Abstract

This study investigated the effect of microwave power (2,400–4,000 W) and drying times (10–30 min) on the quality of dried turmeric in terms of colour (L, a*, b*), moisture content, water activity (aw), ash, antioxidant activity (2,2-dipheneyl-1-picrylhydrazyl; DPPH), total phenolic and curcuminoids content. In addition, Response Surface Methodology (RSM) was implemented to optimize the drying conditions for turmeric. A range of quality parameters, microwave power (W) and time (min) were fitted to quadratic models using a central composite design. The Analysis of Variance (ANOVA) statistic results suggested that the optimal qualities (i.e., aw, value, moisture content, phenolic content, curcuminoid content and EC50 and L value) of dried turmeric were achieved at high vacuum-microwave power (3,500–4,000 W) and long duration (27–30 min). The improvement in the quality of dried turmeric microwave-vacuum drying in these conditions was illustrated through the enzymatic browning reaction via inhibition of polyphenol oxidase which suppressed the formation of the brown pigments and increased the phenol substrates.

Keywords: Turmeric, Curcuminoids, Dehydration, Microwave-vacuum, Optimization

Introduction

Turmeric (Curcuma longa L.), a member of the Zingiberaceae family, is one of the common spices used in Asian cuisine. It grows primarily in tropical and sub tropical regions including India, Bengal, China, Taiwan, Sri Lanka, Jeva, Peru, Australia and Thailand (Suresh et al. 2009). Turmeric has been reported to have a role in preventing human diseases such as cancer (as antioxidants and anti-carcinogenic) and cardiovascular diseases (Prathapan et al. 2009). These medical properties have been credited mainly to the curcuminoids which are abundant in turmeric rhizome (Maheshwari et al. 2006). Nowadays, animals and human trials suggest that curcuminoids have no toxicity even at high doses; therefore, turmeric is a safe ingredient in medicines and cosmetics (Goel et al. 2008). Commercially, turmeric can be sold either fresh or as dried powder. However, dried turmeric powder is more often sold all around the world but the price varies depending on many factors including quality—ie moisture content, appearance (color), and phenolic contents (Jose and Joy 2009). Sun drying is a traditional method; however, it takes a long time (about 10–15 days) and it affects the quality of the product, especially curcuminoids (Sampathu et al. 1988; Prathapan et al. 2009). Therefore, to preserve this bioactive compound a better drying method is needed.

Drying or dehydration is a method of food preservation that has been used all over the world for centuries. Drying involves removing moisture from food; moisture is necessary for bacteria growth that eventually causes food spoilage and deterioration (Flores 2007). One of the primary drying methods is microwave vacuum drying.

Microwave vacuum drying is a method that accumulates the advantages of rapid energy transfer from microwave drying and fast mass transfer at low temperatures from vacuum heating (Giri and Prasad 2007). This drying method decreases drying time and uses a lower temperature; thus it will increase the qualities of dry food products including color, texture and nutrients such as proteins, carbohydrates, lipids, antioxidants and vitamins (Prathapan et al. 2009; Sommano et al. 2011; Polovka and Suhaj 2010). In addition this microwave–assisted drying consumes less specific energy compared to the convention hot-air method as is evident in Yongsawatdigul and Gunasekara’s (1996) experiment which studied the effect of microwave vacuum drying on canberry and Kumar’s et al. (2011) experiment which studied the optimal condition of microwave assisted hot air drying of okra. Both experiments showed that specific energy consumption was reduce due to the reduction of the drying time, as microwave power was increased. However, there is no more current information available on the extent of the bioactive components and quality of turmeric during microwave-vacuum drying. Therefore, the aim of this research project is to examine the effects of microwave-vacuum drying (microwave power and drying time) on turmeric qualities including color, water activity (aw), ash content, EC50 value, total phenolic content and curcuminoid content as well as to determine the optimal drying condition of turmeric.

Materials and methods

Plant material

Fresh turmeric rhizomes (Curcuma longa L), with uniform size and maturity, free from diseases, were bought from a local market in Chiang Mai, Thailand during June–October 2010. At the laboratory, they were cleaned under running tap water and then placed on a rack at room temperature for 2 h. The turmeric skins were then removed. Finally, the cleaned turmeric rhizomes were sliced to about 0.5 mm in thickness using fruit slicers.

Drying equipment

An industrial microwave-vacuum dryer from Marchcool Industry, Thailand was used for this experiment. The microwave power (600–4,000 W) and processing time were varied using digital display. The microwave chamber continuously rotated at a speed of 20 rpm.

