Abstract

Millet based complementary foods were developed using sorghum (Sorghum vulgare), rice (Oryza Sativa), besan (Cicer arietinum; Bengal gram dhal flour), legume mix (Green gram and roasted Bengal gram; Phaseolus aureus Roxb and Cicer arietinum) and soybean (Glycine max Merr) with a lab scale twin screw extruder. The extrudates were subjected to acceptability studies initially and at the end of the storage period i.e. 3 months at laboratory level by panel of judges using a 5-point hedonic scale. Physico-chemical characteristics like bulk density, piece density and expansion ratio were measured and proximate principles were assessed. Soy and legume mix were found to have low bulk density as well as high expansion ratio. The developed extrudates were made into fine powder and sieved through a 60 mm mesh. Malted ragi flour at 15 % level was added to the powdered extrudates to develop the complementary mixes with low bulk density. Raw formulas without malt and with malt; extruded mixes without malt and with malt were studied for viscosity. The developed mixes were made into porridge and fed to the infants and the opinions about the acceptability of mixes were collected from the mothers. The complementary mixes with malted ragi showed reduced viscosity and formed good, smooth slurry and well accepted both by children and their mothers. Extruded soy and legume mixes with addition of 15 % malt were found to have satisfactory functional characteristics and nutritive value and can be explored for bulk preparation.

Keywords: Complementary foods, Millets, Extrusion cooking, Viscosity, Acceptability, Malted flours

Introduction

Infants in many developing countries have been reported to suffer from malnutrition. This has often attributed to an inadequate intake of energy and protein and other nutrients in their diets (Dutra-de-oliveira 1991). The traditional complementary foods/weaning foods, often given to infants in certain developing countries such as India, consist of thin gruel which is made from cereal or cereal flour. Such porridges are characterized by high viscosity and low energy output per unit volume of food, necessitating frequent feedings to meet the daily energy requirements of the child. It was reported that malting reduces dietary bulk and improves digestibility of grains. (Brandtzaeg et al. 1981).

Complementary foods produced by sophisticated technologies are costly and is not within the reach of low income groups. It is therefore desirable to develop low cost complementary foods adopting simple technologies, so that the foods can be supplied at affordable prices. Extrusion cooking is one of the contemporary food processing technologies applied for preparation of a variety of inexpensive snacks, specialty and supplementary foods (Harper and Jansen 1985). It reduces the anti nutritional factors, renders the product microbial safe and enhances the consumer acceptability (Nibedita and Sukumar 2003). It also reduces the destruction of nutrients, improves starch and protein digestibility.

Millets have traditionally been a part of Indian diets though in recent years people have shifted to cereals due to various reasons. However, an interest in the nutritional and functional value of millets has, once again, been rekindled. Millets lack in good quality protein, so combining them with soy/pulse or milk protein would enhance both quantity and quality of protein in millet products. Such a product if developed using extrusion technology, would be low in fat, high in protein and fibre, rich in other functional aspects. The extrudates could be powdered and added with malted cereal to prepare suitable weaning mix for Infants. High viscosity (higher dietary bulk) of the extruded millet could be a disadvantage for its use in weaning formulations, but it could be lowered considerably with addition of cereal malt to the extrudates (Sumathi et al. 2007). Accordingly, the present communication deals with the formulation of millet based complementary foods with utilization of extrusion technology.

Materials and methods

Development of extrudates

Raw materials

The raw materials used for product development such as sorghum, rice, defatted soy flour Bengal gram dhal, roasted Bengal gram dhal and green gram dhal were procured from local wholesale market.

Dehulling and milling

Separation of the glume tissue from the millet is essential to prepare food products from millet as the glumes happen to be a non edible component. The separation not only facilitates application of the moisture effectively for decortication or debranning the millet, but also enhances the consumer acceptability of products. Accordingly, milling the deglumed millet in a friction mill after incipient moist conditioning was possible without causing loss due to breakage. Sorghum was cleaned to remove stones and other extraneous matter. The sorghum was conditioned with water for 2–3 min and dehulled in a dehuller (model Dehuller mobile trolley 5 kg capacity per batch 3 HP-3 phase motor) for 6–8 min. During this step the dehuller removes the outer coarse fibre or husk with minimum degree of cracking of the grain. The grain collected from the dehuller was then winnowed and milled into flour in a lab model mill. The rice and legumes were also cleaned and milled into flour of uniform mesh size of 60 mm. Defatted soy flour was procured from a local firm ‘Crazy foods” which sells the soy products like flour, nuggets, flakes etc.

