Abstract

Automation has the potential to aid humans with a diverse set of tasks and support overall system performance. Automated systems are not always reliable, and when automation errs, humans must engage in error management, which is the process of detecting, understanding, and correcting errors. However, this process of error management in the context of human-automation interaction is not well understood. Therefore, we conducted a systematic review of the variables that contribute to error management. We examined relevant research in human-automation interaction and human error to identify critical automation, person, task, and emergent variables. We propose a framework for management of automation errors to incorporate and build upon previous models. Further, our analysis highlights variables that may be addressed through design and training to positively influence error management. Additional efforts to understand the error management process will contribute to automation designed and implemented to support safe and effective system performance.

Keywords: automation, imperfect automation, error, error management, human-automation interaction

1. Introduction

Modern automated systems are present in a multitude of environments, including aviation, process control, transportation, and healthcare. These technologies are designed to support overall system performance, assisting human operators with tasks such as information acquisition and processing, decision making, and action execution (Parasuraman et al. 2000). Many automated systems are not perfectly reliable, often due to technological limitations. For example, automation that involves sensing certain states in the environment may err because its sensors have limited detection capabilities. Although these errors may be rare, the resulting consequences can be severe.

Examples of serious consequences are not hard to find. One recent incident involved a family and their in-vehicle navigation aid (Clark 2011). This family was sightseeing in California’s Death Valley when they instructed their navigation aid to give them directions for getting home. Following the instructions provided by their navigation aid did not lead them home; rather, the family became lost in Death Valley at the height of summer (it turns out the system was relying on outdated maps). Although the family was located after three days, a similar incident occurred two years prior in which a mother and son were lost for five days. The mother survived, but her son did not.

These unfortunate events highlight the important role that the human serves when working with imperfect automation. If the individuals in the previous cases had had access to another source of information, such as a paper map, they could have sought to verify the automation’s suggested directions and realized they were being sent into the middle of nowhere. Humans are the last safeguard before automation errors propagate into accidents. This human role involves ‘error management’, which is the process of detecting errors, understanding why errors occurred, and correcting errors (Kontogiannis and Malakis 2009). Unfortunately, because of humans’ prominent role in this chain of events, they often receive the majority of the blame when their efforts fail. However, “the enemy of safety is not the human: it is complexity” (Woods et al. 2010, p. 1).

Understanding the process of error management is key to enhancing safe and successful automation interactions. Yet there has not been a systematic review of the nature of this complexity with the goal of identifying the variables that influence a human’s ability to manage automation errors. We conducted an analysis of the research literature from the fields of human-automation interaction and human error to identify the factors that influence the error management process. We identified and organized the automation, person, task, and emergent variables that influence error management of automation. This organizational framework serves multiple purposes. First, it provides a heretofore non-existent integration of the research literature pertinent to managing errors of automated system. Second, it can guide improvements in error management by identifying the potentially relevant variables to be addressed through design and training. And third, our analysis revealed gaps in the literature and needs for future research to ensure successful management of automation errors.

2. Overview of the review process

Research on human interaction with automated systems is extensive. Because the focus of the current investigation was to understand how various factors influence how well an individual manages automation errors, several criteria were used to select relevant publications from the body of literature on human automation interaction. First, if participants interacted with an automated system, the experiment had to include a version of the automated system that was less than 100% reliable. This departure from perfect reliability could result in automation errors, which we defined as an error committed by the automation during which the automation does not behave in a manner that is consistent with the true state of the world. Therefore, we do not include situations during which the automation behaves as it should, and an overall system error occurs because the human operator is deficient in some way, such as not understanding what mode the automaton is in, or supplying the automation with inaccurate information.

Automation errors may include misses and false alarms (Green and Swets 1988), misdiagnoses, and inappropriate action implementation. Automation designers know that certain errors, such as misses, will occur when they set the threshold for detection (i.e., beta). One might argue that because these errors are part of the automation’s programming, they should not be considered errors. However, we contend that an error has occurred if the automation behaves in a manner that is inconsistent with the true state of the world. The navigation aid example illustrates an automation error in which the automation recommended the use of roads that were no longer in existence.

In addition to automation errors, automation failures can also occur. During failures, the automation is non-responsive, not available, or not functional, and therefore forces the human to perform the task manually. For example, Woods et al. (2010) described an automatic infusion controller used during surgery to control the rate that drugs are delivered to the patient. If the controller cannot regulate flow or detects one of many potential device conditions, it is programmed to turn off after emitting an alarm and warning message. In this scenario, the operator of the automation would need to detect that the controller had turned off, then explain and understand what caused the failure, which may be necessary to controlling the system manually or getting the system back online (correction). One might assume that detecting an automation failure is a trivial matter, but there are numerous instances in commercial aviation (e.g., Eastern Flight 401, China Airways Flight 006) during which pilots failed to detect that their automation had disengaged. Although automation errors and failures represent two different categories of activity, both require error management by the human. Thus, the empirical research in this review included studies investigating both errors and failures.

