Abstract

Emulsifiers of different structures and functionalities are important ingredients usually used in baking cakes with satisfactory properties. In this study, three emulsifiers including distilled glycerol mono stearate (DGMS), lecithin and sorbitan mono stearate (SMS) were used to bake seven eggless cakes containing soy milk and optimization was performed by using mixture experimental design to produce an eggless cake sample with optimized properties. Physical properties of cake batters (viscosity, specific gravity and stability), cake quality parameters (moisture loss, density, specific volume, volume index, contour, symmetry, color and texture) and sensory attributes of eggless cakes were analyzed to investigate functional potential of the emulsifiers and results were compared with those of control cake containing egg. Almost in all cases emulsifiers, compared to the control cake, changed properties of eggless cakes significantly. Regarding models of different response variables (except for some properties) and their high R2 (99.51–100), it could be concluded that models obtained by mixture design were significantly fitted for the studied responses.

Keywords: Modeling, Eggless cake, Emulsifier, Soy milk, Physical and sensory properties

Introduction

Egg, wheat flour, sugar and fat are the major ingredients in cake baking. Among different ingredients used in cake making, egg is the most costly ingredient and significant source of cholesterol (Ashwini et al. 2009) but it has high nutritional value and multi-functional properties, including emulsification, coagulation, foaming and flavor (Kohrs et al. 2010; Yang and Baldwin 1995). Because of functional roles of egg in cake production, it would be difficult to reduce or substitute egg in cake completely (Ashwini et al. 2009). Therefore, the use of vegetable proteins for partial or total substitution of eggs in cake formulations appears to be an interesting objective. On the other hand, emulsifiers that have common use in the baking industry, have the ability to provide the necessary aeration and gas bubble stability during the baking process (Turabi et al. 2008). Generally, high-quality cakes have various attributes, including high volume, uniform crumb structure, tenderness, shelf life and tolerance to staling (Gomez et al. 2007) that could be achieved by applying different types of emulsifiers. Different emulsifiers have already been tried for partial or total substitution of egg in cake. In the study of Ashwini et al. (2009), two different emulsifiers namely glycerol monostearate (GMS) and sodium stearoyl-2-lactylate (SSL) were added to the eggless cake samples in combination with different hydrocolloids. In the study done by Turabi et al. (2008) gluten-free cake batter was made from rice flour, gums and emulsifier to model the rheological characteristics of gluten-free cake batter. Also the influence of shortening–based emulsifier gels including sodium stearoyl-2 lactylate (SSL), distilled glycerol monostearate (DGMS), propylene glycol monostearate (PGMS), polysorbate–60 (PS–60), and sorbitan monostearate (SMS) on the rheological and baking properties of cake batters containing 120 g egg on flour basis was studied by Jyotsna et al. (2004).

The most important factor affecting the function of an emulsifier is its physical state. The emulsifiers used for cake baking should be in the α-gel state to create a stabilizing film to cover the bubble surfaces (Jyotsna et al. 2004). In the cake batter, all α-gel emulsifiers decrease density and increase incorporation of air into the batter (Richardson et al. 2002). In fact, hydration of powdered emulsifiers by dispersion in hot water before use, results in the formation of functional α-crystalline form (Jyotsna et al. 2004). For example, the lipophilic fatty acid chain in monoglycerides, diglycerides, and triglycerides protects the hydrophilic glycerol section, preventing water from interacting with the hydrophilic section of the emulsifier. Hydrated emulsifiers have a modified configuration with their hydrophilic sections exposed to the surface. This configuration enables them to interact with water and become functional ingredients in food systems (Baker 1997). This alpha-gel configuration allows easier distribution of the emulsifier to the interface resulting in maximum functionality (Richardson et al. 2002).

Because few publications have assessed the effect of emulsifiers and especially emulsifier blends on eggless cake characteristics; therefore the objective of this study was to determine the influence of different emulsifiers (DGMS, lecithin and SMS), varying in origin and chemical structure, on quality and physicochemical properties of completely eggless cake containing soy milk. The most commonly encountered form of monoglycerides is glycerol monostearate (GMS) and its more refined distilled form, DGMS (distilled). This emulsifier has a long history of use as a softening (anti-staling) agent and is able to form complexes with the starch, which slows down the retrogradation process in the baked product during storage (Cauvain and Young 2006). Lecithin has also been used in the food industry since the 1930s. Lecithin is a mixture of polar lipids and is extracted from the degumming process of crude vegetable oils (Szuhaj 2005). Sorbitan fatty-acid esters are sorbitol-derived analogs of mono- and diglycerides that are slightly more water soluble. These emulsifiers can be used in emulsions where enhanced aeration properties are desired (O’Brien 2004; Wetterau et al. 1964; Stauffer 1999). The other objectives of this study were to investigate possible interaction between the emulsifiers and analyze different functions of the emulsifiers influencing batter and cake properties.

Materials and methods

Materials

Commercial wheat flour (protein content of 8.7 %, Golha Co. Tehran, Iran), three different types of emulsifiers including DGMS (distilled glycerol mono stearate), SMS (sorbitan mono stearate) (Asia Pars Behbood Co, Chenaran, Iran) and lecithin (Toos Arjan Co., Mashhad, Iran), full fat soy flour (protein content of 40 %, Toos Soya Co., Mashhad, Iran), double acting type baking powder (Sahar Samin Nan Co., Tehran, Iran) were purchased. Sugar, fresh egg, liquid oil, salt, banana essence and fresh milk were bought from local market.

Preparation of soy milk

In order to prepare soy milk, hot water (90–95 °C) was added into soy flour with the weight ratio of 3:1 (water: flour). Then this mixture was mixed with mixer (High speed Moulinex, DFC3, France) for 20 min and soy milk was established with protein content of 10 %.

Preparation of emulsifier gels

The emulsifier gels were prepared using dispersions of emulsifiers made in the ratio of 0.5: 2: 1 (emulsifier: water: oil). Dispersions were heated under continuous agitation to a temperature of 60 ° C. Emulsifier gels were obtained after cooling.

Cake formulation and preparation

Formulations (according to the control formulation described by Majzoobi et al (2013) with some changes) of seven eggless cakes along with the formulation of control cake are given in Table 1. First emulsifiers (Table 1) and oil were whipped for 4 min with stirrer at speed 3 (SINBO SMX 2725 STAND MIXER, China). Finally baking powder was added to the mixture for 30 s. Then in a separate bowl sugar and soy milk were mixed for 3 min (speed 3). In the next step, oil and emulsifier mixture was added to the bowl and then sifted wheat flour, salt, essence and milk were added and mixed for 2.5 min (speed 2). Then cake batter was transferred into 10 cm-diameter cake pans (each 105 g) and baked for 40 min at 180 ° C using electrical oven (Gastroback, model Art Nr. 42810, Germany). Cakes were cooled after baking at room temperature for 30 min and then packed in zip plastic packs. Each formulation was baked one time and each experiment was done in 4 replicates (batter stability test in 2 replicates).

Table 1.

