Abstract

Polymer hydrogels have been widely explored as therapeutic delivery matrices because of their ability to present sustained, localized and controlled release of bioactive factors. Bioactive factor delivery from injectable biopolymer hydrogels provides a versatile approach to treat a wide variety of diseases, to direct cell function and to enhance tissue regeneration. The innovative development and modification of both natural-(e.g., alginate (ALG), chitosan, hyaluronic acid (HA), gelatin, heparin (HEP), etc.) and synthetic-(e.g., polyesters, polyethyleneimine (PEI), etc.) based polymers has resulted in a variety of approaches to design drug delivery hydrogel systems from which loaded therapeutics are released. This review presents the state-of-the-art in a wide range of hydrogels that are formed though self-assembly of polymers and peptides, chemical crosslinking, ionic crosslinking and biomolecule recognition. Hydrogel design for bioactive factor delivery is the focus of the first section. The second section then thoroughly discusses release strategies of payloads from hydrogels for therapeutic medicine, such as physical incorporation, covalent tethering, affinity interactions, on demand release and/or use of hybrid polymer scaffolds, with an emphasis on the last 5 years.

Keywords: Polymerization, Polymeric biomaterial, Bioactive molecules, Controlled release, Release mechanism

1. Introduction

Bioactive factor delivery is a promising strategy to treat a variety of human diseases and enhance tissue regeneration, and this field has progressed significantly with the accelerated development of novel biomaterials and technologies [1–6]. The term ‘bioactive factor’ refers to small-molecule drugs like anticancer drugs [7,8], genetic agents [9–11] and proteins such as growth factors (GFs) [2,12], which have been used to treat human diseases, guide and direct cell functions and/or enhance tissue regeneration. Hydrogels, highly-hydrated three-dimensional networks of crosslinked hydrophilic polymer, hold great potential in pharmaceutical and biomedical applications [4,13–18]. They are of great interest due to their ability to locally deliver entrapped therapeutics at the sites of interest in vivo in a spatiotemporally controlled and sustained fashion.

Since the first introduction of poly(2-hydroxyethyl methacrylate) (PHEMA) hydrogels in the 1960s by Wichterle and Lim [19], advancements in polymer science have been made through creation of a wide variety of hydrogels using either synthetic or natural polymers as building blocks. Several synthetic polymers, such as polyesters, polyphosphazene and poly(ethylene glycol) (PEG), have been widely used to fabricate hydrogels [15,20,21]. They not only present little risk of biological pathogen transmission, but can be tailored to obtain a wide range of well-defined chemical structures, controllable degradability and desirable mechanical properties [22,23]. Natural polymers (e.g., collagen, fibrin, dextran (DEX), chitosan, alginate (ALG), hyaluronic acid (HA), gelatin, and peptides and other proteins) represent a diverse platform for producing hydrogels with high inherent bio-compatibility, biodegradability, capacity for regulating cell behavior and low toxicity of degradation products [24–26]. Nevertheless, while synthetic polymers can exhibit low biocompatibility and may generate toxic byproducts, natural materials often display poor mechanical properties, offer limited control over degradation profiles, exhibit batch-to-batch variation from animal and plant sources and may possess pathogens or elicit immune responses [24,27]. There has been growing interest over the past two decades in creating a variety of hydrogel matrices which combine the advantages of both synthetic and natural polymers for therapeutic delivery [28–32]. Hydrogel networks with engineered properties and functionality via chemical modifications have been designed to provide different controlled release mechanisms of loaded therapeutics [31,33–37].

Appropriate materials must be selected and modified to fabricate hydrogels with desired properties to meet demanding requirements of specific delivery applications. Ideally, hydrogel scaffolds engineered for therapeutic bioactive molecule delivery in medicine should meet several important criteria: (1) scaffold materials and their degraded products should be biocompatible or elicit minimal immunological reactions by host tissues; (2) gelation mechanisms must allow for mild, homogeneous encapsulation conditions for therapeutics without damaging them; (3) control of polymer network porosity, which facilitates therapeutics transport, is often valuable for tailoring the release profiles of loaded bioactive factors; (4) hydrogels should have degradation properties permitting persistence of constructs during release periods and temporal control over release profiles.

This review describes recent progress in the area of engineered polymer hydrogels for therapeutic delivery systems. Various synthetic strategies for the preparation of hydrogels including environmentally responsive, chemically crosslinked, ionically crosslinked and biomolecule recognition hydrogels are presented. Then, therapeutic release strategies from hydrogels, such as physical incorporation, covalent tethering, affinity interactions, on-demand release and/or use of hybrid polymer scaffolds, with an emphasis on work from the last 5 years, will be discussed. Finally, an outlook on future directions of hydrogel-based delivery systems is provided.

2. Hydrogel design for delivery of bioactive factors

Progress in polymer synthesis and chemical modification of both synthetic and natural polymers has resulted in diverse methods for constructing hydrogel scaffolds for therapeutics delivery. This section will present a range of strategies that have been exploited to engineer hydrogels. These include self-assembly of polymers and peptides, formation of covalent or ionic bonds between polymer chains, and biomolecule recognition. Advantages and disadvantages of different hydrogel crosslinking approaches are presented in Table 1.

Table 1.

Advantages and disadvantages of crosslinking methods.

| Crosslinking methods | Advantages | Disadvantages |

|---|---|---|

| Self-assembly | No crosslinkers required; reversible; mild gelation upon exposure to external stimuli (e.g., pH, temperature, etc.) | Typically mechanically weak gels |

| Photocrosslinking | Spatiotemporal control over gelation | Light source and initiator required |

| Thiol/acrylate Michael reaction | High specificity; controllable gelation kinetics; mild gelation under physiological conditions | Sometimes an organic base (i.e., triethanolamine) used |

| Disulfide formation | High specificity; controllable gelation kinetics under physiological conditions | Oxidizing agents often required |

| Schiff’s base reaction | Controllable gelation kinetics; mild gelation under physiological conditions | Lack of specificity: aldehyde groups can react with amines of bioactive factors and tissue extracellular matrix molecules |

| Enzyme-mediated reaction | High specificity; gelation in mild conditions | Instability of some enzymes; active enzymes may remain following gelation |

| Click reaction | High specificity; high reaction efficiency; controllable gelation rate | Toxic Cu(I) catalyst often required |

| Ionic crosslinking | Gelation in mild conditions; potentially reversible | Charged therapeutics may interfere with crosslinking |

| Molecular recognition | High specificity; gelation in mild conditions | Sometimes mechanically weak gels and rapid degradation |

2.1. Self-assembly of polymers

Self-assembly of polymers provides a simple method to prepare physically crosslinked hydrogels for controlled drug delivery. Addition of chemical crosslinking agents is not required, which reduces the potential toxicity of these systems. Self-assembly occurs with some polymers as a result of intra- and intermolecular forces, such as hydrogen bonding and hydrophobic interactions. Aqueous solutions of these polymers undergo sol-to-gel transition upon self-assembling in response to external stimuli such as pH and temperature.

2.1.1. Self-assembly of polymers in response to temperature

Self-assembly of thermo-responsive (or thermogelling) polymers is one of the most popular methods to fabricate hydrogels by a simple change in temperature [38–40]. Temperature-sensitive polymers can be synthesized by post-polymerization grafting of a hydrophobic block to a hydrophilic block or by co-polymerization to create amphiphilic diblock (AB), triblock (ABA or BAB type) or multiblock copolymers. A is a hydrophilic block like PEG (also known as poly(ethylene oxide) (PEO)) while B is a hydrophobic block such as a polyester, poly(propylene oxide) (PPO) (also called poly(propylene glycol) (PPG)), or poly(N-isopropylacrylamide) (PNIPAm). The amphiphilic block copolymers self-assemble in water to form micelles with shells of hydrophilic blocks and cores of hydrophobic blocks at low temperatures, and association of the micelles at elevated temperatures triggers gelation [13]. The temperature at which a thermo-responsive polymer solution changes to a gel is called the gelation temperature.

Poloxamer (ABA type PEO-PPO-PEO polymer) (Fig. 1a), known commercially as Pluronic® (BSAF) or Synperonic® PE (ICI), was the first reported block copolymer system used to form thermo-sensitive hydrogels [41,42]. An aqueous solution of Pluronic® self-assembled to form micelles at ambient temperature, and gelation occurred as a result of association of the micelles at body temperature [43,44]. However, this polymer displayed no capacity for degradation and hydrogels composed of it exhibited weak mechanical strength and short residence time [13,45,46], which limited its applicability for therapeutics delivery. To enhance its stability and mechanical strength, multiblock copolymers of Pluronic® were prepared by coupling PEO and PPO segments or Pluronics® using phosgene or hexamethylene diisocyanate (HDI) as coupling agents, respectively [41]. The multiblock copolymer hydrogels showed significant increases in stability and mechanical strength in comparison to commercial Pluronic® hydrogels at the same concentrations. Even though the resulting multiblock copolymers were more stable in water, they were still not degradable. Aliphatic esters, like poly(ε-caprolactone) (PCL) and poly(lactic acid) (PLA), have been coupled to the ends of Pluronic® via ring opening polymerization (ROP) of corresponding ε-caprolactone (CL) and lactic acid (LA) monomers using stannous octoate (Sn(oct)2) as a catalyst to prepare hydrolytically degradable Pluronic® hydrogels [47,48]. Recently, a multiblock copolymer of Pluronic® based on acid labile acetal linkages was created by reaction of Pluronic® and di-(ethylene glycol) divinylether (DEGDVE) in the presence of a p-toluenesulfonic anhydride (p-TSA) catalyst [49]. Its hydrolytic degradation rate increased with decreasing pH, and the hydrolysis of the hydrogels released Pluronic®, diethylene glycol and acetaldehyde, which do not decrease the pH of the surrounding environment [50].

Fig. 1.

Chemical structures of several (a–j) synthetic and (k–n) natural polymers.

