Abstract

Experiments were carried out to optimize the process parameters for production of papaya powder using foam-mat drying. Papaya pulp was foamed by incorporating methyl cellulose (0.25, 0.5, 0.75 and 1 %, w/w), glycerol-mono-stearate (1, 2, 3 and 4 %, w/w) and egg white (5, 10, 15 and 20 %, w/w) as foaming agents. The maximum stable foam formation was 72, 90 and 125% at 0.75 % methyl cellulose, 3 % glycerol-mono-stearate and 15 % egg white respectively with 9°Brix pulp and whipping time of 20 min. The foamed pulp was dried at air temperature of 60, 65 and 70 °C with foam thickness of 2, 4, 6, 8 and 10 mm in a batch type cabinet dryer. The drying time required for foamed papaya pulp was lower than non-foamed pulp at all selected temperatures. Biochemical analysis results showed a significant reduction in ascorbic acid, β-carotene and total sugars in the foamed papaya dried product at higher foam thickness (6, 8 and 10 mm) and temperature (65 and 70 °C due to destruction at higher drying temperature and increasing time. There was no significant change in other biochemical constituents such as pH and acidity. The organoleptic and sensory evaluation of the quality attributes of papaya powder obtained from the pulp of 9°Brix added with 3 % glycerol-mono-stearate, whipped for 20 min and dried with a foam thickness of 4 mm at a temperature of 60 °C was found to be optimum to produce the foam-mat dried papaya powder.

Keywords: Papaya pulp, Foaming agents, Foam expansion, Foam thickness, Drying, Moisture content

Introduction

Foam-mat drying is one of the simple methods of drying in which a liquid concentrate along with a suitable foaming agent is subjected to dehydration in the form of a mat of foam at relatively low temperature. Rate of drying in this process is comparatively very high because of an enormous increase in the liquid–gas interface, in spite of the fact that the heat transfer is impeded by a large volume of gas present in the foamed mass. Drying occurs in multiple constant rate periods due to periodic bursting of successive layers of foam bubbles, thus exposing new surfaces for heat and mass transfer as the drying progresses. This method is suitable for any heat sensitive, sticky and viscous materials which cannot be dried by spray drying. The dehydrated powder/flakes are superior to drum and spray dried products because of its honeycomb structure and better reconstitution properties. The dried product has desired properties such as rehydration, controlled density and retain volatiles that would be lost during the drying of non-foamed materials (Morgan et al. 1961; Hart et al. 1963; Berry et al. 1965; Chandak and Chivate 1972, 1974; Martin et al. 1992; Kudra and Ratti 2006).

Many researchers have reported that the increased interfacial areas of foamed materials are the responsible factors for its induced drying rate. Certain foams such as the ones from soymilk (Akintoye and Oguntunde 1991) and starfruit (Karim and Wai 1999) exhibit higher drying rates in the beginning of foam-mat drying, whereas for other materials such as bananas (Sankat and Castaigne 2004; Thuwapanichayanan et al. 2008), mango powder (Kadam et al. 2010), tomato juice (Kadam and Balasubramanian 2011; Kadam et al. 2012), mandarin powder (Kadam et al. 2011), drying rates are greatly accelerated at the end of drying. Selected food materials such as mango, banana, guava, apple (Jayaraman et al. 1974), mango (Baldry et al. 1976), egg melonge (Rao et al. 1987; Rao 1993), tomato and pine apple (Jayaraman 1993), pine apple (Hassan and Ahmed 1998), mango pulp (Rajkumar et al. 2007a, b) have been dried to produce powder/flakes by using foam-mat drying technique.

Papaya (Carica papaya Lin.) is one of the important fruits of tropical and subtropical regions. It is highly perishable in nature and cannot be stored longer. It has rich in β-carotene, vitamin-C, carbohydrates, minerals and good source of energy (Gopalan et al. 1972). Papaya can be made into jam, jelly, nectar, dried into slabs, canned in the form of slice, etc. This excellent fruit is practically neglected due to some unknown reason. In this context, papaya can be converted into value added product like powder by adopting a simple process technique (foam-mat drying). The powder is used for preparation of nectar, ice cream flavour, ready to eat fruited cereals, etc. Since there is no systematic work has been carried out on dehydration of papaya, the investigation has been carried out with the following specific objectives for the process development of papaya powder using foam mat drying. (1) To optimize the concentration of papaya pulp and level of foaming agents to be incorporated (2) To study the drying characteristics of foamed papaya concentrate (3) To analyses the nutritive value of the (foam mat dried) papaya powder.

Materials and methods

The essential processing steps involved in the foam-mat drying of papaya pulp are: selection of fruits and foaming agents, peeling, pulping, pretreatment, incorporation of foaming agent, whipping, spreading the foam in the form of thin mat, drying under selected temperature, scraping, grinding, sieving, packing and sealing.

Selection of fruits and foaming agents

The study was carried out with ‘CO-2’ variety which assumes significance due to its excellent flavour and taste. The fresh and ripened papaya fruits were procured from the orchard of the Tamil Nadu Agricultural University, Coimbatore. The fruits were washed in running water and kept at atmospheric condition till the desired peel colour is attained. Fully ripened fruits were peeled manually using a stainless steel knife and percentage of peel, seeds and pulp present in the papaya were determined. The flesh portions were pulped using a mixer grinder (Sumeet, India) and the pulp was passed through a sieve of IS 50. Biochemical analyses of fresh papaya pulp such as acidity, pH, total soluble solids (TSS), total sugars, ascorbic acid and β-carotene contents were carried out to evaluate their relative loss during foam mat drying. Foaming agents were used within the limits stipulated in section 60 of the Prevention of Food Adulteration Act (1955), India. The foaming agents such as methyl cellulose (MC), glycerol-mono-stearate (GMS) and egg white were selected and used for the foaming experiment on wet pulp weight basis.