Cake formulation and matrix of Simplex Centroid Mixture experimental design for the emulsifiers

| Ingredients | Amount in control cake (on flour basis) | Amount in eggless cakes (on flour basis) | Amount in eggless cakes (%) |

|---|---|---|---|

| Wheat flour | 100 | 100 | 29.78 % |

| Egg or soy milk | 60 (egg) | 60 (soy milk) | 17.92 % |

| Milk | 56 | 56 | 16.73 % |

| Oil | 35 | 35 | 10.45 % |

| Sugar | 75 | 75 | 22.40 % |

| Water | 4 | 4 | 1.19 % |

| Baking powder | 3 | 3 | 0.89 % |

| Salt | 0.2 | 0.2 | 0.06 % |

| Banana essence | 0.5 | 0.5 | 0.15 % |

| Emulsifier | 0 | 1 | 0.29 % |

| Eggless cake number | X1(DGMS) (on flour basis) | X2 (Lecithin) (on flour basis) | X3 (SMS) (on flour basis) |

| 1 | 0 | 0 | 1 |

| 2 | 0 | 0.5 | 0.5 |

| 3 | 0.5 | 0 | 0.5 |

| 4 | 1 | 0 | 0 |

| 5 | 0 | 1 | 0 |

| 6 | 0.5 | 0.5 | 0 |

| 7 | 0.33 | 0.33 | 0.33 |

HLB values for the emulsifiers are DGMS: 4, lecithin: 3–4 and SMS: 5.9

Batter viscosity

Batter viscosity was measured according to the procedure described by Ebeler et al. (1986). A funnel with a top inside diameter of 10 cm and a bottom inside diameter of 1.6 cm was used. The funnel was filled with batter and then the batter was allowed to flow for 15 s. Then the amount of batter flowed from the funnel was weighed and it was divided by 15 and viscosity values are reported in g/s. Thus higher values indicate lower viscosities. This method is a simple form of the procedure that is done by Bostwick consistometer that measures how far the batter flows in 30 S (Zhou et al. 2011).

Batter specific gravity

Specific gravity (density) of cake batter was measured by dividing weight of a certain volume of batter by the weight of an equal volume of water using the following equation:

|

1 |

Batter emulsion stability

Prepared cake batters were transferred into cylindrical plastic tubes (12 cm height and 1.4 cm internal diameter) and centrifuged at 5,000 rpm for 15 min. Emulsion stability of cake batters was calculated by the following equation:

|

2 |

Where %H is the emulsion stability percent, H1 is the height of stable emulsion remained in the tube after centrifugation and H0 is the initial height of batter transferred into the tube.

Cake moisture loss during baking and after 5 days of storage

Moisture loss during baking was calculated by the equation bellow:

|

3 |

Where W1 is the weight of cake batter transferred into each cake pan (105 g) and W2 is the weight of baked cake after 30 min cooling at room temperature. Also cake samples were weighed after 5 days of storage.

Cake density and specific volume

Cake density was measured by the seed displacement method (AACC method 1988) and data are reported in both g/cm3 (density) and cm3/g (specific volume).

|

4 |

Where, W represents weight (g), V represents volume (cm3), and ρ represents density (g/cm3). The specific volume was calculated by dividing the volume of the cake by its weight:

|

5 |

Volume index

Volume index of cakes were measured according to the AACC method 10–91 (AACC 1983). Cakes were cut vertically through their center and the heights of the samples were measured at three points (B, C, D) along the cross-sectioned cakes using the template. Volume index was calculated by the following equation:

|

6 |

Where C is the height of the cake at the center and B and D are the heights of the cake sample at the points 2.5 cm away from the center towards the left and right sides of the cake.

Cake contour and symmetry

Contour and symmetry indices were calculated using the following equations:

|

7 |

|

8 |

B, C and D were introduced above in the volume index section.

Texture analysis

Texture characteristics of cake crumb (firmness, cohesiveness, springiness and chewiness) were evaluated using a texture analyzer (QTS Faranel CNS, UK). Crumb of the cake samples were cut into cube shapes with 2.5 cm diameter and they were compressed to 25 % of their original height at a speed of 100 mm/min using a cylindrical probe (35 mm diameter) and a 5 kg load cell (AACC method 2000).

Cake color (crust and crumb)

Color measurement was performed by image processing technique using photographs taken by scanner (Konika Miynolta, bi 2 hub 450). Images format was converted from RGB into L*, a*, b* system by Image J software (version 1.42 e) and color parameters were obtained for both crust and crumb of cake samples.

Sensory evaluation

Hedonic sensory evaluation (5-point scale) was carried out with ten panel members. Sensory characteristics were crust color, crust appearance, internal texture appearance, texture softness, crust softness, cake resistance to cutting, cake volume, total appearance, taste and overall acceptability.

Experimental design and statistical analysis

Mixture approach (Simplex Centroid mixture design) was used to prepare seven eggless cake samples using different proportions of three emulsifiers. According to this design, consisted of three components in this case (DGMS, SMS and lecithin), sum of the factors (emulsifiers) was 1 % on wheat flour basis in all cake formulations. In fact, mixture design was employed to determine the effects of the emulsifiers on different physicochemical and sensory properties of cakes. Therefore, seven experimental runs were performed based on the mixture design. This type of statistical design requires that the sum of active components (independent variables) always equal a constant weight-percent of the total formulation and the other components must not change. All responses were fitted on quadratic poly nominal model and following equation was used by Design Expert software (version 6.0.2) to investigate the effect of three emulsifiers as independent variables on various dependent variables (batter characteristics, cake quality attributes and sensory properties) as responses of the following equation:

|

9 |

Where Y is the response for different dependent variables, b parameters are the coefficients of the equation and x1,x2 and x3 were considered as DGMS, lecithin and SMS, respectively. Significance of each coefficient in the model was accepted or rejected based on the P-value and statistical diferrences were determined at 95 % confidence level. Analysis of variance was carried out using Design expert software (6.0.2) and contour plots were drawn by Minitab software (Minitab 16 statitical software) to better visualize the effects of the three emulsifiers on different characteristics of eggless cake samples. Finally, optimization was done to determine optimum levels of emulsifiers. Besides, a cake sample was prepared with egg as control.

Results and discussion

Evaluating Mixture design to predict data

P-value, estimated regression coefficients, R2 and adjusted R2 for each model are shown in Table 2. Responses were analyzed as functions of independent variables including DGMS, lecithin and SMS. Variation in each model, predicted for each response, was assessed as a function of linear and interaction terms. High coefficients of determination (R2), adjusted R2 and values of < 0.05 of P-value for models and independent variables were used as statistical parameters to evaluate appropriateness of the estimated models. Analysis of variance was performed to investigate the adequacy of predicted models and determine the significant variables (Gharibzahedi et al. 2012). The results showed satisfactory and high coefficients of determination ranging from 99.92 to 100.0 and adjusted R2 values of 99.51 to 100 almost for all responses. Except for some parameters, all predicted models were significant and well-fitted for responses as P values of the models were < 0.05. Fitting actual responses to the predicted ones, estimated by mixture design, showed high adequacy of quadratic models for predicting responses as dependent variables. Thus, more than 99.51 % of variability of different characteristics could be explained by the mixture design method.

Table 2.

