Abstract

We report the field methodology of a 32-month monitoring study with temperature dataloggers as Stove Use Monitors (SUMs) to quantify usage of biomass cookstoves in 80 households of rural Guatemala. The SUMs were deployed in two stoves types: a well-operating chimney cookstove and the traditional open-cookfire. We recorded a total of 31,112 days from all chimney cookstoves, with a 10% data loss rate. To count meals and determine daily use of the stoves we implemented a peak selection algorithm based on the instantaneous derivatives and the statistical long-term behavior of the stove and ambient temperature signals. Positive peaks with onset and decay slopes exceeding predefined thresholds were identified as “fueling events”, the minimum unit of stove use. Adjacent fueling events detected within a fixed-time window were clustered in single “cooking events” or “meals”. The observed means of the population usage were: 89.4% days in use from all cookstoves and days monitored, 2.44 meals per day and 2.98 fueling events. We found that at this study site a single temperature threshold from the annual distribution of daily ambient temperatures was sufficient to differentiate days of use with 0.97 sensitivity and 0.95 specificity compared to the peak selection algorithm. With adequate placement, standardized data collection protocols and careful data management the SUMs can provide objective stove-use data with resolution, accuracy and level of detail not possible before. The SUMs enable unobtrusive monitoring of stove-use behavior and its systematic evaluation with stove performance parameters of air pollution, fuel consumption and climate-altering emissions.

Keywords: iButtons, Sensors, Improved cooking stoves, Indoor air pollution, Energy use behavior, Household biomass fuel

1. Introduction

We define “Stove Use Monitors” (SUMs) as devices that objectively quantify stove use through direct measurements of physical or chemical parameters (temperature, heat flux, light, current, motion, gas concentrations, etc.) on stoves, kitchens, cookware or food. A “Stove Use Monitoring System” (SUM-System) is defined as a platform of tools including SUMs, device readout, data transmission and storage interfaces, data analysis algorithm, database management and reporting tools for the systematic study of stove adoption and use. We previously used small temperature loggers as SUMs [1] to document the initial adoption of chimney stoves by rural households in Guatemala. In this paper, we followed an extended group of 80 homes from the RESPIRE/CRECER stove trial [2,3] from January 2008–November 2010 and recorded temperature signals from their chimney cookstoves during 16 monitoring periods of 28 days each (a total of 31,112 stove-days) in alternating months and from a subgroup of traditional open-cookfires. In this paper we report the data collection protocols for both types of stoves, but focus on the analysis methods to obtain measures of daily use and meal frequency from the chimney-stove temperature signals.

2. Materials and methods

2.1. Temperature datalogger characteristics

We used the Thermochron iButtons 1921G (Maxim Integrated Products, Sunnyvale, CA) as SUMs. These devices enclose a silicon temperature sensor, a memory, a signal processing circuitry and a battery in a stainless steel can that has the size and appearance of a coin cell battery (Fig. 1B). This model operates between −40 °C and 85 °C, and can record up to 2048 temperature and date-time readings with ±1 °C accuracy. Communication with the sensors to program them or download data is by momentary contact with a special probe and is easily done in the field with a PDA, smartphone, or laptop computer. Tutorials on the use of these monitors can be found elsewhere [4]. There are other devices available commercially that have similar capabilities.

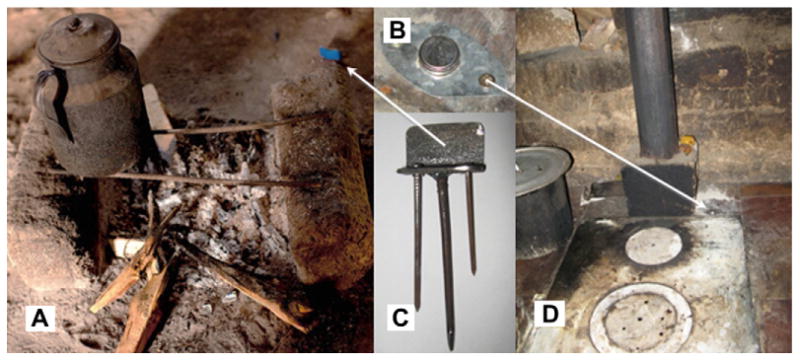

Fig. 1.

To record stove activity we used stove use monitor (SUMs) attached to metal brackets (C) Nailed into the dirt floor facing the center of the fire and 20–30 cm away from it (A). In the chimney-cookstoves (D) We attached the SUMs to the cookstove body with metal sheet holders (B).

2.2. SUMs placement and sampling frequency

The chimney cookstoves (Fig. 1D) have a brick, mud and cement body, and were built with standardized dimensions by the same local manufacturer using the “Plancha” cookstove design [5–7]. Although locally known by this name, not being centrally manufactured, design and construction details may vary in other regions. The indoor cookfires consisted of a few rocks or bricks (usually 2–3) arranged to lift the pots above the open cookfire (Fig. 1A). We used two locally made holders for the SUMs: perforated metal sheets to attach the monitors to the chimney-cookstove body (Fig. 1B) and metal brackets nailed into the dirt floor and facing the center of the open cookfire (Fig. 1C). In the chimney cookstoves, the SUMs were attached to the back surface at the chimney base (Fig. 1D) to capture conducted heat and were set to record every 20 min. In the open cookfires, the brackets were nailed 20–30 cm away from the fire (Fig. 1A) to capture thermal radiation and the SUMs were set at a 10-min sampling rate.

