Abstract

Pulses (pea, chickpea, lentil, bean) are an important source of food proteins. They contain high amounts of lysine, leucine, aspartic acid, glutamic acid and arginine and provide well balanced essential amino acid profiles when consumed with cereals. The influence of partial substitution of wheat flour with chickpea flour at the levels of 10, 20 and 30 % was carried out to study their pasting properties and bread making quality. Pasting properties were determined using Micro Visco-Amylo-Graph Analyser and Farinograph. The pasting temperature increased with increase chickpea flour concentration and the temperature of pasting ranged between 62 to 66.5 °C. No peak of viscosity curve was found for pure chickpea flour and have higher pasting temperature than pure wheat flour. Chickpea flour addition increased the water absorption and dough development time (p < 0.05), Regarding dough stability, it appears that 10 % chickpea exhibited higher stability and resistance to mechanical mixing values than the control, while it decreased as the substitute level increases from 20 % to 30 %. The dough surface of the wheat dough and the blend with 10 % was classified as “normal”, however the blend with 20 % and 30 % produced “sticky” dough surface. The presence of chickpea flour in dough affected bread quality in terms of volume, internal structure and texture. The color of crust and crumb got progressively darker as the level of chickpea flour substitution increased. While the substitution of wheat flour with 10 % chickpea flour gave loaves as similar as control.

Keyword: Chickpea flour, Wheat pasting properties, Bread quality, Sensory evaluation

Introduction

The supplementation of wheat flour with chickpea flour would greatly improve the protein nutritional quality of bread. This high protein content in the chickpea supplemented breads would be of nutritional importance in most developing countries, such as Africa and Asia, where many people can hardly afford high portentous foods because of their expensive costs. Chickpea cultivars are broadly divided into two groups, desi and kabuli. Kabuli seeds are large and light colored beans, and are characterized by their larger size, ram-head shape and low fibre content (Singh et al. 1991). The seeds of desi cultivars are small, wrinkled at beak, with brown, black or green color.

The influence of additives of non bakery crops on the pasting behavior is related mainly to their different (in comparison to wheat) starch and protein complex. The addition of legumes to wheat flour delays the pasting temperature and deteriorates the baking properties of bread. The unique bread making properties of wheat flour can be attributed mainly to the ability of its gluten proteins to form a viscoelastic network when mixed with water. The reduction of viscoelastic properties of wheat flour dough, after substitution by legume flour, reduces bread making potential. Knorr and Betschart (1978) suggested that the weakening effect of foreign proteins on wheat flour dough’s was the result of a dilution of the gluten structure by the added protein. The farinograph is one of the most widely used recording dough mixers. The two Z-shaped blades of the farinograph mixer rotate at constant speeds and subject the dough to mixing at constant temperature. The farinogram generated from testing a flour are analyzed to obtain quantitative information on arrival time (time required for the top of the curve to cross the 500 Brabender Unit (BU) line), peak time (time required for dough to reach maximum consistency without breakdown), departure time or time to breakdown (time lapsed until the top of the curve permanently drops below the 500 BU line), stability (time difference between arrival time and departure time), mixing tolerance index (MTI, the difference in BU’s between the peak time and peak time plus 5 min), and water absorption. Farinograph is commonly used for determining the water absorption of flour, especially in industrial settings (Mondal and Datta 2008).

Full understanding of the rheological behavior of flour dough is of great importance from the practical point of view. Dough rheology directly affects the baking performance of flours, and rheological analyses have been made in order to optimize dough formulation. Although dough rheology has long been investigated, there remains a significant lack of understanding. This lacks of progress is due to the complexity of this biological system (Masi et al. 2001). Therefore, the aim of this study was undertaken to determine the pasting behavior and backing characteristics of wheat flour enrichment chickpea flour. This could be utilized for the development of composite blends from locally produced chickpea at small scale industry level as value-add products.

Materials and methods

Raw materials

Chickpea seeds (Cicer arietinum L) variant kabule was bought from local market in Berlin, Germany. Chickpea flours were obtained after grinding chickpea grains in a laboratory hammer mill (Retsch—Germany) until they could pass through a 1.0 mm screen. Commercial wheat flour type 405 was obtained from Lidl Market (Berlin—Germany).

Chemical analysis

Proximate composition was carried out according to ICC Standard Methods (ICC 2001). Moisture content was determined by drying the samples at 105 °C to constant weight (ICC 109/01). Ash content was determined by calcinations at 900 °C (ICC 104/1). Nitrogen content was determined by using Kieldahl method with factor of 5.7 to determine protein content (ICC 105/2). The total lipid content was determined by defeating in the soxhelt apparatus with hexane (ICC 136). The determination of starch content was assessed using a polarimetric method according to Ewers, modified by (Davidek et al. 1981). All the measurements of analyzed samples were made in triplicate.

