Abstract

Photochemical processes enable spatial and temporal control of reactions, which can be implemented as an accurate external control approach in both polymer synthesis and materials applications. “Click” reactions have also been employed as efficient tools in the same field. Herein, we combined photochemical processes and thiol-Michael “click” reactions to achieve a “photo-click” reaction that can be used in surface patterning and controlled polymer network formation, owing to the ease of spatial and temporal control through use of photolabile amines as appropriate catalysts.

Introduction

The “click” reaction concept, as first introduced by Kolb, Finn, and Sharpless in 2001, is a rubric that generally defines a set of selective and highly efficient reactions that are modular in nature and exhibit nearly ideal (e.g., 1:1 stoichiometry and complete) reactivity.1 Over the past decade, the “click” concept has been employed by thousands of researchers in a range of reactions, including bioconjugation, polymer synthesis/modification, surface functionalization, cross-link network formation, and dendrimer synthesis.2 The Cu-catalyzed azide–alkyne cycloaddition (CuAAC),3 radical thiol–ene/yne reaction,4 thiol–Michael addition reaction,5 and thiol–isocynate reaction4,6 are a few of the select group of reactions employed in the literature that exhibit “click” reaction characteristics under appropriate conditions.

Unfortunately, though several of these reactions have been photoinitiated,7 many of these “click” reactions lack the control afforded by light initiation that enables the user to dictate precisely where and when the reaction will commence, as seen in photoinitiation of the thiol–ene/yne “click” reaction. To address this issue, several researchers have utilized a scheme whereby the catalyst is created or activated utilizing light; thus, a reaction that is otherwise limited by slow kinetics becomes spatiotemporally controlled. For example, the archetypical CuAAC “click” is readily photoinduced by employing a radical photoinitiator to convert Cu(II) to Cu(I) (i.e., the catalytic form of copper).8 Besides this photocatalytic strategy, another approach to photoclick reactions is based on photoinduced/generated reactive substrates/intermediates via the “click” reaction, including light activation of cyclopropenones for strain-promoted azide–alkyne cycloaddition;9 UV induced generation of a nitrile imine intermediate for 1,3-dipolar cycloaddition;10 light activated diene for Diels–Alder reaction;11 and phototriggered generation of a nitrobenzyl aldehyde for oxime formation.12 These photoclick reaction schemes enable a variety of new applications for click reactions, such as photopatterning,11c,13 polymer modification;14 bioconjugation,15 surface immobilization,16nanoparticle modification,17 and spatiotemporal control in biochemical labeling.18

Although many endeavors have been made to expand the quality and quantity of photoclick reactions, there are still a large number of “click” reactions that are not efficiently photoinitiated, such as the thiol–Michael addition. The thiol–Michael addition is an efficient and fast tool in both polymer chemistry and materials science.5 In most cases, these reactions are performed utilizing base (e.g., hexylamine or triethylamine) or nucleophile (e.g., dimethylphenyl phosphine) catalysts,19 and previous attempts to photoinitiate this reaction have been limited.20 Perhaps the most straightforward route to enable photocontrol of the thiol–Michael addition is to trigger the reaction using the photorelease of a catalyst. Recently, for example, we have demonstrated a photocaged amine catalyst for thiol–Michael addition.21 Herein, we greatly expand the photoinduced thiol–Michael concept to new photocaged amine catalysts and more efficient photolabile species (Scheme 1). Here, with terminology similar to that used by others,22 we refer to structures such as these as photocaged amines, implying not a physical cage but rather a chemical structure in which the absorption of a photon has the potential for freeing the amine and leading to a dramatic increase in basicity. Furthermore, we demonstrate the utilization of these species as an approach for photoinduced polymer network formation and surface modification. Amine-based catalysts (e.g., triethylamine) are the most common and widely used catalysts for the thiol–Michael addition reaction in organic chemistry. In most cases, amines play a role of a base that deprotonates the thiol, generating a reactive thiolate anion. The thiolate anion then reacts with an electron poor vinyl group, such as an acrylate, creating a highly reactive carbo-anion, which subsequently abstracts a hydrogen from another thiol to reinitiate the reaction cycle. The result of this reaction cycle is that all thiol and electron poor species are covalently linked via a thioether bond, typically at near quantitative conversion. Often guanidine and its derivatives are used as a “superbase” for various reactions in organic synthesis owing to their high pKa values. (guanidine pKa = 13.6)23 In this work, we use a photocaged superbase to accelerate the kinetics of the phototriggered thiol–Michael addition.

