Abstract

Biscuit can be used as a functional food to deliver nutraceuticals to consumers. One such natural nutraceutical oryzanol is present in rice bran oil. Oryzanol possesses a variety of health benefits which include reduction of cholesterol in blood, improvement of capillary action of blood vessels, anti-aging effect and others. Biscuit is a well known cereal based processed food and the fortification of oryzanol into the biscuits will go a long way to provide antioxidant rich, highly stable and acceptable functional food to the consumers. Biscuits were prepared with commercially available fat (CF) and oryzanol fortified fat (OFF). The control biscuits (CB) and oryzanol fortified biscuits (OFB) were packed in 200 gauge polypropylene pouches, stored at 27 °C with different relative humidity (RH 11 %, 22 %, 32 %, 44 % and 56 %) and analysed for its stability during storage of 120 days. Critical moisture content of OFB (4.8 %) was slightly less than that of CB (5.3 %). The fat content of the CB (12.2 %) and OFB (12.5 %) did not change during storage while free fatty acid content (0.36 % and 0.60 %) and peroxide value (0.08 and 0.17 meq. O2/100 g biscuit) respectively for CB and OFFB was showed small but significant changes during storage. Oryzanol content (292 mg) and radical scavenging activity (81.1 %) of OFB did not change during storage. The biscuits had a shelf life of minimum 3 months at 27 °C. Oryzanol in OFB showed good stability during baking and storage of biscuits.

Keywords: Functional food, Oryzanol concentrate, Oryzanol fortified biscuits, Sensory analysis, Storage stability

Introduction

Biscuit is a well known cereal based processed food, prepared from wheat flour, sugar, salt, shortening, a leavening system composed of sodium or potassium bicarbonate and leavening acid, water and milk solids. It also contains flavoring and coloring agents, nutrient suppliments, preservatives, antioxidants and reducing agents (Lauck 1981). Recently, biscuits are designed as functional foods to provide nutritive and health protecting substances in the daily diet. These novel products have beneficial effects on health and are able to reduce the risk of developing chronic diseases. Vitali, Verdina and Sebecic have made an attempt to improve the mineral content and bioaccessibility of biscuits by modifying its basic composition (Vitali et al. 2008).

Antioxidants have received great attention in preventing the oxidation of fats and oils containing processed foods and it acts as oxidation inhibitor in these products (Adegoke et al. 1998). Synthetic antioxidants such as butylated hydroxy anisole (BHA), butylated hydroxy toluene (BHT), propyl gallate (PG) and tertiary butyl hydroquinone (TBHQ) are the commonly used antioxidants in foods. However, the synthetic antioxidants not only show antioxidant properties, but are also suspected to have an adverse effect on health such as carcinogenic effect (Kahl 1984). Thus, its use as food additive has been banned in some countries. Therefore, the synthetic antioxidants are replaced with natural plant based ingredients which include antioxidants, antimutagens and anticarcinogens. The addition of natural antioxidants in foods play a major role as food antioxidants and are also able to prevent different types of cancer and coronary heart diseases (Marnett 2000). Phenols and polyphenols are the most active dietary antioxidants (Shahidi and Naczk 1995). Fruits and vegetables are the principal source of these compounds and are able to reduce the risk of chronic and degenerative diseases (Shahidi and Naczk 1995). Natural extracts from aromatic plants and spices are being widely used in foods such as dairy, bakery products, etc. (Pokorny 1991). Cinnamon, mace, clove, poppy seed and sesame seeds are the most commonly used spices in bakery products (Bassiouny et al. 1990). Vanitha et al. have made an attempt to utilize plant extracts to improve the stability of biscuits (Vanitha et al.2005).

The edible oils and oil seeds are the rich source of variety of active components, which includes tocopherols, tocotrienols, phenolics, flavonoids, sterols, phospholipids, carotenoids, triterpenyl alcohols (Shahidi and Shukla 1996). These components can be separated during processing and can be utilized in food as nutraceuticals. Rice bran oil extracted from the bran of Oryza sativa is one of the potential source of variety of natural antioxidants, which includes lecithin, oryzanol, tocopherols, tocotrienols, squalene and phytosterols and are now widely used as active ingredients in health foods, food additive, pharmaceutical and cosmaceutical products (Gopala Krishna 2002; De Deckere and Korver 1996). Bhanger et al. (2008) utilized rice bran extracts for the preparation of cookies having nutritive and health benefits (Bhanger et al. 2008). Lecithin has been used in the food industry as an emulsifier and also for treating cancer. Tocopherols and tocotrienols are potent antioxidant and anticarcenogenic agents (Xu et al. 2001). Squalene shows antioxidant, anti-dermatic and anti-tuberculosis properties (Sayre and Saunders 1990; Gopala Krishna 2002). Oryzanol is a powerful antioxidant and it has many beneficial biological effects. It includes reduction of cholesterol in blood, improvement of capillary action of blood vessels, anti-aging effect, antidandruff effect, anti-itching properties, decreases plasma cholesterol, platelet aggregation, hepatic cholesterol absorption and aortic streaks formation, increases fecal bile acid secretion, anti-ulcerogenous properties (Xu et al. 2001; Narasimha Rao 2003). Oryzanol is also being utilized as medicinal antioxidant to improve the stability of pharmaceutical products (Juliano et al. 2005).

