Abstract

The present study was carried out to study the effect of incorporation of fibre rich pumpkin powder and guar gum on the farinographic characteristics of wheat flour. The flour and pumpkin powder were assessed for proximate composition, total dietary fibre, minerals and β-carotene. Pumpkin powder contained appreciable amount of fibre, minerals and β-carotene. The effects of incorporation of different levels of pumpkin powder and guar gum along with pumpkin powder on farinographic characteristics were studied. Dough development time, dough stability, time to break down and farinograph quality number increased whereas mixing tolerance index decreased with incorporation of pumpkin powder (> 5 %) and guar gum (1.0 and 1.5 %) along with pumpkin powder in the flour. Resistance to extension as well as extensibility of dough prepared increased significantly by adding pumpkin powder (5–15 %) whereas increase in resistance to extension only was noticed with inclusion of guar gum (0.5–1.5 %) to flour containing 5 % pumpkin powder. Results indicated that pumpkin can be processed to powder that can be utilized with guar gum for value addition.

Keywords: Pumpkin powder, Farinographic characteristics, Guar gum, β-carotene

Introduction

In this era of industrialization and technological advancement, the lifestyle of people has changed a lot. In this changing lifestyle, demand for ready-to-eat, ready-to-cook and convenient mixes like baked products, pasta products is raised considerably. Wheat is worldwide most important and least expensive crop available for creating fabricated food high in nutrition. The quantity and diversity of products made from wheat are traditional, baked, pasta products and ready-to-eat snacks. Pasta products and ready-to-eat snacks are very popular among young generation. However, these products are rich in starch, fat and energy but devoid of fibre as these products are made from refined flour/semolina. Low fibre intake in the diet has been associates with cardiovascular problem, obesity, diabetes, diverticular diseases and gastrointestinal problem (Tripathi and Mishra 2008). Dieticians recommend high fibre diets to prevent these diseases. The hypocholesterolemic and hypolipidemic action of fibre have been well documented (Azrag and Uro 2001).

Nutritional awareness and public education have increased the demand for high fibre foods. Fibre content can be increased by using high fibre sources such as cereal bran, pulse husk, fruits and vegetables. Studies on the use of vegetable fibre are scanty. Vegetables are good source of fibre and contain appreciable amount of protective nutrients like vitamins and minerals which help in preventing various diseases. In recent years, the interest in exploration, development and evaluation of functional foods for the target population has increased considerably amongst the researchers and technologists. Scientists are exploring the ignored crops which are otherwise rich source of phytochemicals of human interest for combating the deadly diseases like cancer and cardiovascular diseases. Pumpkin is one such vegetable gaining popularity as its technological and nutritional characteristics are equal or even better than those of widely cultivated vegetables and fruits. Pumpkin (Cucurbita moschata) is a cheaper vegetable and good source of β-carotene (precursor of vitamin A), fibre, and minerals (Dhiman et al. 2007, 2009) and incorporation of β-carotene rich materials in the human diet is considered a cost-effective approach to vitamin-A related health problems (Berteram and Bortkiewicz 1995). Also consumption of foods containing carotene helps preventing skin diseases, eye disorders and cancer (Bendich 1989). Pumpkin is consumed in a variety of ways such as fresh or cooked as well as being stored, frozen or canned (Figueredo et al. 2000) but in India it is mostly consumed as fresh vegetable and only a limited part goes for candy, preserve and sweets making and holds a vast potential in the manufacture of value added products.

Guar gum is an important source of soluble dietary fibre that acts as a bulk forming laxative and as such claimed to be effective in promoting regular bowel movements, relief constipation and chronic functional bowel ailments. It is also cheap and ideal for snack food as it prevents moisture migration. There is a global trend towards development of healthy snacks/ products and incorporation of fruits and vegetables in traditional extruded products may represent a strategy for value addition of these products. Since there is no comprehensive information available in literature on these aspects and in order to explore the possibilities of incorporation of pumpkin powder and guar gum in wheat flour, the present work was planned to study the effects of incorporation of pumpkin powder and guar gum on rheological properties of wheat flour.