Thermo-sensitive hydrogels based on PEG with aliphatic esters such as PLA, PCL, poly(glycolic acid) (PGA), and poly[(R)-3-hydroxybutyrate] (PHB) have been attractive for bioactive factor delivery because of their biocompatibility and degradability by hydrolysis of ester linkages [51–54]. For example, ABA type PEG-poly(D,L-lactide-co-glycolide)-PEG (PEG-PLGA-PEG) triblock copolymers formed hydrolytically degradable hydrogels [55]. The copolymers were synthesized by two steps. First, the diblock copolymers of monomethoxy PEG-PLGA (MPEG-PLGA) were synthesized via ROP of D,L-lactide (DLLA) and glycolide (GA) on MPEG in the presence of Sn(oct)2 as a catalyst, and subsequently, the triblock PEG-PLGA-PEG copolymers were prepared by coupling the diblock MPEG-PLGA copolymers to each other using an HDI coupling agent. The copolymer solutions existed at low temperatures, but became gels at 37 °C (sol-to-gel transition) [56–58], which were suitable for encapsulation and delivery of labile proteins [59,60]. An in vitro degradation test showed that these hydrogels maintained their integrity for more than 1 month. In another report, BAB type triblock copolymers with PLGA blocks flanked by a central PEG block (PLGA-PEG-PLGA) (Fig. 1b) have also been synthesized via ROP of DLLA and GA on PEG without the need of a coupling agent [61,62]. PLGA-PEG-PLGA exhibited a similar sol-to-gel transition trend to PEG-PCLA-PEG. Gelation and degradation of these hydrogels could be tailored by varying the molecular weight of the hydrophobic and hydrophilic blocks, the composition of the hydrophobic blocks, polymer concentration and additives. Gelation behavior of PLGA-PEG-PLGA was also modulated by incorporation of various end groups (i.e., hydroxyl, acetyl, propionyl, and butanoyl groups) [63]. An increase in hydrophobicity of the copolymers lowered their transition temperature. Several other di- and triblock thermo-sensitive copolymers for therapeutics delivery based on PEG with PCL and poly(δ-valerolactone) (PVL) have also been prepared via ROP using CL and δ-valerolactone (VL) [52,64–66]. Additionally, thermo-responsive poly(ether ester urethane) multiblock copolymers consisting of PEG, PHB and PPG underwent sol-to-gel transition as a result of micellar packing [54].

PNIPAm is one of the most widely explored polymers for use as a thermo-gelling material. PNIPAm is soluble in aqueous solution at room temperature but precipitates above 32 °C (phase transition temperature) due to its coil-to-globule transition [67]. Incorporation of PNIPAm with other polymers results in copolymers that exhibit sol-to-gel phase transition in aqueous solution in response to increased temperature. Radical polymerization is often used to incorporate NIPAm with other methacrylate or acrylate monomers/polymers to create PNIPAm-based polymers. For example, a PNIPAm-poly(2-metha-cryloyloxyethyl phosphorylcholine)-PNIPAm (PNIPAm-MPC-PNIPAm) (Fig. 1c) copolymer was synthesized via atom transfer radical polymerization (ATRP) [68]. ATRP of NIPAm usually takes place in two steps: (1) the preparation of macro-initiator and (2) the addition of NIPAm to the macro-initiator to result in block copolymers. The polymer solution formed a gel as temperature was raised above 32 °C due to hydrophobic interactions between the polymer chains during the formation of a micellar network. It is important to note that ATRP uses CuBr as a catalyst that needs to be removed before the resulting polymers are used as drug delivery systems. Another group used reversible addition-fragmentation chain transfer (RAFT) to produce poly(NIPAm-b-methyl methacrylate) (PNIPAm-PMMA) (Fig. 1d) [69]. Similar to ATRP, RAFT also requires two steps: (1) the synthesis of a macromer-containing chain transfer agent (macro-CTA) and (2) the stepwise addition of NIPAm to the macro-CTA. Partial dehydration of the PNIPAm segment in the polymer above 31 °C led to hydrogel formation.

Degradable, biocompatible and thermo-responsive polyphosphazenes (Fig. 1e) also display sol-to-gel phase transition in aqueous solutions with increasing temperature, and have the potential for bioactive factor delivery [70]. These polymers have been prepared through multi-step syntheses. First, dichlorophosphazene polymers were synthesized via melt polymerization reaction of hexachlorocyclotriphosphazenes using aluminum chloride (AlCl3) as a catalyst. Then, a hydrophilic PEG block and a hydrophobic block were conjugated to the dichlorophos-phazene polymer backbone to obtain hydrogel macromers. The hydrophobic blocks could be di-, tri-, and oligo-peptides or single modified amino acids (e.g., L-isoleucine ethyl ester (IleOEt), D,L-leucine ethyl ester (LeuOEt), L-valine ethyl ester (ValOEt)). Functional substituents could be easily conjugated to the polymer backbone to control hydrogel properties (e.g., gel strength, degradability, etc.) [37,71,72].

An ABA-type triblock copolymer consisting of MPEG and poly(propylene fumarate) (PPF) results in a thermo-sensitive gel that is further stabilized through crosslinking of unsaturated double bonds on PPF [73]. PPF was prepared via transesterification of diethyl fumarate and propy-lene glycol with zinc chloride (ZnCl2) as a catalyst and hydroquinone as a radical inhibitor. Subsequently, trans-esterification of PPF and MPEG was performed to result in the MPEG-PPF-MPEG (Fig. 1f).

It was reported that physical interaction of enantiomeric poly(L-lactide) (PLLA) and poly(D-lactide) (PDLA) induces stereocomplexation between the two enantiomers [74]. This finding was utilized to create hydrogels when blending aqueous solutions of enantiomeric PLLA and PDLA grafted to DEX [75]. Mechanical strength of the hydrogels decreased with increased temperature and was restored when the temperature was lowered. The mechanical strength and formation of the hydrogels could be modulated by changing the molecular weight, the degree of substitution of the enantiomers and/or the polymer concentration. Mixing of enantiomeric PEG-P(L-lactide)-PEG (PEG-PLLA-PEG) and PEG-P(D-lactide)-PEG (PEG-PDLA-PEG) triblock copolymers induced sol-to-gel transition [76]. Hydrogels were formed when temperature increased to 37 °C and they became solutions above 70 °C. Similarly, hydrogels can be formed by stereocomplexation of enantiomeric PEG-(PLLA)8 and PEG-(PDLA)8 star block, and PEG-(PLLA)2 and PEG-(PDLA)2 triblock copolymers [77,78].

In addition to self-assembly of synthetic polymers, natural materials chemically modified with synthetic molecules can also self-assemble in aqueous media to form hydrogels. For example, chitosan, a polysaccharide derived from the partial deacetylation of naturally abundant chitin, has been extensively studied for biomedical and pharmaceutical applications on account of its biocompatibility, biodegradability (mainly by lysozyme) and non-toxicity (Fig. 1l). Chitosan can form physical hydrogels when conjugated with several polymers. For instance, PEG-aldehyde was coupled to chitosan via Schiff’s base reaction followed by reduction with sodium cyanoborohydride (NaBH3CN) to yield PEG-g-chitosan [79]. The resulting graft polymer was a solution at low temperatures and transformed to a gel at body temperature. The gelation was attributed to hydrophobic interactions between the polymer chains, which leads to association of chitosan segments and a decrease in PEG mobility. Similarly, Pluronic®-g-chitosan also exhibits thermo-reversible sol-to-gel transition upon heating [80].

2.1.2. Self-assembly of polymers in response to both pH and temperature

Ionic polymers that are sensitive to pH (and often to temperature) can ionically interact with counter-ionic bioactive factors; hence, they may be valuable for bioactive molecules delivery. In this section, we review some polymers bearing cationic or anionic groups that exhibit sol-to-gel transition in response to both pH and temperature.

A poly(amidoamine)-PEG-poly(amidoamine) (PAA-PEG-PAA) copolymer (Fig. 1g) was synthesized by the addition of 4,4-trimethylene dipiperidine (TMDP) and 1,10-decylene diacrylamide to amine-functionalized PEG via Michael-type step polymerization [81]. The PAA block is hydrophilic at low pH, but it becomes more hydrophobic at a higher pH and/or temperature because of deprotonation of the tertiary amine groups on PAA. Micelles formed as the hydrophobicity of PAA increased and aggregation of the micelles at higher pH and/or temperature led to gelation. Unlike polymers bearing amine groups, a triblock copolymer with a central PEO block flanked by poly(methoxydi(ethylene glycol) methacrylate-co-methacrylic acid) (P(DEGMMA-co-MAA)-b-PEO-b-P(DEGMMA-co-MAA)) synthesized through ATRP could gel at acidic pH as a result of the carboxylic acid groups [82]. In addition, synthesized multiblock poly(amino urea urethane) (PAUU) composed of PEG, 2-hydroxyethyl piperazine and HDI could form a gel in response to pH and temperature [83]. However, these copolymers are not degradable; hence, their practical application as therapeutics delivery vehicles of biologics may be limited.

One approach to prepare degradable pH- and temperature-sensitive polymers is that non-degradable ionic groups have been coupled to hydrolytically degradable thermo-sensitive polymers. The first example of biodegradable pH- and temperature-sensitive copolymer hydrogels was based on anionic oligomer sulfamethazine (OSM) [84]. A biodegradable thermo-sensitive triblock copolymer of poly(CL-co-LA)-PEG-poly(CL-co-LA) (PCLA-PEG-PCLA) was synthesized via ROP of CL and LA monomers on PEG; subsequently, the OSM was conjugated to the end groups of the copolymer using 4-(dimethylamino)pyridine (DMAP)/N,N′-dicyclohexylcarbodiimide (DCC) chemistry. At high pH (e.g., 8.0), the OSM blocks were ionized and the block copolymer was a free flowing sol. Deionization of the OSM at lower pH (e.g., 7.4) resulted in sol-to-gel transition with increasing temperature. The gel window was adjusted by varying the molecular weights of OSM, PEG and the PCLA blocks as well as the polymer concentration [84]. Similarly, cationic biodegradable poly(β-aminoester)s (PAE)s were extended to an acrylate-activated PCL-PEG-PCL copolymer via Michael addition polymerization using 1,4-butandiol diacrylate (BDA) and TMDP [85,86]. The polymers underwent sol-to-gel transition at basic pH but were solutions at acidic pH. Recently, a series of dual responsive amphiphilic block copolymers based on poly(amino ester urethane) (PAEU) (Fig. 1h) or PAE with a central PEG block were synthesized via Michael addition polymerization, which formed gels at body temperature [87,88]. These polymers are constructed such that their pH-sensitive segments can hydrolyze in aqueous media, without conjugating to hydrolysable temperature sensitive polymers. Cationic chitosan has also been used to prepare pH- and temperature-sensitive hydrogels. Palmitic acid N-hydroxysuccinimide (PANHS) ester was grafted to chitosan to produce a biodegradable and biocompatible pH-triggered N-palmitoyl-chitosan hydrogel in the pH range of 6.5–7.0 [89]. Rheological measurements demonstrated that the hydrogel storage modulus remained constant between 4 and 50 °C. The gelation process involved a balance between charge repulsion and hydrophobic interactions.