These settings were determined with a two-stage protocol that first ensured the iButtons operated below 85 °C and then determined the sampling rate and location that would provide sufficient data resolution to track usage at the meal level without interfering with the householder's activities.

In the first stage of the protocol, we monitored the temperature dynamics during the maximum fuel feeding intensity accomplished by a household cook or local field-worker during cooking. The monitoring was done with temperature-indicator labels placed at multiple cookstove surface points and different distances from the cookfire center. The labels are made of liquid crystal or other temperature sensitive materials that reversibly (RLC-50, Omega) or irreversibly (and TL-S, Omega) change color at specific temperature thresholds. High-temperature thermocouples or other temperature indicators like crayons and lacquers can also be used at this stage. Those label locations in the cookstove and cookfire that did not exceed the monitor manufacturer's limit of 85 °C were selected for the next stage. In the second stage, we recorded temperature in the selected locations during regular cooking cycles in actual homes during 1–2 days. We sampled at 30-s resolution with a multichannel thermocouple datalogger (TC-8, Picco Technologies) to determine the appropriate sampling frequency and we also measured with the iButtons and the labels.

We selected the locations where first derivatives of temperature signals provided distinct identification of the stove activity episodes. The choice of sampling frequency is a tradeoff between: 1) the frequency of visits that can be afforded given the maximum storage capacity of the devices and 2) the temporal resolution required to measure stove use at the desired level of detail (day, meal, cooking task) given the thermal inertia at the stove location and the nature of the cooking cycles. For example, to capture the details or duration of the cooking cycles in a portable stove used for cooking small food volumes a faster sampling frequency might be needed than the frequency settings for a SUM placed in the tiled surface of a high-mass chimney stove like the one in this project. Another consideration for placement and sampling frequency is that the batteries of most temperature dataloggers exhibit longer lifetimes at lower sampling frequencies and lower operating temperatures.

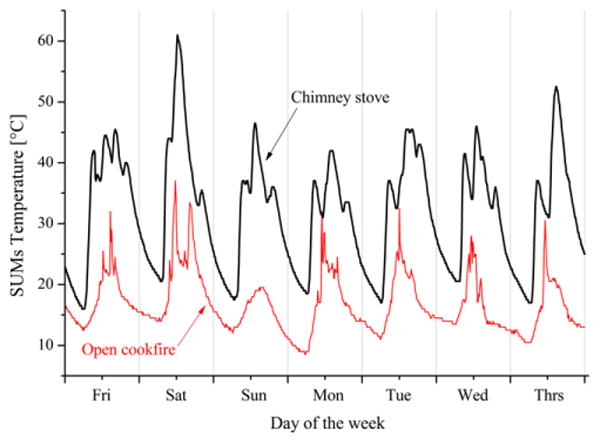

Fig. 2 depicts example of the temperature signals recorded from the chimney stoves and open cookfires.

Fig. 2.

Temperature signals recorded with the dataloggers used as stove use monitors (SUMs in the surface of a chimney cookstove (20-min sampling rate, thick line) and nearby an open cookfire (10-min sampling rate, thin line)). The chimney-cookstove traces illustrate the peaks due to the main cooking events through the day. On Sunday, the open cookfire is not lit and the ambient temperature fluctuation is registered.

2.3. Stove use questionnaires

Questionnaires of chimney-cookstove and open-cookfire frequency of use, time spent cooking and hours that the cookstove was lit at each mealtime were performed quarterly as part of the RESPIRE/CRECER study. The responses of the primary cooks at each household to the questions about frequency of chimney-cookstove use were matched with their SUMs measured usage during the periods of the 15 days preceding the questionnaire. The statistics on the number of daily meals and the hours of stove activity were used to define the average number and duration of “meals” in the population. All the questions are reproduced in the Supplemental Material.

2.4. Data collection and management

Data downloading and programming of the monitors were done in the field with PDAs (Palm IIIc and Palm m105) and data transferred to a PC in a comma-separated format (.csv) using the ThermoChron System software and probes (Scanning Devices Inc., Lexington, MA). The SUMs were programmed to start in a delayed mode and collected after the sampling period ended.

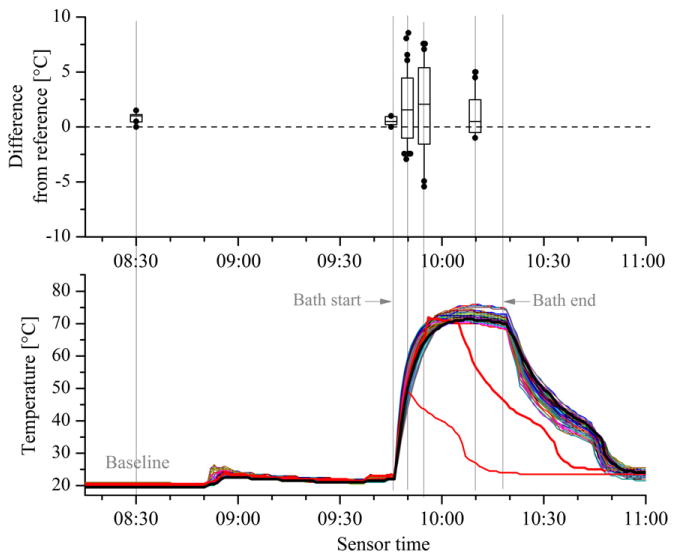

At the end of each monitoring year, we brought all monitors to the project headquarters and performed water bath comparative measurements to detect those with anomalous readings. The monitors were placed together with a new iButton in a re-sealable plastic bag inside a small container with water at 70–75 °C. The setup was allowed to reach thermal equilibrium with the surroundings at about 25 °C, as measured with a reference mercury thermometer (0.5 °C accuracy, VWR 610-16-048). The sampling frequency was set to 1 min during the comparative procedures.

