in 100 ml of distilled water for 12 h. The extracts were filtered using Whatman filter paper No 42. Procedures described by Harborne (1998) in their studies were used for testing the qualitative presence of the tannin, alkaloid, flavonoid, steroid, terpenoid and saponin in SRP and bread samples.

Thin layer chromatography

The presence of steroids, alkaloids and saponins were further analyzed by thin layer chromatography (TLC) for confirmation. TLC of alcoholic extract on Silica Gel-G plate was performed. Tests for confirming the presence of these phytochemicals were done by the method suggested by Harborne (1998).

Results and discussion

Texture profile of SRP incorporated bread

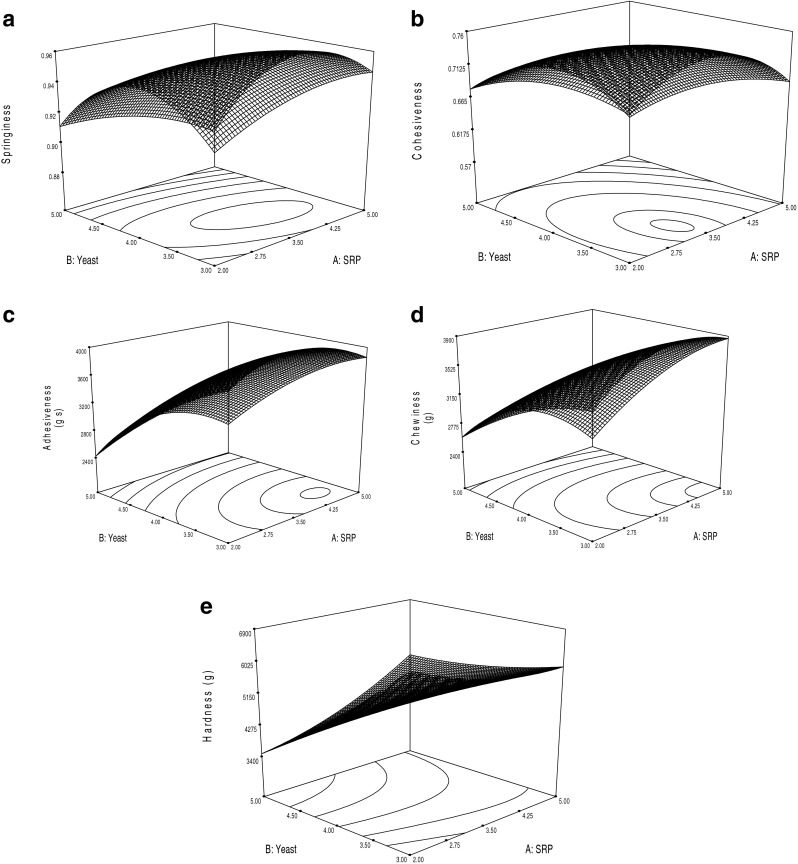

Textural properties of a bakery item are important for both the producers and consumers as texture affects the overall consumer acceptance (Jaworska and Hoffmann 2008). Bread, particularly its crust, has been studied extensively with the help of many instruments. Textural attributes like springiness, cohesiveness, and adhesiveness are obtained through sensory analysis or by texture analysis using texture profile analysis, with a correlation to ingredients (Carson and Sun 2001). The effects of SRP incorporation on texture profile of bread are shown in Table 1. Response surface plots for each of the textural parameters under study are presented as Fig. 1a to e.

Fig. 1.

Effect of the levels of Shatavari root powder and yeast on instrumental texture quality parameters of bread – a springiness b cohesiveness c adhesiveness d chewiness e hardness

As indicated in Table 1, textural attributes namely springiness, cohesiveness, adhesiveness, chewiness and hardness varied in the range of 0.87 to 0.96, 0.54 to 0.74, 2023.4 to 4068.7 g sec, 2166.6 to 3867.0 g and 3645 to 6779 g, respectively. The average TPA of market samples was observed with springiness, cohesiveness, adhesiveness, chewiness and hardness as 0.94, 0.51, 2080.3 g sec, 1949.8 g and 4021 g, respectively.