Formulations used

Based on mass different formulations with 100 % Sorghum (S), 100 % Rice (R), S+R = 60 + 40, S+R+Besan (B) = 50 + 30 + 20, S+R+Legume mix (LM, Green gram+Roasted Bengal gram; 75 + 25) = 50 + 30 + 20 and S+R+Soy (Sy) = 50 + 30 + 20 were made to prepare the extrudates. Initially the formulations were conditioned to a moisture level of 17 % considering its initial moisture level and extruded in lab scale twin screw extruder.

The extruder

A twin screw extruder (Scientech Engineers, Calcutta) was used for the preparation of the extrudates

Extrusion conditions

To optimize the process variables of extrusion cooking for preparation of the extrudates of maximum possible expansion ratio with desirable internal and apparent texture, the blended samples were tempered by adding a predetermined amount of water by spraying and mixed in a mixer thoroughly to adjust the feed moisture content to 17 % and were packed in a polythene bag, kept overnight in a refrigerator at 4 °C for moisture equilibrium. The operating conditions were fixed at 400 RPM screw speed; 15 kg/h feed rate; 3 mm diameter of the die. The temperature profile in the barrel zone towards die were 105 °C. The extrudates were collected when the operation conditions were at steady state, cooled at room temperature, dried in the oven at 100 °C for 20 min.

Physical characteristics

Expansion ratio was determined by taking the diameter of 10 extrudates using a Vernier calipers and dividing by the diameter of the die used (Singh et al. 2000). Piece density was determined by taking the weight and volume of 10 extrudates from each formulation. To arrive at an estimate of volume, the length as well as diameter of 10 pieces of the product was measured. The volume was calculated from the expression IIr2h. The weight of the pieces was divided by the volume to obtain density and expressed as g/cm3 (Singh et al. 2000). Bulk density was determined by filling a 1 L measuring cylinder with the extrudates slightly above the litre mark. The cylinder was tapped 10 times till the products measured up to the litre mark. The weight of the extrudates was taken and the bulk density was calculated.

Proximate composition

The moisture content of the samples was determined by following the method of AOAC (1980). Carbohydrate content was estimated by the difference. The energy values of the extrudates were determined by computation and expressed in kilocalories. The crude protein content of the samples was estimated according the Microkjeldhal method AOAC (1990) procedure and calculated as the product of percent nitrogen and a multiplication factor. The amount of fat in the food mixes was determined using soxhlet method of AOAC (1980). The ash and crude fibre content of the sample was estimated by AOAC (1984) method. The calcium, phosphorus and iron content in the samples were calculated based on the nutritive value of Indian foods (Gopalan et al. 2004).

Development of complementary/weaning mixes based on extrudates

The developed extrudates were made into fine powder and sieved through a 60 mm sieve. To develop the complementary mixes with low bulk density, malted ragi flour at 15 % level was added to the powdered extrudates.

Malting of ragi

Ragi was cleaned thoroughly and soaked overnight in water. Next day morning, water was drained and ragi was tied in a wet muslin cloth and kept for 24 h in a dark place. The sprouted ragi was subjected to drying and roasted on slow flame until a pleasant aroma was obtained. The sprouts were decorticated and milled into malt flour according to Malleshi and Desikachar (1982).

Storage studies

The extrudates were packed in metallised polyester terphalalene (MPET) packs and stored at room temperature (30–35 °C) for 3 months

Sensory evaluation

Sensory evaluation was carried out by seven semi-trained judges initially and after 3 months storage period using a 5-point Hedonic rating scale (Amerine et al. 1965) for sensory attributes like colour, appearance, flavour, taste, texture and overall acceptability.

Preparation of gruels

The gruels were prepared by taking 15 g of complementary mix (with and without addition of malt) and made into slurry with little water and added to 100 ml of boiling water and cooked for 2 min.

Viscosity of gruels

Raw formulas with and without malt, extruded mixes with and without malt were studied to measure the viscosity using Brookefiled viscometer (Model RV; Brookefiled Engineering Inc., Stoughton, WI, USA) according to Brandtzaeg et al. (1981).

