Abstract

The physical properties of wheat kernel were determined and related to pulverizing performance by correlation analysis. Nineteen samples of wheat cultivars about similar level of protein content (11.2–12.8 % w.b.) and obtained from organic farming system were used for analysis. The kernel (moisture content 10 % w.b.) was pulverized by using the laboratory hammer mill equipped with round holes 1.0 mm screen. The specific grinding energy ranged from 120 kJkg−1 to 159 kJkg−1. On the basis of data obtained many of significant correlations (p < 0.05) were found between wheat kernel physical properties and pulverizing process of wheat kernel, especially wheat kernel hardness index (obtained on the basis of Single Kernel Characterization System) and vitreousness significantly and positively correlated with the grinding energy indices and the mass fraction of coarse particles (> 0.5 mm). Among the kernel mechanical properties determined on the basis of uniaxial compression test only the rapture force was correlated with the impact grinding results. The results showed also positive and significant relationships between kernel ash content and grinding energy requirements. On the basis of wheat physical properties the multiple linear regression was proposed for predicting the average particle size of pulverized kernel.

Keywords: Wheat, Physical properties, Hardness, Pulverizing, Grinding

Introduction

Wheat is one of the most important crops in the world in terms of its geographical distribution, area under cultivation and total production. Most of the wheat that is produced is consumed by humans (75–78 %). Secondly, it is used as feed but also for industrial purposes (16–17 %) and propagation material (9–10 %) (Psaroudaki 2007). Size reduction is one of the most important unit operations in wheat processing. The selection of comminution method depends on the direction of wheat use. The most common way of wheat kernel size reduction is a gradual reduction process during wheat flour milling. This breaks down the tempered wheat grain in a series of grinding stages. Each grinding stage produces a blend of coarse, medium and fine fractions including flour. These mixtures are then sieved and purified to allow for a good separation of bran and endosperm. The white flour obtained in this way consists mainly of the starchy endosperm, whereas bran with the aleurone layer and germs are by-products. White flour can be used to produce variety of products that have good sensory properties. However this kind of flour is nutritionally useless and contains lower amounts of health-promoting components such as: fibre, minerals, vitamins, and antioxidants. These compounds are mainly located in wheat bran (Slavin et al. 1999; Singh et al. 2012; Das et al. 2010). Wheat bran is the outer layer of wheat grain making up about 13 % of weight of whole grain and a good source of proteins and minerals apart from being a rich source of dietary fiber. The fiber in wheat bran is mainly of insoluble type. (Yadav et al. 2009; Dhingra et al. 2012). Epidemiological studies showed that the intake of wholemeal wheat products was consistently associated with a reduced risk of type 2 diabetes, metabolic syndrome and coronary heart disease in both men and women in epidemiological studies (Steffen et al. 2003; Sahyoun et al. 2006). Production of whole grain flour is easier and less energy consuming than that of white patent flour production. The different types of grinding mills can be used to this end. The most commonly applied in practice are the roller mills. However they have little effect on fiber size reduction. The hammer mills are more appropriate for grinding fiber-rich bran and germ and thus for whole grain flour production (Prabhasankar and Rao 2004).

Wheat is also an important crop in organic farming (Mäder et al. 2007). Organic agriculture is of particular interest with regard to healthy, ecologically-friendly produced food, because inputs of chemicals are not allowed (Nelson et al. 2004; Zuchowski et al. 2011). With the increasing consumer pressure to reduce the use of pesticides, fertilizers, veterinary medicines and growth promoters in food production systems, the demand for organic foods continues to rise. The organic food market has become a rapidly growing sector of most developed agricultural economies around the world. Over the past 10 years, the number of organic farms in the European Union has more than doubled to about 190 000 certified organic farms in 2008 (Breustedt et al. 2011). Especially wheat varieties form organic farming are preferred to wholemeal flour production. Recent studies proved that a organically produced wheat is characterized by the significantly higher level of phenolic compounds in comparison to wheat cultivated in the conventional system (Zuchowski et al. 2011).

The grinding performance depends on the size reduction method and the properties of raw materials. A lot of studies have addressed the relations between the properties of wheat kernel hardness and size reduction process, especially with reference to the milling process. This property affects the tempering requirements, flour particle size, flour density, starch damage, water absorption, and milling yield (Turnbull and Rahman 2002; Hrušková and Švec 2009; Barak et al. 2012). Most of the methods to assess grain hardness are empirical and based on the overall properties of whole grains. The Single Kernel Characterization System (SKCS) is the one of one of the most innovative techniques in order to provide accurate, rapid, convenient and informative methods of measuring of wheat kernel hardness. Beside of this the SKCS measures the weight, diameter, and moisture of (usually) 300 individual kernels within 5 min, and provides information in the form of means and distributions (Muhamad and Campbell 2004). The numerous workers have applied the SKCS to a range of studies and have concluded that it gives useful results, especially for prediction wheat milling performance (Osborne et al. 1997; Muhamad et al. 2008). However there are no studies concerning the relation between SKCS parameters and impact grinding results, especially in relation to wholemeal flour production. Also, in addition to hardness, several other kernel parameters, including weight, size, shape and virtuousness and mechanical properties determined on the basis of wheat kernel compression test are believed to affect milling (Symons et al. 2003).

There are few studies that have been carried out on the relationships between the wheat kernel properties and the impact size reduction. Thus the objective of this study was to investigate the influence of the physical properties of wheat kernels on the pulverizing process, especially the relations between parameters obtained on the basis of SKCS and the pulverizing results were evaluated.

Materials and methods

Material

Investigations were carried out on 19 wheat cultivars (Triticum aestivum, ssp. vulgare) Bogatka, Bombona, Bryza, Cytra, Figura, Kobra Plus, Legenda, Nawra, Ostka Strzelecka, Parabola, Raweta, Rywalka, Smuga, Tonacja, Tybalt, Vinjet, Wydma, Zadra and Żura. The grain came from the organic field experiment conducted in 2010 at Osiny Experimental Station belonging to the Institute of Soil Science and Plant Cultivation (State Research Institute) located in Puławy. These varieties are commercially important and commonly used in the production of the flour used for baking bread. Moreover, there are no investigations concerning the impact grinding characteristics of this cultivars.

The initial moisture content of kernel ranged from 8.5 % to 9.8 % (w.b.). The samples of wheat were prepared by adding water to adjust moisture content to 10 % (w.b.) and storing for 48 h.