Materials and methods

Procurement of materials

The wheat variety (WH-912) was procured from Department of Plant Breeding, CCS Haryana Agricultural University, Hisar, Haryana, India. Pumpkin was obtained from local market of Hisar, Haryana, India. Guar gum was obtained from Merck limited, Worli Mumbai, India.

Milling of wheat

The wheat was cleaned for extraneous matter, immature and wrinkled seeds. The grains were conditioned to obtain 15 % moisture and milled in Brabander Quardamat Junior Mill.

Development of pumkin powder

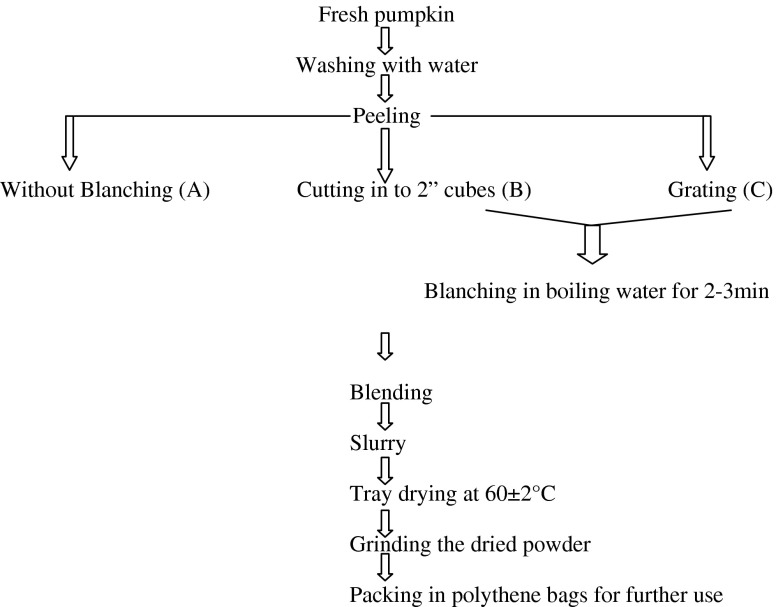

For the development of pumpkin powder, 1 Kg fresh pumpkins were washed with water and peel was removed. Three types of powders were prepared so as to standardize the process i.e. without blanching (A), blanching after cutting into pieces (B) and blanching after grating (C). The edible portion was cut into small pieces (approx 2″ cubes) and blended in electric blender as such (A) or after blanching in boiling water for 2–3 min (B and C). The slurry obtained was dried by spreading on polythene sheet in a thin layer in tray drier at 60 ± 2 °C. Dried product was ground in electric grinder to a fine powder and powder was packed in polythene bags till further use (Fig. 1).

Fig. 1.

Flow diagram of development of pumpkin powder

Chemicals

The chemicals used for investigation were of analytical grade reagents (A.R.) from standard suppliers like British Drug Houses (B.D.H.), Central Drug House (C.D.H.), S.D. fine chemicals (SDFCL) and Sisco Research lab, India.

Chemical evaluation of pumpkin powder and flour

The flour and powder were analyzed for proximate composition, mineral content, and total dietary fibre using standard AOAC method (1995) and β-Carotene in the sample was separated by column chromatography and estimated colorimetrically according to the standard methods of analysis (AOAC 1995).

Rheological properties

Sample of flour and flour blended with pumpkin powder (5 %, 10 %, 15 %) and wheat pumpkin powder blended with guar gum (0.5 %, 1 %, 1.5 %) was analyzed for Farinographic characteristics and extensibility of dough by using standard method (AACC 1995).

Farinographic characteristics

Farinograph measures the force during mixing of dough. The dough properties were determined using Brabender Farinograph equipped with 10 g bowl according to AACC method (1995). Ten g sample was weighed and transferred to bowl. Appropriate amount of water was added to get dough of consistency 500 BU (Brabender Unit). The test was run for 15 min and the following parameters were interpreted from the farinogram.

Water absorption

The water absorption by the flour is defined as the amount of water required to center the farinograph curve on 500 BU line for flour-water dough.

