Abstract

The effects of incorporating guar gum (GG) and gum arabic (GA) in cheese-making milk with various fat contents (0.4, 0.9, and 1.4 %) on chemical and rheological properties of Iranian white cheese were evaluated by response surface method (RSM). As GG concentration increased, dry matter content of cheese samples decreased due to the high water binding capacity of this gum. A similar trend was also observed for GA at concentrations less than 150 ppm. The higher the GG concentration, the higher was the free fatty acid content of cheese samples. GA at concentrations more than 150 ppm, increased the storage modulus (G′), causing an undesirable hard texture for the product. The G′ and stress at fracture (бf) of samples decreased by the increasing concentration of GG incorporated into the cheese-making milk. Response surface minimization of rheological indices for Iranian white cheese showed that combination of two hydrocolloids (GG in the concentration range 75–170 ppm and GA at concentrations <75 ppm) would provide the softest texture.

Keywords: Iranian white brined cheese, Low fat cheese, Fat replacer, Hydrocolloid, Rheology

Scientific evidences link diets high in fat to the increased risk of obesity, atherosclerosis, coronary heart disease, elevated blood pressure and tissue injury (Madadlou et al. 2005). This has increased the health-related concern of consumers, causing a dramatic increase in the demand for low and reduced fat foods (Katsiari et al. 2002; Kavas et al. 2004). Dairy products are one of the most widely consumed low-fat foods and a significant increase has been observed in the consumption of low-fat cheese (Konuklar et al. 2004). Fat is not of solely nutritional significance in cheese, but has an important role in the development of favorite texture and appearance of the product. Low-fat cheese varieties are usually characterized by rubbery texture, off-flavour, poor meltability and undesirable color compared to their full fat counterparts (Mistry 2001). These drawbacks are mostly originated from the dramatically increased protein content in cheese curd and extensive cross linking of protein chains in the cheese matrix. Amongst various approaches developed to produce low-fat cheese with improved properties, incorporation of fat replacers into cheese curd is the most famous technique (Koca and Metin 2004). Fat replacers are protein and carbohydrate-based compounds used to simulate the functional and organoleptic attributes of fat with a substantial reduction in calorific value (Drake and Swanson 1995; Rodriguez 1998; Mistry 2001). Romeih et al. (2002) investigated the effects of two commercial hydrocolloid fat replacers (Simplesse® D-100 and Novagel™ NC-200) on chemical, physical and sensory attributes of low-fat white brined cheese. Incorporation of fat replacers caused an increase in moisture content and cheese yield leading to a great improvement in cheese texture. Rahimi et al. (2007) reported that the texture of low fat Iranian white brined cheese improved by adding gum tragacanth. However, undesirable characteristics emerged in cheese samples at higher concentrations of tragacanth after 6 weeks of ripening. Kumar et al. (2011) produced a low fat paneer with superior quality by incorporating 0.2 % soy protein isolate as the fat replacer.

Gum arabic (GA) also known as gum acacia is well dissolved in water with emulsifying, suspending and mild viscosity increasing properties. Guar gum (GG) also shows a very high water binding characteristic. These properties make them appropriate candidate compounds for retaining the whey within cheese curd during whey expulsion stage.

Response surface methodology (RSM) is a collection of statistical and mathematical techniques useful for improving and optimizing processes in which a response of interest in influenced simultaneously by several variables leading to a faster and more precise optimization. The aim is to find a combination of factors that will lead to an optimum response (Madadlou et al. 2009).

Iranian white cheese, a major item in diet throughout Iran is matured in brine for about 45 to 90 days (Azarnia et al. 1997). It resembles Beyaz peynir (Turkish white cheese) and Feta but differs from latter in method of preparation (Madadlou et al. 2006). Iranian white brined cheese has 18–20 % fat. There is very limited information in the literature on the application of GG and GA as fat replacers in production of low fat Iranian white cheese. Hence in this study, the effect of GG and GA on physicochemical and rheological properties of low-fat white brined cheese was evaluated and the optimum incorporation level was determined with RSM.