Doughs preparation

Five blends were prepared by mixing the wheat flour with chickpea flours in the proportions of 100:0, 90:10, 80:20, 70:30 and 0:100 (wheat : chickpea w/w) using a mixer with a spiral blade, which is usually used for dough mixing. The doughs were prepared by mixing different blends with 62 % water for 5 min in a mixer at 25 °C. Immediately after mixing, dough was transferred to the measuring system.

Evaluation of dough properties

The dough mixing and pasting properties of the different wheat /chickpea flour blends were studied using Micro Visco-Amylo-graph and Farinograph (Brabender, Duisburg, Germany). Pasting characteristics were determined according to ICC standard method Nr.169. Flour 12 g was suspended in 92 ml distilled water. The flour-water suspension were equilibrated at 30 °C for 1 min., heated from 30 °C to 95 °C in a rotating bowl and stirred at 115 min−1 at heating rate of 3 °C/min and then held at 95 °C for 15 min and cooled down again to 30 °C at 3 °C/min, held at 30 °C for 1 min. Total running time of the pasting process was 60 min. The micro visco-amylo-graph measures beginning of gelatinization, gelatinization maximum, gelatinization temperature, viscosity during holding and viscosity at the end of cooling. The viscosity was expressed in Brabender Units (BU). The Farinograph measurements were conducted according to the constant flour weight procedure of ICC method 115/1 and all measurements was made at room temperature (25 °C). From the Farinograph curves, water absorption (percentage of water required to yield dough consistency of 500 BU), dough development time (DDT, time to reach maximum consistency), stability (time during dough consistency is at 500 BU) and elasticity (band width of the curve at the maximum consistency), degree of softening (difference (in BU) between the line of the consistency and the medium line of the torque curve 12 min after development time) and finally farinograph quality number (F.q.n) (the point of the curve in which the curve has decreased by 30 BU after the maximum based on middle line of the diagram), were determined.

Baking test

Breads were prepared according to ICC-Standard Nr.131 as follows: 500 g (wheat flour or wheat flour substituted with 10, 20 or 30 % chickpea flour), were first dry-mixed in the mixer bowl for 1 min Next, 1 % sugar, 1.2 salt %, 3 % fresh compressed yeast, previously dissolved in water, were added followed by the addition of water up to 500 BU consistency and the dough kneading process was continued for a total of 5 min and placed in baking pans then a proofing cabinet at 30 °C 75–80 % relative humidity. After 45 min fermentation, the dough was punched down to remove gases, proofed for further 45 min and baked at 240 °C for 30 min. During baking, some water was vaporized in the oven to avoid any extreme dryness of the bread crust. Each baking test was conducted in triplicate.

Sensory evaluation

Evaluation of the baked loaves quality characteristics was carried out following cooling to room temperature for 2 h. Sensory evaluation was performed by 10 trained panelists who were graduate students and staff members of the Department of Rheology, Institute of Food Technology and Food Chemistry, Technical University, Berlin. Loaves were randomly assigned to each panelist. The panelists were asked to evaluate each loaf for appearance, crumb texture, crumb grain, crust color, taste, odor and overall acceptability. A 10 point scale was used where 10″excellent and 1″extremely unsatisfactory.

Statistical analysis

Analysis of variance (ANOVA) was carried out using SAS program (Statistical Analysis System version. 9.1) SAS Institute Inc. (Inc 2004). The rheological properties and bread characteristics of wheat dough with or without chickpea were analysed using ANOVA. When the treatment factor effect was found significant, indicated by a significant F-test (p < 0.05), differences between the respective means were determined using least significant difference (LSD) and considered significant when p < 0.05. Mean ± standard deviation of three replicates were used.

Results and discussion

Chemical composition of wheat and chickpea flours

The proximate composition varied among wheat flour as well as chickpea raw flour. Protein, fat and ash contents in chickpea raw flour (25.5 ± 1.05, 5.0 ± 0.18, and 2.8 ± 0.07 g/100 g respectively) were higher than that recorded in wheat flour (11.9 ± 0.56, 1.8 ± 0.32, and 0.40 ± 0.03 g/100 g respectively). However, starch was detected in wheat flour (63.5 ± 0.61 g/100 g) at higher level than that found in chickpea raw flour (51.2 ± 0.26 g/100 g). These results confirmed by statistical analysis, which highly significant differences (p < 0.05) were observed between the two type of flours.