Dough development time

The time to the nearest half min. from the first addition of the water to the development of maximum consistency of the dough i.e. the point immediately before the first indication of weakening is defined as the dough development time. This value is also referred to as “peak time” or “mixing time”.

Dough stability

This is defined as the difference in time to the nearest half min., between the point where the top of curve intercepts 500 BU line (arrival time) and the point where the top of the curve leaves the 500 BU line (departure time). This value indicates the tolerance of flour to mixing.

Time to break down

This is time from the start of mixing to the time at which the consistency has decreased 30 FU (Farinographic Unit) from the peak point. It is determined by drawing a horizontal line through the centre of curve at its highest point and a parallel line 30 units lower. The time from the start of mixing until the centre of the descending curve crosses this lower line is the time to break down.

Mixing tolerance index

This value is the difference in BU from the top of the curve at the peak to the top of curve measured at 5 min. after the peak is reached. Flours which have good tolerance to mixing have low mixing tolerance index and higher the mixing tolerance index, the weaker is the flour.

Extensibility of dough

Samples of wheat flour and flour blended with pumpkin powder and guar gum were assessed for extensibility of dough using Kieffer Dough and Gluten Extensibility Rig (A/KIE) using 5 kg load cell.

Twenty grams flour was taken and dough was prepared using water to obtain dough consistency of 500 BU. The dough was kept for 20 min. to relax. The dough was rolled into sausage shape and placed on greased Teflon groove based clamped arrangement to get small strips. After 40 min the strips were taken and placed across grooved region of the sample plate. Then the kieffer rig was fixed on the TAXT Plus Texture analyzer. The strip of dough was centrally extended by a hook passing through the sample until its elastic limit (at the maximum force). At this point the maximum force and distance were noted to indicate the dough extensibility.

The results were expressed as:

Mean maximum force (g) i.e. resistance to extension.

Mean distance at maximum force (mm) i.e. extensibility.

Statistical analysis

The data obtained in triplicate was subjected to analysis of variance (ANOVA) technique and analyzed according to one factorial completely randomized design (CRD) with the help of Statistical Package for the Social Sciences (SPSS). The critical difference value at 5 % level was used for comparison.

Results and discussion

Composition of wheat flour and pumpkin powder

The results regarding composition of wheat flour and pumpkin powder indicates that pumpkin contained appreciable amount of nutrients. Wheat flour contained approximately 11.1 % moisture, 12.4 % protein, 1.4 % fat, 10.1 % total dietary fibres, 1.2 % crude fibre and 0.63 % ash while the respective amounts in pumpkin powder were 4.8 %, 11.6 %, 2.4 %, 28.3 %, 16.9 % and 6.7 %. Pumpkin powder contained higher amount of calcium (121.7 mg/100 g), iron (7.1 mg/100 g), zinc (3.1 mg/100 g) and β-carotene (1.8 mg/100 g) than that of wheat flour which contained 17.0 mg/100 g calcium, 5.3 mg/100 g iron and 2.8 mg/100 g zinc. Similar results were reported by Murkovic et al. 2002. So pumpkin powder can be incorporated to increase fibre, ash, calcium, total dietary fibre, fat and β-carotene in wheat flour based food products.

Effect of incorporation of various levels of pumpkin powder and guar gum on farinographic characteristics