Materials and methods

Culture, rennet, and gums

A lyophilized direct-to-vat mixed culture (FRC-60.Chr. Hansen Dairy Cultures, Hoersholm, Denmark) containing Lactococcus lactis subsp. cremoris, Lactococcus lactis subsp. lactis, Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus was used as starter. As coagulant, chymosin derived by fermentation of Aspergillus niger var. awamori [Standard rennet, Chy-Max, 183 International Milk Clotting Units (IMCU) mL−1, Chr. Hansen Inc., Denmark] was used at a concentration of 4.5 IMCU kg−1 of milk. It was diluted 30 fold with cold water and added to each 5-kg batch of milk. GA (Scharlau Chemie S.A. La Jota, Barcelona, Spain) and GG (Sigma-Aldrich, Steinheim, Germany) were used as fat replacers.

Cheese-making procedure

Fresh bovine milk was pasteurized by a plate heat exchanger (APV, Denmark) at 72 °C for 20 s, cooled to 4 °C, and standardized on 3 levels of fat content 0.4, 0.9 and 1.4 %, through blending the whole pasteurized milk (3.5 % fat) with pasteurized skim milk (0.3 % fat). For each batch of cheese, 5 kg standardized milk was heated to 35 °C and transported to a cheese vat (FT20-MKII cheese vat, Armfield Ltd., Ring wood, Hampshire, UK). GA was dispersed in a small volume of milk, mixed in a mixer and added to cheese-making milk (0, 150 and 300 ppm), while GG was dissolved in 50 mL distilled water, kept at room temperature for overnight and then was mixed in a small volume of milk before addition to cheese milk (0, 75, 150, 300 ppm). The milk was then supplemented with 0.15 g CaCl2 (Scharlau Chemie S.A. La Jota, Barcelona, Spain) per kg milk and held at 35 °C for approximately 55 min after inoculation of culture (0.04 g L−1 milk) for starter maturation before the addition of rennet. The curd was cut crossways in cubes of 2 cm3 (after 50 min) and allowed to settle for 3–5 min. This was followed by gentle agitation at a gradually increasing rate for 10 min to avoid the fusion of freshly cut curd cubs and facilitate whey expulsion. The curds were pressed in molds (25 × 12 × 10 cm) for 1 h by using weights to complete draining. After pressing, curd was cut to a suitable size (7 × 7 × 2 cm) and soaked in sterile brine (22 % w/v) for 16 h at room temperature. At last, the curd pieces were placed in air-tight plastic containers, and were completely immersed in 13 % w/v brine (brine was previously pasteurized at 80 °C for 10 min). Containers were refrigerated at 5–6 °C for the ripening period of 60 days.

Chemical analysis

Cheese samples were analyzed 60 days after manufacturing for dry matter content by drying to constant weight at 105 °C (AOAC 1997), fat content by the Gerber method (James 1995) and salt content by the Volhard method (James 1995). Titratable acidity of cheese samples was determined as base of lactic acid (w/w) (AOAC 1997). Fat extraction from cheese samples was carried out using diethyl ether and the acidity index of fat (meq/100 g of fat) was calculated from alcoholic alkali titration to determine free fatty acid (FFA) (Nunez et al. 1986).

Rheological analysis

Uniaxial analysis

Uniaxial compression, the simplest fundamental test was performed using a HTE universal testing Machine (S-Series Bench U.T.M. Model H5k-S, Hounsfield Test Equipment Ltd., UK). A flat plunger with a 49 mm diameter was attached to the moving crosshead. The cylindrical cheese samples (24 mm diameter, 15 mm height) taken from at least a depth of 2 mm in the cheese block at 6 °C were immediately placed in air-tight containers to prevent dehydration and equilibrated at room temperature (20 ± 1 °C) for 4–4.5 h before testing (Madadlou et al. 2007). Samples were compressed at a speed of 50 mm min−1 with 56.67 % deformation (8.5 mm) from the initial height of the sample. The fracture stress (σf) was measured as the force divided by the initial cross sectional area of the sample (Sipahioglu et al. 1999).

