Abstract

Understanding basic concepts of electronics and computer programming allows researchers to get the most out of the equipment found in their laboratories. Although a number of platforms have been specifically designed for the general public and are supported by a vast array of on-line tutorials, this subject is not normally included in university chemistry curricula. Aiming to provide the basic concepts of hardware and software, this article is focused on the design and use of a simple module to control a series of PDMS-based valves. The module is based on a low-cost microprocessor (Teensy) and open-source software (Arduino). The microvalves were fabricated using thin sheets of PDMS and patterned using CO2 laser engraving, providing a simple and efficient way to fabricate devices without the traditional photolithographic process or facilities. Synchronization of valve control enabled the development of two simple devices to perform injection (1.6 ± 0.4 μL/stroke) and mixing of different solutions. Furthermore, a practical demonstration of the utility of this system for microscale chemical sample handling and analysis was achieved performing an on-chip acid-base titration, followed by conductivity detection with an open-source low-cost detection system. Overall, the system provided a very reproducible (98%) platform to perform fluid delivery at the microfluidic scale.

1. Introduction

The use and application of microfluidic devices has grown exponentially in the last few decades. The miniaturization of complex analytical equipment and the integration of multiple analytical steps have allowed in-situ analysis, reduction of sample and reagents volumes (from mL to μL), and significant improvements in analysis time [1–4]. As a result, microfluidic devices have inundated the analytical landscape and enabled the analysis of a wide number of samples in agricultural [5, 6], chemical, biomedical, and forensic fields [7, 8]. In addition, a variety of strategies have been presented to fabricate devices ranging from standard photolithography [9] to rapid prototyping [10–12]. In this regard, our group has recently presented two versatile and inexpensive approaches to either assemble [13] or engrave microfluidic devices [14]. Despite these advances, it is important to stress the limited number of publications related to instrumentation designed for microfluidic devices [2, 13, 15–18]. In turn, this could be attributed to a combination of limited funding opportunities to support such engineering-oriented endeavors, a gap in interest and/or preparation of classic chemistry students in the area of electronic circuits and software, and the cost of traditional platforms such as LabView (National Instruments, http://www.ni.com/labview/). Although LabView is a solid tool to control systems in a rather commonly-known environment, and has been extensively used to control analytical instrumentation [19, 20]. However, its cost and the need for specific training limit its application in low-resource and educational settings. Recent advances in electronics are not only decreasing the cost but also largely increasing the number of potential platforms to aid in the control of analytical instrumentation. Among them, open-source strategies are gaining strength and are under serious consideration by many organizations [21, 22]. Under this domain, the software is freely licensed to use, copy, study, and change in any way, and the source code is openly shared so that people are encouraged to voluntarily improve the design of such applications. Probably the most successful open source platforms today are Linux and GNU, which have grown tremendously in the last decades [23] and are now present in all Android-based cellphones [24]. The popularity of these operating systems, along with simpler hardware requirements, has promoted the growth of a community of users and hardware platforms such as Intel’s Galileo (http://arduino.cc/en/ArduinoCertified/IntelGalileo), Raspberry Pi (http://www.raspberrypi.org/), Arduino (http://www.arduino.cc/), and Teensy (https://www.pjrc.com/teensy/). Most of these platforms share features such as low cost, a simple programming language, and can provide the means to develop exceptionally low-cost open-source scientific tools suitable for research and development using microfluidic devices. As an example, Arduino boards have been recently used in chemical applications to control remote microchip-CE systems [25], conductivity detectors [26], pH-meters (https://code.google.com/p/phduino/), flow-injection pumps [27], assisted electrochemical etching of scanning probe microscopy tips [28], digital microfluidic devices [29], and a point-of-care assay for pathogen genotyping analysis [30]. Although not specifically focused on the hardware, recent reports have also described the use of Teensy boards to control a microfluidic immunoassay [31] and an electrochemical detector [32]. In order to guide researchers interested in starting with open-source concepts, this article provides a basic description of two microfluidic pumps, fabricated by laser engraving of PDMS sheets and controlled using a Teensy board. Beyond demonstrating the possibility to use laser engraving to fabricate these devices, this paper aims to provide a set of tools to integrate microfabrication and basic electronics into chemistry curricula, using open hardware and source code.

