Abstract

Contaminated environments have a large number of bacteria which can accumulate PHA as their energy reserves. Out of 54 isolated bacterial strains from three groups of contaminated sites 48 were found PHA positive. The sites were grouped on the basis of the type of carbon sources i.e. sugars, fatty acids and much diverse type. Strains MFD5, MFD11, UML3, USL2, SEL2, SEL3, SEL10 and PFW1 produced 69.9 ± 0.29, 75.27 ± 0.45, 65.43 ± 0.1, 72.54 ± 0.27, 76.61 ± 0.28, 61.81 ± 0.05, 71.16 ± 0.09 and 74.92 ± 0.5 percent of PHA to their constant cell weight (CCW) respectively in PHA detection media supplemented with 2% glucose. Molasses, whey, crumbs hydrolysate and palm oil were checked as inexpensive carbon sources. Molasses alone could supply the required nutrients for growth and PHA production. Strain SEL2 produced 47.36 ± 0.45% PHA using 2% molasses at 37 °C and pH 7.0. Upon production optimization the best accumulation (80.95 ± 0.01%) was observed in PHA detection media with 0.2% nitrogen source, 3% molasses, pH 5.0 and 37 °C by the strain SEL2. The overall effect of the presence of increased molasses concentration in the media was positive it increased the accumulation period till 72 h. Enterobacter sp. SEL2 (JF901810) is first time being reported for PHA production.

Keywords: Enterobacter sp. SEL2, contaminated environments, molasses, PHA

Introduction

Biodegradable plastic or polyhydroxyalkanoates (PHA) are linear polyesters synthesized by many wild type natural bacterial isolates. Several different pathways for fermentative production of PHA have been evolved in nature, each best suitable for them according to their natural habitat (Madison and Huisman, 1999). The PHA producing-bacteria are found at various locations particularly contaminated sites have a large diversity of them (Lopez-Cortes et al., 2010). Recent investigations underline the fact that PHA production from pure substrates can be considered as optimized to a high degree. The overall production cost of biodegradable polymer (PHA) production depends greatly on the cost of the carbon source. Hence it is required to enhance economics of PHA production by substituting pure substrates by cheaper and inexpensive carbon sources (Koller et al., 2008; Khosravi-Darani et al., 2013).

The production of PHA in wild type natural bacteria is based on agro-industrial by-products ranging from inexpensive, waste effluents to plant oils, fatty acids and simple carbohydrates. Agro-industrial by-products have been used as an alternative to reduce the production cost (Lee and Gilmore, 2005). Various bacterial strains, either wild-type or engineered have been exploited with a wide spectrum of utilizable carbon sources. There are almost 250 organisms known to produce PHA, but only a few species can produce PHA at a high concentration. The best PHA accumulating bacterial species should have several properties like the high growth rate, capable of utilizing cheap inexpensive carbon sources and have high accumulation percentage. The bacteria having above properties could be obtained by two methods, firstly to isolate from the natural environment and secondly to design genetic recombinant strains. Both of them could gain the desired results for PHA production (Lopez-Cortes et al., 2010).

The present research work aims the isolation of wild type PHA producing bacterial strains from contaminated environments, quantitative estimation of PHA on glucose and agro-industrial based inexpensive carbon sources and the optimization of the highest producers considering selected growth parameters.

Materials and Methods

Sampling

Five contaminated sites were selected for collecting the soil, air and liquid samples i.e. Sugar industry waste dumping site, samples of crude molasses, Prime ghee/oil factory located at More Eimanabad G.T. Road District Gujranwala Punjab Pakistan, civic waste disposal area near Main Sewerage Drain near Gulshan-i-Ravi scheme Lahore Pakistan and the vegetable/fruit market waste disposal site Alipur Chatta District Gujranwala Pakistan.

Bacterial strains

54 bacterial strains were isolated from different contaminated sites. The selected bacteria were non hemolytic and hence were non-pathogenic (Shamala et al., 2012). They were purified by repeatedly streaking on nutrient broth, coded according to the site of their isolation and preserved as nutrient agar slants/glycerol stocks.

Screening of PHA producing bacterial strains

Screening of PHA production by different bacterial strains was done on PHA detection media. For observation of accumulated PHA granules in the bacterial cells, Sudan black staining was done after 24, 48 and 72 hours of incubation (Lee and Choi, 1999). For viable colony staining method 0.25 mg Nile blue A/mL of methanol was added to the sterilized PHA detection media (solid) with 2% glucose to give a final concentration 5μg of dye/mL of the medium. The agar plates were exposed to ultraviolet light (312 nm) after appropriate cultivation period to detect accumulation of polyhydroxyalkanoates granules (Spiekermann et al., 1999).

PHA production with glucose

All the PHA producing bacterial strains were grown in PHA detection media (PDM) (g/L) (NH4)2SO4 0.2, KH2PO4 13.3, MgSO4 1.3, Citric Acid 1.7. Trace element solution 10 mL/L, (g/L, FeSO4.7H2O 10, ZnSO4.7H2O 2.25, CuSO4.5H2O 1, MnSO4.5H2O 0.5, CaCl2.2H2O 2.0, Na2B4O7.10H2O 0.23, (NH4)6Mo7O24 0.1, 35%HCl 10 mL); Bacto agar, 15 g/L. The pH of the medium was adjusted to 6.8–7.0. Glucose was added separately in the final concentration of 2% (Lee and Choi, 1999) in order to estimate the PHA production. The inoculums were prepared in 50 mL of LB broth in 100 mL flask incubated overnight at 37 °C and 150 rpm. The 150 mL of PDM broth was taken in 250 mL conical flask and 2% glucose (Lee and Choi, 1999) was added as the carbon source. Glucose used was of analytical grade. The media was inoculated such as to get the O.D 0.05 at 600 nm and incubated for 24 h at 37 °C and 150 rpm. The 5 mL sample was used for the extraction of PHA.

