Abstract

Background

Metal Inert Gas (MIG) welding and Tungsten Inert Gas (TIG) welding are widely used for mild steel segments in basic metal industries. Pulmonary problems such as asthma, pulmonary inflammation, hyper-responsiveness of airways and higher susceptibility to infections are reported as the result of occupational exposure of welders to ozone and nitrogen oxides. Potent oxidizing agents like ozone and nitrogen oxides are also reported to be a precursor for respiratory problems and cause lipid peroxidation of membranes.

Materials and Methods

A total of 43 nonsmoking MIG and TIG welders and 41 nonsmoking workers without appreciable exposure to any chemicals as the control population were chosen to participate in this study. Occupational exposure to ozone was monitored according to the validated methods. Malondialdehyde (MDA) of blood serum as a biomarker for lipid peroxidation was analyzed using Reverse Phase High Performance Liquid Chromatography. Data obtained from this study were analyzed using t-test, Pearson's correlation coefficient and multiple regression analysis.

Results

A total of 88.4% and 74.4% of welders had exposure to ozone and nitrogen dioxide higher than the permissible limit of occupational exposure, respectively. Generally, exposure of MIG welders to ozone was significantly higher than TIG welders (P = 0.006). However, exposure to nitrogen dioxide gas was comparable in both groups. Serum MDA of welders was significantly higher than that of the control group (P = 0.001). A significant correlation was detected between ozone exposure and level of serum malondialdehyde. Such correlation was not observed for nitrogen dioxide exposure.

Conclusion

Considering the high exposure of welders to ozone and nitrogen dioxide, and higher level of serum malondialdehyde in them compared to controls, risk management is recommended for this group of workers.

Keywords: Ozone, Nitrogen oxides, Welding, Malondialdehyde

INTRODUCTION

There are approximately 800,000 to 1,000,000 workers doing welding as their full time job all over the world (1, 2). In Iran as well, welding is pretty popular as an industrial activity for connecting pieces of metal together. TIG and MIG welding on mild or low carbon steel is widely used in various industries due to the advancements in technology and industrial manufacturing. Metal fumes and gases like ozone and nitrogen oxides are generated during welding (3, 4). These gases cause adverse complications in welders such as headache, chest pain, upper airway dryness, irritation of respiratory mucosa, inflammation of airways, hyper-responsiveness of airways, asthma, susceptibility to viral infections and pulmonary edema (5–8). Ozone and nitrogen dioxide are potent oxidizing agents. They cannot pass the cell membranes but are capable of lipid peroxidation of bio-membranes. Lipid peroxidation can finally result in oxidative deterioration of cell membrane and produce a compound called malondialdehyde which is measurable in blood serum (9). In TIG and MIG welding, ozone and nitrogen oxides are generated in a considerably greater extent than in other types of welding. Noble gases like argon are used to control, stabilize and reinforce the welding point (10, 11).

Considering the significance of mentioned welding techniques and lack of information regarding exposure of Iranian welders to potent oxidizing agents, we decided to monitor occupational exposure of welders to ozone and nitrogen oxides and measure serum level of malondialdehyde in them and compare it with the control group for the first time in Iran.

MATERIALS AND METHODS

This descriptive cross-sectional analytical study was conducted to evaluate exposure of mild steel welders to ozone and nitrogen oxides during TIG and MIG welding. In this study, 43 welders working in the manufacturing of oscillatory tubes and 41 controls (montage workers) with no active exposure to ozone and nitrogen oxides were evaluated. Understudy subjects were interviewed and data regarding their age, work shifts, work history, smoking, history of renal disease or diabetes, medication intake and use of personal protection devices were obtained. Smokers, those suffering from underlying diseases and cases with history of drug consumption were excluded from the study.

Exposure of cases and controls to ozone was evaluated using Occupational Safety and Hygiene Association (OSHA) protocol ID214. Air samples were taken in the breathing zone of workplace for 3 hours with flow rate of 0.5 lit/min. Ozone was collected using nitrite-impregnated glass fiber filters (IGFFs) and analyzed using HPLC-UV (High Performance Liquid Chromatography Ultra-Violet) and wavelength of 210 nm was applied to detect nitrate (12). In order to evaluate exposure of cases and controls to nitrogen oxides, SKC226-40 sorbent sample tubes were used for air sampling according to NIOSH (National Institute of Occupational Safety and Health) method 6014 and air samples were obtained for 60 min with flow rate of 0.1 lit/min. Chemical reagents (hydrogen peroxide, sulfonyl amide and n-1-naphthyl ethylene diamine dihydrochloride) were added and samples were analyzed at 540 nm wavelength using a spectrophotometer (13). After taking samples from breathing air, a 5 ml blood sample was taken from welders and control population. Blood serum was separated with centrifuging (4500 g) for 10 min. Blood serum samples were preserved in plastic tubes at -20 C° until analysis. In order to evaluate lipid peroxidation in welders and controls, malondialdehyde was separated from blood serum of subjects using HPLC with mobile phase (30% 30mM KH2PO4, 70% Methanol) and chromatography column C18 with 30 cm length and flow rate of 1ml/min and analyzed at 254 nm wavelength (14).

