Abstract

Extruded RTE snacks were prepared from flour blends made with corn flour, Bengal gram flour, roots and tuber flours in a proportion of 60–80: 20: 20 respectively and moisture was adjusted to 17–20 %. The roots and tubers flours were developed from potato (Solanum tuberosum), yam (Dioscorea spp.), sweet potato (Ipomoea batatas L.), taro (Colocassia esculenta) and beet root (Beta vulgaris). Different formulations were extruded at 80 ± 5 °C (heater I) and 95–105 °C (heater II) temperature, 300–350 rpm screw speed, 100 ± 10 °C die temperature and 15 ± 2 kg/h feed rate. The exit diameter of the circular die was 3 mm. Sensory acceptability, physical parameters and nutrient analysis along with storage stability of the products was conducted. The fiber and energy content of the RTE extruded snack improved in experimental samples prepared using root and tuber flours. A serving of 100 g of the snack can provide more than 400 Kcal and 10 g of protein. The overall acceptability of RTE extruded products made with potato and taro were highly acceptable compared to yam and sweet potato. The study demonstrates utilization of roots and tuber flours as potential and diverse ingredients to enhance the appearance and nutritional properties in RTE extruded snack.

Keywords: Ready-To-Eat (RTE), Extruded, Snacks, Roots and tubers

Introduction

Root and tuber crops are plants yielding starchy roots, rhizomes, corns, stems and tubers which are grown throughout the world in hot and humid regions. They contain 70–80 % water, 16–24 % starch, trace quantity (<4 %) of proteins and lipids (Hoover 2001) and are important sources of carbohydrates which are used as staple foods in tropical and sub tropical countries (Liu et al. 2006). They are also known to have nutritionally beneficial components, such as a resistant starch (Liu et al. 2006), mucilages (Lee et al. 2003) and antioxidant activity (Nagai et al. 2006). Instead of using carbohydrates containing gluten, roots and tubers can be used as carbohydrate sources as they do not contain any gluten and can help in reduction in the incidence of celiac disease or other allergic reactions to gluten (Rekha and Padmaja 2002). Despite their nutritional and health values, the use and consumption of roots and tubers are generally limited by the fact that they are subjected to extensive post harvest losses as a consequence of their high moisture content, sustained metabolism, and microbial attack, leading to damage during harvest and storage (Egbe and Rickard 1991). These problems could be solved by converting the tubers from perishable to non-perishable products through food processing operations in order to manufacture new food products such as snack foods (Aprianita et al. 2009). These products have become a part of the feeding habits of the majority of the world population because they provide convenient portions and fulfill short-term hunger (Kuntz 1996). One of the most important technologies which has shown great potential for the development of new snack products is extrusion cooking.

Extrusion cooking has been investigated as a means of producing snacks that can be tailored to meet the dietary requirements of particular groups of the population. The work of Siegel and Lineback (1976) identified extrusion as a useful process in respect of the development of a high protein snack to overcome issues of protein malnutrition in the developing world. Ibanoglu et al (2006) and Stojceska et al (2010) investigated the use of extrusion to produce snacks meeting the dietary needs of those on a gluten free diet. Extrusion has been investigated as a means of improving the nutrient profile for example increasing levels of dietary fibre (Stojceska et al. 2010) and enriching foods with nutrients such as lycopene (Shoar et al 2010).

Cereal grains are the commonest raw materials employed in the manufacture of extruded products (Ding et al. 2006 and Hagenimana et al. 2006). For extruded snacks, one of the most desirable physical properties is the degree of expansion because it determines their structure and consequently their quality. Expansion of extrudates can vary considerably depending on both processing conditions and feed composition. Starch based materials are preferred as raw materials to enhance the puffing of extruded snacks. Blackgram (Phaseolus mungo L.) is widely used (alone and in a blend with a cereal, usually rice) in Southeast Asian countries to prepare a large number of traditional foods by drying/steaming/frying to make a number of products that are either ready-to-fry or ready-to-eat (Bhattacharya and Narasimha 2004). Blackgram (Phaseolus mungo L.) has been used to develop acceptable extruded products like pasta (Lakshmi Devi et al. 2013) and RTE extruded snacks (Aparna Kuna et al. 2013). Roots and tubers provide high quantity of starch but low nutritional value. The development of composite extrudates through the mixture of starchy raw materials with other products has been an alternative for obtaining extruded snacks with better sensory, physicochemical and nutritional characteristics (Guy 2001). Some studies have focused on the preparation of extruded snacks from starch mixtures of different sources such as corn, cassava (Rampersad et al 2003), taro flour (Maga et al 1993), wheat starch (Onwulata and Konstance 2002). However, even when these products exhibited good expansion characteristics, they had an odd flavour and acrid taste. Apparently, not much research has been reported which specifically addresses the development of roots and tuber based extruded snack products with a nutritional profile suited to the needs of the snack eating population in the developed world.

Therefore, the present study was aimed to assess the formulation, development and evaluation of physicochemical and sensory properties of tuber based extruded RTE snack, in an attempt to broaden the applications of roots and tuber flours. The roots and tubers assessed in this study were potato (Solanum tuberosum), yam (Dioscorea spp.), sweet potato (Ipomoea batatas L.), taro (Colocassia esculenta) and beet root (Beta vulgaris).

Materials and methods

Raw materials

Corn grits and black gram (Phaseolus mungo Roxb) were obtained from a private mill in Hyderabad. Uniform medium sized mature tubers of potato (Solanum tuberosum), yam (Dioscorea spp.), sweet potato (Ipomoea batatas L.), taro (Colocassia esculenta) and beet root (Beta vulgaris) free from mechanical or pathological injuries were procured from a local farmer.