Experimental design

A 32 factorial in the central composite design was employed to find the optimal drying condition of turmeric. Three different levels of microwave power (2,400, 3,200 and 4,000 W) and drying time (10, 20 and 30 min) were chosen for this experiment based on the preliminary experiment (data not shown). One kg of the sliced turmeric was placed in a single layer onto the microwave-vacuum chamber. Drying was performed in nine different conditions (time vs. temperature) according to Table 1. All experiments were performed in triplicate. Experimental data for the measured physical and chemical properties were obtained according to the recommended optimum conditions. Validation of the response surface model was conducted by comparing the experimental values obtained from an independent set of samples (n = 3) with the predicted value obtained from the optimal model.

Table 1.

The conditions of microwave-vacuum drying of turmeric using 32 Factorial in CCD

| Condition | X1 (watt) | X2 (min) |

|---|---|---|

| 1 | 2400 | 10 |

| 2 | 2400 | 20 |

| 3 | 2400 | 30 |

| 4 | 3200 | 10 |

| 5 | 3200 | 20 |

| 6 | 3200 | 30 |

| 7 | 4000 | 10 |

| 8 | 4000 | 20 |

| 9 | 4000 | 30 |

*X1 = Power, X2 = Time

CCD = Central Composite Designs

Determination of the free radical scavenging activity by the l,l-Diphenyl-2-picrylhydrazyl (DPPH) free-radical scavenging assay

All the fresh and dried turmeric in the experiment were examined for the free radical scavenging activities using the modified DPPH assay method of Blois (1958). Turmeric powder (0.25 mg) was extracted in 25 ml of methanol and centrifuged at 3000 rpm. The supernatant known as methanol extract was then diluted serially from 10−2 to 10−8 and 0.1 ml of each dilution was transferred into a sample tube containing 0.5 ml of 5 mM DPPH. The mixture was kept for 20 min in darkness, and then placed in a spectrophotometer with a reading of its absorbance at 517 nm. DPPH (2,2-diphenyl-1-picrylhydrazyl) is a kind of free radical with a purple color. The antioxidant substance destroys the free radical; therefore it reduces the color of DPPH• in test tubes (Abdel-Hameed 2009; Moon and Shibamoto 2009). DPPH activity was presented as 50 % effective concentration (EC50), the amount of antioxidant substance to inhibit 50 % of remaining DPPH. The EC50 value can be determined from a graph that plotted % remaining DPPH against concentrations of sample solution.

Determination of total phenolic content (TPC)

The total phenolic content (TPC) was determined by a spectrophotometer using Gallic acid as a standard solution (Ragazzi and Veronese 1973). 0.5 mL of different concentrations (10−1–10−3) of diluted methanol extract were transferred into separate tubes which contained 2.5 mL of a 1−10 dilution of Folin-Ciocalteu’s reagent in water. Then, 2.0 mL of a sodium carbonate solution (7.5 % w/v) was added to the solutions. The tubes were then allowed to stand at room temperature for 60 min before absorbance at 75 nm was measured against water. The TPC was expressed as Gallic acid equivalents (GAE) in mg/ g material. The concentration of phenolic in samples was derived from a standard curve of Gallic acid ranging from 10 to 50 g/mL.

Determination of curcuminoids from turmeric using HPLC technique

A HPLC technique for determining the amount of curcuminoid from turmeric was modified from Preecha et al. (2006). A Shimadzu LC-10ATVP HPLC system connected to a Shimadzu SPD-10 AVVP UV–VIS detector and a Prodigy 250 × 4.60 mm/5 μm column (Phenomenex, CA, USA) was used. The mobile phase solutions were 1 % acetic acid and 45 % acetonitrile (CH3CN) and 54 % deionized water. The flow rate was 1 ml / min and the running time was 30 min. The curcuminoids were detected at 425 nm.

Determination of physical properties of dried turmeric

The physical properties of turmeric were analyzed including color using hunter L, a*, b* scale, moisture content and water activity using AOAC method (AOAC 2000).

Statistical analysis

All results were expressed as mean ± standard deviation (SD). Statistical analyses were carried out using the one-way ANOVA and the Duncan’s post-hoc test on a SPSS software (IBM, NY, USA) and statistical significance was taken at P ≤ 0.05. In addition, the Design Expert version 6 program was employed to find the optimal condition in this experiment. The whole experiment was repeated three times.

