Abstract

This study investigated the effect of inulin (0, 1 and 2 %), on some physicochemical properties of frozen yogurt, as well as its effect on flow behavior and probiotic survival. The results showed that the addition of inulin improved overrun, viscosity and melting properties significantly (p < 0.05); when added at 2 % level, it also had significant effect on pH. Total acceptability of samples revealed that frozen yogurt with 2 % inulin had the most appealing sensory characteristics. The flow behavior of all samples showed their pseudoplastic nature; power law was the best model to predict their flow behavior. In terms of probiotic survival, the sample with 2 % inulin significantly improved the viability of Lactobacillus acidophilus and Bifidobacterium lactis.

Keywords: Frozen yogurt, Inulin, Probiotic, Physicochemical properties, Flow behavior.

Introduction

Frozen yogurt is a complex fermented frozen dairy dessert that combines the physical characteristics of ice cream with the taste and nutritional properties of fermented milk products (Soukoulis and Tzia 2008). Consumers often choose to eat frozen yogurt because they expect that it contains less lactose than ice cream with a similar amount of fat, and provides health benefits from the viable bacteria contained in it (Marshall 2001).

Frozen yogurt supplemented with probiotics provides additional health benefits (Davidson et al. 2000). Probiotics play a major role in health and well being beyond basic nutrition (Vanaja et al. 2011). The frozen yogurt environment is not optimum for survival of bacteria (Davidson et al. 2000). Probiotic microorganisms in aerated and frozen products such as ice cream and frozen yogurt can be injured when subjected to oxygen and freezing temperature. Acidity of yogurt also can be a harmful factor for probiotic viability (Magarinos et al. 2007). The formation of ice crystals due to temperature fluctuations during storage may rupture bacterial cells and reduce viability (Davidson et al. 2000). Consequently, manufacturers are interested in developing a process that can provide high densities of robust probiotic strains in the product (Talwalkar and Kailasapathy 2004).

Inulin is a storage polymer derived from a number of plants. It consists of β-2 1-linked fructosyl unit with a terminal glucosyl unit (Paseephol et al. 2008). Inulin's water-binding and texturizing properties are well-known in the food industry (Kip et al. 2006). Soukoulis et al. (2009) reported that addition of fibers such as inulin, increased viscosity and shear thinning behavior significantly. In some studies inulin was used as a fat replacer in yog-ice cream (El-Nagar et al. 2002). Inulin and other prebiotics also have been used to increase the viability of probiotic bacteria (Akalin and Erisir 2008). The effect of inulin on the viability of probiotics in ice cream was studied (Akin et al. 2007; Akalin and Erisir 2008). They found that addition of inulin improved survival of probiotic in ice cream during storage. Dhewa et al. (2010) also eported that Lactobacillus plantarum exhibited the highest specific growth rate in presence of inulin. The objective of this study was to produce a frozen yogurt with high levels of probiotics with the help of added inulin, to determine the probiotics' survival during storage and to examine the product’s physicochemical and flow behavior properties.

Materials and methods

Preparation of yogurt

Milk containing 2.5 % fat and 8.25 % solids not fat (SNF) was standardized to 11 % SNF using skim-milk powder. The standardized milk was heated at 85 °C for 30 min, and then cooled to 42 °C. It was then inoculated with commercial yogurt starter culture (YC-X11, CHR-Hansen, Denmark) at a concentration of 0.2 % and probiotic cultures (Lactobacillus acidophilus (La5) and Bifidobacterium lactis (Bb12), CHR-Hansen, Denmark) at a concentration of 0.03 % followed by incubation at 42 °C. When acidity reached 0.8 % lactic acid, the yogurt was cooled to refrigerator temperature (7 °C).