Flour preparation

Fresh and firm tubers of potato, taro, yam, sweet potato and beetroot were selected for the preparation of flour. Flour extraction was conducted following an established procedure (Alves et al. 2002). The tubers were peeled, washed in purified water, cut into 1–2 cm cubes, and sliced with stainless steel knife into thick chips (<5 mm). These chips were then soaked in sodium metabisulfite (0.075 %) for 5 min and oven dried at 50 °C for 30 h until they reached 13 % moisture. Subsequently, the dried chips were milled into flour and sifted through a 300-μm sieve. Corn grits and black gram (BG) were also milled into flour and sifted through 300-μm sieve. The individual flours were then packed into closed glass containers and stored under dry conditions at room temperature until used for further applications. Corn flour and black gram flour were prepared from corn grits and black gram grains dried at 55 °C for 20 h, which were subsequently ground in a hammer mill and sieved in the same way as the roots and tubers.

Preparation of extruded snacks

A co-rotating twin screw extruder (Scientech Engineers, Kolkata, India) was used for development of the extruded products. The barrel diameter and L/D ratio were 37 mm and 27:1, respectively having screw configuration standardized for processing flour-based products, was used. The barrel was provided with two electric band heaters and two water cooling jackets. A temperature sensor was fitted on the front die plate which was connected to temperature control system on the panel board. The screw profile was made up of conveying self-wiping elements, except for a section consisting of short reverse and forwarding elements, to improve mixing and apply shear to the material being extruded, while restricting flow and building up pressure. The exit diameter of the circular die was 3 mm. A volumetric feeder was used for feeding the dry mixture to the extruder.

Preliminary study

Tuber powders prepared along with corn and BG flours were formulated for trail runs. A preliminary extrusion trial was conducted with different proportions of corn, BG and tuber flours, at a range of extruder conditions, temperature from 80 to 150 °C, moisture rate from 15 to 20 % and screw rotation from 100 to 380 rpm. Based on the most stable product, the expansion and stability of the extruder conditions, and the extrusion conditions for the study were selected. Screw speed was set at 300–350 rpm. The input feed rate was set at 15 kg/h. The cutter (with two blades) speed was set to 100 rpm.

Detailed study

Based on the results of the preliminary study, experimental design and conditions, corn flour, bengal gram (BG) flour and roots and tuber flours were mixed in a proportion of 60:20:20 respectively and moisture was adjusted to 17–20 (depending on moisture content of the ingredients) for different formulations. Snack prepared from corn flour and BG flour in ratio of 80: 20 alone served as control.

Preconditioning

To optimize the process variables of extrusion cooking for preparation of the extruded products of maximum possible expansion ratio, with desirable internal and apparent texture, the blended samples were mixed thoroughly to get a homogenous mixture and tempered by adding a predetermined amount of water, by spraying and mixing in a lab model blender thoroughly to adjust the feed moisture content to 17–20 %. The preconditioned samples were packed in a polythene bag, kept for 2 h in a refrigerator at 4 °C for moisture equilibrium and then fed into the extruder hopper.

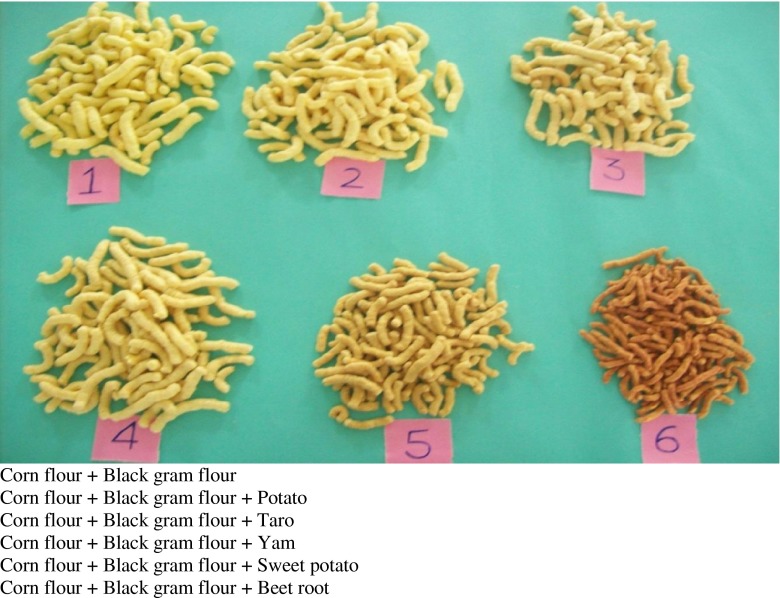

Different formulations were extruded at 80 ± 5 °C (heater I) and 95–105 °C (heater II) temperature, 300–350 rpm screw speed, 100 ± 10 °C die temperature and 15 ± 2 kg/h feed rate. The exit diameter of the circular die was 3 mm. The RTE extruded snacks developed in above conditions are shown in Fig. 1.

Fig. 1.

RTE extruded formulations developed by incorporation of different roots and tuber flour blends

Spicing and drying

The extrudates were sprayed with hot (80 °C) refined sunflower oil (70 mL kg−1 of extruded snacks) in a rotary tumbler. After thorough mixing of puffs with oil, a standardized spice mix (Piper nigrum, Cuminum cyminum and salt at 2.5 % each) was sprinkled to ensure proper coating on each individual puff. The spiced extrudates were dried for 15 min at 70 °C to have better crispness in the final extruded product.

Packaging and storage

The dried products were cooled to room temperature (35 °C) and packaged in Metalized Polyethylene Terephthalate (MPET) with OTR of 0.95 cc/m2/day and WVTR of 1.2 g/m2/day and stored at room temperature i.e., 35 °C ± 4 for 2 months.