A second criterion for our review was that if the experimental investigation included interaction with an automated system, a dependent measure of error management success was required. For example, an experiment may have measured how many of the automation errors were detected by the participant. Although many empirical investigations of human-automation interaction employ imperfect automation, oftentimes the dependent variables relate to other constructs, such as trust in automation, rather than error management success.

Lastly, the review focused on interactions between a single human operator and one or more automated systems. Although it is important to understand how error management occurs in teams composed of multiple humans and multiple forms of automation, this was beyond the scope of the current analysis.

We identified the variables that have been shown to influence the management of automation errors, which we classified into four categories: (1) automation variables, (2) person variables, (3) task variables, and (4) emergent variables (see Table 1). Automation variables included characteristics of the automation such as the reliability of the automation, the types of errors the automation is likely to make, the level of automation, and the nature of the feedback that the automation provides to a human operator. Person variables represented factors that were unique to the individual, and included an individual’s complacency potential (i.e., attitudes that influence complacent monitoring behaviour), nature of training received, and knowledge regarding the automation. Task variables included variables that described the context in which the human and automation are working together. These included the consequence of an automation error if unmanaged by the human, the costs associated with verifying automation’s suggestions or information, and the degree to which the human is held accountable for the results of an automation error. Lastly, emergent variables described factors that result from the interaction between the human and automation. For instance, the trust that an individual has towards a specific piece of automation is the result of not only characteristics of that person (e.g., very trusting), but also aspects of the automation (e.g., reliability), and the task in which they are engaged (e.g., highly critical). The emergent variables included trust in automation, workload, and situation awareness.

Table 1.

Framework for variables influencing error management.

| Category | Definition | Examples |

|---|---|---|

| Automation Variables | Characteristics of the automation | Reliability level Error type Level of automation Feedback |

| Person Variables | Factors unique to the person interacting with automation |

Complacency potential Training received Knowledge of automation |

| Task Variables | Context in which human and automation are working together |

Automation error consequences Verification costs Human accountability |

| Emergent Variables | Factors that arise from the interaction between human and automation |

Trust in automation Workload Situation awareness |

Before we present the empirical evidence regarding how these variables influence a human’s management of automation errors, we first provide an overview of the research on error management processes outside of the automation literature, and discuss how these theoretical frameworks can be applied to human-automation interaction.

3. Error management

Errors have been discussed in the context of socio-technical systems in which errors or failures may originate from the human or the technology involved. Historically, the dominating focus has been error prevention; that is, keeping errors from occurring at all. More recently, perspectives regarding errors have shifted due in part to the distinction of errors and their consequences, as well as the understanding that not all errors can be prevented. Errors may occur, but actions to stop or reduce their consequences can be taken. Therefore, a supplementary goal to error prevention should be error management, or the process of limiting the consequences of error. This approach has also been called resilience engineering and espouses that anticipating possible disturbances or errors in a system is a more valuable effort than attempting to eliminate them completely (Sheridan 2008). Particularly in the case of using imperfect automation, operators cannot prevent the automation from erring, as its designers determine its reliability. But, operators can mitigate the consequences of errors by managing them. Researchers generally agree that error management consists of three components: (a) detection, (b) explanation, and (c) correction (Kontogiannis 1999, 2011, Kanse and van der Schaaf 2001).

Detection involves realizing that something has gone wrong or that an error is about to occur. Explanation is the process of identifying the nature of the error as well as understanding the underlying cause of the error (Kontogiannis 1999). Correction involves modifying the existing plan or developing a new plan as a countermeasure against the potential adverse events of the error (Kanse and van der Schaaf 2001). During the correction stage, operators may have different goals, influenced by the nature of the error, ensuing consequences, and time pressure (Kontogiannis 1999). For instance, correction actions may serve as a strategy to avoid immediate consequences of an automation error. Correction can also be considered from a maintenance perspective, such as replacing a faulty sensor that was responsible for the error to avoid similar errors in the future.

Progression through the three phases is not necessarily linear, and overlap between the phases is possible. Corrective measures can be taken while attempts to explain the source of the error are underway. Particularly in time-restricted situations, operators may take action to correct the error without thoroughly understanding its cause. For instance, Kanse and van der Shaaf (2001) analyzed the sequence in which operators moved through the various error management stages. They discovered that in many cases detection was followed immediately by corrective action, with explanation occurring later. In other situations, an effective plan to correct the error cannot be obtained without first understanding the nature of the error.