Preparation of frozen yogurt

To prepare the control frozen-yogurt mix, sugar (16 %), skim-milk powder (to adjust total solids to 30 %) and commercial emulsifier-stabilizer mix (0.2 %, Dadli company, Iran) were thoroughly mixed together and dissolved in water(200 cc) and then pasteurized. The solution was added to the yogurt (30:70), thoroughly mixed and refrigerated at 7 °C for 15 h. The aged frozen-yogurt mix was frozen using a laboratory batch home ice cream maker (Feller, Germany). The resulting frozen yogurt was placed in plastic cups (50 ml) and hardened at −18 °C. The same procedure was followed for the test samples, with the addition of inulin (DP ≥ 10, Beneo-orafti Co., Belgium) in different levels (0, 1 and 2 %). Inulin was added to mixture of sugar, skim milk powder and after pasteurization was added to yogurt.

Physicochemical properties

The samples' pH was measured with a pH meter (Methrom-827, Switzerland). Acidity was determined with NaOH 0.1 N and phenolphetalein as indicator and stated by lactic acid per cent.

Viscosity of frozen yogurt mixes was determined using a viscometer (RV-DV II Brookfield, Engineering Lab Inc., Stoughton, Mass., and U.S.A). Samples were tested at 5 °C by spindle No. 6. Shear rate and shear stress values were calculated using the viscosity data according to the Mitschka (1982) equations. Plots of shear stress versus shear rate were created for each frozen-yogurt sample at speeds of 10 to 200 rpm. Flow-behavior index (n) and consistency-coefficient (K) values were calculated for each sample. In order to perform a quantitative comparison of materials, it is generally necessary to fit the experimental data to some form of best-fit mathematical equation or model. The model is used to predict the viscosity of a flow as a function of shear stress or shear rate. The Power Law model was used for fitting the flow curve of frozen yogurt:

|

1 |

Where k is the consistency coefficient ( ), γ is the shear rate (s-1), τ is the shear stress (pa) and n is the flow-behavior index. For shear-thinning fluids n < 1, and for shear-thickening fluids n > 1.

), γ is the shear rate (s-1), τ is the shear stress (pa) and n is the flow-behavior index. For shear-thinning fluids n < 1, and for shear-thickening fluids n > 1.

Overrun was measured according to following equation:

|

To evaluate the melting rate, a block of frozen yogurt (30 ± 1gr) was placed on a sieve (mesh: 0.5 mm) on top of a beaker at 25 °C. The time of first dripping was noted and the percent of melted frozen yogurt by weight after 60 min was determined (Akalin and Erisir 2008).

The sensory characteristics of the samples were evaluated by seven trained panel members according to a five-point scale for flavor, color, texture and total acceptability (1 = unpleasant, 5 = pleasant). Flavor was evaluated by the sample's closeness to an acceptable standard and intensity of refreshing yogurt flavor and its relative freedom from any cooked or whey aroma. The color of the frozen yogurt was evaluated as either white or clear. Some attributes of texture (uniform and without gummy, sandy and icy defect) were evaluated. Overall acceptability was also evaluated, based on characteristics including color, texture and flavor (Rezaei et al. 2011).

Enumeration of probiotic bacteria

The count of probiotic bacteria was determined after freezing and during storage of samples. To count Lactobacillus acidophilus, MRS-IM was used and plates were incubated aerobically at 37 °C for 72 h (CHR-Hansen, 2006). Bifidobacterium lactis was counted using MRS-NNL (neomycin sulphate 100 mg/L, nalidixic acid 15 mg/L and lithium chloride 3 mg/L) and L-cystein chloride, and plates were incubated anaerobically at 37 °C for 72 h.

Statistical analysis

For the storage experiment, the set of data was conducted as a split plot in a randomized complete block design. Each replication was considered as a block; inulin treatment was the main unit treatment and days of storage were the subunit treatment. For physicochemical and sensory evaluation, data from each sampling stage were analyzed statistically by completely randomized design. Means with a significant difference (P < 0.05) were compared using Duncan’s multiple range tests. Each experiment was replicated 3 times.

Result and discussion

Physicochemical characteristics

The results showed frozen yogurt containing 2 % inulin had significantly lower pH and higher acidity than the others (P < 0.05) (Table 1). The highest pH and lowest acidity value were observed in the control sample (P < 0.05). Aryana et al. (2007) and Guven et al. (2005) reported that yogurt containing inulin had lower pH and higher acidity compared to control yogurt.