The SKCS (type 4100, Perten Instruments North America Inc., Reno, USA) was used to determine the hardness index (HI), kernel weight (KW), moisture (MC), and diameter (KD) from the analysis of individual kernels (AACC Method 55-10, 2002). The kernels were also evaluated for bulk density (BD) (AACC Method 55-31, 2002) and kernel virtuousness (KV) (Greffeuille et al. 2007), general content of protein (PC) using the Kjeldahl method with a Kjel-Foss Automatic (N·5.83), and content of total ash (KAC) (ICC Standard no. 104/1, ICC 1990). The analyses were conducted in three repetitions for each cultivar.

The slow loading compression test was performed with all wheat cultivars. Laskowski and Łysiak (1999) showed the usefulness of this test for legume seed impact grinding prediction. The uniaxail compression test was carried out on a Zwick Z020/TN2S universal testing machine using two flat, parallel plates. Each kernel was placed on the lower plate of the machine such that the crease was in contact with the bottom plate. The range of the load applied by the measuring head was from 0 to 500 N. The compression rate was adjusted at 10 mm/min. Crushing tests were carried out until a constant distance between the plates of 0.5 mm was achieved. For each test load–deformation data was recorded using testXpert software by Zwick. On the basis of obtained curves (Fig. 1) the mean value of rapture force (Fr) ad force in the end of compression (Fe) for each cultivar were calculated, as well as the mean value of kernel displacements (lr) up to the rapture point. The rapture energy and total compression energy were also calculated (Erc and Et, respectively).

Fig. 1.

A typical load–deformation curve of wheat kernel (cv. Parabola, moisture content 10 % w.b.)

The pulverizing process

The preliminary cleaned samples of individual wheat varieties (moisture content of 10 % w.b.) were pulverized by using the laboratory hammer mill POLYMIX-Micro-Hammermill MFC equipped with round holes 1.0 mm screen. The 20-g samples were weighted just prior to grinding. The mill speed was adjusted to 7,800 rpm to pulverizing. Wheat samples were placed into mil hopper and the entire sample was released into the grinding mechanism. The mill was equipped with a computer system that allowed the recording and analyzing the grinding energy consumption. The amount of energy consumed during grinding was obtained by means of a power transducer (PP71B5, LUMEL, Poland), a data acquisition and a computer system that recorded the data measured by the transducer. The grinding energy was calculated by using special computer software. The energy required to run the mill with no load was determined and subtracted from the total energy to obtain the grinding energy. The unloaded grinder current was monitored prior to grinding and remained constant over all testing. The specific grinding energy (Er) was determined as the ratio of the grinding energy to the mass of the material taken for grinding. The sieving test was used to determine the particle size distribution of the pulverized material. Sieving was carried out for 5 min, by using a laboratory screen (Thyr 2, SASKIA, Germany), and separated into fractions using sieves of sizes, 0.800, 0.630, 0.500, 0.400, 0.315, and 0.200 mm. On the basis of the particle size distribution, the average particle size (dp) was calculated (Velu et al. 2006). The grinding ability index (Ef) was calculated as a ratio of the grinding energy to the surface area of the pulverized material. The surface area of the pulverized material was evaluated according to the procedure described by Jha and Sharma (2010). The Sokołowski’s grinding index (Ks) was calculated on the basis of the size reduction theory described by Sokołowski (1996). Details of the procedure used in determining these indices can be found in Dziki (2011). The distribution of the particle size was evaluated thrice and the values of grinding indices were calculated from the average particle size.

Statistical analysis

The parameters described on the basis of SKCS were determined as a mean value form the analysis of 300 individual kernels, whereas the kernel compression test was done in 50 repetitions. The measurements of grinding energy were replicated ten times. The others experiments were done in triplicate. The obtained data was further subjected to a statistical analysis and the consequent evaluations were analyzed for a variance analysis (one-way ANOVA). The statistical differences between the treatment groups were estimated through Tukey’s test. The Pearson correlation analysis and the multiple linear regression analysis were also carried out on this data. Statistical tests were evaluated by using the Statistica 6.0 software (StatSoft, Inc., Tulsa, USA). All the statistical tests were carried out at a significance level of α = 0.05.

Results and discussion

Wheat kernel properties are presented in Tables 1, 2 and 3. The PC changed in the narrow range from 11.2 % (cv. Kobra Plus) to 12.8 % (cv. Ostka Strzelecka and Bryza), whereas the KAC ranged from 1.73 % (cv. Legeda) to 2.02 % (cv. Bryza). The HI changed from 42.6 to 73.1 for Kobra Plus and Bombona, respectively. According to the classification of HI proposed by Williams (2000), most of the wheat cultivars tested can be classified as medium hard. The primary determinant of wheat hardness is genetically controlled and appears to relate to factors influencing the degree of compactness of endosperm cell components. Environmental and farming conditions during plant growing are also significant in determining this feature of kernel. Marzec et al. (2011) showed that kernel of wheat cultivars cultivated in the organic system of plant production was characterized by the lower hardness (about 10 %) in comparison to wheat cultivated in the conventional farming system, when nitrogen fertilization was used.

Table 1.

The average values of kernel protein content, ash content, bulk density and virtuousness

| Cultivar | PC *, % w.b. | KAC, % w.b. | BD, kgm−3 | KV, % |

|---|---|---|---|---|

| Bogatka | 11.9 ± 0.08d** | 1.9 ± 0.02ghi | 722.1 ± 7.92cdef** | 11.3 ± 2.08c |

| Bombona | 12.7 ± 0.03ij | 1.8 ± 0.01cd | 736.8 ± 5.32ghi | 80.0 ± 4.00l |

| Bryza | 12.8 ± 0.06j | 2.0 ± 0.01l | 735.3 ± 4.02fgh | 72.7 ± 2.5jk |

| Cytra | 12.3 ± 0.01gh | 1.9 ± 0.01jk | 711.9 ± 2.99c | 77.6 ± 2.5kl |

| Figura | 11.3 ± 0.02a | 1.8 ± 0.02de | 731.0 ± 5.04efg | 5.7b ± 0.58bc |

| Kobra Plus | 11.2 ± 0.03a | 1.8 ± 0.01bc | 721.7 ± 5.62cdef | 4.6 ± 0.58ab |

| Legenda | 12.1 ± 0.02e | 1.7 ± 0.01a | 720.8 ± 4.63cde | 0.0 ± 0.00a |

| Nawra | 11.5 ± 0.05b | 1.9 ± 0.02efgh | 725.2 ± 4.19defg | 66.0 ± 3.00hi |

| Ostka Strzelecka | 12.8 ± 0.01j | 1.9 ± 0.01fghi | 732.9 ± 6.74efg | 25.3 ± 1.53d |