Extraction of PHA by SDS addition method

Extraction of PHA was done by the direct addition of sodium dodesyl sulphate (SDS) (Kim et al., 2003). The ratio of SDS and constant cell weight was kept as 0.5 to 1.0. Biomass was collected by centrifugation at 4000 rpm. All the liquid media was removed and constant pellet was weighed and expressed as constant cell weight (CCW) in g/L. One hour incubation was given at 37 °C and 150 rpm after the addition of SDS to constant cell weight. Afterwards heat treatment was given at 121 °C at 15 lb pressure for 15 min and PHA was collected by centrifugation at 4000 rpm upon cooling. Palette was washed by acetone and water, dissolved in chloroform, allowed to evaporate, and PHA weight was noted (Kim et al., 2003). PHA content was calculated as percentage of constant cell weight (CCW).

PHA production using Agro-industrial byproducts

The eight bacterial strains which gave maximum PHA production with glucose were tested for agro-industrial byproducts like molasses (Gouda et al., 2001), whey, crumbs hydrolysate (Santimano et al., 2009) and palm oil (Marsudi et al., 2008). All these carbon sources were purchased from the local market.

PHA production optimization

Three bacterial strains (MFD11, SEL2 and PFW1) proved the highest producer of PHA through screening experiments, were subjected to optimization experiments with molasses as carbon source. Forty percent stocks were prepared of crude molasses, autoclaved and stored at 4 °C for future use. Two types of experimental modifications in four different sets were made for observing the effect of media on the growth and PHA production. Firstly, the molasses was added in the water (set 1), considering it as media for growth and PHA production (DAWM) and secondly, the addition of molasses (set 2, set 3 and set 4) in the PHA detection media (Table 1). Ammonium sulphate was used as nitrogen source in the PHA detection media. Varying concentrations (0%, 0.1% and 0.2%) of nitrogen source were selected along with the different concentration of molasses (1%, 2% and 3%) to examine the effect on the growth and PHA production (set 2, set 3 and set 4). The experiments were conducted on different temperatures (30 °C, 37 °C and 45 °C) and at different pH (7.0, 5.0 and 4.0) (Yuksekdag et al., 2004).

Table 1.

Experimental set up for optimization of PHA production.

| Set 1 | Set 2 | Set 3 | Set 4 |

|---|---|---|---|

|

|

|

|

| 1.DAW+ 1% M (v/v) | 4.PDM+1% M (v/v)+ No nitrogen source | 7.PDM+1% M (v/v)+ 0.2% ammonium sulphate (w/v) | 10.PDM+1% M (v/v)+ 0.4% ammonium sulphate (w/v) |

| 2.DAW+ 2% M (v/v) | 5.PDM+2% M (v/v)+ No nitrogen source | 8.PDM+2% M(v/v)+ 0.2% ammonium sulphate (w/v) | 11.PDM+2% M (v/v)+ 0.4% ammonium sulphate (w/v) |

| 3.DAW+ 3% M (v/v) | 6.PDM+3% M (v/v)+ No nitrogen source | 9.PDM+3% M (v/v)+ 0.2% ammonium sulphate (w/v) | 12.PDM+3% M (v/v)+ 0.4% ammonium sulphate (w/v) |

PDM; PHA Detection Media: DAW; Distilled autoclaved water: M; Molasses.

Results and Discussion

In our studies we adopted the strategy to isolate the bacterial strains from natural environments. As a result of screening of contaminated environments, the 54 bacterial strains were isolated out of which 48 were found to have good potential of PHA production. These non pathogenic, sudanophilic and Nile blue A positive, potential PHA producing bacterial strains were broadly divided into three groups depending upon the types of organic carbon source available to them in nature.

The group 1 included the bacterial strains which were isolated from sugar factory waste contaminated soil and crude molasses sample and were supposed to utilize different types of sugars as carbon source for their growth and PHA accumulation. Molasses is the residual syrup generated in sugar-refining mills after repeated sugar extraction by applying crystallization to sugarcane. At this point, sugar extraction is no longer economically viable, despite still having relatively high sucrose content. Low-grade molasses, inappropriate to be used in food or feed, has been suggested as substrate to produce PHA (Solaiman et al., 2006). The 20 bacterial strains MFD1 -MFD11, UML1, UML3, UML4, UML6, UML9, VM2, VM3, VM4 and VM5 were included in this group.

The group 2 was included oil/ghee waste contaminated environment bacterial strains. In this type of environment, the carbon source was supposed to be different types of fatty acids. The 12 bacterial strains isolated were USL1, USL2, USL4, USL6 and PFG1-PFG8. The group 3 comprised the civic waste and vegetable fruit market waste contaminated environment. A total of 16 bacterial strains i.e. SEL1, SEL2, SEL3, SEL4, SEL5, SEL6, SEL7, SEL8, SEL9, SEL10, SEL11, SEL12, SEL14, PFW1, PFW2 and AS3 were included in this group. This type of environment supposed to have much diverse type of carbon sources from simple to complex. The main source of organic carbon is waste water from different sources like municipal, pulp and paper industry, starch and cheese manufacturing industries which have high content of fatty acids (Ceyhan and Ozdemir, 2011).

PHA production with glucose

For quantitative estimation of PHA production in the selected 48 potential PHA producing bacterial strains were grown in shake flask cultures. For the purpose of comparison and in view of providing uniform growth conditions to all the isolated bacterial strains, the PHA detection media was initially supplemented with 2% glucose as carbon source at pH 7.0 and at 37 °C with agitation speed of 150rpm. The glucose is the simplest sugar and is an important carbohydrate. It is a primary carbon and preferred energy source widely used by many type of microorganisms (Pandey et al., 2000). Table 2 represents the estimated %PHA and CCW (g/L) of all PHA producing bacterial strains. The data indicated that the 88.88% of the isolated bacterial strain were capable of using glucose for the accumulation of PHA. In group 1, the strains MFD4, MFD5, MFD11 and UML3 produced respectively 54.2 ± 0.67%, 69.9 ± 0.29%, 75.27 ± 0.45% and 65.43 ± 0.1% PHA of their CCW. The range of production was observed from 75.27 ± 0.45% to 13.11 ± 0.09%. As Silva et al. (2004) described the high cell density cultures are indispensable in a PHA production process since they allow high productivity. The findings also supported that majority of the isolated bacteria from sugar industry waste contaminated sites were Pseudomonad which were capable of growing rapidly and synthesizing PHA at the same time using different types of sugars (Madison and Huisman, 1999).