The addition of SRP in bread affected textural properties by increasing its crumb hardness, adhesiveness, chewiness, cohesiveness and by decreasing the springiness. Shatavari incorporation significantly (p < 0.05) affected TPA of experimental samples in comparison to the market average, except for trial 2 and 3. In these trials, SRP levels 2.0 and 3.5 % were used with yeast levels (5.00 and 5.40 %) above central point of design. The changes in the textural characteristics of bread were likely a result of dilution of wheat gluten, change in nature of starch and enrichment of fibre due to incorporation of SRP (Abdelghafor et al. 2011). The detrimental effects of increased hardness, deformation energy and gumminess on bread texture have been reported by Kaack et al. (2005) and were interpreted as being due to soluble non-starch polysaccharides, insoluble non-starch polysaccharides, cellulose and lignin. These components are also found in SRP. Quadratic models and response surface plots, generated from the TPA data, for textural attributes are discussed below.

Springiness

The second degree polynomial obtained by response surface analysis showing the effect of % SRP level (A) and % yeast (B) on springiness resulted in the following equation:

|

1 |

The model, shown as Eq. 1, was found statistically significant (p < 0.01) with F value as 56.04 and R2 value as 0.98. The response surface plot generated for springiness is shown in Fig. 1a, which shows that simultaneous rise in yeast and SRP levels resulted in an increase in springiness, initially. Both the process variables indicated interactive behaviour as seen from circular contour lines (Fig. 1a). Increasing the yeast level to a certain limit in bread recipe, gives higher specific volume, as excess fermentation of the dough may cause collapse of the bread and low springiness. The increase in springiness with SRP initially could be attributed to the presence of glucose in shatavari herb (Anon 2007), which may serve as food for the action of yeast. This could also be a reason to justify interactive effect of yeast and SRP.

Cohesiveness

The TPA data for cohesiveness fitted into a polynomial of second order and is shown as Eq. (2).

|

2 |

The R2 value for the model was 0.91 and F value (p < 0.01) was 13.45, which implied that the model was significant. Three dimensional response surface plot indicating the effect of SRP and yeast on cohesiveness is shown as Fig. 1b which indicated that there is an interative effect of SRP and yeast on cohesiveness of the bread.

Adhesiveness

Multiple regression model of adhessiveness versus SRP and yeast resulted in the following equation:

|

3 |

The model was significant (p < 0.01) with F value as 9.35 and R2 value of 0.87. For breads, adhesiveness indicates the degree to which the product adheres to the palate after compression between the tongue and the palate (Setser 1993). The response surface plot for adhesiveness as influenced by levels of SRP and yeast is shown in Fig. 1c. It can be seen that by increasing the level of yeast, there is a decrease in adhesiveness. However, there was an increase in adhesiveness with higher SRP levels. The levels of yeast were observed to have an important role in controlling adhesiveness in bread. When SRP was varied from 3 to 5 %, keeping yeast level constant at 5.00 %, adhesiveness varied from 2400 to 3200 g sec. However, maximum hardness in experimental samples was near 4000 g sec, as shown in Fig. 1c.

Chewiness

The data observed for chewiness fitted into a quadratic model given as Eq. (4). The model qualified the test for significance (p < 0.01) with F value as 17.84 and R2 as 0.93.

|

4 |

Slightly chewy crust is desirable in bread (Setser 1993). Figure 1d shows the response surface plot for chewiness as influenced by levels of SRP and yeast. Initially, an increase in yeast level from 3.00 to 4.20 %, increased the chewiness of bread. But for yeast levels above 4.20 %, there was a decrease in chewiness. However, by increasing the level of shatavari, chewiness increased from 2500 to 4000 g.

Hardness

Multiple regression analysis of hardness versus SRP and yeast yielded the following quadratic model:

|

5 |

The model was significant (p < 0.01) with R2 and F value as 0.99 and 110.95, respectively. The response surface plot for hardness, as influenced by level of SRP and yeast, is shown as Fig. 1e. It can be seen that by increasing the level of yeast, hardness of bread decreased. However by increasing the levels of SRP, there was increase in hardness of bread.