2.1.3. Self-assembly of polymers based on inclusion complexes

Hydrogels formed based on inclusion complexes between polymers and cyclodextrins (CDs) have gained increasing interest as promising materials for therapeutic delivery [90,91]. CDs are cyclic oligosaccharides composed of 6, 7 or 8 D(+)-glucose units circled by D(+)-1,4-bonds (called α-, β- and γ-CD, respectively) with a hydrophobic inner cavity and a hydrophilic exterior. Several molecules can penetrate to the cavity of CDs to form inclusion complexes with necklace-like supramolecular structures, which have been used as a crosslinking method for preparation of supramolecular hydrogels [91]. For example, a linear water-soluble polymer such as high molecular weight PEO could be inserted into the pocket of α-CD to induce inclusion complexes [90,92]. The supramolec-ular self-assembly of the inclusion complexes in water induced physically crosslinked hydrogels. Gelation kinetics depended on the concentration of PEO and α-CD as well as the molecular weight of PEO. The use of linear, high molecular weight PEG to produce supramolecular inclusion complexes led to the rapid dissociation (a few days) of the resulting hydrogels. To prepare more stable hydrogels, triblock copolymers composed of a central PPO flanked with PEO blocks were used to form inclusion complexes with α-CD [93,94]. PEO-PHB-PEO could also gel in the presence of α-CD due to the cooperative effect of complexation of PEO with α-CD and hydrophobic interactions between PHB blocks [95]. The use of the polymers with the central hydrophobic blocks resulted in more stable hydrogels. Recently, β-CD/cholesterol inclusion complexes driven by hydrophobic and van der Waals interactions induced thermo-reversible hydrogels when β-CD and cholesterol end-capped 8-arm PEG solutions were mixed [96,97]. The hydrogel properties were a function of the polymer concentration, α-CD/cholesterol stoichiometry, molecular weight of PEG [97] and PEG architecture [98]. Mass loss of the hydrogels in phosphate-buffered saline (PBS) occurred through surface degradation. It is important to note, however, that when some therapeutics are included in the inclusion complex approach for hydrogel preparation, they can competitively interact with the CDs, leading to changes in the physical and chemical properties of gels.

2.1.4. Self-assembly of peptides

Self-assembly of peptides and proteins is a promising approach for constructing hydrogels with many potential biomedical applications including bioactive molecule delivery [99–103]. Peptides and proteins can have α-helix, β-sheet, and random coil structures under specific conditions and their building blocks can be prepared with controllable hydrophobic, hydrophilic and ionic characteristics [103]. Their self-assembly is highly specific among the peptide building blocks, sensitive to external stimuli (such as pH or temperature discussed in the previous sections, or ionic strength) and reversible [104]. Zhang and colleagues utilized self-assembling technology to prepare macroscopic peptide hydrogels. An ERK 16 peptide (Ala-Glu-Ala-Glu-Ala-Lys-Ala-Lys)2 displayed β-sheet structure in water, and it assembled to form a stable macroscopic hydrogel membrane in PBS [105]. The complementary ionic bridges between negatively charged Glu and positively charged Lys on one side of the β-sheet and hydrophobic interactions between Ala molecules on the other side resulted in gelation. The same group also used this approach to fabricate other self-assembling peptide hydrogels [101,106–109]. Yang and colleagues introduced peptide-grafted copolymers gelling through the formation of antiparallel heterodimeric coiled-coils [110]. The peptide-grafted copolymers forming antiparallel heterodimeric coiled-coils were synthesized via 3 steps. First, amino functionalized poly(N-(2-hydroxypropyl)methacrylamide) (PHPMA) was prepared though free radical polymerization in the presence of HPMA and N-(3-aminopropyl)methacrylamide (APMA) using an AIBN catalyst. Next, the resulting polymer was functionalized with maleimide groups, and finally, cysteine-modified pentaheptad peptides (CCE and CCK) were attached to the polymer via thioether bonds. The equimolar mixtures of CCE and CCK grafted polymers self-assembled through the two-stranded α-helical coiled-coil formation between CCE and CCK, resulting in reversible hydrogel formation. The same group also applied that synthetic route for conjugating cysteine-modified β-sheet peptide, Cys-Gly-Gly tripeptides-modified Beta11, to the polymer via thioether bonds [111]. Beta11 (Ac-Thr-Thr-Arg-Phe-Thr-Trp-Thr-Phe-Thr-Thr-Thr-NH2) peptide is produced via solid phase synthesis. The resulting peptide-grafted copolymer formed a gel as a result of self-assembly of the copolymers through intermolecular association of the peptides into antiparallel β-sheets. The polymer solution formed gels in minutes to days, depending on polymer concentration. In other work, an artificial protein composed of short “leucine zipper” end blocks flanking a water polyelectrolyte domain was synthesized using recombinant DNA methods [112]. A “leucine zipper” is a protein–protein binding domain containing dimers of parallel, amphipathic α-helices that form a coiled-coil. The gelation of the artificial protein was driven by the formation of coiled-coil aggregates of the terminal “leucine zipper” peptide domains. The gels changed to a fluid as the coiled-coil aggregates dissociated with increasing temperature and pH. In addition, thermo-reversible hydrogels were also obtained by conjugation of polyalanine (PA) to PPG-PEG-PPG bis(2-aminopropyl ether) (PLX) via ROP of the N-carboxy anhydrides (NCA) of alanine in the presence of PLX [113]. The PA-PLX-PA copolymer in aqueous solution displayed sol-to-gel transition with increasing temperature. As temperature increased, secondary structure of PA changed from random coil structure to β-sheet, leading to sol-to-gel transition. Recently, a series of copolymers of MPEG-poly(L-glutamate)s with different hydrophobic side groups, such as methyl, ethyl, n-propyl and n-butyl has been synthesized via ROP and they underwent sol-to-gel transition when temperature increased [114]. The partial dehydration of MPEG and β-sheet formation in the polypeptides led to the gelation.

2.2. Chemically crosslinked hydrogels

In contrast to physically crosslinked hydrogels, chemically crosslinked networks can be constructed through chemical reactions, for example: Schiff’s base, enzyme-mediated, click, photopolymerization, Michael-type addition, and disulfide formation reactions. The chemical crosslinking methods result in hydrogels with controllable crosslink density and network properties.

2.2.1. Photocrosslinked hydrogels

Photocrosslinked hydrogels have gained great attention in biomedical applications because aqueous macromer solutions can form in situ hydrogels under short exposure to visible or ultraviolet (UV) light in the presence of light-sensitive compounds (called photoinitiators). The most common approach involves UV light decomposing photoinitiators to generate free radicals which initiate methacrylate or acrylate end-capped macromers to produce photocrosslinked hydrogels with low cytotoxicity [115]. Photopolymerization strategies can provide excellent spatiotemporal control over network formation and fast gelation kinetics (seconds to minutes) at room or physiological temperatures, and produce minimal heat, which is desirable for in situ encapsulation of fragile bioactive factors [115]. The hydrogels can be fabricated in vitro before being implanted into the body [31] or the photopolymerizable macromer solutions can be injected into the body and the gels are then formed by applying UV light externally through skin [17,116]. A limitation of these systems is the decreased penetration of the UV light though increased tissue depth [116], however UV light may be applied at specific locations using, for example, a fiber optic cable. Hydrogel properties such as mechanical strength and degradation rate are tailored by varying crosslink density, polymer concentration and polymer molecular weight [28,117,118].

Sawhney et al. first introduced a photopolymeriz-able and biodegradable hydrogel consisting of a synthetic poly(α-hydroxy acid)-PEG-poly(α-hydroxy acid) triblock copolymer terminated with acrylate groups [119]. The macromer was synthesized via ROP of DLLA on PEG and subsequently reacted with acryloyl chloride (AC) to terminate the macromer with acrylate groups. An acrylated macromer solution with 2,2-dimethoxy-2-phenylacetophenone (Irgacure 651) photoinitiator or a mixture of ethyl eosin and triethanolamine rapidly formed a gel under exposure to UV light or visible light, respectively. In addition, PEG-diacrylate (PEGDA) was also found to form biocompatible hydrogels in the presence of Irgacure 651 photoinitiator (Fig. 1i) [120]. Even though the ester end groups of PEGDA are hydrolytically cleavable, the hydrogel is stable at physiological conditions. Therefore, PEGDA has been mixed with biodegradable PEG-lactic acid-diacrylate (PEGLADA) to enhance its degradation [121]. Recently, photopolymerizable thermo-sensitive triblock copolymers composed of a central PEG block extended with partly methacrylated poly(HPMA lactate) (PHPMAlac) blocks at two ends formed hydrogels under exposure to UV light (Fig. 1j) [122]. Changing the degree of methacrylation and molecular weight of the PEG blocks could regulate gel strength and degradation rate.

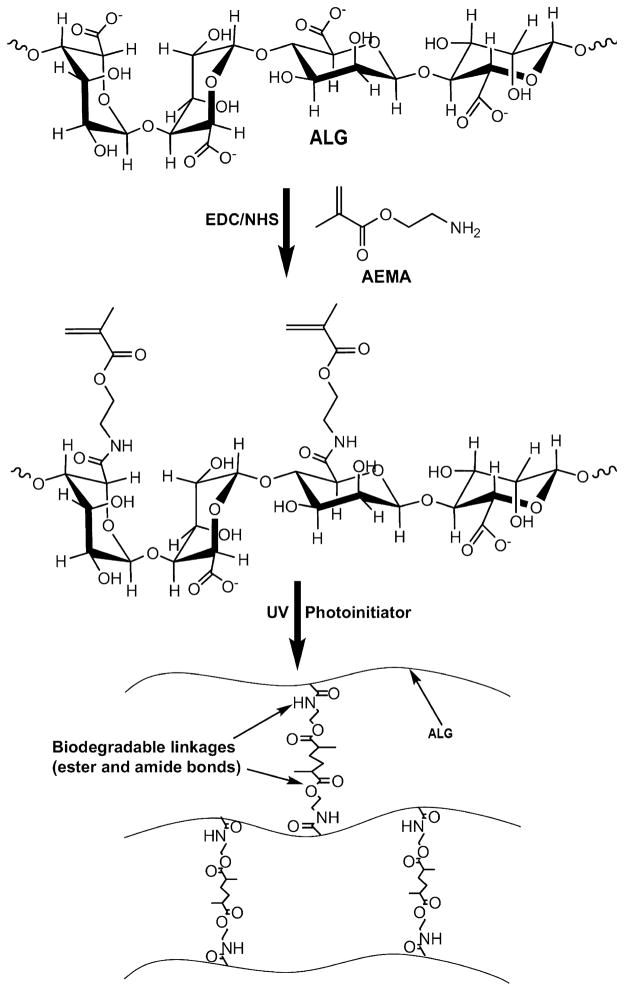

Methacrylated HA conjugates were synthesized by coupling synthetic GMA or methacrylic anhydride (MA) to natural HA (Fig. 1k), and then they were exposed to UV light in the presence of 4-(2-hydroxyethoxy)phenyl-(2-hydroxy-2-propyl)ketone (Irgacure 2959) photoinitiator to fabricate cytocompatible hydrogels [123,124]. Recently, our lab has developed biodegradable, cytocompatible hydrogels for therapeutics delivery using methacrylated ALG (ALG-MA) [28,31,125–129]. The material was produced using EDC chemistry (Fig. 2) by conjugating 2-aminoethyl methacrylate (AEMA) to carboxylic acid groups of ALG in the presence of 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS). Swelling behavior, mechanical properties and degradation profiles depend on the degree of methacrylation as well as the surrounding aqueous environment composition. Similarly, water-soluble natural carboxymethylcellulose (CMC) was coupled with AEMA via EDC chemistry to achieve CMC-AEMA macromers [130]. The macromers were photocrosslinked with PEG-dimethacrylate (PEGDM) to form cytocompatible and degradable hydrogels.