The manufacturer reports no known physical mechanism for the monitors to go out of calibration [8] and separate assessments of their performance [9] have found their accuracy to be within manufacturer's specifications. Nevertheless, we retired some sensors that significantly drifted down from the reference in the water bath. Fig. 3B summarizes one of the comparative experiments and illustrates the behavior of the anomalous monitors, which is not apparent during the baseline period. Rather than a drift in calibration, these two monitors stopped recording temperature for 20–30 min. After they “woke up”, the first reading was stored in the next memory location and was assigned the time stamp that followed the last temperature recorded. Thus, the temperature decay experienced by the entire group of monitors at 10:20 in Fig. 3A was registered at an earlier time by the abnormal monitors. When the anomalous monitors are excluded from the analysis, the deviations (with respect to the reference iButton) in the temperature and rate of change of the group were within the range of variability expected from the experimental setup (Fig. 3A).

Fig. 3.

Annual comparative temperature measurement performed in all deployed monitors. The temperature dataloggers were placed for 30 min in a water bath. The lines in the lower graph (left axis) depict the temperature traces of the group of 80 monitors. The two anomalous monitors that drifted down from the reference were retired. The upper boxplots (right axis) show the absolute temperature deviation of the group without the anomalous monitors from the reference monitor measured at the times signaled with the vertical lines. In the boxplots the centerlines are median, the boxes enclose one standard deviation and the back dots are outliers (values outside the 5th and 95th percentiles).

For quality assurance and data management a field form was filled out for each monitor at each household visit. Field forms and stove use questionnaires were double-entered and a clean database was generated using SAS/STAT software 9.1 (SAS Institute Inc., Cary, NC) to ensure matching of the household, monitor and file names. The field forms are included in the Supplemental Material.

2.5. Algorithm for analysis of stove temperature measurements

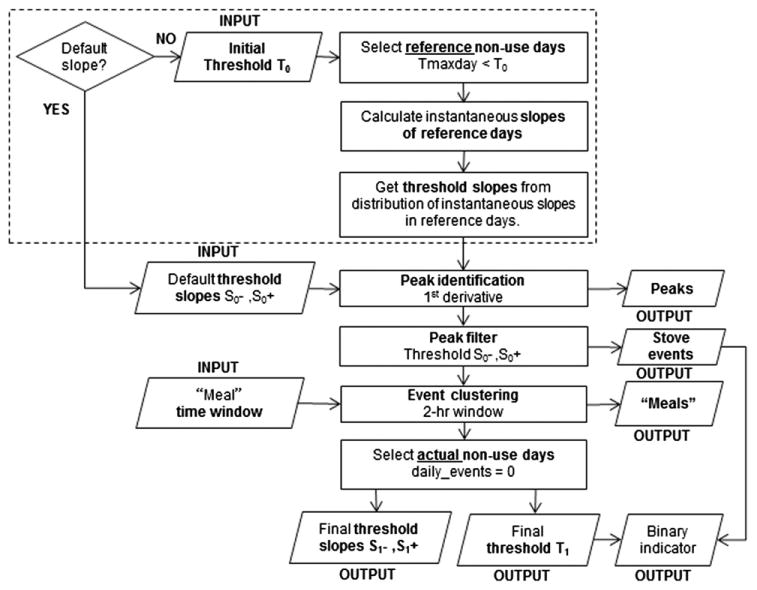

We implemented an algorithm to determine daily use and quantify the frequency of stove activity through the day based on the instantaneous derivative and long-term behavior of stove and ambient temperature signals (Fig. 4). This paper focuses on the analysis of the chimney-cookstove data (the results of the open-cookfire signals are presented elsewhere). Only 30,122 stove-days were used for the algorithm, the data from the first monitoring period when households were learning to use the cookstoves were excluded.

Fig. 4.

Flow diagram of the stove temperature signals analysis.

First, we detected the signal peaks using the data analysis and graphing software Origin 8.1 (OriginLab, Northampton, MA), and the rest of the analysis was done using SAS/STAT. Positive peaks were filtered from those due to the diurnal indoor kitchen temperatures, noise or outside heating events using threshold slope values (S0+ and S0−) on the onset and decay of the peaks. The threshold slopes (dashed box in Fig. 4) were obtained a posteriori, from the days that the sampled homes did not use the chimney cookstove according to an initial threshold temperature (T0). The instantaneous derivatives of these reference non-use days were obtained and the 1st and 99th percentiles of the derivatives distribution were selected as S0− and S0+ respectively.

Positive peaks were defined as “fueling events” only if the positive slopes of the onset and the negative slopes of the decay exceeded S0+ and S0− respectively. We defined the fueling events as the minimum unit of stove use and adjacent events found within a fixed-time window were then clustered in a single “cooking event”. The time length of the clustering window was determined from the average duration of meals obtained from the recall questionnaires and from the temporal distribution of all the stove events registered in all days and households. We consider these cooking events to be reasonable approximations of a “meal” for this particular chimney cookstove and population. Lastly, the temperature distribution of the days with zero fuel events was studied to determine the best final threshold temperature values (Tf) for the “binary indicator of daily use” (δ). Fig. 4 shows the flow diagram of the algorithm for identification of stove use activity.