Foaming experiments

A pilot study was carried out to determine the level of foaming agents to be incorporated. About 100 ml of papaya pulp was taken in a 500 ml graduated transparent fiber glass container. Whipping was done using an electric beater at various levels of selected foaming agents. Foam was not developed in the pulp. This may be due to its high consistency. When the pulp was adjusted to lower concentration, the foam was developed rapidly. Hence, it was adjusted to different concentrations (12, 11, 10, 9, 8 and 7°Brix) from its initial concentration (13°Brix) by using pearson square method (Siddappa et al. 1998). The fruit pulp with desired concentration was heated at 90 °C for 5 min and cooled to room temperature and was treated with potassium metabisulphite at 0.05 % (w/w) (Jayaraman et al. 1974). The foaming agents such as methyl cellulose (0.25, 0.50, 0.75 and 1 %, w/w), glycerol-mono-stearate (1, 2, 3 and 4 %, w/w) and egg white (5, 10, 15 and 20 %, w/w) were incorporated subsequently during whipping till maximum foam expansion was attained. The foam expansion was measured as described by Patel et al. (1988):

|

1 |

Where,

- FE

is the foam expansion, per cent

- V0

is the initial volume before whipping, ml

- V1

is the final volume after whipping, ml

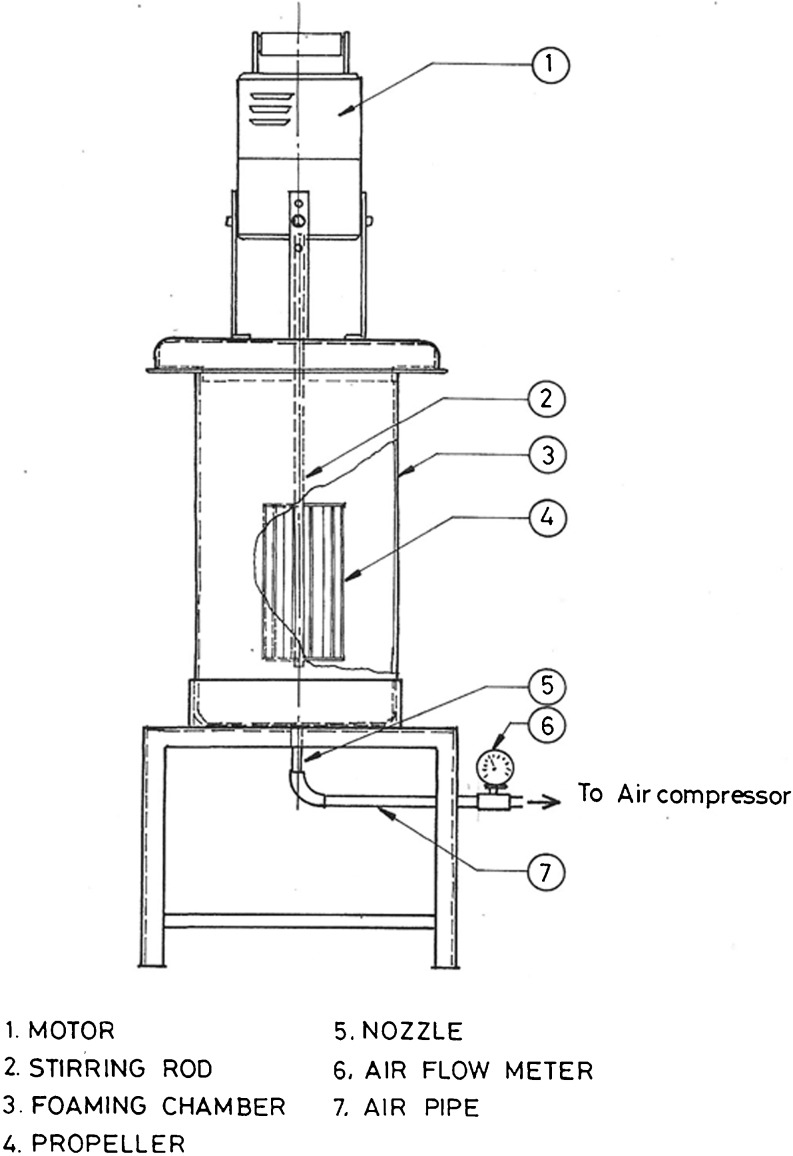

To produce large amount of foam for conducting drying studies, an experimental setup was fabricated (Fig. 1). It consists of a 153 mm diameter and 280 mm height open foaming cylindrical stainless steel chamber bottom was connected to a nozzle which was in turn connected to a 12 mm diameter pipe. The pipe was connected to an air compressor through a regulating valve. The air compressor was used for supplying air to the foaming chamber. The stirring mechanism consisted of a 17 mm diameter rod fixed with 8 stainless steel propeller blades. The height and diameter of the propeller blade were 150 and 100 mm respectively. The stirring mechanism’s rod was connected to the shaft of electric motor having 0.25 horse power mounted on the top lid. The speed of the rotation of the propeller was 1,440 rpm. The pre-determined papaya pulp concentrate and foaming agents were taken in the foaming chamber on w/w basis. The propeller was allowed to rotate and air was introduced to the chamber at the rate 0.03 m3/min until maximum foam formation. The air flow rate was controlled by air flow meter. The foamed slurry was directly discharged from the chamber by removing top lid along with electric motor. Triplicate determinations were made on each sample and mean values were computed. The influence of pulp concentration and levels of foaming agents on foam expansion was statistically analyzed by factorial completely randomized design (Cochran and Cox 1957).