Table 1.

Effect of inulin on physicochemical properties of frozen yogurt (n = 3)

| Frozen yogurt | pH | Acidity (% lactic acid) | Overrun (%) | Viscosity(cp) | First dripping time (S) | Melting rate (%) |

|---|---|---|---|---|---|---|

| control | 5.1a | 0.64 ± 0.010b | 22.3 ± 0.90c | 1522 ± 13.2b | 1032 ± 160.8b | 96.4 ± 1.01a |

| Inulin 1 % | 5.0ab | 0.70 ± 0.012ab | 33.5 ± 1.21b | 2353 ± 18.5a | 1253 ± 78.8b | 93.8 ± 2.30a |

| Inulin 2 % | 4.9b | 0.75 ± 0.060a | 38.5 ± 2.79a | 2404 ± 9.7a | 2264 ± 25.5a | 84.5 ± 5.70a |

Cp centi poise

a,b,cMeans in the same column indicated by different letters were significantly different (P < 0.05)

Effects of different levels of inulin on viscosity are shown in Table 1. Adding inulin increased viscosity significantly compared to control frozen yogurt, but there was no significant difference between two concentrations of inulin. Because of the hygroscopic nature of inulin, it could bind water and form a gel-like network (El-Nagar et al. 2002). Akin et al. (2007) found that addition of inulin caused more viscosity in ice cream. Adapa et al. (2000) found that ice-cream mixes containing a carbohydrate-based fat replacer exhibited a viscous behavior because of their capability for imbibing water, which increase viscosity.