Data were first evaluated by Kolmogorov-Smirnov test to ensure their normal distribution and then were analyzed using t-test, Pearson's correlation coefficient and regression models. SPSS version 16 software was used for data analysis and P < 0.05 was considered statistically significant.

RESULTS

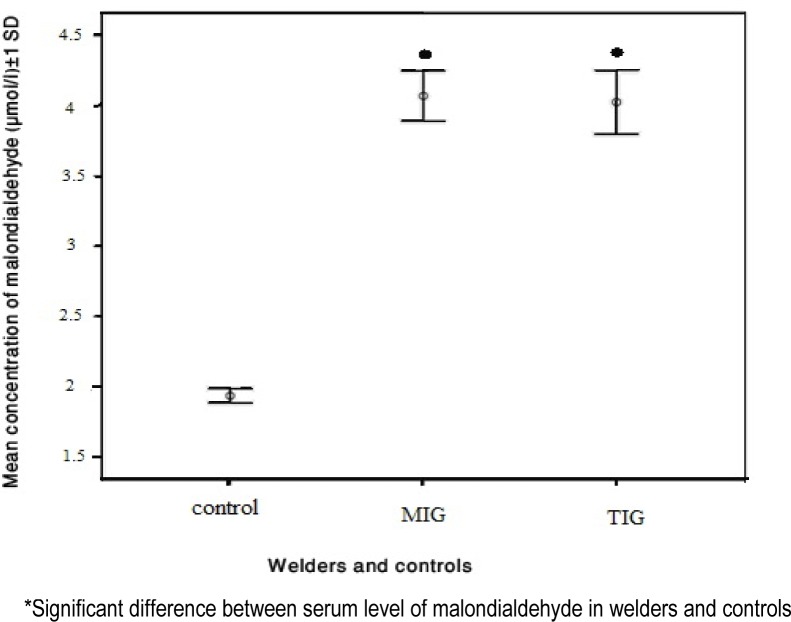

Table 1 summarizes characteristics of welders and controls. According to this table, the 2 groups were similar in terms of mean age and work history. Concentration of ozone and nitrogen oxide pollutants was measured in the breathing air of work place. A total of 88.4% and 74.4% of welders had exposure to ozone and nitrogen dioxide higher than the permissible limit of occupational exposure, respectively. However, level of nitrogen oxide was lower than the permissible limit (Table 2). Exposure to ozone and nitrogen oxide during MIG welding was higher than TIG welding (P = 0.006). However, concentration of nitrogen dioxide was not significantly different in the 2 types of welding (Table 2). Serum level of malondialdehyde in welders was compared with that of controls and mean level of malondialdehyde in blood serum of both TIG and MIG welders was significantly higher than the control group (P = 0.001). However, no significant difference was detected in this respect between TIG and MIG welders (Figure 1).

Table 1.

Demographic characteristics of understudy subjects.

| Variable | Welders (n = 43) | Controls (n = 41) | ||

|---|---|---|---|---|

| Mean±SD | Range | Mean±SD | Range | |

| Age (year) | 27.6±4.7 | 20-39 | 27.2±3.3 | 22-35 |

| Work history (year) | 4.6±3.6 | 1-20 | 4.6±3.0 | 1-13 |

Table 2.

Comparison of the measured concentrations of ozone and nitrogen oxides (mean±SD) as ppm in the breathing air of welders with standard permissible exposure limit in TIG and MIG welding.

| Oxidizing agents | All welders | Control group (n = 41) | Standard ** | Exposure> permissible limit | TIG (n = 20) | MIG (n = 23) | p-value * |

|---|---|---|---|---|---|---|---|

| Ozone | 0.30±0.19 | *** | 0.1 | 88.4% | 0.21±0.12 | 0.37±0.22 | 0.006 |

| Nitrogen dioxide | 3.41±0.63 | *** | 3 | 74.4% | 3.54±0.65 | 3.29±0.60 | 0.21 |

| Nitrogen oxide | 0.52± 3.0 | *** | 25 | 0 | 0.41±2.70 | 0.54±3.20 | 0.006 |

Comparison of exposure of welders in TIG and MIG welding

Iranian Occupational Hygiene Standard

Below the detectable rate of 0.07 ppm for ozone and 0.25 ppm for nitrogen oxides

Figure 1.