| Parabola | 12.1 ± 0.06ef | 1.9 ± 0.02hij | 747.3 ± 7.22ij | 66.0 ± 4.00hi |

| Raweta | 12.3 ± 0.04g | 1.9 ± 0.01k | 765.4 ± 6.93k | 69.7 ± 5.03ij |

| Rywalka | 12.4 ± 0.03h | 1.8 ± 0.01bc | 734.8 ± 5.80fgh | 0.0 ± 0.00a |

| Smuga | 11.6 ± 0.05c | 1.8 ± 0.01ab | 732.6. ± 6.59efg | 0.0 ± 0.00a |

| Tonacja | 11.9 ± 0.02d | 1.8 ± 0.01defg | 747.4 ± 4.73hij | 23.7 ± 0.58d |

| Tybalt | 12.7 ± 0.03ij | 1.8 ± 0.02bcd | 716.3 ± 4.15cd | 62.7 ± 3.21h |

| Vinjet | 12.3 ± 0.02gh | 1.8 ± 0.01def | 697.0 ± 4.76b | 42.67 ± 1.53f |

| Wydma | 12.6 ± 0.05i | 1.9 ± 0.02jk | 666.2 ± 5.12a | 24.3 ± 1.53d |

| Zadra | 12.0 ± 0.06e | 1.9 ± 0.01efgh | 766.8 ± 5.68k | 53.3 ± 3.01g |

| Żura | 12.2 ± 0.01gh | 1.9 ± 0.01ij | 749.9 ± 7.32j | 33.7 ± 2.08e |

* PC protein content, KAC kernel ash content, BD bulk density, KV kernel virtuousness

** The values are expressed as mean ± SD (n = 3). The values designated by the different letters in the columns of the table are significantly different (α = 0.05)

Table 2.

The average values of parameters obtained on the basis of SKCS test

| Cultivar | HI * | KW, mg | KD, mm | MC, % |

|---|---|---|---|---|

| Bogatka | 49.2 ± 12.12b** | 41.3 ± 5.12h | 3.0 ± 0.25hi | 9.8 ± 0.85a |

| Bombona | 73.1 ± 13.23j | 33.0 ± 6.03ab | 2.8 ± 0.23abc | 10.1 ± 0.96a |

| Bryza | 65.6 ± 14.04hi | 32.9 ± 4.82ab | 2.8 ± 0.28ab | 9.9 ± 0.87a a |

| Cytra | 70.0 ± 16.19ij | 31.1 ± 7.78a | 2.8 ± 0.24 a | 10.1 ± 0.88a |

| Figura | 53.9 ± 11.10cd | 36.8 ± 6.33ef | 2.9 ± 0.21defg | 9.9 ± 0.92a |

| Kobra Plus | 42.6 ± 14.37a | 37.2 ± 5.21ef | 2.9 ± 0.23defg | 10.0 ± 0.87a |

| Legenda | 46.8 ± 13.52b | 40.6 ± 4.89h | 3.1 ± 0.29i | 10.0 ± 0.78a |

| Nawra | 63.5 ± 14.23hg | 36.0 ± 8.03def | 2.8 ± 0.24abc | 10.1 ± 0.79a |

| Ostka Strzelecka | 56.4 ± 12.76def | 35.4 ± 6.64cde | 2.9 ± 0.26bcd | 9.7 ± 0.80a |

| Parabola | 66.5 ± 11.72hi | 39.6 ± 6.28gh | 2.9 ± 0.22defg | 10.1 ± 0.82a |

| Raweta | 67.3 ± 14.81hi | 34.6 ± 5.42bcd | 2.8 ± 0.27a | 10.1 ± 0.88a |

| Rywalka | 47.9 ± 12.33b | 36.4 ± 7.20def | 2.9 ± 0.28def | 9.9 ± 0.89a |

| Smuga | 50.7 ± 14.79bc | 37.3 ± 6.86ef | 3.0 ± 0.24efg | 10.0 ± 0.93a |

| Tonacja | 50.4 ± 13.62bc | 39.4 ± 7.13gh | 3.0 ± 0.23fgh | 10.0 ± 0.78a |

| Tybalt | 57.2 ± 11.41def | 39.6 ± 8.31gh | 2.8 ± 0.269cde | 10.1 ± 0.88a |

| Vinjet | 60.6 ± 12.24fg | 33.5 ± 7.27bc | 2.8 ± 0.22ad | 9.8 ± 0.93a |

| Wydma | 55.0 ± 10.27cde | 33.3 ± 6.42abc | 2.8 ± 0.27abcd | 9.9 ± 0.98a |

| Zadra | 59.7 ± 11.23efg | 34.5 ± 5.53bcd | 2.8 ± 0.23abc | 10.1 ± 0.97a |

| Żura | 56.2 ± 12.61d | 37.9 ± 6.14fg | 3.0 ± 0.24gh | 10.1 ± 0.83a |

* HI hardness index. KW kernel weight, KD kernel diameter, MC moisture content

**The values are expressed as mean ± SD (n = 300). Values designated by the different letters in the columns of the table are significantly different (α = 0.05)

Table 3.

The mechanical properties of wheat kernel obtained on the basis of compression test

| ay | F r *, N | F e, N | l r, mm | E rc, mJ | E t, mJ |

|---|---|---|---|---|---|

| Bogatka | 76.6 ± 7.82a** | 989.2 ± 117.02cdef | 0.16 ± 0.062a | 7.1 ± 4.12a | 422.4 ± 75.34bcde |

| Bombona | 98.8 ± 8.93ghi | 92.3 ± 125.21bcde | 0.16 ± 0.101a | 6.9 ± 3.81a | 425.4 ± 82.20bcde |

| Bryza | 99.6 ± 10.08ghi | 853.7 ± 137.94abcd | 0.17 ± 0.059a | 9.6 ± 5.59ab | 358.0 ± 67.96ab |

| Cytra | 103.0 ± 11.24i | 806.0 ± 114.25ab | 0.19 ± 0.113ab | 10.3 ± 4.36ab | 371.9 ± 68.48abcd |

| Figura | 72.1 ± 9.38ab | 954.2 ± 144.36bcde | 0.20 ± 0.154ab | 8.9 ± 3.77ab | 388.1 ± 88.05abcd |

| Kobra Plus | 70.2 ± 13.77ab | 887.8 ± 127.18bcde | 0.19 ± 0.052ab | 8.0 ± 3.14a | 372.6 ± 75.64abcd |

| Legenda | 82.5 ± 7.90abcdef | 1034.9 ± 147.58def | 0.18 ± 0.033ab | 8.7 ± 3.42a | 459.7 ± 90.98de |