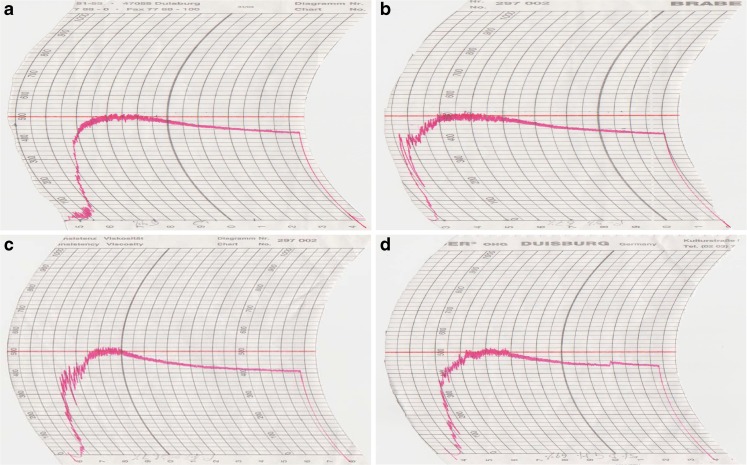

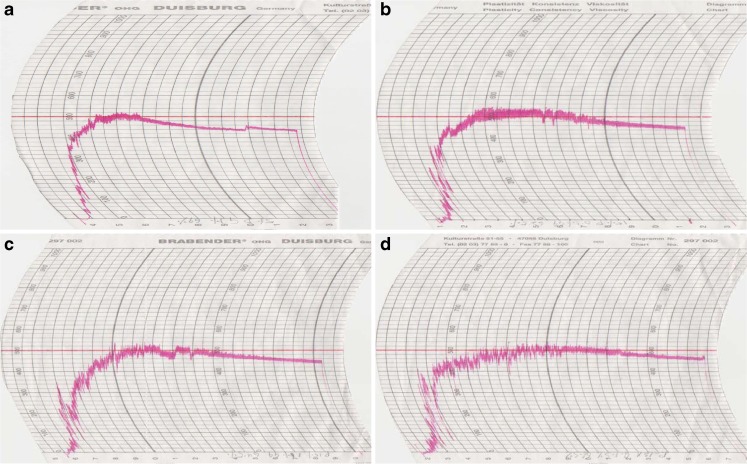

Farinograph is mainly used to predict the amount of water to be added to flour so as to get dough of fixed consistency (500 BU) during mixing and to measure the mixing characteristics of flour. The water absorption, dough development time, dough stability, mixing tolerance index, time to breakdown and fariographic quality number of wheat flour were 69.0 %, 2.5 min, 1.7 min, 70.0 BU, 5.1 min and 51.5, respectively. Incorporation of pumpkin powder and guar gum in flour altered the fariographic properties of the dough. Guar gum (0.5, 1.0 and 1.5 %) was incorporated in the flour containing 5, 10 and 15 % pumpkin powder and the data regarding the farinographic characteristics of dough containing different levels of pumpkin powder and different level of guar gum (0.5, 1.0 and 1.5 %) is presented in (Tables 1, 2, 3). Supplementation of wheat flour with pumpkin powder resulted in decreased water absorption (Fig. 2). This may be due to dilution of gluten. The quantity of water added is considered to be very important for distribution of dough materials, their hydration and the gluten protein network. The time required for control dough to reach 500 BU consistency was also modified by addition of pumpkin powder and guar gum (Figs. 2, 3, 4, 5). Similar results have been reported when apple pomace was incorporated in wheat flour (Masoodi et al. 2001). Dough development time either increased or showed no change with addition of pumpkin powder. An increase in dough development time was reported when wheat flour is supplemented with rice bran (Laurikainen et al. 1998). This change could have been due to differences in physiochemical properties between the constituents of pumpkin powder and wheat flour (Wang et al. 2002). Also, the consistency of dough was maintained at 500 BU for longer time because of competition of water between starch and fibre of pumpkin that implies that the dough is more stable and have more resistance against mechanical mixing. Mixing tolerance index is the difference in BU from the top of curve at the peak to the top of curve measured at 5 min after the peak is reached. Flours which have good tolerance to mixing have low mixing tolerance index and lower the mixing tolerance index, the stronger is the flour. Results indicate that with increasing concentration of pumpkin powder in the formulation, there was significant decrease in mixing tolerance index. Time to breakdown and farinographic quality number is also indicative of quality of flour. Similar results have been found with increasing level of guar gum (0.5, 1.0 and 1.5 %) in pumpkin powder supplemented wheat flour (5, 10 and 15 %). But water absorption either increased or showed no change with increasing level of guar gum. This is because guar gum is an hydrocolloid that retains more water that resulted in dough viscosity of flour at 500 BU for more time. The observed effect agrees with the increased dough development time found when xanthan gum was added in wheat dough (Rosell et al. 2001). Similar effects of fibre from different cereals has been reported on rheological characteristics of wheat flour dough and a significant increase is found in water absorption from (63.88–76.28 %) and (63.52–69.85 %) with addition of rice and wheat bran, respectively (Sudha et al. 2007).