Scheme 1. Principle Photolytic Pathway of NVOC–Amine and NPPOC–Amine Compounds.

Materials and Methods

Materials

6-Nitroveratryl chloroformate, 2-(2-nitrophenyl)propyl chloroformate, N,N-diisopropylethylamine (DIPEA), hexylamine(HA), diethylamine (DEA), triethylamine (TEA), N,N,N′,N′-tetramethylguanidine (TMG), trimethylolpropane trimethacrylate (TMPTMA), and trimethylolpropane triacrylate (TMPTA) were purchased from Sigma-Aldrich. Pentaerythritol tetrakis(2-mercaptoacetate) (PETMA) was obtained from TCI-America. Acryloxyethyl thiocarbamoyl rhodamine B was purchased from Polyscience, Inc. All chemical reagents were obtained commercially and used without further purification.

Methods

Synthetic Procedure for Photolabile Amines

NVOC-HA

6-Nitroveratryl chloroformate (2 mmol, 551 mg) in 10 mL of CH2Cl2 was added dropwise to a stirred solution of hexylamine (2 mmol, 264 μL) and DIPEA (4 mmol, 344 μL)in 20 mL of CH2Cl2 at 0 °C. The reaction was stirred at ambient temperature for 8 h. The mixture was washed with brine (30 mL × 3) and dried with anhydrous Na2SO4. The crude product was purified by silica gel column chromatography using hexane:EtOAc (1:1) to give a pure product (537 mg, 79%) as a light yellow oil. 1H NMR (400 MHz, chloroform-d): δ 7.70 (s, 1H), 7.00 (s, 1H), 5.50 (s, 2H), 3.96 (d, J = 8.1 Hz, 6H), 3.21 (q, J = 7.0 Hz, 2H), 1.57–1.45 (m, 2H), 1.37–1.22 (m, 6H), 0.93–0.82 (m, 3H). 13C NMR (101 MHz, chloroform-d): δ 153.60, 148.25, 110.47, 108.34, 63.57, 56.56, 56.51, 41.37, 31.59, 30.09, 26.54, 22.70, 14.14, 17.78, 17.32, 13.98. Mass: calcd for C16N24N2O6 [M + H]+, 341.1708; found, 341.1710.

NVOC-DEA

6-Nitroveratryl chloroformate (2 mmol, 551 mg) in 10 mL of CH2Cl2 was added dropwise to a stirred solution of diethyl amine (2.4 mmol, 248 μL) in 20 mL of CH2Cl2 at 0 °C. The reaction was stirred at ambient temperature for 8 h. The mixture was washed with brine (30 mL × 3) and dried with anhydrous Na2SO4. The crude product was purified by silica gel column chromatography using hexane:EtOAc (1:1) to give a pure product (505 mg, 81%) as a light yellow oil. 1H NMR (400 MHz, chloroform-d): δ 7.70 (s, 1H), 7.01 (s, 1H), 5.53 (d, J = 0.6 Hz, 2H), 3.95 (d, J = 2.0 Hz, 6H), 3.34 (q, J = 7.1 Hz, 4H), 1.16 (d, J = 8.6 Hz, 6H). 13C NMR (101 MHz, chloroform-d): δ 155.31, 153.53, 148.09, 139.98, 128.77, 110.16, 108.31, 63.95, 56.53, 56.38, 42.27, 41.56, 14.39, 13.62. Mass: calcd for C14N20N2O6[M + H]+, 313.1395; found, 313.1400.

NVOC-TMG

6-Nitroveratryl chloroformate (2 mmol, 551 mg) in 10 mL of CH2Cl2 was added dropwise to a stirred solution of N,N,N′,N′-tetramethylguanidine (2.5 mmol, 313 μL) in 20 mL of CH2Cl2 at 0 °C. The reaction was stirred at ambient temperature for 8 h. The mixture was washed with brine (30 mL × 3) and dried with anhydrous Na2SO4. The crude product was purified by silica gel column chromatography using MeOH:DCM (1:10) to give a pure product (445 mg, 63%) as a light yellow oil. 1H NMR (400 MHz, chloroform-d): δ 7.70 (s, 1H), 7.20 (s, 1H), 5.56–5.49 (m, 2H), 3.95 (d, J = 9.3 Hz, 6H), 2.89 (s, 12H).13C NMR (101 MHz, chloroform-d): δ 166.94, 159.80, 153.72, 147.75, 130.46, 109.88, 108.12, 63.86, 56.54, 56.49, 40.04. Mass: calcd for C15N22N4O6 [M + H]+, 355.1613; found, 355.1615.