Table 2.

Percentage PHA production in Sudanophilic, Nile Blue A positive bacterial strains in PHA detection media using glucose as carbon source.

| Strain code | CCW g/L | PHA% |

|---|---|---|

| MFD1 | 51 ± .01 | 45.64 ± 0.65 |

| MFD2 | 33.5 ± 0.09 | 20.51 ± 0.56 |

| MFD3 | 35 ± 0.09 | 29.41 ± 0.34 |

| MFD4 | 19.66 ± 0.03 | 54.2 ± 0.67 |

| * MFD5 | 20.33 ± 0.2 | 69.9 ± 0.29 |

| MFD6 | 27.33 ± 0.4 | 48.53 ± 0.35 |

| MFD7 | 15 ± 0.43 | 48.71 ± 0.08 |

| MFD8 | 9.33 ± 0.45 | 38.09 ± 0.45 |

| MFD9 | 24.66 ± 0.5 | 13.11 ± 0.09 |

| MFD10 | 70.66 ± 0.65 | 18.13 ± 0.1 |

| * MFD11 | 27 ± 0.7 | 75.27 ± 0.45 |

| VM2 | 53 ± 0.08 | 37.73 ± 0.49 |

| VM3 | 23 ± 0.09 | 39.13 ± 0.33 |

| VM4 | 14 ± 0.08 | 42.85 ± 0.98 |

| VM5 | 43 ± 0.46 | 37.09 ± 0.80 |

| UML1 | 50.66 ± 0.34 | 23.93 ± 0.6 |

| * UML3 | 26 ± 0.48 | 65.43 ± 0.1 |

| UML4 | 16.33 ± 0.08 | 43.03 ± 0.4 |

| UML6 | 19 ± 0.43 | 47.64 ± 0.92 |

| UML9 | 31.66 ± 0.67 | 41.81 ± 0.86 |

| PFG1 | 31.66 ± 0.45 | 43.75 ± 0.75 |

| PFG2 | 29 ± 0.56 | 41.22 ± 0.65 |

| PFG3 | 35 ± 0.08 | 53.3 ± 0.75 |

| PFG4 | 30.33 ± 0.09 | 55.32 ± 0.65 |

| PFG5 | 36 ± 0.64 | 50.49 ± 0.34 |

| PFG6 | 47 ± 0.09 | 37.35 ± 0.65 |

| PFG7 | 26.33 ± 0.45 | 36.35 ± 0.39 |

| PFG8 | 14.33 ± 0.34 | 47.74 ± 0.3 |

| USL1 | 55.66 ± 0.45 | 36.16 ± 0.63 |

| * USL2 | 39 ± 0.32 | 72.54 ± 0.27 |

| USL4 | 27.66 ± 0.56 | 32.39 ± 0.48 |

| USL6 | 64.66 ± 0.48 | 44.44 ± 0.2 |

| SEL1 | 41 ± 0.09 | 56.01 ± 0.56 |

| * SEL2 | 39 ± 0.09 | 76.61 ± 0.28 |

| * SEL3 | 32 ± 0.07 | 61.81 ± 0.05 |

| SEL4 | 16 ± 0.32 | 52.5 ± 0.07 |

| SEL5 | 42 ± 0.46 | 35.71 ± 0.43 |

| SEL6 | 17 ± 0.67 | 35.29 ± 0.09 |

| SEL7 | 30 ± 0.08 | 33.33 ± 0.31 |

| SEL8 | 23.5 ± 0.07 | 47.74 ± 0.52 |

| SEL9 | 25 ± 0.65 | 32.93 ± 0.34 |

| * SEL10 | 21.5 ± 0.63 | 71.16 ± 0.09 |

| SEL11 | 11 ± 0.46 | 54.54 ± 0.45 |

| SEL12 | 27 ± 0.49 | 44.44 ± 0.32 |

| SEL14 | 20 ± 0.58 | 11.11 ± 0.56 |

| PFW2 | 43.66 ± 0.35 | 14.26 ± 0.55 |

| * PFW1 | 11 ± 0.42 | 74.92 ± 0.5 |

| AS3 | 24.33 ± 0.07 | 9.91 ± 0.69 |

CCW; Constant Cell Weight.

Highest PHA producing strains selected for PHA production with agro- industrial byproducts.

The 37% of the PHA producing strains were isolated from group 2. It indicated that although the strains were isolated from fatty acid rich environment but they were also capable to grow and accumulate PHA in the presence of sugars as well. The strains PFG3, PFG4, PFG5 and USL2 exhibited 53.3 ± 0.75%, 55.32 ± 0.65%, 50.49 ± 0.34% and 72.54 ± 0.27% PHA production (Table 2). From group 3, the 38% bacterial strains were isolated. The bacterial strains SEL1, SEL2, SEL3, SEL4, SEL10, SEL11 and PFW1 produced 56.01 ± 0.56%, 76.61 ± 0.28%, 61.81 ± 0.05%, 52.5 ± 0.76%, 71.16 ± 0.98%, 54.54 ± 0.45% and 74.92 ± 0.5%. The group 3 was the civic waste contaminated environment; here the carbon and energy source was the main anthropogenic waste (Ceyhan and Ozdemir, 2011) and domestic wastewater (DWW). Table 2 also indicated that the strains MFD5, MFD11, UML3, USL2, SEL2, SEL3, SEL10 and PFW1 produced 69.9 ± 0.29, 75.27 ± 0.45, 65.43 ± 0.1, 72.54 ± 0.27, 76.61 ± 0.28, 61.81 ± 0.05, 71.16 ± 0.09 and 74.92 ± 0.5 percent of PHA to their constant cell weight (CCW) respectively. Strain AS3 produced 9.91 ± 0.69% of PHA which is the lowest content observed and strainSEL2 produced 76.61 ± 0.28% polymer which is the highest amongst all the 48 strains. The strain MFD10 produced the highest biomass 70.66 ± 0.65% but it accumulated only 18.13 ± 0.1% PHA (Table 2).