3. Results and discussion

3.1. Analysis of the chimney-cookstove temperature measurements

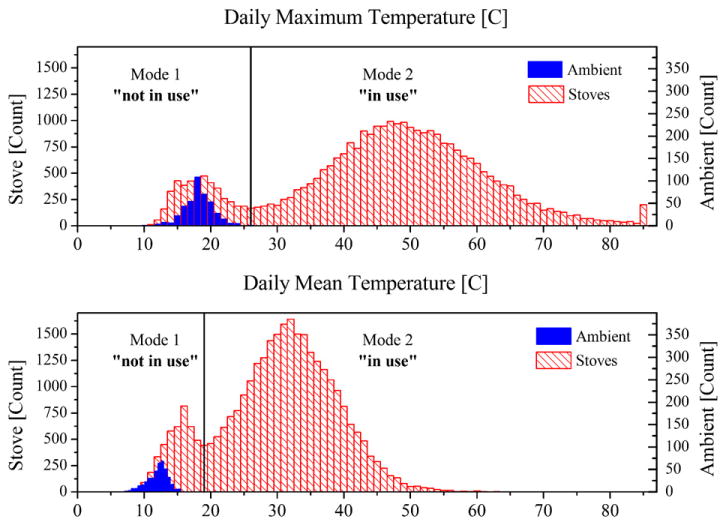

The temperature of the stoves that are not in use is expected to closely follow the indoor kitchen temperature, which in turn will be a function of the interaction of ambient temperature with the kitchen structural characteristics and the potential presence of another cookstove or cookfire (the only heating sources used in the region). This is illustrated in Fig. 5 which shows the bimodal distributions of daily maximum Fig. 5A) and daily mean (Fig. 5B) cookstove temperatures of the 30,122 stove-days analyzed (histograms with stripes). In both graphs, the first mode defines the surface temperature values when the chimney cookstoves are not in use. In Fig. 5A, this mode overlaps with the distribution of the daily maximum ambient temperatures recorded with the project weather station located at the research site (CR800, Campbell Scientific Inc., Logan, UT) observed during the same sampled days (histogram in solid color). The second mode defines the range of temperatures when the cookstoves are being used. Its dispersion reflects the variability between households and within days in the temperature used for cooking, as well as the ambient temperature differences by day and by location. The daily minimum and range of cookstove temperatures have similar bimodal distributions (data not shown).

Fig. 5.

Count distribution of cookstove temperatures (histogram with stripes, left axis) and ambient temperatures (histogram in solid color, right axis) for all monitored days and households. The daily maximum distribution is shown in the upper graph and the lower graph shows the daily average temperatures (30,122 stove-days monitored). The vertical lines are the minimum values in the range between modes, which are the cutoffs used as initial thresholds to differentiate temperatures from stoves and days in use.

Using the minimum value between modes as the initial cutoffs (T0 = 26 °C from the maximum temperatures and T0 = 19 °C from the daily averages), we selected two sets of reference no-use days and obtained the instantaneous derivatives of their signals (see the Supplemental Material). These non-use cookstove derivatives reflect the response of the cookstove thermal mass to the ambient temperature cycle and to other heating sources in the kitchen. It is possible that they also include some misclassified in-use days from those cookstoves operated at atypically low temperatures. The 99th and 1st percentiles of the distributions were used as S0− and S0+ respectively. Through iterative tests of several individual signals we found that a triggering slope of S0+ = 0.038 °C°min−1 during the 40 min previous to the temperature peak and an exit slope of S0− = −0.038 °C min−1 in the following hour after the peak were sufficient to filter most fueling events in the temperature signal. The number of daily fueling events in the main dataset was counted and days with one or more events were assigned a binary indicator of use δ = 1, and a value δ = 0 otherwise.

We observed that the feeding or stirring of fuel during cooking could cause consecutive peaks in the signal during the cooking period of a single meal. Therefore, fueling events separated by less than 2 h were clustered and counted as single cooking events. The clustering window size was based on the average time length for meal preparation and the average time that the chimney cookstove was lit on each meal, both from the quarterly recall questionnaires answered by the monitored households (Table 1). The clustering window was also determined by the distribution through the day of all the cookstove events measured with the SUMs, which showed three well-defined peaks centered at the hours of 09:00, 14:00 and 20:00. This clustering of records has been used in similar research problems [10] and seems to work well on this stove type and population as discussed below.

Table 1.

Daily hours that the chimney cookstove is lit and that the cooks spend cooking at each mealtime, according to recall questionnaires (reproduced in the Supplemental Material) performed in the SUMs monitored households.

| Time spent daily preparing meal | Time that chimney cookstove is lit at every meal | |||

|---|---|---|---|---|

|

|

|

|||

| Hours | 95% C.I. | Hours | 95% C.I. | |

| Meal | ||||

| Breakfast | 1.42 | (1.34, 1.50) | 2.51 | (2.38, 2.63) |

| Lunch | 1.38 | (1.30,1.45) | 2.07 | (1.94, 2.19) |

| Dinner | 1.39 | (1.27, 1.50) | 2.41 | (2.28, 2.55) |

| Nixtamala | 0.53b | (0.50, 0.57) | 1.14 | (1.05, 1.23) |

| Otherb | – | – | 1.36c | (0.98, 1.74) |

Nixtamal: maize kernels cooked with an alkaline additive for the preparation of dough to make tortillas. This traditional cooking practice requires boiling the corn in large pots with water and lime, steeping, washing and subsequent grinding of the corn kernels with stones.