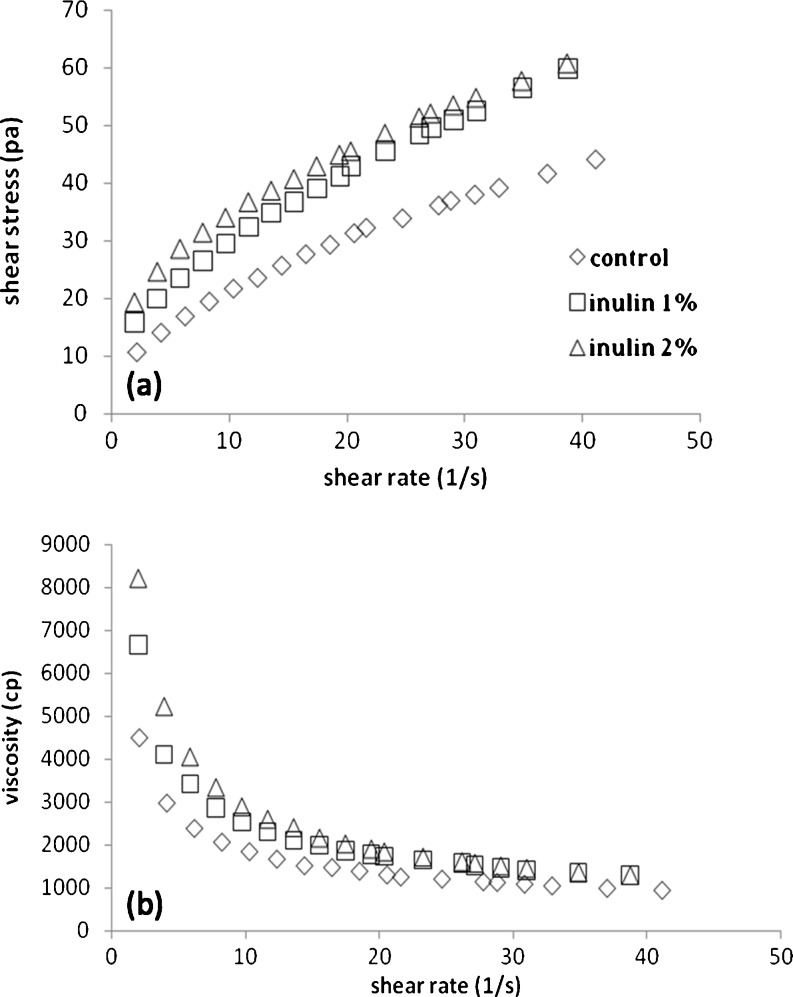

Figure 1a shows the flow curves of the inulin-containing samples and control frozen-yogurt mixes on day 1 by plotting shear rate versus shear stress. The lack of linear characteristic indicates a deviation from Newtonian behavior. The flow-behavior indices (n) of all samples were below 1, and frozen yogurt with 2 % inulin had the highest deviation from Newtonian fluids (Table 2). The viscosity curve of these samples revealed the shear-thinning nature of frozen yogurts (Fig. 1-b); adding inulin increased this property. Previous reports also emphasized the effect of inulin on enhancing shear-thinning behavior (Paseephol et al. 2008).

Fig. 1.

Effect of shear rate on shear stress (a) and apparent viscosities (b) of different frozen-yogurt mixes (n = 3)

Table 2.

Values of power-law model parameters of inulin treatment of frozen yogurt

| Inulin Concentration (%) | n | k | R2 |

|---|---|---|---|

| 0 | 0.514 | 6.514 | 0.998 |

| 1 | 0.403 | 15.456 | 0.996 |

| 2 | 0.312 | 20.005 | 0.997 |

n flow behavior index; k consistency coefficient; r 2 correlation coefficient

Table 2 gives the value of the rheological parameter obtained by fitting using the power-law model. This model, which satisfactorily fitted experimental data for each sample, had the highest correlation coefficient (0.996 ≤ r2 ≤ 0.998). The parameters of the power-law model showed that increasing levels of inulin were followed by increased viscosity, a decreased flow-behavior index (n) and an increased consistency coefficient.

The addition of inulin increased the overrun of frozen yogurt (Table 1). Samples containing 1 and 2 % of inulin were significantly different from each other (P < 0.05). Overrun depends on the amount of air trapped in frozen yogurt and influences the quality of products (Moeenfard and Mazaheri Tehrani 2008). It has been shown that Akin et al. (2007) found that inulin had no significant effect on ice-cream overrun. However, addition of inulin significantly increases the overrun of ice cream (Akalin and Erisir 2008; Akalin et al. 2008). There is a relation between viscosity and overrun. Increase in concentration of inulin, and therefore increase in viscosity, improved overrun (Moeenfard and Mazaheri Tehrani 2008).

The results showed that adding 1 % inulin had an insignificant effect on time of first dripping, but adding 2 % inulin prolonged the time for melting significantly (P < 0.05) (Table 1). The effect of inulin on time of first dripping was similar to that reported by Akin et al. (2007). Inulin can form a sticky network in yogurt-ice cream that results in more resistance to melting (El-Nagar et al. 2002). It has been previously shown that ice creams with higher overrun melt more slowly (Sofjan and Hartel 2004). The result confirmed the same for frozen yogurt. This increase in melting time might be attributed to the lower heat-transfer rate of air trapped in the mixture (Moeenfard and Mazaheri Tehrani 2008). Sofjan and Hartel (2004) also found that air is a good insulator and slowed the rate of heat transfer in ice cream.

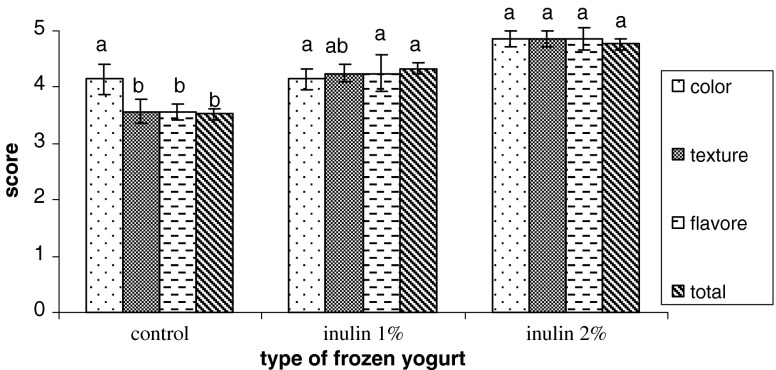

Based on the results of this study, addition of inulin caused improvement in flavor, texture and total acceptance (Fig. 2). Similarly, Kip et al. (2006) reported that inulin can be used successfully to improve the mouth feel of yogurt. In contrast, Akin et al. (2007) reported that inulin had no effect on the sensory properties of ice cream.