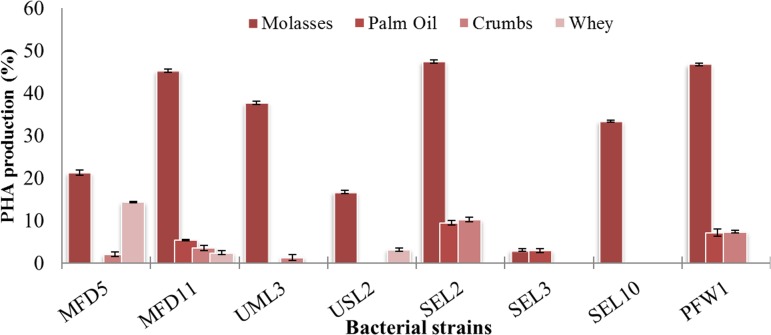

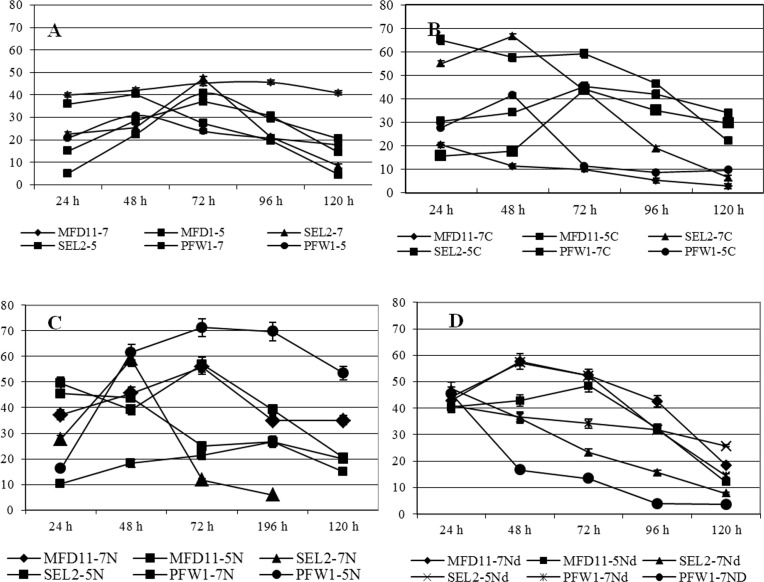

PHA production with Agro-industrial byproducts

Several bacteria are known to produce PHA from agro-industrial residues (Shamala et al., 2012) so in an attempt to search for a new wild type strain, satisfying the qualities of a good candidate for industrial production of PHA from agro-industrial byproducts, shake flask cultures for 8 maximum PHA producing bacterial strains were cultivated under the same growth conditions as described earlier (Table 2). The percent PHA accumulation by bacterial strains MFD5, MFD11, UML3, USL2, SEL2, SEL3, SEL10 and PFW1 is represented in Figure 1. The strain MFD5 accumulated 21.23 ± 0.61% PHA on molasses, 2.0 ± 0.5% on crumbs hydrolysate, 14.28 ± 0.2% on whey but when palm oil was used as carbon source PHA could not be detected. The bacterial strain MFD11 was able to accumulate PHA on all the 4 selected carbon sources. It has accumulated 37.21 ± 0.41% on molasses, 5.32 ± 0.1% on palm oil, 3.5 ± 0.62% on crumbs hydrolysate and 2.34 ± 0.45% on whey. The strains SEL2, SEL3, SEL10 and PFW1 were not able to use whey for PHA accumulation. It is apprehended that as the lactose is the major component of whey (Fonseca and Antonio, 2006) which could not be used by the selected bacteria (Figure 1). Crumbs hydrolysate could not be used by USL2, SEL3 and SEL10 while the palm oil could not be used by the bacterial strains MFD5, UML3, USL2 and SEL10 for the accumulation of PHA. In spite of the fact that the palm oil has the highest content of saturated fatty acid, the PHA accumulation was very low. The low production of PHA could be explained on the basis of non availability of palm oil to bacteria at 37 °C (Fonseca and Antonio, 2006). The maximum PHA production was observed in strain SEL2 (47.36 ± 0.45) in molasses based media (Figure 1). Each organism is best adapted to its environment and could utilize the resources provided by the nature (Madison and Huisman, 1999). The uniform conditions of growth were only provided for the purpose of comparison of PHA production ability of the selected bacterial strains. PHA production was quite high in the glucose medium and the bacterial strains MFD11, SEL2 and PFW1 shown accumulation of PHA equally well with molasses. The bacteria could accumulate higher PHA content on molasses as compared to oil, whey and bakery residue hydrolysate (Santimano et al., 2009). Keeping in view the findings of this section of discussion the three bacterial strains MFD11, SEL2 and PFW1 were the most suitable for further optimization.

Figure 1.

Accumulation of percentage PHA using different agro-industrial byproducts by selected bacterial strains. The bacterial strain MFD11 showed PHA accumulation on all the four carbon sources (Molasses, Palm Oil, Crumbs Hydrolysate and Whey) employed. The strain MFD5, UML3 and USL2 were not able to use palm oil for PHA production. The strain SEL10 showed accumulation only by using molasses. The highest PHA accumulation was observed with molasses.

