Abstract

This study aimed to develop a type of hamburger meat product and evaluate the physical features and sensory formulations of oatmeal flour, flour of green banana pulp, flour of green banana peel, flour of apple peel and pulp of Green Banana as fat substitutes. Regarding color, the formulations containing fat substitutes based on green banana presented lower values for b* and L*. Hamburgers with added oatmeal and apple peel flour obtained high values of a* and low values of L*, producing the reddest burgers. Substitutes based on green banana differed from others, resulting in a higher yield of burgers and water-holding capacity during cooking, besides having lower toughness and less shrinkage. The sensory acceptance test for untrained consumers suggests that the flour of peel and pulp of green banana, and oatmeal flour are excellent choices for fat-substitution in beef burger. Although fat contributes to a series of physical and sensory attributes such as softness, juiciness and yield, it is possible to reduce the lipid content in beef burgers without depreciating the quality of food through the use of the following fat substitutes: oat flour, apple peel flour, green banana pulp flour, green banana peel flour and green banana pulp.

Keywords: Beef burger, Low-fat, Fat substitutes, Technological characteristics, Sensory analysis

Introduction

In recent years, beef consumption has shown continuous growth. Much of this growth is related to the sector of frozen meat products, especially burgers. The consumption of these meat products has increased so much that one single “fast food” network sells more than 100 billion hamburgers annually worldwide at a rate of 75 burgers per second (Spencer et al. 2005).

The popularity of hamburger lies in its favorable sensory characteristics, practicality and high content of protein with high biological value, vitamins and minerals, which has transformed it into a habitually consumed food in many countries (Ramadhan et al. 2011). This product is prepared from minced meat, and traditionally, contains up to 30 % fat. If the meat is too lean, then the texture is rubbery and additional fat is necessary to provide the desired degree of succulence, with an acceptable flavor and texture (Carrapios 2007; Angor and Al-Abdullah 2010). However, high fat intake is related to an increased risk of obesity, some cancers, high cholesterol blood rates, hypertension and coronary heart disease (United States Department of Health and Human Services 1998; United States Department of Agriculture 1995; Krauss et al. 1996; Khalil 2000). For these reasons, many health organizations have alerted the beef industry about the need to develop meat products with reduced fat and to value food products with reduced amounts of fat (Troy et al. 1999; Turhan et al. 2005).

To make this product healthier, some prospects for the reduction of the lipid content of hamburger meat have been proposed. Several studies highlighted the possibility of replacing some of the fat with another ingredient or a combination of ingredients known as fat replacers (Troy et al. 1999; Sáyago-Ayerdi et al. 2009).

The development of low fat foods seems to be simple at first but demands great efforts in research and development because fat contributes to sensory attributes like softness, juiciness and yield that are considered to be important by consumers (García et al. 2002). However, research has found that some fat substitutes composed of carbohydrates like starches and fibers, among others, can improve the physical and sensory characteristics of meat products with reduced fat when used at concentrations of up to 3 % (Berry 1994; Desmond et al. 1998; Troy et al. 1999; Anderson and Berry 2000). It is also important to note that meat does not contain fiber and is frequently associated with the appearance of diseases in the human digestive tract (Mansour and Khalil 1997).

An interesting alternative for food production is the use of waste fruit (mainly from fruit peels and scrap) as feedstock. This is a concrete and plausible proposal as the residues of fruits are sources of fiber, vitamins, minerals, flavonoids and phenolic substances with beneficial health effects that may assist in preventing the development of several chronic diseases (Oliveira 2002).

Addition of vegetable products in meat products can improve its functional properties, minimizing the product cost and improving or at least maintaining nutritional and sensory qualities of end products (Turhan et al. 2007; Ali et al. 2011). Vegetables could also serve as fillers, binders, fat replacers and sources of dietary fiber and natural antioxidants in a meat system (Hedrick et al. 1994; Ali et al. 2011).

Ali et al. (2011) evaluated the effect of potato flakes as fat replacer on the quality attributes of low-fat beef patties: cholesterol content of low-fat patties decreased as level of potato flakes increased; cooking yield and water holding capacity increased with increasing the levels of potato flakes; overall acceptability for beef patties formulated with potato flakes was high. Kaack and Pedersen (2005) used by-products from industrial processing of potato flour and yellow peas as ingredients in low-fat high-fiber sausages: the formulations resulted in sausages with excellent flavor and texture, an attractive color, in addition to a reduction of the caloric value. Anderson and Berry (2000) evaluated some properties of lower-fat beef patties made with inner pea fiber: the use of this fiber improved tenderness and cooking yield, without negative effects on juiciness and flavor. Besbes et al. (2008) used pea fiber wheat fiber concentrates as dietary fibers in beef burger formulation: the use of these fibers increased the cooking yield, decreased the shrinkage, and minimized production cost without degradation of sensory properties.

This study aimed to develop a type of hamburger meat product with vegetable substitutes of fat. The formulations were based on replacement of fat by oatmeal flour, green banana pulp flour, green banana peel flour, apple peel flour and green banana pulp. A study of the physical characteristics and sensory acceptance was carried out to evaluate the characteristics of formulations containing fat substitutes.