Table 1.

Effect of incorporation of various levels of guar gum on farinographic characteristics of flour supplemented with 5 % pumpkin powder (n = 3)

| Parameter | Flour supplemented with 5 % Pumpkin powder | Guar gum (%) | C.D. at 5 % | ||

|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | |||

| Water absorption (%) | 67.0 ± 0.0 | 67.0 ± 0.0 | 69.0 ± 0.33 | 70.0 ± 0.0 | 0.552 |

| Dough development time (min.) | 2.5 ± 0.0 | 2.5 ± 0.0 | 2.5 ± 0.0 | 3.5 ± 0.08 | 0.138 |

| Dough stability (min.) | 2.0 ± 0.83 | 2.1 ± 0.16 | 2.3 ± 0.11 | 2.4 ± 0.08 | 0.110 |

| Mixing Tolerance Index (BU) | 70.0 ± 1.6 | 70.0 ± 1.6 | 60.0 ± 1.6 | 60.0 ± 1.6 | 5.5 |

| Time to break down (min.) | 5.1 ± 0.0 | 5.1 ± 0.16 | 5.5 ± 0.0 | 6.0 ± 0.0 | 0.276 |

| Farinographic quality number | 51.5 ± 0.0 | 51.5 ± 1.6 | 55.0 ± 0.0 | 60.0 ± 0.0 | 2.76 |

n number of replicates, C.D. at 5 % Critical Difference at 5 %, BU Brabender unit

Table 2.

Effect of incorporation of various levels of guar gum on farinographic characteristics of flour supplemented with 10 % pumpkin powder (n = 3)

| Parameter | Flour supplemented with 10 % pumpkin powder | Guar gum (%) | C.D. at 5 % | ||

|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | |||

| Water absorption (%) | 65.0 ± 0.0 | 65.0 ± 0.0 | 67.0 ± 0.0 | 68.5 ± 0.16 | 0.276 |

| Dough development time (min.) | 2.7 ± 0.0 | 2.7 ± 0.0 | 3.0 ± 0.16 | 3.7 ± 0.08 | 0.309 |

| Dough stability (min.) | 3.0 ± 0.08 | 3.1 ± 0.08 | 3.3 ± 0.0 | 3.5 ± 0.16 | 0.338 |

| Mixing Tolerance Index (BU) | 60.0 ± 1.6 | 60.0 ± 0.0 | 55.0 ± 0.0 | 30.0 ± 1.6 | 3.90 |

| Time to break down (min.) | 6.0 ± 0.08 | 6.0 ± 0.05 | 6.5 ± 0.03 | 10.3 ± 0.01 | 0.477 |

| Farinographic quality number | 60 ± 0.83 | 60 ± 0.51 | 65 ± 0.33 | 103 ± 0.13 | 4.77 |

Table 3.

Effect of incorporation of various levels of guar gum on farinographic characteristics of flour supplemented with 15 % pumpkin powder (n = 3)

| Parameter | Flour supplemented with 15 % pumpkin powder | Guar gum (%) | C.D at 5 % | ||

|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | |||

| Water absorption (%) | 62.5 ± 0.16 | 62.5 ± 0.0 | 64.4 ± 0.0 | 68.5 ± 0.16 | 0.276 |

| Dough development time (min.) | 4.1 ± 0.08 | 4.1 ± 0.01 | 4.5 ± 0.16 | 3.7 ± 0.08 | 0.309 |

| Dough stability (min.) | 3.5 ± 0.08 | 4.5 ± 0.03 | 5.0 ± 0.05 | 3.5 ± 0.16 | 0.338 |

| Mixing Tolerance Index (BU) | 50 ± 1.6 | 25 ± 0.0 | 20 ± 0.0 | 30.0 ± 1.6 | 3.90 |

| Time to break down (min.) | 7.5 ± 1.6 | 10.5 ± 0.0 | 12.5 ± 0.16 | 10.3 ± 0.01 | 0.477 |

| Farinographic quality number | 75 ± 1.6 | 105 ± 0.0 | 125 ± 1.6 | 103 ± 0.13 | 4.77 |

Fig. 2.