Optimization of PHA with sugar cane molasses

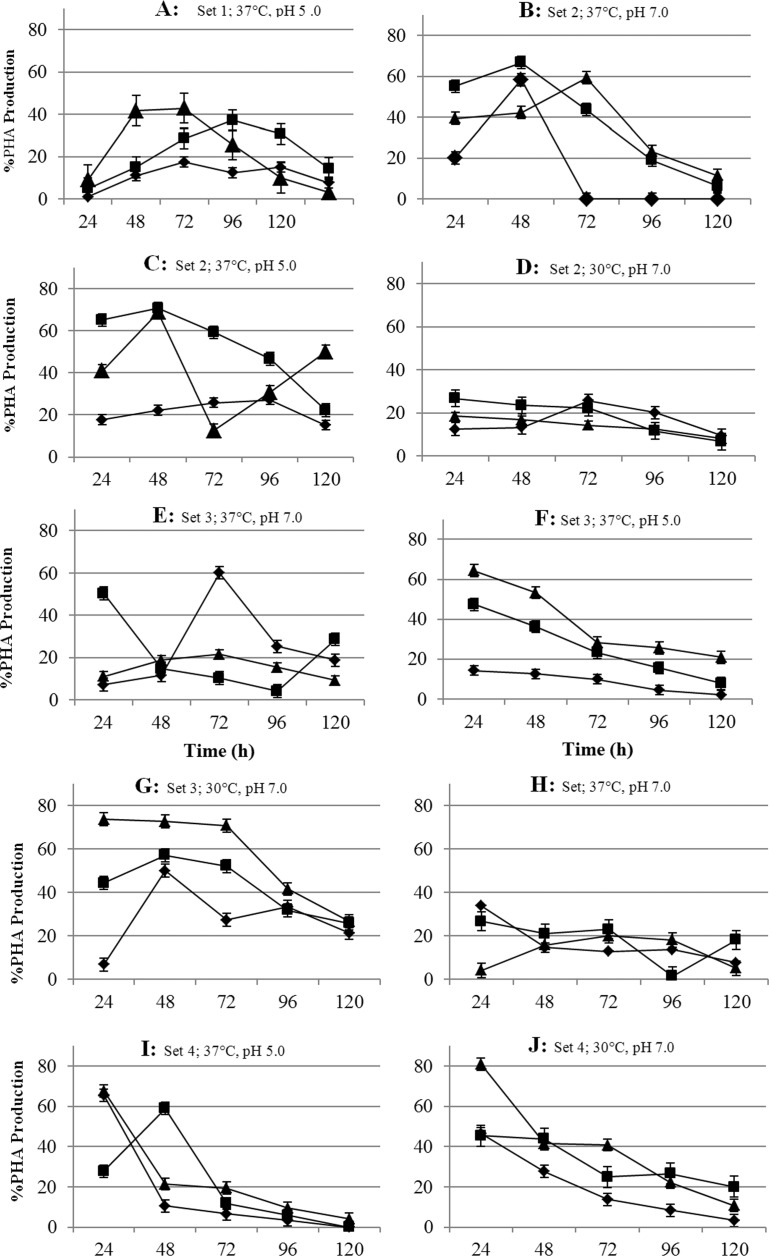

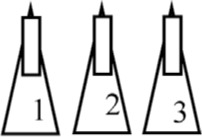

Five different parameters were selected for optimization, the molasses as media for growth and PHA synthesis, effect of carbon source concentration, nitrogen source concentration, pH and temperature (Table 1). The optimization experiments were done with three bacterial strains (MFD11, SEL2 and PFW1) but graphical data has only shown for SEL2 which was highest PHA producer (Figure 2).

Figure 2.

PHA production optimization studies in bacterial strain Enterobacter sp. SEL2 under different experimental conditions. M; Molasses

Molasses as media

In MFD11 the maximal PHA production (45.6 ± 0.54%) was observed with 2% molasses at 37 °C and pH 7.0 which occurred between 72 to 96 h. No growth was observed at pH 5.0 and 4.0 at higher temperature 45 °C and lower temperature 30 °C. The pH 5.0 was somewhat favourable for the growth and PHA production of the strain MFD11. It accumulated 40.34 ± 0.3% PHA at pH 5.0 and at 37 °C. The lower pH and higher temperature negatively influenced the performance of the strain MFD11. The strain was not able to grow at lower pH (4.0). The strain SEL2 excelled in PHA production as it accumulated 47.2 ± 0.4% with 2% molasses at pH 7.0. It was also noted that the strain accumulated 42.86 ± 0.9% PHA at pH 5.0 in the same media and at 37 °C (Figure 2A). The strain PFW1 produced 40.71 ± 0.5% PHA at 37 °C and pH 7.0. It was able to accumulate 30.86 ± 0.54% at pH 5.0. The bacterial strain could not able to grow and accumulate PHA at lower temperature and pH. The optimal temperature and pH was noted as 37 °C and pH 7.0. Molasses based distilled autoclaved media supported the growth of bacterial strains MFD11, SEL2 and PFW1. Higher temperature (45 °C) and lower pH 4.0 influenced the growth and no growth was observed in all of the three strains. SEL2 showed better capability of molasses utilization for PHA accumulation at pH 5.0 and 37 °C.

Growth and PHA production in molasses based PHA detection media (PDM)

The effect of molasses concentration was also noted by replacing the DAWM with the PDM (Set 2). The PDM was not supplemented with ammonium sulphate. The nitrogen was only provided by the molasses. The bacterial strain MFD11 showed declining trend in growth as well as in PHA accumulation ability. The lowering in the temperature improved the PHA production and lowering in the pH did not affected much. By observing carefully it was noted that the strain MFD11 accumulated 56.52 ± 0.5% with 1% molasses at pH 7.0 and 30 °C and 40.55 ± 0.03% in 2% molasses also at pH 7.0 and 30 °C. Another trend was observed that the strain MFD11 showed considerable growth at pH 4.0 and 37 °C but no PHA accumulation was detected. The strain SEL2 behaved differently. It accumulated 58.33 ± 0.02% PHA 1% molasses, 66.66 ± 0.1% in 2% molasses and 59.25 ± 0.9% in 3% molasses at 37 °C and pH 7.0 (Figure 2B). It accumulated 70.58 ± 0.1% PHA and 68.75 ± 0.2% PHA at pH 5.0 and 37 °C (Figure 2C). At pH 4.0 and 37 °C, growth and PHA production was only observed 2% molasses. At 30 °C, the PHA content decreased (Figure 2D). The maximal accumulation period was observed between 24 and 72 h of growth. The only exception being at pH 5.0 and 37 °C where the maximum accumulation was observed between 48 to 96 h of growth. No growth was observed at 45 °C. For PFW1 the optimal pH and temperature was observed to be 37 °C and 5.0 respectively. The PHA content accumulated was 56.25 ± 0.2% at pH 5.0 and 41.66 ± 0.3%. The PHA content in 2% and 3% molasses at pH 7.0 was estimated as 43.99 ± 0.3% and 49.51 ± 0.01% respectively. The optimal period for the accumulation was observed between 24 to 72 h.