Sensory evaluation

Sensory assessments were conducted in a purpose-built, ten-booth sensory evaluation laboratory. The panel of 30 members consisted of staff and graduate students of the Department of Foods and Nutrition, Post Graduate & Research Centre of Acharya N G Ranga Agricultural University. The panelists had no knowledge of the project objectives. All the six samples were coded using random three-digit numbers and served with the order of presentation counter-balanced. Panelists were provided with a glass of water, and instructed to rinse and swallow water between samples. They were given written instructions and asked to evaluate the products for acceptability based on its texture, taste, flavor, mouth feel and overall acceptability using five-point hedonic scale (1 = dislike extremely to 5 = like extremely; Meilgaard et al. 1999).

Physical parameters

Physical parameters like length, diameter, weight, volume, bulk density and expansion ratio of the selected extruded products were recorded. Ten samples each of the different products were taken for measurement and mean of the ten values were recorded.

Length, diameter, weight and volume

Length (cm), diameter (mm), weight (gm) and volume (cm3) of the selected extrudates was measured using standard methods (Singh et al. 2000).

Expansion ratio

The radial expansion of the selected extrudates at different portions was measured using vernier calipers and an average of ten measurements was recorded. The expansion ratio was calculated based on the cross sectional diameter of the extrudate and the extruder die. It is expressed by average of diameter of ten extrudates divided by diameter of the die used (Singh et al. 2000).

Bulk density

Bulk density was determined by filling a 1 L measuring cylinder with the selected extrudates slightly above the liter mark. The cylinder was tapped 12 times till the products measured up to the liter mark and was expressed as g/cm3 (Singh et al. 2000).

Proximate analysis

Proximate analysis was conducted for the six extruded product formulations. Protein content was estimated from the crude nitrogen content of the sample determined by the MicroKjeldhal method (N × 6.25) (AOAC 1990). Fat content of the samples was estimated by Soxhlet method given by American Oil Chemists Society (AOCS 1981). Total ash was determined using procedure given by Association of Official Analytical Chemists (AOAC 1984). Moisture content of the extruded products was determined using procedure given by Association of Official Analytical Chemists (AOAC 1990). Crude fiber content of the samples was determined by the procedure given by Association of Official Analytical Chemists (AOAC 1990). Carbohydrate was calculated by difference method. Energy content was computed from the tables (Gopalan et al. 1991).

Microstructure of extrudates using scanning electron microscope

The most accepted sample and the control samples were viewed and photographed on a Scanning Electron Microscope (SEM) operating with magnification from 35× to 200× to study the external and internal appearance of extrudates which related to expandable characteristics of products. For microscope study, dried extrudates samples were mounted over the stubs with double-sided conductivity tape and applied a thin layer of gold over the samples using an automated sputter coater for about 3 min (Bozzola and Russell 1999). The samples were scanned in a scanning electron microscope at various magnifications at RUSKA Lab, College of Veterinary Sciences, S.V.V. University, Hyderabad, India.

Storage studies

The samples were stored in MPET packaging material and were withdrawn after 60 days and examined for the changes in moisture and sensory parameters. Before conducting the sensory parameters, the samples were tested for microbial safety, free fatty acids and peroxide value for quality check. The moisture content of the extruded products was determined using procedure given by Association of Official Analytical Chemists (AOAC 1990). Sensory analysis was conducted in a similar way as was conducted on 0th day (Meilgaard et al. 1999).

Statistical analysis

General linear model (GLM) procedure in Statistical Analysis System Software (SAS version 9.1, Statistical Analysis System Institute, Inc. Cary, NC) was used for all the analysis. Least significant difference (LSD) method was used to make pair wise comparisons between quantitative variables coming from three or more independent groups. The difference within each level under each variable was tested at a 95 % confidence interval.

Results & discussions

Physical parameters

Table 1 shows the results of the physico-chemical analysis.

Table 1.

Mean physical parameters of the developed extruded products

| S.No. | Samples | Length | Diameter | Weight | Volume | Bulk density | Expansion ratio |

|---|---|---|---|---|---|---|---|

| 1. | Control | 4.36 ± 0.08d | 8.84 ± 0.34e | 0.23 ± 0.08b | 2.48 ± 0.16e | 0.05 ± 0.01a | 5.86 ± 0.26e |

| 2. | C + BG + potato | 3.58 ± 0.06b | 6.26 ± 0.42b | 0.21 ± 0.06b | 1.14 ± 0.12b | 0.09 ± 0.02b | 4.24 ± 0.19b |

| 3. | C + BG + yam | 4.26 ± 0.12a | 7.47 ± 0.29c | 0.30 ± 0.11c | 1.93 ± 0.15d | 0.06 ± 0.01c | 5.03 ± 0.22c |

| 4. | C + BG + beetroot | 3.08 ± 0.14a | 5.06 ± 0.41a | 0.18 ± 0.05a | 0.62 ± 0.08a | 0.15 ± 0.03a | 3.44 ± 0.18a |

| 5. | C + BG + taro | 3.54 ± 0.09b | 7.48 ± 0.39c | 0.16 ± 0.04a | 1.58 ± 0.20c | 0.04 ± 0.02a | 5.01 ± 0.24c |

| 6. | C + BG + sweet potato | 4.12 ± 0.16c | 8.06 ± 0.28d | 0.24 ± 0.07b | 2.11 ± 0.18d | 0.05 ± 0.02a | 5.42 ± 0.31d |

Values are expressed as mean ± standard deviation of ten determinations

Mean values with similar superscripts within a column do not differ significantly (P > 0.05)

C corn, BG black gram

Length and diameter (mm)

The length of the extrudates ranged from 3.08 ± 0.14 to 4.36 ± 0.08 cm. The diameter was observed to be in the range of 5.06 ± 0.41 to 8.84 ± 0.34 mm. The highest diameter of 8.84 ± 0.34 mm was observed for control product made from corn and BG flour alone. The least diameter was observed for the product made from corn, BG and beetroot flour. The extrudates made with yam and taro were not significantly different (p < 0.05) but the extrudates made with potato, beetroot, sweet potato and control were all statistically different (p < 0.05) in the diameter of the extrudate.