| Nawra | 86.7 ± 8.51bcdefgh | 1149.6 ± 128.33f | 0.19 ± 0.069ab | 8.9 ± 4.23ab | 511.4 ± 99.22e |

| Ostka Strzelecka | 82.3 ± 9.76abcdef | 837.4 ± 133.58abc | 0.20 ± 0.117ab | 9.8 ± 4.55ab | 359.2 ± 72.32abc |

| Parabola | 101.8 ± 11.22hi | 1008.2 ± 148.75cdef | 0.22 ± 0.121ab | 14.5 ± 7.77b | 495.8 ± 84.05be |

| Raweta | 90.2 ± 9.43cdefghi | 906.4 ± 112.11bcde | 0.19 ± 0.164ab | 8.3 ± 3.93a | 386.2 ± 72.78abcd |

| Rywalka | 74.7 ± 6.89abc | 712.2 ± 117.96a | 0.19 ± 0.063ab | 8.4 ± 4.31a | 293.3 ± 68.04a |

| Smuga | 79.6 ± 7.33abcde | 904.1 ± 109.05bcde | 0.22 ± 0.047ab | 11.1 ± 5.10ab | 384.2 ± 74.24abcd |

| Tonacja | 86.1 ± 11.29bcdefg | 1045.8 ± 124.33def | 0.26 ± 0.092b | 14.0 ± 6.82ab | 458.1 ± 89.46cde |

| Tybalt | 97.2 ± 9.46fghi | 1033.2 ± 146.58def | 0.19 ± 0.122ab | 10.1 ± 5.18ab | 509.9 ± 94.33e |

| Vinjet | 93.6 ± 10.84efghi | 857.4 ± 106.09abcd | 0.16 ± 0.091a | 7.7 ± 3.27a | 357.4 ± 72.65abcd |

| Wydma | 80.6 ± 7.13abcde | 992.6 ± 116.25cdef | 0.18 ± 0.066ab | 13.0 ± 6.49ab | 447.1 ± 88.15bcde |

| Zadra | 85.4 ± 7.09abcdefg | 896.3 ± 112.98bcde | 0.26 ± 0.173a | 13.4 ± 6.23ab | 377.7 ± 75.82abcd |

| Żura | 85.6 ± 8.36abcdefg | 924.0 ± 122.08bcde | 0.18 ± 0.062ab | 8.9 ± 4.12a | 415.2 ± 88.07bcde |

* F r rapture force, F e force in the end of compression, l r kernel displacement up to the rapture point, E r rapture energy, E t total compression energy

** The values are expressed as mean ± SD (n = 50). The values designated by the different letters in the columns of the table are significantly different (α = 0.05)

The KW ranged from 31.1 mg (cv. Cytra) to 41.3 mg (cv. Bogatka), result, whereas the KD and BD changed from 2.75 mm (cv. Cytra) to 3.10 mm (cv. Legenta), and from 666 kgm−3 (cv. Wydma) to 767 kgm−3 (cv. Zadra), respectively. The results showed significant correlations between HI and KW (r = −0.61), KD (r = −0.74), and KAC (r = 0.57).

The KV ranged from 0 % (cv. Legenda, Rywalka and Sumuga) to 80 % (cv. Bombona). The KV is generally attributed to the degree of compactness of the endosperm. Thus vitreous kernels are usually harder and of higher protein content than the non-vitreous (starchy) kernels (Symons et al. 2003). The results confirmed strong significant correlation between KV and HI (r = 0.93). Environmental conditions during growth and maturation (water and nitrogen availability, temperature, etc.) play a major role in the development of vitreousness. Kernel of wheat cultivars cultivated in the organic system of plant production is usually characterized by lower vitreousness in comparison to wheat cultivated in the conventional system including nitrogen fertilization (Marzec et al. 2011).

The values of Fr ranged from 70.2 to 103.0 N for Kobra Plus and Cytra, respectively, whereas the values Fe changed from 712 N (cv. Rywalka) to 1150 N (cv. Nawra). The results showed significant correlations between the Fr and HI (r = 0.84). Significant correlation was also found between Fr and KV (r = 0.88).

The values of lr changed from 0.158 to 0.259 mm, whereas the Erc and the Et ranged from 6.9 to 14.5 mJ and from 293 to 511 mJ, respectively. These indices did not significantly correlated with other properties of wheat kernel.