Effect of chickpea incorporation on the pasting properties of wheat flour

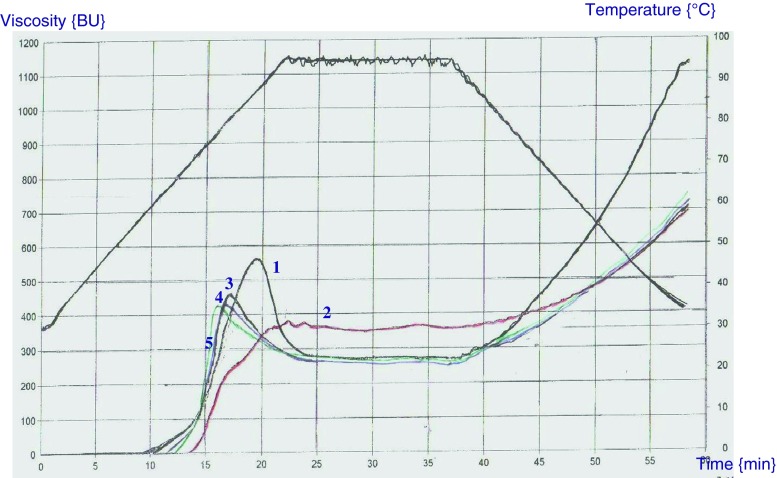

Pasting properties of chickpea, cowpea and yellow pea starches were influenced by granule swelling, as pointed out by (Ratnayake et al. 2001). It has been speculated that high contents of other components, especially fat and protein, influence the swelling power and pasting properties of starches (Schoch and Maywald 1968). The pasting properties of wheat flour suspension with or without addition of chickpea were studied. The pasting temperature was found to increase with addition of chickpea, but decrease peak viscosity and peak viscosity temperature (Fig. 1). These results similar to (Hamaker and Griffin 1993; Yang and Chang 1999) who indicated that proteins in rice flour restrict starch granules swelling and reduce the viscosity. Another possible reason, the higher lipid content (about 5 %) of chickpea flour leads to a decrease in the viscosity function through the formation of lipid-amylose complexes (Wood 2004). The high pasting temperature may be due to the higher resistance to swelling and rupture of chickpea starch (Singh et al. 2004) and its high content of protein. Most legume starches have been reported to exhibit type C (restricted swelling) viscosity pattern (Hoover and Ratnayake 2002; Schoch and Maywald 1968).

Fig. 1.

Pasting curves of wheat flour (WF), chickpea flour (CF) and their blends. (1) 100 % WF; (2) 100 % CF, (3) 10 % CF, (4) 20 % CF, (5) 30 % CF

No peak of viscosity curve was found for pure chickpea flour and has higher pasting temperature than pure wheat flour. The temperature of pasting of wheat–chickpea blends ranged between 62 to 66.5 °C more than the wheat flour 60.8 °C and lower than the chickpea flour 72 °C. Zeleznak and Hoseney (1987) reported that the gelatinization temperature obtained was considerably higher than for wheat starch 55.6 to 63.0 °C, chickpea 63.5 to 69.0 °C and horse bean 61.0 to 70.0 °C starches. Table 1 showed that drastic decrease in final pasta viscosities at 30 °C for wheat–chickpea blends than the control. These results was in agreement with (Balasubramanian et al. 2011) who reported that there was a decreasing trend in degree of gelatinization with increase in legume incorporation level. All the samples showed gradual increase in viscosity up to the end of cooling time. Miles et al. (1985) reported that increase in final viscosity might be due to the aggregation of the amylose molecules.

Table 1.

Pasting properties of wheat flour (WF), chickpea flour (CF) and their blends

| WF:CF (%) | Beginning of pasting phase | Peak or maximum viscosity | Viscosity at beginning the cooling phase (BE) | Final viscosity at 30 °C (BE) | ||

|---|---|---|---|---|---|---|

| Time (min) | Temperature (°C) | Viscosity (BE) | Temperature (°C) | |||

| 100:0 | 10.2 ± 0.11a | 60.8 ± 0.32a | 560 ± 24a | 88.3 ± 1.25a | 267 ± 2a | 1132 ± 33a |

| 0:100 | 10.5 ± 0.09a | 62.0 ± 0.10ab | 468 ± 32b | 80.9 ± 2.01ab | 264 ± 6a | 724 ± 45bc |

| 90:10 | 11.4 ± 0.43ab | 64.6 ± 0.28b | 444 ± 26c | 80.0 ± 1.09ab | 283 ± 3b | 705 ± 25c |

| 80:20 | 12.2 ± 0.59c | 66.5 ± 1.12c | 466 ± 19b | 79.6 ± 0.89ab | 297 ± 5bc | 758 ± 34b |

| 70:30 | 14.0 ± 0.21d | 72.0 ± 1.23d | 379 ± 27d | 95.2 ± 1.45c | 356 ± 8ab | 694 ± 18d |

Mean ± standard deviation of three replicates. Means in the same column with different letters are significantly different (p < 0.05)

