Abstract

Idli is a traditional fermented food and is consumed in India and Srilanka. The objective of the present study is to select the ingredients for optimum desirable product characteristics and to identify the optimum ratios of ingredients and fermentation time with respect to sensory attributes using Response Surface Methodology (RSM). The sensory attributes included were color, appearance, texture, taste and overall quality. Preliminary trials were conducted using five variants of rice and common black gram dhal before framing a model using Central Composite Rotatable Design (CCRD). From the study it was found that a desirable score of 0.7439 was obtained for sensory attributes of idli made with the ratio of 3: 1.475 for IR20 idli rice and ADT3 variety black gram (with husk removed after soaking) fermented for 10.2 h. Principal Component Analysis (PCA) helped to discriminate the samples and attributes within the data matrix, depending upon their inter relationships.

Keywords: Fermented food, Idli, Response Surface Methodology (RSM), Principal Component Analysis (PCA), Sensory attributes, Parboiled rice, Black gram

Introduction

Fermented foods are defined as foods that have been subjected to the action of selected microorganisms by which a biochemically and organoleptically modified substrate is produced, resulting in an acceptable product for human consumption (Tamang 1998). There are different types of fermented foods, in which a range of different substrates are metabolized by a variety of microorganisms to yield products with unique and appealing characteristics (Campbell-Platt 1994). Fermented foods supply important nutrients, particularly proteins and amino acids. People become familiar with particular fermented foods produced in their part of the world, and many of these foods became an integral part of the local diet (Caplice and Fitzgerald 1999) and culture, and were regarded as essential for human consumption and nutrition. Idli is one such food, which is prepared from low cost staple crop, which helps to improve the health condition. Its composition includes rice and black gram. In the traditional idli batter, fermentation takes place due to the microflora present in the raw materials and in the environment leading to the several changes that has impact on digestibility and nutritional value bringing about desirable changes (Soni and Sandhu 1989). The example of idli illustrates the opportunities of co-fermentation of cereals (rice) and leguminous seeds (black gram) (Young and Pellet 1994).

A large proportion of the world cereal production is processed by fermentation prior to consumption. The enhancement of attractive flavor and texture and the improved shelf-life and digestibility as a result of fermentation, are important reasons for fermenting cereals before consumption (Nout 2009). Characteristic variables such as water content, i.e. before and after soaking or fermentation, duration and temperature affect the cereal fermentation (Hammes and Ganzle 1998). This sour and spongy type breakfast food (Idli) of India and Sri Lanka constitutes an important group of naturally fermented food (Ramakrishnan 1979). Legume contains more of proteins than cereals (Geervani and Theophilus 1981). Changes in the nutritive value of proteins as a result of fermentation are particularly important for cereals and legumes. These sources of protein often are of lower nutritional quality than animal products, and they tend to be major dietary sources of protein for people with marginal and sub-marginal protein intake. Therefore, fermentation processes that consistently improve protein quality or availability of cereal or legumes could have a positive impact on the diets of people (McFeeters 1988).

Cereal and legume being the important component of idli, the present study is done to find out the interrelationship between the substrates during fermentation at different fermentation time and different ratios of the substrates on the sensory attributes of idli including desirable and non-desirable parameters with the objectives to select the ingredients for optimum desirable product characteristics and to identify the optimum ratios of ingredients and fermentation time with respect to sensory attributes using Response Surface Methodology (RSM). Several researchers have used RSM successfully to optimize the conditions for making products like boondi (Ravi and Susheelamma 2005), tandoori roti, puri and parotta.

Materials and methods

Materials

In the current study, the most commonly used local variety of rice namely IR 20 and a protein rich black gram variety Aduthurai 3 (ADT3) were used. The proximate values of the ingredients are shown in Table 1. Nutritional composition of the raw ingredients (idli rice—IR 20, black gram variety ADT 3) and optimized idli were determined. Nutrients like starch, amylose, total carbohydrates, total sugars by Sadasivam and Manickam (2008), protein, fat and crude fibre (Cunniff 1995) were estimated.

Table 1.

Proximate composition (%) of rice and black gram

| Rice (variety IR 20) | Black gram (variety ADT3) | |

|---|---|---|

| Total carbohydrates | 84.0 ± 3.52 | 65.8 ± 3.02 |

| Protein | 6.5 ± 0.32 | 24.2 ± 1.20 |

| Fat | 0.27 ± 0.13 | 0.87 ± 0.02 |

| Ash | 0.57 ± 0.02 | 2.9 ± 0.00 |

| Crude fibre | 0.20 ± 0.01 | 0.70 ± 0.03 |

| Moisture | 8.0 ± 0.32 | 5.5 ± 0.21 |

Mean ± SD (n = 3)

Preparation of idli

Before framing the design using CCRD, preliminary trails were conducted to choose the best suited rice, variation of black gram and ratios of rice and black gram dhal. The variants of rice chosen were parboiled rice, raw rice, ration rice, broken rice and red rice. The variations in black gram dhal were black gram with husk, husk removed and husk removed after soaking. The different ratios of rice to black gram dhal used were 3:1, 3:1.5, 3:2, 3:2.5, 3:3 and 4:1 respectively. The difference in batter volume after fermentation and the texture of idli based on sensory was used to screen the ingredients and ratios. The result of the preliminary study is discussed to show the reason for choosing the maximum and minimum values for the independent variables chosen to frame the model. The rice and black gram dhal were mixed at different ratios as per the CCRD. To carry out the experiment framed using CCRD, the rice and black gram dhal were soaked for 4 h and ground separately to a coarse consistency and mixed together. The batter was left overnight (time based on the developed design) for fermentation with addition of salt. The fermented batter was mixed thoroughly to expel the gas formed due to the release of carbon-dioxide . The batter was poured in idli mould, and steamed in the idli steamer for 15 min. The cooked idlis were kept for sensory analysis.