Oryzanol is a fat soluble phytochemical comprising esters of ferulic acid with sterols (Xu and Godber 1999; Gopala Krishna 2002). This is mostly found in rice bran oil. The crude rice bran oil contains 1.5–2.9 % oryzanol and is lost into soap stock during chemical refining of rice bran oil (Gopala Krishna et al. 2001). Thus this valuable nutraceutical is not available for use. Physical refined rice bran oil retains, almost all the amount of oryzanol present in the starting crude rice bran oil. However, physical refined rice bran oil is not as popular as chemical refined rice bran oil. Sakina and Gopala Krishna have recently developed a process for the extraction of oryzanol from physicaly refined rice bran oil for making use in foods as an additive (Indian patent pending). Reports on preparation of biscuits using oryzanol/oryzanol concentrate are scanty. This study has focused on the preparation of oryzanol fortified biscuits with the utilization of oryzanol as oryzanol concentrate. The effect of incorporating oryzanol concentrate to biscuits on sensory quality, stability during baking and storage of biscuits were investigated.

Materials and methods

Biscuit ingredients, chemicals and solvents used

The ingredients used in the formula of biscuits were refined wheat flour, commercially available emulsified fat ‘Marvo’ (M/s Hindustan lever Ltd, India), sugar (powdered sugar passing through 220 μm mesh), sodium chloride, sodium carbonate, ammonium bicarbonate, baking powder (Ranbaxy Laboratories, Punjab, India), liquid glucose, skimmed milk powder and water. All ingredients used in the biscuit formulation were of food grade. All chemicals and solvents used were of analytical grade.

Preparation of oryzanol concentrate

Oryzanol concentrate was prepared from rice bran oil according to a recently developed process (Indian patent pending). Rice bran oil was processed in such a way to get an oryzanol enriched fraction which after further processing yielded oryzanol concentrate having 15–20 % oryzanol. This was further refined to get a less FFA oryzanol concentrate and was used to prepare oryzanol incorporated fat.

Preparation of oryzanol incorporated fat

Fat was melted at 65 ± 1 °C to get liquid oil. Pre-weighed oryzanol concentrate (contains SAFA: MUFA: PUFA = 35: 36: 29 and oryzanol = 17 %) were added to the molten fat and blended at 65 ± 1 °C using mechanical stirrer at 180 rpm for 15 min. The oryzanol incorporated fat was cooled to room temperature and stored at 4 °C for 24 h to attain complete solidification. This fat was used for the preparation of oryzanol fortified biscuits. The oryzanol incorporated fat had a SAFA: MUFA: PUFA of 53:35:12 with 2.4 % oryzanol and the starting fat had a SAFA: MUFA: PUFA of 57: 34: 9 which were almost similar.

Preparation of biscuits

The biscuit samples were prepared in two sets viz., control biscuit (CB) and oryzanol fortified biscuit (OFB) as per the published procedure (Sai Manohar and Ha-ridas Rao 1999). 90 g of sugar and 60 g of fat and 9 g of liquid glucose were creamed for 1 min at speed 1 (61 rpm) and continued for 3–4 min at speed 2 (125 rpm) in a Hobart mixer (model N 50, North York, Ontario, Canada). Skimmed milk powder (3 g), sodium bicarbonate (1.5 g), ammonium bicarbonate (3 g) and sodium chloride (3 g) were completely dissolved in water, added to the above cream, mixed at speed 1 (61 rpm) for 1 min with further mixing for 2 min at speed 2 (125 rpm) to get smooth cream. Wheat flour (300 g) sieved twice with baking powder (0.9 g) was added and mixed for 3 min at speed 1 (61 rpm) to get biscuit dough. The dough was sheeted to a thickness of 3.5 mm and cut into round shapes using 51 mm diameter dough cutter. The cut dough was transferred to aluminium trays, placed in baking oven (APV, Queensland, Australia) and baked at 200 °C for 9 min. Biscuits were cooled to room temperature (25 °C), immediately packed in polypropylene bags and used for the study.

Equilibrium moisture content (EMC)

Equilibrium moisture data was generated by directly placing the previously weighed biscuits in petri dishes at 27 °C equilibrated to different relative humidity ranging between 11% and 92 % RH in desiccators using several saturated salt solutions (aw between 0.112 [LiCl] and 0.940 [KNO3]). They were weighed periodically in analytical balance till they attained constant weight or showed the signs of mould growth. The percent loss or gain was calculated from equilibrated samples and equilibrium moisture content was calculated by subtracting the respective loss in weight, or by adding gain in weight to the initial moisture content (Lopez et al. 1995). All the measurements were carried out in three replicates and average values were reported.