Results and discussion

Chemical properties of fresh turmeric

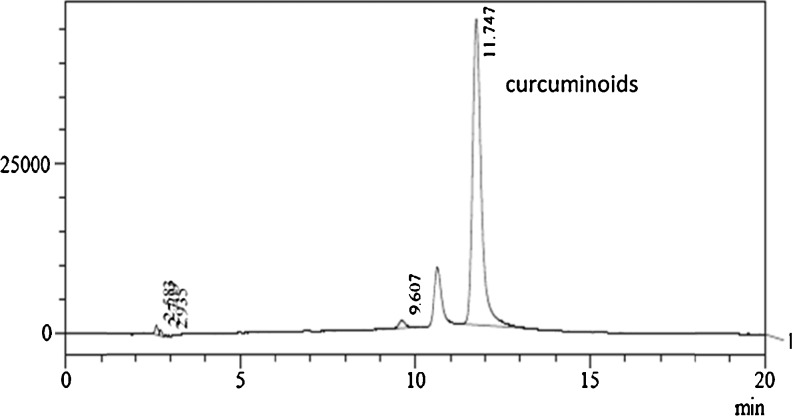

The qualities of fresh turmeric samples including moisture content, ash content, antioxidant activity (EC50), total phenolic content (TPC) and curcuminoid content, are shown in Table 2. The average moisture content of the fresh turmeric sample is 91.52 % which is higher than the 70–80 % shown in the study of Singh et al. (2010). The disparity of moisture content could be due to many factors as harvest season and turmeric varieties. The ash content of the turmeric sample is 96 %; the EC50 value is 57.19 ± 3.21 mg/L which is slightly higher than Paramapojn and Gritsanapan (2009)’s numbers (18.29 ± 0.05 to 40.33 ± 2.24 mg/L). The EC50value represents antioxidant activity; the lower value means more antioxidant activity (Thaikert and Paisooksantivatana 2009). Table 2 shows that the turmeric sample has a very high total phenolic content (TPC) (59.62 ± 6.96 mg GAE/ g dry basis) especially when compared to the study of Tangkanakul et al. (2009) which found 13.407 mg GAE/g. Similar to the moisture content, the amount of TPC in turmeric varies depending on the growth area, harvest season and turmeric varieties. Figure 1 illustrates the chromatogram of curcuminoids standard using the HPLC method. The figure shows that the retention time of curcuminoid peak is 11.747 and using HPLC to analyze the amount of curcuminoids is an appropriate method. Table 2 also shows that the curcuminoids of the fresh turmeric is as high as 9.39 g/100 g dry basis, which is similar to the study of Sikkhamondhol et al. (2009).

Table 2.

Chemical properties of fresh turmeric sample used in the experiment

| Components | Fresh turmeric |

|---|---|

| Moisture content (%) | 91.5 ± 0.65 |

| Total ash content (%) | 6.9 ± 0.06 |

| EC50 (mg/L) | 57.2 ± 3.21 |

| Total phenolic content (mg GAE/ g dry basis) | 59.6 ± 6.96 |

| Curcuminoid content (g/100 g dry basis) | 9.4 ± 3.38 |

*Values are mean of triplications ± SD (Standard Deviation)

Fig. 1.

Chromatogram of standard curcuminoid analyzed by HPLC. RT = 11.75 min

Effect of microwave-vacuum drying on physical properties

Water activity (aw) and colour parameters of microwave-vacuum dried tumeric in each condition are illustrated in Table 3. Results show that aw values of 0.20, 0.28 and 0.19 at conditions 3, 6 and 9, respectively, are significantly lower than other conditions. Generally, food with aw < 0.6 is safe from bacterial and yeast spoilage as well as biochemical activities (Perera 2005). However, the range of aw value from 0.4 to 0.6 is considered to be the optimal condition of Non-enzymatic browning. Therefore, to minimize this reaction, decreasing aw value of food (by heating) to below 0.4 is the best way to slow down this reaction and extend the shelf life of the dried products (Perera 2005). L, a* and b* values in Table 2 indicate the color of dried turmeric by lightness (L), redness (a*) and yellowness (b*). In addition, the L value was used as the indicator to determine the browning potential of dried fruit and vegetable products (Oms-Oliu et al. 2006; Prathapan et al. 2009). In our study, increasing drying time from 10 min to 30 min significantly increased the L value of dried turmeric (Condition 3, 6 and 9 compared to treatments 1, 4 and 7). In addition, the results suggest that products might remain brighter in colour when increasing microwave-vacumm power up to 4000 W. This could be explained through the enzymatic degradation of the two enzymes involved in the browning mechanism viz. polyphenol oxidase (PPO) and/or peroxidase (POD). The similarity, found in the study of Prathapan et al. (2009), showed that the activities of these two enzymes decreased when temperature were over 70 °C. However, the a* and b* values of the products are not significantly different (8.6 to 23.2 for a* and 23.5 to 37.5, for b*). These colour spaces suggests that the dried turmeric has orange-red colour.

Table 3.