Fig. 2.

Effect of inulin on sensory quality of frozen yogurt (n = 3) a,bMeans in the same column indicated by different letters were significantly different (P < 0.05)

Probiotic survival

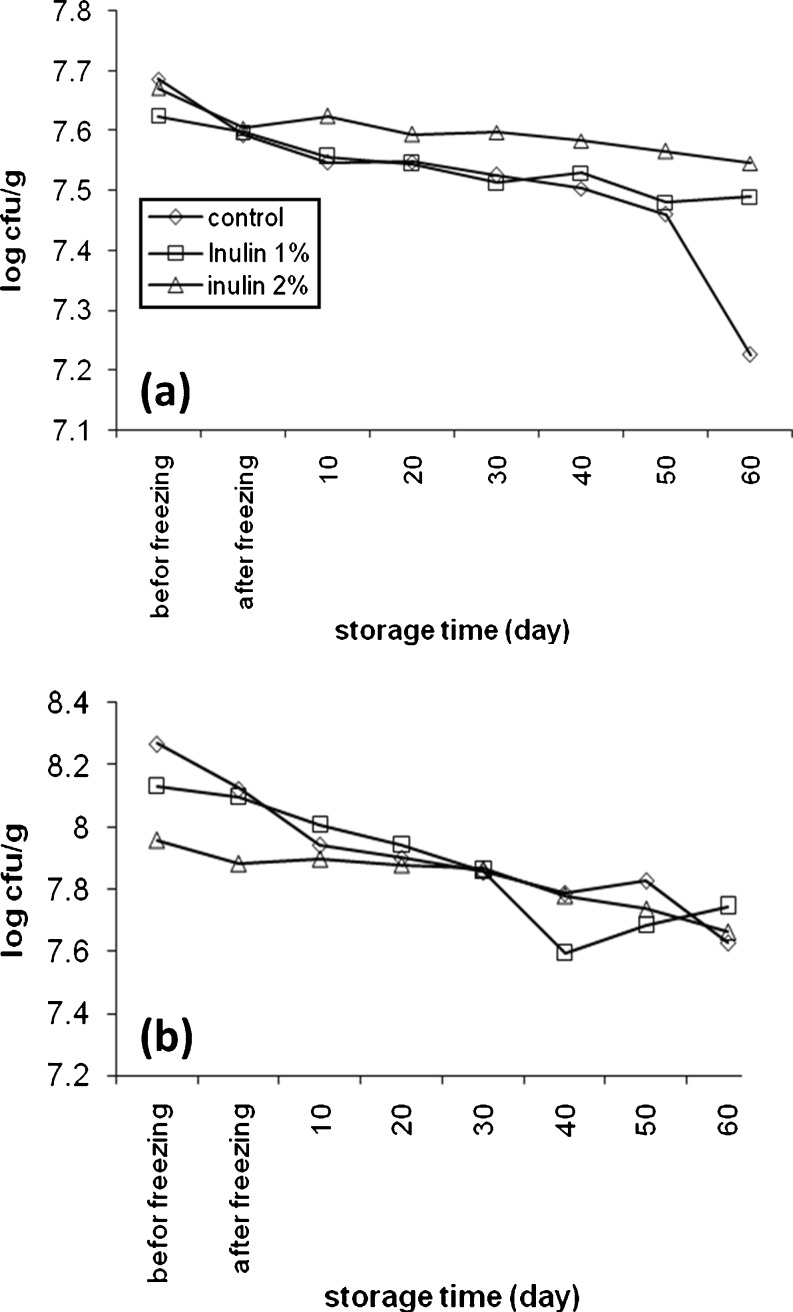

The results showed that probiotic counts in frozen yogurt decreased during storage significantly (P < 0.05), although study with yogurt/ice-cream mixtures have established that the medium possesses cryoprotective properties, due to the presence of casein, sucrose and lactose (Holcomb and Frank 1991). Decline in bacteria counts after freezing could be as a result of cold shock during freezing and osmotic pressure. Overrun also could be considered as a destructive factor for probiotic bacteria because most of the Lactobacillus and Bifidobacterium spp. are gut-derived organisms and thus microaerophilic (Magarinos et al. 2007; Cruz et al. 2009). Furthermore, ice crystals formed during freezing and mechanical stress could contribute to the decreased count of probiotics.

Considering the results, there was 0.2 log decrease in Lactobacillus acidophilus survival rate and 0.4 log for Bifidobacterium lactis after storage. Although the Bifidobacterium population was higher than the Lactobacillus acidophilus, the decline rate of Bifidobacterium was greater than that of Lactobacillus acidophilus because the former is more sensitive to air corporation and acidity than the latter. Survival of Bifidobacterium is more affected more by acidity (Cruz et al. 2009). Results of data regression analysis in this study also revealed a negative correlation between acidity and Bifidobacterium survival (p = 0.008, r = −0.809).