By comparing the data presented, it can be concluded that all the three selected strains (MFD11, SEL2 and PFW1) could accumulate PHA in the molasses media (DAWM) but the PHA production was comparatively high in PHA detection media (PDM) with molasses as carbon source. The optimal temperature for PHA production was 37 °C and optimal pH was 5.0. The 2% molasses concentration was best for the accumulation of PHA. The strain SEL2 was the best candidate which accumulated highest PHA content 70.58 ± 0.1% and could grow and accumulate PHA at a wide range of temperature and pH (Yuksekdag et al., 2004).

Although the PHA production ability of different organisms could not be compared due to the diversity of the different organisms and the PHA production and the growth conditions (Khanna and Srivastava, 2005) and as each organism is best adapted to its environment and could utilize the resources, the nature has provided it (Madison and Huisman, 1999). But under the uniform condition of growth the PHA production ability was evaluated to measure the effect of different media. PDM facilitated highest PHA production. In the DAWM, the PHA production was observed in all the three selected strains. So it is established that the molasses alone can supply the required nutrients for growth as well as to some extent PHA production (Gouda et al., 2001). Comparatively better growth was observed in PHA detection media than DAWM and PHA production is considerably high in PHA detection media in all three selected bacterial strains provided that other conditions like molasses concentration (2%), ammonium sulphate (0.2%) concentration kept constant at pH 7.0 and at 37 °C.

The optimal ammonium sulphate concentration was evaluated in PDM by varying the molasses (carbon source) concentration along with the temperature and pH as discussed in the previous section (Set 3). The highest PHA production (80.95 ± 0.01%) was estimated for strain SEL2 at pH 5.0 and at 37 °C (Figure 2F). At 37°C and 30 °C at pH 7.0 the bacterial strain SEL2 accumulated 67.74 ± 0.1 and 60.1 ± 0.1% PHA respectively (Figure 2E, G). Having a careful look in the data presented one thing was very interesting and obvious that the strain PFW1 showed growth and PHA production (10.92 ± 0.1%) at 45 °C and pH 7.0. Likewise, the bacterial strain SEL2 was also able to grow and accumulate PHA (11.65 ± 0.11%) at pH 7.0 and 45 °C. Another different behavior was noted that the strains MFD11 and PFW1 showed growth and PHA accumulation at pH 4.0 at 37° C, whereas the strain SEL2 was not able to grow at pH 4.0. The optimal time for the highest accumulation was observed between 36 to 72 h. The bacterial strain SEL2 appeared to be the best candidate for future optimization studies and experiments.

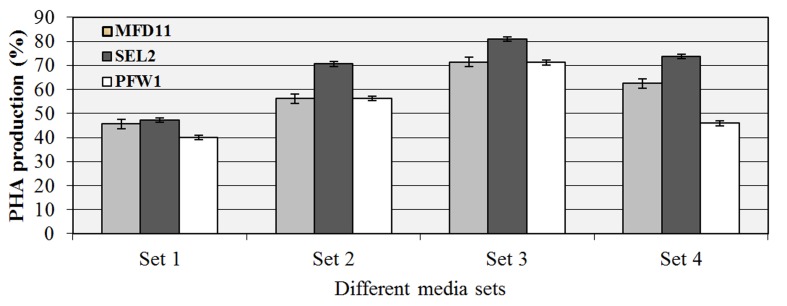

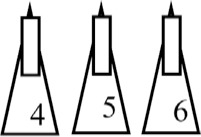

The effect of carbon and nitrogen ratio on growth and PHA production

The strain MFD11 accumulated 71.43 ± 0.9% and strain PFW1 accumulated 71.23 ± 0.8% PHA. The increased PHA accumulation was not the function of increased biomass. The 0.2% (w/v) concentration of ammonium sulphate with increasing concentration of carbon source positively influenced the growth of the selected strains as well as the PHA production ability. This data when critically compared with the data where no nitrogen source was supplied to the bacterial strains, a clear difference in growth and PHA production pattern had appeared. A general increase in the biomass was observed along with the improved percentage of accumulated PHA (). The effect was not the strain specific (Figure 3).

Figure 3.

The evaluation of the effect of increased nitrogen source concentration on the PHA production by MFD11, SEL2 and PFW1. Set 1; Molasses based Distilled autoclaved water media, Set 2; PHA detection media with no nitrogen source, Set 3; PHA detection media with 0.2% nitrogen source, Set4; PHA detection media with 0.4% nitrogen source.(The other parameters of growth were 2% molasses (Carbon source), pH 7.0 and 150 rpm in shake flask culture).

Effect of increased nitrogen concentration on the growth and PHA production

This section of the optimization experiments included the effect of increased concentration of the ammonium sulphate on the growth behavior and PHA accumulation of the three selected bacterial strains MFD11, SEL2 and PFW1 (Set 4). The concentration of ammonium sulphate used was 0.4% which was doubled the amount used in the previous section. Increasing the concentration of nitrogen along with the increase in molasses content positively influenced the growth of the bacteria at lower pH and at higher temperature. In bacterial strain MFD11 57.65 ± 0.2% PHA was observed in 2% molasses at pH 7.0 and 37 °C, 48.4 ± 0.5% in 2% molasses at pH 5.0 and 37 °C. The 56.61 ± 0.2% PHA content was observed in 3% molasses at pH 7.0 and 30°C. The 54.08 ± 0.5% PHA content was estimated in 3% molasses at pH 7.0 at 45 °C. Considerable growth was detected at pH 4.0 at 37 °C and pH 5.0 at 45 °C but no accumulated PHA could be detected under these conditions. The strain SEL2 showed growth and PHA production under a wide range of growth conditions. SEL2 accumulated 64.29 ± 0.8% PHA at pH 7.0 (Figure 2H) and 73.68 ± 0.1% at pH 5.0 at 37 °C in 3% molasses (Figure 2I). The accumulation of PHA was also observed at pH 7.0 at 30 °C (33.83 ± 0.2%) and 45 °C (6.56 ± 0.2%) respectively (Figure 2J). The increased carbon to nitrogen ratio positively influenced the growth and PHA production in SEL2 (Saranya and Shenbagarathai, 2010). The bacterial strain PFW1 did not showed growth at lower pH at any selected temperatures. The PHA accumulation was observed in 3% molasses (45.91 ± 0.4%) and in 2% molasses (45.65 ± 0.4%) at pH 7.0 and 5.0. The decreasing trend was observed in accumulated content of PHA by the strain PFW1. The optimal period for the highest accumulation was also shifted from stationary phase to growth phase. It was observed that maximum PHA was accumulated between 24 h of growth phase. In the presence of increased nitrogen to carbon ratio the optimal phase of PHA accumulation was different for each selected strains and under different growth conditions (Temperature and pH) (Saranya and Shenbagarathai, 2010). The Figure 3 showed the effect of increased nitrogen source concentration on the PHA production ability of three selected bacterial strains.