Materials and methods

Preparation of green chunky banana pulp, peel fruit flours, and oatmeal

Fruits that could not be sold for direct consumption (fruit dismembered of the banana bunch) were employed for the preparation of the pulp and flour and were bought at a local market of Lavras, MG. All fruits were sanitized (immersion in 5 mg L−1 sodium hypochlorite for 1 min) before processing. The bananas were used in maturation stage of 1 (Tapre and Jain 2012).

To obtain the green chunky banana pulp, green bananas were mashed and frozen at −10 °C. The three other types of fruit flours (apple peel, green chunky banana peel and green chunky banana pulp) were prepared in the same fashion. The peels or pulps were crushed, dried in a lyophilizer (Labconco, FreeZone 4.5 L) for 36 h and then ground in a hammer mill (Treu, model 112 M989, São Paulo, Brasil). The standards were made on an 80-mesh-cell sieve. After preparation, the products were stored in polypropylene airtight (80 × 37 × 56, W x H x L) until the use in burger formulations. Oatmeal flour (mark Quaker) was bought at local market of Lavras, MG.

Hamburger patty formulation

The meat (10 kg of fresh rump, Nelore, 2 years old) for burgers formulations was acquired at butcher shop inspected by the Brazilian health agency, at Lavras, MG.

Initially, all apparent fat and connective tissue were removed from the meat. The meat and fat (back fat) were then ground separately in a grinder (5 mm hole openings in the grinder plate) two times to obtain good uniformity. After grinding, this material was divided on 1 kg blocks, vacuum-packed in vacuum pouches, and then frozen at −18 °C until processing and characterization.

Good handling practices were followed during burger formulation (Brasil 1997). For each burger formulation, thawed meat (on cooling) at a temperature between −1.6 and −3.0 °C, monitored by a thermometer, was used.

The formulations were prepared according to Table 1.

Table 1.

Experimental details of the formulations of beef burgers. Ingredients in % w/w

| Formulation | F1a | F2a | F3 | F4 | F5 | F6 | F7 |

|---|---|---|---|---|---|---|---|

| Meatb | 88.0 | 79.0 | 85.0 | 85.0 | 85.0 | 85.0 | 85.0 |

| Cold mineral water | 10.5 | 10.5 | 10.5 | 10.5 | 10.5 | 10.5 | 10.5 |

| Salt | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Added fat | – | 9.0 | – | – | – | – | – |

| Oatmeal flourc | – | – | 3.0 | – | – | – | – |

| Flour of green banana pulpd | – | – | – | 3.0 | – | – | – |

| Flour of green banana peele | – | – | – | – | 3.0 | – | – |

| Flour of apple peelf | – | – | – | – | – | 3.0 | – |

| Pulp of Green Bananag | – | – | – | – | – | – | 3.0 |

aconventional formulation

bMeat without apparent fat and connective tissue

cmoisture 2.8 %; fat 19.4 %; ashes 4.5 %; protein 37.5 %; carbohydrates 35.7 %

dmoisture 3.0 %; fat 0.6 %; ashes 2.8 %; protein 4.2 %; carbohydrates 89.5 %

emoisture 5.8 %; fat 11.3 %; ashes 9.8 %; protein 8.4 %; carbohydrates 64.6 %

fmoisture 6.2 %; fat 4.4 %; ashes 1.3 %; protein 3.2 %; carbohydrates 84.9 %

gmoisture 68.3 %; fat 1.5 %; ashes 3.2 %; protein 4.6 %; carbohydrates 22.4 %

For preparation of beef burgers, the ingredients and the meat were mixed in a paddle mixer (FDSP, SHSJ Paddle Mixer Feed) for 6 min. After salt (dissolved in 50 ml cold water (4 °C)) was added. For the production of hamburgers, 90 g portions were packed in polyethylene plastic, molded by hand press into a mold 13 cm in diameter. After molding, the hamburgers were frozen in waxed cardboard boxes, vacuum-packed and kept at temperatures below −18 °C until analysis.

Thermal treatment

After thawing at 4 °C for 12 h, the burgers were cooked on an electrical grill (stainless steel, 110 × 23 × 45 cm, 5,450 W) at 150 °C for about 12 min (7 min on one side and 5 min on the other side).

Technological characterization

Cooking yield

The yield percentage was calculated according to the following equation proposed by Berry (1992):

|

1 |

Shrinkage after cooking

The hamburger shrinkage percentage due to cooking was determined according to the following equation proposed by Berry (1992):

|

2 |

Water-holding capacity

The hamburgers (cooked strips) water-holding capacity (WHC) was determined according to the methodology adapted by Troy et al. (1999). Samples of 1.0 cm in thickness and weighing approximately 5.0 g were taken from the burgers. These samples were wrapped in common cotton, packed in quantitative filter paper and centrifuged at 4,000 rpm for 10 min. After centrifugation, samples were taken from the cotton and weighed. The WHC was calculated according to the following equation:

|

3 |

where:

- A

weight of sample before centrifugation (g)

- D

sample weight after centrifugation (g)

- U

initial moisture content of the sample (g).