Fig. 2.

Synthesis of methacrylated alginate (ALG) and hydrogel formation via photocrosslinking. Reproduced with permission from [28]. Copyright 2009 Elsevier.

Recently, step-growth thiol-ene photopolymerization based on a reaction of a thiol and a vinyl group in the presence of a photoinitiator has been exploited to prepare hydrogels [131]. In contrast to chain growth of acrylate macromers upon UV exposure, the thiol-ene reaction forms step growth networks. The thiol-ene reactions rapidly complete using small amount of photoinitiator and are not influenced by oxygen inhibition [132]. The hydrogels are mainly based on 4-arm-PEG, which was reacted with 5-norbornene-2-carboxylic acid (NORB) to form 4-arm-PEG-NORB. Subsequently, the NORB-terminated PEG solution containing Irgacure 2959 crosslinked with dithiol-functionalized chymotrypsin-degradable peptides under exposure to UV light to result in hydrogel formation [131]. The light first abstracted a hydrogen atom from a thiol to generate a thiyl radical that then propagated across a carbon-carbon double bond of norbornene. Thereafter, the resulting radical on the carbon double bond reacted with another thiol to form a thioether linkage, which released another thiyl radical. The norbornene groups were completely consumed by 12 min, and the photopolymerization kinetics could be controlled by changes in initiator concentration. Degradation of the step growth thiol-ene hydrogels composed of 4-arm-PEG-NORB and dithiol crosslinkers depended on pH and crosslinking density [133].

2.2.2. Michael addition

Michael reaction between thiol groups and methacry-late/acrylate or vinyl groups occurs rapidly at physiological conditions without the addition of chemicals or catalysts or interaction with amine groups of proteins [134]. The reaction allows macromer solutions to gel in contact with living tissue, biologic molecules and cells without crosslinking to them, and is suitable for forming hydrogel matrices for bioactive molecule delivery. Elbert et al. first introduced this type of hydrogel by mixing PEG-acrylates with PEG-dithiol at 1:1 stoichiometry and physiological pH [134]. A solution of PEG-octaacrylate and PEG-dithiol formed a gel within a minute but complete gelation required more than 1 h at physiological conditions. The hydrogels formed with a greater number of acrylate groups display lower swelling ratios and slower degradation rates compared to those with a lower number of acrylate groups. Albumin was homogeneously encapsulated into the gels during gelation without reacting with the macromers. Disulfide formation between thiol groups was negligible on the time scale of the gelation process [135]. A simultaneously physically and chemically gelling polymer system consisting of poly(NIPAm-co-cysteamine) and PEGDA was reported by another group [136]. NIPAm first was copolymerized with N-acryloxysuccinimide (NASI) via free radical polymerization. The resulting poly(NIPAm-co-NASI) was then modified with cysteamine via a reaction of NASI and the amine group of cysteamine to obtain thermo-sensitive poly(NIPAm-co-cysteamine). In addition to exhibiting thermo-sensitive gelation due to the presence of NIPAm, poly(NIPAm-co-cysteamine) also crosslinked with PEGDA via Michael-type reaction. The physically and chemically crosslinked material displayed much improved mechanical properties compared to the poly(NIPAm-co-cysteamine) physical gels alone.

Shu and colleagues combined modified natural and synthetic polymers to form hydrogels in situ via Michael-type addition [137]. Dithiobis(propanoicdihydrazide) (DTP) was reacted with HA via EDC chemistry followed by reducing their initial disulfide bonds using dithiothreitol (DTT) to obtain thiolated HA (i.e., HA-DTP). A mixture of HA-DTP and PEGDA solutions formed hydrogels within 9 min. In a separate work, thiolated-DEX (DEX-SH) was crosslinked with PEG-tetracrylate or DEX-vinyl sulfone (DEX-VS) to create hydrogels that rapidly formed in situ under physiological conditions [138]. To synthesize DEX-SH, DEX (Fig. 1m) was first activated with 4-nitrophenyl chloroformarate, which subsequently was reacted with cysteamine. DEX-VS was prepared by the reaction of DEX with vinyl sulfone alkanoic acid, a product of the reaction between mercaptoalkanoic acid and divinyl sulfone. Recently, hydrogels based on thermo-sensitive triblock copolymers with HA-SH have been reported [139]. Methacrylated/acrylated thermo-sensitive triblock copolymers consisting a central PEG block flanked by two (PNIPAm)/PHPMAlac) blocks formed a physical gel at body temperature, which was further crosslinked with HA-SH to yield an injectable, degradable hydrogel. Acrylated copolymers showed higher reactivity toward HA-SH compared to methacrylated analogs, resulting in more rapidly formed gels with higher mechanical strength. Interestingly, a cysteine-containing matrix metalloproteinase (MMP) sensitive peptide susceptible to proteolytic degradation was used to form hydrogels via Michael reaction with multi-arm PEG-VS [30,140], and these resultant hydrogels could be broken down by cells proteolytically invading the matrices [140]. The reaction rate of hydrogels formed with these macromers could be regulated by pH and the addition of charged amino acid residues in close proximity to the cysteine residue, which modulated the pKa of the thiol groups [141].

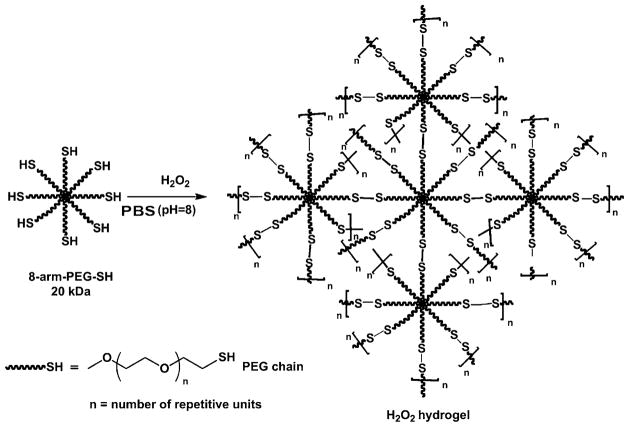

2.2.3. Disulfide formation

Polymers with thiol groups, or thiomers, can form inter-and/or intramolecular disulfide bonds at pH above 5 in the absence of toxic crosslinkers to yield in situ hydrogels [142,143]. Disulfide crosslinked hydrogels form via oxidation of thiol groups in air or oxidizing agents. While air drives disulfide formation over a time period of several minutes to hours, oxidizing agents (i.e., H2O2, sodium periodate (NaIO4), ammonium persulfate ((NH4)2S2O8), sodium hypochlorite (NaOCl) and sodium borohydride (NaBH4)) can reduce the reaction time [144]. Shu et al. introduced reversible hydrogels from thiolated HA through a disulfide crosslinking strategy under physiological conditions [32]. HA-dithiobis(butyric dihydrazide) (HA-DTB) was prepared in the same way to the synthesis of HA-DTP. The number of disulfide linkages formed increased when the thiol groups were oxidized by hydrogen peroxide (H2O2) rather than air. HA-DTP displayed faster gelation when in contact with air compared to HA-DTB, due to the lower pKa of thiols in HA-DTP. Similarly, gelatin was modified with DTP using EDC chemistry and the resulting gelatin-DTP crosslinked with HA-DTB to form hydrogels [145]. 8-arm-PEG-SH formed gels through intra- and/or intermolecular disulfide bridges in the presence of H2O2 (Fig. 3) [146]. In contrast, hydrogels resulted from the exclusively intermolecular disulfide formation between 8-arm-PEG-SH and 8-arm-PEG-S-thiopyridyl (8-arm-PEGS-TP) at pH 8.0 without oxidation. In a separate work, pyridyl disulfide-modified HA (HA-PD) was crosslinked with PEG-dithiol via thiol-disulfide exchange reaction in minutes to produce hydrogels at physiological conditions [147]. HA was reacted with 1,6-diaminohexane using EDC chemistry to obtain amine-modified HA, followed by reaction with N-succinimidyl 3-(2-pyridyldithio)propionate (SPDP), yielding HA-PD. However, the gelation process generated potentially toxic chromogenic pyridine-2-thione byproducts that could be removed by incubating the formed gels in aqueous solution.

Fig. 3.

Schematic illustration of intra- and inter-molecular crosslinking of 8-arm-poly(ethylene glycol)-thiol (8-arm-PEG-SH) by H2 O2 in PBS (pH 8) via formation of disulfide linkages.

Reproduced with permission from [146]. Copyright 2011 Elsevier.