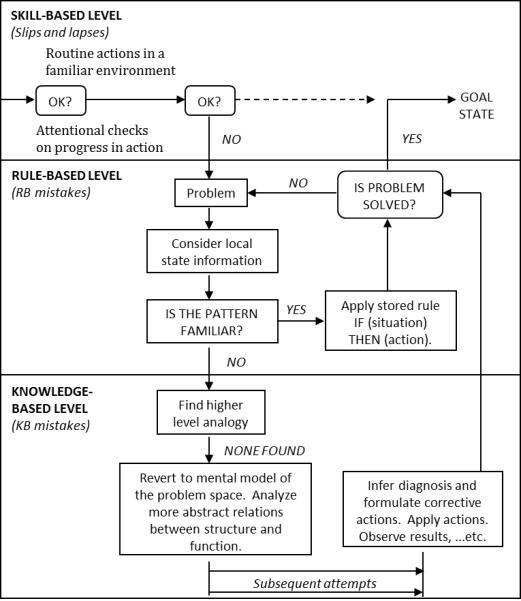

To further understand the processes involved in the three phases, one can turn to Reason (1990), who proposed a generic error-modelling system (GEMS) to describe how humans manage various types of self-committed, human errors. As depicted in Figure 1, behaviour proceeds from the routine actions at the skill-based level to the rule- and knowledge-based levels in the event of issues being detected. Detection of an error occurs by means of attentional checks, during which higher levels of cognition come to the forefront and determine whether behaviour is running according to the established plan, or whether the plan needs to be altered to reach the goal. Attentional checks may fail as a result of inattention (omitting a critical check) or overattention (checking at an inappropriate time).

Figure 1.

The mechanics of the generic error modeling system (GEMS), adapted from Reason (1990).

After a problem has been detected, behaviour transitions from monitoring to problem solving. The first attempt at problem solving occurs at the rule-based level wherein an individual will search for an applicable, pre-established corrective procedure. If a stored rule successfully resolves the problem, behaviour continues towards the goal state. If a stored rule is not sufficient, then behaviour proceeds to the knowledge-based level. At the knowledge-based level, problem solving may occur through the use of analogies, mental models, or abstract relationships.

Although this description suggests that this process is predominantly linear in nature, Reason pointed out that switching from one level of performance to another is unlikely to be so clear cut. Rather, it is more likely that behaviour occurs at multiple levels simultaneously, and that the transitions between the levels may not just proceed down from skill- to rule- to knowledge-based, but back up and down multiple times. For example, if one finds an applicable rule at the rule-based level, then enacting that rule may involve routinized actions at the skill-based level.

GEMS can be used to describe the behaviour of a human operator interacting with imperfect automation to accomplish a task. The same attentional checks used to assess the operator’s own performance should also be used to check that the automation is working properly. In cases where a problem with the automation is detected, either an error or a failure, the importance of accessing stored rules and knowledge and using them effectively to problem solve cannot be understated. This process can make the difference between an automation error that was recovered from and an error that led to an accident.

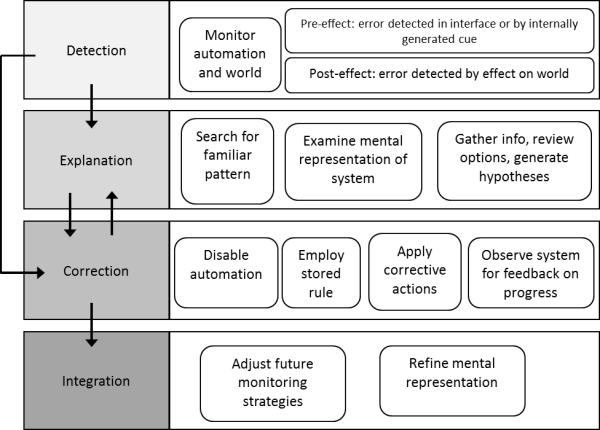

3.1 Summary of error management

Literature on error management describes the process individuals engage in to mitigate the consequences of an error. Error detection, explanation, and correction are necessary components in recovering from automation errors as well. Reason’s (1990) GEMS can be used to further understand the detailed cognitive paths that are traversed to explain and ultimately correct automation errors. On that basis, we developed a framework highlighting the error management processes in a human-automation interaction context (see Figure 2). This framework illustrates how each phase might occur in an interaction with automation. Detection occurs by monitoring the automation and the world and can happen before or after the error affects the world. For example, an error in the drip rate of an automated infusion pump may be noticed by a healthcare provider who physically sees that the medication is dripping faster than it should be (pre-effect), or the error may be detected once the patient has a negative medical reaction to the overdose of medication (post-effect).

Figure 2.

Depiction of the error management process as it occurs in human-automation interaction.

The explanation phase of our framework borrows from Reason’s (1990) rule-based level in which individuals search for familiar patterns to compare their current situation to. In interactions with automation, operators may similarly examine their memory of previous automation errors for a comparable event, and apply stored rules as a means of correction. If such a pattern is not available, the explanation phase also contains elements inspired by the Reason’s knowledge-based level, which described how individuals use their mental representation of the problem space, or of the automation in our case, to make explanatory connections. This process may also involve generating and testing hypotheses, followed by the observations of outcomes on the system, which can lead to multiple iterations of corrective attempts.