Serum level of malondialdehyde in controls, TIG and MIG welders

Occupational exposure to ozone, age and work history were significantly correlated with serum level of malondialdehyde. Exposure of welders to nitrogen dioxide or nitrogen oxide was not significantly correlated with malondialdehyde in blood serum. In the control group, a significant correlation was detected between age and work history with serum malondialdehyde. After adjusting for work history, the small correlation coefficient between occupational exposure to ozone and serum level of malondialdehyde increased from 0.349 to 0.447 (P = 0.003)(Table 3).

Table 3.

Correlation coefficient for association of malondialdehyde serum level and under study variables in both groups.

| Variables | Welders (n = 43) | Controls (n = 41) | ||

|---|---|---|---|---|

|

| ||||

| Pearson's correlation coefficient | P-value | Pearson's correlation coefficient | P-value | |

| Ozone | 0.349 | 0.022 | ||

| Nitrogen dioxide | -0.028 | 0.857 | ||

| Nitrogen oxide | -0.063 | 0.687 | ||

| Age | 0.304 | 0.047 | 0.583 | 0.001 |

| Work history | 0.735 | 0.001 | 0.546 | 0.001 |

| Ozone after adjustment for work history | 0.447 | 0.003 | ||

| Nitrogen dioxide | -0.083 | 0.602 | ||

| Nitrogen oxide | 0.09 | 0.569 | ||

In the regression model, r2 coefficient for determining the relationship between occupational exposure to ozone and malondialdehyde serum level was calculated to be 0.122. R2 coefficient was 0.54 for relationship between work history and malondialdehyde serum level and 0.632 for occupational exposure to ozone and work history with serum concentration of malondialdehyde. Regression analysis showed that exposure to ozone and especially duration of exposure had a significant effect on serum level of malondialdehyde. Duration of exposure alone is responsible for 54% of changes in serum malondialdehyde level (Table 4).

Table 4.

Regression model for association between ozone and work history variables and serum malondialdehyde level in welders (n = 43)

| Independent variable | R Square | P-value | Linear formula |

|---|---|---|---|

| Ozone | 0.122 | 0.05 | MDA = 3.557 + 1.647 Ozone |

| Work history | 0.54 | 0.001 | MDA = 3.179 + 0.188 Experience |

| Ozone and work history | 0.632 | 0.001 | MDA = 2.773 + 0.183 Experience + 1.435 Ozone |

DISCUSSION

Occupational exposure of steel welders in both TIG and MIG welding to oxidizing agents like ozone and nitrogen oxides has been reported in the literature (15). In this study, welders were exposed to ozone and nitrogen oxides concentrations of 0.30±0.19 ppm and 3.41±0.63 ppm, respectively. The permissible exposure limit is 0.1 ppm for ozone and 3 ppm for nitrogen oxides according to the Iranian Occupational Safety and Hygiene Association. Most workers had exposure to ozone and nitrogen dioxide greater than the permissible limit which can cause headache, chest pain, upper airway dryness, airways inflammation, airways hyper-responsiveness, asthma, susceptibility to viral infections and pulmonary edema (5, 6, 7, 8). MIG welders in this study had significantly greater exposure to ozone compared to TIG welders. This has also been reported in some other studies and is probably due to the higher voltage of electric arc (16). In various studies, welders have been reported to be exposed to ozone and nitrogen dioxide in the concentration range of 1.32-4.8 ppm and 1.7-7 ppm, respectively (17–19) which was higher than range of exposure among Iranian welders. It should be mentioned that concentration of ozone or nitrogen oxides in the work environment of welders depends on the frequency of welding, quality of the ventilation system used in the work place and method of air sampling and analysis. In previous studies, exposure to ozone was measured using simple methods like indicator tubes or direct reading instruments. Unfortunately, these methods are not approved as reliable accredited techniques by scientific organizations. However, methods used in the present study are accepted and accredited by the OSHA (12) and therefore our obtained results regarding exposure of welders to ozone are more reliable.