Fig. 1.

Foam developing unit

Drying experiments

For drying studies, batch type cabinet drier (Kilburn, India) having heating unit, blower, drying chamber, air outlet openings and thermostat was used. The drier was run some times in order to stabilize the desired temperature inside the chamber. The homogeneous foamed papaya pulp was evenly spread on the food grade non-sticky stainless steel round plates of 16.5 cm diameter at foam thickness of 2, 4, 6, 8 and10 mm. These plates were kept in the aluminium tray size of 90 × 40 × 2.5 cm having 5 mm diameter holes. The foam thickness was arrived by multiplying the foam of known density (mass/volume) with drying area to get in terms of ‘g/mm’. Similarly non-foamed papaya pulp thickness was also arrived. The aluminium trays were then placed on the tray stand in position for drying. The temperature inside the drying chamber was measured by using thermometer. The foamed and non-foamed papaya pulps were dried at different temperatures viz., 60, 65 and 70 °C with an air flow rate of 2.25 m3/min. The drying temperatures and thickness of foam were selected based on the previous studies (Jayaraman et al. 1974; Jayaraman 1993; Hassan and Ahmed 1998). The round plates were taken out of the drying chamber at every 1 hour interval for determination of weight loss. Moisture content was recorded using a digital electronic balance having least count of 0.01 mg (Citizen Instruments, Pune, India) on initial and final weight basis. The drying was ceased when the weight of the samples recorded constant values. Experiments were conducted in triplicate. The moisture content (%) on dry basis and rate of drying were calculated as described by Chakraverty (1997):

|

2 |

Where,

- MC

is the moisture content, % dry basis

- Wm

is the weight of moisture in the sample, gm

- Wd

is the weight of dry matter of the sample, gm

Quality analysis

The dried foam was scraped after cooling the trays to room temperature and the product was ground to a fineness of 250 μm and packed immediately in high density polythene bags having 300 gauges to prevent the moist air diffusion. The samples were stored at ambient conditions for periodical evaluations. To distinguish the relative changes in nutrients, papaya powder samples were analysed for different biochemical properties viz., pH, acidity, ascorbic acid, total sugars and β-carotene after reconstituting the powder to its original moisture content by following standard procedures (Ranganna 2000). The biochemical contents of the reconstituted foam mat dried papaya powder with three replications were statistically analysed as completely randomized block design using AGRES statistical package (P ≤ 0.05). Sensory evaluation for acceptability of papaya powder samples were evaluated by 9-point Hedonic scale (where 9 = like extremely, 1 = dislike extremely) with a panel of 10 untrained judges for colour, flavour, taste and overall acceptability by using unknown codes (Ranganna 2000) and the results obtained were analysed statistically by completely randomized block design using AGRES statistical package (P ≤ 0 .01).

Results and discussion

Various biochemical contents of fresh papaya pulps were determined as total soluble solids (13°Brix), acidity (0.33 g/100 g), ascorbic acid (145 mg/100 g), total sugar (7.8 g/100 g), β–carotene (4.056 mg/100 g) and pH (5.2). The results obtained on biochemical properties are in comparison with the results reported by Pandey (1997), Aruna et al. (1998) and Workneh et al. (2011).