Dynamic rheological measurements

Small amplitude oscillatory shear measurements were performed with a UDS 200 rheometer (Universal Dynamic Spectrometer, Physica Messtechnik GmbH, stuttgart Germany). The measuring geometry consisted of two parallel plates with a diameter of 25 and 1 mm gap size (sample thickness). Samples cut at least from a depth of 1 cm in the cheese blocks at 6 °C were immediately placed in air-tight containers and equilibrated at room temperature (20 ± 1 °C) for at least 4 h. A small piece of cheese was placed on the lower plate and the upper plate was slowly lowered until the gap size was obtained. Excessive cheese was trimmed off carefully with razor blade and the sample was allowed to rest for 15 min in the rheometer to relax from the stresses induced during the sample handling to relax. The linear viscoelastic range was found by performing a strain sweep. Frequency was set on 10 Hz as the percentage of strain varied from 0.01–2.58 % resulting in a strain sweep (Rahimi et al. 2007). Storage modulus (G′) which is a measure of elastic nature (Steffe 1996; Madadlou et al. 2007) was calculated.

Statistical analysis

A D-Optimal experimental design was used to study the effects of 4 levels of GG (0, 75, 150, 300 ppm), 3 levels of GA (0, 150, 300 ppm) and 3 levels of milk fat (0.4, 0.9, and 1.4). The values for runs are given in Table 1. The statistical analysis of data was performed using MINITAB Statistical Software, (Version 15). The full-term-second order polynomial response surface models were fitted to each response variable, according to the following equation:

|

where Y = predicted response; β0 = a constant, βi = linear coefficient, βi = square coefficient, βij = interaction coefficient and Xi and Xj represent the various independent variables.

Table 1.

D-optimal experimental design in levels of variable

| Run | Block | GGa (ppm) | GAb (ppm) | MFc (%) |

|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 1.4 |

| 2 | 1 | 300 | 300 | 1.4 |

| 3 | 1 | 300 | 0 | 0.4 |

| 4 | 1 | 75 | 150 | 0.9 |

| 5 | 2 | 300 | 0 | 1.4 |

| 6 | 2 | 300 | 300 | 0.4 |

| 7 | 2 | 300 | 0 | 1.4 |

| 8 | 2 | 0 | 0 | 0.4 |

| 9 | 3 | 0 | 150 | 0.4 |

| 10 | 3 | 150 | 0 | 0.9 |

| 11 | 3 | 0 | 150 | 0.4 |

| 12 | 3 | 0 | 300 | 1.4 |

| 13 | 4 | 150 | 150 | 1.4 |

| 14 | 4 | 300 | 150 | 0.9 |

| 15 | 4 | 150 | 150 | 1.4 |

| 16 | 4 | 0 | 300 | 0.4 |

| 17 | 5 | 300 | 150 | 1.4 |

| 18 | 5 | 0 | 300 | 0.9 |

| 19 | 5 | 150 | 0 | 0.4 |

| 20 | 5 | 0 | 300 | 0.9 |

| 21 | 6 | 150 | 300 | 0.4 |

| 22 | 6 | 300 | 150 | 0.4 |

| 23 | 6 | 150 | 300 | 0.4 |

| 24 | 6 | 0 | 0 | 0.9 |

aGuar gum; bGum arabic; cMilk fat

Adjusted R2 was obtained by excluding terms one by one from the model and when this decreased the R2, the terms was re-included in the model. All generated models explained adequately the variation of the responses with satisfactory R2 values (R2 > 0.80) and non significant lack of fit. By keeping one variable at central levels, 3-D plots of two variable factors vs. predicted responses were drawn (Derringer and Suich 1980).

Results and discussion

RSM model

Multiple linear regression analysis of the experimental data yielded second order polynomial models. Table 2 summarizes the estimated regression coefficients of the models for the responses, along with the corresponding R2 and F values. Adjusted R2 of variation responses were higher than 0.80 and models had non significant lack of fit (P > 0.05). To visualize the combined effects of GG, GA and milk fat on the responses, response surface and contour plots were generated for each fitted model in function of two variables, while keeping the other variable at the central value.

Table 2.

Regression coefficients of second-order polynomial model for the responses variable

| Coefficients a | DM (%) | Ln Fat | FFA (meq/100 g) | Salt (%) | Acidity (%w/w) lactic acid | Log (G′) | (Log (бf |

|---|---|---|---|---|---|---|---|

| β0 | 31.91 | −0.152 | 17.07 | 5.12 | 2.313 | 5.22 | 3.25 |

| linear | |||||||

| β 1 | −0.07 *** | −0.004 | 0.001 *** | 0.004 *** | – | −0.011 *** | −0.007 *** |