One critical component of error management that has thus far been understated or absent in the literature to date is the process of integration. Integration describes the process of learning that occurs as a result of experiencing automation errors or failures. This exposure may give the human more detailed information regarding the automation’s capabilities and limitations, circumstances under which errors may be more likely to occur, and heuristics that may lead to quicker error correction. These insights must be integrated into the human’s mental representation of the automation and task, resulting in a more refined and complete understanding. This may then influence future instances of error management because it may lead a human to adjust his/her monitoring strategies and allow for better error detection.

4. Human-automation interaction variables

Many empirical investigations have examined the variables influencing how a person handles automation errors, and these have included automation, person, task, and emergent variables (see Table 1). We analysed this literature with respect to error management to identify both the relationships that have been documented as well as gaps that remain in the literature. We would have liked to organize the automation literature research by the relevant phase of error management (detection, explanation, correction, integration). However, the majority of studies in the human-automation literature have focused on detection or a simplified method of correction as their dependent variable, thereby limiting our ability to classify studies according the phases of error management. We will return to this issue in the discussion.

4.1 Automation variables

4.1.1 Reliability

One of the most widely investigated characteristics of automation is its reliability level. Reliability can be thought of as the “probability that the automation would make a correct classification” (Riley 1996, p. 23). Not surprisingly, research has demonstrated that using perfectly reliable automation results in superior system performance when compared to manual performance (Moray et al. 2000, Dixon et al. 2005). Further, using 100% reliable automation results in superior performance compared to imperfect automation (Kantowitz et al. 1997, Moray et al. 2000).

What is less clear is how performance varies when using imperfect automation compared to performing the task manually. In such situations, is overall performance better served by a human manually performing the task without any automated assistance, thereby avoiding the trouble of managing automation errors, or is performance superior when a human uses automation prone to errors? Our review indicated that the answer is not as simplistic as it might seem.

In a study by Skitka et al. (1999), participants either worked with an 88% reliable automated monitoring aid or were required to monitor the task manually without any automation. Of interest to the researchers were six of the 100 trials in which the automation group failed to receive prompts to critical events. Because the manual condition never received prompts throughout all 100 trials, the two groups could be compared on those six trials. Participants using the automated aid missed significantly more of the critical events than those working manually. For the 94 trials when the automation was correct, those in the automated aid condition had significantly better performance.

This finding suggests that imperfect automation benefited performance, but only when the automation was correct. When the automation failed, those in the manual conditions had an advantage. To better understand the driving forces behind these performance differences, Skitka et al. (1999) correlated participants’ error rates with measures of perceived task difficulty, effort, beliefs that automation improves accuracy of responses, and diffusion of responsibility. Of those, delegating the responsibility of system monitoring to the automation and attitudes that the automation was infallible were associated with higher omission and commission error rates.

Although the group using automation suffered performance decrements during the automation miss trials, this group demonstrated better overall performance than those not using automation. Maltz and Shinar (2004) similarly found that individuals in a driving simulator maintained safer driving distances if they used an imperfect warning aid compared to no aid at all. Additionally, experienced air traffic controllers using imperfect automation were as likely to detect a potential conflict (which the automation missed) as the controllers who were performing the task manually (Metzger and Parasuraman 2005). It appears that imperfect automation generally leads to better or comparable performance compared to manual task performance. Given this finding, using imperfect automation is a better choice because it would result in the same or better levels of performance and reduce the workload placed on the operator.

Because imperfect automation does appear to provide significant support, one might assume the best approach would be to accept a certain level of inaccuracy but get as close to 100% reliability as possible. This strategy would reduce the number of automation errors, thereby increasing overall performance. Researchers have suggested that this logic is flawed and noted that there appears to be a tradeoff that occurs with more reliable (still <100% reliable) automation (Bainbridge 1983, Wickens et al. 2010). Indeed, Sorkin and Woods (1985) noted that optimizing the automation’s performance alone did not lead to gains in overall system performance. In a comparison between 80% and 60% reliable automation, participants using 60% reliable automation had better decision making accuracy for trials when the automation was unreliable (Rovira et al. 2007).

These data reflect that automation that errs can support human performance, and it appears that in some cases, more error-prone automation may provide a greater benefit than less error-prone automation. But at what point does error-prone automation become no longer useful? Wickens and Dixon (2007) focused on modelling the role of reliability in human interaction with automated diagnostic aids. Their goal was to determine whether there is a reliability level below which the automation fails to provide any benefit or begins to impair performance. A linear regression revealed the predicted crossover point in reliability to be 70%, such that when using automation less than 70% reliable, task performance was worse than if the person were doing the task manually. Further, Wickens and Dixon’s analysis suggested that when automation reliability dropped below 70%, individuals continued to depend on the automation but failed to correct its errors, and did so as a means of preserving their cognitive resources for the other tasks.