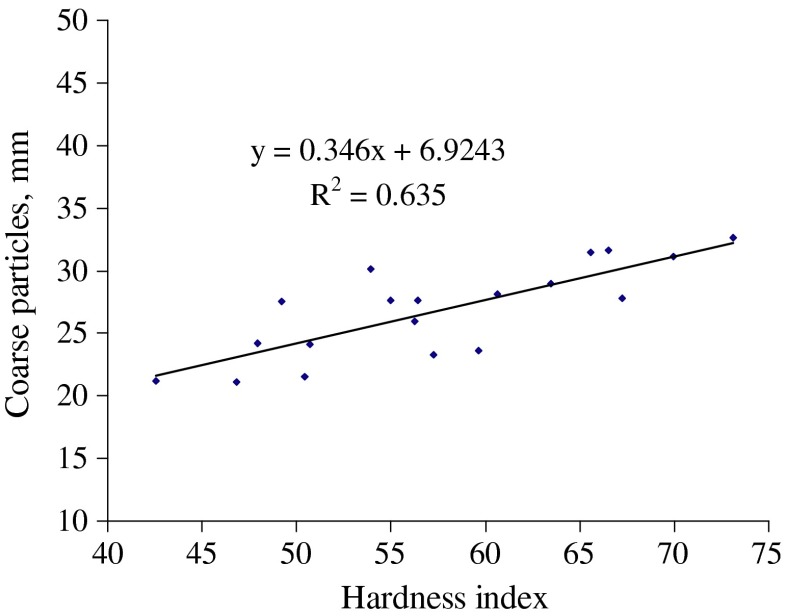

The particle size distributions of the pulverized wheat were given in Table 4. The highest mass fraction was obtained for the small (<0.2 mm) and the coarse (0.5–0.63 mm) particles. The dp of the pulverized wheat ranged from 0.311 mm (cv. Kobra Plus and Tonacja) to 0.369 mm (cv. Bombona and Wydma). The summary of the most statistically significant correlations between the kernel properties and the particle size distribution of pulverized wheat was given in Table 5. The HI and Fr were significantly and negatively correlated with the mass fraction of small particles (< 0.2 mm) (r = −0.67) . Literature data showed that during milling, the wheat hardness significantly affected the mass fraction of fine particles (Muhamad and Campbell 2004). The soft wheat kernels are characterized by a lower degree of adhesion between starch granules and protein matrix and thus the higher mass fraction of fine particles is produced (Haddad et al. 1999). This relation is commonly used for evaluation the wheat hardness on a basis of the mass fractions of small particles (Greffeuille et al. 2006). Beside this, the results showed that during the pulverizing process the HI and Fr were significantly and positively correlated with the mass fraction of the coarse particles (> 0.5 mm). However the stronger correlation (r = 0.797) was found between the HI and this fraction (Fig. 2). It points that the mass fraction of these particles could be an indirect indicator of wheat hardness. The results also showed significant and negative correlations between dp and KW, and KD (r = −0.54 and −0.57, respectively), and a positive correlation between dp and KAC (r = 0.45). It can be caused by the presence of small kernels in wheat cultivars which characterize by greater ratio of bran to endosperm and thus the higher ash content in comparison to sound wheat kernels. The bran is more resistant to pulverizing then endosperm, thus the greater ratio of bran to endosperm can result in the increase of dp value. The dp was also positively correlated with KV and Fr (r = 0.56 and 0.55, respectively). Greffeuille et al. (2007) found that the size of the coarse particles produced during wheat milling was mainly influenced by vitreousness.

Table 4.

Particle size distribution (%) and the average particle size of the pulverized wheat samples

| Cultivar | Range of class, mm | d p *, μm | |||||

|---|---|---|---|---|---|---|---|

| 0.63–0.8 | 0.5–0.63 | 0.4–0.5 | 0.315–0.4 | 0.2–0.315 | <0.2 | ||

| Bogatka | 3.3 ± 0.15e** | 24.3 ± 0.31h | 15.3 ± 0.12cd | 12.3 ± 0.13a | 13.6 ± 0.18d | 31.3 ± 0.51e | 341.2 ± 5.83ab |

| Bombona | 5.0 ± 0.21a | 27.6 ± 0.25a | 16.3 ± 0.22a | 12.2 ± 0.19ae | 12.3 ± 0.33a | 26.3 ± 0.34a | 369 .4± 4.50b |

| Bryza | 5.0 ± 0.18a | 26.5 ± 0.21j | 13.3 ± 0.07h | 11.3 ± 0.33f | 12.4 ± 0.24a | 31.6 ± 0.62e | 349.6 ± 3.54c |

| Cytra | 5.0 ± 0.23m | 26.6 ± 0.33j | 16.1 ± 0.36a | 12.4 ± 0.24ae | 12.5 ± 0.28a | 27.9 ± 0.63b | 360.8 ± 7.38b |

| Figura | 5.4 ± 0.25h | 24.7 ± 0.35g | 14.1 ± 0.25g | 10.8 ± 0.21fg | 10.6 ± 0.12f | 34.4 ± 0.42ij | 343.2 ± 5.03a |

| Kobra Plus | 2.3 ± 0.10f | 18.8 ± 0.24e | 15.3 ± 0.18d | 12.6 ± 0.32a | 14.0 ± 0.21d | 36.9 ± 0.24f | 311.0 ± 5.08d |

| Legenda | 2.3 ± 0.21f | 18.9 ± 0.18e | 14.6 ± 0.33e | 13.7 ± 0.08d | 13.0 ± 0.27e | 37.6 ± 0.18g | 309.04 ± 3.12d |

| Nawra | 4.9 ± 0.25a | 24.1 ± 0.12h | 13.9 ± 0.21i | 11.7 ± 0.17e | 11.0 ± 0.30f | 34.5 ± 0.49i | 338.8 ± 4.42ab |

| Ostka Strzelecka | 3.6 ± 0.08i | 24.1 ± 0.07h | 14.5 ± 0.38ge | 12.9 ± 0.34c | 13.4 ± 0.14e | 31.6 ± 0.57e | 340.1 ± 6.39a |

| Parabola | 3.7 ± 0.11b | 28.0 ± 0.38a | 16.7 ± 0.25a | 12.4 ± 0.24b | 11.9 ± 0.16b | 27.4 ± 0.38b | 36.29 ± 4.32b |

| Raweta | 4.6 ± 0.15n | 23.2 ± 0.33i | 14.8 ± 0.23e | 11.0 ± 0.20g | 12.6 ± 0.24g | 33.9 ± 0.44j | 337.4 ± 7.53ab |

| Rywalka | 4.2 ± 0.23g | 20.0 ± 0.23f | 18.7 ± 0.33f | 12.0 ± 0.18e | 12.5 ± 0.23ag | 32.6 ± 0.48h | 335.6 ± 3.35b |

| Smuga | 2.0 ± 0.25j | 22.1 ± 0.21c | 16.0 ± 0.19c | 12.8 ± 0.39c | 13.0 ± 0.27e | 34.2 ± 0.36i | 325.2 ± 6.86e |

| Tonacja | 1.9 ± 0.18k | 19.6 ± 0.15f | 16.4 ± 0.24a | 12.5 ± 0.21ac | 11.0 ± 0.35f | 38.5 ± 0.35k | 311.0 ± 3.83d |

| Tybalt | 3.0 ± 0.06c | 20.3 ± 0.36b | 14.5 ± 0.26b | 12.6 ± 0.19bc | 14.2 ± 0.34c | 35.4 ± 0.42c | 318.7 ± 7.36e |

| Vinjet | 5.6 ± 0.15d | 22.5 ± 0.24ck | 15.9 ± 0.33c | 13.1 ± 0.38c | 14.3 ± 0.42c | 28.6 ± 0.53d | 341.2 ± 6.10ab |

| Wydma | 3.9 ± 0.13l | 23.7 ± 0.14i | 15.8 ± 0.25c | 11.7 ± 0.30f | 14.0 ± 0.18d | 31.0 ± 0.43l | 368.7 ± 4.99b |

| Zadra | 1.6 ± 0.06o | 22.1 ± 0.28c | 14.6 ± 0.28e | 12.5 ± 0.21ae | 14.7 ± 0.17h | 34.7 ± 0.24i | 350.3 ± 7.22c |

| Żura | 3.2 ± 0.14e | 22.8 ± 0.32k | 14.5 ± 0.08ge | 10.9 ± 0.09g | 13.3 ± 0.21e | 35.4 ± 0.41c | 360.8 ± 4.29b |

* d p average particle size

**The values are expressed as mean ± SD (n = 3). The values designated by the different letters in the columns of the table are significantly different (α = 0.05)

Table 5.