WF: Wheat Flour

CF: Chickpea Flour

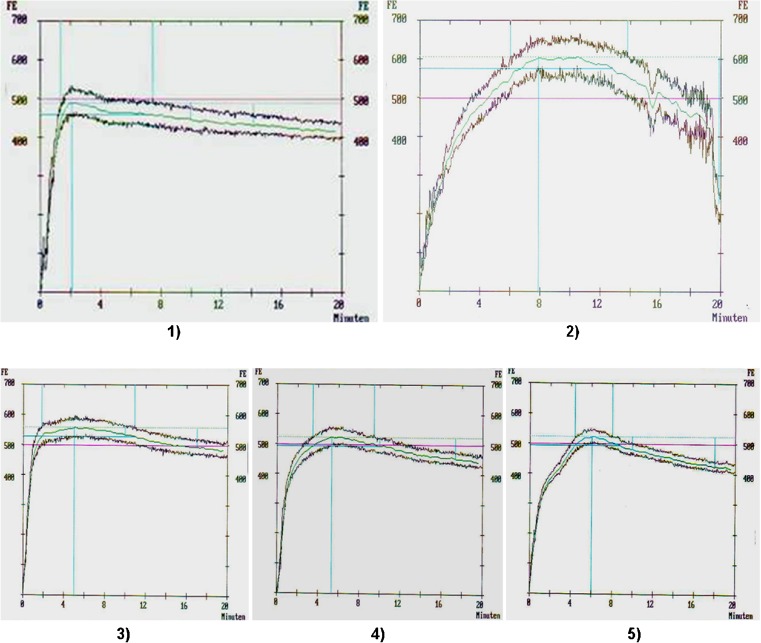

Effect of chickpea incorporation on dough mixing properties

The addition of chickpea to wheat flour brought about some significant changes in its dough mixing behavior as measured by the farinograph (Fig. 2). Farinograph data of wheat flour (control) and those of the substituted with chickpea, at a 10, 20 or 30 % level, are shown in Table 2. Substituting wheat flour with chickpea flour increased the water required for optimum bread making absorption (p < 0.05) (from 58.8 % for wheat flour to 62.5 % for the 30 % chickpea flour). Water absorption increased with increasing amount of chickpea flour added. Similar result was also reported by Dodok et al. (1993) who reported that replacement of wheat flour by 20 % chickpea flour increased water absorption about 2 %. However, in an earlier study, Yousseff et al. (1976) found that substitution of wheat flour with (5 %) chickpea flour resulted in a 1 % reduction in water absorption on average. The increased water absorption was attributed to increased total protein and pentosan content, especially ribose and deoxyribose (non-starch polysaccharides) as soon as the reduction in the proportion of insoluble protein fractions (via chickpea flour addition) of the composite flour. (Anton et al. 2008; Collar et al. 2007; Fernandez and Berry 1989; Narpinder et al. 1991; Sathe et al. 1981; Shahzadi et al. 2005).

Fig. 2.

Farinogram of wheat flour (WF), chickpea flour (CF) and their blends. (1) 100 % WF; (2) 100 % CF, (3) 10 % CF, (4) 20 % CF, (5) 30 % CF

Table 2.

Farinogram characteristics of wheat flour (WF), chickpea flour (CF) and their blends

| WF:CF (%) | Dough consistency (BU) | Water absorption (%) | Development time (min) | Stability (min) | Degree of softening (BU) | F.q.n |

|---|---|---|---|---|---|---|

| 100:0 | 491 ± 4.58a | 58.8 ± 0.13a | 2.1 ± 0.23a | 6.1 ± 0.43a | 44 ± 3.12a | 69 ± 2.27a |

| 0:100 | 608 ± 5.56d | 63.2 ± 0.18d | 7.9 ± 0.27d | 7.8 ± 0.86d | 2 ± 0.36d | 128 ± 3.61d |

| 90:10 | 559 ± 3.61bc | 59.9 ± 0.08ab | 5.0 ± 0.12b | 9.1 ± 1.22b | 24 ± 1.05c | 109 ± 4.36c |

| 80:20 | 530 ± 2.65ab | 61.0 ± 0.17ab | 5.3 ± 0.32b | 6.0 ± 0.09a | 30 ± 1.17b | 98 ± 1.05bc |

| 70:30 | 528 ± 6.56ab | 62.5 ± 0.10bc | 6.0 ± 0.26c | 3.6 ± 0.46c | 42 ± 1.61a | 87 ± 2.65b |

Mean ± standard deviation of three replicates. Means in the same column with different letters are significantly different (p < 0.05)

WF: Wheat Flour

CF: Chickpea Flour

F.q.n: Farinograph quality number

An increase in water absorption, following incorporation of various vegetable protein concentrates or isolates to wheat flour, has also been reported by other researchers who attributed the water absorbing capacity of these protein preparations to their ability to compete for water with other constituents in the dough system. According to these authors the ability of these proteins to absorb high quantities of water results in doughs which exhibit increased farinograph water absorption values (Dervas et al. 1999; Doxastakis et al. 2002; El-Adawy 1997; El-Soukkary 2001). The quantity of added water is considered to be very important for the distribution of the dough materials, their hydration and the gluten protein network development.

The time required for the control dough to reach 500 BU consistency was also modified by chickpea addition. During this phase of mixing, the water hydrates the flour components and the dough is developed. Dough development time (DDT) was significantly higher (p < 0.05) for all wheat-chickpea blends than control (2.1 min), while between chickpea samples no significant difference was observed at different concentration (p > 0.05) (Table 2). The increase in dough development time resulting from chickpea addition could have been due to the differences in the physicochemical properties between the constituents of the chickpea and those of the wheat flour, as has been previously reported by Dodok et al. (1993) who studied the incorporation of chickpea flour in wheat flour.