Shear force

The shear force (kgf) was measured on cooked hamburger. The pieces of meat 2.5 cm in length and 1 cm in thickness were taken from two different areas of each sample. The methodology of Abularach et al. (1998) was used with a texture analyzer (Stable Micro System, model TA-XT2, Surrey, England) equipped with a Warner-Bratzler cell operating at a speed of 200 mm/min.

Color measurement

The color of cooked samples were measured with a colorimeter (Minolta, model CR 300, Osaka, Japan), operating on the CIE system to measure the parameters L*, a* and b* (10 mm aperture opening, D65 illuminant source, and 90° viewing angle). The color was measured from a three-dimensional color diagram (L* a* b*), where L* indicates lightness, a* chromaticity indicates green (-) to red (+) and b* chromaticity indicates blue (-) to yellow (+).

Sensory analysis

Each one of the seven formulations was evaluated by 80 untrained adult consumers belonging to this university. The acceptance test was carried out on two sections (four samples in first section, and three samples in second section) with the same 80 consumers. The evaluated attributes were appearance, taste, texture, overall aspect, and intent to purchase. The acceptance test was performed using a 9-point hedonic scale (9 = I like extremely, 1 = I dislike extremely) and the purchase probability using a 5-point scale (5 = I definitely would buy the product; 1 = I certainly would not buy the product). The tests were conducted in an enclosed cab with white illumination, and the samples were placed on a white workbench and coded with three random digits (Cruz et al. 2013a).

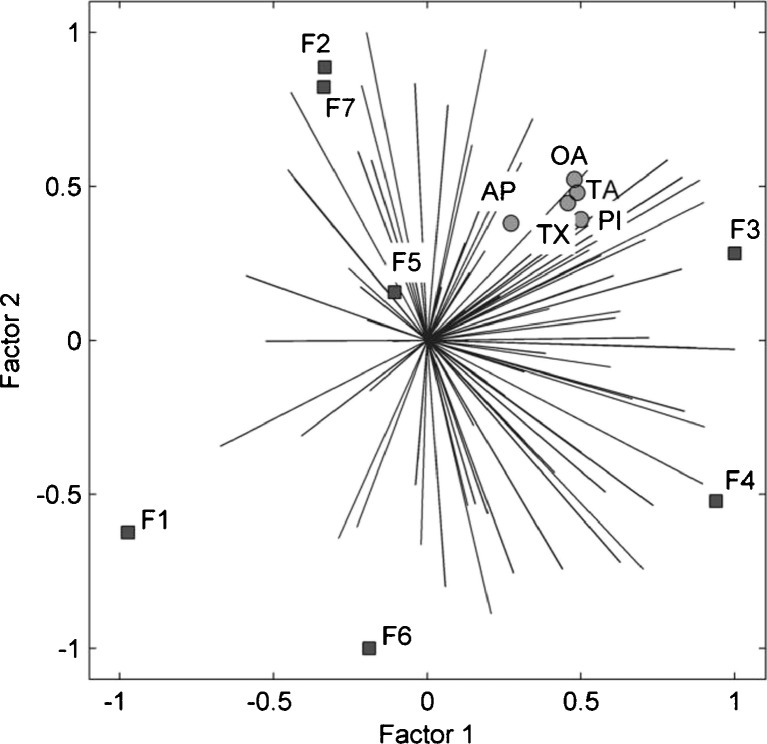

Sensory data were statistically analyzed by a three-way internal preference mapping (Nunes et al. 2011). The calculations were performed using the SensoMaker software (Pinheiro et al. 2013).

The three-way preference map was obtained by PARAFAC (Parallel Factor Analysis) (Bro 1997) from a three-dimensional data conformation consisting of seven samples × 80 consumer × five attributes. PARAFAC is a method employed for the decomposition of higher-order data, and it can be considered a generalization of PCA for multidimensional data (Bro 1997). PARAFAC is able to provide an exploratory interpretation of the samples and variables, taking into account the different K conditions in which the data were generated. Therefore, PARAFAC is able to decompose an I × J × K array, which, in the case of internal preference mapping studies, is an array of products × consumers × attributes. PARAFAC provides parameters (loadings) that directly reflect the variability in the three modes of interest (i.e., samples, consumers, and attributes). Then, the first two factors of each loading mode are plotted on a bidimensional graph. The first mode represents the samples, the second mode represents the consumers, and the third mode represents the attributes. The interpretation of the three-way internal preference maps obtained by PARAFAC is made in a similar manner to that of regular internal preference maps, i.e., based on the positions of points in the graphs (Nunes et al. 2011). In the present study, PARAFAC models with different numbers of factors were calculated and the criteria CORCONDIA and explained variance were used to determine the appropriate number of components. This number was assessed through of the model with the highest number of components, the greatest explained variance and a valid value for CORCONDIA, close to 100 % (Cruz et al. 2012).

Results and discussion

Color parameter evaluation

Color evaluation of hamburger samples was performed to determine the influence of fat substitutes on this physical feature, which is one of the main parameters of quality that leads to consumer purchase and overall acceptability of the meat product.

Table 2 shows the variation of L*, a* and b* according to different fat substitutes employed in the formulation of beef hamburgers.

Table 2.

