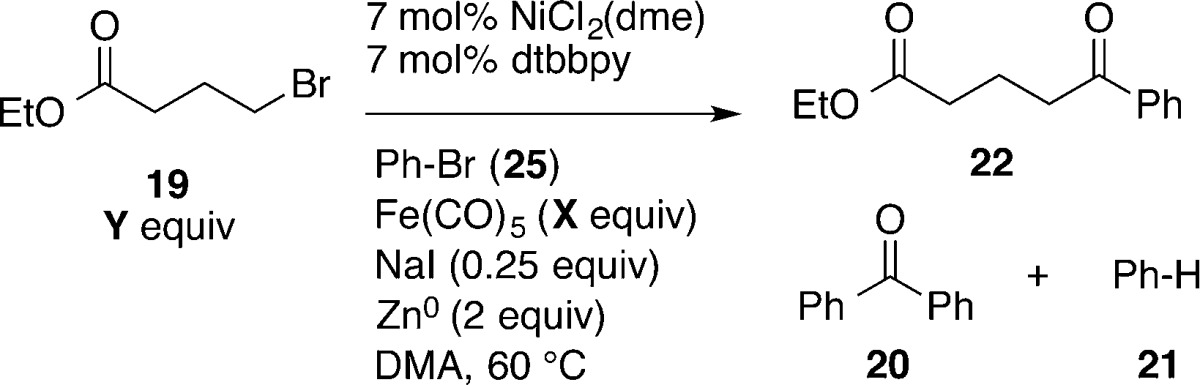

Table 4. Optimization and Controlsa.

| entry | notes | X | Y | 22 | 20 | 21 |

|---|---|---|---|---|---|---|

| 1 | 0.35 | 2.50 | 69 | 5 | 4 | |

| 2 | 0.35 | 2.25 | 72 (60) | 6 | 6 | |

| 3 | 0.35 | 2.0 | 56 | 7 | 8 | |

| 4 | 0.35 | 1.5 | 50 | 9 | 15 | |

| 5b | 0.40 | 2.0 | 51 | 7 | 8 | |

| 6c | 0.45 | 2.0 | 42 | 3 | 5 | |

| 7c | 0.50 | 2.0 | 32 | 3 | 4 | |

| 8d | no NaI | 0.35 | 2.0 | 0 | 0 | 0 |

| 9 | LiI for NaI | 0.35 | 2.0 | 49 | 7 | 7 |

| 10 | KI for NaI | 0.35 | 2.0 | 48 | 4 | 8 |

| 11 | 5 mol % catalyst | 0.35 | 2.0 | 42 | 6 | 9 |

| 12e | no dtbbpy | 0.35 | 2.25 | 0 | 0 | 2 |

| 13e,f | no Ni or Zn | 0.35 | 2.0 | 0 | 0 | 1 |

| 14e,g | no Ni | 0.35 | 2.0 | <1 | <1 | 0 |

| 15c,g | no Zn | 0.35 | 2.25 | 25 | <1 | 4 |

| 16 | 6/1 DMA/THF | 0.35 | 2.25 | 76 | 7 | 0 |

| 17 | 1/1 DMA/THF | 0.35 | 2.25 | 52 | 7 | 3 |

| 18e,g | 1/2 DMA/THF | 0.35 | 2.25 | <1 | 0 | 1 |

Reactions were run on a 0.75 mmol scale in 3 mL of DMA. Yields are uncorrected GC yields vs dodecane. The yield in parentheses is an isolated yield of purified product.

PhBr (8%) remained.

PhBr (27%–47%) remained.

Starting materials were unchanged after 40 h, except for a 13% yield of hydrodehalogenated 19.

PhBr (75%) remained.

Alkyl-Br 19 not consumed.

Dialkyl ketone (12–23%) was formed.