Regarding dough stability, it appears that the dough sample containing 10 % chickpea exhibited higher stability and resistance to mechanical mixing values than the control, while it decreased as the substitute level increases from 20 % to 30 %. In general, the stability value is an index of the dough strength, with higher values indicating stronger dough. The increase in the stability time was related to the amount of substitution. Thus, stability times of 6.0 and 3.6 min are observed for the dough supplemented with 20 and 30 % chickpea, respectively.

Dough softening degree increased significantly with increasing amount of chickpea flour in blends. Similar changes in dough characteristics on blending with cowpea flour and chickpea flour were observed by (Fernandez and Berry 1989; Mustafa et al. 1986; Sharma et al. 1999). As the chickpea flour concentration in blends increased, the farinograph quality number F.q.n steadily decreased. Strong flours are characterized by a long development time, high stability with a small degree of softening, and high F.q.n; while poor flours weaken quickly, resulting in low quality number F.q.n. Up to 10 % chickpea flour incorporation, the flour became stronger with high stability and higher F.q.n. The changes in dough characteristics upon addition of chickpea flour may be attributed to dilution of gluten-forming proteins causing weakening of dough’s (Belitz et al. 1986). Variation in hydration behavior of two proteins may be another reason for differences in dough characteristics.

In general, the increasing of the dough development time from 2.1 min for wheat flour dough to 6 min for 30 % chickpea flour and the reduction of dough stability to 3.6 min demonstrated to weakening of the gluten network configuration during the kneading. This is attributed to an intense incompatibility between the protein spectrum of chickpea and wheat gluten protein. It is assumed that the increasing of chickpeas in blend-flours, the requirements energy for the optimal development of dough consistency increased, which lead to increased mechanical agitation requirement of non-gluten proteins in the dough system through the chickpea proportion. This conclusion is consistent with the results of studies by Roccia et al. (2009) who found that the substitution of wheat protein by soy protein decreased mixture elasticity, indicating dough network weakening. One other reason for the weakening of dough strength resulting from vegetable protein addition could stem from the fact that the substitution of gluten proteins by the non-gluten-forming vegetable proteins causes a dilution effect and consequently weakens the dough. Despite of the higher glutenin content of the chickpea about 18.1 %, addition of chickpea lead to a weakening of the gluten network. This confirms the data from literature that the both protein fractions (gliadin and glutenin) must be present for optimal gluten network development in a specific ratio.

Influence of chickpea incorporation on bread properties

Dough handling was not affected at low levels up to 20 % supplementation, but more than 20 % level of chickpea flour supplementation, the dough became sticky and was difficult to process. The dough surface of the wheat dough and the blend with 10 % was classified as “normal” to “still normal”. The blend with 20 % and 30 % were described as “something sticky” and “sticky” (Fig. 3).

Fig. 3.

Dough surface characteristics containing different levels of chickpea (CF). (1) 100 % wheat flour (WF); (2) 90 % WF and 10 % CF; (3) 80 % WF and 20 % CF; (4) 70 % WF and 30 % CF

The effect of the chickpea incorporation on the fresh bread characteristics is summarized in Tables 3, 4. The volume of the control bread sample was significantly higher than that of samples incorporating chickpea (p < 0.05). As the level of chickpea supplementation increased (10 to 30 %), the loaf volume of the corresponding fortified breads gradually decreased. Dervas et al. (1999) and Doxastakis et al. (2002) also reported a decrease in bread volume with increasing levels of lupine or soy flour and attributed this decrease to the dilution of the wheat gluten by the legume protein.

Table 3.

Loaf characteristics of wheat flour and chickpea - wheat composite flours

| WF:CF (%) | Baking loss (%) | Loaf height (cm) | Loaf weight (g) | Loaf volume (cm³) | Specific volume (cm³/g) |

|---|---|---|---|---|---|

| 100 : 0 | 16.7 ± 0.48a | 12.0 ± 0.74a | 338.4 ± 24.3a | 1520 ± 48a | 4.49 ± 0.40a |

| 90 : 10 | 16.0 ± 0.42a | 11.8 ± 0.13a | 341.2 ± 15.5a | 1380 ± 64ab | 4.04 ± 0.51ab |

| 80 : 20 | 15.8 ± 0.40ab | 11.0 ± 0.91ab | 339.8 ± 5.4a | 1310 ± 75ab | 3.86 ± 0.21b |

| 70 : 30 | 14.9 ± 0.36b | 9.5 ± 0.58b | 339.5 ± 12.6a | 1090 ± 36b | 3.21 ± 0.13c |

Mean ± standard deviation of three replicates. Means in the same column with different letters are significantly different (p < 0.05)

WF: Wheat Flour

CF: Chickpea Flour

Table 4.