P-value, estimated regression coefficients, R2 and adj R2 for the adjusted models to experimental data in mixture design for each response

| Source/P value | Batter viscosity | Batter density | Moisture loss | Cake density | Specific volume | Volume index | Firmness | Chewiness | L* | b* | Overall acceptability |

|---|---|---|---|---|---|---|---|---|---|---|---|

| regression | 0.045 | 0.037 | 0.034 | 0.048 | 0.024 | 0.043 | 0.002 | 0.048 | 0.033 | 0.048 | 0.005 |

| Linear | 0.027 | 0.027 | 0.024 | 0.030 | 0.015 | 0.031 | 0.001 | 0.029 | 0.020 | 0.036 | 0.012 |

| DGMS × Lecithin | 0.470 | 0.116 | 0.031 | 0.053 | 0.025 | 0.032 | 0.014 | 0.355 | 0.104 | 0.031 | 0.002 |

| DGMS × SMS | 0.092 | 0.037 | 0.076 | 0.579 | 0.129 | 0.064 | 0.004 | 0.080 | 0.049 | 0.279 | 0.768 |

| Lecithin × SMS | 0.159 | 0.035 | 0.042 | 0.762 | 0.124 | 0.082 | 0.007 | 0.228 | 0.096 | 0.075 | 0.006 |

| Regression coefficients | Batter viscosity | Batter density | Moisture loss | Cake density | Specific volume | Volume index | Firmness | Chewiness | L* | b* | Overall acceptability |

| DGMS (b1) | 0.219 | 1.06 | 13.425 | 0.416 | 2.416 | 106.461 | 1.169 | 3.186 | 69.904 | 36.563 | 3.499 |

| Lecithin (b2) | 0.389 | 1.060 | 12.575 | 0.419 | 2.403 | 106.461 | 1.079 | 2.486 | 65.844 | 38.003 | 3.699 |

| SMS (b3) | 0.089 | 0.990 | 9.755 | 0.486 | 2.054 | 95.461 | 1.929 | 5.656 | 68.054 | 37.303 | 3.899 |

| DGMS × Lecithin (b12) | 0.030 | −0.043 | −5.441 | −0.123 | 0.700 | 39.777 | 0.181 | 0.517 | 1.750 | −3.586 | 2.403 |

| DGMS × SMS (b13) | 0.190 | 0.136 | −2.201 | 0.008 | −0.137 | −20.222 | −0.598 | −2.542 | −3.749 | 0.373 | 3.030 |

| Lecithin × SMS (b23) | −0.109 | −0.143 | 4.018 | 0.004 | −0.143 | 15.777 | −0.338 | −0.862 | −1.909 | −1.466 | −0.796 |

| R2 | 99.93 | 99.95 | 99.96 | 99.99 | 99.98 | 99.94 | 100.00 | 99.92 | 99.96 | 99.92 | 100.00 |

| adj R2 | 99.58 | 99.71 | 99.75 | 99.52 | 99.88 | 99.61 | 100.00 | 99.52 | 99.77 | 99.51 | 99.99 |

Non-significant responses are omitted

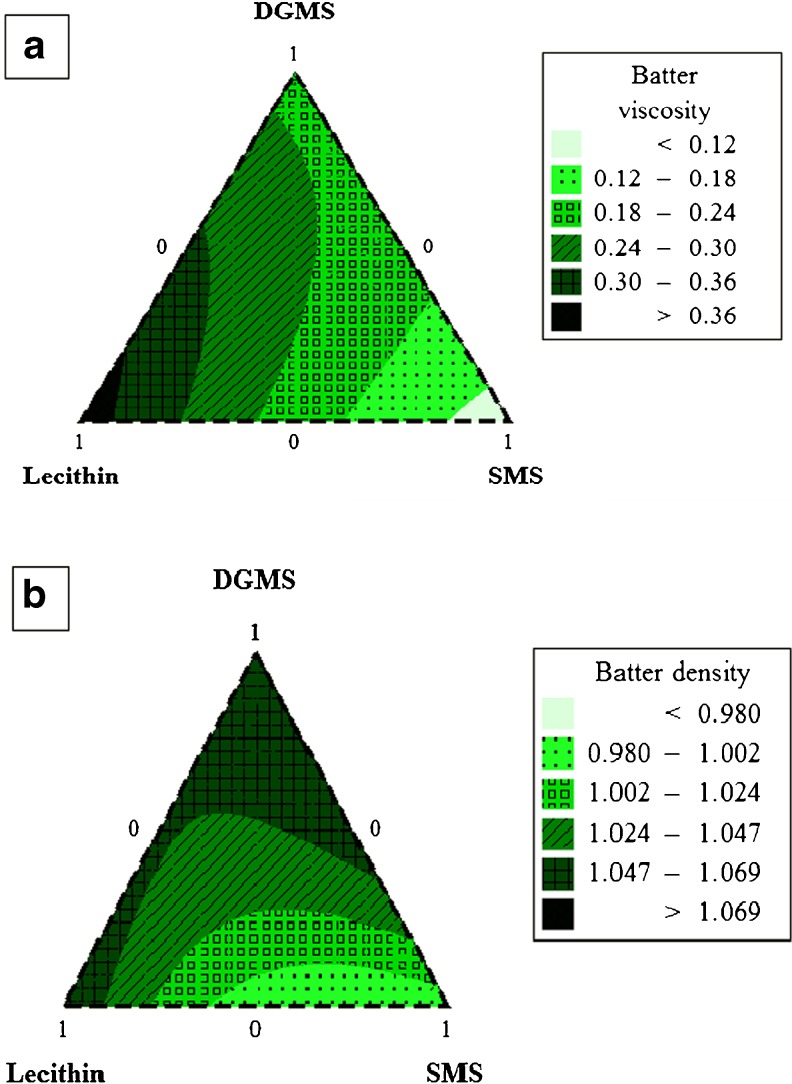

Batter viscosity, density and stability

Results related to the batter properties are shown in Tables 2 and 3, showing that batter viscosity was a function of linear effects of emulsifiers in the order of SMS, DGMS and lecithin. Batter prepared with SMS had the highest viscosity (Fig. 1a). The most probable reason is higher HLB value of SMS compared to the other emulsifiers used. Higher HLB results in more capability to absorb water that could bring about higher viscosity. In contrast, lecithin produced eggless cake batter with the lowest viscosity. These observations were in agreement with the results obtained by previoues researches who offered an explanation of the mechnism by which lecithin reduces intra-particle friction for chocolate. Moisture present in chocolate adhers to the surface of the sugar particles. When lecithin is introduced, the hydrophilic functional group in lecithin attaches itself to the sugar surface while the lipophilic group is left to project out into the surrounding oil phase. This enables the particles to slip more easily over each other reducing the viscosity. It should take into account that viscosity reducing effect of lecithin is seen when only sugar is present in the formula (Hasenhuettl 2008). In addition, lower viscosity was observed for control compared to those of eggless batters. This might be mainly related to the lower viscosity of egg than that of soy milk as egg replacer in eggless batters. Actually, the increase in the water absorption capacity of ingredients reduces the amount of free water available to facilitate the movement of particles in batters and consequently gives high viscosity (Ronda et al. 2011).

Table 3.

Effect of different emulsifiers on batter and cake quality parameters

| Cake number | Batter viscosity (g/s) | Batter density (g/cm3) | Batter stability (%) | Moisture loss (%) | Cake density (g/cm3) | Specific volume (cm3/g) | Volume index (mm) | Contour (mm) | Symmetry (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.09 | 0.990 | 90.30 | 9.75 | 0.486 | 2.055 | 95.5 | 7.5 | 1.50 |

| 2 | 0.21 | 0.990 | 100.00 | 12.19 | 0.454 | 2.191 | 104.75 | 5.5 | 2.00 |

| 3 | 0.20 | 1.060 | 98.02 | 11.06 | 0.454 | 2.199 | 95.75 | 6.25 | 0.25 |

| 4 | 0.22 | 1.063 | 91.90 | 13.42 | 0.416 | 2.417 | 106.5 | 12.00 | 1.00 |

| 5 | 0.39 | 1.069 | 98.48 | 12.57 | 0.418 | 2.404 | 106.5 | 6.75 | 2.75 |

| 6 | 0.31 | 1.050 | 93.94 | 11.66 | 0.387 | 2.583 | 116.25 | 10.50 | 3.00 |

| 7 | 0.25 | 1.030 | 100.00 | 11.47 | 0.426 | 2.343 | 107.07 | 9.66 | 2.33 |

| Control | 1.57 | 1.023 | 79.24 | 13.94 | 0.448 | 2.232 | 106.00 | 5.00 | 2.00 |

Fig. 1.