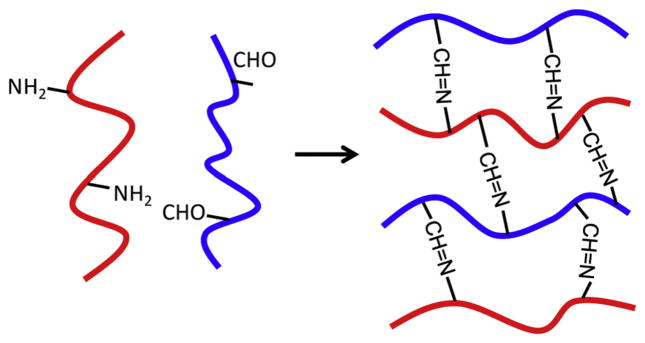

2.2.4. Schiff’s base reaction

Schiff’s base crosslinking reaction is a condensation of aldehyde with amine groups without use of any chemicals or catalysts. Therefore, macromers with aldehyde groups can react with those containing amine groups to form hydrogels at physiological conditions (Fig. 4). Polysaccharides are often oxidized by the reaction with NaIO4 to create aldehyde groups on their main chain. Gelation reaction of aldehyde-modified DEX (DEX-CHO) and amino groups in gelatin was reported by Schacht et al. for the preparation of in situ forming hydrogels [148]. The gelation rate was dependent on macromer solution pH and ionic strength, and gel strength increased with the degree of DEX oxidation. In another work, Schiff’s base crosslink-formation between aldehyde groups in DEX-CHO and hydrazide groups in adipic acid dihydrazide (AAD) resulted in gel formation within 2–4 min [149]. Degradation rate of the hydrogels decreased with increasing AAD concentration. Solutions of oxidized-ALG and gelatin in the presence of borax (sodium tetraborate or Na2B4O7) rapidly formed gels in a few seconds to less than a minute [150]. Decreased gelation time was achieved when increasing the macromers concentration, borax concentration and/or extent of oxidation. DEX-CHO or oxidized carboxymethylcellulose (CMC-CHO) could also copolymerize with hydrazide-modified carboxymethyldextran (CMDX-ADH) to form hydrogels [151]. In addition, oxidized HA (HA-CHO) has been crosslinked with N-succinyl-chitosan (S-chitosan) via Schiff’s base reaction for preparation of injectable biodegradable in situ formed hydrogels [152]. Chitosan has poor solubility in water under physiological pH; therefore, the succinyl groups were introduced at the N-position of the glucosamine units to enhance its solubility. Gelation occurred within 1–4 min as a function of HA-CHO and S-chitosan ratio. In addition, pH and temperature dually responsive injectable hydrogels based on biocompatible glycol chitosan and thermo-sensitive benzaldehyde-capped Pluronic® were reported [153]. In the approach using Schiff’s base reaction to form hydrogels, aldehydes of macromers can also react with some tissues and encapsulated payloads containing amine groups [154,155], which leads to delayed release or/and may alter hydrogel properties.

Fig. 4.

Schematic of hydrogel formation via Schiff’s base crosslinking reaction (–CH=N–) upon mixing of a macromer containing reactive amine groups with another macromer containing aldehyde groups in aqueous solutions under physiological conditions.

2.2.5. Enzyme-crosslinked

Enzymatic reactions provide an excellent strategy to prepare chemically crosslinked hydrogels because they exhibit high specificity and can occur in aqueous media at physiological conditions without unwanted side reactions or cytotoxicity [156].

Some solutions of modified macromers can be crosslinked by addition of horseradish peroxidase (HRP) and H2O2 to form hydrogels [157]. HRP is a single-chain b-type hemoprotein that acts as a catalyst for inducing the oxidative coupling of phenol moieties in the presence of H2O2 as an oxidant. The oxidative reaction proceeds at C–C and C–O sites between the phenols under mild conditions. Kurisawa et al. reported an in situ biocompatible hydrogel system based on HA-tyramine using a peroxidase catalyzed oxidation reaction [157]. The amine group of tyramine was conjugated to the carboxylic acid groups of HA through EDC chemistry to create HA-tyramine conjugates, which gelled quickly within 20 s upon oxidation by H2O2 and HRP. In vivo gelation was performed via injection into mice using a syringe. Subsequently, different materials such as chitosan [158], DEX [159], CMC [160], ALG [161], PEG/CD [162] and gelatin/4-arm PPO-PEO [163] have been used to prepare chemically crosslinked hydrogels using peroxidases.

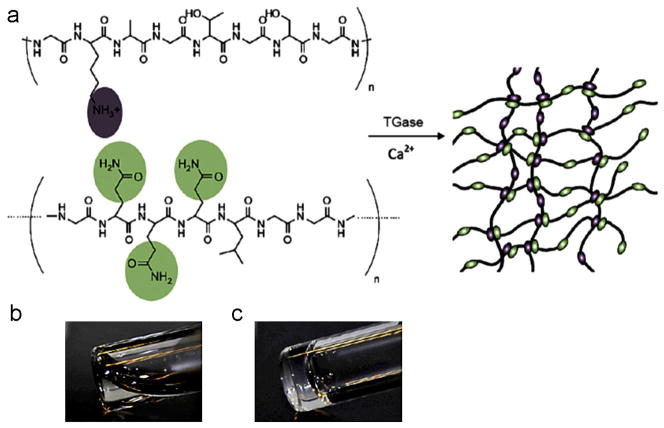

Transglutaminases (TGase) catalyze the formation of covalent γ-glutamyl-ε-lysine bonds between the γ-carboxamide group of a peptide-bound glutamine residue and ε-amino group of a peptide bound lysine or the primary amino group of polyamine in a calcium-dependent reaction [164]. TGase has been exploited to catalyze formation of hydrogels under mild and biocompatible conditions. Schense and colleagues prepared fibrin hydrogels by covalently crosslinking bi-domain peptides during fibrinogen polymerization to fibrin through the action of TGase factor XIIIa [165,166]. PEG-peptide conjugates containing glutamine and lysine residues formed in situ hydrogels within minutes under physiological conditions in the presence of TGase [167]. TGase was also used to prepare enzyme-crosslinked gelatin hydrogels which were resistant to thermal degradation, but susceptible to proteolytic degradation [168]. Additionally, cytocompatible TGase-catalyzed hydrogels were prepared via the crosslinking of genetically engineered protein polymers serving as lysine substrates with random coil glutamine containing proteins (Fig. 5) [169]. Complete crosslinking occurred within 2 min under physiological conditions with catalysis by TGase. Changing compositions of precursors regulated gel strength, swelling properties and microstructure of the hydrogels. When incubated in a plasmin solution over the course of 1 week, the hydrogels degraded at different rates depending on hydrogel composition.

Fig. 5.

(a) Protein polymer hydrogel formation by transglutaminase (TGase) enzymatic crosslinking. The top of (a) is engineered protein polymer as a lysine substrate and the bottom of (a) is random coil glutamine containing protein. (b and c) Photographs of the precursor solution before and after enzymatic gelation.

Reproduced with permission from [169]. Copyright 2010 Elsevier.

In addition to HRP/H2O2 and TGase enzymes, other enzymes, such as tyrosinase [170], phosphopantetheinyl transferase [171], an acid phosphatase [172], thermolysin [173], lysyl oxidase [174] and an esterase [175], have been harnessed to catalyze hydrogel formation. However, the instability of some enzymes (such as TGase and tyrosinases) and the presence of remaining enzymes within biomaterials following gelation must be considered when using this gelation approach.

2.2.6. Click reaction

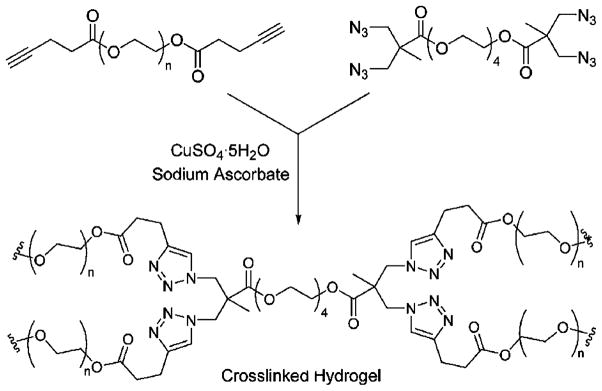

Click chemistry described reactions that exhibit high efficiency, high specificity and controllable reaction kinetics, and it is of interest as a crosslinking strategy for hydrogel formation. One example of click chemistry is a Huisgen cycloaddition reaction between an organic azide and an alkyne. The reaction is fast and complete when copper (I) (Cu(I)) is used as a catalyst. However, the presence of Cu(I) in the hydrogels is undesirable because of its potential toxicity [176], and it needs to be removed prior to using the formed hydrogels in biomedical applications [177]. The first example of “click reaction”-based hydrogels used poly(vinyl alcohol) (PVA) [178]. PVA was functionalized with 1-azido-2-aminoethane and propargylamine (or N-methylpropargylamine) to prepare azide- and alkyl-modified PVAs, respectively. Upon simple mixing of the PVA macromers in the presence of Cu(I) and sodium ascorbate in water, the hydrogels formed via chemoselective 1,3-cycloaddition between azido and alkynyl functional groups of PVA within minutes. The properties of these hydrogels were highly dependent on the polymer structure and concentration, stoichiometry, and catalyst concentration. This chemistry was also used to prepare PEG (Fig. 6) [177,179], HA [180], guar [181] and thermo-sensitive p(NIPAm-co-HEMA)/cellulose [182] gels. Recently, a Cu(I)-free azide-alkyne click reaction has been explored for the preparation of hydrogels [183]; however, it took hours to days for hydrogel formation. In addition, hydrogels have also been formed via the Cu(I)-free Diels–Alder reaction; similar to the Cu(I)-free azide-alkyne system, hydrogel precursor solutions required long incubation times for gelation [184]. Although click chemistry is a promising potential method for making hydrogels, more efforts are needed to improve its applicability.

Fig. 6.

Hydrogel formation of diacetylene-functionalized and tetraazide-functionalized poly(ethylene glycol) macromers via click chemistry. Reproduced with permission from [177]. Copyright 2006 Royal Society of Chemistry.

2.2.7. Other chemical crosslinking methods

Genipin, a natural product, isolated from gardenia fruit can crosslink functional amine groups of macromers to form biocompatible hydrogels [185–189]. The genipin crosslinker has been employed to fabricate hydrogels based on polymers containing primary amine groups, such as amine-terminated PEG [187,190], gelatin [191] and chi-tosan [192,193].

Redox reactions that use ammonium persulfate/N,N,N′,N′-tetramethylethylene diamine (APS/TEMED) or APS/ascorbic acid can produce free radicals in aqueous solutions for polymerization of methacrylate/acrylate-modified macromers. Hydrogels based on DEX and PEG methacrylate [194], PEGLADA [195], and LA-Pluronic®-LA acrylate [196], poly(propylene fumarate-co-ethylene glycol) [P(PF-co-EG)] acrylate [197] and acrylate functionalized ortho-nitrobenzylether (o-NBE)-PEG-o-NBE [198,199] were synthesized via redox reactions.