Physical properties of dried turmeric slice using microwave-vacuum dryer

| Conditions | Water activity (aw) | Color attributes | ||

|---|---|---|---|---|

| L | ac (ns) | bc (ns) | ||

| 1 | 0.99 ± 0.00a | 44.9 ± 3.11 b | 19.7 ± 3.11 | 26.0 ± 5.78 |

| 2 | 0.97 ± 0.01 a | 45.1 ± 1.15 b | 18.7 ± 3.32 | 23.5 ± 2.96 |

| 3 | 0.20 ± 0.06b | 56.2 ± 4.22 a | 22.3 ± 1.74 | 36.7 ± 6.67 |

| 4 | 0.98 ± 0.07 a | 47.9 ± 2.36ab | 19.1 ± 3.18 | 30.6 ± 4.94 |

| 5 | 0.96 ± 0.02 a | 45.6 ± 3.63 b | 23.3 ± 2.96 | 25.0 ± 3.60 |

| 6 | 0.28 ± 0.13 b | 56.5 ± 3.67 a | 19.5 ± 1.66 | 37.5 ± 6.79 |

| 7 | 0.99 ± 0.00 a | 46.1 ± 2.60 b | 19.3 ± 1.03 | 28.6 ± 3.63 |

| 8 | 0.95 ± 0.02 a | 48.7 ± 3.68ab | 22.6 ± 3.12 | 24.0 ± 6.07 |

| 9 | 0.19 ± 0.05b | 56.0 ± 2.57 a | 20.7 ± 2.79 | 33.5 ± 6.90 |

cValues are mean of triplications ± SD. Within the same parameters, the values followed by the same superscript letters are not significantly different (P ≤ 0.05).

Effect of microwave-vacuum drying on chemical properties

A high themal process may affect the stability of bioactive compounds in food including vitamins and trace elements. For example, heating Irish brown seaweeds over 95 °C decreased its phenolic content (Sommano et al. 2011; Rajauria et al. 2010). A similar result was found in curcuminoids as it was shown that boiling or pressure cooking of turmeric for 10–20 min resulted in the reduction of curcuminoid content by 20–50 % (Suresh et al. 2007). However, Bambirra’s et al. study (2002) showed that heating at 50–100 °C had no effect on curcuminoid content. Therefore, an appropriate temperature (not too high nor too low) to dry the tumeric may play a crucial role in preserving phenolic compounds including curcuminoids in turmeric. Microwave-vacuum drying is an option for drying fruit and vegetables to preserve bioactive compounds. With this method, heat is penetrated throughout the food, resulting in faster heat transfer in a short time, while in traditional heating, heat is transferred slowly from the outermost layer to the centre of the food (Gowen et al. 2006)

The chemical properties of dried turmeric after microwave-vacuum drying are shown in Table 4. The highest amount of total phenolic content (TPC) was found in the dried turmeric “condition 3” which dried with microwave power at 2400 W for 30 min. For this result, Polyphenol oxidase (PPO) may play a crucial role as a similar result was found in the study of Prathapan et al. (2009). The study found that fresh turmeric had less TPC than turmeric that was dried with a hot air oven at 60–100 °C. This result indicates that heat from hot air oven inactivates PPO which is thermally unstable after 60 °C (Chisari et al. 2007). In addition, turmeric that was dried at 80 °C for 30 min had the highest amount of TPC. However, when the drying temperature was increased to 100 °C, the amount of TPC sharply decreased due to the nonemzymatic oxidation of polyphenols (Prathapan et al. 2009). This result indicates that the amount of TPC correlates to the inactivation of PPO in tumeric by using a heat treatment that is neither too low nor too high. The EC50 values from Table 4 show that increasing drying time siginificantly decreases EC50 values. This result indicates that longer microwave vacuum drying time increases antioxidant activity in dried turmeric and relates to the amount of curcuminoids which is also highest (19.04 g/100 g dry basis) in the turmeric that was dried at 4000 w for 30 min (condition 9). As curcuminoids are an active compound which has high antioxidant activity (Tangkanakul et al. 2009) when the amount of curcuminoids increases, the antioxidant activity will increase. However, the maximum amount of curcuminoids were found in “condition 9” which has the lowest moisture content (appox. 4.6 %). Accordingly, the moisture content rather than the heat treatment may be responsible for the curcuminoid content because normally heat treatment (up to 100 °C) has no effect on the amount of curcuminoids in turmeric (Tangkanakul et al. 2009)

Table 4.