Experimental design

Response surface methodology

A response surface methodology as explained by Box and Wilson (1951) was conducted to determine the relative contributions of two predictor variables (ratio of rice to black gram dhal and fermentation time) to the quality of the idli. RSM is an effective tool for optimizing complex processes and has been widely applied in the food industry (Wong et al. 2003; Lee et al. 2006; Sin et al. 2006). A CCRD was constructed using software package Statistica (1999). Maximum and minimum predictor values were chosen after carrying out preliminary cooking trails. Five levels of each predictor variable were incorporated into the design. Table 2 shows levels of predictor variables. RSM reduces the number of experiment trials needed to evaluate multiple parameters and their interactions. For idli preparation different ratios of rice to black gram dhal and fermentation time can be optimized using RSM keeping temperature constant (30 °C).

Table 2.

Central composite rotatable design: coded and actual values of independent variables

| Experimental design points | Rice : black gram Ratio (w/w) | Fermentation time (h) | ||

|---|---|---|---|---|

| Actual | Coded | Actual | Coded | |

| X1 (w : w) | x1 | X2 (h) | X2 | |

| 1 | 3 : 0.72 | −1.000 | 10.58 | −1.000 |

| 2 | 3 : 0.72 | −1.000 | 13.42 | 1.000 |

| 3 | 3 : 1.78 | 1.000 | 10.58 | −1.000 |

| 4 | 3 : 1.78 | 1.000 | 13.42 | 1.000 |

| 5 | 3 : 0.50 | −1.414 | 12.00 | 0.000 |

| 6 | 3 : 2.00 | 1.414 | 12.00 | 0.000 |

| 7 | 3 : 1.25 | 0.000 | 10.00 | −1.414 |

| 8 | 3 : 1.25 | 0.000 | 14.00 | 1.414 |

| 9 | 3 : 1.25 | 0.000 | 12.00 | 0.000 |

| 10a | 3 : 1.25 | 0.000 | 12.00 | 0.000 |

aCentre point repeated 3 times

Optimization of idli using RSM

The procedure was based on the hypothesis that quality attributes (desirable and undesirable parameters) of idli were functionally related to ratios of rice to black gram dhal and fermentation time, and attempts were made to fit multiple regression equations describing the responses. Two coded independent variables in the process were rice to black gram dhal ratio (X1) and fermentation time (X2). Five levels of each of the independent variable were chosen for the study; thus, there were 15 combinations, including the replicates of the center point that were performed in random order, based on an experimental CCRD for two factors as shown in Table 2.

Sensory analysis of idli

Idli samples were coded and served to ten panel members for analysis. The sensory attributes included color, appearance which includes fluffiness and compactness, texture which includes sponginess, firmness and stickiness and also other attributes like fermented aroma, sour taste and overall quality of the idli. The desirable parameters included were color, fluffiness, sponginess and fermented aroma. The undesirable parameters included were compactness, firmness, stickiness and sourness. The score card also had an option to give the score for overall quality of the sample. The panelists evaluated three sets of samples at separate time. The first set included samples made with ratios 3:0.5 and 3:0.72 of rice and black gram dhal respectively, the second set included samples made with ratio 3:1.25 and the third set included samples made with ratios of 3:1.78 and 3:2 with the respective fermentation time as shown in Table 2. In each set 3 samples of idli were placed for evaluation. The panel members were given a fifteen point rating scale to evaluate the idli. The ranges (low to high) of the quality of idli were given by panelist by marking a line on the rating scale. The marking in the rating scale was counted as the score by using a measurement scale.

Quantitative descriptive analysis (QDA)

The principle of QDA is based on the ability to train panelists to measure specific attributes of a product in a reproducible manner to yield a comprehensive quantitative product description amenable to statistical analysis (Ghosh and Chattopadhyay 2011). The panel members were selected and trained to evaluate the sample based on the desirable and undesirable parameters for idli.

Statistical analysis of data

Comparison between the means of increase and decrease in batter volume based on the different rice used was computed using least significant difference (LSD). The independent variables and dependent variables (responses) were fit to the second-order polynomial function and examined for the goodness of fit. The R2 or coefficient of determination is defined as the ratio of explained variation to the total variation and is a measure of the degree of fit (Haber and Runyon 1977). All experimental designs and statistical data were analyzed and response surface graphs, ANOVA, regression analysis were reported using Statistica (StatSoft, OK, USA) software.

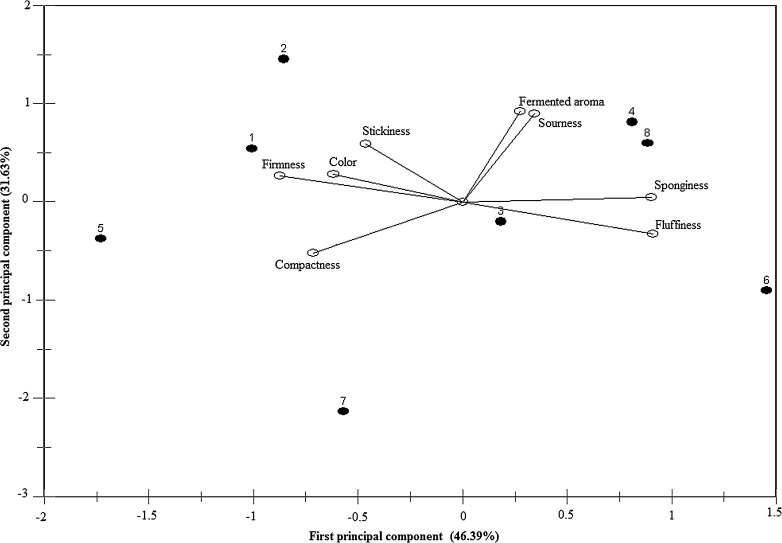

Principal component analysis (PCA)

Principal component analysis (PCA) is a statistical technique that can be applied to QDA data to reduce the set of dependent variables (i.e., attributes) to a smaller set of underlying variables (called factors) based on patterns of correlation among the original variables (Lawless and Heymann 1998). PCA of the fermented food sample was performed with the data collected from the panelists after scoring through 15 point rating scale.