Weight (g) & volume (cm3)

More the expansion in the product, less is the weight of the extrudates and vice versa. In the present study the weight of the extrudates ranged from 0.16 ± 0.04 to 0.3 ± 0.11 g. Extrudates made by incorporating beetroot had least expansion ratio of 3.44 ± 0.18 but since the length (3.08 ± 0.14 cm) was also less, the final weight was less. The mass of the extrudates made from sorghum in combination with rice, bengal gram, legume mix and soy ranged from 1.3 to 2.4 g (Lakshmi Devi et al. 2012). The volume of the extrudates ranged from 0.62 ± 0.08 to 2.48 ± 0.16 cm3. The products made from beetroot were observed to have less length, diameter, weight and volume when compared to other extrudates.

Bulk density (g/cm3)

The bulk density of the product ranged from 0.04 ± 0.02 to 0.15 ± 0.03 g/cm3. The highest value was observed for beetroot and the least for colocasia. The highest values for bulk density could be due to high moisture content of 3.29 % and least expansion ratio (3.44 ± 0.18) shown in Tables 1 and 2. Similar values were reported by Jyothi et al. (2009) in arrowroot starch extrudates and Priyanka et al. (2012) in extrudates made with egg albumin powder and cheese powder. The bulk density ranged from 0.13 to 0.19 g/cm3.

Table 2.

Proximate analysis of extruded snacks (per 100 g)

| Ingredients | Protein (g) | Fat (g) | Total ash (g) | Moisture (g) | Fiber (g) | CHO (g) | Energy (Kcal) |

|---|---|---|---|---|---|---|---|

| Control | 11.24 ± 0.14c | 7.13 ± 0.20b | 6.09 ± 0.18d | 2.14 ± 0.23a | 0.68 ± 0.06a | 72.86 ± 0.38b | 400.08 ± 2.60a |

| C + BG + potato | 10.52 ± 0.23a | 8.71 ± 0.14d | 0.54 ± 0.26a | 2.76 ± 0.09b | 0.96 ± 0.04b | 75.64 ± 0.44c | 431.86 ± 3.14c |

| C + BG + yam | 10.73 ± 0.19b | 7.90 ± 0.17c | 3.32 ± 0.28c | 3.08 ± 0.26c | 1.01 ± 0.08b | 73.08 ± 0.32b | 415.48 ± 2.89b |

| C + BG + beetroot | 11.91 ± 0.29d | 5.14 ± 0.26a | 1.34 ± 0.30b | 3.29 ± 0.18d | 0.70 ± 0.12a | 77.62 ± 0.52d | 403.82 ± 4.02a |

| C + BG + taro | 11.18 ± 0.21c | 10.89 ± 0.19e | 3.26 ± 0.16c | 3.06 ± 0.25c | 1.41 ± 0.18c | 68.22 ± 0.48a | 433.24 ± 3.89e |

| C + BG + sweet potato | 10.46 ± 0.16a | 6.46 ± 0.25b | 3.28 ± 0.14c | 3.04 ± 0.22c | 1.02 ± 0.06b | 74.68 ± 0.39c | 406.84 ± 3.62a |

Values are expressed as mean ± standard deviation of three determinations.

Mean values with similar superscripts within a column do not differ significantly (P > 0.05)

C corn, BG black gram

Expansion ratio

Maximum expansion was seen for control extrudates (5.86 ± 0.26) and the least for products made from corn, BG and beetroot flour (3.44 ± 0.18). In a similar study of extrudates made from arrowroot starch, expansion ratio ranged from 3.2 to 6.09 depending on the percentage of feed moisture (Jyothi et al. 2009). Chinnaswamy (1993) has summarized many factors that affect expansion of starchy materials. Extrusion pressure is a better predictor of expansion than is die nozzle, length or diameter ratio. Starches with 50 % amylose showed optimal expansion, barrel temperatures close to 150 °C and low feed moisture favor expansion. Certain additives may also improve the expansion than does the starch alone.

Proximate analysis

The results of proximate analysis are given in Table 2. The initial (0th day) moisture content of all the extrudates varied from 2.14 ± 0.23 to 3.29 ± 0.18 g%. This is desirable for extruded snacks to maintain the crispiness. Similar levels of moisture values of 0.7 to 2.7 g were reported for RTE extrudates made from sorghum and rice (Lakshmi Devi et al. 2012), moisture level of 1.13 to 2.01 g in extruded pasta made from wheat flour (Triticum aestivum), semolina (Triticum durum), green gram (Pharsalus aureus Roxb), black gram (Phaseolus mungo Roxb), cheese flavor and fish mince (Katla Katla) (Lakshmi Devi et al. 2013).

The protein content of the control and the experimental samples were in the range 10.46 ± 0.16 to 11.91 ± 0.29 g. However statistically significant differences were observed between control, taro and potato, sweet potato and yam and beetroot incorporated extrudates (p < 0.05). The highest protein content of 11.91 ± 0.29 g was seen in extrudates made from corn, BG and beetroot flours. The lowest protein content of 10.46 ± 0.16 g was seen in extrudates made from corn, BG and sweet potato flours. In a similar study by Prasad et al. (2007) protein content of sorghum and soy (80:20) extrudates was reported to be 16.4 g. The highest protein value of 18.2 g was reported in extruded snack from buffalo meat with 60 % corn flour (Anand et al. 2005).