NPPOC-DEA

2-(2-Nitrophenyl)propyl chloroformate (2 mmol, 587 mg) in 10 mL of CH2Cl2 was added dropwise to a stirred solution of diethylamine (2 mmol, 248 μL) and DIPEA (4 mmol, 344 μL) in 20 mL of CH2Cl2 at 0 °C. The reaction was stirred at ambient temperature for 8 h. The mixture was washed with brine (30 mL × 3) and dried with anhydrous Na2SO4. The crude product was purified by silica gel column chromatography using hexane:EtOAc (1:1) to give a pure product (302 mg, 54%) as a light yellow oil. 1H NMR (400 MHz, chloroform-d): δ 7.71 (dd, J = 8.1, 1.2 Hz, 1H), 7.62–7.40 (m, 2H), 7.33 (ddd, J = 8.1, 7.3, 1.5 Hz, 1H), 4.28–4.11 (m, 2H), 3.66 (h, J = 6.9 Hz, 1H), 3.31–2.90 (m, 4H), 1.33 (d, J = 7.0 Hz, 3H), 0.95 (d, J = 69.8 Hz, 6H). 13C NMR (101 MHz, CDCl3): δ 155.56, 150.61, 137.92, 132.56, 128.26, 127.29, 124.01, 69.01, 41.87, 41.23, 33.54, 18.09, 13.86, 13.50. Mass: calcd for C14N20N2O4 [M + H]+, 281.1496; found, 281.1497.

NPPOC-TMG

2-(2-Nitrophenyl)propyl chloroformate (2 mmol, 587 mg) in 10 mL of CH2Cl2 was added dropwise to a stirred solution of TMG (2.5 mmol, 313 μL) in 20 mL of CH2Cl2 at 0 °C. The reaction was stirred at ambient temperature for 8 h. The mixture was washed with brine (30 mL × 3) and dried with anhydrous Na2SO4. The crude product was purified by silica gel column chromatography using MeOH:DCM (1:10) to give a pure product (336 mg, 52%) as a light yellow oil. 1H NMR (400 MHz, chloroform-d): δ 7.66–7.59 (m, 1H), 7.48–7.41 (m, 2H), 7.24 (ddd, J = 8.2, 5.3, 3.4 Hz, 1H), 4.19 (dd, J = 6.9, 1.3 Hz, 2H), 3.66–3.53 (m, 1H), 2.72 (s, 12H), 1.28 (d, J = 6.9 Hz, 3H). 13C NMR (101 MHz, CDCl3): δ 166.24, 160.20, 150.40, 138.39, 132.60, 132.57, 128.53, 128.33, 127.10, 127.03, 124.12, 124.03, 68.45, 67.60, 53.52, 39.77, 36.46, 33.95, 18.62, 17.70. Mass: calcd for C15N22N4O4[M + H]+, 323.1714; found, 323.1725.

Real-Time Fourier Transform Infrared (FT-IR) Spectroscopy

Reaction kinetics were monitored by FT-IR spectroscopy at a series scan rate of one scan per 2 s. These studies were performed on a Nicolet 750 Magna FT-IR spectrometer with a KBr beam splitter and an MCT/A detector under dry air. Samples were sandwiched between two NaCl windows and placed into a horizontal transmission apparatus. The sample thicknesses were approximately 200 μm. The conversion of thiol and vinyl functional groups was assessed by monitoring the disappearance of the peak areas centered around 2567 and 812 cm–1, respectively.

Photopatterning

A monomer mixture containing PETMA/TMPTMA, 2 mol % NPPOC-TMG and 1 mol % acryloxyethyl thiocarbamoyl rhodamine B was spread on the top of thiol-modified glass with a thickness of 200 μm. A photomask was placed on top of the glass slide and 320–390 nm (20 mW/cm2) UV light was irradiated for 4 min, and unreacted species were then washed off by solvent wash (DCM and DMF).