2. Experimental section

2.1. Hardware

In a nutshell, Teensy is a complete USB-based microcontroller development system with a very small footprint and capable of implementing many types of projects. All programming is done via the USB port and either a PC or Macintosh. Among the currently available models, Teensy 2 was selected for all experiments described in this manuscript. This board is based on an ATmega 32U4 microprocessor, featuring small size (1.78 cm × 3.05 cm), low power consumption (3 mA at 3.3 V), high processing speed (16 MHz), 25 I/O pins, and pulse width modulation (PWM, 7 pins). PWM is a very important function because it can be used to generate analog results with a digital signal (square wave) that is switched between on (5V) and off (0V). By adjusting the time allocated to each state, the effective voltage in the output pin can be regulated to control electric motors, relays, LEDs, and other peripherals. As most programs written for Arduino can run on Teensy, all of the standard Arduino functions (digitalWrite, pinMode, analogRead, etc.) as well as Arduino libraries can be used. The language is based on Wiring (http://wiring.org.co/) and, unlike C++, the header and functions are automatically added when the application is compiled (using WinAVR). To generate a code, users should simply install the Arduino program, connect the microcontroller to the USB port on the computer, type commands, select the model of the microcontroller and USB port where it is plugged in, and click run. The code can be also uploaded to the microcontroller using Teensy Loader after a simple reboot function (pressing the only push button on the board). Unless a new sequence is uploaded, the microcontroller will automatically run the code every time is powered up.

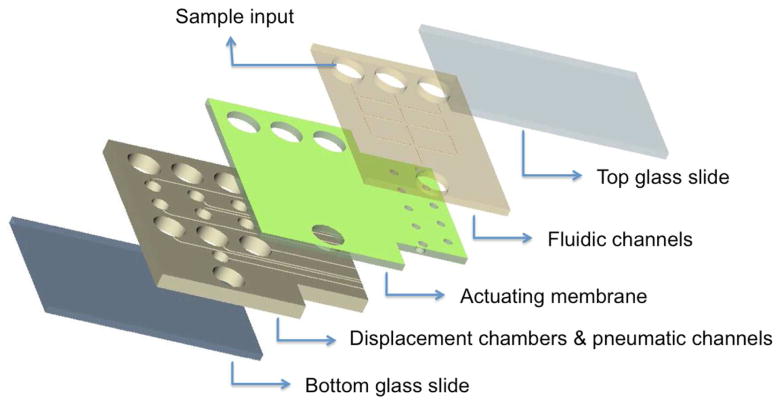

2.2. Microfluidic Pumps

For this project we used a series of synchronized, pneumatically-actuated microvalves, integrated on hybrid glass-polymer devices. These microvalves were first developed by Grover et al. [33] and have been employed for automated handling of fluids on chip [34]. Briefly, these microvalves structures consist of a flexible elastomer membrane (e.g. PDMS) sandwiched between two glass layers, each etched with features corresponding to pneumatic inputs and fluidic channels [33, 35–38]. By applying either pressure or vacuum the membrane (placed above the displacement chambers) is deflected, allowing the movement of liquids from/to the microvalve to the channels. The actuation of three valves in series generates a peristaltic pump that allows the transfer of fluid at a rate of nL to μL per cycle [33, 37].

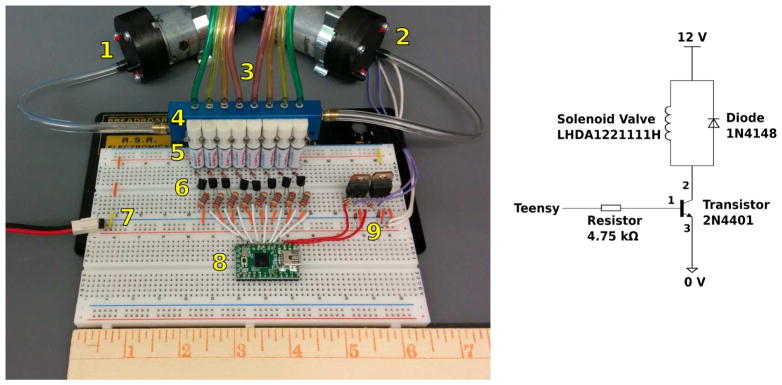

The design and operation of these microvalves was adapted from a previous publication [39]. The microvalves are operated by a series of solenoids (LHDA1221111H, Lee Co; Essex, CT) mounted on a manifold (LFMX0510538BF, Lee Co), according to the diagram shown in Figure 1A. A block diagram showing the connections is provided in the Supplementary Information. Depending upon the state of the solenoids, the microvalves are either open (i.e., when the solenoid is connected to the house vacuum line) or closed (when solenoid is connected to the house N2 line). The solenoids (through the manifold) were connected to two pneumatic pumps (model 061/06 30131, Bühler MotorGmbH; Nuremberg, Germany) to provide either vacuum or pressure. These pneumatic and vacuum pumps (operated only when required) were also controlled using the Teensy board via TIP122 transistors (marked as 9 in Figure 1A). Connection between the manifold and the device was accomplished using Tygon tubing (marked as 3 in Figure 1A) and standard needles (30G).