Evaluation of stability

The biscuits were packed in 200 gauge polypropylene pouches of water vapour transmission rate (WVTR) 4.5 g/m2/day under 90 % RH at 38 °C and stored at 27 ± 1 °C adjusted with the relative humidity (RH) of 11 %, 22 %, 32 %, 44 % and 56 % for a period of 120 days (Romildo et al. 2009). The stability of fat in biscuits was evaluated periodically at an interval of 30 days during the storage period of 120 days. Free fatty acid content (FFA), peroxide value (PV), moisture content, crude fat and oryzanol content were evaluated to monitor the stability of the biscuits during the storage period. The above analysis was carried out in three replicates and average values were reported.

Evaluation of physical characteristics

The biscuits were evaluated for weight (g), diameter (D-mm), thickness (T-mm), spread ratio (D/T) and breaking force (g). The diameter (D) and thickness (T) of six biscuits were measured by placing them edge to edge and by stacking one above the other respectively (Sai Manohar and Ha-ridas Rao 1999). To obtain the average value, measurements were made by rearranging and restacking. The average weights of 8 biscuits were reported. The breaking force of the biscuits was measured in a Texture Analyser according to a triple beam snap technique described by Sai Manohar and Haridas (Sai Manohar and Ha-ridas Rao 1999).

Evaluation of sensory characteristics

The sensory analysis of biscuits was carried out by a panel of six experienced judges by assigning score for each quality attributes such as color (0–10), surface character (0–10), crumb color (0–10), texture (0–20), taste (0–20), mouth feel (0–10) and overall quality (0–80). The higher sensory scores indicate the better quality of the biscuits (Hooda and Jood 2005).

Chemical analysis of prepared biscuits

Moisture content

Moisture content of the stored biscuits was analysed after every 30 days. The biscuits were ground to a fine powder; 10 g of the ground samples were taken in aluminum moisture cups and placed in an oven at 100 ± 1 °C for the period of 75 min or till a constant weight was obtained. The moisture contents were expressed on dry basis (method no. Ac 2–41 1997) (AOCS 1998).

Crude fat content

Analysis was carried out at every 30 days interval according to AOCS Official Butt-tube Method Ac 3–44. Biscuits were ground to a fine powder, dried in oven at 100 ± 1 °C, packed in 26 mm × 60 mm thimbles and extracted with hexane by Soxhlet extraction. The extracts was desolventized by vacuum flash evaporation (Rotavapor RE 121A, Buchi, Switzerland) at controlled temparature and were subjected to various analyses.

Free fatty acid content

FFA was analysed according method Ca 5a–40 (AOCS 1998). The fat extracted from the stored biscuits was titrated against 0.1N NaOH solution in neutralized alcohol medium using phenolphthalein as indicator (method No. Ca 5a–40) (AOCS 1998). The FFA was calculated according to Gopala Krishna et al. (Gopala Krishna et al. 2006a) and expressed as percentage of oleic acid.

Peroxide value

Peroxide value was analysed according to AOCS method Cd 8–53 (1998). The fats were extracted from the stored biscuits using chloroform at room temperature and titrated against 0.1N sodium thiosulphate solution in the presence of potassium iodide solution using starch as the indicator. PV was expressed as meqO2/Kg of fat from which PV/100 g biscuit was calculated.

Oryzanol content

Oryzanol content was determined by spectrophotometric method using UV–vis spectrophotometer (model-UV-1601, Shimadzu, Kyoto, Japan) by measuring the optical density at 314 nm of the fat taken in hexane followed by calculation using the extinction coefficient of 358.9 and expressed as g/100 g fat and reported as milligram/100 g biscuit (Gopala Krishna et al. 2006b).

Radical scavenging activity

The radical scavenging activity of the samples were measured by 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical scavenging assay with control fat (CF) and oryzanol incorporated fat (OIF) with respect to before baking, after processing and after storage (120 days). The analysis was performed according to published procedure (Bhatnagar et al. 2009). The freshly prepared solutions of DPPH at a concentration of 10−4 M (4 ml) were added to the sample weight of 200 ± 1 mg. This mixture was vortexed for 20 s and absorbance were taken at 515 nm and maintained at room temperature. The decreases in absorbance at 515 nm were monitored for 30 min, 45 min and 60 min. The absorbance was recorded with UV–VIS spectrophotometer. The radical scavenging activity was estimated from difference in the absorbance of toluenic DPPH solution with and without sample (control). The percentage inhibition was calculated from the following equation

|

Where A is the absorbance of control and B is the absorbance of samples. Three replicates for each sample were assayed.

Statistical analysis

The experiment was carried out in quadruplicate. All the quality parameters were analysed in quadruplicate and the data obtained for each parameters were expressed as mean±standard deviation. The t-test was used to compare physical and sensory characteristics among CB and OFB. One-way anova was used to calculate significant difference in the CB and OFB stored at different RH regarding their moisture uptake, fat content, free fatty acid liberation, peroxide value and oryzanol retention (Steele and Torrie 1980).