Results and discussion

Effect of rice variants on batter volume

In the present study five variants of rice namely ration rice, raw rice, broken rice, red rice and parboiled rice were used for idli making. The rise in CO2 production can be correlated with the increase in batter volume (Sridevi et al. 2010). The percentage of increase in batter volume was significant (p < 0.05) in the batter prepared with ration rice, followed by parboiled rice, raw rice, broken rice, and red rice. Though there is high increase in batter volume, after expulsion of gas the volume of batter gets significantly decreased in ration rice, whereas the batter volume did not show significant decrease in parboiled rice. Table 3 shows the effect of rice varieties on batter volume.

Table 3.

Effect of rice variants on the batter volume after fermentation

| Parameters | Varieties of rice | ||||

|---|---|---|---|---|---|

| Parboiled rice | Ration rice | Raw rice | Broken rice | Red rice | |

| Initial volume of the batter (cm3) | 221.6 ± 2.05 d | 211.1 ± 1.55 b | 218.6 ± 0.98 c | 200.5 ± 0.14 a | 238.2 ± 0.14 e |

| Final volume of the batter (cm3) | 306.1 ± 3.74 e | 299.7 ± 1.41 d | 275.8 ± 2.61 b | 248.8 ± 2.61 a | 293.7 ± 3.53 c |

| Batter volume increased after fermentation (%) | 38.1 ± 1.27 c | 42.0 ± 0.70 d | 26.2 ± 0.35 b | 24.1 ± 0.21 a | 23.3 ± 0.28 a |

| Volume of the batter after expulsion of gas (cm3) | 202.0 ± 0.56 e | 150.8 ± 0.84 a | 181.0 ± 0.70 c | 193.0 ± 1.83 d | 158.0 ± 1.41 b |

| Batter volume decreased after expulsion of expulsion of gas (%) | 34.0 ± 1.41 b | 49.7 ± 0.00 d | 34.4 ± 0.63 b | 22.4 ± 1.41 a | 46.1 ± 0.00 c |

Mean values in a row with different letters differ significantly p < 0.05 by Least Significant Difference (n = 3)

The nature of idli based on sensory showed variation with the variety of rice used. As the idli prepared from parboiled rice is very soft when compared with idli made with other varieties. Parboiled rice may be best suited for idli making which is in par with the report given by Juliano and Sakurai (1985) that parboiled rice is better suited than raw rice for producing idli, i.e., it is soft without becoming sticky. The idli prepared using very light colored parboiled rice are preferred by consumers traditionally accustomed to eating raw rice. Sowbhagya et al. (1991) studied the effect of variety, parboiling and ageing of rice on the quality of idli and reported that the normal parboiled rice is best suited for making idli as shown by its higher scores for softness. In the present study the idli made of parboiled rice is soft and it may also be due to fact proved by Sharma et al. (2008) that the greater starch damage in parboiled rice during wet grinding, attribute to its greater susceptibility to undergo damage owing to its softness after soaking as well as to the longer duration of grinding favoring parboiled rice to be suited for idli making. Roy et al. (2010) noted that the hardness and adhesion of cooked rice were dependent not only on the moisture content but also on the forms and variety of rice. Roy et al. (2004, 2008), Islam et al. (2001) and Shimizu et al. (1997) reported that the hardness of the cooked rice depend on the moisture content of cooked parboiled and untreated rice. In case of idli, steaming increases the moisture content of idli and it is a major factor that makes idli made with parboiled rice softer and for the same reason that red rice has acquired more moisture which affected its texture losing firmness.

Effect of black gram on batter volume

The percentage of increase in batter volume was significant at five per cent level (Table 4) for the batter made from parboiled rice and black gram used with husk, and thou the idli made from the same batter were spongy, the color was unappealing to the panel members. The difference in batter volume was not significantly higher with the batter made from the black gram with husk removed. On the other hand, though, the percentage of increase in batter volume was low in the batter made from parboiled rice and black gram dhal with husk removed after soaking, the texture was very spongy and the color was also appealing making this variation a better choice in terms of color and texture on sensory basis.

Table 4.

Effect of black gram (var. ADT 3) on the batter volume after fermentation

| Particulars | Black gram | ||

|---|---|---|---|

| BHR | BHRAS | BWH | |

| Initial volume of the batter (cm3) | 263.8 ± 0.14 b | 271.4 ± 0.14 c | 226.1 ± 0.84 a |

| Final volume of the batter (cm3) | 339.2 ± 0.13 b | 376.9 ± 0.07 c | 324.1 ± 0.0 a |

| Batter volume increased after fermentation (%) | 28.6 ± 0.00 a | 38.9 ± 0.07 b | 43.3 ± 0.07 c |

| Volume of the batter after expulsion (cm3) | 248.7 ± 0.35 b | 256.3 ± 0.42 c | 211.1 ± 0.07 a |

| Batter volume decreased after expulsion of gas (%) | 26.7 ± 0.00 a | 32.0 ± 0.00 b | 34.9 ± 0.14 c |

Mean values in a row with different letters differ significantly p < 0.05 by Least Significant Difference (n = 3)

BHR black gram husk removed, BHRAS black gram husk removed after soaking, BWH black gram with husk

Effect of ratios of rice to black gram dhal on batter volume

The percentage of increase in batter volume was high for the ratio 3:3.5 (w/w) of rice to black gram dhal respectively with 5 % significance followed by other ratios such as 3:3, 3:2.5 and so on. When the texture of idli was compared on sensory basis, the idli made of ratio 3:1 was very spongy compared to idli made of other ratios of rice and black gram dhal showing that the proportions of compositions of the substrate also have an important role in the outcome of the product. Table 5 shows the effect of ratios of ingredients on batter volume. Hence for the further study parboiled rice namely IR 20, black gram variety namely ADT 3 with husk removed after soaking was used to find the effect of ingredients and descriptive sensory profile of idli.

Table 5.