Figure 1.

Figure 1A: Picture of the arrangement showing the pneumatic circuit (1–2: pneumatic pumps, 3 pneumatic connections to the device, 4: manifold, and 5 solenoids), and the electronic circuit (7: power, 8: Teensy, and 9 transistors to control the pneumatic pumps).

Figure 1B: Electric circuit designed to control the solenoid valves.

Each solenoid (#5 in the picture, one for each microfluidic valve) was driven by transistors and controlled by a port in the Teensy board, as illustrated in the diagram shown in Figure 1A. The solenoid valves were opened and closed upon receiving (from the Teensy board) 5 or 0 V, respectively (signal of up to 40 mA and 5 V).

The transistors (2N4401, used for devices requiring a higher current or voltage) used in this assembly (Figure 1B) work as keys, turning on and off components connected to the corresponding output pins. The transistors have three terminals: base, collector, and emitter (identified as ports 1, 2 and 3 respectively, in Figure 1B). The base (key) was connected to the microcontroller; the collector was connected in series with the electronic component, and the emitter pin was grounded. Upon sending the appropriate signal, the microcontroller can apply 5 V to the base pin in the transistor, allowing the current to flow between the base and emitter, and connecting the circuit between the collector and the emitter. As also shown in Figure 1B, a 4.75 kΩ resistor was added between the Teensy board and the transistor to limit the current flow (1 mA) and prevent damaging the microcontroller. The diode (1N4148) works as a protective circuit, minimizing the interference caused by opening/closing the solenoids and the vacuum/pressure pumps can lead to unnecessarily high currents and heating in the circuit. This simple assembly is very versatile and allows controlling any device consuming up to 5 V/30 mA (when connected directly to the Teensy board) or 12 V/45 mA (when connected to the transistor). A similar arrangement was recently used to activate a fluidic valve in an electrochemical sensor [40].

2.3. Software

The microcontroller was programmed by writing a list of instructions in a language that the Teensy is able to interpret. The instructions are executed one at a time and in the linear order defined in the sequence. For all the experiments herein described, the program was written to turn on and off a series of solenoid valves, for a given period of time. Each solenoid was connected at a certain pin of the microcontroller (named as port) and identified with a number. Therefore, a statement to turn on a solenoid valve connected to port #8 should be written as

digitalWrite(8, HIGH);

where the command “digitalWrite()” instructs the microcontroller to send a signal to one of the ports of the board, in this case port number 8. This signal can be either HIGH or LOW. If the signal sent is HIGH, the board will apply 5 V and turn on the solenoid valve connected to such a port. If the signal sent is LOW, the board will apply 0 V and turn off the solenoid valve connected to that port. The character “;” indicates to the microcontroller the end of the statement. To control the time length the board applies the signal, the following command can be used:

delay (1000);

where “delay()” instructs the board to wait a certain period of time (1000 ms) before executing the next command. Finally, every program written in Arduino needs two more commands:

void setup () {}

void loop () {}

The first command is similar to the boot function in a conventional computer. So all commands to be run during this period should be placed between the keys. Example:

void setup () {

pinMode (8, OUTPUT);

}

The “pinMode()” command will be executed only once during boot and instructs the microcontroller to use port 8 for sending signals. This command is needed, because each port may be configured as input (default) or output. All commands that are inside the keys of the “loop()” command will be executed sequentially. When the last command is finished, the microcontroller will come back to the first command in the loop and restart the sequence. As an example, the following sequence will turn the valves on ports 2 and 4, wait 5 seconds and then turn them off:

void setup(){

pinMode(2, OUTPUT);

pinMode(4, OUTPUT);

}

void loop(){

digitalWrite(2, HIGH);

digitalWrite(4, HIGH);

delay(5000);

digitalWrite(2, LOW);

digitalWrite(4, LOW);

}

A sample of the code used to control one of the devices is available as Supplementary Information.