| β 2 | −0.02 * | −0.0009 * | 0.009 ** | 0.0066 | 0.0006* | −0.004 | – |

| β 3 | 0.7 | 3.257 *** | −11.61 ** | 2.243 ** | −1.885*** | 0.865 *** | −0.312 *** |

| interaction | |||||||

| β 12 | – | – | −6.4× 10−5** | – | – | – | – |

| β 13 | −0.01 * | 0.0013 ** | – | 0.0101 *** | – | – | – |

| β 23 | – | −0.0014 ** | −0.007 | −0.0074 *** | – | – | – |

| square | |||||||

| β 11 | 0.00014 * | 7.87× 10−6** | 6.55× 10−5** | −2.8× 10−5** | – | 2.73× 10−5*** | 1.39× 10−5*** |

| β 22 | 9.47× 10−5* | 5.67× 10−6* | – | – | – | 1.26× 10−5*** | – |

| β 33 | – | −1.296 *** | 6.038 ** | −1.761* | 1.227 *** | −0.771 ** | – |

| Adj-R2b | 0.953 | 0.974 | 0.846 | 0.908 | 0.8 | 0.972 | 0.958 |

| F | 57.925 | 86.286 | 14.357 | 26.272 | 19.00901 | 92.95 | 123.47 |

| P(F)c | p < 0.0001 | p < 0.0001 | p < 0.0002 | p < 0.0001 | p < 0.0001 | p < 0.0001 | p < 0.0001 |

| Lack of Fit | 0.20 | 0.51 | 0.55 | 0.62 | 0.13 | 0.25 | 0.50 |

alower scripts1, 2 and 3 indicate guar gum (ppm), gum arabic (ppm) and milk fat (%), respectively.

bAdj-R2 = adjusted R2.

cP (F) = probability of F.