Idli batter volume characteristics as affected by parboiled rice and black gram dhal (without husk)

| Particulars | Rice and black gram ratio (w/w) | |||||

|---|---|---|---|---|---|---|

| 3 : 1 | 3 : 1.5 | 3 : 2 | 3 : 2.5 | 3 : 3 | 3 : 3.5 | |

| Initial volume of the batter (cm3) | 150.7 ± .07a | 241.2 ± 0.28c | 301.5 ± 0.21d | 324.1 ± 0.14e | 339.2 ± 1.13f | 414.6 ± 0.07g |

| Final volume of the batter (cm3) | 248.7 ± 1.13a | 316.6 ± 0.84c | 422.7 ± 0.07d | 452.3 ± 0.07e | 467.4 ± 0.00f | 603.1 ± 0.07g |

| Batter volume increase after fermentation (%) | 65.0 ± 0.0a | 31.3 ± 0.07c | 40.2 ± 0.07d | 39.6 ± 0.28e | 37.8 ± 0.35f | 45.5 ± 3.0.07g |

| Volume of the batter after expulsion (cm3) | 158.3 ± 0.21a | 173.4 ± 0.0b | 233.7 ± 0.14d | 248.7 ± 0.28e | 256.3 ± 0.14f | 301.5 ± 0.0g |

| Batter volume decrease after expulsion of gas (%) | 36.3 ± 0.28b | 45.2 ± 0.28d | 44.7 ± 0.28c | 45.0 ± 1.41d | 44.2 ± 1.13c | 50.0 ± 0.14e |

Mean values in a row with different letters differ significantly p < 0.05 by Least Significant Difference (n = 3)

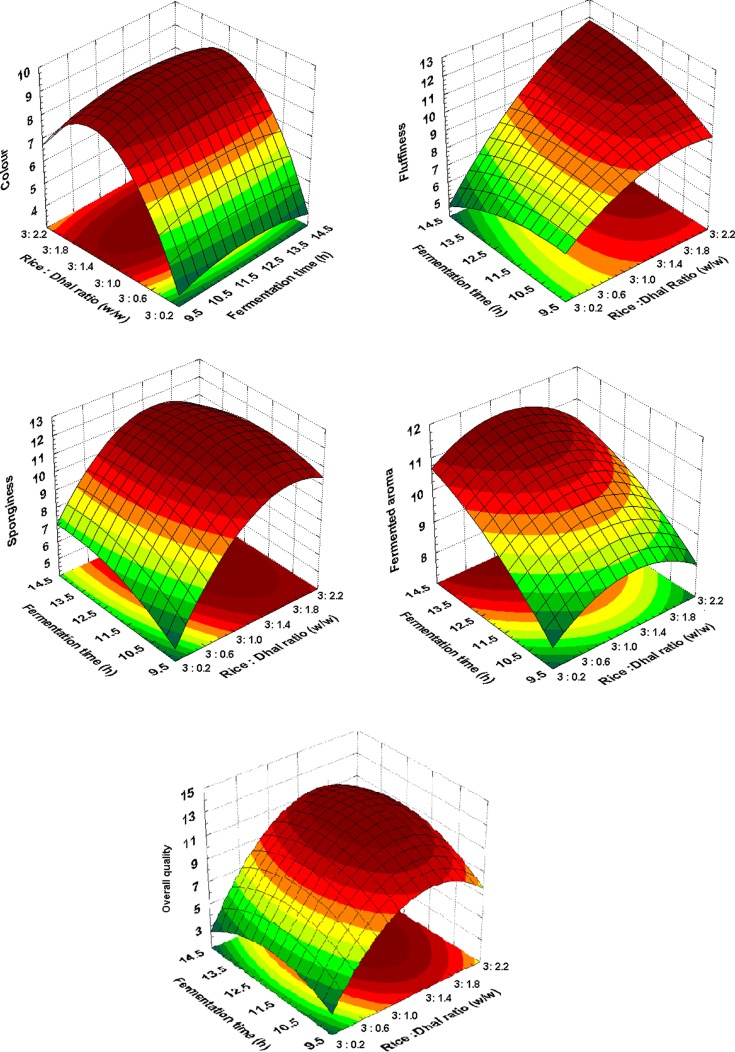

Desirable parameters of idli

The desirable and undesirable parameters of idli were evaluated by sensory analysis because the sensory evaluation of different cooked varieties of idlis revealed the wide acceptance of the conventional product due to its attractive aroma, taste and consistency (Soni and Sandhu 1989). The sensory parameters as shown in Table 6 were studied for the idli made from the parboiled rice and black gram dhal with husk removed after soaking with the ratios framed using CCRD at varying temperature. The idli showed remarkable difference in the sensory parameters in relation to the ratios and timing of fermentation which is supported by the study done by Ghosh and Chattopadhyay (2011) which states that the changes during fermentation affect the physical properties like appearance, texture, aroma, flavor and overall acceptability and these parameters are vital to assess the acceptability of the product in the consumer point of view. Table 7 shows the regression co-efficient values for the desirable parameters. The R2 values for color, fluffiness, sponginess were 0.953, 0.915 and 0.806 respectively which reaches unity favoring the product. Figure 1a to d shows the relation between rice and black gram dhal ratio and fermentation time on the desirable parameters of idli.

Table 6.

Experimental designs and mean scores of sensory attributes

| Experimental design points | Dependent variables | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Color | Fluffiness | Sponginess | Fermented aroma | Compactness | Firmness | Stickiness | Sourness | Overall quality | |

| 1 | 8.7 ± 0.22 | 8.2 ± 0.26 | 9.7 ± 0.47 | 10.2 ± 0.69 | 8.7 ± 0.57 | 9.2 ± 0.47 | 11.3 ± 0.46 | 8.5 ± 0.40 | 9.2 ± 0.34 |

| 2 | 9.2 ± 0.14 | 7.4 ± 0.38 | 10.6 ± 0.43 | 11.1 ± 0.62 | 8.5 ± 0.46 | 9.6 ± 0.53 | 11.1 ± 0.50 | 9.6 ± 0.58 | 8.7 ± 0.33 |

| 3 | 6.9 ± 0.21 | 10.1 ± 0.38 | 11.0 ± 0.83 | 10.2 ± 0.47 | 9.2 ± 0.58 | 5.8 ± 0.42 | 9.8 ± 0.44 | 8.9 ± 0.45 | 11.4 ± 0.73 |

| 4 | 7.3 ± 0.29 | 10.7 ± 0.41 | 11.2 ± 0.62 | 10.9 ± 0.46 | 8.1 ± 0.55 | 6.2 ± 0.43 | 9.2 ± 0.41 | 10.3 ± 0.38 | 11.7 ± 0.43 |