Results and discussion

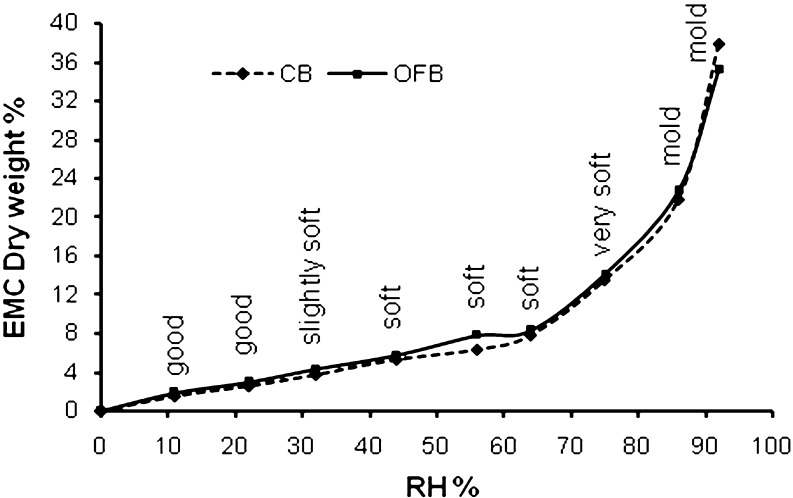

Moisture sorption isotherm of oryzanol incorporated biscuits

Both control (CB) and oryzanol fortified biscuits (OFB) exhibited sigmoid-shaped isotherm and nearly overlapped with each other indicating that the similarity in the moisture sorption behavior among CB and OFB. This is probably due to the similarity in the chemical composition including moisture, protein and carbohydrate contents. As can be seen in Fig. 1, the CB with an initial moisture content (IMC) of 2 % equilibrated to 13 % RH and OFB samples equilibrated to 32 % RH with an IMC of 0.8 % equilibrated to <10 % RH. The biscuits contain wheat flour, fat and shortening, sugar, salt and flavouring agents. They are predominantly sensitive to moisture and oxygen reaction. Hence, biscuits have to be protected from these reactants. In view of this, 200–250 g pearlised biaxially oriented polypropylene (BOPP) material can be suggested as packaging material for these biscuits. Along with design suitable package for these products, the effect of moisture on other quality characteristics of biscuits was also studied.

Fig. 1.

Moisture sorption isotherm and structural behavior of control (CB) and oryzanol fortified biscuits (OFB). EMC equilibrium moisture content. Each observation is a mean of four replicate analysis (n=4)

Structural behavior of oryzanol fortified biscuits at different relative humidity

The effect of RH on the structural consistency on the basis of crispness was also analysed during the moisture sorption study of biscuit samples. The observations are shown in Fig. 1, which indicates that the biscuits were good in crispness up to the RH level of 22 %. The biscuits crispness got reduced to slightly soft at the level of 32 % RH. The biscuits crispness was lost during the direct exposure of biscuits at further increased level of RH. The biscuits structural consistency becomes soft up to the RH level of 64 %, very soft at the RH level of 75 % and at the higher level of RH (>86 %) mold growth was observed on the surface of the CB and OFB. The sensorial and textural analyses were not carried out at this stage, although, as the loss in crispness was same for both CB and OFB during the sorption study.

Sensory profile of oryzanol fortified biscuits

The sensory and physical characteristics of CB and OFB as the mean score for all the parameters including sensory and physical properties are summarized in Table 1. The t-test indicated that the incorporation of oryzanol concentrate to the fat did not have any significant influence (p > 0.05) on the color (8.0), surface character (8.0), crumb color (8.0), texture (17.5), taste (17.5) and mouth feel (8.0) of the biscuits (Table 1). Hence, it was observed that the OFB and CB were similar in properties and hence were acceptable in terms of sensory characteristics.

Table 1.

Effect of oryzanol fortification on the sensory and physical characteristics of biscuits

| Samples | Sensory characteristics | Physical characteristics | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Color (0–10) | Surface Character (0–10) | Crumb Color (0–10) | Texture (0–20) | Taste (0–20) | Mouth feel (0–10) | Overall quality (0–80) | Diameter (D)(mm) | Thickness (T) (mm) | Spread ratio (D/T) | Breaking force (N) | |

| CB | 8.0a | 8.0a | 8.0a | 18.0a | 18.0a | 8.0a | 68.0a | 56.0b | 6.5b | 8.6a | 14.3a |

| OFB | 8.0a | 8.0a | 8.0a | 17.5a | 17.5a | 8.0a | 67.0a | 57.5a | 6.5b | 8.8a | 13.9a |

CB control biscuits and OFB Oryzanol fortified biscuits. The values in bracket indicate sensory scores for different sensory quality attributes. Values are the mean of different analyses (n = 6 panelists for sensory characteristics and n = 4 for physical characteristics). Values in the same column with common letters are not significantly different at p < 0.05

Physical characteristics of oryzanol fortified biscuits

Among the various physical characteristics like spread (8.6, 8.8 D/T), thickness (6.5, 6.5 mm), weight (7.8, 8.2 g), diameter (56.0, 57.5 mm) and instrumental measurement like breaking strength (14.3, 13.9 N) were analysed for both CB and OFB and were found to have similar physical properties (p < 0.05).