*p < 0.05

**p < 0.01

***p < 0.001

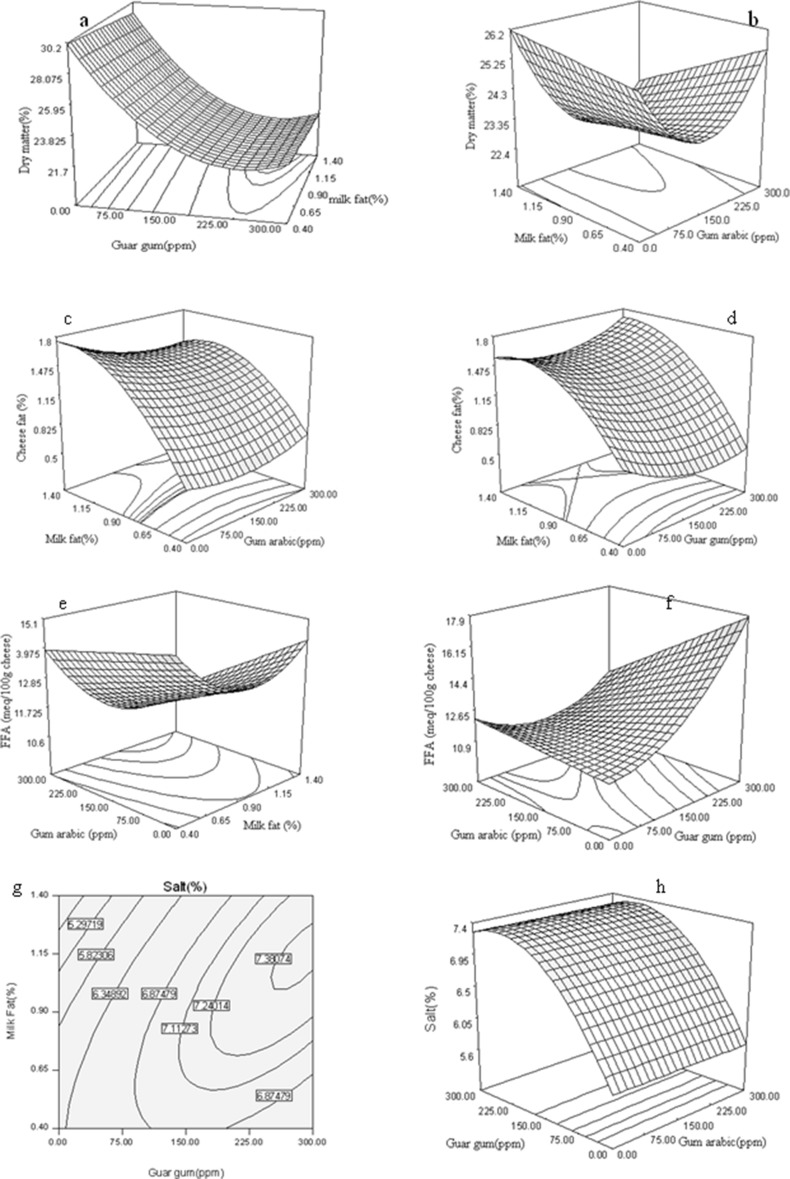

Cheese composition

The effects of fat content and incorporation of two hydrocolloids in the cheese curd on dry matter, fat content, FFA, salt and acidity of cheese at the end of ripening were evaluated by RSM and the data are shown in Fig. 1. It was observed that dry matter content of cheese samples (Fig. 1a and b) decreased as the concentration of GG increased. A similar trend was observed for GA at concentrations less than 150 ppm. GG has a high water binding capacity and is well known for its food thickening (Saha and Bhattacharya 2010) and stabilizing property in milky systems. It has a high galactose content and therefore swells and disperses almost completely in both cold and hot water (Saha and Bhattacharya 2010). Supplementation of cheese-making milk with GG most probably retards the curd syneresis during whey expulsion leading to a lower dry mater content in the final cheese curd. Similar results about fat replacers have been reported by Tuinier et al. (2000) and Zalazar et al. (2002). For GA-supplemented cheese samples at concentrations less than 150 ppm, as expected dry matter content had a direct relation with fat content in cheese-making milk. Figure 1c and d show the interactive effects of GG and GA concentrations and milk fat percentage on fat content of low-fat Iranian white cheese. As expected (Rudan, et al. 1999) the lower the fat content of cheese-making milk, the lower was the percentage of fat in cheese curd. At higher percentages of fat in cheese-making milk, increasing concentrations of GA and GG decreased and increased cheese fat content, respectively (Fig. 1c and d). The former is attributed to the reduction in fat percentage as the concentration of GA increased in cheese dry matter. The latter is however again attributed to the retarded whey expulsion and retention of milk fat globules in cheese matrix.

Fig. 1.

Influence of milk fat level, guar gum and gum arabic concentrations on chemical composition of low-fat Iranian White cheese