| 5 | 8.6 ± 0.19 | 8.0 ± 0.39 | 7.6 ± 0.35 | 9.6 ± 0.43 | 9.4 ± 0.74 | 11.5 ± 0.50 | 8.3 ± 0.43 | 8.2 ± 0.37 | 7.5 ± 0.27 |

| 6 | 5.2 ± 0.42 | 11.4 ± 0.67 | 12.3 ± 0.51 | 9.5 ± 0.42 | 7.8 ± 0.65 | 5.3 ± 0.35 | 7.4 ± 0.35 | 8.1 ± 0.53 | 11.6 ± 0.59 |

| 7 | 8.6 ± 0.23 | 9.6 ± 0.51 | 10.4 ± 0.46 | 8.3 ± 0.61 | 9.7 ± 0.65 | 5.8 ± 0.52 | 7.1 ± 0.35 | 6.4 ± 0.29 | 9.8 ± 0.41 |

| 8 | 8.3 ± 0.49 | 10.2 ± 0.54 | 11.3 ± 0.32 | 11.4 ± 0.61 | 8.1 ± 0.53 | 4.9 ± 0.52 | 7.1 ± 0.38 | 9.7 ± 0.42 | 11.7 ± 0.59 |

| 9 | 9.1 ± 0.46 | 9.7 ± 0.43 | 11.5 ± 0.58 | 10.4 ± 0.60 | 8.5 ± 0.68 | 5.7 ± 0.44 | 7.7 ± 0.43 | 9.1 ± 0.44 | 12.1 ± 0.33 |

| 10 | 8.8 ± 0.44 | 10.2 ± 0.64 | 11.4 ± 0.51 | 10.7 ± 0.47 | 8.7 ± 0.51 | 5.4 ± 0.53 | 7.4 ± 0.35 | 9.3 ± 0.49 | 11.9 ± 0.49 |

Table 7.

Regression co-efficient for desirable sensory parameters

| Independent variables | Regression co-efficient | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Color | Fluffiness | Sponginess | Fermented aroma | Overall quality | Compactness | Firmness | Stickiness | Sourness | |

| Mean/Interaction | −6.367 | −2.919 | −18.396 | −6.970 | −39.697 | 16.848 | 27.570 | 36.448 | −17.399 |

| 1. Rice : Dhal ratio (L) | 6.722 | −0.551 | 10.968 | 3.152 | 10.062 | 3.359 | −18.180 | −15.245 | 0.959 |

| Rice : Dhal ratio (Q) | −3.332* | −1.068 | −2.465 | −0.974 | −4.263* | −0.112 | 5.804 | 5.762 | −0.770 |

| 2. Fermentation time (L) | 2.019 | 1.899 | 3.4125 | 2.072 | 7.0723 | −1.357 | −1.353 | −2.905 | 3.677 |

| Fermentation time (Q) | −0.081 | −0.101 | −0.121 | −0.061 | −0.299 | 0.059 | 0.055 | 0.125 | −0.132 |

| 1L by 2L | −0.033 | 0.465 | −0.233 | −0.066 | 0.266 | −0.299 | 0.000 | −0.132 | 0.099 |

| R 2 | 0.953 | 0.915 | 0.806 | 0.646 | 0.952 | 0.941 | 0.948 | 0.853 | 0.884 |

*p < 0.05

L linear effect, Q quadratic effect

Fig. 1.

Relation between rice to black gram dhal ratio and fermentation time on the desirable sensory parameters of idli a Color b Fluffiness c Sponginess d Fermented aroma f Overall quality

Color

The color of the idli varied with the difference in ratios of the ingredients and change in fermentation time. There was improvement in the color of idli with increase in fermentation time. As the ratio of black gram dhal increased there was gradual decrease in brightness of idli color due to the black gram dhal content.

Fluffiness and sponginess of idli

Texture of idli is very critical from consumer point of view, it should be spongy, soft and fluffy (Ramakrishnan 1979; Radhakrishnamurthy et al. 1961; Desikachar et al. 1960). The texture of idli is influenced by many variables like raw material, quantity, soaking time, grinding conditions, fermentation temperature and time and adjuncts on quality of idli (Desikachar et al. 1960; Radhakrishnamurthy et al. 1961). The fluffiness and sponginess increased with increase in the ratio of black gram dhal and fermentation time. The maximum score for fluffiness is 11.4 for the idli made of ratio 3:2 at 12 h fermentation time.

The important factor affecting the texture (sponginess, firmness and stickiness) of the idli is the starch content of the ingredients which is supported by the study done by Tharanathan and Mahadevamma (2003), that apart from its energy contribution, starch content is the major factor which governs the texture of idli and as a result, to the organoleptic properties of food. It was reported that the spongy texture of idli is also due to the presence of surface active proteins (globulin) that generate a foamy character resulting in the porous structure to the idli and this porous structure is stabilized even during steaming process by the presence of viscogenic mucilaginous polysaccharide called arabinogalactan (Susheelamma and Rao 1979) proving that this viscosity and foam stabilizing properties of native polysaccharide is a special functional value of foods prepared from black gram (Tharanathan et al. 1994). As the starch content of IR20 rice is 79.5 % and that of black gram is 52 % and the protein content of rice and dhal were 6.46 and 24.16 respectively the texture of the developed idli is found to be good.

Fermented aroma

In case of fermented foods the shelf-life, texture, taste and aroma of the final product is improved because of fermentation. The changes in fermentation depend on the available nutrients in the starting materials, the unique metabolic abilities of the fermenting microorganisms and possible interactions among all of these elements (McFeeters 1988). The response surface graph reveals that fermented aroma increased with increase in fermentation time. Mukherjee et al. (1965), Rajalakshmi and Vanaja (1967) have reported that black gram naturally possess Leuconostoc mesenteroides, and the gas, acid and several volatile compounds are formed during fermentation which contribute to a complex blend of flavors in the products (Chavan et al. 1989).