Only 50% of the responses to the quarterly questionnaires reported cooking Nixtamal on the day prior to the household visit.

Only 24% of the responses reported another mealtime, equally split between cooking food for animals and cooking an intermediate meal.

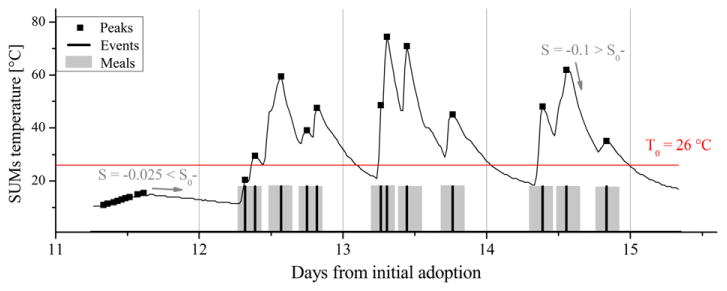

Fig. 6 illustrates the results of the identification of peaks (squares), filtering to select fueling events (vertical lines) and clustering of events into meals (gray rectangles). Using this algorithm, we estimated that the fraction of days in use from all chimney cookstoves and days monitored (the “percent stove-days”) [7] in the 15 monitoring periods had a mean value of 89.4% (95% CI: 87.9, 90.9). The population average of the meals per day was 2.44 meals (95% CI: 2.38, 2.49) and the average cooking events per day 2.98 (95% CI: 2.91, 3.05).

Fig. 6.

Determination of meals from the SUMs temperature signals from a chimney stove. Conditioning on triggering and exit slopes (S0) the peaks detected are filtered to distinguish stove events (days 12–14) from ambient temperature fluctuations (day 11). Stove events (vertical lines) that are with a 2-h fixed window are clustered into meals (gray squares). The triggering and exit slopes are obtained from those days when the threshold temperature T0 was not exceeded, presumably because the stove was not in use.

In Fig. 5, the coincidence of the right tail of the ambient distribution (histogram in solid color) with the bi-modal cutoff lines suggests that records of past meteorological data for the location of interest could also be used to select T0 before data collection begins. Indeed, the Guatemalan Institute of Meteorology (INSIVUMEH) meteorological station located in San Marcos (Latitude: 14.6 N, Longitude:91.5 W, Altitude: 2420 m), approximately 50 km south and at a similar elevation to our research site (Latitude: 14.6 N, Longitude: 90.8 W, Altitude: 2686 m), reported absolute maximum temperatures around 26 °C during the years of our study [11].

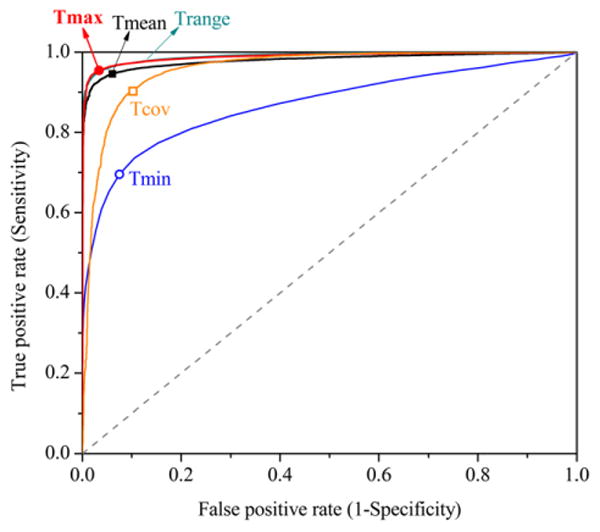

To assess the accuracy of the count of days in use when a single temperature threshold is applied to all households and seasons, we compared the days in use that were identified with the peak counting algorithm with those that simply exceeded the thresholds (regardless of the peak count). The results are presented in the ROC (receiver operating characteristic) curves [12] in Fig. 7. In the curves, for every temperature threshold parameter (mean, minimum, maximum, range and coefficient of variation) the fraction of hits where the single threshold was exceeded and the number of peaks was greater than zero (true positives) are plotted against the fraction of false alarms (false positives) for different values of T0.

Fig. 7.

ROC curve comparing the specificity and sensitivity to detect daily use of different thresholds, compared to the determination of use by peak detection. Lines passing through the left top corner have higher sensitivity and higher specificity and are preferred. Each line represents the sensitivity–specificity combinations for different threshold values of a temperature distribution. The marked points represent specific thresholds for the daily maximum (T0 = 26 °C), mean (T0 = 19 °C), range (T0 = 11 °C), minimum (T0 = 16 °C) and coefficient of variation (17%) for the 31,112 stove-days monitored.

In the figure, the daily maximum, range and mean temperatures perform similarly and are better choices than the coefficient of variation and the daily minimum for this site, as measured by the larger area under their ROC curves (greater specificity and greater sensitivity). The accuracies of the threshold values derived from the bimodal distributions are listed in Table 2.

Table 2.

Performance of specific stove temperature threshold values to identify the daily use diagnosed with the peak algorithm.

| ROC curve | Performance of specific thresholds | |||||

|---|---|---|---|---|---|---|

|

|

|

|||||

| Area | 95% C.I. | Accuracya | Sensitivityb | Specificityc | ||

| Daily parameter | T0 | |||||

| Range | 0.990 | (0.989, 0.992) | 11 °C | 0.95 | 0.95 | 0.96 |

| Maximum | 0.989 | (0.987, 0.991) | 26 °C | 0.96 | 0.95 | 0.97 |

| Mean | 0.980 | (0.977, 0.983) | 19 °C | 0.95 | 0.95 | 0.93 |

| Coefficient of variation | 0.959 | (0.956, 0.962) | 17% | 0.90 | 0.90 | 0.90 |

| Minimum | 0.869 | (0.861, 0.877) | 16 °C | 0.72 | 0.70 | 0.92 |

Accuracy = Sensitivity × (% use days detected with algorithm) + Specificity (% non-use days detected with algorithm).