Crude fat content of oryzanol fortified biscuits on storage

Table 2 shows the crude fat content of CB and OFB during the storage at different humidity conditions. The crude fat content of CB (12.2 %) and OFB (12.5 %) indicated that there was a very small change in crude fat content at the various relative humidity conditions studied. The variance analysis of fat content showed that there was no significant difference (p > 0.05) in the fat content during storage at different relative humidities studied.

Table 2.

Fat content of different biscuits and Oryzanol content of Oryzanol fortified biscuits during storage (27 °C) at different relative humidity (RH)

| Biscuits | RH (%) | Storage period, days | ||||

|---|---|---|---|---|---|---|

| 0 | 30 | 60 | 90 | 120 | ||

| Fat % (on dry basis) | ||||||

| CB | 11 | 12.2 ± 0.07a | 12.3 ± 0.07a | 12.4 ± 0.03a | 12.3 ± 0.06a | 12.3 ± 0.07a |

| OFB | 11 | 12.5 ± 0.01a | 12.6 ± 0.06a | 12.5 ± 0.01a | 12.5 ± 0.06a | 12.5 ± 0.01a |

| CB | 22 | 12.2 ± 0.07a | 12.2 ± 0.06a | 12.2 ± 0.03a | 12.2 ± 0.02a | 12.2 ± 0.06a |

| OFB | 22 | 12.5 ± 0.01a | 12.3 ± 0.07a | 12.3 ± 0.04a | 12.3 ± 0.01a | 12.3 ± 0.04a |

| CB | 32 | 12.2 ± 0.07a | 12.2 ± 0.07a | 12.3 ± 0.05a | 12.3 ± 0.02a | 12.3 ± 0.04a |

| OFB | 32 | 12.5 ± 0.01a | 12.5 ± 0.01a | 12.4 ± 0.03a | 12.5 ± 0.00a | 12.4 ± 0.02a |

| CB | 44 | 12.2 ± 0.07a | 12.3 ± 0.07a | 12.2 ± 0.02a | 12.3 ± 0.06a | 12.3 ± 0.03a |

| OFB | 44 | 12.5 ± 0.01a | 12.5 ± 0.02a | 12.5 ± 0.02a | 12.5 ± 0.07a | 12.5 ± 0.05a |

| CB | 56 | 12.2 ± 0.07a | 12.3 ± 0.02a | 12.3 ± 0.04a | 12.2 ± 0.05a | 12.3 ± 0.05a |

| OFB | 56 | 12.5 ± 0.01a | 12.4 ± 0.07a | 12.5 ± 0.04a | 12.5 ± 0.05a | 12.5 ± 0.09a |

| Biscuits | RH (%) | Oryzanol (mg/100 g biscuits) | ||||

| OFB | 11 | 292 ± 7.5a | 289 ± 6.3a | 284 ± 11.2a | 284 ± 7.5a | 286 ± 3.8a |

| OFB | 22 | 292 ± 7.5a | 291 ± 6.2a | 284 ± 3.7a | 286 ± 1.2a | 286 ± 4.9a |

| OFB | 32 | 292 ± 7.5a | 284 ± 6.2a | 290 ± 5.0a | 291 ± 1.2a | 285 ± 7.5a |

| OFB | 44 | 292 ± 7.5a | 284 ± 7.5a | 289 ± 2.5a | 285 ± 2.5a | 292 ± 2.5a |

| OFB | 56 | 292 ± 7.5a | 286 ± 2.5a | 292 ± 6.3a | 283 ± 5.0a | 291 ± 5.0a |

CB control biscuits, OFB oryzanol fortified biscuits. The values in the row with same superscript does not indicate significant changes (p < 0.05)

Values are the mean±SD of four replicate analysis (n = 4)

EMC equilibrium moisture content. Each observation is a mean of four replicate analysis (n = 4)