Acceptability of weaning mixes at field level

Thirty lactating mothers attending anganwadi centers located at urban area (Mallepalli-Vijayanagar colony) and one at rural area (Khanapur), Hyderabad and Ranga Reddy districts respectively were selected for consumer acceptability studies. The weaning mix based on extrusion with addition of malt in comparison with out addition of malt was demonstrated. The developed mixes were made into porridge and fed to the infants at anganwadi centers. Sample packets of weaning food were distributed to mothers to feed their respective children at home. The opinion about the acceptability of mixes was collected from the mothers.

Statistical analysis

The results were subjected to statistical analysis with the window stat programme. Mean and standard deviation for ten replicates were calculated. Two way analysis of variance (ANOVA) was used to know the significant differences between the different treatment combinations and storage period.

Results and discussion

Sensory evaluation

The mean sensory scores for different extrudates before and after storage for three months are given in Table 1. The extrudates containing protein sources scored well for colour and appearance; the highest score was for a combination of sorghum + rice + soy. However, there was no significant difference between the samples. Significant change in color was observed after the storage period of three months. The extrudates containing protein sources scored well for flavor and taste. However, after three months storage period flavor and taste was reduced. The samples containing legume mix in addition to sorghum and rice had a crispy and crunchy texture and scored highest, which could be due to cereal and pulse combination, which contributes crispy texture even in traditional recipes like muruku, sev etc. Similarly Adesina et al. (1998), Jyoti kiran Singh et al. (2003) and Narayana Prasad et al. (2007) have also found the extruded product obtained from a blend of cereal and pulse possessed the most acceptable characteristics than cereal based extrudates. The organoleptic quality of the extruded snacks developed based on maize, rice, and pulses (Lakshmi Devi et al. 2005) were highly acceptable. There was a significant difference for texture and over all acceptability after storage for 3 months. This may be due to oxidative rancidity and chemical reactions that occur within food.

Table 1.

Sensory characteristics of the extrudates before and after 3 months of storage period in MPET packs at room temperature (30–35 °C)

| Sensory attributes | Storage period | Products | ‘F’ value | |||||

|---|---|---|---|---|---|---|---|---|

| Sorghum | Rice | S+R | S+R+B | S+R+LM | S+R+Soy | |||

| Colour & Appearance | Before | 4.4 ± 0.53 | 3.8 ± 0.69 | 4.2 ± 0.75 | 4.0 ± 0.81 | 4.4 ± 0.78 | 4.4 ± 0.53 |

|

| After | 4.1 ± 0.37 | 3.8 ± 0.69 | 3.8 ± 0.69 | 3.5 ± 0.97 | 3.5 ± 0.78 | 3.4 ± 0.53 | ||

| Flavour | Before | 4.0 ± 0.57 | 4.14 ± 1.06 | 3.85 ± 1.06 | 4.0 ± 0.57 | 4.5 ± 0.53 | 4.5 ± 0.53 |

|

| After | 2.5 ± 1.51 | 2.7 ± 1.89 | 2.5 ± 1.71 | 2.28 ± 1.60 | 2.5 ± 1.81 | 2.5 ± 1.71 | ||

| Texture | Before | 4.5 ± 0.53 | 4.5 ± 0.53 | 4.4 ± 0.53 | 4.4 ± 0.53 | 4.5 ± 0.53 | 4.4 ± 0.53 |

|

| After | 4.2 ± 0.48 | 4.4 ± 0.53 | 4.4 ± 0.53 | 4.1 ± 1.06 | 4.4 ± 0.53 | 4.2 ± 0.48 | ||

| Taste | Before | 4.2 ± 0.48 | 4.5 ± 0.53 | 4.5 ± 0.78 | 4.5 ± 0.78 | 4.7 ± 0.75 | 4.7 ± 0.48 |

|

| After | 2.2 ± 0.95 | 2.8 ± 1.77 | 2.8 ± 1.46 | 2.4 ± 1.51 | 3.0 ± 1.63 | 2.7 ± 1.89 | ||

| Overall Acceptability | Before | 4.2 ± 0.48 | 4.2 ± 0.56 | 4.2 ± 0.48 | 4.2 ± 0.48 | 4.5 ± 0.53 | 4.3 ± 0.69 |

|

| After | 3.4 ± 0.97 | 3.0 ± 1.0 | 3.1 ± 1.06 | 2.7 ± 0.95 | 3.1 ± 1.06 | 3.0 ± 1.0 | ||