Chemical properties of dried turmeric slice using microwave-vacuum dryer

| Conditions | EC50 (mg/L) | Total phenolic content (mg GAE/ g dry basis) | Curcuminoids (g /100 g dry basis) | Moisture content (%) |

|---|---|---|---|---|

| 1 | 59.56 ± 6.964 a | 54.95 ± 19.173 b | 10.08 ± 0.373 b | 74.18 ± 0.780a |

| 2 | 23.71 ± 2.363 c | 38.14 ± 1.506 b | 4.32 ± 0.687 b | 56.94 ± 1.456c |

| 3 | 46.76 ± 3.097 abc | 113.10 ± 17.679 a | 10.34 ± 6.944 b | 6.59 ± 0.236f |

| 4 | 57.58 ± 12.340 a | 46.31 ± 15.31 b | 6.924 ± 0.577 b | 76.24 ± 0.842a |

| 5 | 37.10 ± 14.536 abc | 34.29 ± 6.911 b | 4.19 ± 0.085 b | 50.08 ± 0.217d |

| 6 | 24.12 ± 5.947 c | 47.44 ± 8.772 b | 8.37 ± 1.757 b | 6.85 ± 0.431f |

| 7 | 52.98 ± 12.185 ab | 49.19 ± 18.606 b | 8.68 ± 2.202 b | 68.22 ± 0.309b |

| 8 | 23.41 ± 13.614 c | 24.62 ± 13.013 b | 5.18 ± 3.794 b | 41.53 ± 0.196e |

| 9 | 32.94 ± 6.183 bc | 48.68 ± 8.842 b | 19.04 ± 0.379 a | 4.59 ± 0.178 g |

*Values are mean of triplications ± SD. Within the same parameters, the values followed by the same superscript letters are not significantly different (P ≤ 0.05).

EC50 = Half maximal (antioxidant activity) effective concentration

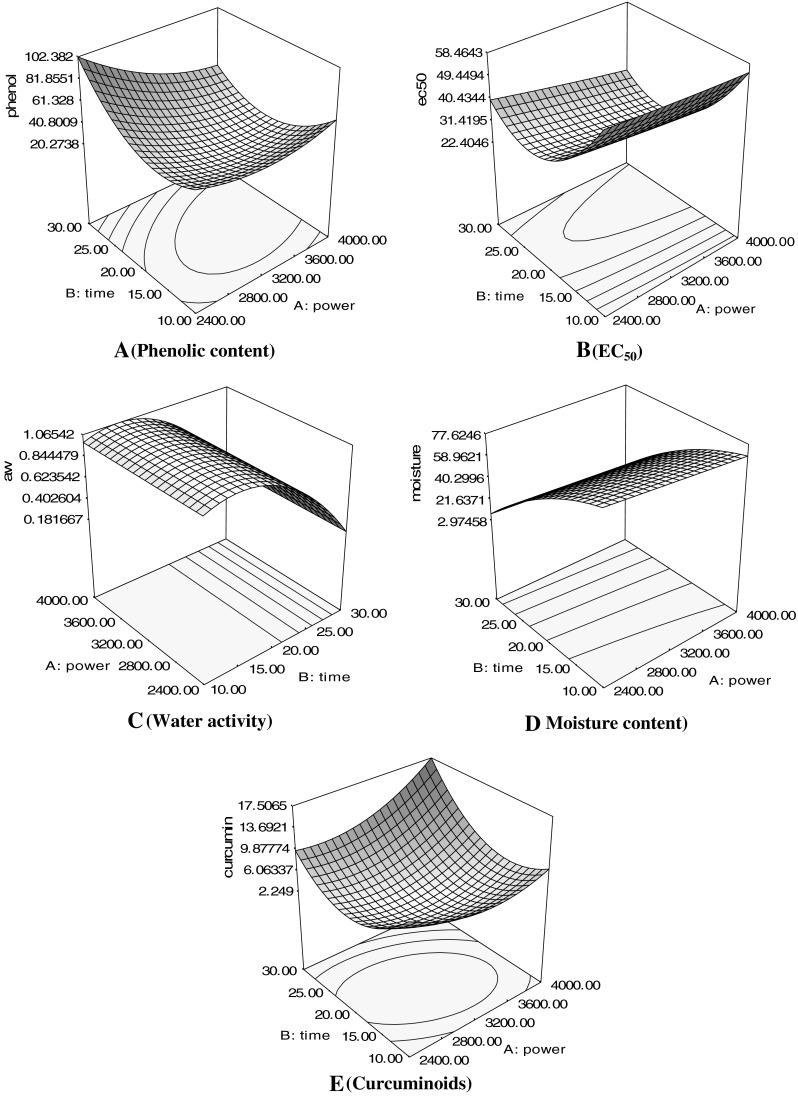

Response surface methodology of physical and chemical attributes of dried turmeric by microwave-vacuum dryer