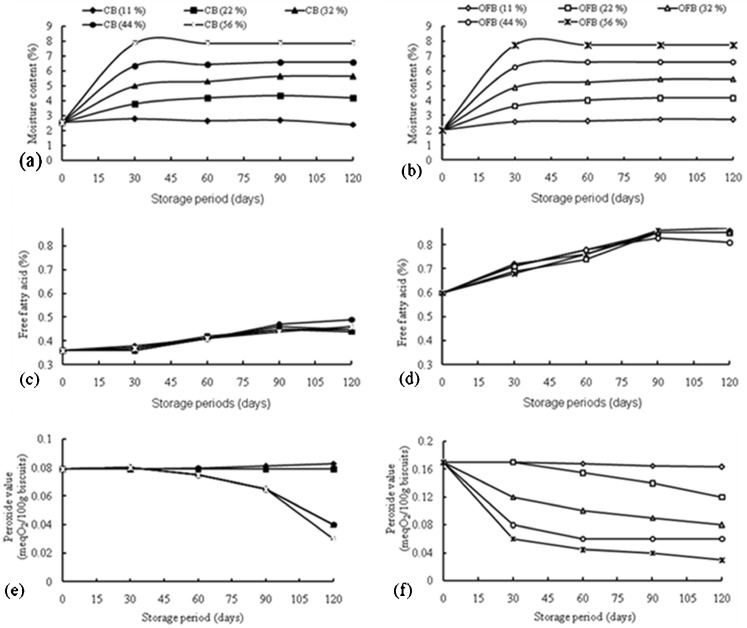

Moisture content of oryzanol fortified biscuits on storage

Biscuits are moisture sensitive products and are able to develop oxidative rancidity and hydrolytic rancidity at very low moisture content. The moisture content of the stored biscuits mainly depends on the water vapour transmission rate (WVTR) of the packaging material and the storage conditions. Figure 2 shows the moisture content of packed and stored CB and OFB samples at various relative humidity (RH). The initial moisture content of CB (2.6 %) and OFB (2.0 %) were significantly different, and OFB showed a lower value than the CB. Further, the moisture content of the biscuit samples CB and OFB (2.8–7.8 %, 2.6–7.7 %) were significantly different (p < 0.05) during the first 30 days of storage at different RH. The moisture content of CB and OFB did not change during the further storage period of 45–120 days at different RHs.

Fig. 2.

Changes in moisture content, and rancidity parameters of control biscuit (CB) and Oryzanol fortified biscuits (OFB) during storage at 27 °C and different relative humidity (RH) conditions. The figure showing the 1) moisture content of stored (a) CB and (b) OFB, 2) free fatty acid value of (c) CB and (d) OFB and 3) the peroxide value of (e) CB and (f) OFB at 27 °C with different relative humidity conditions

Free fatty acid content of oryzanol fortified biscuits on storage

Free fatty acids formation is responsible for the undesirable aroma, flavor and bitterness in biscuits. The high free fatty acid content of the stored biscuits is mainly contributed by the partial hydrolysis of fats. Figure 2 shows the free fatty acid content of CB and OFB during the storage of 0–120 days at 27 ± 1 °C with different relative humidity. The FFA of CB (0.36 %) and OFB (0.6 %) indicating the fats, which are used for the preparation of biscuits were good in quality. The increase in FFA content of CB (0.36–0.49 %) and OFB (0.6–0.85 %) were significant during the storage period. The variance analysis showed significant increases in their FFA content (p < 0.001). All the biscuits stored at different RH exhibited similar increasing trend in FFA. However, the FFA of CB and OFB showed slight increase, the humidity variation did not show any effect on the liberation of free fatty acids during storage. As per the BIS Specification of Biscuits, the maximum FFA limit (as oleic acid) in the biscuit by mass is 1.2 % (IS: 1011 2002). Here, the FFA of all the stored biscuits were within the permitted limit (<1 % on fat basis) indicating that the biscuits were stable against hydrolytic rancidity.

Peroxide development of oryzanol fortified biscuits on storage

Biscuit consists of wheat flour, fat, emulsifier, sugar, salt and flavoring agents, they are predominantly sensitive to oxygen reaction. The large surface area of biscuits increases the exposure of oxygen and light and this may increase the possibility of oxidation. Although, PV is conventionally used for measuring the oxidative deterioration in fats and oils, accurate assessment of oxidative deterioration in biscuits cannot be made, because the peroxide formed during the early stages of oxidation may have been converted in to stable aldehydes, ketones, acids and alcohols following the free radical termination mechanism (Bhanger et al. 2008). Figure 2 shows the effect of RH variation on the peroxide development/decomposition of stored CB and OFB. The CB were stable at 22 % RH and at 11 % RH have shown significant increase in PV (p < 0.001) after 90 days of storage. The decomposition of peroxide was observed after the storage period of 30 days at 32 %, 44 % and 56 % RH. The maximum decomposition was during the storage at 56 % RH. The OFB samples have shown significant increase (p < 0.001) in peroxide decomposition at different RHs. The minimum peroxide decomposition of OFB was observed at 11 % RH. But, successive increase in the RH showed significant increase in the peroxide decomposition and maximum peroxide decomposition was at 56 % RH. The significant variation among the peroxide value of CB and OFB during the storage is mainly due to the oxidation of unsaturated fatty acids (MUFA: PUFA=35:12) present in the OFB than the CB (MUFA: PUFA=34:9). The results showed that the oxidative deterioration of the biscuit sample was mainly dependent on the relative humidity in which it was stored.

Stability of oryzanol in fortified biscuits upon storage

Most of the naturally occurring antioxidants could be significantly lost during baking and storage and at high temperature most of these undergo decomposition. In this study, the oryzanol fortified biscuits were baked at 200 °C and it did not alter at the baking temperature. Table 2 shows the oryzanol content of OFB during storage at different relative humidity conditions. In addition, oryzanol (292 mg/100 g biscuits) was not affected by storage over a period of 120 days at different relative humidity conditions (p > 0.05). The results of present study indicated that there was no change in the oryzanol content (292 mg) and was stable at different RHs during storage period of 120 days.