Mixture contour plots for a batter viscosity and b batter density. The measurements were performed in 4 replicates

Low specific gravity (density) is desired in cake batter because it indicates that more air is incorporated into the batter (Turabi et al. 2008). The specific gravity of batter represents total air holding capacity of the batter during mixing. However, the final cake volume is not only dependent on initial air incorporated into the batter but also its capacity to retain air during baking (Frye and Setser 1991). Data analysis exhibited that SMS had the most positive effect on batter density and aeration followed by DGMS and lecithin. This result could be interpreted by the increase in batter viscosity caused by SMS. High viscosity of batter would improve air holding capacity during high speed mixing and whipping.

From interaction terms, SMS-lecithin mutual interaction showed the most significant effect on the batter density (Fig. 1b). It seems that lecithin has worked synergistically with SMS to improve aeration, suggesting that lecithin helped to facilitate or potentiate this effect. In addition, some of the batters had lower specific gravity than the control, showing that more air was incorporated into the batters containing different emulsifiers. Emulsifiers reduced batter density from 1.023 g/cm3 for the control batter to 0.99 g/cm3 for the batters with SMS and SMS + lecithin blend. In fact, the formation and stabilization of foams benefit from the addition of emulsifiers, which help aeration by lowering the surface tension between the liquid and gas phases, reducing the amount of energy required to generate a larger interfacial area (Sahi and Alava 2003; Turabi et al. 2008; Gomez et al. 2007; Zhou et al. 2011). Another possible explanation for this result is lower viscosity of control batter that caused more disruption of air bubbles during high power mixing. In fact, a batter of low viscosity cannot hold the bubbles sufficiently. Generally, air incorporation depends on the speed and the design of the beater, and the viscosity and the surface tension of the batter (Sahi and Alava 2003). Stability test results revealed high stability for all of the eggless batters (90–100 %). All samples showed higher stability compared to the control batter. Genarally, in cake system there are two types of interface, air in water and oil in water, must be stabilized. Regarding high ability of egg proteins in foaming and producing air bubbles, it seems that in control batter egg components have mainly stabilized air in water system (air bubbles). Therefore oil in water emulsion of lower stability was obseved for this batter. In contrast, we hypothesised that in eggless batters oil in water emulsion was stabilized by soy milk and air bubbles by the emulsifiers. Also emulsifiers can denature proteins through interactions. Once proteins become denatured, they will uncoil and allow the hydrophobic sections, usually oriented toward the center of the protein molecule, to interact with other molecules. This can greatly affect the stability of emulsions (Baker 1997). Among different emulsifiers, lecithin had the highest effect on batter stability followed by DGMS and SMS. However the differences in batter stability values were not significant (p > 0.05).

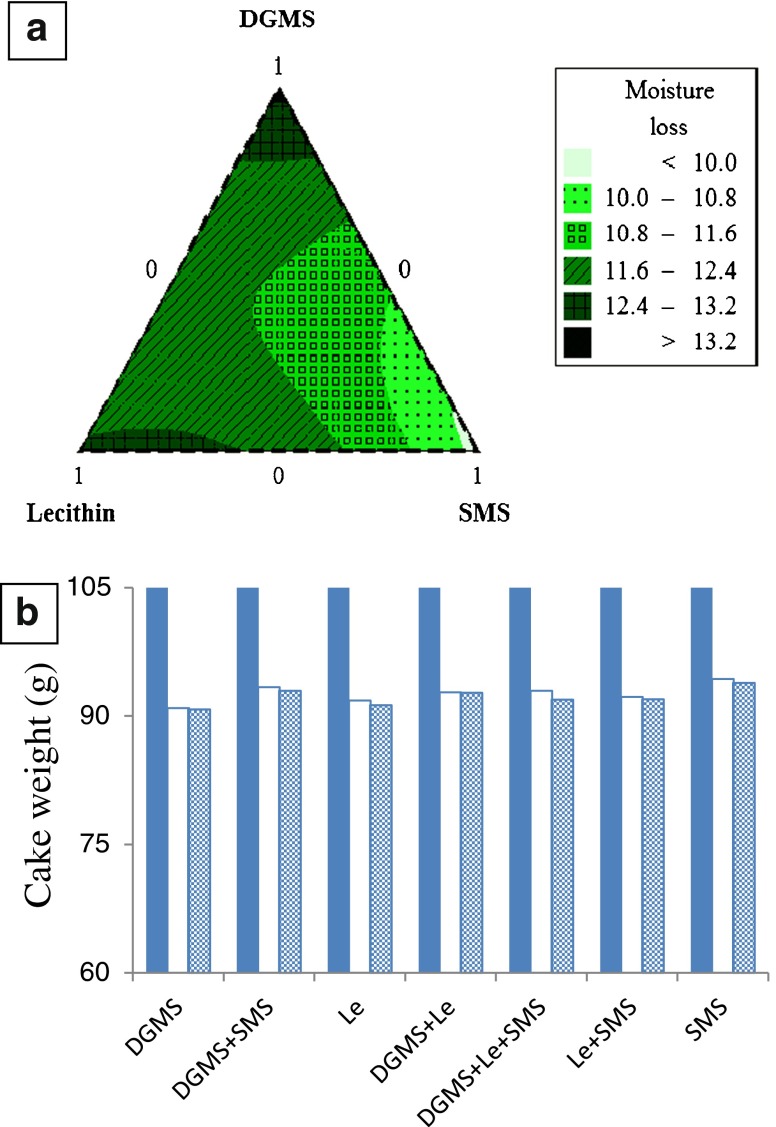

Moisture loss

Statistical analysis exhibited that moisture loss was dependent on the type and concentration of the emulsifiers (p < 0.05). It was found that the cake containing SMS lost the lowest amount of moisture during baking compared to the cakes containing DGMS, lecithin or emulsifier combinations. This result was expected for the cake prepared with SMS. As discussed before, it was surely due to the higher ability of SMS to bind and retain water. Furthermore, as it is obvious in Fig. 2a. that shows the influence of emulsifier content on moisture loss, addition of DGMS and lecithin increased moisture loss and as SMS concentration increased from 0 to 1 %, on both DGMS–SMS and lecithin-SMS edges, weight loss of cakes decreased. Effect of different emulsifiers and their blends on cake weight after baking and after 5 days of storage is shown in Fig. 2b. No considerable changes occurred after 5 days of storage (90.91–94.77 after baking and 90.77–93.88 after 5 days of storage on the basis of 105 g batter).

