Abstract

Aim:

The aim of this study is to evaluate, the influence of four types of sterilization/disinfection procedures (autoclave, hot air oven, glutaraldehyde, and ultraviolet [UV] light) on the tensile strength and surface topography of three orthodontic wires (stainless steel (SS), titanium - molybdenum alloy [TMA], and cobalt chromium (CoCr)).

Materials and Methods:

Sample comprised of three types of 8 inches straight length segments of orthodontic wires. They were divided into three groups according to wire composition comprising of 50 samples each. Totally 50 samples of each group were then equally divided into five subgroups according to sterilization method. After sterilization and disinfection of the experimental group, surface topography was examined with scanning electron microscope (SEM) and tensile strength was tested using universal testing machine.

Result:

The results of this study show that the mean ultimate tensile strength (UTS) of SS wire after four sterilization procedures were similar to the control group (1845.815 ± 142.29 MPa). The mean UTS of TMA wire increases after four sterilization procedures when compared with the control group (874.107 ± 275.939 MPa). The mean UTS of CoCr wire remains same after UV light disinfection, but increases after other three sterilization procedures when compared with the control group (1449.759 ± 156.586 MPa). SEM photographs of the present study shows gross increase in pitting roughness of the surface topography of all the three types of wires after four types of sterilization.

Conclusion:

Orthodontists who want to offer maximum safety for their patients can sterilize orthodontic wires before placement, as it does not deteriorate the tensile strength and surface roughness of the alloys.

KEY WORDS: Beta titanium, CoCr, stainless steel, sterilization, surface topography, tensile strength

Now-a-days, public is demanding and the health-care providers are striving to achieve, a higher level of protection. Orthodontic wires are frequently packaged in unsterile sealed packs with instructions on the wrapper, generally advising for autoclave sterilization.

If sterilization does not alter the properties of wires in an unfavorable direction, there is the possibility for dentists to systematically sterilize wires before placing them in the oral environment. The effect of sterilization on tensile properties and surface topography, which is of importance for corrosion behavior and the performance of sliding mechanics, has not been extensively studied.

In this study, the influence of four types of sterilization/disinfection procedures (autoclave, hot air oven, glutaraldehyde, and ultraviolet [UV] light) on the tensile strength and surface topography of three orthodontic wires (stainless steel [SS], titanium - molybdenum alloy [TMA], and CoCr) have been evaluated.

Materials and Methods

Sample comprised of three types of 8 inches straight length segments of orthodontics wires.

0.016″ × 0.022″ SS wires - Unitek, 3MCorp, CA, USA

0.016″ × 0.022″ TMA-Ormco, Glendora, CA, USA

0.016″ × 0.016″ CoCr - Ormco, Glendora, CA, USA.

Four different sterilization/disinfection procedures carried out with

Autoclave (UNIQUE CLAVE C-79 B) -250°F (121°C) for 15 min under 15 psi pressure

Dry heat sterilizer (The ILE Corporation) - 320°F (160°C) for 60 min

Chemical Sterilization -2% glutaraldehyde (Glutehyde) for 8-10 h

Radiation disinfection with UV light (SONADKA, THANE) (240-280 nm) – 6–10 h.

Tensile strength of the wires after sterilization was tested using

FIE – universal testing machine - (UNITEK 94100)

-

Surface topography of the wires after sterilization was tested using

- Scanning electron microscope (SEM)-(HITACHI S-3400N)

- Ion sputter – HITACHI E-1010.

Method

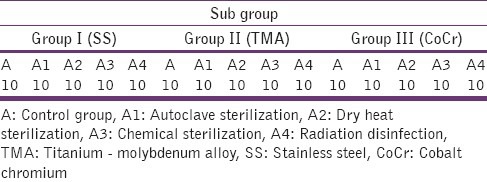

They were designated as Group I, II and III, respectively comprising of 50 samples each. Totally 50 samples of each group was then equally divided into five subgroups [Table 1].

Table 1.

Samples

Surface topography examination

After sterilization and disinfection of the experimental group, surface topography was examined with SEM. 1 cm segment of each sample (control group as well as the experimental group) were placed on a Brass stub, which was previously coated with a doubled sided carbon tape. Brass stub was then placed into the sample holder.

Sample holder was placed inside specimen chamber. Magnification of the sample was adjusted and photographs at ×100 and ×300 were recorded.

Tensile strength testing

Each sample of 8 inches was standardized to 7 inches length and tensile strength was tested using universal testing machine [Figure 1]. Test was carried out for both, control group as well as the experimental group. The ends of the wire were attached to the fixtures of the universal testing machine out of which one was movable while the other was fixed. The wire was thus stretched vertically until it was fractured at which point the readings were noted. Same procedure was repeated for each sample.