L*, a*, and b* of different formulations of hamburgers containing alternative fat substitutes

| Formulations | L* | a* | b* |

|---|---|---|---|

| F1 | 32.09 ± 1.57 a | 5.70 ± 0.08 a | 4.46 ± 0.06 c |

| F2 | 43.32 ± 0.29 b | 5.63 ± 0.17 a | 4.42 ± 0.37 c |

| F3 | 31.93 ± 1.18 a | 7.80 ± 0.15 c | 3.31 ± 0.17 b |

| F4 | 31.44 ± 0.22 a | 6.49 ± 0.23 b | 2.31 ± 0.18 a |

| F5 | 30.22 ± 0.46 a | 6.48 ± 0.35 b | 2.04 ± 0.06 a |

| F6 | 31.80 ± 0.20 a | 8.38 ± 0.38 c | 3.08 ± 0.14 b |

| F7 | 30.45 ± 0.53 a | 6.56 ± 0.36 b | 2.27 ± 0.16 a |

Values are mean of three replicates. Means in a column with different letters are significantly different (P < 0.05)

The L* parameter (lightness) exhibited results between 29.55 and 43.32. Formulation F2 showed the highest L* value compared to the others. As this parameter reflects the brightness of the hamburger, this formulation was the palest, which can be explained by presence of fat in this formulation. These results are consistent with studies on processed meat products that show that the addition of fat results in paler products has a dilutive effect on color (Troutt et al. 1992; Seabra 2002; Figueiredo 2002; Aleson-Carbonell et al. 2005; Turhan et al. 2005). The no fat treatments had low values of L*, and they were the darkness treatments. Previous work reports that the partial or total removal of fat from beef burgers results in a darker color, probably due to the decrease in light as described by Figueiredo (2002). Besides it can be supposed that the darker color of the no fat hamburgers was due to non-enzymatic browning reaction during the cooking between carbohydrates present in the substitutes and amino acids of the meat.

The a* parameter showed values between 5.66 and 8.11. The burgers with fat substitutes reached the highest values of a*; in other words, these samples were redder compared to F1 and F2. The formulations F6 and F3 were redder than the others. The literature reveals that the incorporation of fat substitutes in meat products may increase the red color of processed foods, and this increase is proportional to the amount of substitute used in the preparation (Pietrasik 1999; Crehan et al. 2000).

The F4, F5 and F7 formulations showed lower b* values than the others. The addition of fat substitutes in this study reduced the b* value, resulting in products that were less yellowish but had color characteristic of the identity and quality of beef burgers. This reduction in b* values can be justified by the substitutes used in this research having a good potential for moisture retention, which has a dilutive effect on the chromaticity, as described by Aleson-Carbonell et al. (2005). Similar results were found by Turhan et al. (2005).

Characteristics of water-holding capacity, yield, shrinkage, and shear force

The physical characteristics of yield, shrinkage, water-holding capacity and shear force for the seven formulations are presented in Table 3.

Table 3.

Yield, shrinkage, water-holding capacity (WHC) and shear force of different formulations of beef burgers containing alternative fat substitutes

| Formulation | WHC (%) |

Yield (%) |

Shrinkage (%) |

Shear force (kgf) |

|---|---|---|---|---|

| F1 | 56.7 ± 1.0 a | 68.6 ± 0.5 a | 19.7 ± 0.7 c | 3.7 ± 0.2 b |

| F2 | 54.5 ± 0.9 a | 69.1 ± 0.5 a | 19.7 ± 0.5 c | 4.0 ± 0.3 b |

| F3 | 74.5 ± 0.8 b | 72.2 ± 0.3 b | 16.5 ± 0.4 b | 2.2 ± 0.1 a |

| F4 | 78.8 ± 0.6 c | 86.7 ± 0.9 c | 13.3 ± 0.6 a | 1.7 ± 0.1 a |

| F5 | 80.9 ± 1.1 c | 87.3 ± 0.8 c | 13.2 ± 0.5 a | 1.8 ± 0.1 a |

| F6 | 74.9 ± 1.0 b | 73.1 ± 1.0 b | 17.4 ± 0.5 b | 2.0 ± 0.3 a |

| F7 | 79.9 ± 0.9 c | 88.9 ± 0.8 c | 12.8 ± 0.3 a | 1.9 ± 0.2 a |

Values are mean of three replicates. Means in a column with different letters are significantly different (P < 0.05)

Water-holding capacity

WHC is a meat property describing the ability to retain water through self-structuring. It is a technological parameter used by the meat industry because it is related to post-slaughter weight loss, along with the quality and yield of meat and meat products. WHC also influences the sensory quality of meat because water loss during cooking can affect the juiciness and softness of meat (Aleson-Carbonell et al. 2005).

Samples of hamburger with fat substitutes had higher water-holding capacity than F1 and F2, as illustrated in Table 3. Formulations F4, F5 and F7 highlighted with respect to this parameter. This may be explained by the high total starch content in the banana products, which is gelatinized at high temperatures, and absorbs water into starch granules with concomitant swelling (Rodríguez-Ambriz et al. 2008; Ali et al. 2011). The F6 and F3 formulations also are good alternative for fat substitutes in burgers because its substitutes increase yield with respect to the conventional product. The ability of these substitutes of fat to hold moisture in meat samples has favorable implications in the final product quality by preventing excessive moisture loss in products thus avoiding undesirable crunchy and flaky texture (Ali et al. 2011). Additionally, oats (F3) provide better intestinal function and gastric emptying, which result in greater satiety (Troy et al. 1999).