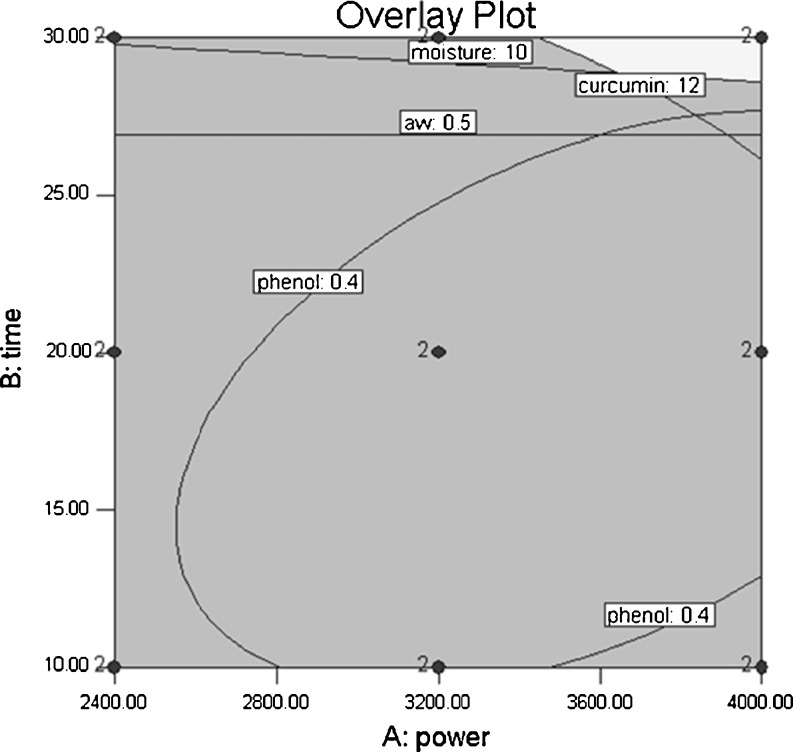

According to the regression relationships in Table 5, microwave power and drying time had significant effects on aw, moisture content, EC50 value, TPC and curcuminoids of dried turmeric at p ≤ 0.05; however, there was no regression relationship found in the colour values. The response surface relations were illustrated in Fig. 2 for each of the significant attributes. The significant regression relationships such as aw value, moisture content, etc. were selected to determine the optimisation condition using Design Expert ver.6. The results in Fig. 3 illustrated that using microwave power between 3500–4000 W and drying time for 27–30 min were an optimal condition to dry turmeric using a microwave-vacuum dryer. The mechanism suggested that, in this condition, the system has removed most of the moisture from turmeric slices (at maximum microwave power and time). On the other hand, the amount of TPC and curcuminoids were the least at the lowest microwave power and with drying for the shortest time. Therefore, heating the turmeric slices at 4000 W for 30 min will result in the best combination of low aw value and moisture content and high TPC and curcuminoid content. This phenomenon could be explained through the enzymatic browning pathway that had the enzyme polyphenol oxidase involved (Prathapan et al. 2009). When the enzyme was denatured (generally at temperature >70 °C), the substrates of the reaction (i.e., Phenolics and curcuminoids) would become available, resulting in colour retention (no browning pigments).

Table 5.

Regression models of physical-chemical attributes of microwave-vacuum dried turmeric

| Quality attributes | Regression equation | p-value | R2 |

|---|---|---|---|

| Water activity (aw) | Y = 0.277 + 0.108 X2 - 3.717E - 003 X22 | <0.0001 | 0.9961 |

| Moisture content (%) | Y = 100.065 - 7.201E-003X1 + 0.175X2-0.098 X22 + 1.183E-004 X1 X2 | <0.0001 | 0.9923 |

| Antioxidant potential (EC50) | Y = +119.806 + 1.957E-004 X1-7.404 X2 + 0.176 X22-2.263E-004 X1 X2 | 0.0047 | 0.6606 |

| Total phenolic content | Y = +247.010-0.101 X1-4.193 X2 + 1.889E-005 X21 + 0.276 X22-1.833E-003X1 X2 | 0.0005 | 0.8116 |

| Total Curcuminoids | Y = 87.128-0.036 X1 - 3.213 X2 + 4 869E - 006 X21 + 0.060 X22 + 3.156E-004 X1X2 | 0.0023 | 0.7534 |

*X1 = Power, X2 = Time

Fig. 2.

Response surface relation between micro wave power (watt), time (min) with phenolic content (a), EC50 (b), water activity (c), moisture content (d) and curcuminoids (e)

Fig. 3.