Dynamic Mechanical Analysis (DMA)

The mechanical properties (E′ and E″) of the fully formed polymer networks were analyzed with a TA Q800 dynamic mechanical analyzer.3 A rectangular sample geometry was used with dimensions of 10.72 mm × 2.2 mm × 0.90 mm for the PETMA/TMPTMA/TMPTA. Experiments were performed over a temperature range of −40 to +80 °C with a scanning rate of 2 °C/min. Finally, the Tg was determined as the maximum of the tan δ curve (where tan δ = E″/E′).

Results and Discussion

All photolabile catalysts were prepared through classic amidation of amines and NVOC-Cl or NPPOC-Cl (see Supporting Information). The photolysis of each catalyst proceeded in MeOH at 0.025 mM concentration (UV–vis data of the photobases are presented in the Supporting Information). The photochemical properties of each catalyst are calculated and listed in Table 1. The NPPOC amines exhibit larger quantum yields than NVOC amines, indicating that the photolysis of NPPOC amines are more efficient than NVOC under UV irradiation, which is in agreement with previous results. The photocleavage of NVOC amines involves an intramolecular redox process that generates o-nitrosobezaldehyde which can be quenched by nucleophiles such as amines. o-Nitrosoaldehyde-derived byproducts have a strong UV absorption which prevents efficient light absorption by the NVOC-amines as these byproducts act as an “internal filter”. However, since the photocleavage of NPPOC amines has an entirely different mechanism, which consists a light-induced β elimination that generates o-nitrostyrene that is nonreactive toward free amines, no such byproducts are produced (Scheme 1).24

Table 1. Photochemical Properties of Photolabile Amines.

| entry | compound | ε368/cm–1 M–1 | Φchem |

|---|---|---|---|

| 1 | NVOC-HA | 4780 | 0.0013 |

| 2 | NVOC-DEA | 1776 | 0.0085 |

| 3 | NVOC-TMG | 1988 | 0.0074 |

| 4 | NPPOC-HA | 4600 | 0.0010 |

| 5 | NPPOC-DEA | 196 | 0.2014 |

| 6 | NPPOC-TMG | 240 | 0.1497 |

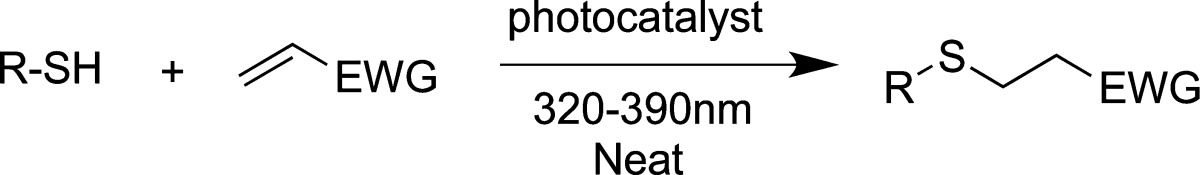

To investigate the catalytic activity of these photolabile amines toward thiol–Michael addition, we employed thiol glycolate and ethyl acrylate as model reactants. The yields of the catalyst used in this model reaction (as shown in Table 2) are readily divided into two distinct categories: photolabile base (NPPOC-HA, NPPOC-DEA, NVOC-HA, NVOC-DEA) and photolabile superbase (NPPOC-TMG, NVOC-TMG). Catalysis of the thiol–acrylate additions with NPPOC-TMG and NVOC-TMG have higher yields than the others at the same catalyst loading owing to the stronger basicity (larger pKa) of TMG. Additionally, the catalyst load of 1 mol % NPPOC-TMG is still effective in achieving over 90% conversion in 1 h.

Table 2. Scope of Photo Thiol–Michael Addition Catalyzed by Various Photo-Caged Aminesa.

Key: (a) Reaction yields are determined by 1H NMR. (b) Reaction condition: thiol (1 mmol), electron deficient vinyl (1 mmol) and photolabile catalysts irradiated using a Hg source with 320–390 nm band-pass filter at 20 mW/cm2 for either 30 or 60 min (as indicated).