2.4 Fabrication of the PDMS devices

Microdevices were constructed with three layers of PDMS (0.010 in, HT-6240, Rogers Corporation; Carol Stream, IL) permanently sealed to two glass slides (Propper Manufacturing Co., New York, NY). Although previous reports have used patterned PDMS with different thicknesses, the selection of using glass slides (to provide structural support) was based on cost and availability. All channels and chambers were fabricated by laser engraving the PDMS sheets using a computer controlled CO2 laser engraver (Epilog Mini 24; Denver, CO). Specific details about the system and the capabilities to fabricate microfluidic devices can be found elsewhere [14]. Selecting a power of 10.5 W and an engraving speed of 50 % speed allowed engraving channels of 160 μm (depth) by 340 μm (width). To engrave reservoirs, a power of 13.5 W and a speed of 50% were selected. Representative images of the channels and reservoirs obtained by this method are available in the Supplementary Information section. Because the laser engraving process can generate soot that spreads around the ablation site and could potentially hinder the sealing process, the PDMS sheets were engraved between the two protective sheets of plastic (polyethylene terephthalate) that served as sacrificial layers. To minimize the presence of debris, the engraved PDMS layers were lightly brushed and then immersed in water/methanol and placed in an ultrasonic bath (Branson) for 20 min. After removing the protective sheets, the PDMS layers were oxidized along with the microscope slides using an oxygen plasma (PDC-32G, Harrick; New York, NY) during 45 sec and then brought into conformal contact to form an irreversible bond. Each on-chip pump was constructed by stacking channels and three displacement chambers, along a top channel. When vacuum is applied to the displacement chamber (below the actuator membrane), a connection between the channels in the top layer is formed allowing the passage of liquids. When the vacuum is released (and/or pressure is applied), the membrane is pushed back against the channel, expelling the liquid and blocking the channel. When the actuation of two or more chambers is synchronized, they can be used to mobilize fluids. As described by Mora et. al. [18, 39], the flow rate obtained with this type of pump depends on the dimensions of the fluidic channel, the displacement chamber volume, and the valve actuation times. For the experiments described in this manuscript, the micropumps were assembled according to Figure 2. The device was assembled in two halves, with the PDMS layer containing the displacement chambers bound to the bottom glass slide, and the membrane with the fluidic channels bound to the top glass slide. These halves were sandwiched around a third PDMS layer; the actuating membrane, which prior to incorporation into the device, was selectively oxidized (the regions of the activating membrane above the displacement chambers were protected from oxidation to prevent contact bonding). This strategy allowed the valve to open/close once the layer containing the fluidic channels was permanently sealed. According to preliminary results, the valve can be also assembled using standard paper clamps, therefore avoiding the need of a plasma cleaner. Such alternative could bolster the development and use of these devices in educational settings or communities with limited financial resources.

Figure 2.

Schematic diagram of the arrangement of the layers used to assemble the device fabricated by laser engraving of PDMS sheets.

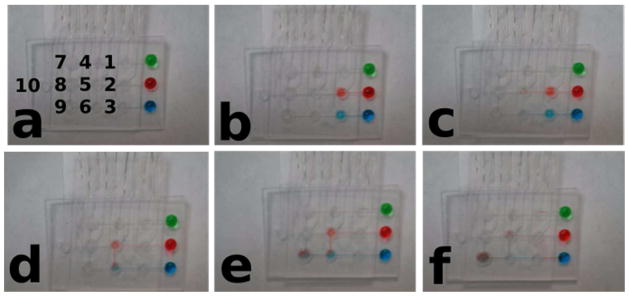

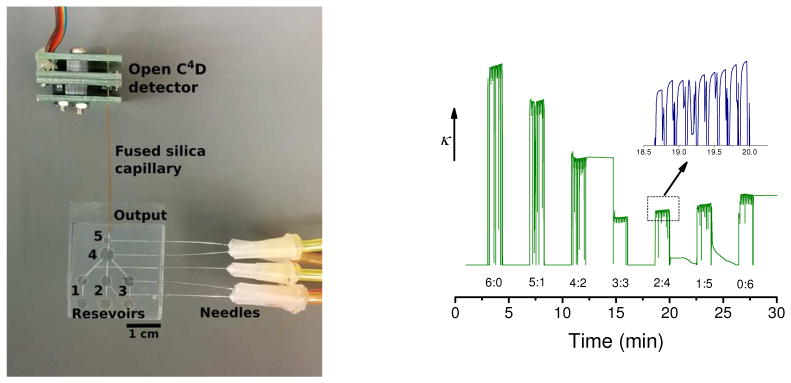

Pictures of representative devices produced are shown in Figure 3 and Figure 4 and will be discussed in the corresponding sections.

Figure 3.

Pictures of six consecutive frames corresponding to the system during operation.

Figure 4.

Figure 4A: Picture of the device fabricated in PDMS/glass and interfaced with a conductivity detector. The device consists of 3 sample inlets, five microvalves, and one sample outlet.

Figure 4B: Relative conductivity values of the solution resulting from mixing different ratios of NaOH and HCl, each at a concentration of 10−3 M.

2.3 Materials and solutions

As an example to demonstrate the capabilities of the devices fabricated with this novel approach, mixing of standard food dyes (Adams Extract and Spice, TX) and an acid-based titration were performed. The latter was accomplished by mixing different ratios of solutions containing either NaOH (1×10−3 M, Fisher Scientific) or HCl (1×10−3 M, Merck KgaA, Darmstadt, Germany) prepared in deionized water (Nanopure Diamond, Thermo Fisher Scientific Inc., USA).