Sensory evaluation of control bread and bread from wheat–chickpea composite flours

| WF:CF (%) | Appearance | Crumb texture | Crumb grain | Crust color | Taste | Odor | Overall acceptability |

|---|---|---|---|---|---|---|---|

| 100 : 0 | 9.0 ± 0.56a | 9.0 ± 0.52a | 9.3 ± 0.56a | 9.3 ± 0.56a | 9.1 ± 0.53a | 8.9 ± 0.55a | 9.0 ± 0.56a |

| 90 : 10 | 8.5 ± 0.46a | 8.6 ± 0.75a | 8.3 ± 0.36a | 8.5 ± 0.62a | 8.4 ± 0.09a | 8.0 ± 0.78ab | 8.4 ± 0.84a |

| 80 : 20 | 6.7 ± 0.34b | 6.2 ± 0.62b | 6.5 ± 0.70b | 6.1 ± 0.72b | 6.0 ± 0.75b | 7.1 ± 1.04b | 6.3 ± 0.59b |

| 70 : 30 | 4.3 ± 0.64c | 4.1 ± 0.53c | 4.0 ± 1.55c | 2.5 ± 0.46c | 2.4 ± 1.45c | 3.2 ± 0.49c | 3.9 ± 0.77c |

Mean ± standard deviation of ten panelists. Means in the same column with different letters are significantly different (p < 0.05)

WF: Wheat Flour

CF: Chickpea Flour

The decrease in bread volume is also consistent with the findings of El-Adawy (1997) who worked with sesame seed protein preparations and reported that sesame protein isolate incorporation provided loaves with a lower specific volume, the extent of reduction depending on the substitution level. It appears, therefore, that the decrease in bread volume resulting from chickpea addition is most likely due to the combined effects of gluten dilution and mechanical disruption of the gluten network structure by the chickpea particles.

It can also be hypothesized that the chickpea flour suppress the amount of steam generated, as a result of their high water absorption capacity, leading thus to reduced loaf volume and greater crumb firmness. Skendi et al. (2010) observed that inclusion of b-glucan in wheat flour was accompanied by a decrease in loaf specific volume, the extent of decrease depending on b-glucan level. In addition, examination of the loaf internal structure revealed that the crumb of the chickpe-containing bread contained a greater number of gas cells compared to the control (Fig. 4).

Fig. 4.

Loaf volume, crust color and crumb structure of breads containing different levels of chickpea (CF). (1) 100 % wheat Flour (WF); (2) 90 % WF and 10 % CF; (3) 80 % WF and 20 % CF; (4) 70 % WF and 30 % CF

Concerning baking losses, as can be observed in Table 3 the water retention capacity was to some extent enhanced by the incorporation of chickpea in wheat flour bread formulations. Additionally, chickpea-enriched breads had slightly higher moisture content than the control due to a higher water addition during bread making (higher farinographic absorption) and capacity of chickpea protein to retain more water than gluten. The control bread exhibited good crumb structure than the chickpea-enriched breads, indicating that chickpea addition exhibited a more resistant to deformation crumb (Fig. 4). This behavior is reasonable considering that the control sample was prepared with wheat flour only that resulted in a stronger and more organized gluten network, due to its higher content of the gluten proteins. Chickpea addition brought a marked increase in crumb hardness probably as a result of the thickening of the crumb walls surrounding the air cells and the strengthening of the crumb structure by the protein particles.

The color of crust and crumb got progressively darker as the level of chickpea flour substitution increased. The darkening of bread containing chickpea might have been attributed to an increased Maillard reaction taking place during baking due to higher lysine content. In the Maillard reaction reducing carbohydrates react with free amino acid side chain of protein mainly lysine and lead to amino acid-sugar reaction products (polymerized protein and brown pigments). This reaction may compromise the nutritional value of foods through the blocking and destruction of essential amino nutrients (Hurrell 1990). Color of wheat flour bread was light brown which increased significantly upon increasing the level of substitution. Typical loaves are obtained with substitution of wheat flour by chickpea flour at 10 % levels (Fig. 4).

Most people who have tried bread from chickpea-wheat flour mixes have found the texture, taste and frequently the color to be appealing. Substitution of chickpea flour at 10, 20 or 30 % leads to reduced bread making potential degree of reduction depends on the substituent level. However, substitution up to 20 % chickpea flour gives parameter values at least as good as the control sample and produces acceptable bread in terms of weight, volume, crumb structure and color. This result is similar to Yadav et al. (2011) who reported that the sensory properties of biscuits prepared by replacing refined wheat flour up to 20 % each with plantain and chickpea flour were more or less similar to those of control biscuits. The blend with more than 20 % shows a substantial decrease in all values measured. There appears to be a potential market for chickpea flour in bread making.