Farinogram of wheat flour (a) and flour supplemented with 5 % (b), 10 % (c), 15 % (d) pumpkin powder

Fig. 3.

Farinogram of wheat flour containing 5 % pumpkin powder (a) and flour supplemented with 0.5 % (b), 1.0 % (c), 1.5 % (d) guar gum along with pumpkin powder

Fig. 4.

Farinogram of wheat flour containing 10 % pumpkin powder (a) and flour supplemented with 0.5 % (b), 1.0 % (c), 1.5 % (d) guar gum along with pumpkin powder

Fig. 5.

Farinogram of wheat flour containing 15 % pumpkin powder (a) and flour supplemented with 0.5 % (b), 1.0 % (c), 1.5 % (d) guar gum along with pumpkin powder

Extensibility of dough

The resistance to extension and extensibility of control dough was 23.0 g and 95.2 mm, respectively. Extensibility as well as resistance to extensibility increased with incorporation of pumpkin powder; higher the level of pumpkin powder more was the extensibility and resistance to extensibility. No change in extensibility was witnessed with incorporation of guar gum (0.5–1.5 %) in the flour containing pumpkin powder (Table 4). This is likely due to interactions between the fibre and the wheat proteins. Incorporation of guar gum to the pumpkin powder supplemented wheat flour only gives the strength.

Table 4.

Effect of incorporation of various levels of pumpkin powder and guar gum on dough extensibility (n = 5)

| Samples | Level of supplement | Max. force1 (g) | Distance at max. force2 (mm) |

|---|---|---|---|

| Wheat flour | 0 | 23.0 ± 1.0 | 95.2 ± 0.30 |

| Pumpkin powder (%) | 5 | 26.0 ± 0.0 | 96.3 ± 0.25 |

| 10 | 43.0 ± 0.0 | 96.6 ± 0.22 | |

| 15 | 48.0 ± 0.0 | 97.6 ± 1.02 | |

| C.D. at 5 % | 0.001 | 0.618 | |

| Wheat flour + 5 %pumpkin powder | 0 | 22.0 ± 0.0 | 96.3 ± 0.26 |

| Guar gum (%) | 0.5 | 24.0 ± 1.0 | 96.7 ± 0.31 |

| 1.0 | 33.0 ± 1.0 | 96.3 ± 0.14 | |

| 1.5 | 33.0 ± 1.0 | 96.4 ± 0.03 | |

| C.D. at 5 % | 0.002 | N.S | |

| Wheat flour + 10 %pumpkin powder | 0 | 43.0 ± 0.0 | 95.9 ± 0.228 |

| Guar gum (%) | 0.5 | 45.0 ± 1.0 | 94.8 ± 0.037 |

| 1.0 | 45.0 ± 1.0 | 95.2 ± 0.187 | |

| 1.5 | 46.0 ± 2.0 | 95.3 ± 0.063 | |

| C.D. at 5 % | N.S | N.S | |

| Wheat flour + 15 %pumpkin powder Guar gum (%) | 0 | 48.0 ± 2.0 | 97.6 ± 0.11 |

| 0.5 | 48.0 ± 1.0 | 97.9 ± 0.11 | |

| 1.0 | 48.0 ± 1.0 | 97.8 ± 0.35 | |

| 1.5 | 48.0 ± 2.0 | 97.5 ± 0.01 | |

| C.D. at 5 % | N.S | N.S |

1Max. force (kg) represent resistance to extensibility

2Distance at max. force (mm) represent extensibility

Conclusions

Results indicate that pumpkin contained appreciable amount of nutrients; it contained more calcium, iron, zinc, total dietary fibre and β-carotene than wheat flour, so pumpkin powder can be incorporated to increase fibre, ash, calcium, total dietary fibre, fat and β-carotene in wheat flour based food products. The addition of pumpkin powder and guar gum to wheat flour brought some significant changes in the dough mixing behaviour as measured by farinograph and these farinographic characteristics of flour supplemented with pumpkin powder indicate that pumpkin powder supplemented flour can be used for making good quality bread. Results also indicate that with incorporation of pumpkin powder, extensibility as well as resistance to extensibility increased significantly. Addition of pumpkin powder in wheat flour resulted in rubber like properties and incorporation of guar gum to the pumpkin powder supplemented wheat flour give only strength.