Fig. 2.

a Mixture contour plot for moisture loss and b effect of different emulsifiers on cake weight before baking (105 ± 1 g) ( ), after baking (

), after baking ( ) and after 5 days of storage (

) and after 5 days of storage ( ). The measurements were performed in 4 replicates

). The measurements were performed in 4 replicates

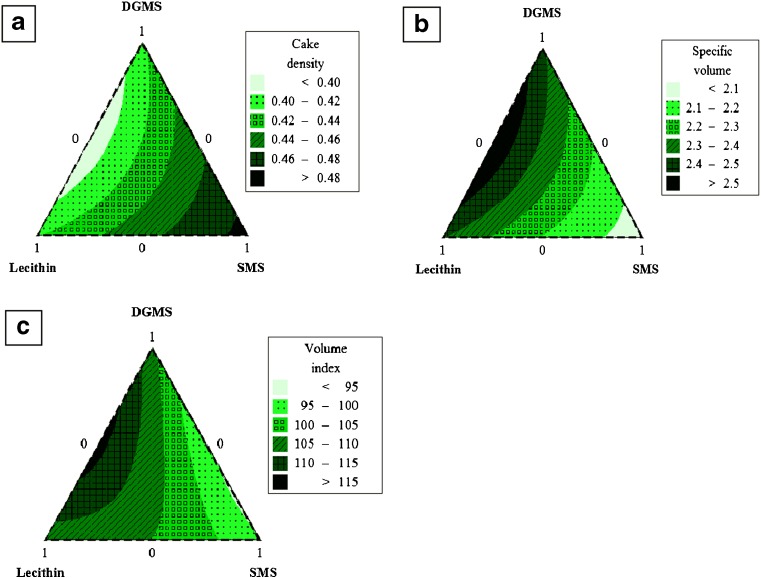

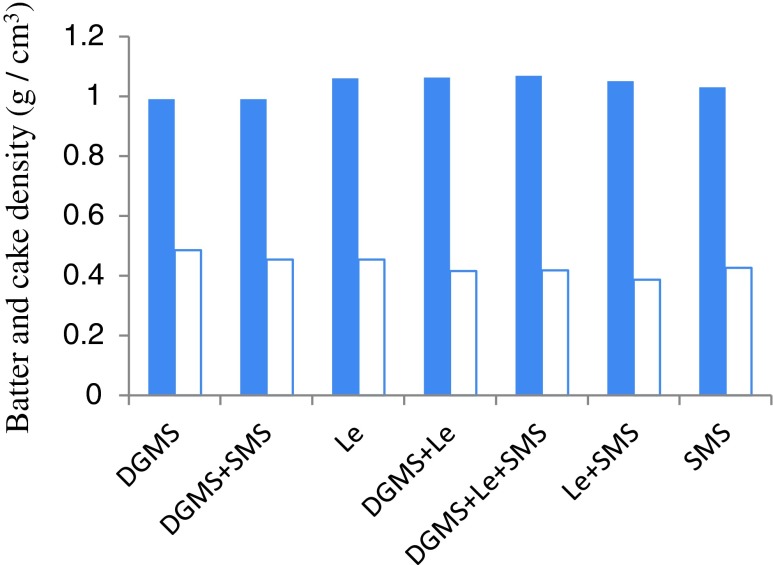

Cake density, specific volume and volume index

The data relevant to cake density, specific volume and volume index are shown in Table 3 and contour plots of cake density, specific volume and volume index as functions of DGMS, lecithin and SMS concentration are presented in Fig. 3. As it is obvious, addition of emulsifiers decreased cake density from 0.448 for control cake to 0.387 for the cake with DGMS-Lecithin blend. DGMS and lecithin were found to be the most significant variables affected cake density (p < 0.05). The cake sample located on the SMS vertex showed the highest density that must be due to its higher ability to retain water. Generally the amount of air cells in cake depends on several reasons including mixing conditions, amount of egg white, baking powder and water vaporization during baking that is of high importance. Emulsifiers with higher HLB values tend to bound water more effectively. Thus water vaporization was limited in SMS-prepared cake compared to the other samples that consequently resultd in more water retaintion during baking, so water was not allowed to vapor, make air cells and expand the cake volume before the cake structure sets. In addition, results (Fig. 3a) showed that cake density was dependent on DGMS-lecithin interaction (but not significantly), showing that DGMS and lecithin had synergistic effect on improving cake density. Similar result was reported in previous researches about interaction between PGMS and lecithin which was effective on cake volume (Zhou et al. 2011; Hasenhuettl 2008). Furethermore, control cake showed higher density compared to some of the eggless samples. This may be due to its lower batter viscosity that, as discussed before, may cause disruption of air bubbles during mixing. In fact there is an optimum cake batter viscosity to achieve cakes with high volume; if the viscosity of the batter is too low, batter cannot hold the air bubbles and the cake collapses in the oven. On the contrary, a too highly viscous batter can restrict its expansion during baking (Sahi and Alava 2003; Ronda et al. 2011). Figure 4 shows the difference between batter and cake density for each formulation. As it is obvious in this figure, batter density decreases during baking and converting batter to cake. This decrease in density must be directly related to the heating process. Generally during baking the aerated emulsion is converted to a porous solid cake, resulting in high cake volume. During this phase transition, heating process can cause several changes including expanding air cells, increasing water vaporization and enhancing air bubbles produced from baking powder.

Fig. 3.

Contour plots for a cake density, b specific volume and c volume index. The measurements were performed in four replicates

Fig. 4.

The difference between batter ( ) and cake (

) and cake ( ) density

) density

Results showed that the variation in cake specific volume was dependent on the linear and DGMS-lecithin interaction terms. Addition of emulsifiers changed specific volume of eggless cakes as follows: cake with DGMS had the volume of 2.417 cm3/g, cake with lecithin 2.404 cm3/g and value of 2.055 cm3/g was observed for SMS-prepared cake. This observation was similar to the results found by Jyotsna et al. (2004) who reported that among the emulsifier gels used in cakes containing 120 g egg on flour basis, cake with PS–60 gel showed a maximum increase in specific volume followed by the cakes baked with SSL, DGMS, PGMS, and SMS gels.

Volume index of cake indicates the amount of air entrraped in cake throught the cake crumb. Although high volumes do not always indicate a desirable cake, low volumes generally indicate a heavy and less desirable crumb (Brooker 1993; Zhou et al. 2011). Volume index values and contour plot of volume index indicated that cake samples containing DGMS or lecithin had equal volume values and higher values with respect to the SMS-prepared sample. As discussed before for cake density, this result was expected.

Cake contour, symmetry and shape

Contour values are shown in Table 3. Generally, cakes with higher volume exhibited higher central loaf height. The emulsifiers studied caused no significant difference in contour and symmetry indices. Generally, a peaked cake would have a high contour value and a flat cake would have a low value of contour. Also low symmetry value is favorable. All treatments resulted in cakes with intermediate contour values, showing cakes with appropriate rounded surfaces. Contour, symmetry and shape of samples can be seen in Figs. 5 and 6.

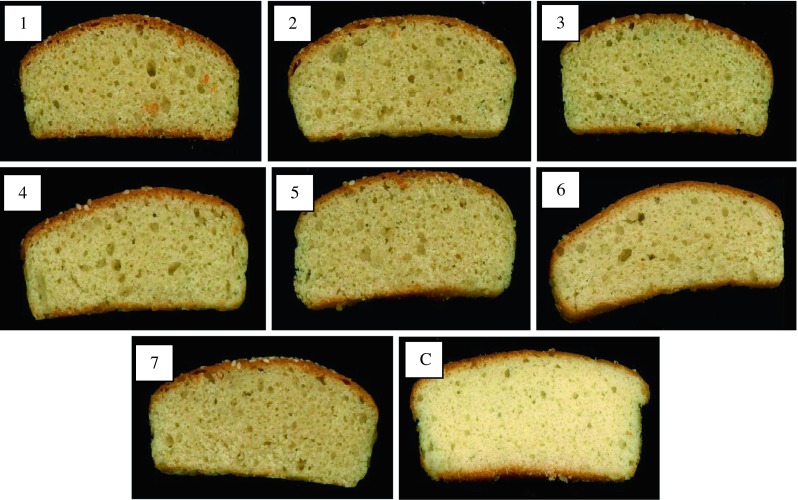

Fig. 5.

Photographs of eggless cakes containing soy milk and different blends of emulsifiers, C: Control cake

Fig. 6.