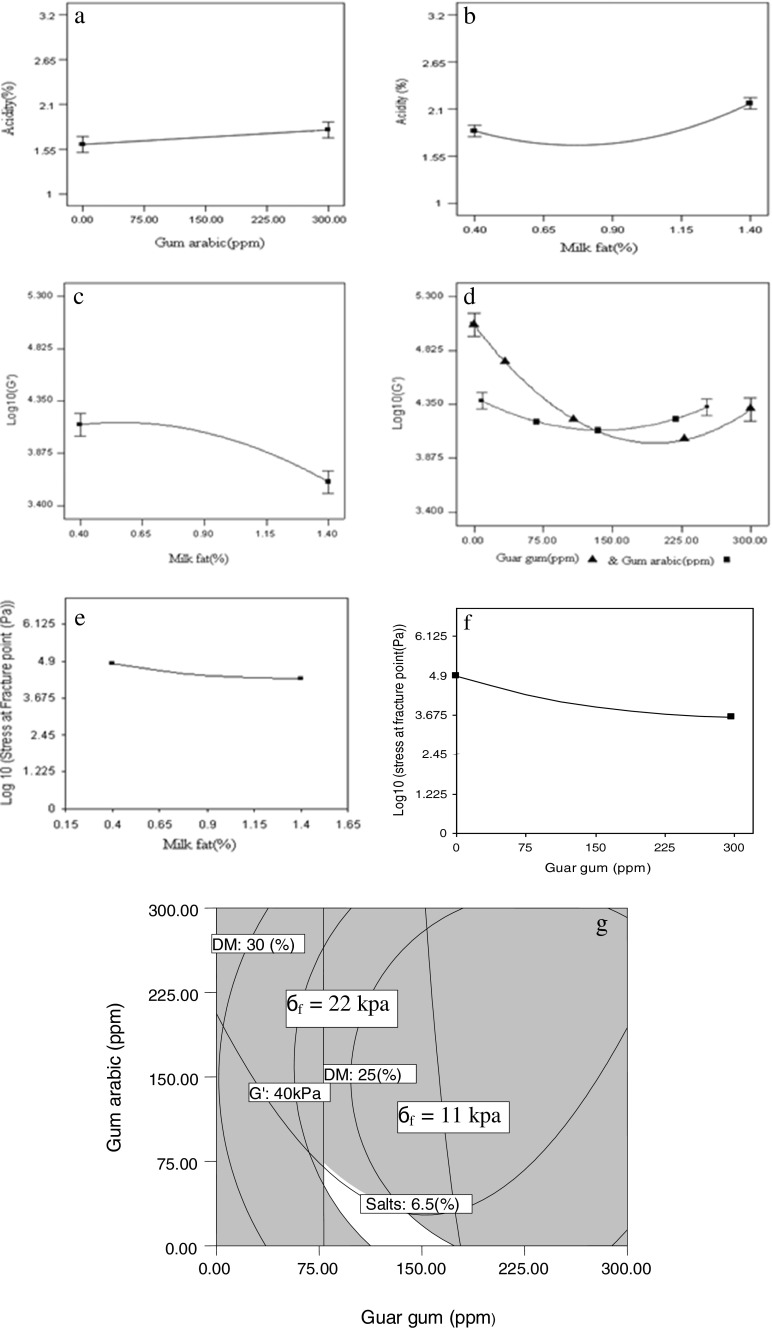

The extent of lipolysis in cheese expressed as FFA (meq/100 g cheese) declined as milk fat percentage increased up to 1 % but a further increase enhanced the lipolysis (Fig. 1e). GG concentration had a significant influence on lipolysis degree (Fig. 1f); the higher the gum concentration, the higher was the measured FFA. It is attributed to the higher moisture content in GG-supplemented cheese samples, which favors the enzymatic reactions and microbial growth (Romeih et al. 2002; Kavas et al. 2004). Increased concentration of GA decreased the FFA level due probably to the decline in moisture content of cheese. GA is a low viscosity gum (Saha and Bhattacharya 2010) and shows a relatively low affinity for binding water molecules. Fat content of samples had an inverse relation with their salt content while GG incorporation into cheese curd increased the salt content (Fig. 1g and h). These observations could be attributed to the differences observed in moisture of samples (Volikakis et al. 2004; Kavas et al. 2004). As shown in Fig. 1h GA did not have a significant interaction with GG on the salt content. There was no interaction between GG, GA and milk fat on acidity of samples and therefore their influence was studied individually. GG did not affect the acidity, while incorporation of GA influenced it (Fig. 2a). It is observed that increasing concentration of GA increased cheese acidity. Milk fat had a quadratic effect on cheese acidity and increased the acidity of low-fat cheese (Fig. 2b).

Fig. 2.

Influence of guar gum, gum arabic and milk fat on acidity (a and b), storage modulus (G΄; c and d) and fracture stress (e and f) of low-fat Iranian White cheese. Plot g demonstrates the optimum region (white zone) for rheological indices identified by overlaying plots of the responses as the function of guar gum and gum arabic

Rheological analysis

Milk fat content and concentration of GG and GA incorporated into the cheese-making milk did not show interactive effects on dynamic moduli of samples. The individual influence of aforementioned factors on log G′ and log σf of samples is shown in Fig. 2c–f. Fat and moisture act as the filler in the casein matrix of cheese texture (Kahyaoglu and Kaya 2003; Madadlou et al. 2005), providing its lubricity and softness. When fat content decreased, moisture did not replace the fat reduction on equal basis (Rudan et al. 1999; Romeih et al. 2002) and hence, the total filler volume decreased. This made the texture of low fat cheese harder than its full fat counterpart, which led to the increased G′ and σf (Fig. 2c–f). With the increasing concentration of GG, values for G′ and σf decreased due most probably to the increased moisture to protein ratio. At high GG concentrations, cheese texture became very soft and its protein matrix decomposed. The amount of residual rennet in cheese curd is increased as its moisture content increases. This would stimulate the proteolysis rate causing an extensive softening of texture (Zalazar et al. 2002).