To examine the kinetic details of photo thiol–Michael addition of each catalyst, we monitored the conversion during irradiation using real-time Fourier transform infrared (FT-IR) spectroscopy (Figure 1). As expected, the TMG superbase catalysts both exhibited fast kinetics, where the reaction containing the NPPOC-TMG catalyst achieves over 85% conversion within 2 min under continuous irradiation, which is comparable to the radical initiated thiol–ene reaction.25 Additionally, the decrease of irradiation time from 2 to 0.5 min reduced the reaction rate and conversion owing to the reduced TMG generated. (See Supporting Information)

Figure 1.

Thiol conversion versus time monitored by FT-IR for the model reaction between thiol glycolate and ethyl acrylate with 5 mol % photolabile catalyst irradiated using a Hg light source equipped with 320–390 nm (20 mW/cm2) (filled square, NPPOC-TMG; open square, NVOC-TMG; filled triangle, NPPOC-DEA; open triangle, NVOC-DEA; open circle, NVOC-HA).

To demonstrate the spatial and temporal control of the thiol–Michael addition, we selected NPPOC-TMG as a photocatalyst for the formation of a polymer network. Photopatterning is a straightforward method to demonstrate the spatial control in a photopolymerization reaction. A mixture of pentaerythritol tetrakis(2-mercaptoacetate) (PETMA), trimethylolpropane trimethacrylate (TMPTMA), 1 mol % acryloxyethyl thiocarbamoyl rhodamine B, and 2 mol % NPPOC-TMG were placed on the top of the thiol-modifed microscope slide (Figure 2). The samples were then irradiated through a photomask with 320–390 nm light (i.e., predominately the I-line of a Hg source). After 4 min of irradiation, the crude mixture was washed with solvents to remove the unreacted, non-cross-linked material. The patterning was visually confirmed (Figure 3), indicating spatial control of the thiol–Michael addition polymerization using the NPPOC-TMG photocatalyst. The profilometer scan of the patterned surface on the glass slide gave the height and diameters of the resulting cubic spots. For this photopatterning experiment, it is worth noting that diffusion of the base will reduce the resolution of the feature if long irradiation times are used. However, the rapid formation of the polymerized networks also significantly reduces the catalyst diffusion, which improves the feature fidelity.

Figure 2.

Monomers used for polymer networks formation.

Figure 3.

Photopatterning with 320–390 nm (20 mW/cm2) light of a tetra-thiol (PETMA) and trimethacrylate (TMPTMA) thiol-Michael addition monomer system (1 mol % rhodamine B-modifed acrylate was used as dye to provide contrast). Key: (a) Cubic size: width ∼ 400 μm, height ∼200 μm. (b) The width of the CU buff logo is ∼16 mm.

Temporal control of the thiol–Michael addition is demonstrated in a kinetically controlled two-stage reaction scheme. The typical base catalyzed thiol–acrylate addition and thiol–methacrylate addition reactions have significantly different reaction rates owing to the inductive effect of the methyl group in the methacrylate.26 Using a one-pot reaction methodology, we mixed butyl thiol glycolate, ethyl acrylate, and methyl methacrylate stoichiometrically as well as 1 mol % TEA and 1 mol % NPPOC-TMG, used as catalysts. In the first stage, the acrylate and thiol species readily undergo a Michael addition in the presence of TEA. The 1H NMR monitored acrylate conversion was 90% after 5 h while the methacrylate conversion was only 9%. At a later time, when the TEA-catalyzed acrylate reaction was near completion, the TMG superbase was activated using light. The 1H NMR results indicated that the acrylate achieved complete conversion, and the methacrylate conversion also reached 90% (Figure 4). Thus, these results indicate that we can control the basicities of catalysts in the thiol-Michael system through this photolabile superbase.

Figure 4.

C=C conversion of thiol–acrylate (stoichiometric mixture of butyl thiol glycolate and methyl acrylate with 1 mol % TEA) and thiol–methacrylate (stoichiometric mixture of butyl thiol glycolate and ethyl methacrylate with 1 mol % NPPOC-TMG) monitored by 1H NMR.