Photographs of sliced eggless cakes containing soy milk and different blends of emulsifiers, C: Control cake

Cake texture

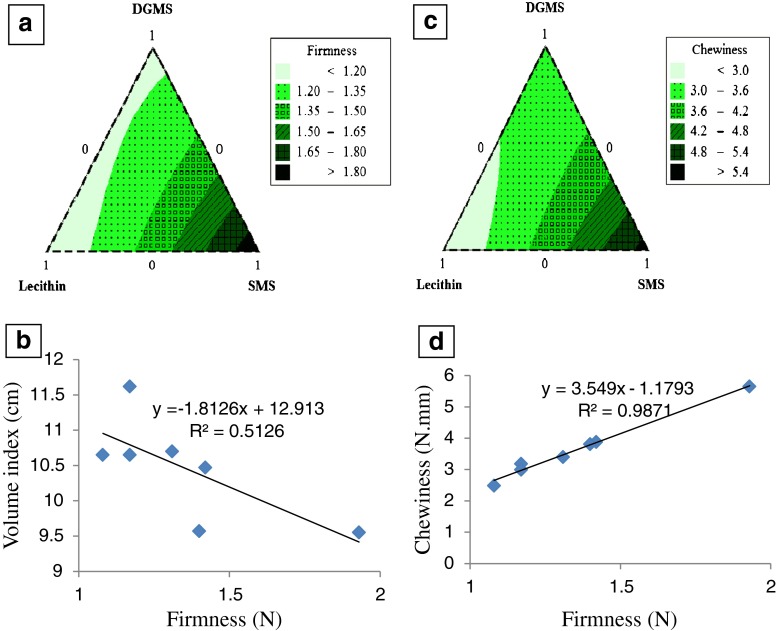

Results of texture measurements are shown in Table 4 and contour plots for texture data are presented in Fig. 7. As it is obvious from the model regression coefficients, the variation in firmness model was mostly influenced by linear effects of emulsifiers. As exhibited in Fig. 7a, the increase in DGMS and lecithin in both SMS-DGMS and SMS-lecithin edges appears to bring about an appreciable decrease in firmness and the cakes prepared with lecithin, DGMS and DGMS-lecithin blend were softer compared to the other cakes. In addition, some of the eggless samples showed softer texture compared to the control cake. Generally emulsifiers inhibit the swelling of starch granules by preventing amylose from leaching out of the granule and also by forming a film around the granule (Siswoyo and Morita 2001; Richardson et al. 2002). Both complexing and inhibition of granular swelling increase the gelatinization temperature of starch that consequently reduces firming effect of retrogradation (O’Brien 2004). Besides, helical structure of amylose, with a hydrophobic inner surface (Stauffer 1999) allows emulsifiers or other organic acids to insert themselves into the helix and form a complex. Emulsifiers that most easily form insoluble complexes with amylose demonstrate the greatest anti firming and shelf-extension effects. Saturated monoglycerides have been found to form helical inclusion complexes with amylose (Jang and Pyun 1996; Ghani et al. 1999). Also, water vaporization in the samples made with DGMS and lecithin produced more air cells and softer texture. In contrast, higher ability of SMS to bound water, due to its higher HLB, produced the firmest sample.

Table 4.

Effect of different emulsifiers on cake textural, color and sensory parameters

| Cake number | Firmness (N) | Springiness (mm) | Cohesiveness (-) | Chewiness (N.mm) | L* (crust) | a* (crust) | b* (crust) | L* (crumb) | a* (crumb) | b* (crumb) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.93 | 4.25 | 0.62 | 5.65 | 44.03 | 18.83 | 43.89 | 68.06 | 0.078 | 37.30 |

| 2 | 1.42 | 4.16 | 0.65 | 3.88 | 44.91 | 21.33 | 46.81 | 66.45 | −1.705 | 37.30 |

| 3 | 1.40 | 4.22 | 0.61 | 3.81 | 40.61 | 20.23 | 42.00 | 68.02 | 0.160 | 37.04 |

| 4 | 1.17 | 4.22 | 0.65 | 3.18 | 46.28 | 20.20 | 48.31 | 69.91 | −0.709 | 36.56 |

| 5 | 1.08 | 4.15 | 0.70 | 2.48 | 49.45 | 20.86 | 49.74 | 65.85 | 0.333 | 38.00 |

| 6 | 1.17 | 3.88 | 0.69 | 2.99 | 47.46 | 20.66 | 49.66 | 68.29 | −0.595 | 36.40 |

| 7 | 1.31 | 3.95 | 0.63 | 3.40 | 53.42 | 17.57 | 51.76 | 67.55 | 0.420 | 36.74 |

| Control | 1.20 | 4.35 | 0.78 | 4.07 | 37.12 | 23.63 | 41.25 | 84.66 | 2.010 | 29.41 |

| Cake number | Crust color | Crust appearance | Internal texture appearance | Texture softness | Crust softness | Cake resistance | Cake volume | Total appearance | Taste | Overall acceptability |

| 1 | 4.1 | 4.3 | 3.7 | 3.9 | 4.3 | 3.6 | 3.6 | 3.7 | 4 | 3.9 |

| 2 | 3.5 | 3.6 | 3.9 | 3.9 | 4.2 | 3.7 | 4.3 | 3.7 | 3.8 | 3.60 |

| 3 | 4.11 | 4.2 | 3.8 | 4.1 | 4.3 | 3.7 | 4.1 | 4 | 4 | 3.70 |

| 4 | 4.5 | 4.5 | 3.7 | 3.2 | 3.8 | 4 | 4.1 | 4.2 | 3.1 | 3.50 |

| 5 | 3.9 | 3.9 | 4 | 3.9 | 4.4 | 4.2 | 4.6 | 4.2 | 3.4 | 3.70 |

| 6 | 4.5 | 4.5 | 4.2 | 4.4 | 4.55 | 3.8 | 4.6 | 4.7 | 4.1 | 4.20 |

| 7 | 4 | 3.8 | 3.6 | 4.2 | 4.1 | 4.2 | 4.3 | 3.9 | 3.3 | 3.88 |

| Control | 4.4 | 4.4 | 4.6 | 4.6 | 4.6 | 4.4 | 4.2 | 4.3 | 4.3 | 4.4 |

Fig. 7.

a Mixture contour plot for firmness, b volume index vs. firmness, c mixture contour plot for chewiness and d chewiness vs. firmness. The measurements were performed in four replicates

Figure 7b plots the relationship between cake volume index and firmness. As stated by previous researchers (Stauffer 1999; Zhou et al. 2011) about bread staling and high ratio layer cake, higher volume usually results in lower initial firmness. Our results was exactly similar to that of reported by Zhou et al. (2011) who opined that cake firmness reduction was associated with volume increase. However, the relationship in both works was not strong. The R2 values of 0.47 (Zhou et al. 2011) and 0.51 (present study) indicated that half of the variability in the data can be attributed to the changes in cake volume, which indicates that the improvement in the softness was due to both an increase in cake volume and anti-firming effect of emulsifiers (Zhou et al. 2011).

There was no statistical difference among the data obtained for cohesiveness and springiness of samples and all samples showed satisfactory springiness values.

Figure 7c shows chewiness as a function of DGMS, lecithin and SMS. Results exhibited that the required energy to chew cake samples was dependent on the linear effects. Comparing firmness and chewiness contour plots showed that chewiness was associated with firmness. Figure 7d (plot of chewiness as a function of firmness with R2 value of 0.98) confirms the positive correlation between firmness and chewiness. Similar result was reported by Gomez et al. (2007) who stated that chewiness is a parameter dependent on firmness.