The fat values were in a very broad range of 5.14 ± 0.26 to 10.89 ± 0.19 g with the highest value in taro incorporated extrudates and the least in beetroot incorporated extrudates respectively. The fat content in the RTE extrudates was due to the spicing (added oil & spices) given to all the extrudates to improve the palatability rather than fat content of the raw ingredients.

Ash content was very high (6.09 ± 0.18 g) in the control sample when compared to the experimental samples. The ash content of experimental samples, ranged from 0.54 ± 0.26 to 3.32 ± 0.28 g. The extrudates made by incorporating yam, taro and sweet potato have statistically similar ash content (3.32 ± 0.28, 3.26 ± 0.16 and 3.28 ± 0.14 respectively), whereas the potato (0.54 ± 0.26) and beetroot (1.34 ± 0.30) incorporated extrudates had statistically different ash content.

The crude fiber content unlike ash was least in the control sample (0.68 ± 0.06 g) while in the experimental extrudates, the values ranged from 0.70 ± 0.12 to 1.41 ± 0.18 g. The fiber content in extruded snacks made with rice and chickpea also showed a similar value of 1.38 g (Bhattacharyya et al. 1997).

The energy value of all the products was almost similar ranging from 400.08 ± 2.60 to 433.24 ± 3.89 kcal. There were significant differences between control, beetroot, sweet potato and potato and yam and taro. All the products meet the desired requirement of being utilized as a supplementary food i.e., providing 400 Kcal and 10 g of protein / 100 g of serving. This indicates that the roots and tuber flour incorporated RTE extrudates can be efficiently utilized as a product for supplementary feeding programmes.

Sensory evaluation

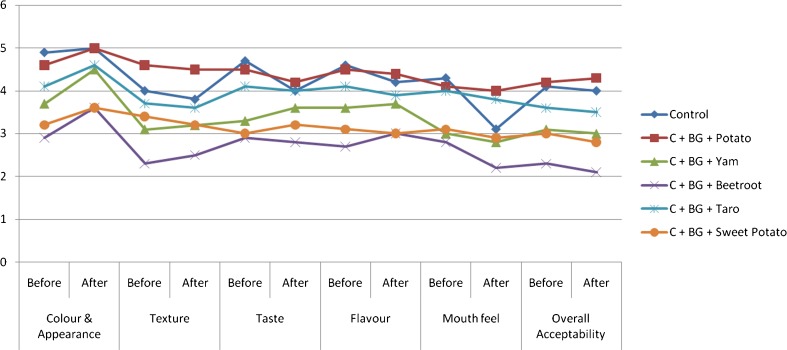

Thirty panelists took part in the sensory analysis on 0th day and 60th day (after storage). They indicated liking of colour & appearance, texture, taste, flavor, mouth feel and overall acceptability on a five-point scale. Figure 2 shows the results of sensory evaluation. As far as colour and appearance was concerned statistically significant differences (p < 0.05) were noted between control and beetroot; control and sweet potato; control and yam incorporated RTE extruded samples but not between the control and potato on 0th day of sample preparation. There were no significant differences (p < 0.05) between the colour and appearance on 60th day of storage of the RTE extrudates between the control—potato, taro—yam and beetroot—sweet potato incorporated extrudates indicating not much change in colour during storage. Control sample was liked for its color by all panel members as compared to other extruded products. This could be attributed to the fact that control sample was prepared with corn (80 %) and BG flour (20 %) imparting it bright yellow colour whereas experimental extruded snacks were prepared in combination with corn (60 %), BG flour (20 %), roots and tuber flours (20 %) which might have changed the bright yellow colour and rendered it light yellow colour. Extrudates made by incorporating beetroot were light pink in colour which could be attributed to the beetroot pigments.

Fig. 2.

Mean sensory scores of the extruded products

With respect to texture, RTE extrudates made with potato were liked the most followed by control, taro, sweet potato, yam and beetroot both before and after the storage period. With respect to taste and flavor, control was liked the most followed by potato, taro, yam, sweet potato and beetroot on 0th day. The products were crispy but were not porous because of low expansion ratio of 3.4. Theoretically, the amylase and amylopectin ratio influences the textural properties of the finished starch-based extruded products. Amylopectin promotes puffing, giving a very light and fragile product and homogenous texture with smooth and sticky external surface. Conversely high amylose produce harder product and less expansion (Harper 1981).

Taste and flavor evaluation on 60th day showed that potato was liked the most followed by control, taro, yam, sweet potato and beetroot. However there was no statistically significant difference (p < 0.05) between the taste of potato incorporated and control extrudates. The panelists reported a typical sweet taste in sweet potato and beetroot incorporated RTE extrudates before and after the storage period. There was no prominent flavor of the incorporated roots and tubers in the final product. There was a significant difference (p < 0.05) in the sensory results of mouth feel attribute between the control, potato, taro and sweet potato, yam, beetroot extrudates on 0th day. On 60th day there was significant difference (p < 0.05) between the mouth feel of potato and control; potato and sweet potato; potato and yam; potato and beetroot extruded products. However there was no significant difference between control and potato incorporated extruded products.