Contributor Information

Himani Kundu, Email: kundu.himani@yahoo.in.

Raj Bala Grewal, Email: grewalrb@gmail.com.

Ankit Goyal, Email: ankit_goyalg@yahoo.co.in.

Neelam Upadhyay, Email: neelam_2912@yahoo.co.in.

Saurabh Prakash, Email: singhsaurabh1983@gmail.com.

References

- AACC. (1995) Approved methods of AACC American Association of Cereal Chemists, St Paul, Minn

- AOAC . Official methods of analysis. 15. Washington: Association of official Analytical Chemist; 1995. [Google Scholar]

- Azrag RM, Uro ABO. Hypoglyceamic effects of guar gum and wheat bran enriched bread. Ahfad J. 2001;18:30–36. [Google Scholar]

- Bendich A. Carotenoids and the immune response. J Nutr. 1989;119:112–115. doi: 10.1093/jn/119.1.112. [DOI] [PubMed] [Google Scholar]

- Berteram JS, Bortkiewicz H. Dietary carotenoid inhibit neoplastic transformation and modulate gene expression in mouse and human cell. Am J Clin Nutr. 1995;62:132S–136S. doi: 10.1093/ajcn/62.6.1327S. [DOI] [PubMed] [Google Scholar]

- Dhiman AK, Muzaffer S, Attri S. Utilization of pumpkin (Cucurbitamoschata) for product development. Him J Agric Res. 2007;33:223–227. [Google Scholar]

- Dhiman AK, Muzaffer S, Attri S. Functional constituents and processing of pumpkin: a review. J Food Sci Technol. 2009;40(3):411–417. [Google Scholar]

- Figueredo E, Minguez A, Luis VL. Allergy to pumpkin and cross reactivity of other cucurbitaceae fruits. J Allergy Clin Immunol. 2000;106:402–403. doi: 10.1067/mai.2000.108109. [DOI] [PubMed] [Google Scholar]

- Laurikainen T, Harkonen H, Autio K, Poutanen K. Effects of enzymes in fibre enriched baking. J Sci Food Agric. 1998;76:239–249. doi: 10.1002/(SICI)1097-0010(199802)76:2<239::AID-JSFA942>3.0.CO;2-L. [DOI] [Google Scholar]

- Masoodi FA, Chauhan GS, Tyagi SM, Kumbhar BK, Kaur H. Effect of apple pomace incoprporation on rheological characteristics of wheat flour. Int J Food Prop. 2001;4(2):215–223. doi: 10.1081/JFP-100105188. [DOI] [Google Scholar]

- Murkovic M, Mulleder U, Neunteufl H. Carotenoid content in different varieties of pumpkins. J Food Compos Anal. 2002;15:633–638. doi: 10.1006/jfca.2002.1052. [DOI] [Google Scholar]

- Rosell CM, Rojas JA, Benedito de Barber C. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloids. 2001;15:75–81. doi: 10.1016/S0268-005X(00)00054-0. [DOI] [Google Scholar]

- Sudha ML, Vetrimani R, Leelavathi K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007;2:1365–1370. doi: 10.1016/j.foodchem.2005.12.013. [DOI] [Google Scholar]

- Tripathi S, Mishra HN. Effect of addition of some herbal mixtures on antioxidants and sensory quality of extruded snack products. Beverage Food world. 2008;6:30–33. [Google Scholar]

- Wang J, Rossel CM, Benedito de Barber C. Effect of addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002;79:221–226. doi: 10.1016/S0308-8146(02)00135-8. [DOI] [Google Scholar]