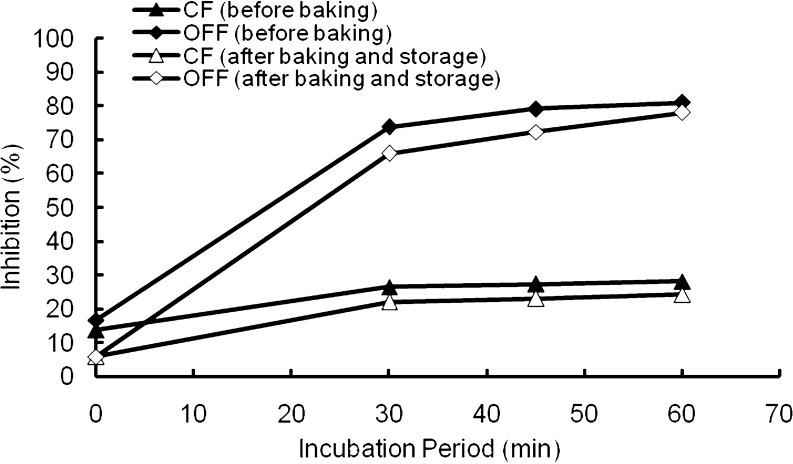

DPPH radical scavenging activity of oryzanol fortified fat added to biscuits before and after processing and storage

Figure 3 shows the radical scavenging activity of control fat (CF) and oryzanol fortified fat (OFF) before and after baking and after 120 days of storage. The ability of the radical scavenging activity was tested using stable radical DPPH in toluene. The results show that the incorporation of oryzanol concentrate to the fat increases the free radical scavenging activity (81 ± 1 %) than the control fat (28.1 ± 1 %) after 60 min of incubation. It was interesting to note that the DPPH radical scavenging activity of control fat and oryzanol incorporated fat did not alter during baking and storage.

Fig. 3.

Radical scavenging activity of control fat (CF) and oryzanol fortified fat (OFF) before baking and after baking and storage

Conclusions

The present study evaluated the possibility of fortification of oryzanol into the commercially available emulsified fat to provide about 300 mg of oryzanol per 100 g of biscuits and its stability during different relative humidity conditions at room temperature of around 27 °C. The oryzanol fortified biscuits showed same physical, chemical and sensory properties as compared to the control biscuits during storage at 27 °C with higher thermal stability and storage stability of oryzanol in the biscuits. Recently, Preeti Chandrashekar et al. (2012) have reported that the incorporation of oryzanol concentrate into groundnut oil showed serum and liver cholesterol lowering property when fed to male Wistar rats (Preeti Chandrashekar et al. 2012). Thus, it can be used as the functional food to deliver hypocholesterolemic and hypolipidemic benefits to consumers. The biscuits have shown a minimum of 3 months shelf life at 27 °C and may provide health benefits as above.

Acknowledgments

The authors are thankful to Dr. V. Prakash, Director, CFTRI, Mysore, for providing infrastructural facilities and showing keen interest in this research. Thanks are also due to Dr. B.R. Lokesh, Head, Department of LSTF for his suggestions during the course of this work.

References

- Adegoke GO, Vijay Kumar M, Gopala Krishna AG, Varadaraj MC, Sambaiah K, Lokesh BR. Antioxidants and lipid oxidation in foods, a critical appraisal. J Food Sci Technol. 1998;35:283–298. [Google Scholar]

- AOCS (1998) Official methods of the American Oil Chemists Society, 4th edn. AOCS method no. Ac 2–41, (1997) The AOCS Official Butt-tube Method Ac 3–44, AOCS method Nos. Ca 5a–40 (1998) AOCS method Nos. Cd 8–53 (1998) American Oil Chemists Society, Champaign, IL, USA

- Bassiouny SS, Hassanien FR, Alif El-Razik, El-Kayati SM. Efficiency of antioxidants from natural sources in bakery products. Food Chem. 1990;37:297–305. doi: 10.1016/0308-8146(90)90110-P. [DOI] [Google Scholar]

- Bhanger MI, Iqbal S, Anwar F, Imran M, Akhtar M, Zia-Ul-Haq M. Antioxidant potential of rice bran extracts and its effects on stabilization of cookies under ambient storage. Int J Food Sci Technol. 2008;43:779–786. doi: 10.1111/j.1365-2621.2007.01515.x. [DOI] [Google Scholar]

- Bhatnagar AS, Prasanth Kumar PK, Hemavathy J, Gopala Krishna AG. Fatty acid composition, oxidative stability, and radical scavenging activity of vegetable oil blends with coconut oil. JAOCS. 2009;86:991–999. [Google Scholar]

- Chandrashekar P, Prasanth Kumar PK, Ramesh HP, Lokesh BR, Gopala Krishna AG (2012) Hypolipidemic effect of oryzanol concentrate and low temperature extracted crude rice bran oil in experimental male wistar rats. J Food Sci Technol. doi:10.1007/s13197-012-0628-9 [DOI] [PMC free article] [PubMed]

- De Deckere EAM, Korver O. Minor components of rice bran oil as functional foods. Nutr Rev. 1996;54S:120–126. doi: 10.1111/j.1753-4887.1996.tb03831.x. [DOI] [PubMed] [Google Scholar]