2.3. Ionically crosslinked hydrogels

Several ions, such as divalent cations (e.g., Ca2+) and anions (e.g., β-glycerophosphate (BGP)), can result in reversible hydrogels upon formation of ionic bridges between the ions and some biomaterials (e.g., chitosan, ALG). BGP was slowly added to a chitosan solution to obtain a clear liquid solution with pH of 7.15 [200]. The BGP/chitosan solution became a gel when exposed to body temperature and the gelation temperature increased with decreasing degree of deacetylation of chitosan. The addition of BGP to the chitosan solution affected electrostatic and hydrophobic interactions and hydrogen bonding between chitosan chains, which drove gel formation. One of the most studied methods to crosslink ALG is the use of divalent cation crosslinking agents (e.g., Ca2+, Ba2+, etc.) [201–203]. The crosslinking occurs between the divalent cations and the carboxylic acid groups in α-guluronic acid (G) of ALG, resulting in an egg-box structure, and the divalent cations need to crosslink with a minimum 20 G in a row for ALG hydrogels to form [204]. Calcium sulfate (CaSO4), calcium chloride (CaCl2) and calcium carbonate (CaCO3) are examples of some of the chemicals that have been used to ionically crosslink ALG with calcium [205]. Reaction of ALG with highly soluble CaCl2 resulted in hydrogels with nonuniform structure because of the difficulty in controlling the gelation kinetics, which occurred rapidly. In contrast, CaSO4 and CaCO3 allowed for crosslinking at a slower rate because of their lower solubility. ALG has been crosslinked with CaCO3 in the presence of D-glucono-d-lactone to form hydrogels with structural uniformity and controllable, consistent mechanical properties [205]. The addition of D-glucono-d-lactone triggers liberation of Ca2+ from CaCO3, which is not soluble in water at neutral pH. Hence, by lowering the pH, the crosslinking reaction was controlled by the liberated Ca2+. At lower temperatures, the crosslinking was slower, resulting in hydrogels with well-ordered structure and enhanced gel strength [201]. ALG with greater G content formed hydrogels with greater stiffness than those made with lower G content ALG [206].

2.4. Biomolecule recognition

Molecular recognition based on interactions between biological molecules (e.g., protein–ligand, protein–DNA, DNA–DNA, etc.) is important for many biological processes in living organisms [127]. Incorporation of such biomolecules into polymers can result in biomolecule recognition hydrogels [207]. These hydrogels can respond to free specific molecules in solution by, for example, swelling or shrinking, which renders them valuable for regulating delivery of therapeutics.

For example, antibodies are globular proteins that use their specific binding portions to recognize and capture foreign molecules, namely antigens, in the body. Antibody–antigen recognition occurs in the immune system via multiple noncovalent interactions such as electrostatic forces, hydrogen bonds, van der Waals forces and hydrophobic forces [208]. Utilizing this natural recognition phenomenon, antigen responsive hydrogels were prepared by incorporating an antigen and a corresponding antibody into a semi-interpenetrating network (semi-IPN) [209]. Goat anti-rabbit immunoglobulin G (GAR IgG) as the antibody and rabbit IgG as the antigen were chemically conjugated to NASI to create vinyl-antibody and -antigen. A linear copolymer consisting of the vinyl GAR IgG and acry-lamide (AAm) was then synthesized. The antibody–antigen semi-IPN was prepared by copolymerization of vinyl antigen using N,N′-methylene bisacrylamide (MBA) as a crosslinker in the presence of the GAR IgG copolymer. The hydrogel was able to swell rapidly by addition of free rabbit IgG but shrunk gradually in the absence of the antigen. The swelling was dependent upon the free rabbit IgG concentrations, which demonstrated that the semi-IPN was sensitive to the presence of exogenous antigen. Free rabbit IgG dissociated the antibody–antigen bonds.

Molecular imprinting is an efficient way to prepare cavities in crosslinked polymer networks for molecular recognition. To create a molecularly imprinted hydrogel, a print molecule is physically entrapped in a hydrogel, and subsequently it is removed from the hydrogel to yield selective molecular recognition sites or molecular cavities. Upon immersion in a solution containing the same print molecules, the molecularly imprinted hydrogels recognize these molecules via shape complementarity at the previously imprinted sites and can bind reversibly. An example of such hydrogels is molecularly imprinted hydrogels prepared via copolymerization of AAm with acrylic acid (AAc) in the presence of “print molecules” like norephedrine or adrenaline [210]. The hydrogels were swollen at low temperatures and collapsed at high temperatures. In the swollen state, swelling ratio of the hydrogels prepared using norephedrine as an imprint molecule did not change by the addition of norephedrine. In contrast, in the collapsed state the hydrogels showed an increased swelling ratio as norephedrine concentration in water increased. Similarly, swelling ratio of the hydrogels using adrenaline as a print molecule increased when adrenaline was added in the collapsed state only. These results indicate that the hydrogels only memorized the print molecules when they were in the collapsed state. In addition, the hydrogels prepared using norephedrine did not recognize adrenaline and those with adrenaline did not recognize norephedrine. The enhanced adsorption of the corresponding guest molecules was likely due to the formation of molecule-specific binding sites during the hydrogel shrinkage. These molecular recognition hydrogels were responsive to the concentration of guest molecules in the swelling media.

Another approach involved tumor marker responsive hydrogels prepared by biomolecular imprinting using lectin and antibody molecules as ligands for a tumor-specific marker responsive glycoprotein (α-fetoprotein (AFP)) [211]. Lectins and antibodies were used to recognize polysaccharide and peptide chains in AFP. Vinyl groups were first introduced to lectin and polyclonal anti-AFP antibody (anti-AFP) to form polymerizable molecules. pAAm-grafted lectins were then synthesized by the polymerization of vinyl-lectin with AAm. The hydrogels containing lectin–AFP–antibody complexes were prepared by copolymerization of pAAm-grafted lectin, the vinyl-antibody, AAm and MBA in the presence of template AFP. Then, AFP-imprinted hydrogels were obtained by removing AFP from the resulting hydrogels. The swelling ratio of the AFP-imprinted gels decreased rapidly with increasing AFP concentrations in surrounding media, due to the interactions of AFP with the lectin and antibody. The formation of lectin–AFP–antibody crosslinks led to the shrinking of the gels, which indicates that the AFP-imprinted gels were tumor marker-responsive.

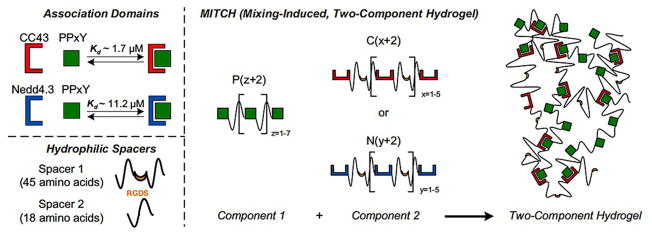

Molecular recognition physical hydrogels were prepared upon mixing two components using a concept of protein–protein interactions between specific peptide domains [212]. In this work, multiple repeats of WW (named after their tryptophan (W) residues; CC43 and Nedd4.3 variants) associated with proline-rich peptide (PPxY) domains, leading to sol-to-gel phase transition and hetero-assembly of the peptide domains at physiological conditions (Fig. 7). Hydrophilic spacers (spacer 1 connects CC43 and Nedd4.3; spacer 2 connects PPxY) were introduced to increase the flexibility of the protein chains, which facilitated accessibility and binding between the WW and PPxY. Spacer 1 contained a cell-adhesion peptide Arg-Gly-Asp-Ser (RGDS), to promote cell adhesion and proliferation within the resulting biorecognition hydrogels. The transient physically crosslinked hydrogels formed by the two components had shear moduli ranging from 9 to 50 Pa and were shear-thinning, injectable and self-healing. Another two component hydrogel based on protein–protein interactions was also reported [213]. Tetratricopeptide repeat (TPR) was engineered in tandem arrays using a spacer, which formed a rigid super helix with eight repeats per super helical turn. The TPR arrays bind 4-arm PEG-peptide (CGYGGDESVD) components in aqueous solution at room temperature without using any chemicals to form self-assembling hydrogels.

Fig. 7.

Schematic of the two-component hydrogel formation. (Top left) Two WW domains (CC43 and a Nedd4.3 variant) bind the same proline peptide (PPxY) via molecular recognition and Kd represents binding affinity. (Bottom left) Hydrophilic spacers connect CC43 and Nedd4.3 (spacer 1) or proline peptides (spacer 2). RGDS is a cell-adhesion peptide that is on spacer 1. (Right) Three engineered protein families were designed: C[x + 2], N[y + 2], and P[z + 2]. Hydrogels form upon mixing component 1 with component 2 (either C[x + 2] or N[y + 2]).

Reproduced with permission from [212]. Copyright 2009 Proc Natl Acad Sci USA.

Recently, Lu and colleagues engineered shear-thinning hydrogels by a dock-and-lock mechanism utilizing the specific binding between the docking and dimerization domain (DDD) of cyclic adenosine monophosphate (cAMP)-dependent protein kinase A (PKA) and the anchoring domain (AD) of A-kinase anchoring protein (AKAP) [214]. When DDD forms a type-X helix bundle, it associates with α-helical and amphipathic AD with strong affinity. The DDD protein was engineered to be a telechelic form with end-groups derived from the RIIα subunit of cAMD-PKA that could dimerize (docking step). AD was conjugated to multi-arm PEG to create a crosslinker that binds to the docked protein (locking step). Hydrogels could rapidly form upon mixing of the DDD protein and the crosslinker at physiological conditions. The mechanical and degradation properties of the resulting hydrogels could be regulated through the concentration and ratio of the crosslinker and DDD protein, and the density of peptide on the crosslinker.

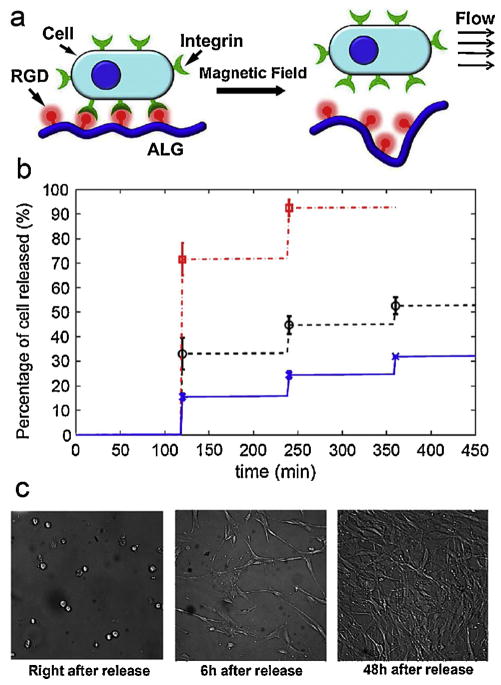

Cells can bind to cell-adhesive peptides such as RGD via transmembrane integrin receptors [215]. Utilizing this concept, RGD-modified polymers could form hydrogels via cell mediated crosslinking [216]. For example, RGD-conjugated ALG could form a gel upon mixing with cells, whereas unmodified ALG does not. However, the modified ALG could not form a gel with the cells if they were pre-mixed with free RGD as this occupied their integrin receptors and decreased their capacity to interact with RGD bound to the ALG. These hydrogels exhibited weak mechanical properties, and therefore, present challenges for their use in therapeutics delivery applications.