Significant correlation coefficients between wheat kernel properties and percentage of particle size fractions of pulverized sample

| Particle size fractions, mm | HI * | F r | KW | KD | KV | KAC |

|---|---|---|---|---|---|---|

| 0.63–0.8 | 0.58** | −0.54 | −0.60 | |||

| 0.5–0.63 | 0.79 | 0.56 | −0.48 | 0.62 | 0.60 | |

| 0.4–0.5 | ||||||

| 0.315–0.4 | −0.59 | |||||

| <0.2 | −0.67 | −0.55 | 0.52 | 0.52 | −0.50 | |

| d p | 0.75 | 0.55 | −0.54 | −0.57 | 0.56 | 0.45 |

Fig. 2.

Relation between wheat hardness index and the mass fraction of coarse particles (>0.5 mm) (n = 19)

The analysis of regression showed that the changes of dp can be described by the following equations:

|

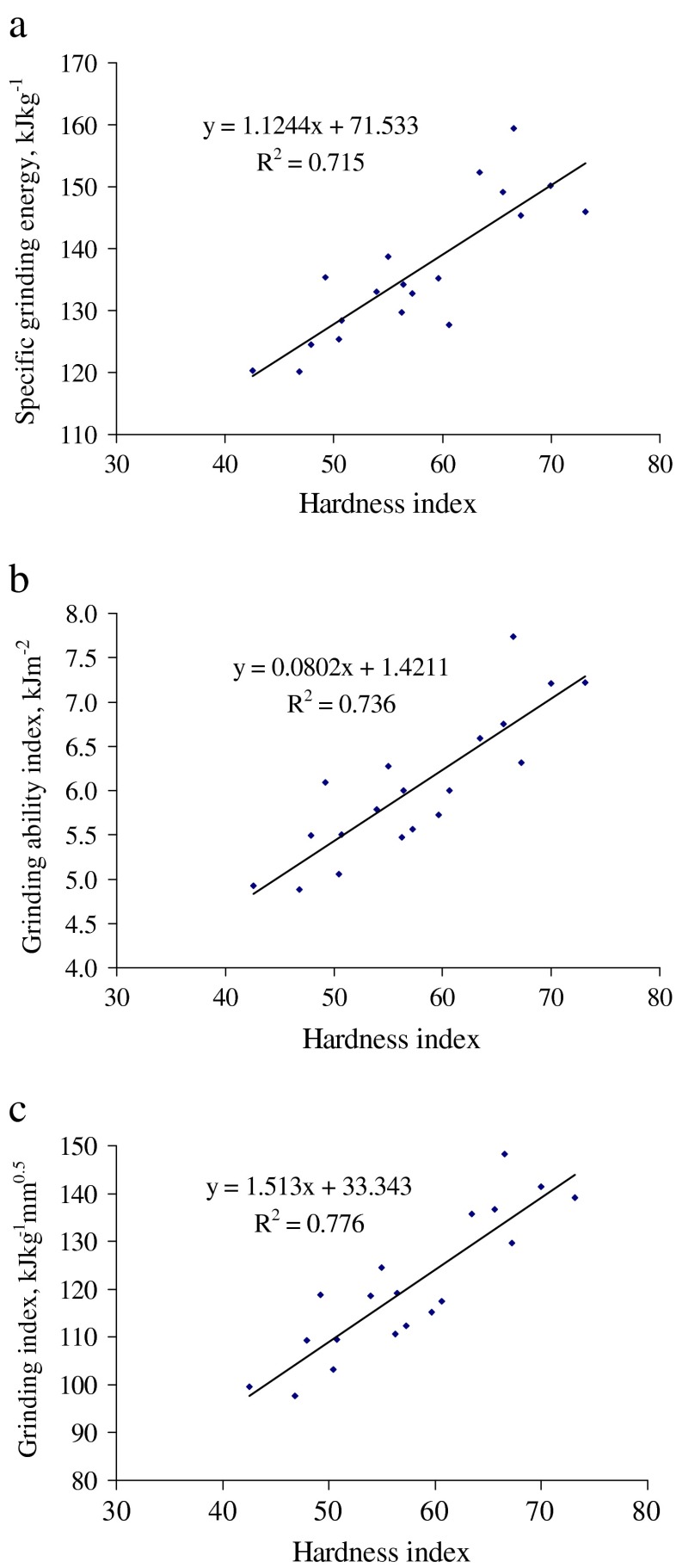

The results of pulverizing energy requirements showed that Er ranged from 120 kJkg−1 (cv. Legenda and Kobra Plus) to 159 kJkg−1 (cv. Parabola). Also, for these cultivars the highest and the lowest values of Ef and Ks index were obtained, i.e. from 4.88 kJm−2 to 7.74 kJm−2 and from 97.7 kJkg−1 mm0.5 to 148,6 kJkg−1 mm0.5, respectively (Table 6). The grinding energy requirements depend on many factors, such as grinding method, kernel properties, moisture content and especially on the degree of fineness (Dziki 2008). Laskowski and Łysiak (1999) and Laskowski et al. (2005) obtained the similar values of Er during the impact grinding of legume seed and rye kernel, but the higher values of Er for barley kernel. In the most works concerning the milling process of wheat kernel the energy requirements are mainly evaluated for the first first-break roller mill. Fang et al. (1998) showed that the Er for the first first-break roller mill ranged from 12 to 20 kJkg−1. The similar values of Er were obtained by Pujol et al. (2000).

Table 6.