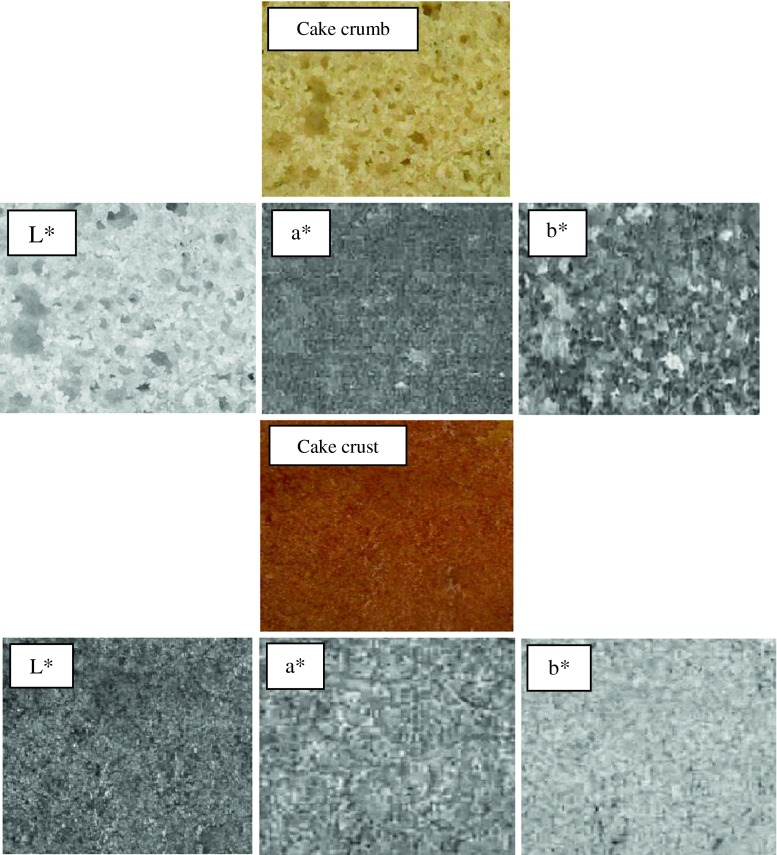

Crust and crumb color of cake

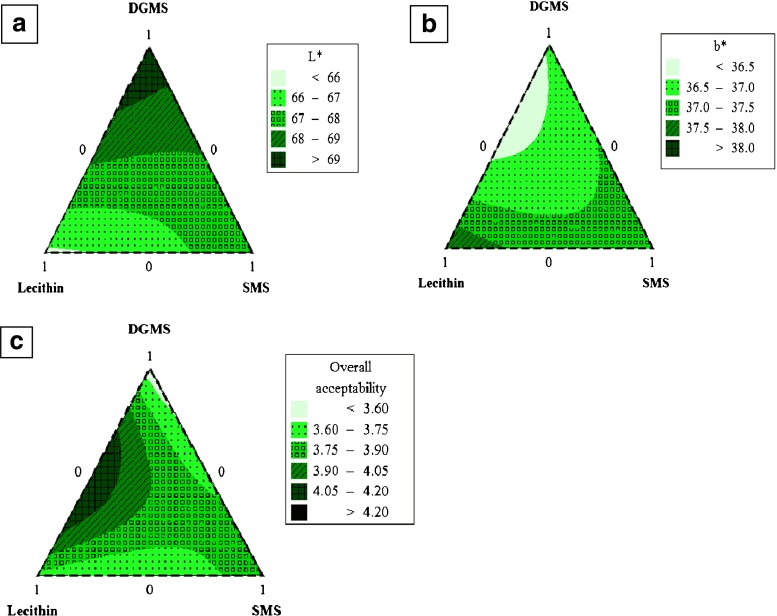

Typical image process images are shown in Fig. 8. Results showed that crust color of the eggless cakes was not dependent on the emulsifiers and their blends. It seems that baking temperature and time were the main important factors that influenced color of the cake crust. Furthermore, control sample showed the lowest lightness and the highest redness (Table 4). The reason for this observation could be more browning reactions (maillard) occurred in the control due to the higher content of protein (egg protein of 12.5 % compared to the concentration of protein in soy milk that is 10 %). In contrast, crumb of the control cake was the lightest sample. This was due to the lighter color of whole egg compared to soy milk and that maillard reaction influences just the cake crust. In addition, DGMS and SMS resulted in lighter crumb compared to the sample containing just lecithin. This could be due to the special brown color of lecithin. Parameter a* was not influenced by emulsifiers and b* was more affected by lecithin. Furthermore, lecithin blends with both DGMS and SMS reduced the influence of lecithin on b* and produced cakes of higher yellowness (Fig. 9b). This is due to the white color of DGMS and SMS gels compared to the color of liquid lecithin.

Fig. 8.

Typical image process technique images for cake crumb and crust and different color parameters

Fig. 9.

a and b Mixture contour plots for color parameters of cake crumb and c sensory overall acceptability. The measurements were performed in four replicates

Sensory evaluation results

Sensory scores are presented in Table 4. Generally, all eggless cake samples were highly desirable to the panelists with respect to their high overall acceptability (scores of 3.5 to 4.2). Among eggless cakes, sample 6 (with DGMS-lecithin blend) was more appreciated by panelists than the rest of the cakes (acceptability score of 4.2). According to the results and observations explained in the previous sections, this result was expected. Low density, high volume, desirable crumb and crust softness, appearance and crust color are the important parameters that resulted in the highest acceptability score for the cake sample number 6. The lowest score of overall acceptability was assigned by panelists to the sample four having just DGMS as emulsifier (located on DGMS vertex). This may be expected due to its lower score of taste (3.1) compared to the other cake samples. Because of satisfactory scores of sample four in terms of other characteristics (higher than 3.7) and lower taste score of sample 6 (the best eggless cake) compared to that of control, it can be concluded that 0.5 % essence on flour basis has not been enough to cover the taste produced by the emulsifiers and soy milk. Despite lower scores in some characteristics, control sample showed the highest acceptability score probably due to its more desirable taste that confirms previous reasons. Acceptability predicted model was found to be dependent on the linear (p < 0.05) and DGMS-lecithin and lecithin-SMS interaction terms (p < 0.01). Contour plot (Fig. 9c) shows the influence of individual and combination effects of different emulsifiers on overall acceptability model, showing that DGMS-lecithin blend was found to have the most significant effect on the changes of overall acceptability model.

In terms of the other sensory attributes (shown in Table 4), almost all scores were more than 3.5 (as an acceptable suggested value in sensory evaluation). Comparing all sensory properties of eggless cakes, cake sample containing DGMS-lecithin combination showed the highest desirability almost for all sensory parameters (almost scores of more than 4 and in some cases more than 4.5) that shows high acceptance of this cake sample.

Optimization

Numerical optimization was performed by Design expert software to determine the optimum levels of independent variables (as process variables). The indices used for optimization were target values for moisture loss (11.66), firmness (1.17), chewiness (2.99), crumb L* (68.29), crumb b* (36.40), minimum value for cake density (0.387) and maximum values for specific volume (2.583), volume index (116.25) and overall acceptability (4.20). Target values were selected based on the experimental data of the cake sample number 6.

Results showed that the optimum region would be at combined levels of 0.49 % DGMS, 0.5 % lecithin and 0.01 % SMS. The corresponding response values for characteristics predicted under the recommended optimum conditions were moisture loss 12.58, firmness 1.17, chewiness 2.96, crumb L* 68.27, crumb b* 36.39, cake density 0.386, specific volume 2.580, volume index 116.21 and overall acceptability 4.19.