Please refer to text for abbreviations of formulations

NS not significant

(n = 7)

*Significant at 5 % level

**Significant at 1 % level

Physical parameters of the extrudates

The mean physical parameters of different extrudates are given in Table 2. The length of the extrudates was lower in sorghum than other formulations and minimum expansion was seen for the product which contained sorghum, rice and Bengal gram flour than other formulations. Similarly maximum expansion was seen in rice followed by S+R and sorghum. The more the starch contents of the extrudates the more the expansion (Linko et al. 1981) but the more the protein the less the expansion (Faubion et al. 1982; Adesina et al. 1998). The weight, bulk density and piece density of the cereal and legume based extrudates was higher than cereal based extrudates. Among legume based extrudates, weight, bulk density and piece density of sorghum, rice and besan was higher than other formulations.

Table 2.

Physical parameters of extrudates

| Sensory attributes | Products | ‘F’ value | |||||

|---|---|---|---|---|---|---|---|

| Sorghum | Rice | S+R | S+R+B | S+R+LM | S+R+Soy | ||

| Length (mm) | 19.9 ± 3.03 | 27.2 ± 3.88 | 27.5 ± 3.51 | 27.0 ± 3.63 | 28.2 ± 3.93 | 27.3 ± 3.40 | 7.542* |

| Diameter (mm) | 8.2 ± 0.69 | 8.8 ± 0.64 | 8.4 ± 0.66 | 7.7 ± 0.68 | 8.4 ± 0.63 | 8.3 ± 0.68 | 2.906 NS |

| Weight (gms) | 1.3 ± 0.72 | 1.6 ± 0.63 | 2.2 ± 0.95 | 1.8 ± 0.61 | 2.3 ± 0.70 | 2.4 ± 0.61 | 3.748** |

| Bulk density | 0.07 ± 0.06 | 0.08 ± 0.05 | 0.07 ± 0.04 | 0.08 ± 0.04 | 0.08 ± 0.04 | 0.08 ± 0.05 | 0.11 NS |

| Piece density (g/cm3) | 1.2 ± 0.32 | 0.9 ± 0.25 | 1.4 ± 0.26 | 2.3 ± 0.31 | 1.4 ± 0.42 | 1.5 ± 0.19 | 24.28** |

| Expansion ratio | 10.9 ± 0.49 | 12.5 ± 0.44 | 11.5 ± 0.32 | 9.6 ± 0.33 | 11.5 ± 0.34 | 11.2 ± 0.37 | 60.43** |

Please refer to text for abbreviations of formulations

NS not significant

(n = 10)

* Significant at 5 % level

**Significant at 1 % level

Proximate composition of the extrudates

The nutrients like moisture, protein, fat, ash and crude fibre were determined in unspiced extrudates by AOAC methods. The results are tabulated in Table 3. The moisture level was higher in rice, S+R+Soy and lower in S+R+B extrudates. However, the optimum moisture level in all the extrudates is required to maintain the crispness. The protein content was higher in S+R+Soy, followed by S+R+LM and S+R+B extrudates which could be due to addition of pulses. The fat content was higher in rice extrudates than the other formulated extrudates. The energy value of all products was similar ranging from 374 to 386 Kcal. The S+R+Soy had high calcium, phosphorus and iron content followed by S+R+LM, S+R+B, sorghum, S+R and rice. The pulse and cereal based extrudates meets the nutritional requirements of infant supplementary food i.e. providing 300 Kcal and 10 g protein/ 100 g i.e. S+R+Soy, S+R+LM, S+R+B than cereal based extrudates. With addition of ragi malt the nutritive value of products will be enhanced and viscosity can be reduced. Karuna et al. (1991) and Sumathi et al. (2007) have prepared extruded weaning mixes with higher protein content in moisture free extrudates made from a combination of millets and found more nutritious and better acceptability.

Table 3.