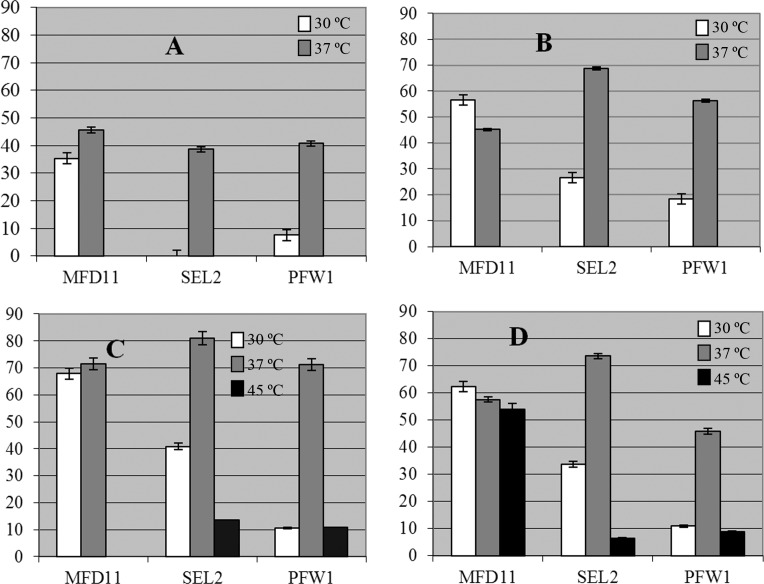

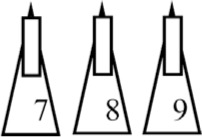

It was indicated that Set 2 facilitated highest PHA production. In Set 1, the PHA production was observed in all the three selected strains but comparatively the accumulated PHA percentage is lower. The Bacterial strain SEL2 exhibited highest PHA production in all conditions employed. The Figure 4 shows the effect of different selected temperature on the growth pattern of strains MFD11, SEL2 and PFW1 in different media set 1, 2, 3 and 4.

Figure 4.

The evaluation of the effect of different temperatures on the selected bacterial strains MFD11, SEL2 and PFW1 in different media (Figures A; Set 1, B; Set 2, C; Set 3, D; Set 4). Y-axis; PHA production (%), X-axis, Codes of bacterial strains; Set 1, Molasses based Distilled Autoclaved Media; Set 2, PHA Detection Media with no nitrogen source, C; Set 3, PHA Detection Media with 0.2% nitrogen source, Set 4, PHA Detection Media with 0.4% nitrogen source.

Because temperature, pH and agitation rate all affect dissolved oxygen levels and mass transfer efficiency, these environmental factors profoundly affect cellular growth and production. The bacteria were isolated from the mesophilic environments so it is expected to have the growth temperature range from 15–40 °C. In this context most of the bacteria did not showed growth at the temperature 45 °C (Figure 4A, 4B). It was observed that the presence of nitrogen source had a positive influence on the PHA production (Figure 4C) and it was increased with the increase in the carbon to nitrogen concentration (Figure 4D). The nitrogen provided the precursors for protein synthesis so the stress of temperature could be covered in the presence of nitrogen source (Saranya and Shenbagarathai, 2010). The Figure 5A (set 1) showed the accumulation of PHA at pH 5.0 was high as compared to 7.0 in all strains except in strain PFW1. The crude molasses has a pH 5.0 so it was assumed that the nutrients were best available at this pH. The strain PFW1 was isolated from civic waste contaminated site so it might not be able to grow well on molasses so its accumulation was also low. In PDM1 which provides necessary salts for the accumulation of PHA without nitrogen source did not affect much the accumulation ability in pH 5.0 or 7.0. The only exception was strain MFD11, its accumulated percentage dropped at both of the pH but comparatively at pH 7.0 the percent PHA content was better. The media has also affected the accumulation ability as it can be observed by the comparison of Figure 5A and 5B the percentage accumulation was comparatively high in all the three tested strains in the PHA detection media with no nitrogen source (PDM) (Madison and Huisman, 1999). The Figure 5C and 5D represent the effect of pH variation in media with nitrogen source and under increased nitrogen concentration. The overall effect of the presence of nitrogen in the media was positive when the carbon source concentration was increased (Saranya and Shenbagarathai, 2010). If all the four media were compared the best production was observed in PDM with 0.2% nitrogen source, 3% molasses and 37 °C by the strain SEL2. The SEL2 was identified as Enterobacter sp. It has 98% homology with the Enterobacter sp. (JF23). Strain was designated as Enterobacter sp. SEL2 (JF901810). Although non-pathogenic strains of Enterobacter sp. were reported for the industrial level production of polymers (Dahiya et al., 2005) but it was not reported earlier for the production of PHA.

Figure 5.

The evaluation of the effect of power of hydrogen ion concentration (pH) on the PHA accumulation in different selected media by MFD11, SEL2 and PFW1, Y-axis; PHA production (%), X-axis; cultivation time (h). A: DAWM, B: PDM1, C: PDM2, D: PDM3, The digit 7 represents pH; 7.0 and 5 represents pH 5.0, Letter C represents carbon source; 2% molasses, N; 0.2% ammonium sulphate, Nd; 0.4% ammonium sulphate.