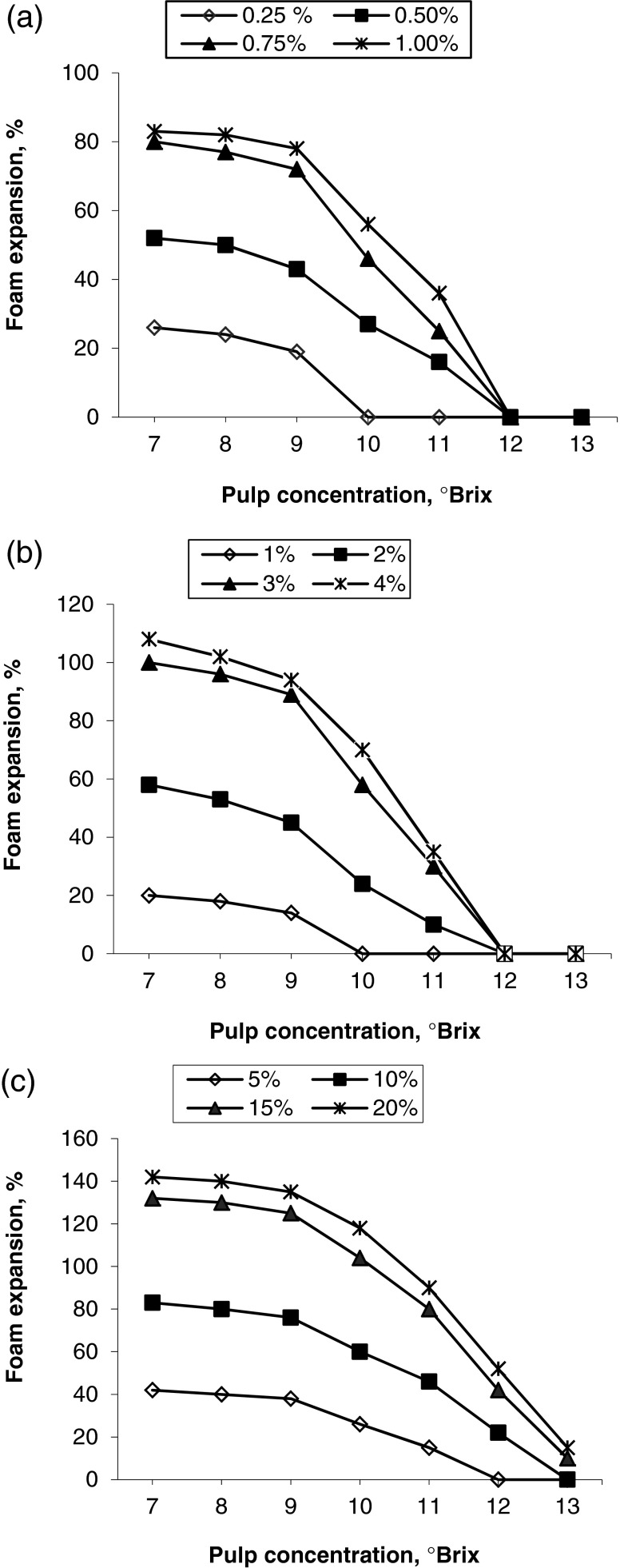

Effect of levels of foaming agents and pulp concentration on foam expansion

Effect of pulp concentration and levels of foaming agents on foam expansion is shown in Fig. 2. From the figure, it is seen that all the foaming agents have got no influence over the foam formation at higher concentration of the pulp (13 and 12oBrix). As the concentration of pulp decreased, the foam volume increased with amount of foaming agent increased and whipping time upto 20 min. The effect may be explained in terms of shear force applied on the system. Figure 2(a) shows that when the concentration of methyl cellulose was 0.75 % the volume increase in the papaya foam was as high as 72 %. Beyond this level, addition of the foaming agent did not produce appreciable changes in the foam expansion. The lowering of the concentration of papaya pulp below 9oBrix did not yield much change in the foam expansion. The foam expansion was 72 % and 78 % at 0.75 % and 1 % methyl cellulose respectively and it was higher as compared to 0.25 % and 0.5 % methyl cellulose. Similar results were reported earlier by Rajkumar et al. (2007b) for mango pulp and Kaushal et al. (2011) for seabuckthorn.

Fig. 2.

Effect of pulp concentration and levels of foaming agents on foam expansion. Foaming agents viz., a methyl cellulose, CV = 3.61 % b GMS, CV = 3.47 % c egg white, CV = 4.15 %. Each observation is the mean of three replicates (n = 3), significant at 1 % level

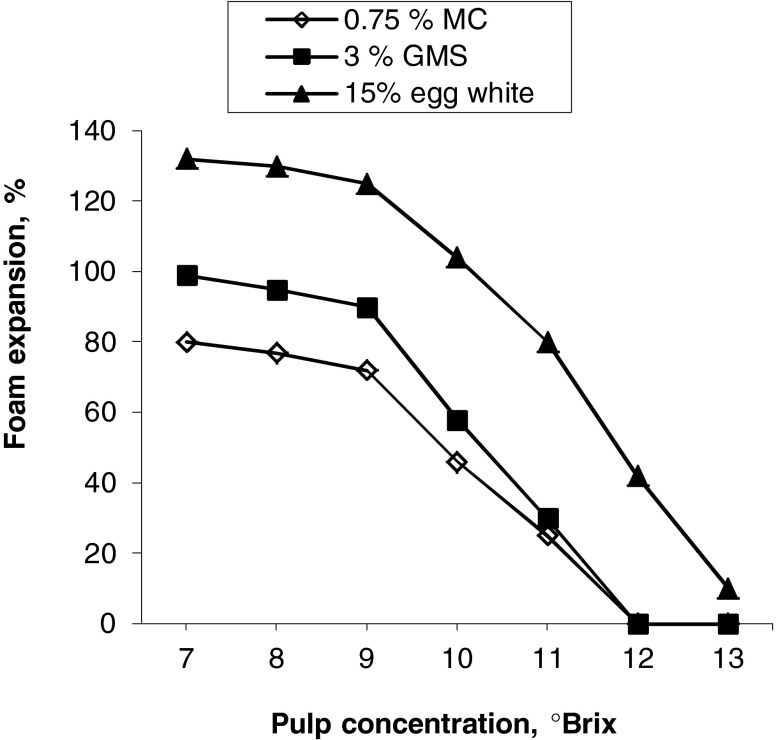

From the Fig. 2(b), it is seen that the foam expansion was increased with increase in levels of GMS upto 3 %. Further addition of this did not facilitate much foam expansion. The foam expansion was gradually increased upto 9°Brix pulp concentration and there after no appreciable change in foam volume. Hence, the maximum foam expansion (90 %) at 9oBrix papaya pulp using 3 % GMS was optimized. Similar trend was reported by Sankat and Castaigne (2004) for bananas. It is observed from Fig. 2(c) that the foam formation was low at 5 % egg white in all levels of pulp concentration a compared to higher levels. There was no appreciable increase in foam expansion after 15 % egg white. This might be due to saturation point of egg albumin solubility under experimental conditions. The foam expansion (125 %) obtained at 9oBrix pulp concentration with 15 % egg white was adjusted to optimization. This was closely followed at 8 and 7oBrix pulp concentration and 20 % egg white. These findings were in confirmation with the results obtained by Patel et al. (1988) and Thuwapanichayanan et al. (2008) for banana. The foam expansion was significantly influenced by pulp concentrations and levels of the foaming agents at 1 % level. The effect of pulp concentration on foam expansion at optimized level of foaming agents is presented in Fig. 3. From the figure, it is clearly seen that there was no foam formation at 13 and 12°Brix and was increased upto 9°Brix pulp concentration. Thereafter no appreciable foam expansion at 8 and 7°Brix pulp concentration took place. Hence, the pulp concentration of 9°Brix was optimized as the maximum foam expansion of 72 %, 90 % and 125 % at 0.75 % methyl cellulose, 3 % GMS and 15 % egg white respectively. The optimized foamed pulps were taken for drying studies.

Fig. 3.