Sensitivity = (number of days detected as in-use by both the algorithm and the T0)/(number of days detected as in-use by the algorithm).

Specificity = (number of days detected as non-use by both the algorithm and the T0)/(number of days detected as non-use by the algorithm).

The initial purpose of T0 is the selection of reference non-use days from where the slopes S0− and S0+ that characterize cooking events are determined. Alternatively, these slopes might potentially be estimated a priori from simulated cooking cycles in the laboratory or from a heat transfer model of the monitor at the stove surface. Or they could be measured in the field by purposively sampling in “reference kitchens” of actual households where the stove monitored with the SUMs is never lit but is still subject to the diurnal and household temperature changes. The stove and/or ambient temperature signals from the reference kitchens can also be used to obtain differential-temperature signals (monitored stove temperature minus reference stove or minus ambient) that are de-trended from the influence of the stove thermal inertial, ambient temperature or external heating sources. Although we do not discuss differential temperatures in this paper, they are crucial to estimate with accuracy the duration of the stove time in use. If the SUMs signals are not de-trended, the cooling-down of a stove could be mistakenly counted as time in use [7].

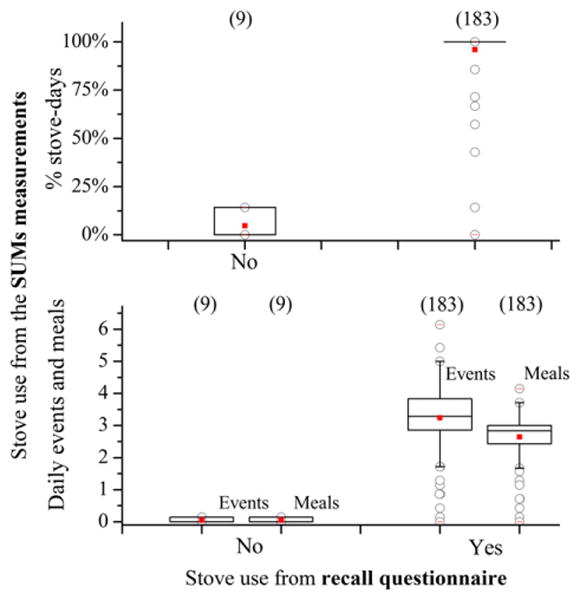

3.2. Comparison with recall questionnaires

Fig. 8 compares the binary responses to the question: “Are you using the Plancha for cooking?” (Yes/No responses) with the SUMs measured daily meals and percent days of use during the 15-day period preceding the quarterly questionnaire. The questionnaires were consistent with the SUMs measures. The mean measured usage of the admitted users was 96% stove-days (95% CI: 93.5%, 99.3%), 3.24 daily events (95% CI: 3.01, 3.38) and 2.65 meals (95% CI: 2.55, 2.74). The outliers that lower the mean percent days for this group comprise only 5% of the observations; only three measurements were below the 50% use and the group had a 100% median.

Fig. 8.

Chimney cookstove usage from recall questionnaires (horizontal axis) showed good agreement with the percent days of use (above) and the daily meals and events (below) measured with the SUMs (vertical axis) during the 15 days preceding the questionnaire. The centerline represents the median, the squared red dot the mean value and the box encloses the interquartile range (25th–75th percentile). The whiskers depict the 5th and 95th percentiles, and values outside the whiskers are outliers. The sample size of each group is shown in parenthesis (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

In our analysis we define “meals” as distinct time-spaced peaks in stove temperature. The precise determination of “meals” from fueling events, however, could be a non-trivial task in other populations since the duration and separation of meals can vary across households and seasons, and the fueling patterns for a given meal course can vary from day to day depending on the food cooked and fuel used. Additional or alternative parameterizations of stove use (and appropriate validations) could be needed for other outcomes of interest like the duration of cooking, and for its correlation with the duration of exposure or the amount of fuel consumed.

3.3. Field performance of monitors

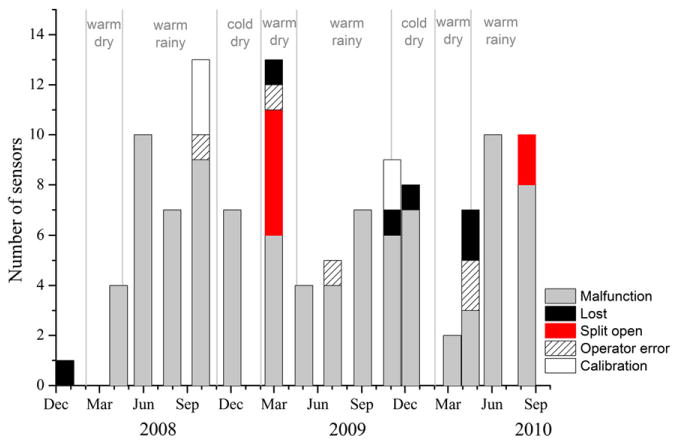

During the 2.6 years of data collection 192 monitors were used in total, with an average of 80 SUMs deployed every monitoring round (except the first round where 50 were deployed) and a total of 112 monitors that had to be replaced. Fig. 9 shows the number of monitors lost in the project office or in the households; malfunctioning (non-responsive or yielding corrupted data); with the case split open or expanded due to overheating beyond the manufacturer's maximum temperature ratings; programmed incorrectly (operator error); or found with significant deviations in the annual reference measurements (“calibration”).