To demonstrate our kinetically controlled thiol–Michael strategy in polymer network formation, we used PETMA, TMPTA, and TMPTMA (Figure 2) as multifunctional monomers and 1 mol % TEA as a stage 1 catalyst and 2 mol % NPPOC-TMG as a photo-triggered stage 2 catalyst (Figure 5). TEA-catalyzed thiol–acrylate reaction resulting in a polymer network with a glass transition temperature (Tg) of 12 °C. Subsequently, the sample was irradiated using 320–390 nm light, triggering the release of the TMG superbase to catalyze the thiol–methacrylate Michael addition. The stage-2 polymer network formed with a Tg at 35 °C (Figure 5). The formation of a polymer network and mechanical property modification using a two-stage thiol–Michael addition based on kinetic differences demonstrates the temporal control of using a caged superbase.27

Figure 5.

Plots of tan δ and elastic modulus vs temperature for two stage networks formed through thiol–acrylate–methacrylate monomer cross-linking (PETMA–TMPTA–TMPTMA, molar ratio = 3:2:2) system. Stage 1 (predominately the thiol–acrylate cross-linking reaction) data are in red and stage 2 (the subsequent thiol-methacrylate cross-linking reaction) data are in black.

Conclusions

In summary, we designed and synthesized five different photoinduced amine catalysts for the thiol–Michael addition to enhance both the quantum yield of the photolabile group and the basicity of the amine catalyst. All these catalyst were evaluated in a model thiol–Michael addition reaction between thiol and acrylate. Among these photocaged amines, photolabile superbases (NVOC-TMG and NPPOC-TMG) exhibit excellent catalytic activities and achieve over 90% conversion within several minutes. The successful implementation of these photocaged catalysts in both photopatterning and kinetically controlled two-stage polymer network formation demonstrates the capability of photo thiol–Michael addition for spatiotemporal control. This work provides a new route for thiol–Michael catalysis on-demand (via light activation) and will enable new applications of this reaction in polymer chemistry and materials science.

Acknowledgments

We acknowledge financial support from the National Science Foundation (CHE 1214109) and the National Institutes of Health (U01 DE023777).

Supporting Information Available

Experimental details, catalyst preparation, photolysis data, and NMR spectra. This material is available free of charge via the Internet at http://pubs.acs.org.

The authors declare no competing financial interest.

Funding Statement

National Institutes of Health, United States

Supplementary Material

References

- Kolb H. C.; Finn M. G.; Sharpless K. B. Angew. Chem., Int. Ed. 2001, 40, 2004. [DOI] [PubMed] [Google Scholar]

- a Golas P. L.; Matyjaszewski K. Chem. Soc. Rev. 2010, 39, 1338. [DOI] [PubMed] [Google Scholar]; b Iha R. K.; Wooley K. L.; Nystrom A. M.; Burke D. J.; Kade M. J.; Hawker C. J. Chem. Rev. 2009, 109, 5620. [DOI] [PMC free article] [PubMed] [Google Scholar]; c Xi W.; Scott T. F.; Kloxin C. J.; Bowman C. N. Adv. Funct. Mater. 2014, 24, 2572. [Google Scholar]

- a Rostovtsev V. V.; Green L. G.; Fokin V. V.; Sharpless K. B. Angew. Chem., Int. Ed. 2002, 41, 2596. [DOI] [PubMed] [Google Scholar]; b Tornoe C. W.; Christensen C.; Meldal M. J. Org. Chem. 2002, 67, 3057. [DOI] [PubMed] [Google Scholar]

- a Lowe A. B. Polym. Chem. 2010, 1, 17. [Google Scholar]; b Hoyle C. E.; Bowman C. N. Angew. Chem., Int. Ed. 2010, 49, 1540. [DOI] [PubMed] [Google Scholar]

- Nair D. P.; Podgorski M.; Chatani S.; Gong T.; Xi W. X.; Fenoli C. R.; Bowman C. N. Chem. Mater. 2014, 26, 724. [Google Scholar]

- Li H. B.; Yu B.; Matsushima H.; Hoyle C. E.; Lowe A. B. Macromolecules 2009, 42, 6537. [Google Scholar]

- Tasdelen M. A.; Yagci Y. Angew. Chem., Int. Ed. 2013, 52, 5930. [DOI] [PubMed] [Google Scholar]