Welders were exposed to nitrogen dioxide and nitrogen oxide concentrations of 3.41±0.63 ppm and 3.0±0.52 ppm, respectively. Concentration of nitrogen dioxide was within the permissible exposure limit in 26% of cases but for nitrogen oxide this rate was below the permissible limit set by the Iranian Occupational Safety and Hygiene Association in 100% of cases (20). Considering the concentration of nitrogen oxides and lack of correlation between occupational exposure of welders to nitrogen oxide or nitrogen dioxide and their serum level of malondialdehyde, it does not seem that exposure to nitrogen oxides would be problematic. On the other hand, ozone is a stronger oxidizing agent than nitrogen oxides (21, 22) and most welders in this study had exposure to concentrations greater than the permissible limit (0.1 ppm) for this gas. Therefore, ozone plays a more significant role in health status of TIG and MIG welders.

Considering the potential impacts of ozone and nitrogen dioxide on the pulmonary system and potential of causing lipid peroxidation in cell membranes (9, 23), we measured the serum level of malondialdehyde as an indicator for oxidative stress (24). Serum level of malondialdehyde was 4.05±0.92 µmol/l in welders and 1.94±0.32 µmol/l in controls which confirms the results of a previous study regarding the higher level of malondialdehyde in blood serum of welders compared to controls (15). A significant relationship was observed between serum malondialdehyde level and exposure to ozone alone and in association with work history. It seems that exposure of welders to ozone has a cumulative effect on their health. It should be mentioned that no significant association was observed between serum level of malondialdehyde in welders and exposure to nitrogen oxide or nitrogen dioxide which can be due to the exposure rate lower than permissible exposure limit in welders to these gases and also weaker oxidizing power of them compared to ozone (22).

Biological monitoring in recent occupational toxicologic studies has been suggested as a more comprehensive method for determining exposure of workers to hazardous agents (18, 22). Based on our study results and those of Fidan regarding limited exposure of TIG and MIG welders to iron oxide fume, ozone and nitrogen oxides (9), oxidative stress can only be caused as the result of exposure to oxidizing agents like ozone and nitrogen oxides and measurement of serum level of malondialdehyde as an indicator of lipid peroxidation seems beneficial.

This study was the first to evaluate exposure to oxidizing agents in Iran. Further investigations are required on oxidative stress in welders as a prognostic factor for pulmonary diseases. Based on such studies, a biologic standard can be set for risk assessment in welders to prevent pulmonary diseases. Also, considering the exposure rate of Iranian welders to ozone and nitrogen oxides and higher serum level of malondialdehyde in them compared to controls, risk management should be taken seriously in this group of workers.

REFERENCES

- 1.Han SG, Kim Y, Kashon ML, Pack DL, Castranova V, Vallyathan V. Correlates of oxidative stress and free-radical activity in serum from asymptomatic shipyard welders. Am J Respir Crit Care Med. 2005;172(12):1541–8. doi: 10.1164/rccm.200409-1222OC. [DOI] [PubMed] [Google Scholar]

- 2.Nomination of welding fumes for toxicity studies. National Institute for Occupational Safety; Available from: http://ntp.niehs.nih.gov/ntp/htdocs/chem. [Google Scholar]

- 3.SKC, Industry Guide Welding, Publication 1447. Available from: www.skcinc.com/instructions/1447. [Google Scholar]

- 4.Ashby HS. Preventing potential health problems through proactive controls. Professional Safety. 2002:55–60. [Google Scholar]

- 5.Kreit JW, Gross KB, Moore TB, Lorenzen TJ, D'Arcy J, Eschenbacher WL. Ozone-induced changes in pulmonary function and bronchial responsiveness in asthmatics. J Appl Physiol. 1989;66(1):217–22. doi: 10.1152/jappl.1989.66.1.217. [DOI] [PubMed] [Google Scholar]

- 6.Aris RM, Christian D, Hearne PQ, Kerr K, Finkbeiner WE, Balmes JR. Ozone-induced airway inflammation in human subjects as determined by airway lavage and biopsy. Am Rev Respir Dis. 1993;148(5):1363–72. doi: 10.1164/ajrccm/148.5.1363. [DOI] [PubMed] [Google Scholar]

- 7.Olin AC, Andersson E, Andersson M, Granung G, Hagberg S, Torén K. Prevalence of asthma and exhaled nitric oxide are increased in bleachery workers exposed to ozone. Eur Respir J. 2004;23(1):87–92. doi: 10.1183/09031936.03.00044402. [DOI] [PubMed] [Google Scholar]