García et al. (2002) found that with fiber fruits and cereals in the manufacture of low-fat sausages, the water content in such products was higher than that in others, probably due to increased water-holding capacity of these fibers, mainly soluble.

These results are relevant for food industries, which have sought alternative technologies to improve the water-holding capacity of meat products. Water loss is a problem for traders and consumers due to the reduction in weight of meat and the accumulation of fluid around it. Color, texture and acceptability depend on the product’s ability not to lose water (Morón-Fuenmayor and Zamorano-García 2004; Hautrive et al. 2008).

Data from this study and others conducted in the same field show that burgers without fat, made with alternative fat substitutes, have a high WHC, resulting in a juicier product and suggesting that the addition of some substitutes has a positive influence on the ability of meat products to retain water (Desmond et al. 1998; Troy et al. 1999; Khalil 2000; Anderson and Berry 2001; Seabra 2002).

Yield and shrinkage

The formulations without added fat had a higher yield upon cooking compared to conventional products (F1 and F2). This improvement could be due to the increased in moisture binding by the added fat substitutes, and on the other hand, the loss in control beef patties might be attributed to the excessive fat separation and water release during cooking (Ali et al. 2011). It is reported that flour-based fat substitutes, which are rich in starch and pectin, upon contact with water, form gels that result in greater retention of water and lipids in food (Aleson-Carbonell et al. 2005). The lower yield of the F1 and F2 formulations can also be attributed to excessive fat separation and water during cooking (Mansour and Khalil 1997; Khalil 2000; Turhan et al. 2005). According to Table 3, among the fat substitutes evaluated, the formulation with the highest yield (88.98 %) was the F7 formulation, followed by F5 and F4, which had yields of 87.35 % and 86.71 %, respectively. As mentioned, these fat substitutes from green chunky bananas have high capacities for water retention and higher swelling.

The relationship between the type of fat substitute and yield after cooking is in agreement with literature results in which burgers with reduced fat levels and added fat substitutes had higher-yield formulations with and without fat (Meinhold 1991; Pszczola 1991; Berry 1992; Mansour and Khalil 1997; Desmond et al. 1998; Khalil 2000; Anderson and Berry 2001; Seabra 2002; Aleson-Carbonell et al. 2005; Turhan et al. 2005). However, the formulations in which the green chunky banana was used as a fat substitute had yield values above those quoted by these authors.

The shrinkage of the F3, F4, F5, F6 and F7 formulations was also lower than that of F1 and F2. The hamburgers containing residues of the green banana highlighted with respect to this parameter, as these samples showed the smallest reduction in diameter during cooking. The reduction in diameter is the result of the denaturation of meat proteins with the loss of water and fat. The addition of fat substitutes could contribute to the reduction of this phenomenon because of their water and fat-binding capacities (Besbes et al. 2008).

The literature (Mansour and Khalil 1997; Seabra 2002; Turhan et al. 2005; Anderson and Berry 2000; Besbes et al. 2008) mentioned that meat products containing added fat substitutes shrank less during cooking compared to conventional products (hamburger with and without fat), but some formulations in this study (F4, F5 and F7) exhibited slightly lower values of shrinkage.

Shear force

It was found that there was a change in the characteristic hardness among the formulations under study. Formulation F2, in general, showed the greatest hardness, followed by F1. The other formulations which were used fruits and oatmeal based fat substitutes presented lower force values. These substitutes are source of fibers and should contribute to hygroscopicity and give the final product its characteristic juiciness and less mechanical resistance. The formulations with added fat substitutes showed less hardness. These results corroborate those of the existing literature, which reports that some substitutes may provide better texture to products made with ground beef because these ingredients absorb water, dissolve with the meat protein matrix and result in increased softness of the product (Mansour and Khalil 1997; Desmond et al. 1998; Tsai et al. 1998; Khalil 2000; Aleson-Carbonell et al. 2005; Anderson and Berry 2000).

Principal component analysis

PCA is an exploratory method that seeks to show similarities or differences among samples in a given dataset and allows for acquisition of information about the typical characteristics from the samples based on studied variables, thus facilitating understanding the dataset (Beebe et al. 1998; Cruz et al. 2013b; Souza et al. 2011). Using the principal component analysis (Fig. 1), it was possible to evaluate the similarities between the samples of hamburgers because of their physical characteristics.

Fig. 1.

Scores (a) and loadings (b) plots of PCA for the physical characteristics of the hamburger samples. Formulation no added fat (F1), with added fat (F2), fat substituted for oatmeal (F3), fat substituted for flour of green banana pulp (F4), fat substituted for flour of green banana peel (F5), fat substituted for flour of apple peel (F6), fat substituted for green banana pulp (F7)

Two principal components (PCs) were used and together explained 99.69 % of the total variance observed between samples in this study. The scores plot (Fig. 2a) indicates the formation of three distinct groups. The first group was formed by F1 and F2 samples. According to the loadings plot (Fig. 2b), these formulations are characterized by high strength and greater shrinkage during cooking, as well as lower yield and capacity to retain water. The second group composed of F4, F5 and F7 formulations showed a higher yield during cooking and higher WHC when compared to other treatments. They were also less in hardness and shrinkage in cooking. The third group, formed by F3 and F6 formulations, had intermediate values, mainly for WHC and shrinkage.