It can be inferred from the above findings that the addition of SRP in bread affected textural properties increasing crumb hardness, adhesiveness, chewiness, cohesiveness and decreasing the springiness. The observed differences were more evident when the levels of shatavari were above 4 % as seen in Table 1. Similar results were reported for addition of bran in bread by Collar et al. (2007) and Flander et al. (2007).

Sensory profile of shatavari bread

The average values of sensory scores, given by panel members on a 15 cm line score sensory card are shown in Table 2. The sensory profile of SRP incorporated bread indicated that scores for crust colour, crumb colour, surface texture, wheaty flavour and sweet flavour decreased in experimental samples while scores for denseness, dryness, graininess, yeasty flavour and bitterness were increased due to variation in SRP and yeast levels. For sensory evaluation, denseness and dryness in bread refers to compactness of the cross-section by hand and the amount of saliva absorbed by the sample during mastication, respectively. In view of the comments of the sensory panel, SRP addition up to 3.5 % was acceptable. This SRP level reported bitterness in sensory scores below 5.0. The lower yeast level was also a reason for variation in denseness and dryness as these attributes were scored higher in low yeast levels like in trials T6 and T13. Similarly, sensory attributes like crust colour and sweetness were adversely influenced by the amount of shatavari.

Table 2.

Sensory scores of Shatavari root powder incorporated bread samples on a 15 cm line score sensory card

| Sensory Characters | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | T10 | T11 | T12 | T13 | Market Bread |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crust Colour | 10.5 | 11.3 | 11.3 | 12.3 | 11.8 | 11.2 | 10.9 | 11.8 | 11.1 | 11.8 | 11.8 | 11.8 | 11.2 | 13.1 |

| Crumb Colour | 11.0 | 9.0 | 8.2 | 7.8 | 8.9 | 8.7 | 11.6 | 8.9 | 9.1 | 8.9 | 8.9 | 8.9 | 10.9 | 12.2 |

| Surface Texture | 11.2 | 10.1 | 8.5 | 9.5 | 8.5 | 10.7 | 11.4 | 8.5 | 9.1 | 8.5 | 8.5 | 8.5 | 10.7 | 12.1 |

| Denseness | 7.4 | 9.9 | 9.9 | 7.0 | 6.8 | 10.3 | 7.4 | 6.8 | 8.6 | 6.8 | 6.8 | 6.8 | 10.3 | 5.9 |

| Dryness | 5.8 | 7.5 | 7.5 | 4.6 | 5.8 | 7.5 | 5.8 | 5.8 | 6.4 | 5.8 | 5.8 | 5.8 | 7.5 | 5.5 |

| Graniness | 5.6 | 4.8 | 4.8 | 4.1 | 4.6 | 5.1 | 6.2 | 4.8 | 5.9 | 4.6 | 4.6 | 4.6 | 4.5 | 2.6 |

| Wheaty | 10.2 | 10.5 | 10.5 | 11.6 | 11.8 | 10.5 | 10.2 | 11.8 | 10.3 | 11.8 | 11.8 | 11.8 | 10.5 | 11.9 |

| Sweet | 8.0 | 9.6 | 9.6 | 10.9 | 10.0 | 9.5 | 8.0 | 10.0 | 6.9 | 10.0 | 10.0 | 10.0 | 9.5 | 11.1 |

| Yeasty | 10.1 | 10.6 | 10.6 | 9.8 | 8.9 | 10.0 | 10.1 | 8.9 | 9.3 | 8.9 | 8.9 | 8.9 | 10.0 | 8.5 |

| Bitterness | 7.5 | 4.5 | 3.1 | 2.5 | 4.9 | 4.3 | 8.0 | 4.9 | 7.2 | 4.9 | 4.9 | 4.9 | 4.2 | 1.5 |

Each value is mean of observations by 15 individual members of sensory panel

Qualitative analysis and TLC of SRP incorporated bread

Results obtained from qualitative analysis and chromatograpghical identifications are shown in Tables 3 and 4. The presence of non-nutritive but health protective phytochemicals - steroidal saponin, polycyclic alkaloid, isoflavones and flavonoids were reported in shatavari root by Ashajyothi et al. (2009). In the present study, all the native phytochemicals of SRP, except the flavonoids, were found present in the experimental bread samples at both the levels of shatavari i.e. 3 and 5 %. Absence of flavonoids may be attributed to their loss during baking. Heat loss of flavonoids is also reported by HsiaFen et al. (2000) in their study on flavonoid content and antioxidative activities of several vegetables. TLC results supported quantitative findings for the presence of alkaloids, steroids and saponins in the SRP enriched bread.