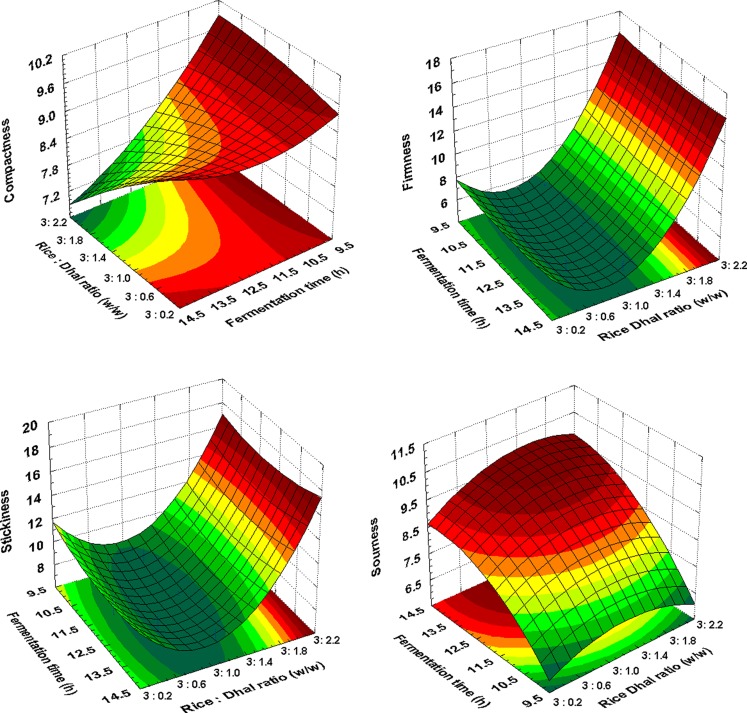

Negative drivers of liking

The compactness was high for the idli made with ratio 3:1.25, followed by 3:0.5 and low for the idli made of ratio 3:2 (Table 6). This shows that the proportion of the ingredients have a direct impact on the quality of the product. Figure 2a shows that compactness decreased with increase in fermentation time and with high quantity of black gram dhal. The firmness of the idli was high for the ratio 3:0.5 and it was noted that firmness decreased with increase in black gram dhal quantity. Figure 2a to d shows the response surface graphs obtained for the undesirable parameters. The undesirable parameter does not insist that the attributes are not required for the product but should have moderate effect on the product. The attributes such as compactness, firmness and stickiness when high are generally disliked by the consumers. Table 8 shows the regression co-efficient values for the undesirable parameters (Fig. 2).

Fig. 2.

Relation between rice to black gram dhal ratio and fermentation time on the undesirable parameters of idli a Compactness b Firmness c Stickiness d Sourness

Table 8.

Simultaneous optimization of process parameters by desirability approach

| Sensory parameters | Constraints imposed | Predicted values | Observed values |

|---|---|---|---|

| Color | Maximum | 8.00 | 8.2 ± 0.64NS |

| Fluffiness | Maximum | 9.81 | 9.6 ± 0.72 NS |

| Sponginess | Maximum | 11.01 | 10.7 ± 1.42 NS |

| Fermented aroma | Optimum | 9.35 | 8.7 ± 0.30 |

| Compactness | Optimum | 9.35 | 8.8 ± 0.39 |

| Firmness | Minimum | 5.26 | 5.6 ± 0.42 NS |

| Stickiness | Optimum | 7.87 | 8.1 ± 0.32 |

| Sourness | Optimum | 7.60 | 7.3 ± 0.28 NS |

| Overall Quality | Maximum | 10.89 | 10.6 ± 0.51 NS |

Rice to black gram dhal ratio = 3: 1.475, fermentation time = 10.2, overall desirability score of 0.7439

NS = no significant difference (p > 0.05)

Stickiness of the idli

The physicochemical properties such as moisture content, adhesion and hardness are all induced by the processing conditions which affect the eating quality of rice. The parboiling treatment given to rice decreases the stickiness (Roy et al. 2004; Kato et al. 1983; Biswas and Juliano 1988; Islam et al. 2001). Rice with low amylose content is generally soft when cooked, whereas rice with high amylose content has higher grain hardness (Juliano 1971). High-amylose rice has more long chains than low-amylose rice (Hizukuri et al. 1989; Radhika et al. 1993). The more long chains, the firmer the rice is when cooked and vice-versa (Bhattacharya 2004). Rice with high water binding capacity normally yields soft texture cooked rice (Mohapatra and Bal 2006). In the present study the amylose content was low in the parboiled rice (32 %) and black gram dhal (17 %) compared to the amylopectin content hence the stickiness is due to the ratios of rice and black gram dhal and the fermentation time. An optimum ratio and fermentation time can yield a product with desirable stickiness.

Sour taste of the idli

Figure 2d show that sourness increased with increase in fermentation time. In the present study the sourness was high (10.3) for the idli made of ratio 3:1.78 at 13.42 h fermentation time. As sourness at an optimum level is preferred an optimum temperature will favor the product.

Overall quality of the idli

Table 6 shows that the overall quality of the idli in sensory basis was high (12.1) for the ratio 3:1.25 at 12 h fermentation time. Figure 1e illustrates the surface graph showing the relation between ratios of rice and black gram dhal and fermentation time on the overall quality of idli taking into consideration all sensory attributes of idli.

Simultaneous optimization

Simultaneous optimization was performed for sensory attributes parameters like color, appearance, texture, taste, aroma and overall quality by imposing desirability constraints. In case of sponginess, the softer idli shows high sponginess. Hence the software finally gives a maximum desirable score and the condition at which the maximum score can be obtained with some constraints by assigning maximal desirability score as 1 and minimal desirability score as 0. Table 8 shows the constraints imposed for idli with better sensory attributes with the desirable value for both independent and dependant variables. The maximum desirable score that can be achieved with the desirable value will be 0.7439. On the basis of these calculations good idli could be made when the rice to black gram dhal ratio is 3:1.475 (w/w), fermented for 10.2 h. The optimum results were validated by performing the experiment at the optimized ratio and fermentation time by comparing the observed and the predicted values. The predicted values are shown in Table 8. The observed and predicted values were not significantly different (P > 0.05) which confirmed the optimization results and proved the predicted model to be correct.