The grinding energy indices of wheat kernel

| Cultivar | E r *, kJkg−1 | E f, kJm−2 | K s, kJkg−1 mm0.5 |

|---|---|---|---|

| Bogatka | 135.4 ± 3.52cde** | 6.1 ± 0.22f | 118.7 ± 2.52ef |

| Bombona | 146.0 ± 4.11efg | 7.2 ± 0.15i | 139.1 ± 4.48ij |

| Bryza | 149.1f ± 4.88gh | 6.8 ± 0.18h | 136.7 ± 3.73hi |

| Cytra | 150.2 ± 3.09gh | 7.2 ± 0.25i | 141.4 ± 3.64j |

| Figura | 133.0 ± 3.84bcd | 5.8 ± 0.22ef | 118.7 ± 2.80ef |

| Kobra Plus | 120.3 ± 2.01a | 4.9 ± 0.13ab | 99.5 ± 2.12ab |

| Legenda | 120.2 ± 4.53a | 4.9 ± 0.16a | 97.7 ± 2.19a |

| Nawra | 152.3 ± 2.68gh | 6.6 ± 0.23gh | 135.8 ± 3.16h |

| Ostka Strzelecka | 134.2 ± 3.53bcd | 6.0 ± 0.26f | 119.3 ± 2.78f |

| Parabola | 159.4 ± 4.07h | 7.7 ± 0.18j | 148.6 ± 3.22k |

| Raweta | 145.3 ± 3.47efg | 6.3 ± 0.23g | 129.6 ± 2.93g |

| Rywalka | 124.4 ± 3.52ab | 5.5 ± 0.30c | 109.2 ± 1.91c |

| Smuga | 128.4 ± 3.50abcd | 5.5 ± 0.15cd | 109.5 ± 3.37cd |

| Tonacja | 125.4 ± 3.46abc | 5.1 ± 0.22b | 103.3 ± 1.52b |

| Tybalt | 132.7 ± 3.54bcd | 5.6 ± 0.23d | 112.3 ± 2.43cd |

| Vinjet | 127.7 ± 3.25abc | 6.0 ± 0.24ef | 117.5 ± 3.30ef |

| Wydma | 138.7 ± 3.47def | 6.3 ± 0.25g | 124.5 ± 2.78g |

| Zadra | 135.2 ± 3.55bcde | 5.7 ± 0.21de | 115.2 ± 1.46de |

| Żura | 129.6 ± 3.35abcd | 5.5 ± 0.22c | 110.6 ± 2.16cd |

* E r specific grinding energy, E f grinding ability index, K s Sokołowski’s grinding index

** The values are expressed as mean ± SD (n = 10). The values designated by the different letters in the columns of the table are significantly different (α = 0.05)

The correlation coefficients between wheat kernel properties and grinding energy indices were presented in Table 7. The strongest positive correlations were observed between these indices and HI (Fig. 3). The grinding energy indices were also significantly correlated with and KV, Fr and KAC (positive correlations), and KW, and KD (negative correlations). However the PC did not correlate with these indices. Różyło et al. (2003) found a positive correlation between wheat kernel protein content and specific grinding energy. However they took into account a wide extent of wheat protein content (from 11.5 % to 17.3 %). Generally it is proved that wheat hardness is regulated mainly by the protein called friabilin. This surface protein complex is present in larger amounts in soft wheat cultivars compared to the hard ones (Hrušková et al. 2006).

Table 7.

Significant correlation coefficients between wheat kernel properties and grinding energy indices

| HI * | F r | KW | KD | KV | KAC | |

|---|---|---|---|---|---|---|

| E r | 0.85** | 0.67 | −0.57 | 0.80 | 0.65 | |

| E f | 0.86 | 0.69 | −0.46 | −0.58 | 0.75 | 0.56 |

| K s | 0.88 | 0.70 | −0.49 | −0.64 | 0.79 | 0.63 |

Fig. 3.

Relation between wheat hardness index and specific grinding energy (a), grinding ability index (b) and Sokolowski’s grinding index (c) (n = 19)

Conclusions

On the basis of data obtained many significant correlations were found between wheat kernel physical properties and pulverizing process of wheat kernel. Most importantly, the HI obtained on the basis of SKCS was significantly and positively correlated with KV and KAC, whereas negative correlations were found between HI and KW and KD. The results showed also positive and significant relationships between KAC and the grinding energy requirements.

This study indicates that HI influences on particle size distribution of pulverized wheat. Especially HI was significantly and positively correlated with the mass fraction of coarse particles (> 0.5 mm). Similar correlation was found between KV and particle size distribution of the pulverized wheat kernel. The multiple linear regression (R = 0.912) was derived for predicting the average particle size of pulverized wheat. Beside of this the HI was strongly correlated with the grinding energy indices.

Among the kernel mechanical properties determined on the basis of uniaxial compression test only the Fr was correlated with the impact grinding (particle size distribution, grinding energy indices).

The results showed that among the studied wheat kernel physical properties the HI and KV are the most useful indices for prediction of wheat impact grinding results.

References

- American Association of Cereal Chemists (2002) Approved methods of the AACC, 10th ed

- Barak S, Mudgil D, Khatkar BS (2012) Effect of flour particle size and damaged starch on the quality of cookies. J Food Sci Technol. doi:10.1007/s13197-012-0627-x49:255-266 [DOI] [PMC free article] [PubMed]

- Breustedt G, Latacz-Lohmann U, Tiedemann T. Organic or conventional? Optimal dairy farming technology under the EU milk quota system and organic subsidies. Food Policy. 2011;36:223–229. doi: 10.1016/j.foodpol.2010.11.019. [DOI] [Google Scholar]

- Das A, Raychaudhuri U, Chakraborty R (2010) Cereal based functional food of Indian subcontinent: a review. J Food Sci Technol. doi:10.1007/s13197-011-0474-1 [DOI] [PMC free article] [PubMed]

- Dhingra D, Michael M, Rajput H, Patil RT. Dietary fibre in foods: a review. J Food Sci Technol. 2012;49:255–266. doi: 10.1007/s13197-011-0365-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dziki D. The crushing of wheat kernels and its consequence on the grinding process. Powder Technol. 2008;185:181–186. doi: 10.1016/j.powtec.2007.10.012. [DOI] [Google Scholar]

- Dziki D. Effect of preliminary grinding of the wheat grain on the pulverizing process. J Food Eng. 2011;104:585–591. doi: 10.1016/j.jfoodeng.2011.01.021. [DOI] [Google Scholar]

- Fang Q, Haque E, Spillman CK, Reddy PV, Steele JL. Energy requirements for size reduction of wheat using a roller mill. T ASAE. 1998;41:1713–1720. doi: 10.13031/2013.17314. [DOI] [Google Scholar]

- Greffeuille V, Abecassis J, Rousset M, Oury F-X, Faye A, Bar L’Helgouac’h C, Lullien-Pellerin V. Grain characterization and milling behaviour of near-isogenic lines differing by hardness. Theor Appl Genet. 2006;114:1–12. doi: 10.1007/s00122-006-0403-2. [DOI] [PubMed] [Google Scholar]

- Greffeuille V, Abecassis J, Barouh N, Villeneuve P, Mabille F, Bar L’Helgouac C, Lullien Pellerin V, Benet JC. Analysis of the milling reduction of bread wheat farina: physical and biochemical characterisation. J Cereal Sci. 2007;45:97–105. doi: 10.1016/j.jcs.2006.07.003. [DOI] [Google Scholar]

- Haddad Y, Mabille F, Mermet A, Abecassis J, Benet JC. Rheological properties of wheat endosperm with a view on grinding behaviour. Powder Technol. 1999;105:89–94. doi: 10.1016/S0032-5910(99)00122-9. [DOI] [Google Scholar]

- Hrušková M, Švec I. Wheat hardness in relation to other quality factors. Czech J Food Sci. 2009;27:240–248. [Google Scholar]