When scores were compared for overall acceptability, statistically significance difference (p < 0.05) was again seen between control, potato and other tuber incorporated extrudates. The scores for overall acceptability indicate that potato incorporated RTE extrudates were most liked followed by control and Taro incorporated RTE extrudates and that storage did not significantly affect the acceptability and palatability of the RTE extrudates. The RTE extruded products made by incorporating 20 % yam, beetroot and sweet potato were less preferred over potato and taro incorporated RTE extruded products. Change in moisture rates, processing parameters and formulations can definitely enhance the sensory properties of the yam, sweet potato and beetroot incorporated RTE extruded products.

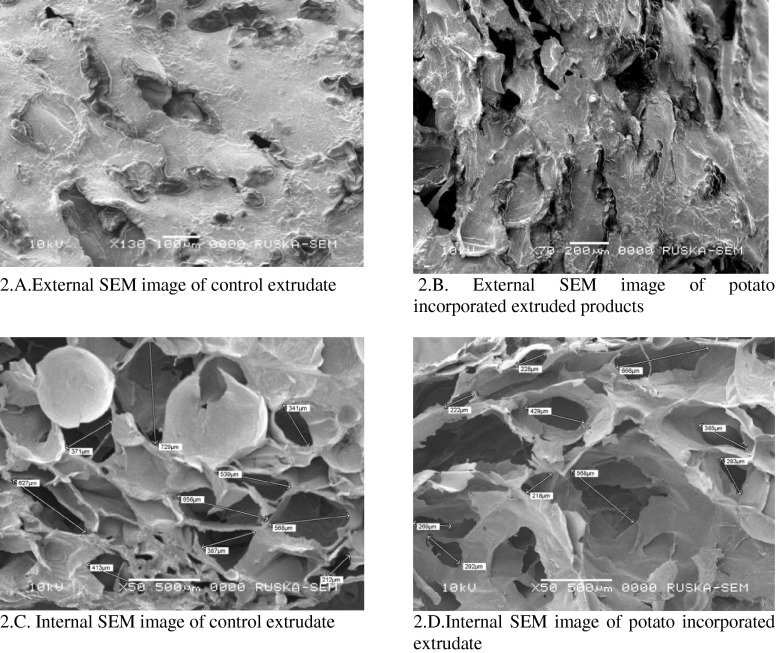

Internal structure of extruded products

As per results of sensory evaluation, the most acceptable samples were the combination of corn + BG + Potato. The most acceptable sample was compared to the control to know the air space distribution using Scanning Electron Microscope (SEM) (Fig. 3). The control sample had non porous external surface (Fig. 3a) whereas the extruded products with potato had a porous external surface (Fig. 3b). When internal structure was compared the control sample (Fig. 3c) was more porous but the size of the pores were small, while in potato incorporated extruded products, the pores were big in size and less in number (Fig. 3d). Rice, corn and taro starch blends were used to prepare snacks by a twin-screw extruder at 141, 150 and 159 °C respectively. Microscopic structures were studied and the samples had porous open celled structures. Extruded products showed large number of flattened and sheared granules. Damage was highest in case of extrusion at 159 °C followed by 150 °C and 141 °C (Bhattacharyya et al 2006).

Fig 3.

SEM images of control and most acceptable extruded snack (potato incorporated extruded products). a External SEM image of control extrudate. b External SEM image of potato incorporated extruded products. c Internal SEM image of control extrudate. d Internal SEM image of potato incorporated extrudate

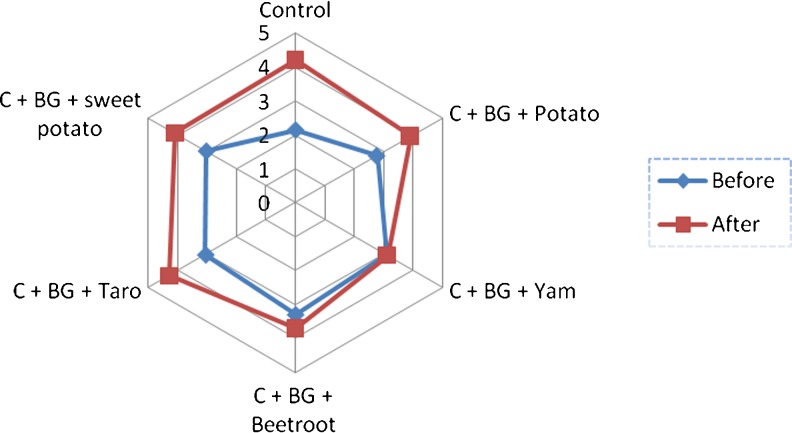

Storage studies

The storage stability of the extruded snacks was evaluated by two parameters i.e. moisture content of the product and sensory evaluation. Developed products were packed in MPET and stored at room temperature. The moisture content of the samples was estimated before and after storage and is show in the Fig. 4.

Fig 4.

Moisture content of the extruded products before and after stored period of 2 months

The results revealed that the initial moisture content of the extruded products ranged from 2.14 to 3.29 g% which was desirable for extruded snacks to maintain the crispness. During storage, an increase in the moisture content was observed in all the samples with a range of 3.1–4.3 g %. The moisture content increased in control by 2.06 g % followed by potato (1.14 g %), taro (1.24 g %) and sweet potato (1.06 g %). The results are in concurrence with the air spaces of the RTE extruded products in a cross sectional view. Control snack had more air cells in the cross sectional view of the extruded products followed by potato and taro. This indicates that more the air spaces in the extruded products, more the increase in moisture content of the RTE extruded products on storage. There was no significant increase in the moisture content of RTE extruded products made from yam (0.02 %) and beetroot (0.41 %). An increase in moisture content in the RTE extruded snacks during storage was reported by Aparna Kuna et al. (2013). The increase in moisture content can be controlled by flushing nitrogen gas before packing the extruded products in MPET packaging material.