Principal component analysis (PCA)

Sensory scores were subjected to PCA analysis. The PCA analysis revealed that PC1 and PC2 accounted for 78 % of the total variance in the data matrix. It is clear from the plot that sensory attributes like sponginess and fluffiness associated with each other strongly on the positive side of the PC1 axis while firmness, compactness, stickiness were clustered together on the negative side of the PC1 axis. The third cluster is formed by fermented aroma and sourness on the positive side of PC2 axis. Sample from the experimental design point 6 was closely associated with desirable sensory attributes like sponginess and fluffiness followed by sourness and fermented aroma. On the other hand, design points 5, 1 and 2 were closely correlated with undesirable sensory attributes like firmness, compactness and stickiness (Fig. 3). From the PCA biplot it is clear that PCA is a powerful technique which can discriminate the samples and attributes within the data matrix, depending upon their inter relationships.

Fig. 3.

Principal Component Analysis biplot with sensory attributes of idli

Conclusion

The texture of the idli in terms of sensory attributes show difference based on the type, quality and quantity of the ingredients used. This study reveals that IR20 parboiled rice in combination with black gram variety ADT3 (husk removed after soaking) will give good idli in terms of sensory attributes. RSM has helped to arrive with the result that the above said ingredients when taken in the ratio of 3:1.475 and fermented for 10.2 h will give idli of desirable score (0.7439). PCA has supported the study to arrive at the interrelationship between the sensory attributes of the idli. This study will support commercial manufacturers to produce idli with uniform quality and taste reaching customer satisfaction.

Acknowledgements

Author is grateful to Pondicherry University for providing necessary facility to carry out the work and to University Grants Commission for providing fellowship to the first author.

References

- Bhattacharya KR (2004) The chemical basis of rice end-use quality. Rice is life: scientific perspectives for the 21st century. Improving rice quality. Proceedings of the World Rice Research Conference held in Tokyo and Tsukuba, Tsukuba, Japan, 5–7 November

- Biswas SK, Juliano BO. Laboratory parboiling procedures and properties of parboiled rice from varieties differing in starch properties. Cereal Chem. 1988;65(5):417–423. [Google Scholar]

- Box GEP, Wilson KB. On the experimental attainment of optimum conditions. J R Stat Soc Ser B Method. 1951;13:1–45. [Google Scholar]

- Campbell-Platt G. Fermented foods-a world perspective. Food Res Int. 1994;27:253–257. doi: 10.1016/0963-9969(94)90093-0. [DOI] [Google Scholar]

- Caplice E, Fitzgerald GF. Food fermentation, role of microorganisms in food production and preservation. Int J Food Microbiol. 1999;50:131–149. doi: 10.1016/S0168-1605(99)00082-3. [DOI] [PubMed] [Google Scholar]

- Chavan JK, Kadam SS, Larry RB. Nutritional improvement of cereals by fermentation. Crit Rev Food Sci Nutr. 1989;28(5):348–400. doi: 10.1080/10408398909527507. [DOI] [PubMed] [Google Scholar]

- Cunniff P. AOAC International. Arlington: Cereal Foods; 1995. [Google Scholar]

- Desikachar HSR, RadhakrishnaMurty R, Rao GR, Kadkol SB. Studies on Idli natural fermentation: part-1—some accompanying changes in the batter. J Sci Ind Res. 1960;19C:168–172. [Google Scholar]

- Geervani P, Theophilus F. Studies on digestibility of selected legume carbohydrates and its impact on the pH of the gastrointestinal tract in rats. J Sci Food Agric. 1981;32:71–78. doi: 10.1002/jsfa.2740320111. [DOI] [PubMed] [Google Scholar]

- Ghosh D, Chattopadhyay P (2011) Application of principal component analysis (PCA) as a sensory assessment tool for fermented food products. J Food Sci Technol. doi:10.1007/s13197-011-0280-9 [DOI] [PMC free article] [PubMed]

- Haber A, Runyon R. General statistics. 3. Reading: Addison Wesley Publishing Company; 1977. [Google Scholar]

- Hammes WP, Ganzle MG. Sour dough breads and related products. In: Wood BJB, editor. Microbiol ferm foods, vol 1. 2. London: Blackie Academic and Professional; 1998. pp. 199–216. [Google Scholar]

- Hizukuri S, Takeda Y, Maruta N, Juliano BO. Molecular structures of rice starch. Carbohydr Res. 1989;189:227–235. doi: 10.1016/0008-6215(89)84099-6. [DOI] [Google Scholar]

- Islam R, Shimizu N, Kimura T. Quality evaluation of parboiled rice with physical properties. Food Sci Technol Res. 2001;7:57–63. doi: 10.3136/fstr.7.57. [DOI] [Google Scholar]

- Juliano BO. A simplified assay for milled rice amylase. Cereal Sci Today. 1971;16(10):334–340. [Google Scholar]

- Juliano BO, Sakurai J. Miscellaneous rice products. In: Juliano BO, editor. Rice chemistry and technology. MN: Am Assoc Cereal Chem St. Paul; 1985. pp. 569–618. [Google Scholar]

- Kato H, Ohta T, Tsugita T, Hosaka Y. Effect of parboiling on texture and flavor components of cooked rice. J Agric Food Chem. 1983;31:818–823. doi: 10.1021/jf00118a035. [DOI] [Google Scholar]

- Lawless HT, Heymann H. Sensory evaluation of food: principles and practices. 2. New York: Chapman & Hall; 1998. p. 608. [Google Scholar]

- Lee WC, Yusof S, Hamid NSA, Baharin BS. Optimizing conditions for enzymatic clarification of banana juice using response surface methodology (RSM) J Food Eng. 2006;73:55–63. doi: 10.1016/j.jfoodeng.2005.01.005. [DOI] [Google Scholar]

- Mcfeeters RF. Effects of fermentation on the nutritional properties of food. In: Karmas E, Harris RS, editors. Nutritional evaluation of food processing, Chapter 16. 3. New York: Van Nostrand Reinhold Company; 1988. pp. 423–446. [Google Scholar]