Effect of pulp concentration on foam expansion at optimum levels of foaming agents. Each observation is the mean of three replicates (n = 3), siginificant at 1 % level, CV = 3.57 %

Effect of thickness on drying characteristics of foamed and non-foamed papaya pulp

The drying of methyl cellulose, GMS and egg white foamed papaya pulps was carried out with five foam thicknesses viz., 2, 4, 6, 8 and 10 mm and three drying temperatures viz., 60, 65 and 70 °C in a batch type cabinet tray dryer. The effect of foam thickness on drying characteristics of foamed papaya pulps at 60 °C is shown in Fig. 4. It is clearly seen from the figure that the moisture removal rate was similar trend in methyl cellulose, GMS and egg white foams. The time taken for drying of foamed papaya pulp from 843.57 to 4.5 ± 0.3 % moisture content on dry basis was 3, 4, 7 and 9 h for 2, 4, 6 and 8 mm thick foam also 9 h for 10 mm foam thicknesses. While time taken for drying of non-foamed papaya pulp was 6, 8, 10, 11 and 12 h for 2, 4, 6, 8 and 10 mm thick respectively to reach the moisture content 18 ± 3 % on dry basis. Similar drying behaviour occurred at 65 and 70 °C. At 65 °C, the drying time of 1, 3, 5, 6 and 7 h for 2, 4, 6, 8 and 10 mm foam thickness respectively to bring the final moisture content 4.5 ± 0.3 % on dry basis whereas it took 4, 5, 7, 8, and 9 h for 2, 4, 6, 8 and 10 mm pulp thickness of non-foamed papaya pulp to bring the moisture content 17 ± 2 % on dry basis. At 70 °C, the drying time for 2, 4, 6, 8 and 10 mm foam thickness were 1, 3, 4, 5 and 6 h respectively to bring the final moisture content 4.5 ± 0.3 % on dry basis. The equilibrium weight could be obtained in 4, 5, 6, 8 and 9 h for 2, 4, 6, 8 and 10 mm pulp thickness of non-foamed papaya pulp respectively with moisture content of 15 ± 2 % on dry basis. From the Fig. 4, it is also observed that the drying of foamed and non-foamed papaya pulp occurred in the falling rate period. The drying time increased as the foam thickness increased and decreased with temperature. This may be due to the fact that moisture migration is higher in less foam thickness than high foam thickness. The rate of moisture removal in the foamed papaya pulp was very high as compared to non-foamed pulp due to fact that the water present in the foamed pulp was in the form of thin films making easily vaporize. These drying results are in confirmation with the drying results reported by Akintoye and Oguntunde (1991) for soymilk, Mishra et al. (2002) for apple, Rajkumar et al. (2007a) for mango and Thuwapanichayanan et al. (2008) for banana.

Fig. 4.

Effect of foam thickness on drying characteristics of foamed papaya pulp at 60 °C. a methyl cellulose foamed pulp b GMS foamed pulp c egg white foamed pulp d Non-foamed pulp. Each value is the mean of three replicates (n = 3), standard error of mean (±)

Effect of drying temperature on quality of foam-mat dried papaya powder

The nutritional qualities of dried product play an important role in selecting the drying parameters and were compared with fresh pulp. The dried foam was scraped after cooling the trays to room temperature and the product was ground to a fineness of 250 μm and packed immediately in high density polythene bags. But non-foamed dried samples of thickness 2 and 4 mm was not able to scrap from the plates because it was fully adhered with the plate whereas 6, 8 and 10 mm thick dried products were turned like leather and cannot grind them.

The biochemical results of the foamed papaya pulp dried at 60, 65 and 70 °C are shown in Table 1. The biochemical changes were comparatively higher in 6, 8 and 10 mm thick foam dried at 65 °C and 70 °C than in 2 and 4 mm thick foam dried at 60 °C. It was found that there was a significant reduction in ascorbic acid (125 to 76 mg/100 g) methyl cellulose treated powder, (104 to 76 mg/100 g) GMS treated powder and (152 to 111 mg/100 g) egg white treated powder. This may be due to the destructive effect of the prolonged thermal treatment, which caused oxidation of the ascorbic acid (Levi et al. 1983). It was also found that there was a significant reduction in β-carotene (4.9 to 4.7 mg/100 g) methyl cellulose treated powder and GMS treated powder and (5.1 to 4.9 mg/100 g) egg white treated powder. Total sugars (36.8 to 36.2 g/100 g), (34 to 37 g/100 g) and 36.7 to 35 g/100 g) in methyl cellulose, GMS and egg white treated powder respectively also changed significantly. Other biochemical contents such as pH (5 to 4.8) and acidity (0.42 to 0.40 %), (0.77 to 0.75 %) and (1.56 to 1.45 %) in methyl cellulose, GMS and egg white treated foamed powder respectively were not significant. Acidity level in egg white treated foamed powder was slightly higher may be due to the acidity content of egg albumin. Similar biochemical changes were reported by Srivastava (1998) for mango, Aruna et al. (1998) for papaya, Hassan and Ahmed (1998) for pineapple, Mishra et al. (2002) for apple, Rajkumar et al. (2007b) for mango and Thuwapanichayanan et al. (2008) for bananas. Based on the biochemical analysis, it was found that the papaya powder treated with methyl cellulose, GMS and egg white dried at 60 °C and foam thickness of 2 and 4 mm retained significantly higher amount of nutritional qualities than other treatments such dried at 65 °C and 70 °C and 6, 8 and 10 mm foam thickness. For selecting the foam thickness, yield of the powder was considered as nutritional values are same in 2 and 4 mm thick foamed powder. The yield obtained from 2 and 4 mm thick foamed papaya powder is presented in Table 2. It is clear from the Table 2 that 4 mm thick dried foamed pulp yielded nearly 100 % more than that of 2 mm thickness for all the temperatures and foaming agents studied.