Conclusion

In conclusion, it appears that the addition of chickpea flour to wheat flour modified the rheological and pasting properties of the dough (creates dough with lower strength and inextensible texture) as well as the characteristics of the produced bread. The addition of chickpea increased the pasting temperature, but decreased the peak viscosity and peak viscosity temperature. No peak of viscosity curve was found for pure chickpea flour and has higher pasting temperature than pure wheat flour. The temperature of pasting of wheat–chickpea blends ranged between 62 to 66.5 °C more than the wheat flour 60.8 °C and lower than the chickpea flour 72 °C. An increase in the farinograph water absorption of the dough was observed in the case of chickpea addition, presumably due to greater water requirement of its proteins in order to become hydrated. The chickpea addition increased the dough development time and stability. This was attributed mainly to chickpea particle entrapment within the gluten network structure as well as to possible association between the gluten and some of the chickpea proteins present possibly in the outer surface of the hydrated particles. Results showed that substituting wheat flour with chickpea flour at level of 10 to > 20 % produced dough with better properties almost similar to the wheat flour dough. Baking tests showed that chickpea addition with more than 20 % significantly impaired the volume, internal structure and texture of the breads. The reason is that these factors attributed primarily to the gluten fraction, which was diluted by the addition of chickpea protein. The bread had a strongly brown color, a hard crust, and was unacceptable to consumers. Supplementing wheat-bread with chickpea at 10 to less than 20 % flour also was acceptable. Development of such functional foods would be beneficial to improve the nutritional status of consumer.

References

- Anton AA, Ross KA, Lukow OM, Fulcher RG, Arntfield SD. Influence of added bean flour (Phaseolus vulgaris L.) on some physical and nutritional properties of wheat flour tortillas. Food Chem. 2008;109(1):33–41. doi: 10.1016/j.foodchem.2007.12.005. [DOI] [PubMed] [Google Scholar]

- Balasubramanian S, Borah A, Singh K, Patil R (2011) Rheological and nutritional quality of selected dehulled legumes blended rice extrudates. J Food Sci Tech 1–6. doi:10.1007/s13197-010-0206-y [DOI] [PMC free article] [PubMed]

- Belitz DH, Kieffer R, Seilmeier W, Wieser H. Structure and Function of Gluten Proteins. Cereal Chem. 1986;63:336–341. [Google Scholar]

- Collar C, Santos E, Rosell MC. Assessment of the rheological profile of fibre-enriched bread doughs by response surface methodology. J Food Eng. 2007;78(3):820–826. doi: 10.1016/j.jfoodeng.2005.11.026. [DOI] [Google Scholar]

- Davidek J, Hrdlicka J, Karvanek M, Pokorny J, Velisek J. Laboratory handbook for foodstuffs. Prague: CR, SNTL-Alfa; 1981. [Google Scholar]

- Dervas G, Doxastakis G, Hadjisavva-Zinoviadi S, Triantafillakos N. Lupin flour addition to wheat flour doughs and effect on rheological properties. Food Chem. 1999;66(1):67–73. doi: 10.1016/S0308-8146(98)00234-9. [DOI] [Google Scholar]

- Dodok L, Modhir AA, Hozova B, Halasova G, Polacek I. Importance and utilization of chickpea in cereal technology. Acta alimentaria. 1993;22(2):119–129. [Google Scholar]

- Doxastakis G, Zafiriadis I, Irakli M, Tananaki C. Lupin, soya and triticale addition to wheat flour doughs and their effect on rheological properties. Food Chem. 2002;77(2):219–227. doi: 10.1016/S0308-8146(01)00362-4. [DOI] [Google Scholar]

- El-Adawy TA. Effect of sesame seed protein supplementation on the nutritional, physical, chemical and sensory properties of wheat flour bread. Food Chem. 1997;59(1):7–14. doi: 10.1016/0308-8146(95)00197-2. [DOI] [PubMed] [Google Scholar]

- El-Soukkary FA. Evaluation of pumpkin seed products for bread fortification. Plant Foods Hum Nutr. 2001;56(4):365–384. doi: 10.1023/A:1011802014770. [DOI] [PubMed] [Google Scholar]

- Fernandez ML, Berry JW. Rheological properties of flour and sensory characteristics of bread made from germinated chickpea. Int J Food Sci Tech. 1989;24(1):103–110. doi: 10.1111/j.1365-2621.1989.tb00623.x. [DOI] [Google Scholar]

- Hamaker BR, Griffin VK. Effect of Disulfide Bond-Containing Protein on Rice Starch Gelatinization and Pasting. Cereal Chem. 1993;70:377–380. [Google Scholar]

- Hoover R, Ratnayake WS. Starch characteristics of black bean, chick pea, lentil, navy bean and pinto bean cultivars grown in Canada. Food Chem. 2002;78(4):489–498. doi: 10.1016/S0308-8146(02)00163-2. [DOI] [Google Scholar]

- Hurrell RF. Influence of the Maillard reaction on the nutritional value of foods. In: Finot HU, Aeschbacher RF, Hurrell RF, Liardon R, editors. The Maillard reaction in food processing, human nutrition and physiology. Birkhëuser Verlag: Basel; 1990. pp. 365–371. [Google Scholar]