Fig. 9.

Data loss rate of the Thermochron iButtons (1921G) used as SUMs in the CRECER study.

We found that following the placement protocols described in Section 2 the overall monitor lifetime of the 1921G models can exceed 1.5 years when placed in stove parts or monitor holders with high thermal mass that keep monitors below 85 °C. This corresponds to the minimum monitor lifetime specified by the manufacturer for a 20-min sampling rate and continuous exposure to 70 °C. The latter is likely to be different for monitors placed in metallic surfaces or close to the fire, as they are exposed to higher daily swings and to temperatures closer to the manufacturer's limits. An average data loss rate of 10% per monitoring round was observed through the study, including sensor performance, handling, programming, downloading and data managing errors. We consider this to be a low bound estimate for stove projects using iButtons as SUMs, given the optimum infrastructure available to our study and the strict protocols followed. We strongly advise the use of holders that enclose the iButtons. This will keep the surface of the sensors clean to make good contact with the reader probe and, most importantly, will also contain the sensors in the case that they split open or expand due to overheating. It must be highlighted the monitors are not waterproof, only water resistant. We observed that in the rainy season some monitors were permanently damaged in those houses where water leaked into the kitchens through the roof and chimney openings, dripping over the monitors. The effects of water in these monitors have been reported elsewhere [13]. Monitor breakdown was also more common in those stoves were the daily temperature was closer to the limit specified by the manufacturer. We did not, however, observed a definite seasonal pattern in the loss of monitor data.

4. Conclusions

In this paper, we assessed the field performance of small low-cost temperature dataloggers as SUMs and implemented an algorithm to obtain counts of the daily meals cooked. We found that with adequate placement, standardized data collection and careful data management the SUMs can provide objective and unobtrusive data of stove use with resolution accuracy and level of detail not possible before. This new tool promises to enable systematic and scalable monitoring of the stove adoption process, to design strategies to optimize it and verify the impacts of biomass stoves. In Box 1, we listed key recommendations for the deployment of SUMs to quantify adoption.

The slow thermal response of the chimney cookstove body and the fairly defined cooking and fueling cycles in the study population facilitated the analysis of the signals without the need for smoothing. This might not be the case when faster sampling rates are used on stove surfaces that conduct heat better, such as a portable metal stove. In such cases, smoothing, signal filtering, spectral analysis and the use of differential temperature signals could be more suitable. At this research site, where the seasonal patterns of the maximum and mean daily ambient temperatures are weak, we found that a single temperature threshold is sufficient to identify days of use through the year and select reference days to characterize the peaks of the meals.

As discussed previously [14], a crucial research effort for the development of the SUMs-Systems is the implementation of platforms with libraries of validated algorithms for different stove types, and to identify the “signature” of the cooking practices with the highest fuel consumption, air pollution emissions and exposures, or climate impacts.

Supplementary Material

Box 1 Ten recommendations for field deployment of iButtonsas stove use monitors (SUMs) to quantify the adoption process. A sample data collection form is included in the Supplemental Material.

SUMs placement and sampling frequency

- Follow the two-stage protocol:

- Stage 1. Determine stove/fire locations and SUMs holder setup that keep SUMs within the temperature limits specified by the manufacturer. Use real-time temperature indicators (labels, lacquers, multi-channel dataloggers) to test locations during a cooking cycle performed at a maximum fueling intensity.

- Stage 2. Record temperature during 2–3 days in actual homes, using the SUMs holder setup at the stove/fire locations selected in (1). Identify the locations that are least obtrusive for the households. Examine temperature traces to:

- 1.1. Verify that signals do not saturate and that SUMs temperature is kept within the manufacturer specified operating limits.

- 1.2. Determine the sampling rate that is adequate for the level of detail desired (days in use, number of meals, duration of cooking events, time that the stove or fire are lit) and for the number of samples needed per monitoring period.

Consider that slower sampling rates and lower operating temperatures lead, in most monitors, to longer battery lifetimes.

Avoid stove/fire locations where water could drip into the monitors.

Consider that some households might change the location within the home where the open cookfires are lit during the monitoring period; or, that they might have multiple open-cookfires or traditional stoves.

Consider placing monitors for ambient and/or kitchen temperatures, to subtract their trends from the stove/fire SUMs signals.

If using iButtons as SUMs, use holder setups that can enclose the monitors in case they split open or expand due to overheating.

SUMs data collection and management

-

7

Train personnel to follow strict protocols to ensure the integrity of the SUMs data and facilitate batch processing of the data files.

-

8

Implement data collection field forms for every SUMs at each deployment-programming-downloading cycle. Document in the forms relevant observations about household behavior not previously registered in the database (for example when the family has migrated, has a new stove, does not lives in the house where the stove was built, etc.). Keep track of sensor performance (monitor malfunctioning, monitors lost, etc.).

-

9

Establish a data file naming protocol that includes all key identifiers in the name string (monitor, community, household, stove ID numbers, start and end date of temperature readings, number of the monitoring cycle), to facilitate browsing of files and expedite batch processing.