Table 1.

Biochemical composition of foam-mat dried papaya powder

| Foaming agents | Biochemical compositions | 60 °C | 65 °C | 70 °C | CD (5 %) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Foam thickness, mm | Foam thickness, mm | Foam thickness, mm | ||||||||||||||||

| 2 | 4 | 6 | 8 | 10 | 2 | 4 | 6 | 8 | 10 | 2 | 4 | 6 | 8 | 10 | ||||

| MC | Acidity (citric acid) % | 0.42 | 0.42 | 0.41 | 0.41 | 0.40 | 0.42 | 0.41 | 0.42 | 0.40 | 0.42 | 0.41 | 0.41 | 0.40 | 0.42 | 0.40 | 0.04 | NS |

| pH | 4.90 | 4.90 | 5.00 | 4.90 | 5.00 | 4.90 | 5.00 | 4.90 | 4.90 | 4.90 | 4.80 | 4.80 | 4.80 | 4.70 | 4.80 | 0.18 | NS | |

| Ascorbic acid (mg/100 g) | 125 | 125 | 118 | 118 | 118 | 97.0 | 97.0 | 90.0 | 90.0 | 90.0 | 90.0 | 83.0 | 83.0 | 76.0 | 76.0 | 1.86 | ** | |

| β – carotene (mg/100 g) | 4.90 | 4.90 | 4.90 | 4.90 | 4.80 | 4.90 | 4.90 | 4.90 | 4.80 | 4.80 | 4.80 | 4.80 | 4.80 | 4.70 | 4.70 | 0.19 | ** | |

| Total sugars (g/100 g) | 36.2 | 36.2 | 36.0 | 36.0 | 36.2 | 36.3 | 36.4 | 36.4 | 36.2 | 36.2 | 36.8 | 36.8 | 36.8 | 36.9 | 36.8 | 1.81 | ** | |

| GMS | Acidity (citric acid) % | 0.76 | 0.75 | 0.75 | 0.76 | 0.76 | 0.76 | 0.76 | 0.77 | 0.76 | 0.77 | 0.76 | 0.77 | 0.77 | 0.76 | 0.77 | 0.06 | NS |

| pH | 4.70 | 4.80 | 4.80 | 4.70 | 4.80 | 4.80 | 4.80 | 5.00 | 4.90 | 4.80 | 4.90 | 4.90 | 4.90 | 4.80 | 4.80 | 0.17 | NS | |

| Ascorbic acid (mg/100 g) | 104 | 104 | 97.0 | 97.0 | 97.0 | 97.0 | 97.0 | 90.0 | 83.0 | 83.0 | 83.0 | 83.0 | 76.0 | 76.0 | 76.0 | 1.65 | ** | |

| β – carotene (mg/100 g) | 4.90 | 4.90 | 4.80 | 4.80 | 4.90 | 4.90 | 4.90 | 4.80 | 4.90 | 4.80 | 4.90 | 4.90 | 4.70 | 4.80 | 4.80 | 0.13 | ** | |

| Total sugars (g/100 g) | 36.0 | 36.8 | 36.0 | 36.0 | 36.0 | 37.0 | 37.0 | 36.8 | 36.8 | 37.0 | 34.2 | 34.2 | 34.0 | 34.6 | 34.6 | 1.64 | ** | |

| EW | Acidity (citric acid) % | 1.45 | 1.49 | 1.49 | 1.56 | 1.55 | 1.53 | 1.53 | 1.53 | 1.54 | 1.50 | 1.50 | 1.51 | 1.50 | 1.51 | 1.50 | 0.09 | NS |

| pH | 4.90 | 4.80 | 5.00 | 5.00 | 5.00 | 5.10 | 4.90 | 4.90 | 4.90 | 5.10 | 4.90 | 4.90 | 5.00 | 5.00 | 4.90 | 0.19 | NS | |

| Ascorbic acid (mg/100 g) | 152 | 152 | 152 | 152 | 145 | 139 | 139 | 139 | 125 | 125 | 125 | 118 | 118 | 111 | 111 | 1.74 | ** | |

| β – carotene (mg/100 g) | 4.90 | 4.90 | 5.00 | 5.00 | 5.00 | 5.00 | 5.10 | 5.10 | 4.90 | 4.90 | 5.00 | 5.00 | 5.00 | 5.00 | 4.90 | 0.09 | ** | |

| Total sugars (g/100 g) | 36.7 | 35.8 | 36.7 | 36.8 | 35.8 | 35.0 | 35.0 | 35.8 | 35.8 | 36.0 | 35.0 | 35.2 | 35.0 | 35.2 | 35.2 | 1.26 | ** | |

(n = 3), NS Non-significant, ** significantly difference at P ≤ 0.05, MC Methyl cellulose, GMS Glycerol mono-stearate, EW Egg white

Table 2.