3. Bioactive factor delivery strategies

Controlled delivery systems based on hydrogels aim to release bioactive molecules to desired anatomical sites in the body in preprogrammed rates over an optimal period of time for a specific application. Well-controlled delivery systems are important to maintain therapeutic levels of bioactive factor in the target tissues. In addition, the systems must be able to protect the structure of entrapped bioactive factors and preserve their therapeutic biological activity during hydrogel preparation and the entire release duration [217].

Prior to being released, bioactive molecules must be incorporated into the hydrogels. Depending on the properties of the bioactive factors and hydrogels, several approaches have been exploited to incorporate them into the polymeric networks. Specifically, the payload can be loaded by (1) immersing lyophilized gels into media saturated with therapeutics [218], (2) homogeneously mixing therapeutics with hydrogel precursor solutions at low temperatures prior to gelation by mild methods [219] or (3) covalently tethering bioactive factors directly to macromers prior to forming a hydrogel [66]. The first method is dependent on the diffusion of the payload, the pore size of hydrogel networks and any potential affinity between therapeutics and hydrogels. Small molecules that are soluble in loading solutions penetrate into the gels more easily than larger ones such as DNA and some proteins, due to the intrinsically small pore size of many hydrogels. While this method may preserve therapeutic stability since, for example, the bioactive factors are not exposed to crosslinking agents or UV light, in some cases there may be limited control over payload amount. On the other hand, the second approach allows for encapsulation of a wide range of therapeutic substances regardless of their size. Nevertheless, the gelation process should be taken into consideration, since harsh gelling processes may damage or denature the payloads. The last method is only applied for molecules bearing functional groups or that can be modified with functional groups that can be chemically bonded with macromers. However, this approach may alter the stability and/or conformation of the covalently bound biomolecules, and therefore their activity.

The release mechanism(s) is strongly dependent on characteristics of bioactive agents and hydrogel networks and their response to specific stimuli, if present. In this section, the major strategies to control release of therapeutics temporally and/or in response to environmental stimuli are detailed along with recent advances in this field. Advantages and disadvantages of the various delivery strategies are shown in Table 2.

Table 2.

Advantages and disadvantages of delivery approaches.

| Delivery strategies | Advantages | Disadvantages |

|---|---|---|

| Physical incorporation—simple diffusion | Straightforward and simple formulation | Initial burst release; limited control over release profile |

| Covalent tethering | Controlled release profiles upon degradation of polymer-therapeutic linkages or hydrogel backbone | Issues regarding maintaining therapeutics’ stability and biological activity |

| Affinity binding | Controlled release kinetics; therapeutics loading of lyophilized scaffolds can be regulated via physical interactions | Potentially limited release of bioactive molecules possessing high affinity with biomaterials |

| On-demand | Controlled release of therapeutics in response to specific external stimuli | Potential toxic effect of external stimuli (e.g., light, electric or magnetic field, ultrasound, enzyme, etc.) |

| Encapsulation of microparticles or nanoparticles containing therapeutics | Controlled release kinetics; potential to deliver multiple therapeutics with individual release rates by incorporation in different particles | Potentially complicated multi-component formulation |

3.1. Physical incorporation of bioactive factors into hydrogels

Bioactive agents can easily be physically incorporated into hydrogel networks. Hydrogel systems containing physically entrapped bioactive factors display release profiles through simple diffusion and/or polymer degradation. In such systems, biomolecule transport through polymer networks is driven by a concentration gradient. In cases where there is no interaction between hydrogel matrices and bioactive molecules, an early rapid burst release profile is usually obtained followed by a smaller amount of retarded release at later time points. Here, one of the important design parameters to regulate the release profiles is the mesh size of the polymer networks that is modulated by the crosslink density [4,220]. An increase in the crosslink density decreases the average molecular distance between the adjacent crosslinks and thus decreases hydrogel mesh size. Therefore, diffusivity of bioactive factors decreases because smaller mesh size increases interactions of molecules with the hydrogel network and can act to confine molecules. Hydrogels that exhibit bulk degradation exhibit reduced crosslink density over time, which increases the pore size of the networks and accelerates molecular transport.

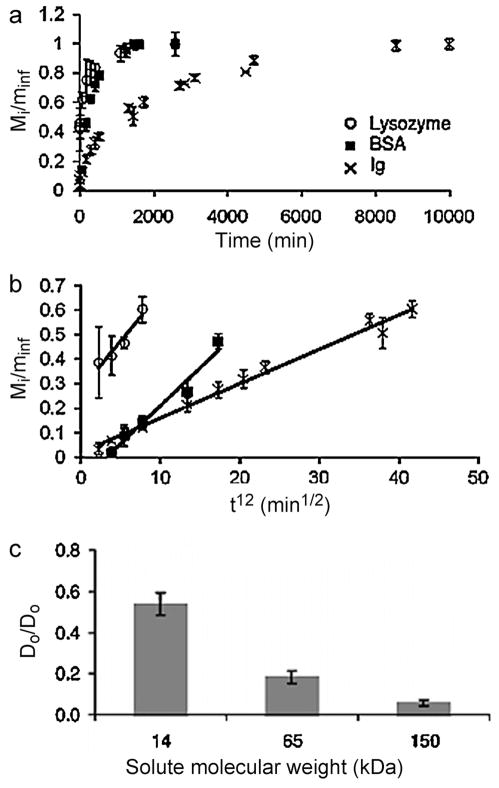

A small molecule drug, dexamethasone (DMT), has been homogeneously encapsulated in HA-tyramine macromers prior to enzymatic gelation [221]. DMT was released from the hydrogels in vitro by simple diffusion for 28 days. The release rate was tuned by varying the crosslink density of the hydrogels. An in vivo study in Sprague Dawley (SD) rats showed that DMT was released into the plasma over 4 weeks, and the released DMT maintained its therapeutic effect for the treatment of rheumatoid arthritis. PEG gels have been employed to release a hydrophilic anti-cancer drug, 5-fluorouracyl (5-FU), both in vitro and to suppress tumor growth in rats [222]. Most of 5-FU was released from lower concentration gels of PEG, which has lower crosslinking density, within 2 days, whereas hydrogels with a higher PEG concentration released the drug over 5 days. A release study in rats revealed the pharmacokinetics of free 5-FU and 5-FU loaded hydrogels. Compared to the rapid clearance of free 5-FU from the plasma within several hours, hydrogel encapsulated 5-FU was released for up to 1 week with a substantial burst release profile. Proteins and genes are also physically incorporated into and released from hydrogels. The diffusion rate of proteins and genes depends predominantly on their size and the crosslink density of hydrogels. For example, PEG hydrogels formed by Michael reaction between thiol and acrylate groups were used for protein release [223]. The smallest protein examined, lysozyme (14.1 kDa), completely diffused out of the hydrogels within 18 h while the largest, bovine γ-globulin (Ig, 150 kDa), was released for up to approximately 7 days (Fig. 8). The diffusion rate of lysozyme was highest, followed by bovine serum albumin (BSA, 65 kDa) and lastly Ig. The crosslinking density of the hydrogels decreased with increasing the molecular weight and decreasing concentration of the macromers, which led to the increased diffusion rate of the proteins. Lysozyme, BSA and Ig were also used as model proteins for release from PHPMAlac-PEG-PHPMAlac [224] and β-CD/cholesterol end-capped 8-arm PEG hydrogels [96]. In addition, short interfering ribonucleic acid (siRNA) was released from ALG hydrogels though a combination of diffusion and polymer degradation [219].

Fig. 8.

Effect of protein size on diffusion through PEG hydrogels: (a) fractional release over time, (b) fractional release (Mi /Minf ) as a function of t1/2, (c) normalized diffusion coefficients (De /Do ). Mi is the released solute at time i and Minf is the concentration of solute at infinite time. De is the effective diffusion coefficient and Do is the maximum diffusion coefficient.

Reproduced with permission from [223]. Copyright 2010 John Wiley and Sons.

Along with chemically crosslinked hydrogels, physically crosslinked hydrogels are also attracting interest as a therapeutics delivery system due to their unique physiochemical properties. For example, PLGA-PEG-PLGA (commercially known as ReGel®) hydrogels released insulin within 4 days with substantial initial burst [53]. However, zinc-complexed insulin diffused out of the hydrogels with a nearly constant release rate over a period of 14 days without initial burst. The same strategy using zinc was applied to control release of glucagon-like peptide-1 (GLP-1) over 2 weeks without any initial burst [60]. The complexation of zinc to these biological molecules reduced the solubility of the complexes, and hence prolonged the duration of the release and reduced the burst effect. The highly soluble biological molecules that were not complexed with zinc likely associated with the hydrophilic domain of ReGel®, and thus diffused rapidly out of the matrices, resulting in the burst release. In addition, modulation of the chemical structure or varying the concentration of the PLGA-PEG-PLGA triblock copolymer comprising the hydrogels affected the release profiles of lysozyme [225]. Higher burst release resulted from lower copolymer concentration and lower PLGA/PEG ratio (hydrophobic/hydrophilic balance).

3.2. Covalent tethering of bioactive factors to hydrogels

Bioactive factors containing amine, carboxylic acid or thiol groups can be covalently bound to the functional groups of hydrogel precursors. This strategy can be favorable for sustaining their retention and/or controlled release. For instance, hydrophobic drugs like doxorubicin (DOX) and paclitaxel (PAC) are poorly soluble in water, but can be dissolved in organic solvents [226]; hence they tend to aggregate during mixing with aqueous macromer solutions prior to gelation. However, they can be reacted with macromers in organic solvents, and then their solubility in aqueous media increased [227]. In addition, molecules such as small hydrophilic drugs, proteins or genetic material can diffuse out of the hydrophilic matrices rapidly when they do not interact with the hydrogels, leading to difficulty in delaying and controlling the release rate [219,228,229]. The covalent incorporation of bioactive molecules permits their retention within hydrogel matrices, and their release is typically controlled through hydrolytic and/or enzymatic cleavage of polymer-therapeutic bonds and/or hydrogel networks.