- a Tasdelen M. A.; Yagci Y. Tetrahedron lett. 2010, 51, 6945. [Google Scholar]; b Adzima B. J.; Tao Y.; Kloxin C. J.; DeForest C. A.; Anseth K. S.; Bowman C. N. Nat. Chem. 2011, 3, 256. [DOI] [PubMed] [Google Scholar]

- Poloukhtine A. A.; Mbua N. E.; Wolfert M. A.; Boons G. J.; Popik V. V. J. Am. Chem. Soc. 2009, 131, 15769. [DOI] [PMC free article] [PubMed] [Google Scholar]

- a Wang Y. Z.; Song W. J.; Hu W. J.; Lin Q. Angew. Chem., Int. Ed. 2009, 48, 5330. [DOI] [PMC free article] [PubMed] [Google Scholar]; b Song W.; Wang Y.; Qu J.; Lin Q. J. Am. Chem. Soc. 2008, 130, 9654. [DOI] [PubMed] [Google Scholar]; c Song W.; Wang Y.; Qu J.; Madden M. M.; Lin Q. Angew. Chem., Int. Ed. 2008, 47, 2832. [DOI] [PubMed] [Google Scholar]

- a Arumugam S.; Popik V. V. J. Am. Chem. Soc. 2012, 134, 8408. [DOI] [PubMed] [Google Scholar]; b Arumugam S.; Orski S. V.; Locklin J.; Popik V. V. J. Am. Chem. Soc. 2012, 134, 179. [DOI] [PubMed] [Google Scholar]; c Arumugam S.; Popik V. V. J. Am. Chem. Soc. 2011, 133, 15730. [DOI] [PubMed] [Google Scholar]

- Pauloehrl T.; Delaittre G.; Bruns M.; Meissler M.; Borner H. G.; Bastmeyer M.; Barner-Kowollik C. Angew. Chem., Int. Ed. 2012, 51, 9181. [DOI] [PubMed] [Google Scholar]

- a Blasco E.; Pinol M.; Oriol L.; Schmidt B. V. K. J.; Welle A.; Trouillet V.; Bruns M.; Barner-Kowollik C. Adv. Funct. Mater. 2013, 23, 4011. [Google Scholar]; b Rodriguez-Emmenegger C.; Preuss C. M.; Yameen B.; Pop-Georgievski O.; Bachmann M.; Mueller J. O.; Bruns M.; Goldmann A. S.; Bastmeyer M.; Barner-Kowollik C. Adv. Mater. 2013, 25, 6123. [DOI] [PubMed] [Google Scholar]; c Dietrich M.; Delaittre G.; Blinco J. P.; Inglis A. J.; Bruns M.; Barner-Kowollik C. Adv. Funct. Mater. 2012, 22, 304. [Google Scholar]; d Gupta N.; Lin B. F.; Campos L.; Dimitriou M. D.; Hikita S. T.; Treat N. D.; Tirrell M. V.; Clegg D. O.; Kramer E. J.; Hawker C. J. Nat. Chem. 2010, 2, 138. [DOI] [PubMed] [Google Scholar]; e Kloxin C. J.; Scott T. F.; Park H. Y.; Bowman C. N. Adv. Mater. 2011, 23, 1977. [DOI] [PubMed] [Google Scholar]

- a Gruendling T.; Oehlenschlaeger K. K.; Frick E.; Glassner M.; Schmid C.; Barner-Kowollik C. Macromol. Rapid Commun. 2011, 32, 807. [DOI] [PubMed] [Google Scholar]; b Oehlenschlaeger K. K.; Mueller J. O.; Heine N. B.; Glassner M.; Guimard N. K.; Delaittre G.; Schmidt F. G.; Barner-Kowollik C. Angew. Chem., Int. Ed. 2013, 52, 762. [DOI] [PubMed] [Google Scholar]

- a Valkevich E. M.; Guenette R. G.; Sanchez N. A.; Chen Y. C.; Ge Y.; Strieter E. R. J. Am. Chem. Soc. 2012, 134, 6916. [DOI] [PMC free article] [PubMed] [Google Scholar]; b Bauer D. M.; Rogge A.; Stolzer L.; Barner-Kowollik C.; Fruk L. Chem. Commun. 2013, 49, 8626. [DOI] [PubMed] [Google Scholar]