However, after 60 days the product contained an appropriate number of bacteria (106 log cfu/g) to deliver health benefits to consumers. Similar results were reported by Ordonez et al. (2000) and Davidson et al. (2000), who stated that after an initial decrease in probiotic bacteria, their count in frozen storage did not change, and at the end of storage the product contained an adequate number of probiotics.

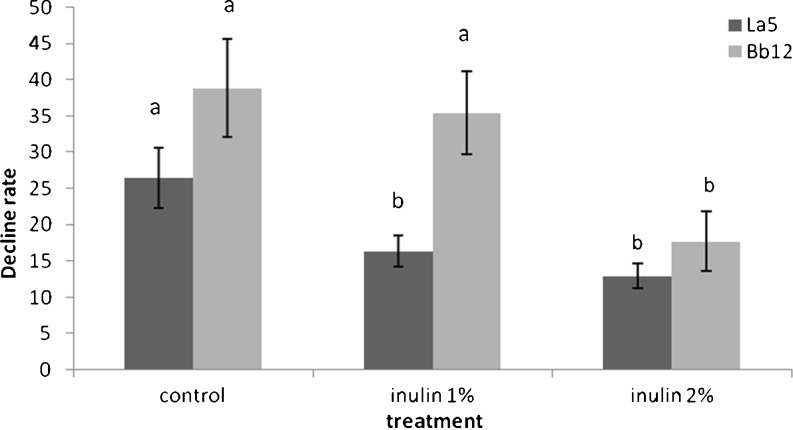

Figures 3-a and 3-b show the variation in probiotic bacterial counts in mix and frozen yogurt with and without inulin addition. The results showed that effects of treatment on both the probiotic bacteria were significant (p < 0.05). Results showed that the drop in viable count of probiotics in the sample containing inulin was lesser than in the control sample. In the control sample, the population of Lactobacillus acidophilus reached to 7.22 log cfu/g at the end of storage; the decline rate was evaluated to be 58.71 % (Fig. 4). In inulin-containing samples, the count of Lactobacillus was 7.49 and 7.54 log cfu/g in frozen yogurt containing 1 and 2 % inulin and decline rate was 26.14 and 22.14 % respectively, after 60 days. The count of Bifidobacterium at the end of storage was 7.62, 7.74 and 7.66 logcfu/g in control, 1 % and 2 % inulin samples respectively. The decline rate in inulin-containing samples was much less than in the control sample; 69.94 % and 22.4 % decrease was seen in the control and 2 % inulin samples, respecively.

Fig. 3.

Changes in a Viable counts of Lactobacillus acidophilus (La5) and b Bifidobacterium lactis (Bb12) in frozrn yogurt during storage (−18 °C) (n = 3)

Fig. 4.