Figure 1.

FIE – universal testing machine (UNITEK 94100)

The tensile strength recorded was the maximum stress value in Mega Pascal (MPa) just prior to fracture of the test wires. Only those breaks, which occurred within the inter-grip span were recorded.

Results

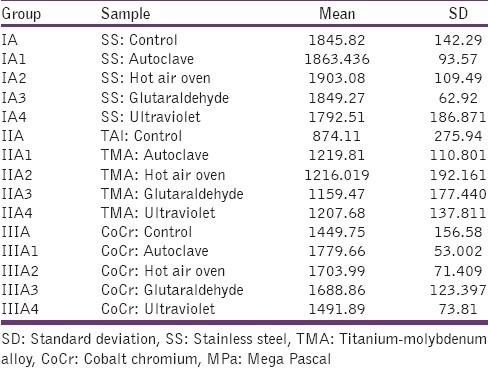

The mean tensile strength value for each subgroup was obtained [Table 2].

Table 2.

Mean and SD of tensile strength (Mpa)

The results of the present study shows that the mean ultimate tensile strength (UTS) of SS wire after autoclave (1863.436 ± 93.565 MPa), hot air oven (1903.083 ± 109.494 MPa), glutaraldehyde (1849.275 ± 62.922 MPa), and UV light disinfection (1792.513 ± 186.870 MPa) procedures were similar to the control group (1845.815 ± 142.29 MPa).

The mean UTS of TMA wire increases after autoclave (1219.808 ± 110.801 MPa), hot air oven (1216.020 ± 192.161 MPa), glutaraldehyde (1159.471 ± 177.442 MPa), and UV light disinfection (1207.68 ± 137.810 MPa) procedures when compared with the control group (874.107 ± 275.939 MPa). Further, there is no significant difference between the sterilization groups.

The mean UTS of CoCr wire increases after autoclave (1779.660 ± 53.001 MPa), hot air oven (1703.997 ± 71.409 MPa), glutaraldehyde (1688.862 ± 123.398 MPa) sterilization procedures, but remains same after UV light disinfection (1491.893 ± 73.814 MPa) procedure when compared to the control group (1449.759 ± 156.586 MPa).

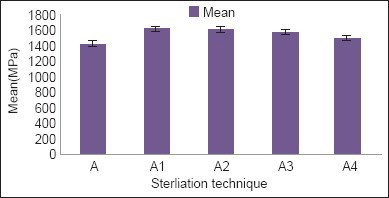

Group-wise comparison, irrespective of sterilization, by Scheffe's multiple comparison test is given in Graph 1. Sterilization wise comparison (irrespective of wire composition) by Scheffe's multiple comparison is shown in Graph 2.

Graph 1.

Group-wise comparison of tensile strength (irrespective of sterilization). G1: Stainless steel, G2: Titanium – Molybdenum alloy, G3: CoCr

Graph 2.

Sterilization wise comparison of tensile strength (irrespective of wire composition). A: Control group, A1: Autoclave sterilization, A2: Dry heat sterilization, A3: Chemical sterilization, A4: Radiation disinfection

Interaction effect of the group and sterilization

The comparison of an interaction effect of the group and sterilization was found to be statically significant at 5%. This indicates the tensile strength of three groups of wires sterilized by four sterilization methods are statistically different. Scheffe's multiple comparison test revealed the following:

After autoclave sterilization

The tensile strength of SS wire is not affected, but the tensile strength of CoCr increases to the level of SS wire.

The tensile strength of TMA wire increases, but it is lesser than SS and CoCr wires.

After hot air oven sterilization

The tensile strength of SS wire is not affected, but the tensile strength of CoCr increases to the level of SS wire

The tensile strength of TMA wire increases, but it is lesser than SS and CoCr wires.

After glutaraldehyde sterilization

The tensile strength of SS wire is not affected, but the tensile strength of CoCr increases to the level of SS wire

The tensile strength of TMA wire increases, but it is lesser than SS and CoCr wires.

After ultraviolet light disinfection

The tensile strength of SS wire is not affected

The tensile strength of TMA wire increases, but it is lesser than SS wires

The tensile strength of CoCr is nonsignificantly affected and near to Tensile strength values of SS and TMA wires indicating that it is nonconclusive.

Discussion

Most of the authors focused their attention on the influence of sterilization/disinfection procedures on NiTi wires,[1,2,3,4,5,6,7,8,9,10] but few studies[3,9,11] have been reported regarding SS and TMA wires and only very less studies have been published regarding CoCr wires. Moreover, these are the wires of choice for the fabrication of loops due to their excellent formability and long working range.