- Hrušková M, Švec I, Jirsa O. Correlation between milling and baking parameters of wheat varieties. J Food Eng. 2006;77:439–444. doi: 10.1016/j.jfoodeng.2005.07.011. [DOI] [Google Scholar]

- ICC (1990) ICC-standard no 104/1, Int Assoc Cereal Chem Vienna, Austria

- Jha SN, Sharma RS. Physical, gravimetric and functional characterization of various milling fractions of popped gorgon nut (Euryale ferox) J Food Sci Technol. 2010;47:564–570. doi: 10.1007/s13197-010-0102-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Laskowski J, Łysiak G. Use of compression behaviour of legume seeds in view of impact grinding prediction. Powder Technol. 1999;105:83–88. doi: 10.1016/S0032-5910(99)00121-7. [DOI] [Google Scholar]

- Laskowski J, Łysiak G, Skonecki S. Properties for grinding and agglomeration. In: Horabik J, Laskowski J, editors. Mechanical properties of granular agromaterials and food powders for industrial practice. Part II. Lublin: Institute of Agrophysics PAS; 2005. pp. 23–25. [Google Scholar]

- Mäder P, Hahn D, Dubois D, Gunst L, Alföldi T, Bergmann H, Oehme M, Amadò R, Schneider H, Graf U, Velimirov A, Fließach A, Niggli U. Wheat quality in organic and conventional farming: results of a 21 year filed experiment. J Sci Food Agric. 2007;87:1826–1835. doi: 10.1002/jsfa.2866. [DOI] [Google Scholar]

- Marzec A, Cacak-Pietrzak G, Gondek E. Mechanical and acoustic properties of spring wheat versus its technological quality factors. J Texture Stud. 2011;42:319–329. doi: 10.1111/j.1745-4603.2011.00284.x. [DOI] [Google Scholar]

- Muhamad II, Campbell GM. Effects of kernel hardness and moisture content on wheat breakage in the single kernel characterization system. Innov Food Sci Emerg Technol. 2004;5:119–125. doi: 10.1016/j.ifset.2003.10.003. [DOI] [Google Scholar]

- Muhamad II, Fang C, Campbell GM. Prediction of breakage during roller milling of mixtures of wheat kernels, based on single kernel measurements. Jurnal Teknologi. 2008;48(F):75–83. [Google Scholar]

- Nelson L, Giles J, Macilwain C, Gewin V. Organic FAQs. Nature. 2004;428:796–798. doi: 10.1038/428796a. [DOI] [PubMed] [Google Scholar]

- Osborne BG, Kotwal Z, Blakeney AB, O’Brien L, Shah S, Fearn T. Application of the single kernel characterisation system to wheat receiving testing and quality prediction. Cereal Chem. 1997;74:467–470. doi: 10.1094/CCHEM.1997.74.4.467. [DOI] [Google Scholar]

- Prabhasankar P, Rao PH. Effect of different milling methods on chemical composition of whole wheat flour. Eur Food Res Technol. 2004;213:465–469. doi: 10.1007/s002170100407. [DOI] [Google Scholar]

- Psaroudaki A. An extensive survey of the impact of tropospheric ozone on the biochemical properties of edible plants. WSEAS Tran Environment and Development. 2007;3:99–110. [Google Scholar]

- Pujol R, Letang C, Lempereur A, Chaurand M, Mabile F, Abecassis J (2000) Description of a micromill with instrumentation handicap measuring grinding characteristics of wheat kernel. Cereal Chem 77:421–427

- Różyło R, Laskowski J, Grundas S. Study of how protein content in wheat grain relates to hardness index and grinding energy. Acta Agrophysica. 2003;2:173–178. [Google Scholar]

- Sahyoun NR, Jacques PF, Zhang XL, Juan W, Mckeown NM. Whole-grain intake is inversely associated with the metabolic syndrome and mortality in older adults. Am J Clin Nutr. 2006;83:124–131. doi: 10.1093/ajcn/83.1.124. [DOI] [PubMed] [Google Scholar]

- Singh B, Sharma HK, Sarkar BC. Optimization of extraction of antioxidants from wheat bran (Triticum spp.) using response surface methodology. J Food Sci Technol. 2012;49:294–308. doi: 10.1007/s13197-011-0276-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Slavin JL, Martini MC, Jacobs DR, Marquart L. Plausible mechanisms for the protectiveness of whole grains. Am J Clin Nutr. 1999;70:459–463. doi: 10.1093/ajcn/70.3.459s. [DOI] [PubMed] [Google Scholar]

- Sokołowski M. Energy consumed in grinding – a new idea of a general law of comminution – new tests stands and testing results. Récents Progress en Génie Procédés. 1996;10:221–226. [Google Scholar]

- Steffen LM, Jacobs DR, Stevens J, Shahar E, Carithers T, Folsom AR. Associations of whole-grain, refined-grain, and fruit and vegetable consumption with risks of all-cause mortality and incident coronary artery disease and ischemic stroke: the Atherosclerosis risk in communities (ARIC) Am J Clin Nutr. 2003;78:383–390. doi: 10.1093/ajcn/78.3.383. [DOI] [PubMed] [Google Scholar]

- Symons SJ, Van Schepdael L, Dexter JE. Measurement of hard vitreous kernels in durum wheat by machine vision. Cereal Chem. 2003;80:511–517. doi: 10.1094/CCHEM.2003.80.5.511. [DOI] [Google Scholar]

- Turnbull KM, Rahman S. Endosperm texture in wheat. J Cereal Sci. 2002;36:327–337. doi: 10.1006/jcrs.2002.0468. [DOI] [Google Scholar]

- Velu V, Nagender A, Prabhakara Rao PG, Rao DG. Dry milling characteristic of microwave dried maize grains. J Food Eng. 2006;74:30–36. doi: 10.1016/j.jfoodeng.2005.02.014. [DOI] [Google Scholar]

- Williams PC (2000) Applications of the Perten SKCS 4100 in flour-milling. Association of Operative Millers Bulletin, March 7421–7424

- Yadav DN, Rajan A, Sharma GK, Bawa AS. Effect of fiber incorporation on rheological and chapati making quality of wheat flour. J Food Sci Technol. 2009;47:166–173. doi: 10.1007/s13197-010-0036-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zuchowski J, Jończyk K, Pecio Ł, Oleszek W. Phenolic acid concentrations in organically and conventionally cultivated spring and winter wheat. J Sci Food Agr. 2011;91:1089–1095. doi: 10.1002/jsfa.4288. [DOI] [PubMed] [Google Scholar]