-

10

Perform reference measurements in all monitors deployed at least annually. For the comparative procedures, simulate heating and cooling cycles with a water bath or with a controlled temperature environment and use a calibrated reference thermometer to detect and withdraw monitors with anomalous behavior.

Acknowledgments

We are in debt to the Guatemalan families in the RESPIRE and CRECER studies who patiently let us into their homes and daily lives. We thank the extraordinary dedication and commitment of all the staff and fieldworkers. In particular, we are grateful to: Biol. Carolina Romero Orellana for her logistic support in the field and valuable assistance with project management, Rudinio Acevedo for valuable assistance with database management, Edgar Coronado for field assistance, Nick Lam for fruitful discussions on data analysis, field support and participation in the early stages of the project, and Tracy Allen for critical advice on sensor selection. The RESPIRE and CRECER studies are made possible through the collaboration of the UC Berkeley School of Public Health, the Universidad del Valle de Guatemala (UVG), the Guatemala Ministry of Health, and are funded by the US National Institute of Environmental Health Sciences (NIEHS #R01ES010178). We acknowledge the support of the Vodafone Wireless Innovation Project. Ilse Ruiz-Mercado acknowledges the support of the UC MEXUS-CONACYT (University of California Institute for Mexico and the United States and El Consejo Nacional de Ciencia y Tecnologia) Doctoral Fellowship for Mexican Students Program. No financial or in-kind support was received from any commercial entity manufacturing or marketing monitoring equipment used in the study.

Footnotes

Appendix A. Supplementary data: Supplementary data related to this article can be found at http://dx.doi.org/10.1016/j.biombioe.2012.09.003.

References

- 1.Ruiz-Mercado I, Lam N, Canuz E, Davila G, Smith KR. Low-cost temperature loggers as stove use monitors (SUMS) Boiling Point. 2008;55:16–8. [Google Scholar]

- 2.[Internet] CRECER. Berkeley, CA: Enviornmental Health Sciences, University of California; [cited: 12 June 2011]. 2010. Overview of chronic respiratory effects of early childhood exposure to respirable particulate matter (CRECER) Available from: http://ehs.sph.berkeley.edu/guat/?page_id=20. [Google Scholar]

- 3.[Internet] RESPIRE. Berkeley, CA: Environmental Health Sciences, University of California; [cited: 12 June 2011]. 2010. Randomized exposure study of pollution indoors and respiratory effects (RESPIRE) Available from: http://ehs.sph.berkeley.edu/guat/?page_id=22. [Google Scholar]

- 4.History of Winter (HOW) Program [Video on the Internet]: National Aeronautics and Space Administration (NASA) [cited: 12 June 2011];Thermochron quest tutorial. 2007 c. Available from: http://ssed.gsfc.nasa.gov/how/HOWmedia/thermochron/loader.swf.

- 5.Granderson J, Sandhu JS, Vasquez D, Ramirez E, Smith KR. Fuel use and design analysis of improved woodburning cookstoves in the Guatemalan Highlands. Biomass Bioenergy. 2009;33:306–15. [Google Scholar]

- 6.Boy E, Bruce N, Smith KR, Hernandez R. Fuel efficieny of an improved wood-burning stove in rural Guatemala: implications for health, environment and development. Energy Sustainable Dev. 2000;4:23–31. [Google Scholar]

- 7.Ruiz-Mercado I, Canuz E, Walker JL, Smith KR. Quantitative metrics of stove adoption using stove use monitors (SUMs) Biomass Bioenergy. 2012 doi: 10.1016/j.biombioe.2013.07.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.[Internet] Maxim Products iButton(R) Devices. Maxim integrated products. [cited:12June 2011];FAQs temperature loggers (Thermochrons) 2011 Available from, http://www.maximic.com/products/ibutton/faq/index.cfm?fuseAction=FAQ.subCategories&CategoryID=19&categoryNamea=Temperature%20Loggers%20%28Thermochrons%29.

- 9.Hubbart J, Link T, Campbell C, Cobos D. Evaluation of a low-cost temperature measurement system for environmental applications. Hydrol Process. 2005;19:1517–23. [Google Scholar]

- 10.Ram PK, Halder AK, Granger SP, Jones T, Hall P, Hitchcock D, et al. Is structured observation a valid technique to measure handwashing behavior? Use of acceleration sensors embedded in soap to assess reactivity to structured observation. Am J Trop Med Hyg. 2010;83:1070–6. doi: 10.4269/ajtmh.2010.09-0763. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Parametros Estacion Catarina San Marcos. Guatemala City, Guatemala: Instituto Nacional de Sismologia, Vulcanologia, Meteorologia e Hidrologia (INSIVUMEH); [cited: 12 June 2011]. Registros historicos datos mensuales estaciones meteorologicas en Guatemala. updated: 2010. Available from: http://www.insivumeh.gob.gt/meteorologia/ESTACIONES/SAN%20MARCOS/Catarina/Temp.%20Media%20CATARINA.htm. [Google Scholar]

- 12.Metz CE. Basic principles of ROC analysis. Semin Nucl Med. 1978;8:283–98. doi: 10.1016/s0001-2998(78)80014-2. [DOI] [PubMed] [Google Scholar]

- 13.Wolaver BD, Sharp JM. Thermochron iButton: limitation of this inexpensive and small-diameter temperature logger. Ground Water Monit Rem. 2007;27:127–8. [Google Scholar]

- 14.Ruiz-Mercado I, Masera O, Zamora H, Smith KR. Adoption and sustained use of improved cookstoves. Energy Policy. 2011;39:7557–66. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.