Table 3.

Presence of phytochemicals in Shatavari root powder incorporated bread samples

| Sample | Tannin | Alkaloid | Flavonoid | Steroid | Terpenoid | Saponin |

|---|---|---|---|---|---|---|

| SRP | – | + | + | + | + | + |

| Bread (SRP 3 %) | – | + | – | + | + | + |

| Bread (SRP 5 %) | – | + | – | + | + | + |

+ and – respectively indicating presence and absence of respective phytochemical

Table 4.

TLC profile for verification of the presence of phytochemicals in Shatavari root powder incorporated bread

| Sample | Alkaloid | Steroid | Saponin |

|---|---|---|---|

| SRP | + | + | + |

| Bread (SRP 3 %) | + | + | + |

| Bread (SRP 5 %) | + | + | + |

+ and – respectively indicating presence and absence of respective phytochemical

Optimization and conclusion

The process variables were optimized using the Design Expert software to obtain SRP-incorporated bread of good acceptability with enhanced functionality. For the higher acceptability of bread, minimum hardness and maximum springiness were given highest priority during the optimization process, while other textural attributes studied were kept at medium priority. As observed from the texture profile of market bread adhesiveness, chewiness and cohesiveness responses were targeted for minimum value. SRP incorporated in bread was found acceptable up to 3.5 % level both on the basis of the textural and sensory profile analysis. In qualitative analysis, SRP levels of 3 % and above showed the presence of phytochemicals in the bread sample. For harnessing the functional value of shatavari, three optimized solutions were worked out with SRP level above 3 % as shown in Table 5. For optimum sensory and functional attributes, solutions with SRP in the range of 3 to 3.5 % were found to be the best. This study is important from the point of view of incorporating functional attributes in bakery products for an enhanced nutritional role.

Table 5.

Optimized levels of Shatavari root powder and yeast

| SRP (%) | Yeast (%) | Springiness | Cohesiveness(g s) | Adhesiveness | Chewiness (g) | Hardness (g) | Desirability (%) |

|---|---|---|---|---|---|---|---|

| 3.00a | 5.00 | 0.91 | 0.69 | 2725.7 | 2701.6 | 3847.3 | 82 |

| 3.50a | 4.96 | 0.91 | 0.68 | 2873.9 | 2744.3 | 4144.1 | 78 |

| 4.55b | 4.75 | 0.91 | 0.64 | 3188.2 | 2863.8 | 4926.3 | 71 |

aOptimized for targeted value

bOptimized for maximum SRP incorporation

References

- Abdelghafor RF, Mustafa AI, Ibrahim AM, Krishnan PG. Quality of bread from composite flour of sorghum and hard white winter wheat. Adv J Food Sci Tech. 2011;3:9–15. [Google Scholar]

- Anon . The Ayurvedic Pharmacopia of India, Part I. 1. New Delhi: Dept of AYUSH, Ministry of Health and Family Welfare, GOI; 2007. [Google Scholar]

- Artan MY, Karim R, Chern BH, Arrifin AA, Man YC, Chin NL. The influence of different formulations of palm oil/palm stearin-based shortenings on the quality of white bread. Middle East J Sci Res. 2010;5:469–476. [Google Scholar]

- Ashajyothi V, Rao PS, Satyavati D. Asparagus Racemosus - A phytoestrogen. J Pharm Tech. 2009;1:36–47. [Google Scholar]

- Bopana N, Saxena S. Asparagus racemosus - Ethnopharmacological evaluation and conservation needs. J Ethnopharmacol. 2007;110:1–15. doi: 10.1016/j.jep.2007.01.001. [DOI] [PubMed] [Google Scholar]