References

- Ceyhan N, Ozdemir G. Poly-hydroxybutyrate (PHB) production from domestic wastewater using Enterobacter aerogenes 12Bi strain. Afr J Microbiol Res. 2011;5(6):690–702. [Google Scholar]

- Dahiya N, Tewari R, Tiwari RP, Hoondal GS. Chitinase production in solid-state fermentation by Enterobacter sp. NRG4 using statistical experimental design. Curr Microbiol. 2005;51:222–228. doi: 10.1007/s00284-005-4520-y. [DOI] [PubMed] [Google Scholar]

- Fonseca GG, Antonio RV. Polyhydroxyalkanoates production by recombinant Escherichia coli harboring the structural genes of the polyhydroxyalkanoate synthases of Ralstonia eutropha and Pseudomonas aeruginosa using low cost substrate. J Appl Sci. 2006;6:1745–1750. [Google Scholar]

- Gouda MK, Swellam AE, Omar SH. Production of PHB by a Bacillus megaterium strain using sugarcane molasses and corn steep liquor as sole carbon and nitrogen source. Microbiol Res. 2001;156:201–207. doi: 10.1078/0944-5013-00104. [DOI] [PubMed] [Google Scholar]

- Khanna S, Srivastava AK. Recent advances in microbial polyhydroxyalkanoates. Process Biochem. 2005;40:607–619. [Google Scholar]

- Khosravi-Darani K, Mokhtari ZB, Amai T, Tanaka K. Microbial production of poly (hydroxybutyrate) from C1 carbon sources. Appl Microbiol Biotechnol. 2013;97(4):1407–1424. doi: 10.1007/s00253-012-4649-0. [DOI] [PubMed] [Google Scholar]

- Kim M, Cho KS, Ryu HW, Lee EG, Chang YK. Recovery of poly 3-hydroxybutyrate from high cell density culture of Ralstonia eutropha by direct addition of sodium dodecyl sulfate. Biotechnol Lett. 2003;25:55–59. doi: 10.1023/a:1021734216612. [DOI] [PubMed] [Google Scholar]

- Koller M, Bona R, Chiellini E, Fernandes EG, Horvat P, Kutschera C, Hesse P, Braunegg G. Polyhydroxyalkanoate production from whey by Pseudomonas hydrogenovora. Bioresource Technol. 2008;99(11):4854–63. doi: 10.1016/j.biortech.2007.09.049. [DOI] [PubMed] [Google Scholar]

- Lee KM, Gilmore FD. Formulation and process modeling of biopolymer (polyhydroxyalkanoate: PHAs) production from industrial wastes by a novel crossed experimental design. Process Biochem. 2005;40:229–246. [Google Scholar]

- Lee SY, Choi J. Polyhydroxyalkanoates: Biodegradable Polymer. In: Arnold L, Demain J, Davis E, editors. Manual of industrial microbiology and biotechnology. 2nd ed. American Society for Microbiology; Washington: 1999. pp. 616–662. [Google Scholar]

- Lopez-Cortes A, Oliverio RF, Hever LB, Humberto CM, Getzabeth GG, Carlos LO. Characterization of polyhydroxyalkanoate and the phaC gene of Paracoccus seriniphilus E71 strain isolated from a polluted marine microbial mat. World J Microb Biotechnol. 2010;26:109–118. [Google Scholar]

- Madison LL, Huisman GW. Metabolic Engineering of Poly3-Hydroxyalkanoates: From DNA to Plastic. Microbiol Mol Biol R. 1999;63:21–53. doi: 10.1128/mmbr.63.1.21-53.1999. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marsudi S, Unno H, Hori K. Palm oil utilization for the simultaneous production of polyhydroxyalkanoates and rhamnolipids by Pseudomonas aeruginosa. Appl Microbiol Biotechnol. 2008;78:955–961. doi: 10.1007/s00253-008-1388-3. [DOI] [PubMed] [Google Scholar]

- Pandey A, Carlos R, Nigam SP, Vanete T, Soccol VT. Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresource Technol. 2000;74(1):69–80. [Google Scholar]

- Santimano MC, Nimali N, Prabhu, Grag S. PHA production using low-cost agro-industrial wastes by Bacillus sp. strain COL1/A6. Res J Microbiol. 2009;4(3):89–96. [Google Scholar]

- Saranya V, Shenbagarathai R. Effect of Nitrogen and Calcium Sources on Growth and Production of PHA of Pseudomonas sp. LDC-5 and it’s Mutant. Cur Res J Bio Sci. 2010;2(3):164–16. [Google Scholar]

- Shamala TR, Vijayendra SVN, Joshi GJ. Agro-industrial residues and starch for growth and co-production of polyhydroxyalkanoate copolymer and α-amylase by Bacillus sp. Cfr-67. Braz J Microbiol. 2012;43(3):1094–1102. doi: 10.1590/S1517-838220120003000036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silva LF, Taciro MK, Ramos ME, Carter JM, Pradella JGC, Gomez JGC. Poly-3-hydroxybutyrate (P3HB) production by bacteria from xylose, glucose and sugarcane bagasse hydrolysate. J Ind Microbiol Biotechnol. 2004;31:245–254. doi: 10.1007/s10295-004-0136-7. [DOI] [PubMed] [Google Scholar]

- Solaiman DKY, Ashby RD, Foglia TA, Marmer WN. Conversion of agricultural feedstock and coproducts into poly(hydroxyalkanoates) Appl Microbiol Biotechnol. 2006;71:783–789. doi: 10.1007/s00253-006-0451-1. [DOI] [PubMed] [Google Scholar]

- Spiekermann P, Bernd HA, Rehm RK, Baumeister D, Steinbuchel A. A sensitive, viable-colony staining method using Nile red for direct screening of bacteria that accumulate polyhydroxyalkanoic acids and other lipid storage compounds. Arch Microbiol. 1999;171:73–80. doi: 10.1007/s002030050681. [DOI] [PubMed] [Google Scholar]

- Yuksekdag ZN, Aslim B, Beyatli Y, Mercan N. Effect of carbon and nitrogen sources and incubation times on poly-beta-hydroxybutyrate (PHB) synthesis by Bacillus subtilis 25 and Bacillus megaterium 12. Afr J Biotechnol. 2004;3(1):63–66. [Google Scholar]