- ICC (2001) ICC Standard methods. International Association for Cereal Chemistry http://www.icc.or.at/, Access date 28/5/2011

- Inc SASI (2004) SAS Online Doc_ 9.1. 9.1 edn. SAS Institute Inc., Cary, NC

- Knorr O, Betschart AA. The relative effect of an inert substance and protein concentrates upon loaf volume breads. LebensmWissTechnol. 1978;11:198–207. [Google Scholar]

- Miles MJ, Morris VJ, Orford PD, Ring SG. The roles of amylose and amylopectin in the retrogradation of starch. Carbohydr Res. 1985;135:271–281. doi: 10.1016/S0008-6215(00)90778-X. [DOI] [Google Scholar]

- Mondal A, Datta A. Bread baking _ a review. J Food Eng. 2008;86(4):465–474. doi: 10.1016/j.jfoodeng.2007.11.014. [DOI] [Google Scholar]

- Mustafa AI, Al-Wessali MS, Al-Basha OM, Al-Amir RH. Utilization of cowpea flour and protein isolate in bakery products. Cereal Foods World. 1986;31(10):756–759. [Google Scholar]

- Narpinder S, Harinder K, Sekhon KS, Buhpinder K. Studies on the improvement of functional and baking properties of wheat-chickpea flour blends. J Food Process Preserv. 1991;15(6):391–402. doi: 10.1111/j.1745-4549.1991.tb00183.x. [DOI] [Google Scholar]

- Ratnayake WS, Hoover R, Shahidi F, Perera C, Jane J. Composition, molecular structure, and physicochemical properties of starches from four field pea (Pisum sativum L.) cultivars. Food Chem. 2001;74(2):189–202. doi: 10.1016/S0308-8146(01)00124-8. [DOI] [Google Scholar]

- Roccia P, Ribotta PD, Prez GT, Leôn AE. Influence of soy protein on rheological properties and water retention capacity of wheat gluten. LWT- Food Sci Technol. 2009;42(1):358–362. doi: 10.1016/j.lwt.2008.03.002. [DOI] [Google Scholar]

- Sathe SK, Ponte JG, Jr, Rangnekar PD, Salunkhe DK. Effects of addition of Great Northern bean flour and protein concentrates on rheological properties of dough and baking quality of bread. Cereal Chem. 1981;58(2):97–100. [Google Scholar]

- Schoch TJ, Maywald EC. Preparation and Properties of Various Legume Starches. Cereal Chem. 1968;45:564–563. [Google Scholar]

- Shahzadi S, Butt MS, Rehman SU, Sharief K. Rheological and baking performance of composite flours. Int J Agr Biol. 2005;7(1):100–104. [Google Scholar]

- Sharma S, Bajwa UH, Nagi HPS. Rheological and baking properties of cowpea and wheat flour blends. J Sci Food Agric. 1999;79(5):657–662. doi: 10.1002/(SICI)1097-0010(199904)79:5<657::AID-JSFA228>3.0.CO;2-3. [DOI] [Google Scholar]

- Singh KB, Subrahmanyam N, Kumar J. Cooking quality and nutritional attributes of some nely developed cultivars of chickpea (Cicer arietinum) L. J Sci Food Agric. 1991;55(1):37–46. doi: 10.1002/jsfa.2740550106. [DOI] [Google Scholar]

- Singh N, Kaur M, Sandhu KS, Guraya HS. Physicochemical, thermal, morphological and pasting properties of starches from some Indian black gram (Phaseolus mungo L.) cultivars. Starch - Stärke. 2004;56(11):535–544. doi: 10.1002/star.200400290. [DOI] [Google Scholar]

- Skendi A, Biliaderis CG, Papageorgiou M, Izydorczyk MS. Effects of two barley ?-glucan isolates on wheat flour dough and bread properties. Food Chem. 2010;119(3):1159–1167. doi: 10.1016/j.foodchem.2009.08.030. [DOI] [Google Scholar]

- Wood JA (2004) Viscosity of chickpea flours. The technical journal of Newport Scientific April:1–4

- Yadav R, Yadav B, Dhull N (2011) Effect of incorporation of plantain and chickpea flours on the quality characteristics of biscuits. J Food Sci Tech 1–7. doi:10.1007/s13197-011-0271-x [DOI] [PMC free article] [PubMed]

- Yang CH, Chang W. Effects of protein and lipid binding to starch on the physicochemical and pasting properties of rice flour. J Food Sci Agr Chem. 1999;1:277–285. [Google Scholar]

- Yousseff SAM, Salem A, Abdel-Rahman AHY. Supplementation of bread with soybean and chickpea flours. Int J Food Sci Tech. 1976;11(6):599–605. doi: 10.1111/j.1365-2621.1976.tb00763.x. [DOI] [Google Scholar]

- Zeleznak KJ, Hoseney RC. The glass transition in starch. Cereal Chem. 1987;64:121–124. [Google Scholar]