Effect of inulin addition on loss percent of Lactobacillus acidophilus (La5) and Bifidobacterium lactis (Bb12) (n = 3). a,bMeans in the same column indicated by different letters were significantly different (P < 0.05)

Conclusion

In conclusion, frozen yogurt containing inulin not only retains its nutritional properties, but good physical and sensory qualities. Addition of inulin—which could potentially be introduced as a prebiotic—improved frozen yogurt's viscosity, overrun and melting properties. In sensory evaluation, panelists preferred frozen yogurts with 2 % inulin over other samples. This product could be introduced as a good vehicle for probiotic bacteria, because the levels of probiotics were higher in samples supplemented with inulin.

Contributor Information

Rahil Rezaei, Email: azar_rahil_64@yahoo.com.

Morteza Khomeiri, Phone: +98-171-4426432, FAX: +98-171-4426432, Email: mkhomeiri@yahoo.com.

Mehran Aalami, Email: mehranalami@yahoo.com.

Mahdi Kashaninejad, Email: kashaninejad@yahoo.com.

References

- Adapa S, Dingeldein H, Schemidt KA, Herald TJ. Rheological properties of ice cream mixes and frozen ice cream containing fat and fat replacer. J Dairy Sci. 2000;83:2224–2229. doi: 10.3168/jds.S0022-0302(00)75106-X. [DOI] [PubMed] [Google Scholar]

- Akalin S, Erisir D. Effects of inulin and oligofructose on the rheological characteristics and probiotic culture survival in low fat probiotic ice cream. J Food Sci. 2008;73:184–188. doi: 10.1111/j.1750-3841.2008.00728.x. [DOI] [PubMed] [Google Scholar]

- Akalin AS, Karagozlu C, Unal G. Rheological properties of reduced-fat and low-fat ice cream containing whey protein isolate and inulin. Eur Food Res Technol. 2008;227:889–895. doi: 10.1007/s00217-007-0800-z. [DOI] [Google Scholar]

- Akin MB, Akin MS, Kirmac Z. Effects of inulin and sugar levels on the viability of yogurt and probiotic bacteria and the physical and sensory characteristics in probiotic ice-cream. Food Chem. 2007;104:93–99. doi: 10.1016/j.foodchem.2006.11.030. [DOI] [Google Scholar]

- Aryana KJ, Plauche S, Rao RM, Mcgrew P, Shah NP. Fat-Free plain yogurt manufactured with inulins of various chain lengths and Lactobacillus acidophilus. J Food Sci. 2007;72:79–84. doi: 10.1111/j.1750-3841.2007.00302.x. [DOI] [PubMed] [Google Scholar]

- Cruz AG, Antunes AEC, Sousa AOP, Faria JAF, Saad SMI. Ice-cream as a probiotic food carrier. Food Res Int. 2009;42:1233–1239. doi: 10.1016/j.foodres.2009.03.020. [DOI] [Google Scholar]

- Davidson RH, Duncan CR, Hackney CR, Eigel WN, Boling JW. Probiotic culture survival and implications in fermented frozen yogurt characteristics. J Dairy Sci. 2000;83:666–673. doi: 10.3168/jds.S0022-0302(00)74927-7. [DOI] [PubMed] [Google Scholar]

- Dhewa T, Pant S, Mishera V (2010) Development of freez dried synbiotic formulation using a probiotic strain of Lactobacilus plantarum. J Food Sci Technol. doi:10.1007/s13197-011-0457-2 [DOI] [PMC free article] [PubMed]

- El-Nagar G, Clowes G, Tudorica CM, Kuri V, Brennan CS. Rheological quality and stability of yog-ice cream with added inulin. Int J Dairy Technol. 2002;55:89–93. doi: 10.1046/j.1471-0307.2002.00042.x. [DOI] [Google Scholar]

- Guven M, Yasar K, Karaca OB, Hayaloglu AA. The effect of inulin as a fat replacer on the quality of set-type low-fat yogurt manufacture. Int J Dairy Technol. 2005;58:180–184. doi: 10.1111/j.1471-0307.2005.00210.x. [DOI] [Google Scholar]