Optimization

At optimization of industrial processes, usually several response variables describing the quality characteristics and measures of the systems are optimized. Some of these variables may be maximized and some may be minimized. In many cases, these responses are competing, i.e., improving one response may have an opposite effect on another one, which further complicates the situation. Several approaches have been used to solve this problem. One is a graphical method that is superimposing the contour diagrams of the different response variables. At the end, optimum zone is obtained (Derringer and Suich 1980). Improvement of rheological properties of low-fat Iranian White cheese was the final goal of our study. Based on the rheological properties of samples (11 k Pa < σf < 22 k Pa, G′ < 40 k Pa), GG and GA concentrations incorporated into cheese-making milk was optimized by graphical method. Figure 2g shows the overlay plot for optimization of low-fat cheese rheology for a milk with 0.4 % fat content. Low fat Iranian white cheese could be produced with σf of 11–22 k Pa, G′ < 40 k Pa, dry matter >25 %, and salt percentage <6.5 % at concentration ranges of 75–170 ppm and <75 ppm for GG and GA, respectively.

Conclusion

Supplementation of cheese-making milk with GG reduced the hardness parameters G′ and σf and therefore could improve the texture of low-fat Iranian white cheese. RSM optimization of milk fat content, GG and GA concentrations incorporated into cheese milk showed that the combination of two hydrocolloids, GG in the range 75–170 ppm and GA at concentrations <75 ppm at 0.4 % fat, would tune the rheological characteristics of cheese.

References

- AOAC, Association of Official Analytical Chemists (1997) Official Methods of Analytical, 16th edn., 3rd rev. Arlington, VA, USA

- Azarnia S, Ehsani MR, Mirhadi SA. Evaluation of the physico chemical characteristic of the curd during the ripening of Iranian Brine cheese. Int Dairy J. 1997;7:473–478. doi: 10.1016/S0958-6946(97)00034-4. [DOI] [Google Scholar]

- Drake MA, Swanson BG. Reduced- and low-fat cheese thecnology: a review. Trend Food Sci Tech. 1995;6:366–369. doi: 10.1016/S0924-2244(00)89192-X. [DOI] [Google Scholar]

- Derringer G, Suich R. Simultaneous optimization of several response variables. J Quality Tech. 1980;12(4):214–219. [Google Scholar]

- James CS. Analytical chemistry of foods. Glasgow: Blackie Academic & Professional; 1995. [Google Scholar]

- Kahyaoglu T, Kaya S. Effects of heat treatment and fat reduction on the rheological and functional properties of Gaziyantep cheese. Int Dairy J. 2003;13:867–875. doi: 10.1016/S0958-6946(03)00113-4. [DOI] [Google Scholar]

- Katsiari MC, Voutsinas LP, Kondyli E, Alichanidis E. Flavour enhancement of low-fat Feta-type cheese using a commercial adjunct culture. Food Chem. 2002;79:193–198. doi: 10.1016/S0308-8146(02)00131-0. [DOI] [Google Scholar]

- Kavas G, Oysun G, Kinik O, Uysal H. Effects of some fat replacers on chemical, physical and sensory attributes of low-fat white pickled cheese. Food Chem. 2004;88:381–388. doi: 10.1016/j.foodchem.2004.01.054. [DOI] [Google Scholar]

- Koca N, Metin M. Textural, melting and sensory properties of low fat fresh Kashar cheeses produced by using fat replacer. Int Dairy J. 2004;14:365–373. doi: 10.1016/j.idairyj.2003.08.006. [DOI] [Google Scholar]

- Konuklar G, Inglett GE, Warner K, Carriere CJ. Use of β-glucan hydrocolloidal suspension in the manufacture of low-fat Cheddar cheese: textural properties by instrumental methods and sensory panels. Food Hydrocolloid. 2004;18:535–545. doi: 10.1016/j.foodhyd.2003.08.010. [DOI] [Google Scholar]

- Kumar SS, Balasubramanian S, Biswas AK, Chatli MK, Devatkal SK, Sahoo J. Efficacy of soy protein isolate as a fat replacer on physico-chemical and sensory characteristics of low-fat paneer. J Food Sci Technol. 2011;48(4):498–501. doi: 10.1007/s13197-010-0193-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Madadlou A, Emam-Djomeh Z, Mousavi ME, Ehsani M, Javanmard M, Sheehan D. Response surface optimization of an artificial neural network for predicting the size of re-assembled casein micelles. Comput Electron Agr. 2009;68:216–221. doi: 10.1016/j.compag.2009.06.005. [DOI] [Google Scholar]