- 8.Willam BA. Recognition of Health Hazard in Industry: A Review of Materials and Processes. Jur Chem Educ. 1995;72(5):A109. [Google Scholar]

- 9.Fidan F, Unlü M, Köken T, Tetik L, Akgün S, Demirel R, et al. Oxidant-antioxidant status and pulmonary function in welding workers. J Occup Health. 2005;47(4):286–92. doi: 10.1539/joh.47.286. [DOI] [PubMed] [Google Scholar]

- 10.World Health Organization. Ozone and other photochemical oxidants. Second Edition. Copenhagen, Denmark: WHO Regional Office for Europe; 2000. Air Quality Guidelines. [Google Scholar]

- 11.Occupational Safety and Health Administration, Sampling and Analytical Methods 2008. Available from: http://www.osha.gov/dts/sltc/methods/index.html. [Google Scholar]

- 12.Occupational Safety and Health Administration Salt Lake Technical Center: Ozone (KIBRT) in Workplace Atmospheres (USDOL/OSHA-SLCAL Method No. ID-214) Salt Lake City, UT: Occupational Safety and Health Administration Salt Lake Technical Center; 1995. [Google Scholar]

- 13.NIOSH. NIOSH Manual of Analytical Methods (NMAM) 4th ed. Cincinnati, OH.: 1994. Nitric oxide and nitrogen dioxide: Method 6700. Available from: http://www.cdc.gov/niosh/docs/2003. [Google Scholar]

- 14.Karatas F, Karatepe M, Baysar A. Determination of free malondialdehyde in human serum by high-performance liquid chromatography. Anal Biochem. 2002;311(1):76–9. doi: 10.1016/s0003-2697(02)00387-1. [DOI] [PubMed] [Google Scholar]

- 15.Holmén A, Blomqvist J, Frindberg H, Johnelius Y, Eriksson NE, Henricson KA, et al. Frequency of patients with acute asthma in relation to ozone, nitrogen dioxide, other pollutants of ambient air and meteorological observations. Int Arch Occup Environ Health. 1997;69(5):317–22. doi: 10.1007/s004200050154. [DOI] [PubMed] [Google Scholar]

- 16.Case LB, Castrop VJ. Preliminary Report on Hygiene Studies of Welding. Industrial Medicine. 1990;9(2):52–55. [Google Scholar]

- 17.Downey EB, Buchan RM, Blehm KD, Gunter BJ. A Comparison of Two Ozone Sampling Methods. American Industrial Hygiene Association Journal. 1983;44(5):333–5. [Google Scholar]

- 18.Azari MR, Williams FM, Kirby J, Kelly P, Edwards JW. Effects of nitrogen oxides on natural killer cells in glass craftsmen and braziers. Occupational and Environmental Medicine. 1996;53:248–51. doi: 10.1136/oem.53.4.248. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Rietjens IM, Poelen MC, Hempenius RA, Gijbels MJ, Alink GM. Toxicity of ozone and nitrogen dioxide to alveolar macrophages: comparative study revealing differences in their mechanism of toxic action. J Toxicol Environ Health. 1986;19(4):555–68. doi: 10.1080/15287398609530952. [DOI] [PubMed] [Google Scholar]

- 20.Iranian Ministry of Health and Medical Education, Center for the Occupational. Permissible Exposure limits of Hazardous Chemicals and Physical Parameter of Workplaces; Arvich Publishing Co; 2002. [Google Scholar]

- 21.Jenkins HS, Devalia JL, Mister RL, Bevan AM, Rusznak C, Davies RJ. The effect of exposure to ozone and nitrogen dioxide on the airway response of atopic asthmatics to inhaled allergen: dose- and time-dependent effects. Am J Respir Crit Care Med. 1999;160(1):33–9. doi: 10.1164/ajrccm.160.1.9808119. [DOI] [PubMed] [Google Scholar]

- 22.Azari MR. Biological markers of occupational exposure to nitrogen oxides; PhD thesis; University of Newcastle Upon Tyne; 1995. pp. 206–207. [Google Scholar]

- 23.Hodges DM, DeLong JM, Forney CHF, Prange RK. Metabolic and Proteomic Markers for Oxidative Stress. New Tools for Reactive Oxygen Species. Pharmacol. 1999;161:23–33. [Google Scholar]

- 24.Que Hee S. Biological Monitoring. Malondialdehyde as biological marker of lipid peroxidation; Van Norstrand Reinhold Company; 2004. pp. 520–525. [Google Scholar]