Yield of papaya powder obtained from optimized foam thickness

| Temperature | Foam thickness (mm) | Yield (kg/m2) | ||

|---|---|---|---|---|

| MC treated | GMS treated | EW treated | ||

| 60 °C | 2 | 0.0587 | 0.0689 | 0.0984 |

| 4 | 0.0939 | 0.147 | 0.1128 | |

| 65 °C | 2 | 0.0784 | 0.0922 | 0.0752 |

| 4 | 0.1572 | 0.1540 | 0.1126 | |

| 70 °C | 2 | 0.0939 | 0.0900 | 0.0898 |

| 4 | 0.1563 | 0.1946 | 0.1495 | |

* MC, GMS and EW: See Table 1. Each value is the mean of three replicates

Sensory evaluation of foam-mat dried papaya powder

The juice was prepared from the papaya powder obtained from 4 mm thick foam and was compared with fresh papaya fruit juice. Table 3 show the effect of drying temperature and foaming agents on sensory attributes of reconstituted papaya powder for different characteristics such as colour, flavour, taste and overall acceptability. From the Table, it is clearly seen that the samples treated with GMS and dried at 60 °C recorded higher ratings on colour, flavour, taste and overall acceptability as compared to the samples dried at 65 °C and 70 °C. The various treatments adopted had not significantly effect on flavour, taste and overall acceptability but significant effect on the colour (Table 3). However, the fresh sample also received the higher rating in all the attributes. However, the flavor and taste of the reconstituted sample at 65 °C and 70 °C received a lower rating. This could be due to the loss of volatiles during the drying process. Similar trend was reported by Hassan and Ahmed (1998) for foam-mat dried pineapple powder juice and Falade and Okocha (2012) for foam-mat dried reconstituted banana paste.

Table 3.

Effect of drying temperature and foaming agents on sensory attributes of reconstituted papaya powder

| Characteristics | Fresh sample | MC treated sample | GMS treated sample | EW treated sample | CD (1 %) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 °C | 65 °C | 70 °C | 60 °C | 65 °C | 70 °C | 60 °C | 65 °C | 70 °C | ||||

| Colour | 6.3 | 6.1 | 6.0 | 5.7 | 6.2 | 5.6 | 5.7 | 5.8 | 5.8 | 5.7 | 1.278 | ** |

| Flavour | 6.7 | 6.6 | 6.4 | 6.1 | 6.8 | 6.3 | 6.0 | 6.5 | 6.2 | 6.0 | 1.46 | NS |

| Taste | 6.8 | 6.7 | 6.1 | 5.9 | 6.8 | 6.2 | 6.0 | 6.2 | 6.0 | 6.0 | 1.438 | NS |

| Overall acceptability | 6.6 | 6.5 | 6.2 | 5.9 | 6.6 | 6.1 | 5.9 | 6.2 | 6.0 | 5.9 | 1.35 | NS |

(n = 10), ** significantly difference at P ≤ 0.01, NS not significant. MC, GMS and EW: See Table 1

Conclusion

The optimum level of methyl cellulose, glycerol-mono-stearate and egg white was found to be 0.75 %, 3 % and 15 % respectively with papaya pulp concentration of 9°Brix and foaming time of 20 min for foam-mat drying of papaya pulp. Based on the nutritional qualities, it was concluded that 2 and 4 mm thick foamed papaya powder at 60 °C retained significantly higher amount of nutritional qualities than the other treatments. Yield of the papaya powder was considered for selecting the foam thickness as nutritional values are same in 2 and 4 mm thick foamed powder. Therefore, 4 mm foam thickness was optimum for foam-mat drying of papaya pulp. It was concluded that the time taken for drying of 4 mm thick foamed papaya pulp was 4, 3 and 3 h at 60, 65 and 70 °C respectively to obtain dried papaya powder of 4.5 ± 0.3 % moisture content on dry basis. Based on the overall study, it was concluded that the papaya pulp of 9°Brix added with 3 % glycerol-mono-stearate whipped for 20 min and dried with a foam thickness of 4 mm at a temperature of 60 °C was found to be optimum to produce the foam-mat dried papaya powder.

References

- Akintoye OA, Oguntunde AO. Preliminary investigation on the effect of foam stabilizers on the physical characteristics and reconstitution properties of foam-mat dried soymilk. Drying Technol. 1991;9(1):245–262. doi: 10.1080/07373939108916651. [DOI] [Google Scholar]

- Aruna K, Dhanalakshmi K, Vimala V. Development and storage stability of cereal-based papaya (Carica papaya L.) powder. J Food Sci Technol. 1998;35(3):250–254. [Google Scholar]

- Baldry GRJ, Breag JC, Caygill RD, Cooke CEM, Lalitha K. Alternative methods of processing of mangoes. Indian Food Pack. 1976;30(5):56–62. [Google Scholar]

- Berry RE, Bissett OW, Lastinger JC. Method for evaluating foams from citrus concentrates. Food Technol. 1965;19(7):144–147. [Google Scholar]

- Chakraverty A (1997) Theory of grain drying. In: Post harvest technology of cereals, pulses and oilseeds, 3rd edn. Oxford & IBH Publishing Co. Pvt. Ltd, New Delhi, pp 25–63

- Chandak AJ, Chivate MR. Recent development in foam-mat drying. Indian Food Pack. 1972;26(6):26–32. [Google Scholar]

- Chandak AJ, Chivate MR. Studies on foam-mat drying of coffee extract. Indian Food Pack. 1974;28(2):17–27. [Google Scholar]

- Cochran WG, Cox GM (1957) Completely randomized designs. In: Experimental designs, 2nd edn. John Killey and Sons Inc., New York, pp 95–102

- Falade KO, Okocha JO. Foam-mat drying of plantain and cooking banana (Musa spp.) Food Bioprocess Technol. 2012;5(4):1173–1180. doi: 10.1007/s11947-010-0354-0. [DOI] [Google Scholar]

- Gopalan C, Ramasastri BV, Balasubramanian SC. Nutritive Value of Indian Foods. Hyderabad, India: Published by National Institute of Nutrition; 1972. [Google Scholar]

- Hart MR, Graham RP, Ginnette LF, Morgan AI. Foams for foam-mat drying. Food Technol. 1963;17(10):90–92. [Google Scholar]

- Hassan M, Ahmed J. Sensory quality of foam-mat dried pineapple juice powder. Indian Food Pack. 1998;52(7):31–33. [Google Scholar]