Optimization point of turmeric drying by microwave-vacuum dryer

An optimal condition was indicated by the response which was at 4000 W for 30 min. Under this optimal condition, the predicted response values for aw value, L value, moisture content, total phenolic content, and curcuminoids content were 0.16 %, 54.99, 0.96 %, 53.14 mg GAE/ g dry basis and 17.45 g /100 g dry basis respectively. Repeated experiments were performed with this condition to validate the predicted optimum. The results from three replications were 0.173 + 0.02 %, 55.23 + 1.84, 2.12 + 1.01 %, 50.67 + 3.79 mg GAE/ g dry basis, and 20.29 + 5.36 g /100 g dry basis for aw, L value, moisture content, phenolic and curcuminoids which validated the predicted value and the model was proven to be reliable.

Conclusion

Over all, drying of turmeric by a microwave-vacuum dryer could be an ideal method for commercial purposes. According to the results of enzymatic browning inhibition, the finished product had a better colour and higher bioactive compounds when turmeric was dried at higher microwave power (up to 4000 W) and for longer drying time ( up to 30 min). Further experiments may focus on the effects of pre-processing on the quality of dried turmeric by microwave-vacuum dryers to determine the stability of bioactive compounds (i.e., curcuminoids) by this type of drying. The better the quality of dry turmeric the greater the amount of TPC and curcuminoids will be to help prevent some human diseases such as cancer and coronary heart disease (Wilken et al. 2011).

Acknowledgment

The authors thank Chiang Mai University and National Research Council of Thailand for funding the research project.

References

- Abdel-Hameed ESS. Total phenolic contents and free radical scavenging activity of certain Egyptian Ficus species leaf samples. Food Chem. 2009;114:1271–1277. doi: 10.1016/j.foodchem.2008.11.005. [DOI] [Google Scholar]

- Official methods of analysis. Washington: Association of Official Analytical Chemists International; 2000. [Google Scholar]

- Bambirra MLA, Junqueira RG, Glória MBA. Influence of post harvest processing conditions on yield and quality of ground turmeric (Curcuma longa L.) Braz Arch Biol Technol. 2002;45:423–429. doi: 10.1590/S1516-89132002000600004. [DOI] [Google Scholar]

- Blois MS. Antioxidant determinations by the use of a stable free radical. Nature. 1958;26:1199–1200. doi: 10.1038/1811199a0. [DOI] [Google Scholar]

- Chisari M, Barbagallo RN, Spagna G. Characterization of polyphenol oxidase and peroxidase and influence on browning of cold stored strawberry fruit. J Agric Food Chem. 2007;155:3469–3476. doi: 10.1021/jf063402k. [DOI] [PubMed] [Google Scholar]

- Flores NC. Drying foods. New Mexico: New Mexico State University; 2007. [Google Scholar]

- Giri SK, Prasad S. Optimization of microwave-vacuum drying of button mushrooms using response-surface methodology. Drying Technology: An International Journal. 2007;25:901–911. doi: 10.1080/07373930701370407. [DOI] [Google Scholar]

- Goel A, Kunnumakkara AB, Aggarwal BB. Curcumin as “Curecumin”: from kitchen to clinic. Biochem Pharmacol. 2008;75:787–809. doi: 10.1016/j.bcp.2007.08.016. [DOI] [PubMed] [Google Scholar]

- Gowen A, Abu-Ghannam N, Frias J, Oliveira J. Optimisation of dehydration and rehydration properties of cooked chickpeas (Cicer arietinum L) undergoing microwave-hot air combination drying. Trends Food Sci Technol. 2006;17:177–183. doi: 10.1016/j.tifs.2005.11.013. [DOI] [Google Scholar]

- Jose KP, Joy CM. Solar tunnel drying of turmeric (Curcuma longa linn. syn. c. domestica VAL.) for quallity improvement. J Food Process Preserv. 2009;33:121–135. doi: 10.1111/j.1745-4549.2008.00287.x. [DOI] [Google Scholar]

- Kumar D, Prasad S, Murthy GS (2011) Optimization of microwave-assisted hot air drying conditions of okra using response surface methodology. J Food Sci Tech. doi:10.1007/s13197-011-0487-9 [DOI] [PMC free article] [PubMed]

- Maheshwari RK, Singh AK, Gaddipati J, Srimal RC. Multiple biological activities of curcumin: a short review. Life Sci. 2006;78:2081–2087. doi: 10.1016/j.lfs.2005.12.007. [DOI] [PubMed] [Google Scholar]

- Moon JK, Shibamoto T. Antioxidant assays for plant and food components. J Agric Food Chem. 2009;57:1655–1666. doi: 10.1021/jf803537k. [DOI] [PubMed] [Google Scholar]