The optimum eggless cake was prepared with the predicted optimum concentrations of DGMS, lecithin and SMS to determine the adequacy of optimization procedure. Then the optimum cake was assessed in terms of some of the properties (data not shown). Comparison between predicted and actual values measured for some of the properties showed high adequacy of optimization and confirmed predictive capacity of mixture models.

Conclusions

Results confirmed high capability of DGMS-lecithin emulsifier blend in combination with soy milk in producing a completely eggless cake that could be a perfect achievement in the cake baking industry. According to the achieved results, the emulsifiers studied could be ranked based on their different functionalities (Table 5):

Table 5.

Ranked order of emulsifiers according to their different functinalities

| Variable | 1a | 2 | 3 |

|---|---|---|---|

| Batter viscosity | SMS | DGMS | Lecithin |

| Emulsion stability | Lecithin | DGMS | SMS |

| Batter density | SMS | DGMS = Lecithin | |

| Cake volume | DGMS = Lecithin | SMS | |

| Cake firmness | SMS | DGMS | Lecithin |

| Moisture loss | DGMS | Lecithin | SMS |

| Cake density | SMS | DGMS | Lecithin |

a1: The highest variable value, 2: average value, 3: the lowest value

References

- AACC (1983) Approved methods of the AACC. Methods 10–91, St Paul, MN: American Association of Cereal Chemists.

- AACC (1988) Approved methods of the AACC. Method 74–09. St. Paul, MN: American Association of Cereal Chemists.

- Approved Methods of the American Association of Cereal chemists. 10. St. Paul, MN: AACC; 2000. [Google Scholar]

- Ashwini A, Jyotsna R, Indrani D. Effect of hydrocolloids and emulsifiers on the rheological, microstructural and quality characteristics of eggless cake. Food Hydrocol. 2009;23:700–707. doi: 10.1016/j.foodhyd.2008.06.002. [DOI] [Google Scholar]

- Baker SR. Maximizing the use of food emulsifiers. MSc thesis. Illinois: University of Illinois; 1997. [Google Scholar]

- Brooker BE. The stabilisation of air in cake batters- the role of fat. Food Struct. 1993;12:285–296. [Google Scholar]

- Cauvain SP, Young LS. Baked Products: science, technology and practice. Oxford: Blackwell; 2006. [Google Scholar]

- Ebeler SE, Breyer LM, Walker CE. White layer cake batter emulsion characteristics: effects of sucrose ester emulsifiers. J Food Sci. 1986;51:1276–1278. doi: 10.1111/j.1365-2621.1986.tb13104.x. [DOI] [Google Scholar]

- Frye AM, Setser CS. Optimizing texture of reduced calorie sponge cakes. Cereal Chem. 1991;69:338–343. [Google Scholar]

- Ghani MBA, Che Man TB, Hashim DM, Rahman RA. A Differential scanning calorimetric (DSC) study on the effects of annealing and sugar emulsifiers on gelatinization of sago starch. J Food Process Eng. 1999;23:443–462. doi: 10.1111/j.1745-4549.1999.tb00397.x. [DOI] [Google Scholar]

- Gharibzahedi SMT, Mousavi SM, Hamedi M, Ghasemlou M. Response surface modeling for optimization of formulation variables and physical stability assessment of walnut oil-in-water beverage emulsions. Food Hydrocoll. 2012;26:293–301. doi: 10.1016/j.foodhyd.2011.06.006. [DOI] [Google Scholar]

- Gomez M, Ronda F, Caballero PA, Blanco CA, Rosell CM. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007;21:167–173. doi: 10.1016/j.foodhyd.2006.03.012. [DOI] [Google Scholar]

- Hasenhuettl GL. Overview of food emulsifiers. In: Hasenhuettl GL, Hartel RW, editors. Food emulsifiers and their applications, 2nd edn. New York: Springer; 2008. p. 1. [Google Scholar]

- Jang JK, Pyun YR. Effect of moisture content on the melting of wheat starch. Starch. 1996;48:48–51. doi: 10.1002/star.19960480204. [DOI] [Google Scholar]

- Jyotsna R, Prabhasankar P, Indrani D, Venkateswara Rao G. Improvement of rheological and baking properties of cake batters with emulsifier gels. J Food Sci. 2004;69:16–19. doi: 10.1111/j.1365-2621.2004.tb17880.x. [DOI] [Google Scholar]

- Kohrs D, Herald TJ, Aramouni FM, Abughoush M. Evaluation of egg replacers in a yellow cake System. Emir J Food Agric. 2010;22:340–352. [Google Scholar]

- Koksel HF. Effects of xanthan and guar gums on quality and staling of gluten free cakes baked in microwave-infrared combination oven. MSc Thesis. Ankara: Middle east technical university; 2009. [Google Scholar]

- Majzoobi M, Hedayati S, Habibi M, Ghiasi A (2013) Effects of corn resistant starch on physicochemical properties of cake. First international e-conference on novel food processing, Mashhad, Iran

- O’Brien RD. Fats and Oils: Formulating and Processing for Applications. Boca Raton: CRC; 2004. [Google Scholar]

- Richardson G, Langton M, Faldt P, Hermansson AM. Microstructure of α-crystalline emulsifiers and their influence on air incorporation in cake batter. Cereal Chem. 2002;79:546–552. doi: 10.1094/CCHEM.2002.79.4.546. [DOI] [Google Scholar]

- Ronda F, Gomez M, Blanco CA, Caballero PA. Effects of polyols and non digestible oligosaccharides on the quality of sugar-free sponge cakes. Food Chem. 2011;90:549–555. doi: 10.1016/j.foodchem.2004.05.023. [DOI] [Google Scholar]

- Sahi SS, Alava JM. Functionality of emulsifiers in sponge cake production. J Sci Food Agri. 2003;83:1419–1429. doi: 10.1002/jsfa.1557. [DOI] [Google Scholar]

- Siswoyo TA, Morita N. Influence of acyl chain lengths in mono- and diacyl-sn-glycerophosphatidylcholine on gelatinization and retrogradation of starch. J Agric Food Chem. 2001;49:4688–4693. doi: 10.1021/jf001357p. [DOI] [PubMed] [Google Scholar]

- Stauffer CE. Emulsifiers. Eagan: Eagan; 1999. [Google Scholar]

- Szuhaj BF. Lecithins. In: Shahidi F, editor. Bailey’s industrial oil and fat products, 1. st. Hoboken: John Wiley and Sons; 2005. pp. 361–465. [Google Scholar]

- Turabi E, Sumnu G, Sahin S. Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocoll. 2008;22:305–312. doi: 10.1016/j.foodhyd.2006.11.016. [DOI] [Google Scholar]

- Wetterau FP, Olsanski VL, Smullin CF. The determination of sorbitan monostearate in cake mixes and baked cakes. J Am Oil Chemist’ Soc. 1964;41:791–795. doi: 10.1007/BF02663958. [DOI] [Google Scholar]

- Yang SC, Baldwin RE. Functional properties of eggs in food. In: Stadelman W, Cotterill O, editors. Eggs science and technology, 1 st edn. New York: Hawworth; 1995. pp. 405–463. [Google Scholar]

- Zhou J, Faubion JM, Walker CA. Evaluation of different types of fats for use in high-ratio layer cakes. LWT - Food Sci Tech. 2011;44:1802–1808. doi: 10.1016/j.lwt.2011.03.013. [DOI] [Google Scholar]