- Jayaraman KS. Some process technologies for the preparation of convenience foods from fruits and vegetables for defence services. Indian Food Indust. 1993;12(5):32–40. [Google Scholar]

- Jayaraman KS, Goverdhanan T, Sankaran R, Bhatia BS, Nath H. Compressed ready to eat fruited cereals. J Food Sci Technol. 1974;11(3):181–185. [Google Scholar]

- Kadam DM, Balasubramanian S. Foam mat drying of tomato juice. J Food Process Preserv. 2011;35(4):488–495. doi: 10.1111/j.1745-4549.2010.00492.x. [DOI] [Google Scholar]

- Kadam DM, Wilson RA, Kaur S. Determination of biochemical properties of foam mat dried mango powder. Int J Food Sci Technol. 2010;45(8):626–1632. doi: 10.1111/j.1365-2621.2010.02308.x. [DOI] [Google Scholar]

- Kadam DM, Rai DR, Patil RT, Wilson RA, Kaur S, Kumar R. Quality of fresh and stored foam mat dried mandarin powder. Int J Food Sci Technol. 2011;46(4):793–799. doi: 10.1111/j.1365-2621.2011.02559.x. [DOI] [Google Scholar]

- Kadam DM, Wilson RA, Kaur S, Manisha Influence of foam-mat drying on quality of tomato powder. Int J Food Prop. 2012;15(1):211–220. doi: 10.1080/10942911003763701. [DOI] [Google Scholar]

- Karim AA, Wai C. Foam mat drying of star fruit puree, stability and air drying characteristics. Food Chem. 1999;64(3):337–343. doi: 10.1016/S0308-8146(98)00119-8. [DOI] [Google Scholar]

- Kaushal M, Sharma PC, Sharma R (2011) Formulation and acceptability of foam mat dried seabuckthorn (Hippophae salicifolia) leather. J Food Sci Technol. doi:10.1007/s13197-011-0236-0 [DOI] [PMC free article] [PubMed]

- Kudra T, Ratti C. Foam-Mat drying: Energy and cost analysis. Can Biosyst Eng. 2006;48:3.27–3.32. [Google Scholar]

- Levi A, Gagel S, Juven B. Intermediate moisture tropical fruit products for developing countries. Technological data on papaya. J Food Technol. 1983;18(6):667–685. doi: 10.1111/j.1365-2621.1983.tb00306.x. [DOI] [Google Scholar]

- Martin RO, Narasimhan G, Singh RK, Weitnaner AC. Food dehydration. In: Heldman DR, Lund DB, editors. Handbook of food engineering. London: Academic; 1992. pp. 530–531. [Google Scholar]

- Mishra HN, Jacob JK, Srinivasan N. Preparation of apple powder and evaluation of its shelf life. Bever Food World. 2002;29(1):49–52. [Google Scholar]

- Morgan AI, Graham RP, Ginnette LF, Williams GS. Recent developments in foam-mat drying. Food Technol. 1961;15(1):37–39. [Google Scholar]

- Pandey PH (1997) Technology of processing papaya. In: Post harvest technology of fruits and vegetables (principle and practices). Saroj Prakasham Publishing Company, Allahabad, India, pp 111–117

- Patel PD, Stripp AM, Fry JC. Whipping test for the determination of foaming capacity of protein: a collaborative study. Int J Food Sci Technol. 1988;23(1):57–63. doi: 10.1111/j.1365-2621.1988.tb00550.x. [DOI] [Google Scholar]

- Rajkumar P, Kailappan R, Viswanathan R, Raghavan GSV. Drying characteristics of foamed alphonso mango pulp in a continuous type foam mat dryer. J Food Eng. 2007;79(4):1452–1459. doi: 10.1016/j.jfoodeng.2006.04.027. [DOI] [Google Scholar]

- Rajkumar P, Kailappan R, Vishwanathan R, Parvathi K, Raghavan G, Orsat V. Thin layer drying study on foamed mango pulp. Int Commiss Agric Biosyst Eng (CIGR) J. 2007;IX:224–238. [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 6. New Delhi: Tata McGraw-Hill Publishing Co. Ltd; 2000. [Google Scholar]

- Rao TSS. Palatability of spray-dried, foam-mat dried and freeze-dried whole egg powders packed in different packaging materials. J Food Sci Technol. 1993;30(4):298–300. [Google Scholar]

- Rao TSS, Murali HS, Rao KRG. Preparation of foam-mat dried and freeze dried whole egg powder (Hen’s) J Food Sci Technol. 1987;24(1):23–26. [Google Scholar]

- Sankat CK, Castaigne FF. Foaming and drying behaviour of ripe bananas. Lebensmittel Wissenshaft und Technolgie. 2004;37:517–525. doi: 10.1016/S0023-6438(03)00132-4. [DOI] [Google Scholar]

- Siddappa GS, Girdharilal, Tandon GL (1998) Syrups and brines for canning. In: Preservation of fruits and vegetables. Published by Indian Council of Agricultural Research, New Delhi, pp 43–52

- Srivastava JS. Mango processing industries-A scenario. Indian Food Pack. 1998;52(6):43–49. [Google Scholar]

- Thuwapanichayanan R, Prachayawarakorn S, Soponronnarit S. Drying characteristics and quality of banana foam mat. J Food Eng. 2008;86(4):573–583. doi: 10.1016/j.jfoodeng.2007.11.008. [DOI] [Google Scholar]

- Workneh TS, Azene M, Woldetsadik K (2011) Effect of packaging materials and storage environment on post harvest quality of papaya fruit. J Food Sci Technol. doi:10.1007/s13197-011-0607-6 [DOI] [PMC free article] [PubMed]