The secondary amine of DOX, an anticancer drug, was reacted with carboxylic acid groups of a polyphosphazene polymer to form stable amide bonds [37]. The hydrolytic degradation of polyphosphazene hydrogels released polymer-DOX conjugates which were taken up by cancer cells. The conjugates were then exposed to lysosomal enzymes and lower pH (4.0–6.5) in the lysosomes and endosomes when they were internalized by cells. Endosomal and lysosomal degradation of the amide linkages between the drug and the polymer in the cells might have mediated the DOX release. The drug was released for 28 days and maintained its ability to inhibit tumor growth in mice. Similarly, PAC, another anticancer drug, bearing a hydroxyl group was conjugated to carboxylic acid groups of polyphosphazene polymers, resulting in hydrolytic ester bonds [230]. The hydrolytic degradation of the ester linkages between the polymers and PAC released the drug over 1 month, and the release rate was promoted at pH 6.8 compared to 7.4.

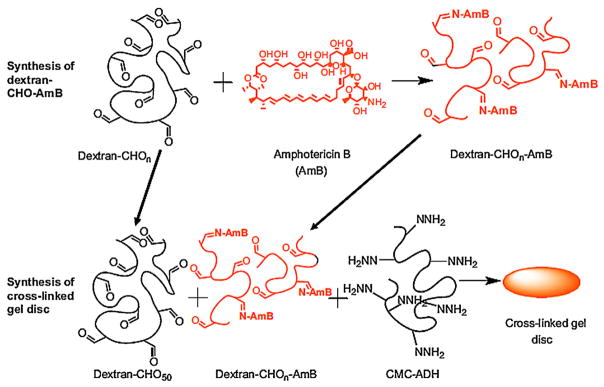

Aldehyde groups can react with amine groups via Schiff’s base reaction to form imine linkages that are degradable via hydrolysis, especially at low pH. For instance, DOX was conjugated to PEG-aldehyde to create DOX-PEG conjugates that were subsequently bound to polymer networks composed of poly(vinyl amine) and PEG through Schiff’s base reaction [231]. The release rate of DOX from the hydrogels was a function of the release media pH and increased with decreasing pH. The rapid hydrolysis of Schiff’s base linkages at acidic pH is likely to be valuable for controlled release in acidic environments in the body, like in some cancer tissues or in endosomes or lysosomes. The same method was employed to conjugate amphotericin B (AmB), an antifungal agent, to aldehyde groups of DEX-CMC hydrogels (Fig. 9) [154]. The release rate was decreased when a higher degree of hydrogel crosslinking was employed.

Fig. 9.

Covalent tethering of amphotericin B (AmB) to aldehyde-modified dextran (DEX-CHO) and conjugation of the DEX-CHO-AmB and DEX-CHO to hydrazide-modified carboxymethylcellulose (CMC-ADH) to form a hydrogel.

Reproduced with permission from [154]. Copyright 2010 Elsevier.

In addition to low molecular weight molecules, proteins containing primary amine groups can also be covalently incorporated into hydrogel networks, and the release of the proteins can be mediated via hydrolysis [66], reduction reaction [232] and/or enzymatic degradation [233]. For example, vascular endothelial growth factor (VEGF) was conjugated to thermo-responsive PVL-PEG-PVL copolymers and the resulting polymer-VEGF conjugates were then blended with PVL-PEG-PVL to construct hydrogels [66]. Since the material degraded slowly, the VEGF, which retained biological activity, was released via hydrolytic degradation for over 40 days. In another work, VEGF-PEG-acrylate conjugates were prepared and copolymerized with a mixture of PEG-DA and proteolytically degradable PEG-DA [233]. The degradation of the hydrogels in the presence of collagenase triggered the release of bound VEGF. Additionally, lysozyme modified with a methacrylamide group through a disulfide spacer was immobilized in methacrylamide hydrogels, and the reduction of the disulfide bonds mediated the release of the protein [232].

The approach of covalent tethering to hydrogels has great promise for controlled delivery of therapeutics; however, there may be concerns about altering their stability or biological activity following chemical conjugation.

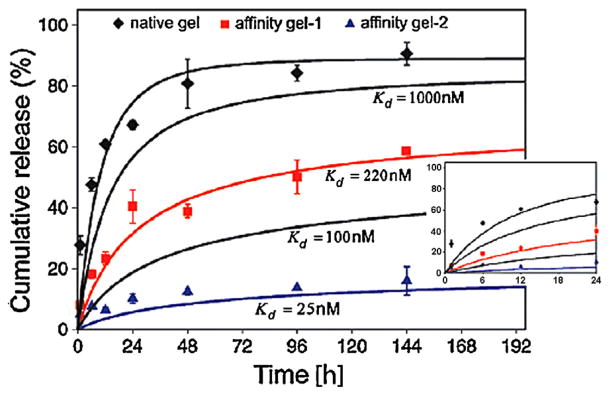

3.3. Affinity binding of bioactive factors with hydrogels

Affinity is also a powerful approach to retain bioactive substances within hydrogel networks [5] which capitalizes on the association of one molecule to another via their opposite charges, hydrophobic interactions, hydrogen bonding, and/or van der Waals forces. Bioactive factor release controlled by simple diffusion through polymer networks usually results in a burst effect or short-term (transient) release profiles as discussed above. Polymer networks functionalized or incorporated with molecules that have affinity with bioactive factors can serve to retain specific payloads in hydrogels through these interactions. Dissociation of the interactions over time can result in sustained release profiles [85]. This method can permit controlled release profiles via physical interactions and regulated therapeutics loading of lyophilized scaffolds.

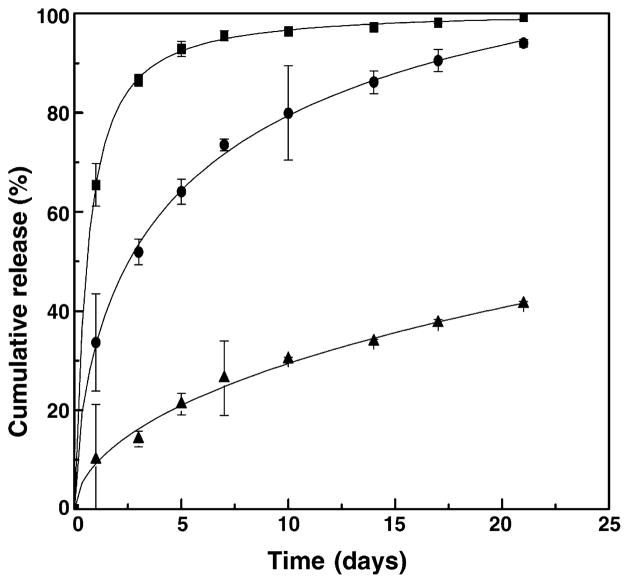

3.3.1. Hydrophobic interactions

Hydrophobic blocks of amphiphilic copolymers can interact with hydrophobic drugs (like DOX and PAC) via hydrophobic interactions in aqueous solutions, and therefore retain them within the polymer networks [234]. Degradation of the hydrophobic regions accelerates release of the hydrophobic drugs by diffusion from the hydrogels.

To study the ability of a hydrophobic polymer to retain a hydrophobic drug in its network, Jeong and colleagues compared the release mechanisms of a more hydrophilic drug, ketoprofen, and a relatively hydrophobic drug, spironolactone, from amphiphilic thermo-sensitive PLGA-PEG-PLGA gels [234]. While ketoprofen released from the hydrogels over 2 weeks with a first-ordered release profile, spironolactone was depleted over 2 months with an S-shaped release profile. The hydrophilic ketoprofen tended to stay in the hydrophilic domains, and thus its major release mechanism was diffusion. The majority of spironolactone tightly associated to the hydrophobic domains and a minority of it was trapped in the hydrophilic domains. Therefore, a small amount of the spironolactone in the hydrophilic domains was released by diffusion at the early stage and it was predominantly released by degradation and diffusion from the hydrophobic sites at the later times. Another hydrophobic anticancer drug, PAC, was released from ReGel® for approximately 50 days, while the release from Pluronic® was completed in 1 day [235]. The rapid release from the Pluronic® hydrogel was likely due to its faster degradation in water than that of ReGel®. In addition, pH dependent release profiles of hydrophobic camptothecin and PAC molecules were achieved from Pluronic® multiblock copolymer hydrogels [236]. The release mechanism at pH 5.0 was predominantly degradation controlled, while it was a combination of both diffusion and degradation controlled at pH 6.5. At pH 7.4, the main mechanism was diffusion controlled since the hydrogel showed no degradation up to 40 days. In addition, the delivery of PAC and DOX was also investigated using pH and temperature-sensitive hydrogels [87,237,238].

3.3.2. Ionic interactions

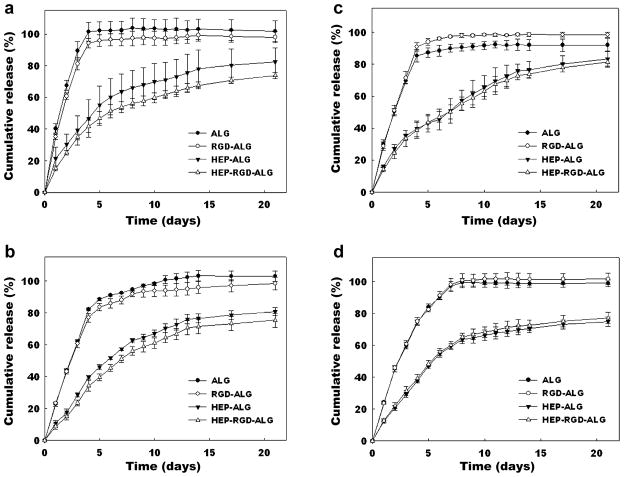

Ionic interactions naturally occurring between two oppositely charged molecules have been applied for controlling the delivery of bioactive molecules. For example, cationic polymers consisting of a high density of positively charged groups (such as PEI, polylysine, PAE and PAA) can condense negatively charged molecules (e.g., anionic proteins and genetic material) into stabilized complexes [239]. Exploiting this ionic binding phenomena, functionalization of hydrogels with ionic molecules that can complex with counter-ionic biomolecules permits their retention within the hydrogels [31]. Degradation of the ionic hydrogels or pH changes trigger the release of the biomolecules, and regulating these processes in concert with tuning the extent of ionic interactions can allow for tailored release profiles of therapeutics.