- Mohapatra D, Bal S. Cooking quality and instrumental textural attributes of cooked rice for different milling fractions. J Food Eng. 2006;73:253–259. doi: 10.1016/j.jfoodeng.2005.01.028. [DOI] [Google Scholar]

- Mukherjee SK, Albury MN, Pederson CS, Vanveen AG, Steinkraus KH. Role of Leuconostoc mesenteroides in leavening the batter of Idli, a fermented food of India. Appl Microbiol. 1965;13(2):227–231. doi: 10.1128/am.13.2.227-231.1965. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nout MJR. Rich nutrition from the poorest—cereal fermentations in Africa and Asia. Food Microbiol. 2009;26:685–692. doi: 10.1016/j.fm.2009.07.002. [DOI] [PubMed] [Google Scholar]

- Radhakrishnamurthy R, Desikachar HSR, Srinivasan M, Subramanyan V. Studies on Idli fermentation-2. Relative participation of black gram flour and rice semolina in the fermentation. J Sci Ind Res. 1961;20C:242–345. [PubMed] [Google Scholar]

- Radhika RK, Ali SZ, Bhattacharya KR. The fine structure of rice-starch amylopectin and its relation to the texture of cooked rice. Carbohydrate Polym. 1993;22:267–275. doi: 10.1016/0144-8617(93)90130-V. [DOI] [Google Scholar]

- Rajalakshmi R, Vanaja K. Chemical and biological evaluation of the effects of fermentation on the nutritive value of foods prepared from rice gram. Br J Nutr. 1967;21:467–473. doi: 10.1079/BJN19670048. [DOI] [PubMed] [Google Scholar]

- Ramakrishnan CV. Studies on Indian fermented foods. Baroda J Nutr. 1979;6:1–54. [Google Scholar]

- Ravi R, Susheelamma NS. Simultaneous optimization of a multi-response system by desirability function analysis of boondi-making: a case study. J Food Sci. 2005;70:s539–s547. doi: 10.1111/j.1365-2621.2005.tb11531.x. [DOI] [Google Scholar]

- Roy P, Shimizu N, Kimura T. Energy conservation in cooking of milled raw and parboiled rice. Food Sci Technol Res. 2004;10:111–116. doi: 10.3136/fstr.10.111. [DOI] [Google Scholar]

- Roy P, Ijiri T, Okadome H, Nei D, Orikasa T, Nakamura N, Shiina T. Effect of processing conditions on overall energy consumption and quality of rice. J Food Eng. 2008;89:343–348. doi: 10.1016/j.jfoodeng.2008.05.015. [DOI] [Google Scholar]

- Roy P, Nei D, Orikasa T, Orikasa T, Okadome H, Thammawong M, Nakamura N, Shiina T. Cooking properties of different forms of rice cooked with an automatic induction heating system rice cooker. Asian J Food Agro-Ind. 2010;3:373–388. [Google Scholar]

- Sadasivam S, Manickam A. Biochemical methods. New Delhi: New Age International (P) Limited Publishers; 2008. pp. 7–11. [Google Scholar]

- Sharma P, Chakkaravarthi A, Vasudeva S, Subramanian R. Grinding characteristics and batter quality of rice in different wet grinding systems. J Food Eng. 2008;88:499–506. doi: 10.1016/j.jfoodeng.2008.03.009. [DOI] [Google Scholar]

- Shimizu N, Kimura T, Ohtsubo K, Toyoshima H. Development of rice quality evaluating technique based on physical properties of cooked rice (Part 1)—effect of cooked rice properties on texture of cooked rice. Jpn Soc Agric Mach. 1997;59:75–82. [Google Scholar]

- Sin HN, Yusof S, Hamid NSA, Rahman RA. Optimization of enzymatic clarification of sapodilla juice using response surface methodology. J Food Eng. 2006;73:313–319. doi: 10.1016/j.jfoodeng.2005.01.031. [DOI] [Google Scholar]

- Soni SK, Sandhu DK. Fermentation of Idli: effects of changes in raw materials and physico-chemical conditions. J Cereal Sci. 1989;10:227–238. doi: 10.1016/S0733-5210(89)80052-9. [DOI] [Google Scholar]

- Sowbhagya CM, Pagaria LK, Bhattacharya KR. Effect of variety, parboiling and ageing of rice on the texture of Idli. J Food Sci Technol. 1991;28:274–279. [Google Scholar]

- Sridevi J, Prakash MH, Vijayendra SVN. Selection of starter cultures for idli batter fermentation and their effect on quality of idlis. J Food Sci Technol. 2010;47:557–563. doi: 10.1007/s13197-010-0101-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Susheelamma N, Rao MVL. Functional role of the arabinogalactan of black gram (Phaseolus mungo L.) in the texture of leavened foods (steamed puddings) J Food Sci. 1979;44:1309–1312. doi: 10.1111/j.1365-2621.1979.tb06426.x. [DOI] [Google Scholar]

- Tamang JP. Role of microorganisms in traditional fermented foods. Indian Food Ind. 1998;17:162–167. [Google Scholar]

- Tharanathan RN, Mahadevamma S. Grain legumes—a boon to human nutrition. Trends Food Sci Tech. 2003;14:507–518. doi: 10.1016/j.tifs.2003.07.002. [DOI] [Google Scholar]

- Tharanathan RN, Changala RG, Muralikrishna G, Susheelamma NS. Structure of a galactoarabinan-rich pectic polysaccharide of native and fermented black gram (Phaseolus mungo) Carbohydr Polym. 1994;23:121–127. doi: 10.1016/0144-8617(94)90036-1. [DOI] [Google Scholar]

- Wong PK, Yusof S, Mohd Ghazali H, Che Man Y. Optimization of hot water extraction of Roselle juice by using response surface methodology: a comparative study with other extraction methods. J Sci Food Agric. 2003;83:1273–1278. doi: 10.1002/jsfa.1416. [DOI] [Google Scholar]

- Young VR, Pellet PL. Plant proteins in relation to human protein and amino acid nutrition. Am J Clin Nutr. 1994;59:1203S–1212S. doi: 10.1093/ajcn/59.5.1203S. [DOI] [PubMed] [Google Scholar]