One compelling explanation for why more reliable automation hurts error management performance comes from research examining complacency, or a state of sub-optimal monitoring behaviour. The idea is that when interacting with reliable automation (but not perfectly reliable), individuals come to believe their dependence on the automation is warranted, and complacent behaviour increases, which reduces the probability of detecting automation errors when they occur. Therefore, if complacency can be disrupted (i.e., by varying reliability), then detection of automation errors should improve.

In an experiment by Parasuraman et al. (1993), four groups of participants were responsible for monitoring an automated aid for errors. In two groups, the automation’s reliability was constant across the experiment at either 87.5% or 56.25%. In the other two groups, the reliability switched between 87.5% and 56.25% after every 10-minute block (12 blocks total). The variable-reliability groups were significantly more likely to detect automation errors than the constant-reliability groups (detection rates of approximately 75% versus 30%). This effect was not present in the first block, but emerged in the second block and increased in later blocks. Parasuraman et al. posited that by varying the reliability, participants became more wary of the automation and increased their vigilance. These findings were replicated by Prinzel et al. (2005) using A’ (a measure of detection sensitivity less sensitive to response distributions than d’) as the dependent variable.

We believe there may be an alternative or supplementary explanation for the benefit of varying automation reliability. Because the variable-reliability group was exposed to two levels of reliability (87.5% and 56.25%), the average level of reliability was approximately 72%. Indeed, Rice and Geels (2010) have found evidence that when using multiple automated systems of varying reliability, individuals tend to merge the reliability of the aids and treat them as a single unit. Because a 72% reliable aid was not included as one of the levels used in the constant-reliability conditions, the performance benefit may be a consequence of this intermediate level of reliability, rather than the varying nature of reliability for the group. Therefore, future investigations should include a constant-reliability group that matches the average of the variable-reliability group to allow for a direct comparison.

Even if varying reliability is an effective method of disrupting complacency, it is not clear how this might be implemented in operational contexts. To vary reliability would require the introduction of contrived automation errors. If operators know the bogus nature of these errors, they may lose substantial trust in the system or reduce their monitoring behaviour. Another possible avenue might be taking the automation offline and forcing periods of manual performance. Empirical research will be necessary to determine if this would result in a comparable performance benefit.

Our analysis identified a factor that often varies between studies of automation reliability; namely, the base rate of the event or signal to be detected by the automation. For example, an automated aid designed to assist with luggage screening is designed to detect the event of a weapon concealed in a suitcase. The base rate of this event, or the probability that it will occur, is very low. This is true for many base rates.

Much of the research examining reliability has used experimental situations in which the base rate is extremely high. For example, in one study a fault that the automation was designed to detect occurred every trial, and each trial lasted approximately 2.5 minutes (Moray et al. 2000). Although this high base rate may represent some operational environments, the other end of the spectrum has not received as much empirical attention.

We need to understand how error detection performance changes as a function of base rate, as vigilance decrements may reduce error management success. One of the few studies that has examined monitoring automation with a very low base rate of errors (i.e., a single failure in a 30 minute session), found that detection rates dropped significantly if the failure occurred in the last 10 minutes of the 30 minute block compared to if it occurred in the first 10 minutes (Molloy and Parasuraman 1996). The high base rates of errors in previous studies may have masked potential vigilance effects and overestimated how capable individuals may be in detecting errors over extended periods of time with rare error events.

It is not clear whether the effects found in the literature will scale up when errors only occur every other day, week, or month, rather than multiple times in an experimental session. Certainly, there are limitations to what can be done experimentally due to time and monetary constraints, but understanding the effect of base rate on error management should be a research priority.

Overall, our analysis revealed that an automated system’s reliability influences a human’s ability to manage automation errors. 100% reliable systems certainly support overall task performance compared to manual task performance. However, the benefit of imperfect automation is not quite as clear. Overall performance can be divided into two categories: (a) performance when the automation is working (routine performance), and (b) performance when the automation is erring or has failed completely (error or failure performance). Although one might conceive that closer approximations to 100% reliability will yield superior performance, this is not necessarily the case. As Bainbridge (1983) suggested, “…the most successful automated systems, with rare need for manual intervention …may need the greatest investment in human operator training” (p. 777).

Explanations for this paradox or tradeoff have included increases in complacency, or suboptimal monitoring of the automation. Greater complacency may be found in highly reliable (but imperfect) automation during routine performance, which leaves the human less vigilant and less able to respond appropriately to automation errors or failures. If this tradeoff does exist, we need to understand why it occurs and whether it is an effect that needs to be eliminated or may be used to automation designers’ advantage.

Moray (2003) has pointed out that the manner in which complacency has been studied is ambiguous. Specifically, complacency is typically defined as monitoring or sampling of the automation below some optimal level; however, this level is typically not defined and detection of error is often measured instead of sampling behaviour. Therefore, to claim that complacent behaviour has occurred in these situations is inappropriate. Further, Moray suggested that when automation is typically reliable, a lack of sampling or monitoring may be a rational decision when other tasks require the operator’s attention, suggesting that the negative connotations associated with complacency are not always suitable.