- Madadlou A, Khosrowshahi A, Mosavi ME. Rheology, microstructure and functionality of low-fat Iranian White cheese made whit different concentration of rennet. J Dairy Sci. 2005;88:3052–3062. doi: 10.3168/jds.S0022-0302(05)72986-6. [DOI] [PubMed] [Google Scholar]

- Madadlou A, Khosrowshahi A, Mousavi ME, Emam-Djome Z. Microstructure and rheological properties of Iranian White cheese coagulated at various temperatures. J Dairy Sci. 2006;89:2359–2364. doi: 10.3168/jds.S0022-0302(06)72308-6. [DOI] [PubMed] [Google Scholar]

- Madadlou A, Mousavi ME, Khosrowshahi A, Emam-Djome Z, Zargaran M. Effect of cream homogenization on textural characteristics of low-fat Iranian White cheese. Int Dairy J. 2007;17:547–554. doi: 10.1016/j.idairyj.2006.07.006. [DOI] [Google Scholar]

- Mistry VU. Low fat cheese technology. Int Dairy J. 2001;11:413–422. doi: 10.1016/S0958-6946(01)00077-2. [DOI] [Google Scholar]

- Nunez M, Garcia-Aser C, Rodrigues-Martin A, Medina M, Gaya P. The effect of ripening and cooking temperature on proteolysis and lipolysis in Manchego cheese. Food Chem. 1986;21:115–123. doi: 10.1016/0308-8146(86)90156-1. [DOI] [Google Scholar]

- Rahimi J, Khosrowshahi A, Madadlou A, Aziznia S. Texture of low-fat Iranian white cheese as influenced by gum tragacanth as a fat replacer. J Dairy Sci. 2007;90:4058–4070. doi: 10.3168/jds.2007-0121. [DOI] [PubMed] [Google Scholar]

- Rodriguez J. Recent advances in the development of low-fat cheeses. Trends Food Sci Tech. 1998;9:249–254. doi: 10.1016/S0924-2244(98)00046-6. [DOI] [Google Scholar]

- Romieh EA, Michaelidou A, Biliaderis CG, Zerfiridis GK. Low-fat white-brined cheese made from bovine milk and two commercial fat mimetics: chemical, physical and sensory attributes. Int Dairy J. 2002;12:525–540. doi: 10.1016/S0958-6946(02)00043-2. [DOI] [Google Scholar]

- Rudan MA, Barbano DM, Yun JJ, Kindstedt PS. Effect of fat content reduction on chemical composition, proteolysis, functionality, and yield of Mozzarella. J Dairy Sci. 1999;82:661–672. doi: 10.3168/jds.S0022-0302(99)75282-3. [DOI] [PubMed] [Google Scholar]

- Saha D, Bhattacharya S. Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Tech. 2010;47(6):587–597. doi: 10.1007/s13197-010-0162-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sipahioglu O, Alvarez VB, Solano-Lopez C. Structure, physico chemical and sensory properties of Feta cheese made whit tapioca starch and lecithin as fat mimetics. Int Dairy J. 1999;9:783–789. doi: 10.1016/S0958-6946(99)00150-8. [DOI] [Google Scholar]

- Steffe JF. Rheological methods in food process engineering. East Lansing: Freeman Press; 1996. [Google Scholar]

- Tuinier R, Grotenhuis ET, de Kruif CG. The effect of depolymerised guar gum on the stability of skim milk. Food Hydrocolloid. 2000;14:1–7. doi: 10.1016/S0268-005X(99)00039-9. [DOI] [Google Scholar]

- Volikakis P, Biliaderis CG, Vamvakas C, Zerfiridis GK. Effects of a commercial oat-β-glucan concentration on the chemical, physico-chemical and sensory attributes of a low-fat white-brined cheese product. Food Res Int. 2004;37:83–94. doi: 10.1016/j.foodres.2003.07.007. [DOI] [Google Scholar]

- Zalazar CA, Zalazar CS, Bernal S, Bertola N, Bevilaequa A, Zaritzky N. Effect of moisture level and fat replacer on physicochemical, rheological and sensory properties of low fat soft cheeses. Int Dairy J. 2002;12:45–50. doi: 10.1016/S0958-6946(01)00130-3. [DOI] [Google Scholar]