3. Results and Discussion

3.1. Mixing

To demonstrate the possibility of sequentially actuating the PDMS-engraved microvalves with the proposed control unit, a series of solutions containing food dyes were pumped and mixed with the aid of the microcontroller. The device shown in Figure 3 comprised four reservoirs (three inlet + 1 outlet) and ten microvalves.

To simplify the experimental setup, the first three valves (directly in contact with the samples) were connected to the same outlet of the manifold following the diagram shown in Figure 1A. Initially, three different dyes were dispensed on the sample reservoirs (Figure 3A). At the initial state, all solenoids are off and all valves are closed. Next, two contiguous microvalves (#2 and #3) were opened to draw the solutions containing the red and blue dyes, respectively. Next, microvalves #5 and #6 were opened (c). Then, microvalves #2 and #3 were closed (d) causing the fluid to advance in the device. To transfer/mix the solution, microvalve #9 was opened (e). Next, microvalves #5 and #6 were closed (f). Finally, to pump the solution out of the device, microvalve #8 was opened, #9 was closed, #10 was opened, and #8 was closed. It is important to note that this simple arrangement allowed moving and mixing the selected solutions while maintaining the green dye within the sample reservoir. This simple arrangement of microvalves could be applied for a series of analytical applications as previously demonstrated with more complex devices fabricated including biochemical [41] and genetic analysis [42, 43] as well as on-chip labeling reactions prior to CE separations [44, 45]. In addition, the proposed approach does not require access to cleanroom facilities or access to specific instrumentation and therefore it can be adapted to most universities or classrooms.

3.2 Titration

In order to demonstrate the potential of the proposed approach to perform simple analytical operations, a titration of HCl with NaOH was performed on chip and monitored by measuring the conductivity of the resulting solution in real time. The device shown in Figure 4A comprises three sample reservoirs, five microvalves, and a fused silica capillary to serve as a connection between the device and the detector. Although the described experiments were performed using 100 μm ID/360 μm OD, 5 cm long capillaries, other capillary sizes can be integrated. In such cases, the conditions during the engraving process should be adjusted to produce a channel that fits the selected capillary OD. For the experiments described in this manuscript, a capacitively-coupled conductivity detector (also available through the open-source environment https://sites.google.com/site/openc4d/) was used [26, 46, 47]. Although the proposed Teensy board has the capacity to control the microvalves as well as the detector, experiments herein described used a second Teensy connected to the C4D mimicking the setup reported in previous manuscripts [26, 46, 47].

For this demonstration, the solution containing HCl was placed in Reservoir 1, while the base was placed in Reservoir 3. Reservoir 2 was used to receive and mix the solutions of acid and base. In this case, the microchip had three operating modes: sample preparation, mixing, and injection (Table 1). During sample preparation, known volumes of acid and/or base were pumped to reservoir 2. According to the results described in the Supplementary information, each stroke of the microvalve can displace 1.6 ± 0.3 μL of solution with a reproducibility of 95% (calculated as the difference in mass after six strokes of the microvalves delivering liquid to a piece of filter paper). Next, the solutions injected into reservoir 2 were mixed by triggering valves 2 and 4 (6 times). Finally, the injection was accomplished by triggering the sequence of valves 2-4-5 (9 times) to assure that all the solution contained in the device was delivered.

Table 1.