- Oms-Oliu G, Aguilo-Aguayo I, Martin-Belloso O. Inhibition of browning on fresh-cut pear wedges by natural compounds. J Food Sci. 2006;71:S216–S224. doi: 10.1111/j.1365-2621.2006.tb15644.x. [DOI] [Google Scholar]

- Paramapojn S, Gritsanapan W. Free radical scavenging activity determination and quantitative analysis of curcuminoids in Curcuma Zedoaria rhizome extracts by HPLC method. Curr Sci India. 2009;97(7):1069–1073. [Google Scholar]

- Perera CO. Selected quality attributes of dried foods. Drying Technol. 2005;23:717–730. doi: 10.1081/DRT-200054180. [DOI] [Google Scholar]

- Polovka M, Suhaj M. The effect of irradiation and heat treatment on composition and antioxidant properties of culinary herbs and spices a review. Food Rev Int. 2010;26:138–161. doi: 10.1080/87559121003590227. [DOI] [Google Scholar]

- Prathapan A, Lukhman M, Arumughan C, Sundaresan A, Raghu KG. Effect of heat treatment on curcuminoid, colour value and total polyphenols of fresh turmeric rhizome. Int J Food Sci Tech. 2009;44:1438–1444. doi: 10.1111/j.1365-2621.2009.01976.x. [DOI] [Google Scholar]

- Preecha B, Wipawee S, Bandid K, Prommin K, Sulakhana M. Quantitative analysis of major components in Khamin Chan and Fathalai capsules by high performance liquid chromatography. Thai Pharm Health Sci J. 2006;1:51–58. [Google Scholar]

- Ragazzi E, Veronese G. Quantitative analysis of phenolics compounds after thin-layer chromatographic separation. J Chromatogr. 1973;77:369–375. doi: 10.1016/S0021-9673(00)92204-0. [DOI] [PubMed] [Google Scholar]

- Rajauria G, Jaiswal AK, Abu-Ghannam N, Gupta S. Effect of hydrothermal processing on colour, antioxidant and free radical scavenging capacities of edible Irish brown seaweeds. Int J Food Sci Technol. 2010;45:2485–2493. doi: 10.1111/j.1365-2621.2010.02449.x. [DOI] [Google Scholar]

- Sampathu SR, Krishnamurthy N, Sowbagya HB, Shankarana-Rayana ML. Studies on quality of turmeric (Curcuma longa L.) in relation to curing methods. J Food Sci Technol. 1988;25:152–155. [Google Scholar]

- Sikkhamondhol C, Teanpook C, Boonbumrung S, Chittrepol S. Quality of bread with added turmeric (Curcuma longa): powder, essential oil and extracted residues. As J Food Ag-Ind. 2009;2:690–701. [Google Scholar]

- Singh G, Arora S, Kumar S. Effect of mechanical drying air conditions on quality of turmeric powder. J Food Sci Tech. 2010;47(3):347–350. doi: 10.1007/s13197-010-0057-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sommano S, Caffin N, Mcdonald J, Cocksedge R. The impact of thermal processing on bioactive compounds in Australian native food products (bush tomato and Kakadu plum) Food Res Int. 2011;3:176–184. [Google Scholar]

- Suresh D, Manjunatha H, Srinivasan K. Effect of heat processing of spices on the concentrations of their bioactive principles: turmeric (Curcuma longa), red pepper (Capsicum annuum) and black pepper (Piper nigrum) J Food Compos Anal. 2007;20:346–351. doi: 10.1016/j.jfca.2006.10.002. [DOI] [Google Scholar]

- Suresh D, Gurudutt KN, Srinivasan K. Degradation of bioactive spice compound: curcumin during domestic cooking. Eur Food Res Technol. 2009;228:807–812. doi: 10.1007/s00217-008-0993-9. [DOI] [Google Scholar]

- Tangkanakul P, Auttaviboonkul P, Niyomwit B, Lowvitoon N, Charoentanmavat P, Trakoontivakorn G. Antioxidant capacity, total phenolic content and nutritional value composition of Asian foods after thermal processing. Int Food Res J. 2009;16:571–580. [Google Scholar]

- Thaikert R, Paisooksantivatana Y. Variation of total curcuminoids content, antioxidant activity and genetic diversity in turmeric (Curcuma longa L.) collections. Kasetsart J. 2009;43(3):507–518. [Google Scholar]

- Wilken R, Veena MS, Wang MB, Srivatsan ES. Curcumin: a review of anti-cancer properties and therapeutic activity in head and neck squamous cell carcinoma. Mol Can. 2011;7:10–12. doi: 10.1186/1476-4598-10-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yongsawatdigul J, Gunasekaran S (1996) Microwave-vacuum drying of cranberries: part 1 energy use and efficiency. J Food Process Press 20 (2):121-143