Fig. 2.

Three-way internal preference map for appearance (AP), taste (TA), texture (TX), overall aspect (OA) and purchase intent (PI). Consumers are represented by ○. Formulation no added fat (F1), with added fat (F2), fat substituted for oatmeal (F3), fat substituted for flour of green banana pulp (F4), fat substituted for flour of green banana peel (F5), fat substituted for flour of apple peel (F6), fat substituted for green banana pulp (F7)

Sensory analysis

The hamburger formulations were evaluated on the sensory attributes of appearance, taste, texture, overall aspect and purchase intention.

The three-way internal preference map obtained by PARAFAC allows for the verification of similarities or differences between samples (by loadings in first mode) and the verification of samples receiving the largest number of high ratings in the sensorial analysis (by loadings in \ond mode), and it considers the ratings of all attributes simultaneously. Then, a global interpretation of the sensory analysis considering all attributes can be made. Moreover, the influence of each attribute on the distinction of the samples and on the rating distribution can be evaluated (by loadings in third mode) (Nunes et al. 2011).

The internal preference map is shown in Fig. 2. Three factors were used to obtain the PARAFAC model, which presented a core consistency (Bro and Kiers 2003; Nunes et al. 2011) of 72.35 %. It can be observed that many consumers approved of formulation F3 in terms of appearance, flavor, texture, overall aspect and purchase intention. This indicates that the F3 formulation was most preferred, having received the greatest amount of high grades and was well reviewed across all attributes of the acceptance. Formulations F4 and F5 were also well accepted, though to a lesser degree. Finally, F1, F2, F6 and F7 had lower acceptance by consumers, yet they were categorized between “like slight” and “like moderately” by consumers.

A low acceptance for formulation based on green chunky banana pulp was foreseen when the pulp of green banana (F7) was added to the other ingredients of the hamburger, resulting a dark, non-homogeneous product. Thus, it is suggested that waste fruit be converted into food powders or flours for they to be used as fat substitutes in beef burger formulations.

In general, the fat substitution in burgers was not received negatively by consumers. These results suggest that flour of peel and pulp of green banana, and oatmeal flour are excellent choices for the replacement of fat in beef burgers. It is assumed that these fat substitutes increased the acceptability of hamburgers, improved the physical characteristics.

Conclusion

Although fat contributes to a series of physical and sensory attributes such as softness, juiciness and yield, it is possible to reduce the lipid content in beef burgers without depreciating the quality of food through the use of the following fat substitutes: oat flour, apple peel flour, green banana pulp flour, green banana peel flour and green banana pulp.

The highest-rated burgers in terms of water-holding capacity, yield, shrinkage and shear force were the formulations containing substitutes based on green bananas.

The scores of the sensory acceptance test suggest that the flour of peel and pulp of green banana, and oatmeal flour are excellent choices for fat-substitution in beef burger, as the notes of tasters showed positive acceptance of hamburgers made with these substitutes.

References

- Abularach MLS, Rocha CE, Felício PE. Quality traits of boneless rib cut (L. dorsi muscle) from Nelore young bulls. Cienc Tecnol Aliment. 1998;18:205–210. doi: 10.1590/S0101-20611998000200012. [DOI] [Google Scholar]

- Aleson-Carbonell L, Fernández-López J, Pérez-Alvarez JA, Kuri V. Characteristics of beef burger as influenced by various types of lemon albedo. Innov Food Sci Emerg Technol. 2005;6:247–255. doi: 10.1016/j.ifset.2005.01.002. [DOI] [Google Scholar]

- Ali RFM, El-Anany AM, Gaafar AM. Effect of potato flakes as fat replacer on the quality attributes of low-fat beef patties. Int J Food Sci Technol. 2011;3:173–180. [Google Scholar]

- Anderson ET, Berry BW. Sensory, shear, and cooking properties of lower-fat beef patties made with inner pea fiber. J Food Sci. 2000;65:805–810. doi: 10.1111/j.1365-2621.2000.tb13591.x. [DOI] [Google Scholar]

- Anderson ET, Berry BW. Effects of inner pea fiber on fat retention and cooking yield in high fat ground beef. Food Res Int. 2001;34:689–694. doi: 10.1016/S0963-9969(01)00089-8. [DOI] [Google Scholar]

- Angor MM, Al-Abdullah BM. Attributes of low-fat beef burgers made from formulations aimed at enhancing product quality. J Muscle Foods. 2010;21:317–326. doi: 10.1111/j.1745-4573.2009.00184.x. [DOI] [Google Scholar]

- Beebe KR, Pell RJ, Seasholt MB. Chemometrics: a practical guide. New York: Wiley; 1998. pp. 81–99. [Google Scholar]

- Berry BW. Low fat level effects on sensory, shear, cooking, and chemical properties of ground beef patties. J Food Sci. 1992;57:537–540. doi: 10.1111/j.1365-2621.1992.tb08037.x. [DOI] [Google Scholar]