Mobilization of the sample sequence

| Mode | Valve # | Operation | Duration (ms) | Code |

|---|---|---|---|---|

| Sample preparation | 1 (or 3) | open | 1500 | digitalWrite(1, HIGH); |

| 4 | open | 4500 | digitalWrite(4, HIGH); | |

| 1 (or 3) | close | 1500 | digitalWrite(1, LOW); | |

| 2 | open | 1500 | digitalWrite(2, HIGH); | |

| 4 | close | 4500 | digitalWrite(4, LOW); | |

| 2 | close | 1500 | digitalWrite(2, LOW); | |

|

| ||||

| Mixing | 2 | open | 1500 | digitalWrite(2, HIGH); |

| 4 | open | 1500 | digitalWrite(4, HIGH); | |

| 2 | close | 1500 | digitalWrite(2, LOW); | |

| 2 | open | 1500 | digitalWrite(2, HIGH); | |

| 4 | close | 1500 | digitalWrite(4, LOW); | |

| 2 | close | 1500 | digitalWrite(4, LOW); | |

|

| ||||

| Injection | 2 | open | 1500 | digitalWrite(2, HIGH); |

| 4 | open | 1500 | digitalWrite(4, HIGH); | |

| 2 | close | 1500 | digitalWrite(2, LOW); | |

| 5 | open | 1500 | digitalWrite(5, HIGH); | |

| 4 | close | 1500 | digitalWrite(4, LOW); | |

| 5 | close | 1500 | digitalWrite(5, LOW); | |

It is important to note that the time required to actuate these microvalves could also have a significant effect on the volume displaced in each stroke. While the values reported provided enough time to open and close each microvalve, faster rates can be achieved at the expense of the volume pumped. For example, changing the actuation time of microvalve #4 during from 1500 ms to 100 ms yielded to a decrease in the displaced volume from 1.6 ± 0.4 μL to 0.82 ± 0.5 μL, respectively. This behavior was attributed to a combination of the time required to activate the electronic components (i.e. pumps) and to pressurize the pneumatic circuit as well as the flexibility of the PDMS layer. Additional information is available as Supplementary Information.

Figure 4B shows the dependence of the conductivity of the solution as a function of the ratio of HCl/NaOH mixed by the microdevice. Each level in the graph is composed of 9 strokes of the pump, delivering the solution resulting from mixing 6 volumes injected in the device at different ratios. In case an improvement in signal/noise ratio is required, the conductivity data can be processed with a simple windowed median filter [48].

It is also worth noting that although the plot is response as a function of time, the flow rate through the detector is not constant, filling the detection region in the detector with either solution or air between injections. The base line of the graph corresponds to the conductivity of the cell filled with air. The signal intensity is a function of both the concentration of species and its conductivity constituents. At the beginning of the titration, the conductivity of the solution is determined by the conductivity of H+ (349.65 × 10−4 m2mol−1 at 25 °C at infinite dilution). As the titration progresses and H+ are consumed, lower signal intensities are obtained, reaching the minimum when equivalent amounts of acid and base are mixed. In such case, the conductivity of the solution is determined by the concentration of Na+ (50.08 × 10−4m2mol−1) and Cl− (76.31 × 10−4 m2mol−1). Beyond the equivalence point, the conductivity of the solution is determined by the excess of OH− (198 × 10−4 m2mol−1) and Na+. It is also important to mention that the large surface-to-volume ratio in the device is significantly higher than the ratios obtained in a standard bench-top titration. Therefore, to completely eliminate the interference of CO2 [49, 50], additional elements or steps should be included, such as to enclose the system in an inert atmosphere or degas the solutions with N2.

It is also worth noting that small differences in the dimensions of the features engraved, as well as variations in the viscosity of the solution could affect the injected volume. To evaluate the overall reproducibility of the device (fabrication plus operation), a solution containing HCl was injected from either Reservoir 1 or Reservoir 3 into Reservoir 2 and then weighed. The results showed that no statistical differences were obtained injecting solutions from Reservoir 1 (10.1 ± 0.1 mg) or Reservoir 3 (10.5 ± 0.4 mg) after performing the experiment by triplicate. To evaluate the effect of the solution viscosity, the solution in Reservoir 1 was replaced with NaOH and the experiment repeated. In this case, similar results were obtained (9.8 ± 0.4 mg) indicating that no statistical differences (98% confidence) were obtained and supporting the reliability of the proposed approach.

4. Conclusions

This manuscript describes some basic recommendations to integrate open-hardware microcontrollers to control the operation of microfluidic devices. For the experiments described, devices were fabricated by assembling a series of PDMS layers patterned with a laser engraver. This method yields results that are comparable to traditional routes using photolithography and etching of glass substrates. The control set-up was based on the integration of a Teensy board and a series of components to provide automated control of the devices using simple software code. Overall, this is a simple, inexpensive, and versatile method to achieve accurate control of the devices using a low-cost interface. Beyond the presented results, we believe this platform could be used to introduce basics concepts of microfabrication and electronics in analytical chemistry and instrumental analysis courses.

Supplementary Material

Acknowledgments

The authors gratefully acknowledge the financial support provided by NASA STTR (Contract #: NNX13CP49C), The University of Texas at San Antonio, and the National Institutes of Health through the Research Centers at Minority Institutions (G12MD007591).