Hence, the purpose of this study was to examine the effect of four different methods of sterilization (autoclave, hot air oven, glutaraldehyde, and UV light) on tensile strengths of SS, TMA and CoCr wires.

Smith et al.[12] compared the effect of four sterilization/disinfection methods (autoclave, dry heat, cold sterilization, and disinfection) on 0.016 inch Beta-titanium wire (TMA, Ormco Corp., Glendora, Calif.) and 0.016 inch stainless steel (Permachrome standard. Unitek, 3M Corp, Monrovia, Calif.). In their study, tensile tests showed no clinically significant difference between before and after sterilization of TMA and SS wires. However, results of this study suggest that there is statistically significant increase in the UTS of the TMA wires following dry heat sterilization autoclaving and glutaraldehyde sterilization. This may be attributed to the fact that tensile strength of rectangular wires used in this study cannot be assumed to be identical to those of round wires. Furthermore, the temperature settings used for autoclave (250°F [121°C] for 15 min as recommended by the manufacturer) and dry heat sterilization (320°F [160°C] for 60 min) used in the present study was lesser than their study (274°F [134.4°C] for 15 min and 320°F [160°C] for 60 min respectively).

Results of this study on SS arch wires are in accordance with those carried out by Smith et al.,[12] Staggers and Margeson,[9] Pernier et al.[8]

Pernier et al.[8] conducted a study to determine the influence of one of the most widely used sterilization processes, autoclaving on the surface parameters and mechanical properties of SS, nickel-titanium and TMA wires. The alloys were analyzed on receipt and after sterilization. The results showed no adverse effects on the surface parameters or on selected mechanical properties. However, results of this study suggest that there is statistically significant increase in the UTS of the TMA wires following autoclave sterilization. The reason for this controversy may be because the cross sections of rectangular wires used in the present study were of lesser size. Furthermore, the temperature settings for autoclaving was lesser (250°F [121°C] for 15 min as recommended by the manufacturer) than their study (134°C for 18 min).

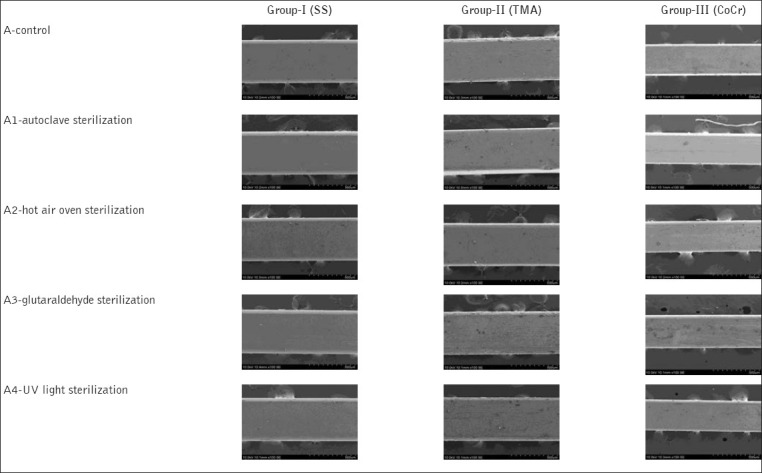

Surface topography

The evaluation of surface topography of three types of wire (SS, TMA, and CoCr wires) before and after four different methods of sterilization (autoclave, hot air oven, glutaraldehyde, and UV light) by SEM suggests the following,

There was gross increase in pitting roughness of the surface topography of all the three types of wires after 4 types of sterilization

The surface is smoothest for SS wires before sterilization when comparing the control groups of three wires (SS, TMA, and CoCr wires) [Figure 2]

UV light disinfection of any of the three wires (SS, TMA, and CoCr wires) affects the surface topography the least [Figure 2].

Figure 2.

SEM photograph showing surface topography of wires before and after sterilization at ×100 magnification

Scanning electron microscope photographs of study shows significant alterations in surface of TMA wire before and after autoclave, hot air oven and glutaraldehyde sterilization. This is contrary to the findings of Staggers and Margeson,[9] who found no significant alteration in surface characteristics of TMA wire before and after sterilization. Reports of Pernier et al.[8] who conducted a study to determine the influence of one of the most widely used sterilization processes, autoclaving on the surface parameters and mechanical properties SS, nickel-titanium and TMA wires also contrary to the present study results. The results showed no adverse effects on the surface parameters.

The results of the SEM evaluation of the wires in the present study is contrary to observations of Grosgogeat et al.[3] who conducted a study to determine the influence of sterilization and surface treatment on the orthodontic arch wire friction coefficient. The sterilization process and surface treatment induced no significant modification of the tribiological properties of SS and TMA wires.