- Berry BW. Fat level, high temperature cooking and degree of doneness affect sensory, chemical and physical properties of beef patties. J Food Sci. 1994;59:10–14. doi: 10.1111/j.1365-2621.1994.tb06885.x. [DOI] [Google Scholar]

- Besbes S, Attia H, Deroanne C, Makni S, Blecker C. Partial replacement of meat by pea fiber and wheat fiber: effect on the chemical composition, cooking characteristics and sensory properties of beef burgers. J Food Qual. 2008;31:480–489. doi: 10.1111/j.1745-4557.2008.00213.x. [DOI] [Google Scholar]

- Brasil (1997) Portaria SVS/MS n° 326, de 30 de julho 1997. Regulamento técnico sobre as condições higiênico-sanitárias e de boas práticas de fabricação para estabelecimentos produtores/industrializadores de alimentos. Diário Oficial da União, 1 ago., pt. 1

- Bro R. PARAFAC. Tutorial and applications. Chemom Intell Lab Syst. 1997;38:149–171. doi: 10.1016/S0169-7439(97)00032-4. [DOI] [Google Scholar]

- Bro R, Kiers H. A new efficient method for determining the number of components in PARAFAC models. J Chemometr. 2003;17:274–286. doi: 10.1002/cem.801. [DOI] [Google Scholar]

- Carrapios AI. Effect of fat content on flavor release from sausages. Food Chem. 2007;103:396–403. doi: 10.1016/j.foodchem.2006.07.037. [DOI] [Google Scholar]

- Crehan CM, Hughes E, Troy DJ, Buckley DJ. Effects of fat level and maltodextrin on the functional properties of frankfurters formulated with 5, 12 and 30 % fat. Meat Sci. 2000;55:463–469. doi: 10.1016/S0309-1740(00)00006-1. [DOI] [PubMed] [Google Scholar]

- Cruz AG, Cadena RS, Faria JAF, Bolini HMA, Dantas C, Ferreira MMC, Deliza R. PARAFAC: adjustment for modeling consumer study covering probiotic and conventional yogurt. Food Res Int. 2012;45:211–215. doi: 10.1016/j.foodres.2011.09.031. [DOI] [Google Scholar]

- Cruz AG, Cadena RS, Alvaro MBVB, Sant’Ana AS, Oliveira CAF, Faria JAF, Bolini HMA, Ferreira MMC. Assessing the use of different chemometric techniques to discriminate low-fat and full-fat yogurts. LWT Food Sci Technol. 2013;50:210–214. doi: 10.1016/j.lwt.2012.05.023. [DOI] [Google Scholar]

- Cruz AG, Cavalcanti RN, Guerreiro LMR, Sant’Ana AS, Nogueira LC, Oliveira CAF, Deliza R, Cunha RL, Faria JAF, Bolini HMA. Developing a prebiotic yogurt: rheological, physico-chemical and microbiological aspects and adequacy of survival analysis methodology. J Food Eng. 2013;114:323–330. doi: 10.1016/j.jfoodeng.2012.08.018. [DOI] [Google Scholar]

- Desmond EM, Troy DJ, Buckley DJ. The effects of tapioca starch, oat fibre and whey protein on the physical and sensory properties of low-fat beef burgers. LWT Food Sci Technol. 1998;31:653–657. doi: 10.1006/fstl.1998.0415. [DOI] [Google Scholar]

- Figueiredo VO. Influence of animal fat substitutes on the quality of Vienna type sausage. Braz J Food Technol. 2002;75:11–17. [Google Scholar]

- García ML, Dominguez R, Galvez MD, Casas C, Selgas MD. Utilization of cereal and fruit fibres in low fat dry fermented sausages. Meat Sci. 2002;60:227–236. doi: 10.1016/S0309-1740(01)00125-5. [DOI] [PubMed] [Google Scholar]

- Hautrive TP, Oliveira FR, Silva ARD, Terra NN, Campagnol PCB. Physicochemical and sensorial analyses of ostrich hamburger. Cienc Tecnol Aliment. 2008;28:95–101. doi: 10.1590/S0101-20612008000500016. [DOI] [Google Scholar]

- Hedrick HB, Aberle ED, Forrest JC, Judge MD, Merkel RA. Principles of meat science. Dubuque: Kendall Hunt Publishing; 1994. pp. 289–298. [Google Scholar]

- Kaack K, Pedersen L. Application of by-products from industrial processing of potato flour and yellow peas as ingredients in low-fat high-fibre sausages. Eur Food Res Technol. 2005;221:313–319. doi: 10.1007/s00217-005-1167-7. [DOI] [Google Scholar]

- Khalil AH. Quality characteristics of low-fat beef patties formulated with modified corn starch and water. Food Chem. 2000;68:61–68. doi: 10.1016/S0308-8146(99)00156-9. [DOI] [Google Scholar]

- Krauss RM, Deckelbaum RJ, Ernst N, et al. Dietary guidelines for healthy Americans. Circulation. 1996;94:1795–1800. doi: 10.1161/01.CIR.94.7.1795. [DOI] [PubMed] [Google Scholar]

- Mansour EH, Khalil AH. Characteristics of low-fat beef burger as influenced by various types of wheat fibers. Food Res Int. 1997;30:199–205. doi: 10.1016/S0963-9969(97)00043-4. [DOI] [Google Scholar]