Parasuraman and Manzey (2010) also argued that complacent behaviour needs to be evaluated independently of detection performance. Such work has been accomplished more recently (see Bahner et al. 2008a, 2008b under the Training section). However, Parasuraman and Manzey also pointed out that normative or optimal sampling models need to take into consideration the cost of sampling and the value of the sampled information.

4.1.2 Nature of errors

In addition to the level of error that the automation commits, the nature of the errors committed has also been examined in relation to error management. Generally, the errors committed by automation are classified as false alarms or misses (Wickens and Carswell 2006). A false alarm occurs when the automation incorrectly detects a signal in the environment, and a miss occurs when a signal is present in the environment, but the automation fails to detect it. The errors committed by many types of automated systems, particularly those designed to detect certain states (such as the presence of a system malfunction), may be considered in this manner according to signal detection theory (Green and Swets 1988).

Sanchez et al. (2011) employed automation designed to assist with collision avoidance. Participants were exposed to either 10 false alarms or 10 misses out of 240 events over the course of the experimental session. The miss group had significantly more errors and lower trust in the automation than the false alarm group, suggesting that misses may be more detrimental to error management than false alarms.

Evidence to the contrary has been reported (Dixon and Wickens 2006). A diagnostic aid was set to be 67% reliable, with the remaining 33% either false alarms or misses. Participants used this aid in addition to performing two other tasks simultaneously. Detection rates for critical events were subdivided based on whether the event occurred during a moment of low or high workload. When workload was low, participants’ detection of critical events was near ceiling, suggesting they were very capable of detecting and correcting when the automation missed or false alarmed. Under conditions of high workload, error type had a significant impact on detection rates. The miss group detected significantly more critical events than the false alarm group. Dixon et al. (2007) also found that misses were associated with greater detection of system failures than false alarms as measured by d’.

False alarms and misses are unavoidable consequences of imperfect automation. The ratio of false alarms to misses is at the discretion of the system designer, who must weigh the relative costs of these two events. Although a miss may constitute an extraordinarily high cost in terms of immediate consequences (a plane flying into the side of a mountain), minimizing misses may not be an appropriate alternative considering the evidence that false alarms are more detrimental to the operators’ error detection. Further research is needed to determine if the effect of false alarms can be reliably mitigated. A limitation of the current research on error types is that the majority of research has focused on early stage automation, or automation responsible for acquiring and analyzing information, but not making decisions or taking action (as defined by Parasuraman and Wickens 2008). Future research should investigate whether the patterns found in early stage automation hold for later stage automation. Stages of automation are discussed further in the following section.

4.1.3 Level of automation

Automation does not operate in an all-or-none fashion (Wiener and Curry 1980). Rather, the degree of control allotted to the human and to the automation moves along a spectrum, such that a higher level of automation (LOA) has greater control or autonomy compared to a lower level of automation. Various accounts have been provided regarding the levels of automation (Endsley and Kiris 1995, Endsley and Kaber 1999, Parasuraman et al. 2000).

In a study using an automobile navigation task, Endsley and Kiris (1995) examined whether using higher levels of automation would hurt decision making performance when the task had to be completed manually. They hypothesized that the time to make a decision during this manual phase would positively correlate with LOA. Their data only revealed an increase in decision time among participants who had been using the highest level of automation compared to participants who had been performing the task manually the entire session. In fact, although decision time varied, the quality of the decisions made was near ceiling for all of the groups.

Endsley further refined and expanded her LOA taxonomy (see Table 2), and she examined the effect of these levels on performance in a dynamic control task (Endsley and Kaber 1999). Each participant completed two trials with two different LOAs. During each trial, three automation failures occurred in which control reverted to manual. Performance data were separated into performance during normal conditions and performance during an automation failure.

Table 2.

Endsley and Kaber’s (1999) hierarchy of levels of automation applicable to dynamic-cognitive and psychomotor control task performance.

| Roles |

||||

|---|---|---|---|---|

| Level of automation | Monitoring | Generating | Selecting | Implementing |

| 1)Manual control | Human | Human | Human | Human |

| 2)Action support | Human/Computer | Human | Human | Human/Computer |

| 3)Batch processing | Human/Computer | Human | Human | Computer |

| 4)Shared control | Human/Computer | Human/Computer | Human | Human/Computer |

| 5)Decision support | Human/Computer | Human/Computer | Human | Computer |

| 6)Blended decision making | Human/Computer | Human/Computer | Human/Computer | Computer |

| 7)Rigid system | Human/Computer | Computer | Human | Computer |

| 8)Automated decision making | Human/Computer | Human/Computer | Computer | Computer |

| 9)Supervisory control | Human/Computer | Computer | Computer | Computer |

| 10) Full automation | Computer | Computer | Computer | Computer |

Although there were significant performance differences between LOAs during normal conditions, the effect of LOA was less pronounced during the automation failures. Performance across the LOAs was not significantly different except that batch processing and automated decision making were worse than manual performance. These two LOA groups also showed the longest time to recover from the automation failure. These data represent a pattern in performance seen in other areas of research, such as automation reliability; that is, it highlights the paradox of automation. A LOA that boosts performance during normal conditions (e.g., batch processing) leads to the worst performance when the automation fails. Endsley and Kaber (1999) explained this particular finding by highlighting that in batch processing, which is a relatively low LOA and should not impair failure performance, participants were likely to try to plan ahead, distracting them from the task at hand and resulting in the poorer performance observed during automation failures.