The increased roughness is due to sterilization, which removes debris or traces of grease which might have remained on the wires after their production, which would have made the real surface roughness to the as-received wires more difficult to observe.

However, the increase in surface roughness was less to cause any clinical effect. The differences are only perceptible when an extremely precise measurement tool is used.

The results of this investigation added scientific credence to the clinicians’ who have been saying that the performance of sterilized Beta Titanium wires were clinically acceptable, as there was no overall statistically significant detrimental decrease in tensile strengths of as received versus sterilized wires. These findings agree with the work of Smith et al.[12] in which they also found no significant difference between as received and sterilized wires.

Hence, the results of study suggest that the currently accepted regimes for sterilization/disinfection do not decrease the tensile strength and have no detrimental effects on the tensile strength of the SS, TMA, and CoCr wires. Thus, it is important to encourage dental practitioners to practice autoclaving the arch wires before clinical application.

Summary and Conclusion

The study has shown that sterilization/disinfection procedures (autoclave, hot air oven, glutaraldehyde, and UV light) influences (increases) the tensile strength of orthodontic wires (SS, TMA, and CoCr wires), but have no deteriorating effect. Hence, orthodontists who want to guarantee maximum safety for their patients can sterilize orthodontic wires before placement, as it does not deteriorate the tensile strength and surface roughness of the alloys.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

References

- 1.Buckthal JE, Mayhew MJ, Kusy RP, Crawford JJ. Survey of sterilization and disinfection procedures. J Clin Orthod. 1986;20:759–65. [PubMed] [Google Scholar]

- 2.Crotty OP, Davies EH, Jones SP. The effects of cross-infection control procedures on the tensile and flexural properties of superelastic nickel-titanium wires. Br J Orthod. 1996;23:37–41. doi: 10.1179/bjo.23.1.37. [DOI] [PubMed] [Google Scholar]

- 3.Grosgogeat B, Jablonska E, Vernet JM, Jaffrezic N, Lissac M, Ponsonnet L. Tribological response of sterilized and un-sterilized orthodontic wires. Mater Sci Eng C Mater Biol Appl. 2006;26:267–72. [Google Scholar]

- 4.Kapila S, Reichhold GW, Anderson RS, Watanabe LG. Effects of clinical recycling on mechanical properties of nickel-titanium alloy wires. Am J Orthod Dentofacial Orthop. 1991;100:428–35. doi: 10.1016/0889-5406(91)70082-8. [DOI] [PubMed] [Google Scholar]

- 5.Kapila S, Haugen JW, Watanabe LG. Load-deflection characteristics of nickel-titanium alloy wires after clinical recycling and dry heat sterilization. Am J Orthod Dentofacial Orthop. 1992;102:120–6. doi: 10.1016/0889-5406(92)70023-4. [DOI] [PubMed] [Google Scholar]

- 6.Lee SH, Chang YI. Effects of recycling on the mechanical properties and the surface topography of nickel-titanium alloy wires. Am J Orthod Dentofacial Orthop. 2001;120:654–63. doi: 10.1067/mod.2001.118997. [DOI] [PubMed] [Google Scholar]

- 7.Mayhew MJ, Kusy RP. Effects of sterilization on the mechanical properties and the surface topography of nickel-titanium arch wires. Am J Orthod Dentofacial Orthop. 1988;93:232–6. doi: 10.1016/s0889-5406(88)80008-8. [DOI] [PubMed] [Google Scholar]

- 8.Pernier C, Grosgogeat B, Ponsonnet L, Benay G, Lissac M. Influence of autoclave sterilization on the surface parameters and mechanical properties of six orthodontic wires. Eur J Orthod. 2005;27:72–81. doi: 10.1093/ejo/cjh076. [DOI] [PubMed] [Google Scholar]

- 9.Staggers JA, Margeson D. The effects of sterilization on the tensile strength of orthodontic wires. Angle Orthod. 1993;63:141–4. doi: 10.1043/0003-3219(1993)063<0141:TEOSOT>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 10.Yang WS, Kin BH, Kim TW. Surface and mechanical changes in nickel titanium wires after heat sterilization. Eur J Orthod. 1999;21:630. [Google Scholar]

- 11.Funk AC. The heat-treatment of stainless steel. Angle Orthod. 1951;21:129–38. doi: 10.1043/0003-3219(1951)021<0129:THOSS>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 12.Smith GA, von Fraunhofer JA, Casey GR. The effect of clinical use and sterilization on selected orthodontic arch wires. Am J Orthod Dentofacial Orthop. 1992;102:153–9. doi: 10.1016/0889-5406(92)70028-9. [DOI] [PubMed] [Google Scholar]