References

- 1.Ríos Á, Zougagh M, Avila M. Anal Chim Acta. 2012;740:1–11. doi: 10.1016/j.aca.2012.06.024. [DOI] [PubMed] [Google Scholar]

- 2.Ryvolová M, Macka M, Preisler J. TrAC Trends Anal Chem. 2010;29:339–353. [Google Scholar]

- 3.Escarpa A, González MC, Crevillén AG, Blasco AJ. Electrophoresis. 2007;28:1002–1011. doi: 10.1002/elps.200600412. [DOI] [PubMed] [Google Scholar]

- 4.Rios A, Escarpa A, Gonzalez MC, Crevillen AG. TrAC Trends Anal Chem. 2006;25:467. [Google Scholar]

- 5.Neethirajan S, Kobayashi I, Nakajima M, Wu D, Nandagopal S, Lin F. Lab Chip. 2011;11:1574–1586. doi: 10.1039/c0lc00230e. [DOI] [PubMed] [Google Scholar]

- 6.Martín A, Vilela D, Escarpa A. Electrophoresis. 2012;33:2212–2227. doi: 10.1002/elps.201200049. [DOI] [PubMed] [Google Scholar]

- 7.Horsman KM, Bienvenue JM, Blasier KR, Landers JP. J Forensic Sci. 2007;52:784–799. doi: 10.1111/j.1556-4029.2007.00468.x. [DOI] [PubMed] [Google Scholar]

- 8.Taudte RV, Beavis A, Wilson-Wilde L, Roux C, Doble P, Blanes L. Lab Chip. 2013 doi: 10.1039/c3lc50609f. [DOI] [PubMed] [Google Scholar]

- 9.Segato TP, Coltro WKT, de Jesus Almeida AL, de Oliveira Piazetta MH, Gobbi AL, Mazo LH, Carrilho E. Electrophoresis. 2010;31:2526–2533. doi: 10.1002/elps.201000099. [DOI] [PubMed] [Google Scholar]

- 10.Coltro WK, Piccin E, Fracassi da Silva JA, Lucio do Lago C, Carrilho E. Lab Chip. 2007;7:931–934. doi: 10.1039/b702931d. [DOI] [PubMed] [Google Scholar]

- 11.Waldbaur A, Rapp H, Lange K, Rapp BE. Anal Methods. 2011;3:2681–2716. [Google Scholar]

- 12.Young EWK, Berthier E, Guckenberger DJ, Sackmann E, Lamers C, Meyvantsson I, Huttenlocher A, Beebe DJ. Anal Chem. 2011;83:1408–1417. doi: 10.1021/ac102897h. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Segato TP, Bhakta SA, Gordon MT, Carrilho E, Willis PA, Jiao H, Garcia CD. Anal Methods. 2013;5:1652–1657. doi: 10.1039/c3ay26392d. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Moreira Gabriel EF, Coltro WKT, Garcia CD. Electrophoresis. 2014 doi: 10.1002/elps.201470140. in press. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Roman GT, Kennedy RT. J Chromatogr A. 2007;1168:170–188. doi: 10.1016/j.chroma.2007.06.010. [DOI] [PubMed] [Google Scholar]

- 16.Felhofer JL, Blanes L, Garcia CD. Electrophoresis. 2010;31:2469–2486. doi: 10.1002/elps.201000203. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Takmakov P, McKinney CJ, Carelli RM, Wightman RM. Rev Sci Instrum. 2011;82:074302. doi: 10.1063/1.3610651. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Mora MF, Stockton AM, Willis PA. Electrophoresis. 2012;33:2624–2638. doi: 10.1002/elps.201200102. [DOI] [PubMed] [Google Scholar]

- 19.Grover WH, Ivester RHC, Jensen EC, Mathies RA. Lab Chip. 2006;6:623–631. doi: 10.1039/b518362f. [DOI] [PubMed] [Google Scholar]

- 20.Berg C, Valdez DC, Bergeron P, Mora MF, Garcia CD, Ayon A. Electrophoresis. 2008:4914–4921. doi: 10.1002/elps.200800215. [DOI] [PubMed] [Google Scholar]

- 21.Hauge Ø, Ayala C, Conradi R. Inform Software Tech. 2010;52:1133–1154. [Google Scholar]

- 22.Marsan J, Paré G. Int J Med Inform. 2013;82:731–741. doi: 10.1016/j.ijmedinf.2013.04.001. [DOI] [PubMed] [Google Scholar]

- 23.Israeli A, Feitelson DG. J Syst Software. 2010;83:485–501. [Google Scholar]

- 24.Hoog A. In: Android Forensics. Hoog A, editor. Syngress; Boston: 2011. pp. 1–40. [Google Scholar]

- 25.da Costa ET, Neves CA, Hotta GM, Vidal DTR, Barros MF, Ayon AA, Garcia CD, do Lago CL. Electrophoresis. 2012;33:2650–2659. doi: 10.1002/elps.201200273. [DOI] [PubMed] [Google Scholar]

- 26.Francisco KJM, do Lago CL. Electrophoresis. 2009;30:3458–3464. doi: 10.1002/elps.200900080. [DOI] [PubMed] [Google Scholar]

- 27.Kongkedsuk J, Hongwitayakorn A, Bootnapang W, Boonto N, Chaisuksant R. Chiang Mai J Sci. 2013;40:224–231. [Google Scholar]