Proximate composition of the extrudates

| Product (100 g) | Moisture (g) | Protein (g) | Fat (g) | Ash (g) | Fiber (g) | CHO (g) | Ca (mg) | P (mg) | Fe (mg) | Energy (kcal) |

|---|---|---|---|---|---|---|---|---|---|---|

| Sorghum | 1.2 | 10.3 | 1.7 | 3.1 | 1.1 | 82.3 | 25 | 222 | 4.1 | 386.7 |

| Rice | 2.6 | 6.8 | 0.4 | 3.5 | 0.8 | 85.7 | 10 | 160 | 0.7 | 374.6 |

| S+R | 2.0 | 8.9 | 1.2 | 3.0 | 1.2 | 83.5 | 19 | 197.2 | 2.7 | 381.1 |

| S+R+B | 0.7 | 11.3 | 1.2 | 3.2 | 1.2 | 82.3 | 28.7 | 257.2 | 3.4 | 385.7 |

| S+R+LM | 1.3 | 11.5 | 1.2 | 2.5 | 1.5 | 81.8 | 37.45 | 268.5 | 3.3 | 381.5 |

| S+R+Soy | 2.6 | 16.6 | 1.5 | 3.4 | 1.6 | 74.1 | 65.5 | 329.0 | 4.4 | 377.1 |

| Ragi Malt (15 %) (n = 2) | 1.96 | 1.0 | 0.1 | 0.4 | 0.5 | 10.8 | 51.6 | 42.4 | 0.5 | 49.2 |

Please refer to text for abbreviations of formulations

NS not significant

*Significant at 5 % level

**Significant at 1 % level

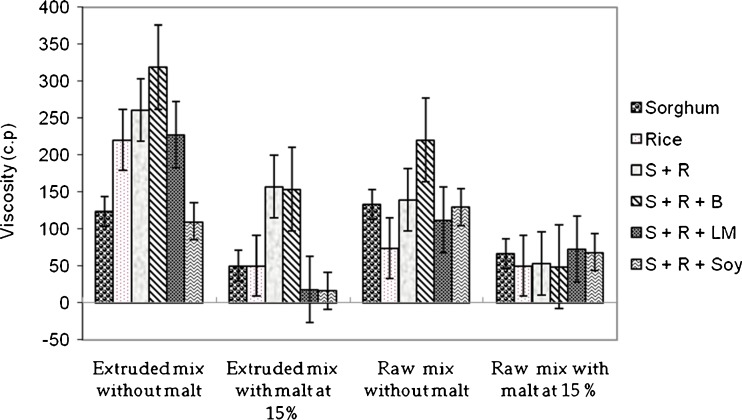

Viscosity

The viscosity values (centipoises) are higher for raw as well as extruded mixes as compared with extruded mixes with addition of ragi malt. There was considerable reduction in viscosity from raw mixes without malt and raw mixes with malt. Similar trend was observed in extruded mixes without malt and with malt for the gruels. The foods reconstituted well and formed slurry of soft consistency when stirred with cold or warm water. The extruded mixes along with malt reconstituted well with hot water as compared to raw mixes with and without malt which need further cooking after mixing with cold water (Fig. 1). The use of malted flour reduces dietary bulk because germination or malting produces and activates amylolytic and proteolytic enzymes which rapidly break down starch and protein respectively into more soluble products. As the starch is broken down by the amylolytic enzymes, its water holding capacity is reduced releasing the water trapped in the gel structures and producing a more liquid gruel (Karuna et al. 1991). Even after adding malt the viscosity of S+R and S+R+B was higher. Similar trend was reported by Karuna et al. (1991) and Wondimu and Malleshi (1996). In S+R+B, the higher viscosity could be due to the presence of starch and proteins. The amylolytic and proteolytic activity of the malt was not sufficient in S+R and S+R+B weaning gruels. Therefore, addition of larger amount of malt may reduce the higher viscosity in those gruels.

Fig. 1.

The viscosity of different weaning gruels

Consumer evaluation of products

The products were tested in both urban and rural areas for acceptability and all the products were well accepted both by children and as well as by their mothers.

Conclusion

The results of the study showed that acceptable complementary foods of good quality can be developed by extrusion cooking with utilizing sorghum, rice and other pulses. Among the different blends studied the most acceptable were soy and legume mix incorporated mixes in terms of all the sensory parameters both at lab level and consumer level. It is recommended to prepare weaning mixes using stored extrudates when ever required to extent the shelf life of the mixes. Extruded soy and legume mixes with addition of 15 % malt were found to have satisfactory functional characteristics and nutritive value and can be explored for bulk preparation.