- a Pauloehrl T.; Welle A.; Bruns M.; Linkert K.; Borner H. G.; Bastmeyer M.; Delaittre G.; Barner-Kowollik C. Angew. Chem., Int. Ed. 2013, 52, 9714. [DOI] [PubMed] [Google Scholar]; b Pauloehrl T.; Welle A.; Oehlenschlaeger K. K.; Barner-Kowollik C. Chem. Sci. 2013, 4, 3503. [Google Scholar]; c Tischer T.; Claus T. K.; Bruns M.; Trouillet V.; Linkert K.; Rodriguez-Emmenegger C.; Goldmann A. S.; Perrier S.; Borner H. G.; Barner-Kowollik C. Biomacromolecules 2013, 14, 4340. [DOI] [PubMed] [Google Scholar]; d Pauloehrl T.; Delaittre G.; Winkler V.; Welle A.; Bruns M.; Borner H. G.; Greiner A. M.; Bastmeyer M.; Barner-Kowollik C. Angew. Chem., Int. Ed. 2012, 51, 1071. [DOI] [PubMed] [Google Scholar]

- a Tucker-Schwartz A. K.; Farrell R. A.; Garrell R. L. J. Am. Chem. Soc. 2011, 133, 11026. [DOI] [PubMed] [Google Scholar]; b Altintas O.; Willenbacher J.; Wuest K. N. R.; Oehlenschlaeger K. K.; Krolla-Sidenstein P.; Gliemann H.; Barner-Kowollik C. Macromolecules 2013, 46, 8092. [Google Scholar]; c Stolzer L.; Ahmed I.; Rodriguez-Emmenegger C.; Trouillet V.; Bockstaller P.; Barner-Kowollik C.; Fruk L. Chem. Commun. 2014, 50, 4430. [DOI] [PubMed] [Google Scholar]

- a Ning X. H.; Guo J.; Wolfert M. A.; Boons G. J. Angew. Chem., Int. Ed. 2008, 47, 2253. [DOI] [PMC free article] [PubMed] [Google Scholar]; b Shafiq Z.; Cui J. X.; Pastor-Perez L.; San Miguel V.; Gropeanu R. A.; Serrano C.; del Campo A. Angew. Chem., Int. Ed. 2012, 51, 4332. [DOI] [PubMed] [Google Scholar]

- Gong T.; Adzima B. J.; Baker N. H.; Bowman C. N. Adv. Mater. 2013, 25, 2024. [DOI] [PubMed] [Google Scholar]

- a Chan J. W.; Hoyle C. E.; Lowe A. B.; Bowman M. Macromolecules 2010, 43, 6381. [Google Scholar]; b Xi W.; Wang C.; Kloxin C. J.; Bowman C. N. ACS Macro Lett. 2012, 1, 811. [DOI] [PubMed] [Google Scholar]

- a Dietliker K.; Husler R.; Birbaum J. L.; Ilg S.; Villeneuve S.; Studer K.; Jung T.; Benkhoff J.; Kura H.; Matsumoto A.; Oka H. Prog. Org. Coat. 2007, 58, 146. [Google Scholar]; b Liang Y. K.; Kiick K. L. Polym. Chem. 2014, 5, 1728. [Google Scholar]

- Stoll R. S.; Hecht S. Angew. Chem., Int. Ed. 2010, 49, 5054. [DOI] [PubMed] [Google Scholar]

- Xi W.; Krieger M.; Kloxin C. J.; Bowman C. N. Chem. Commun. 2013, 49, 4504. [DOI] [PubMed] [Google Scholar]

- a Ishikawa T.; Kumamoto T. Synthesis 2006, 5, 737. [Google Scholar]; b Bochet C. G. J. Chem. Soc., Perkin Trans. 1 2002, 1, 125. [Google Scholar]

- Hasan A.; Stengele K. P.; Giegrich H.; Cornwell P.; Isham K. R.; Sachleben R. A.; Pfleiderer W.; Foote R. S. Tetrahedron 1997, 53, 4247. [Google Scholar]

- Cramer N. B.; Bowman C. N. J. Polym. Sci., Polym. Chem. 2001, 39, 3311. [Google Scholar]

- Li G. Z.; Randev R. K.; Soeriyadi A. H.; Rees G.; Boyer C.; Tong Z.; Davis T. P.; Becer C. R.; Haddleton D. M. Polym. Chem. 2010, 1, 1196. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.