- Holcomb JE, Frank JF. Viability of Lactobacillus acidophilus and Bifidobacterium bifidum in soft-serve frozen yogurt. Cult Dairy Prod J. 1991;26:4–5. [Google Scholar]

- Kip P, Meyerb D, Jellema RH. Inulins improve sensoric and textural properties of low-fat yoghurts. Int Dairy J. 2006;16:1098–1103. doi: 10.1016/j.idairyj.2005.10.011. [DOI] [Google Scholar]

- Magarinos H, Selaive S, Costa M, Flores M, Pizarro O. Viability of probiotic microorganisms (Lactobacillus acidophilus La-5 and Bifidobacterium animalis subsp. lactis Bb-12) in ice cream. Int J Dairy Technol. 2007;60:128–134. doi: 10.1111/j.1471-0307.2007.00307.x. [DOI] [Google Scholar]

- Marshall RT. Frozen dairy dessert. In: Marth EH, Steele JL, editors. Applied dairy microbiology. New York: Deeker Press; 2001. pp. 93–127. [Google Scholar]

- Mitschka P. Simple conversion of Brookfield R.V.T. readings into viscosityfunctions. Rheol Acta. 1982;21:207–209. doi: 10.1007/BF01736420. [DOI] [Google Scholar]

- Moeenfard M, Mazaheri Tehrani M. Effect of some stabilizers on the physicochemical and sensory properties of ice cream type frozen yogurt. Am Eurasian J Agric Environ Sci. 2008;4:584–589. [Google Scholar]

- Ordonez GA, Jeon IJ, Roberts HA. Manufacture of frozen yoghurt with ultrafiltered milk and probiotic lactic acid bacteria. J Food Process Preserv. 2000;24:163–176. doi: 10.1111/j.1745-4549.2000.tb00411.x. [DOI] [Google Scholar]

- Paseephol T, Small DM, Sharkat F. Rheological and texture of set yogurt as affected by inulin addition. J Texture Study. 2008;39:617–634. doi: 10.1111/j.1745-4603.2008.00161.x. [DOI] [Google Scholar]

- Rezaei R, Khomeiri M, Kashaninejad M, Aalami M. Effects of guar gum and arabic gum on the physicochemical, sensory and flow behavior characteristics of frozen yoghurt. Int J Dairy Technol. 2011;64(4):563–568. doi: 10.1111/j.1471-0307.2011.00705.x. [DOI] [Google Scholar]

- Sofjan RP, Hartel RW. Effects of overrun on structural and physical characteristics of ice cream. Int Dairy J. 2004;14:255–262. doi: 10.1016/j.idairyj.2003.08.005. [DOI] [Google Scholar]

- Soukoulis C, Tzia C. Impact of the acidification process, hydrocolloids and protein fortifiers on the physical and sensory properties of frozen yogurt. Int J Dairy Technol. 2008;61:170–177. doi: 10.1111/j.1471-0307.2008.00385.x. [DOI] [Google Scholar]

- Soukoulis C, Lebesi D, Tzia C. Enrichment of ice cream with dietary fibre: effects on rheological properties, ice crystallisation and glass transition phenomena. Food Chem. 2009;115:665–67. doi: 10.1016/j.foodchem.2008.12.070. [DOI] [Google Scholar]

- Talwalkar AI, Kailasapathy KA. The role of oxygen in the viability of probiotic bacteria with reference to L. acidophilus and Bifidobacterium spp. Curr Issues in Intest Microbiol. 2004;5(1):1–8. [PubMed] [Google Scholar]

- Vanaja G, Gotcheva V, Angelov A, Agrawal R. Formation of volatiles and fatty acids of therapeutic importance in the probiotic Lactobacillus plantarum LPcfr adapted to resist GIT conditions. J Food Sci Technol. 2011;48(1):110–113. doi: 10.1007/s13197-010-0110-5. [DOI] [PMC free article] [PubMed] [Google Scholar]