There is not strong evidence for an effect of LOA on error management. There may be certain methodological limitations that reduced the likelihood of uncovering such an effect. The underlying theoretical perspective is that higher LOAs create a more passive role for the human, resulting in more complacency and lower situation awareness, which negatively affects performance during automation failures. However, in both of the previously discussed studies, we believe the experimental procedure did not provide enough time for complacency to form and situation awareness to suffer.

For example, in Endsley and Kiris’s (1995) study, participants were presented with a short text based scenario, and then required to make a decision. On average, the decision time ranged from 15-30 seconds. The probability of complacency forming under these circumstances is low, which we believe is why the effect of LOA on performance was not observed. In Endsley and Kaber’s (1999) study, there were no more than 2-3 minutes of continuous use of the automation at the LOA being tested. This period of use is so brief that it is very unlikely complacency and the subsequent performance decrement would have time to develop. Although it has been shown that complacency can develop in just 20 minutes (Parasuraman et al. 1993), it occurred after 20 minutes of continuous use. The time period in question consisted of 12-13 minutes of use with a 5-minute break partway through, rendering it unlikely that participants had enough time to develop complacent behaviour.

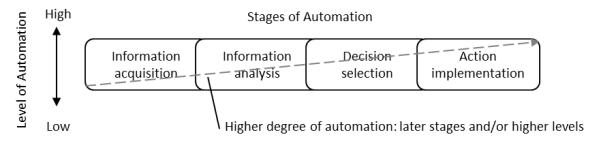

In addition to the LOA taxonomy suggested by Endsley and Kaber (1999), Parasuraman et al. (2000) proposed a model that included four stages of functions that can be performed by the automation or human (see Figure 3). Within each of these stages, the level of automation can range from low to high. As depicted in Figure 3, degree of automation is defined by both the stage and level of automation.

Figure 3.

Illustration of degrees of automation adapted from Wickens et al. (2010). Degree of automation (diagonal line) is defined by higher levels and later stages.

One study that examined the relative benefit of the varying stages of automated support compared information automation (stages 1 & 2) with decision automation (stages 3 & 4). Rovira et al. (2007) found that with 80% reliable automation, when the automation was imperfect, the decision automation was associated with less accurate decisions and longer decision times, whereas the information automation was not. Rovira et al. suggested that the information automation may be less affected by unreliable automation because users will continue to generate alternative courses of action, whereas a user of decision automation may cease engaging in this process.

Wickens et al. (2010) conducted a meta-analysis to determine the extent to which varying the degree of automation leads to a tradeoff in performance between routine and failure conditions (also known as the paradox of automation). Although the initial analysis supported the hypothesized tradeoff, a subsequent analysis called this into question. The original analysis included data points for conditions in which the task was performed manually. When these data points were removed, the effects changed dramatically. The correlation between routine and failure performance switched to positive, although non-significant, showing a trend for higher degrees of automation to result in improved performance when the automation is working correctly and when the automation errs.

Wickens et al. (2010), and recently, Hancock et al. (2013), discussed several possible explanations for the lack of support for the tradeoff. If automation is well designed and operators are well trained, this can actually mitigate or overcome the tradeoff. However, what makes a display or a training program effective in terms of supporting error management performance is not readily apparent. In fact, Lorenz et al. (2002) found that participants using a high LOA actually were faster to identify faults when the automation failed compared to a medium LOA. Data on the sampling behaviour showed that high LOA participants were more likely to sample relevant information, which kept them “in the loop” and prepared to handle automation failures.

The data collected thus far do not paint a clear picture of the relationship between LOA and error management. One could conceive that high LOA supports error management because the automation is handling most of the task leaving the human available to monitor the status of the system. On the other hand, at a lower LOA the human is actively involved in the task at hand and therefore might be more likely to detect an abnormality. Both explanations appear plausible, so further research is needed to identify which scenario represents reality.