The sensory evaluation was done after storage period of 2 months using a 5 point hedonic as was done on 0th day. The results of microbial test, free fatty acids and peroxide value were all within the permissible limits indicating that the RTE extruded products are safe for consumption after 2 months of storage at room temperature. The sensory evaluation results revealed that the texture of the extruded products was not very crunchy as they were on day one and this could be because of the increase in moisture content in the extruded products. Taste and flavor of the extruded products were reported to be almost same as 0th day. The overall acceptability of the potato incorporated extrudates improved after 60th day but control and other RTE extruded products showed a similar or slightly decreased acceptability after storage. However the difference in overall acceptability was not statistically significant. A combination of modified atmospheric packaging with better barrier properties can retain the sensory properties of the extruded products considerably, by retaining the texture of the products.

Snack foods are designed to be less perishable, more durable and more appealing than natural foods. The acceptance of snacks is critical because of the specific quality attributes that attract people. The various sensory quality attributes of snack foods are appearance, texture, taste, colour and flavour. Among them, texture is one of the most important one and it is particularly true for snack foods (Bourne 2002). According to the results, the RTE extruded snacks developed by incorporating the roots and tuber flours were shelf stable up to 2 months at room temperature and their sensory parameters were slightly altered which could be enhanced by improving the packaging of the products.

Conclusion

The results of this study showed that incorporation of root and tuber flours in combination with corn and black gram flours can be effectively used to produce RTE extruded snacks by extrusion cooking. The addition of such ingredients improved the nutrient content of the snacks significantly. The fiber content of the RTE extruded snack has increased two-fold on addition of roots and tuber flours. All the roots and tuber flours incorporated RTE extruded products were meeting more than the requirement of supplementary food i.e., providing 400 Kcal and 10 g of protein / 100 g. Results of the study showed that the acceptable ready to eat snacks products can be developed with corn and black gram by incorporating roots and tubers. Storage studies indicated a slight increase in moisture content of the extruded products after 2 months. However, combination of MPET along with modified atmospheric packaging can help in retaining the texture and other sensory parameters of the extruded products for prolonged shelf life. The study demonstrates potential application of roots and tuber flours for the development of nutritious RTE extruded snacks by replacing more traditional forms of carbohydrates to produce entirely new food products by extrusion cooking.

Acknowledgments

Conflict of interest

The authors report no conflicts of interest. The authors alone are responsible for the content and writing of the paper.

References

- Alves RM, Grossmann MV, Ferrero C, Zaritzky NE, Martino MN, Sierakoski MR. Chemical and functional characterization of products obtained from yam tubers. Starch. 2002;54:476–481. doi: 10.1002/1521-379X(200210)54:10<476::AID-STAR476>3.0.CO;2-6. [DOI] [Google Scholar]

- Anand AM, Lakshmanan V, Mendiratta SK, Anjaneyulu ASR, Bisht GS. Development and quality characteristics of extruded tripe snack from buffalo rumen meat and corn flour. J Food Sci Technol. 2005;42:263–267. [Google Scholar]

- Official methods of analysis. 14. Washington D.C: Association of Official Analytical Chemists; 1984. [Google Scholar]

- Official methods of analysis of the AOAC international. Gaithersburg: Association of Official Analytical Chemists; 1990. [PubMed] [Google Scholar]

- AOCS (1981) Official and tentative methods of the American Oil Chemists society, 3rd edn. Illinois

- Aparna Kuna, Lakshmi Devi N, Kalpana K. Utilization of fish powder in formulation and development of Ready–To–Eat extruded snacks. Fish Technol. 2013;50(3):245–250. [Google Scholar]

- Aprianita A, Purwandari U, Watson B, Vasiljevic T. Physico-chemical properties of flours and starches from selected commercial tubers available in Australia. Int Food Res J. 2009;16:507–520. [Google Scholar]

- Bhattacharya S, Narasimha HV. Controlled stress rheological measurement of blackgram flour dispersions. J Food Eng. 2004;63:135–139. doi: 10.1016/S0260-8774(03)00291-7. [DOI] [Google Scholar]

- Bhattacharyya S, Chakraborty P, Chattoraj DK, Mukherjee S. Physico-chemical characteristics of extruded snacks prepared from rice and chickpea by single screw extrusion. J Food Sci Technol. 1997;34:32–323. [Google Scholar]

- Bhattacharyya P, Ghosh U, Gangopadhyay H, Raychaudhuri U. Physico - chemical characteristics of extruded snacks prepared from rice (Oryza sativa. L), corn (Zea mays. L) and taro (Colocassia esculanta. L) by twin-screw extrusion. J Sci Ind Res. 2006;65:165–168. [Google Scholar]

- Bourne MC. Food texture and viscosity: concept and measurement. 2. Geneva: New York State Agricultural Experiment Station and Institute of Food Science. Cornell University; 2002. pp. 171–189. [Google Scholar]

- Bozzola JJ, Russell LD. Electron microscopy principles and techniques for biologists. 2. Boston: Jones and Bartlett; 1999. [Google Scholar]

- Chinnaswamy R. Basis of cereal starch expansion. Carbohydr Polym. 1993;21:157–167. doi: 10.1016/0144-8617(93)90012-S. [DOI] [Google Scholar]

- Ding QB, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73:142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Egbe AT, Rickard JE. Study on the factors affecting storage of edible aroids. Ann Appl Biol. 1991;119(1):121–130. doi: 10.1111/j.1744-7348.1991.tb04850.x. [DOI] [Google Scholar]

- Gopalan C, Rama Sastry BV, Bala Subramanian SC. Nutritive value of Indian foods National Institute of Nutrition. Hyderabad: ICMR; 1991. [Google Scholar]