- Carson L, Sun XS. Creep-recovery of bread and correlation to sensory measurements of textural attributes. Cereal Chem. 2001;78:101–104. doi: 10.1094/CCHEM.2001.78.1.101. [DOI] [Google Scholar]

- Collar C, Santos E, Rosell CM. Assessment of the rheological profile of fiber-enriched bread dough by response surface methodology. J Food Eng. 2007;78:820–826. doi: 10.1016/j.jfoodeng.2005.11.026. [DOI] [Google Scholar]

- Curic D, Novotni D, Skevin D, Rosell CM. Design of a quality index for the objective evaluation of bread quality: Application to wheat breads using selected bake off technology for bread making. Food Res Int. 2008;41:714–719. doi: 10.1016/j.foodres.2008.05.006. [DOI] [Google Scholar]

- Flander L, Salmenkallio-Marttila M, Suortti T, Autio K. Optimization of ingredients and baking process for improved wholemeal oat bread quality. Food Sci Tech. 2007;40:860–870. [Google Scholar]

- Goel RK, Prabha T, Kumar MM, Dorababu M. Tetratogenicity of Asperagus racemosus Willd. Root, aherbal medicine. Ind J Exp Bio. 2006;44:570–573. [PubMed] [Google Scholar]

- Harborne JB. Phytochemical methods: a guide to modern techniques of plant analysis. 3. New York: Chapman and Hall; 1998. [Google Scholar]

- Hayes PY, Jahidin AH, Reg L, Kerry P, William K, James DV. Steroidal saponins from the roots of Asparagus racemosus. Phytochem. 2008;69:796–804. doi: 10.1016/j.phytochem.2007.09.001. [DOI] [PubMed] [Google Scholar]

- HsiaFen H, ChaoLin C, YanHwa C. Flavonoid contents and antioxidative activities of several vegetables. Taiwan J Agr Chem Food Sci. 2000;38:377–387. [Google Scholar]

- Jaworska D, Hoffmann M. Relative importance of texture properties in the sensory quality and acceptance of commercial crispy products. J Sci Food Agr. 2008;88(10):1804–1812. doi: 10.1002/jsfa.3283. [DOI] [Google Scholar]

- Kaack K, Pedersen L, Laerke HN, Meyer A. New potato fibre for improvement of texture and colour of wheat bread. Eur Food Res Tech. 2005;224:199–207. doi: 10.1007/s00217-006-0301-5. [DOI] [Google Scholar]

- Kamaljit K, Baljeet S, Amarjeet K. Preparation of bakery products by incorporating pea flour as a functional ingredient. Am J Food Technol. 2010;5:130–135. doi: 10.3923/ajft.2010.130.135. [DOI] [Google Scholar]

- Myers RH. Response surface methodology. Boston, MA: Allyn and Bacon; 1971. pp. 1–2. [Google Scholar]

- Setser CS. Sensory evaluation. In: Kamel BS, Stauffer CE, editors. Advances in baking technology. Glasgow, UK: Blackie Academic & Professional; 1993. pp. 254–291. [Google Scholar]

- Singh GS, Sehgal, Kawatra A. Sensory and nutritional evaluation of cake developed from balanced and malted pearl millet. J Food Sci Technol. 2006;43(5):505–508. [Google Scholar]

- Upadhyay A, Sharma HK, Sarkar BC. Characterization and dehydration kinetics of carrot pomace. Agr Eng Int - CIGR Ejournal. 2008;10:1–9. [Google Scholar]

- Vassallo M, Saba A, Arvola A, Dean M, Messina F, Winkelmann M, Claupein E, Lahteenmaki L, Shepherd R. Willingness to use functional breads: applying the health belief model across four European countries. Appetite. 2009;52:452–460. doi: 10.1016/j.appet.2008.12.008. [DOI] [PubMed] [Google Scholar]

- Velavan S, Nagulendran K, Mahesh HB. In vitro antioxidant activity of Asparagus racenosus root. Pharmaco Map. 2007;3:26–33. [Google Scholar]