- Gopala Krishna AG. Nutraceutical components of rice bran oil in relation to processing. J Food Lipids. 2002;12:80–84. [Google Scholar]

- Gopala Krishna AG, Hemakumar KH, Khatoon S. Acidity of oryzanol and its contribution to free fatty acid value in vegetable oils. JAOCS. 2006;83:999–1005. [Google Scholar]

- Gopala Krishna AG, Hemakumar KH, Khatoon S. Study on the composition of rice bran oil and its higher free fatty acids value. JAOCS. 2006;83:117–120. [Google Scholar]

- Gopala Krishna AG, Khatoon S, Shiela PM, Sarmandal CV, Indira TN, Mishra A. Effect of refining of crude rice bran oil on the retention of oryzanol in the refined oil. JAOCS. 2001;78:127–131. [Google Scholar]

- Juliano C, Cossu M, Alamanni MC, Piu L. Antioxidant activity of gamma-oryzanol: mechanism of action and its effect on oxidative stability of pharmaceutical oils. Int J Pharm. 2005;299:146–154. doi: 10.1016/j.ijpharm.2005.05.018. [DOI] [PubMed] [Google Scholar]

- Kahl R. Synthetic antioxidants: Biochemical actions and interference with radiation, toxic compounds, chemical mutagens and chemical carcinogens. Toxicology. 1984;33:185–228. doi: 10.1016/0300-483X(84)90038-6. [DOI] [PubMed] [Google Scholar]

- Lauck RM (1981) Oxidized whey protein concentrate enriched shortening-containing biscuits. US Patent Application 973, 506

- Lopez A, Pique MT, Clop M, Tasias J, Romero A, Boatella J, Garcia J. The hygroscopic behaviour of the hazelnut. J Food Eng. 1995;25:197–208. doi: 10.1016/0260-8774(94)00021-Z. [DOI] [Google Scholar]

- Marnett LJ. Oxyradicals and DNA damage. Carcinogenesis. 2000;21:361–370. doi: 10.1093/carcin/21.3.361. [DOI] [PubMed] [Google Scholar]

- Narasimha Rao BS. Bioactive phytochemicals in Indian foods and their potential in health promotion and disease prevention. Asia Pac J Clin Nutr. 2003;12:9–22. [PubMed] [Google Scholar]

- Pokorny J (1991) Natural antioxidants for food use. Trends Food Sci Tech 223–227

- Romildo MS, Sissi KM, Izabel CFM, Victor HP (2009) Moisture adsorption behavior of biscuits formulated using wheat, oatmeal and passion fruit flour. J Food Process Preserv 33:105–113

- Sai Manohar R, Ha-ridas Rao P. Effect of emulsifiers fat level and type on the rheological characteristics of biscuit dough and quality of biscuits. J Food Agric. 1999;79:1223–1231. doi: 10.1002/(SICI)1097-0010(19990715)79:10<1223::AID-JSFA346>3.0.CO;2-W. [DOI] [Google Scholar]

- Sayre RN, Saunders RM. Rice bran and rice bran oil. Lipid Technol. 1990;2:72–76. [Google Scholar]

- Shahidi F, Naczk M. Food phenolics: sources, chemistry, effect and applications. Lancaster: Technomic Publishing Co; 1995. [Google Scholar]

- Shahidi F, Shukla VKS. Nontriglycerol constituents of fats, oils. Inform. 1996;7:1227–1232. [Google Scholar]

- Hooda S, Jood S. Organoleptic and nutritional evaluation of wheat biscuits supplemented with untreated and treated fenugreek flour. Food Chem. 2005;90:427–435. doi: 10.1016/j.foodchem.2004.05.006. [DOI] [Google Scholar]

- Steele RGD, Torrie JH. Principles and procedures of statistics. New York: Mc Graw- Hill; 1980. [Google Scholar]

- Vanitha R, Urooj A, Kumar A (2005) Evaluation of antioxidant activity of plant extracts and their application in biscuits. Food Chem 90:317–321

- Vitali D, Vedrina Dragojevic I, Sebein B. Bioaccessibility of Ca, Mg, Mn and Cu from whole grain tea-biscuits: impact of proteins, phytic acid and polyphenols. Food Chem. 2008;110:62–68. doi: 10.1016/j.foodchem.2008.01.056. [DOI] [PubMed] [Google Scholar]

- Xu Z, Godber JS. Purification and identification of components of γ-oryzanol in rice bran oil. J Agric Food Chem. 1999;47:2724–2728. doi: 10.1021/jf981175j. [DOI] [PubMed] [Google Scholar]

- Xu Z, Hua N, Godber JS. Antioxidant activity of tocopherols, tocotrienols and γ-oryzanol components from rice bran against cholesterol oxidation accelerated by 2,2′-Azobis (2-methyl propionamide) Dihydrochloride. J Agric Food Chem. 2001;49:2077–2081. doi: 10.1021/jf0012852. [DOI] [PubMed] [Google Scholar]