- Meinhold NM. Processed meats with 38–75 % less fat. Food Process. 1991;52:105–106. [Google Scholar]

- Morón-Fuenmayor OE, Zamorano-García L. Drip loss in raw meat of different animal types. Rev Cient. 2004;14:36–39. [Google Scholar]

- Nunes CA, Pinheiro ACM, Bastos SC. Evaluating consumer acceptance tests by three-way internal preference mapping obtained by Parallel Factor Analysis (PARAFAC) J Sens Stud. 2011;26:167–174. doi: 10.1111/j.1745-459X.2011.00333.x. [DOI] [Google Scholar]

- Oliveira LF. An alternative use for the yellow passion fruit (Passiflora edulis F. Flavicarpa) peel: preserve processing. Cienc Tecnol Aliment. 2002;33:259–262. [Google Scholar]

- Pietrasik Z. Effect of content of protein, fat and modified starch on binding textural characteristics, and colour of comminuted scalded sausages. Meat Sci. 1999;51:17–25. doi: 10.1016/S0309-1740(98)00068-0. [DOI] [PubMed] [Google Scholar]

- Pinheiro ACM, Nunes CA, Vietoris V. SensoMaker: a tool for sensorial characterization of food products. Cienc Agrotec. 2013;37:199–201. doi: 10.1590/S1413-70542013000300001. [DOI] [Google Scholar]

- Pszczola DE. Oat-bran-based ingredient blend replaces fat in ground beef and pork sausage. Food Technol. 1991;45:60–66. [Google Scholar]

- Ramadhan K, Huda N, Ahmad R. Physicochemical characteristics and sensory properties of selected Malaysian commercial chicken burgers. Int Food Res J. 2011;18:1349–1357. [Google Scholar]

- Rodríguez-Ambriz SL, Islas-Hernández JJ, Agama-Acevedo E, Tovar J, Bello-Pérez LA. Characterization of a fibre-rich powder prepared by liquefaction of unripe banana flour. Food Chem. 2008;107:1515–1521. doi: 10.1016/j.foodchem.2007.10.007. [DOI] [Google Scholar]

- Sáyago-Ayerdi SG, Brenes A, Goñi I. Effect of grape antioxidant dietary fiber on the lipid oxidation of raw and cooked chicken hamburgers. LWT Food Sci Technol. 2009;42:971–976. doi: 10.1016/j.lwt.2008.12.006. [DOI] [Google Scholar]

- Seabra LMJ. Cassava starch and oatmeal as fat replacers of lamb burgers. Cienc Tecnol Aliment. 2002;22:244–248. doi: 10.1590/S0101-20612002000300008. [DOI] [Google Scholar]

- Souza SS, Cruz AG, Walter EHM, Faria JAF, Celeghini RMS, Ferreira MMC, Granato D, Sant’Ana AS. Monitoring the authenticity of Brazilian UHT milk: a chemometric approach. Food Chem. 2011;124:692–695. doi: 10.1016/j.foodchem.2010.06.074. [DOI] [Google Scholar]

- Spencer EH, Frank E, Mcintosh NF. Potential effects of the next 100 billion hamburgers sold by McDonalds. Am J Prev Med. 2005;28:379–381. doi: 10.1016/j.amepre.2005.01.009. [DOI] [PubMed] [Google Scholar]

- Tapre AR, Jain RK. Atudy of advanced maturity stages of banana. Int J Adv Eng Res Stud. 2012;1:272–274. [Google Scholar]

- Troutt ES, Hunt MC, Johnson DE, Claus JR, Kastner CL, Kropf DH. Characteristics of low-fat ground beef containing texture-modifying ingredients. J Food Sci. 1992;57:19–24. doi: 10.1111/j.1365-2621.1992.tb05415.x. [DOI] [Google Scholar]

- Troy DJ, Desmond EM, Buckey DJ. Eating quality of low-fat beef burgers containing fat-replacing functional blends. J Sci Food Agric. 1999;79:507–516. doi: 10.1002/(SICI)1097-0010(19990315)79:4<507::AID-JSFA209>3.0.CO;2-6. [DOI] [Google Scholar]

- Tsai SJ, Unklesbay K, Clarke A. Textural properties of restructured beef products with five binders at four isothermal temperatures. J Food Qual. 1998;21:397–410. doi: 10.1111/j.1745-4557.1998.tb00531.x. [DOI] [Google Scholar]

- Turhan S, Sagir I, Ustun NS. Utilization of hazelnut pellicle in low-fat beef burgers. Meat Sci. 2005;71:312–316. doi: 10.1016/j.meatsci.2005.03.027. [DOI] [PubMed] [Google Scholar]

- Turhan S, Temiz H, Sagir I. Utilization of wet okra in low-fat beef patties. J Muscle Foods. 2007;18:226–235. doi: 10.1111/j.1745-4573.2007.00081.x. [DOI] [Google Scholar]

- Nutrition and your health: dietary guidelines for Americans. USA: Washington; 1995. pp. 26–32. [Google Scholar]

- The surgeon generals report on nutrition and health. USA: Washington; 1998. pp. 83–138. [Google Scholar]