References

- Adesina AA, Sowbhagya M, Bhattacharya S, Zakiruddin Ali S. Maize-soy based ready to eat extruded snack food. J Food Sci Technol. 1998;35(1):40–43. [Google Scholar]

- Amerine MA, Pongborn RM, Roessler EB. Principles of sensory evaluation of food. New York: Academic; 1965. [Google Scholar]

- Association of Official Analytical Chemists . Official methods of analysis. 13. Washington: AOAC; 1980. [Google Scholar]

- Association of Official Analytical Chemists . Official methods of analysis. 14. Washington: AOAC; 1984. [Google Scholar]

- Association of Official Analytical Chemists . Official methods of analysis. 15. Washington: AOAC; 1990. [Google Scholar]

- Brandtzaeg B, Malleshi NG, Svanberg U, Desikachar HSR, Mellander O. Dietary bulk as a limiting factor for nutrient intake with special reference to the feeding of preschool children. III: Studies on malted flours from ragi, sorghum and green gram. J Trop Pediatr. 1981;27:184–189. doi: 10.1093/tropej/27.4.184-a. [DOI] [PubMed] [Google Scholar]

- Dutra-de-oliveira JE. Malnutrition in developing countries: the challenges to the responsibilities of the experts. Proc Nutr Soc India. 1991;37:29–38. [Google Scholar]

- Faubion JM, Hoseney RC, Seib PA. Functionality of grain components in extrusion. Cereal Foods World. 1982;27:212–216. [Google Scholar]

- Gopalan C, Ramasastry BV, Balasubramanian SC. Nutritive value of Indian foods. Hyderabad: National Institute of Nutrition, Indian Council of Medical Research; 2004. [Google Scholar]

- Harper JM, Jansen GF. Production of nutritious precooked foods in developing countries by low cost extrusion technology. Food Rev Int. 1985;1:27–97. doi: 10.1080/87559128509540766. [DOI] [Google Scholar]

- Kulkarni KD, Kulkarni DN, Ingle UM. Sorghum malt based weaning food formulations : preparations, functional properties and nutritive value. Food Nutr Bull. 1991;13:322–327. [Google Scholar]

- Lakshmi Devi N, Vijay K, Mallikarjuna R. Development and acceptability of ready to eat snack for the institutionalized elderly. J Food Sci Technol. 2005;42(2):176–179. [Google Scholar]

- Linko PC, Colonna P, Mercier C. HTST extrusion in cereal based materials. Adv Cereal Sci Technol. 1981;4:145–148. [Google Scholar]

- Malleshi NG, Desikachar HSR. Formulation of a weaning food with low hot paste viscosity based on malted ragi and green gram. J Food Sci Technol. 1982;19(5):193–197. [Google Scholar]

- Narayana Prasad N, Siddalingaswmay M, Babu Shah ST, Semwal AD. Protein quality of sorghum soy based extruded snack food. J Food Sci Technol. 2007;44(2):165–167. [Google Scholar]

- Nibedita M, Sukumar B. Extrusion cooking technology employed to reduce the anti nutritional factor tannin in sesame meal. J Food Eng. 2003;56:201–202. doi: 10.1016/S0260-8774(02)00250-9. [DOI] [Google Scholar]

- Singh D, Chauhan GS, Tyagi SM, Suresh I. Nutritional quality of extruded snacks developed from composite of rice brokens and wheat bran. J Food Sci Technol. 2000;37(1):1–5. [Google Scholar]

- Singh JK, Azeem Z, Singh SS. Comparative studies on extruded snack foods with Khesaridhal and chick pea flours. J Food Sci Technol. 2003;40(3):333–336. [Google Scholar]

- Sumathi A, Usha Kumari SR, Malleshi NG. Physico chemical characteristics, nutritional quality and shelf life of pearl millet based extrusion cooked supplementary foods. Int J Food Sci Nutr. 2007;58(5):350–362. doi: 10.1080/09637480701252187. [DOI] [PubMed] [Google Scholar]

- Wondimu A, Malleshi NG. Development of weaning foods based on milted, popped and roller dried barley and chickpea. Food Nutr Bull (UNU) 1996;17(2):169–176. [Google Scholar]