- Guy R. Raw materials for extrusion cooking. In: Guy R, editor. Extrusion cooking: technologies and applications. USA: Woohead Publishing in Food Science and Technology Ltd. CRC Press LLC; 2001. pp. 5–28. [Google Scholar]

- Hagenimana A, Ding X, Fang T. Evaluation of rice flour modified by extrusion cooking. J Cereal Sci. 2006;43(1):38–46. doi: 10.1016/j.jcs.2005.09.003. [DOI] [Google Scholar]

- Harper JM. Extrusion of foods. Vol II. Boca Raton: CRC Press Inc.; 1981. [Google Scholar]

- Hoover R. Composition, molecular structure, and physicochemical properties of tuber and root starches: a review. Carbohydr Polym. 2001;45:253–267. doi: 10.1016/S0144-8617(00)00260-5. [DOI] [Google Scholar]

- Ibanoglu Ş, Ainsworth P, Özer EA, Plunkett A. Physical and sensory evaluation of a nutritionally balanced gluten-free extruded snack. J Food Eng. 2006;75(4):469–472. doi: 10.1016/j.jfoodeng.2005.04.060. [DOI] [Google Scholar]

- Jyothi AN, Sheriff JT, Sanjeev MS. Physical and functional properties of arrowroot starch extrudates. J Food Sci. 2009;74(2):97–104. doi: 10.1111/j.1750-3841.2008.01038.x. [DOI] [PubMed] [Google Scholar]

- Kuntz LA. Creating healthfull salty snacks. Food Prod Des. 1996;6:59–81. [Google Scholar]

- Lakshmi Devi N, Shobha S, Sajid Alavi, Kalpana K, Soumya M (2012) Utilization of extrusion technology for the development of millet based weaning and ready-to-eat snacks for children. J Food Sci Technol 1–6. doi:10.1007/s13197-012-0789-6 [DOI] [PMC free article] [PubMed]

- Lakshmi Devi N, Aparna K, Kalpana K. Utilization of fish mince in formulation and development of pasta products. Int Food Res J. 2013;20(1):219–224. [Google Scholar]

- Lee MH, Lin YS, Lin YH, Hsu FL, Hou WC. The mucilage of yam (Dioscorea batatas Decne) tuber exhibited angiotensin converting enzyme inhibitory activities. Bot Bull Acad Sin. 2003;44:267–273. [Google Scholar]

- Liu Q, Donner E, Yin Y, Huang RL, Fan MZ. The physicochemical properties and in vitro digestibility of selected cereals, tubers, and legumes grown in China. Food Chem. 2006;99:470–477. doi: 10.1016/j.foodchem.2005.08.008. [DOI] [Google Scholar]

- Maga JA, Bang-Liu M, Rey T. Taro (Colocasia esculenta) extrusion. Carbohydr Polym. 1993;21:177–178. doi: 10.1016/0144-8617(93)90014-U. [DOI] [Google Scholar]

- Meilgaard M, Civille GV, Thomas Carr B. Sensory evaluation techniques. 3. Boca Raton: CRC Press LLC; 1999. [Google Scholar]

- Nagai T, Suzuki N, Nagashima T. Antioxidative activity of water extracts from the yam (Dioscorea opposita Thunb.) tuber mucilage tororo. Eur J Lipid Sci Technol. 2006;108:526–531. doi: 10.1002/ejlt.200500231. [DOI] [Google Scholar]

- Onwulata CI, Konstance RP. Viscous properties of taro flour extruded with whey proteins to simulate weaning foods. J Food Process Preserv. 2002;26:179–194. doi: 10.1111/j.1745-4549.2002.tb00479.x. [DOI] [Google Scholar]

- Prasad NN, Siddalinga Swamy M, Babu Sha ST, Semwal AD. Protein quality of sorghum- soy based extruded snack food. J Food Sci Technol. 2007;44(2):165–167. [Google Scholar]

- Priyanka K, Aparna K, Lakshmi DN. Development and evaluation of RTE (Ready To Eat) extruded snack using egg albumin powder and cheese powder. Agric Eng Int CIGR J. 2012;14(4):179–187. [Google Scholar]

- Rampersad R, Badrie N, Comissiong E. Physicochemical and sensory characteristics of flavoured snacks from extruded cassava/pigeonpea flour. J Food Sci. 2003;68(1):363–367. doi: 10.1111/j.1365-2621.2003.tb14166.x. [DOI] [Google Scholar]

- Rekha MR, Padmaja G. Alpha-amylase inhibitor changes during processing of sweet potato and taro tubers. Plant Food Hum Nutr. 2002;52:285–294. doi: 10.1023/A:1021837115267. [DOI] [PubMed] [Google Scholar]

- Shoar DZ, Hardacre AK, Brennan CS. The 494 physico-chemical characteristics of extruded snacks enriched with tomato lycopene. Food Chem. 2010;123:1117–1122. doi: 10.1016/j.foodchem.2010.05.071. [DOI] [Google Scholar]

- Siegel A, Lineback DR. Development, acceptability and proximate analyses of high-protein rice-based snacks for Thai children. J Food Sci. 1976;41:1184. doi: 10.1111/j.1365-2621.1976.tb14413.x. [DOI] [Google Scholar]

- Singh D, Chauhan GS, Tyagi SM, Suresh I0. Extruded snacks from composite of rice brokens and wheat bran. J Food Sci Technol. 2000;37:1–5. [Google Scholar]

- Stojceska V, Ainsworth P, Plunkett A, Ibanoglu S. The advantages of using extrusion processing for increasing dietary fibre level in gluten free products. Food Chem. 2010;121:156–164. doi: 10.1016/j.foodchem.2009.12.024. [DOI] [Google Scholar]