- 28.Jobbins MM, Raigoza AF, Kandel SA. Rev Sci Instrum. 2012;83 doi: 10.1063/1.3695001. [DOI] [PubMed] [Google Scholar]

- 29.Shih SCC, Yang H, Jebrail MJ, Fobel R, McIntosh N, Al-Dirbashi OY, Chakraborty P, Wheeler AR. Anal Chem. 2012;84:3731–3738. doi: 10.1021/ac300305s. [DOI] [PubMed] [Google Scholar]

- 30.Myers FB, Henrikson RH, Xu L, Lee LP. 33rd Annual International Conference of the IEEE EMBS; Boston, Massachusetts USA. 2011; pp. 3668–3671. [DOI] [PubMed] [Google Scholar]

- 31.Novo P, Chu V, Conde JP. Biosens Bioelectron. 2014;57:284–291. doi: 10.1016/j.bios.2014.02.009. [DOI] [PubMed] [Google Scholar]

- 32.Lillehoj PB, Huang MC, Truong N, Ho CM. Lab Chip. 2013:2950–2955. doi: 10.1039/c3lc50306b. [DOI] [PubMed] [Google Scholar]

- 33.Grover WH, Skelley AM, Liu CN, Lagally ET, Mathies RA. Sens Actuat A. 2003;89:315–323. [Google Scholar]

- 34.Duncan PN, Nguyen TV, Hui EE. Proc Natl Acad Sci U S A. 2013;110:18104–18109. doi: 10.1073/pnas.1310254110. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Skelley AM, Scherer JR, Aubrey AD, Grover WH, Ivester RHC, Ehrenfreund P, Grunthaner FJ, Bada JL, Mathies RA. Proc Nat Acad Sci. 2005;102:1041–1046. doi: 10.1073/pnas.0406798102. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Paegel BM, Grover WH, Skelley AM, Mathies RA, Joyce GF. Anal Chem. 2006;78:7522–7527. doi: 10.1021/ac0608265. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Willis PA, Hunt BD, White VE, Lee MC, Ikeda M, Bae S, Pelletier MJ, Grunthaner FJ. Lab Chip. 2007;7:1469–1474. doi: 10.1039/b707892g. [DOI] [PubMed] [Google Scholar]

- 38.Grover WH, Ivester RHC, Jensen EC, Mathies RA. Lab Chip. 2006;6 doi: 10.1039/b518362f. [DOI] [PubMed] [Google Scholar]

- 39.Mora MF, Greer F, Stockton AM, Bryant S, Willis PA. Anal Chem. 2011;83:8636–8641. doi: 10.1021/ac202095k. [DOI] [PubMed] [Google Scholar]

- 40.Vasudev A, Kaushik A, Tomizawa Y, Norena N, Bhansali S. Sens Actuators B. 2013;182:139–146. [Google Scholar]

- 41.Kim J, Kang M, Jensen EC, Mathies RA. Anal Chem. 2012;84:2067–2071. doi: 10.1021/ac202934x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Grover WH, Mathies RA. Lab Chip. 2005;5:1033–1040. doi: 10.1039/b505840f. [DOI] [PubMed] [Google Scholar]

- 43.Jensen EC, Zeng Y, Kim J, Mathies RA. J Lab Autom. 2010;15:455–463. [Google Scholar]

- 44.Bowen AL, Martin RS. Electrophoresis. 2010;31:2534–2540. doi: 10.1002/elps.201000029. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Willis PA, Stockton AM. In: Fundamental Concepts, Practical Applications, and Limitations of Capillary Electrophoresis and Microchip Capillary Electrophoresis. Garcia CD, Carrilho E, editors. Wiley and Sons; New York: 2013. [Google Scholar]

- 46.Brito-Neto JGA, Fracassi da Silva JA, Blanes L, do Lago CL. Electroanalysis. 2005;17:1198–1206. [Google Scholar]

- 47.Brito-Neto JGA, Fracassi da Silva JA, Blanes L, do Lago CL. Electroanalysis. 2005;17:1207–1214. [Google Scholar]

- 48.do Lago CL, Juliano VF, Kascheres C. Anal Chim Acta. 1995;310:281–288. [Google Scholar]

- 49.do Lago CL, Vidal DTR, Rossi MR, Hotta GM, da Costa ET. Electrophoresis. 2012;33:2102–2111. doi: 10.1002/elps.201200080. [DOI] [PubMed] [Google Scholar]

- 50.Rossi MR, Vidal DTR, do Lago CL. Food Chem. 2012;133:352–357. doi: 10.1016/j.foodchem.2012.01.039. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.