4.1.4 Feedback

A critical component of well-designed automation is the feedback provided by the automation to the human. This feedback is the only way the automation communicates information to the human regarding its behaviour and the overall state of the system. A breakdown in communication or lack of feedback may have profound effects on a human’s understanding of the automation’s actions, which can result in severe performance decrements if the automation errs or fails. Automation with poor feedback capabilities has been described as silent (Woods 1996). Norman (1990) posited that a lack of appropriate feedback is at the heart of many of the issues raised regarding the implementation of automation. A case study from the aviation domain presented in his writing nicely illustrates this point. Below is a quotation from an accident report filed with the NASA Aviation Safety Reporting System:

Shortly after level off at 35,000 ft.…the second officer brought to my attention that he was feeding fuel to all 3 engines from the number 2 tank, but was showing a drop in the number 3 tank. I sent the second officer to the cabin to check that side from the window. While he was gone, I noticed that the wheel was cocked to the right and told the first officer who was flying the plane to take the autopilot off and check. When the autopilot was disengaged, the aircraft showed a roll tendency confirming that we actually had an out of balance condition. The second officer returned and said we were losing a large amount of fuel with a swirl pattern of fuel running about mid-wing to the tip, as well as a vapor pattern covering the entire portion of the wing from mid-wing to the fuselage. At this point we were about 2000 lbs. out of balance… (Norman 1990, p. 139)

In this case, the autopilot had compensated for the weight imbalance caused by the fuel loss. However, because the automation did not provide feedback to the pilots indicating that it was compensating for imbalance more than usual, the fuel leak may have gone unnoticed had it not been for the second officer’s detection of the discrepancy. Even though the source of the discrepancy was unknown to the second officer, by voicing his observation to the rest of the crew, he exchanged important information that set an investigation into action. In the same way, if the automation could have “voiced” its observation that it was compensating more than normal, this likely would have alerted the crew to the problem.

A lack of feedback has been linked to lapses in mode awareness, which refers to “an operator’s knowledge and understanding of the current and future automation configuration, including its status, targets, and behaviour” (Sarter 2008, p. 506). One may consider mode awareness a subcomponent of the more encompassing construct of situation awareness. Although in many cases decrements in mode awareness may be the result of poor feedback from the automation, there is also evidence that in cases where feedback is available to operators, they may not allocate attention to it (Sarter et al. 2007).

Well-designed cues can effectively draw a human’s attention to relevant output from the automation. Nikolic and Sarter (2001) discovered this in a study investigating the relative merit of peripheral visual feedback, or feedback that can be processed using peripheral rather than foveal vision. Participants using peripheral cues detected significantly more mode transitions and detected them significantly faster than participants using a traditional feedback display that required foveal vision.

Although the perceptual characteristics of feedback may be important, another critical aspect of acquiring feedback is the process of gathering pieces of information from various sources, and integrating the information to create an understanding of the automation’s behaviour and resulting system state. Skjerve and Skraaning (2004) conducted a series of experiments to investigate this process among experienced nuclear power plant operators. They argued that by designing an interface that provides explicit feedback and increases the observability of the system, human-automation cooperation will be enhanced, which will benefit overall performance.

Participants worked in multi-person crews in the experimental scenarios, in which they were responsible for maintaining normal operation and responding to critical plant occurrences (such as malfunctions). Operators’ ability to detect critical plant events and their response times to these events was superior when using an experimental interface, wherein the automation’s activity was made explicit through the addition of graphical and verbal feedback, compared to the conventional interface.

It is important to recognize that in many, if not most, cases, incorporating appropriate feedback requires increasing the complexity of the displays. However, as Skjerve and Skraaning’s (2004) work demonstrated, this increased display complexity actually supported performance, because the task of gathering information from various sources to produce an understanding of the automation’s behaviour was reduced or eliminated. Unfortunately, it is easy to imagine an interface where the opposite situation might occur. The feedback may become an additional element that must be monitored and its potential benefit is lost if not well implemented. This may be particularly true in cases where an operator is working with multiple automated systems that are poorly integrated and focus on different task subgoals.

4.1.5 Summary of automation variables

Aspects of the automation itself (e.g., reliability level, nature of errors, level of automation, and feedback to the human) influence an operator’s ability to manage errors. Contrary to what one might expect, more is not necessarily better for reliability and level of automation. That is, higher reliability and higher levels of automation have been associated with greater complacency, which can lead to worse error management. This is certainly an area warranting further research as these phenomena are negatively related to error management.

4.2 Person variables

4.2.1 Complacency potential

Individuals’ level of complacency has been shown to be an important predictor of whether they will manage errors effectively. Complacency is not only affected by aspects of the automation and the task, but also by aspects of the person. Singh et al. (1993a) identified complacency potential as an attitude towards automation that individuals bring to a situation that, when combined with environmental and automation variables, may result in complacent behaviour. Singh et al. (1993a) developed the Complacency-Potential Rating Scale (CPRS) to capture an individual’s potential for complacency by measuring favourable and unfavourable attitudes towards different aspects of automation.

Singh et al. (1993b) used the CPRS to determine the extent to which complacency potential predicted failures of monitoring. The reliability of the automation was manipulated to be either constant or variable. A median split was used to classify participants as either low or high complacency. In the variable reliability condition, complacency potential participants did not affect detection performance, suggesting that the effect of variable reliability (discussed earlier in the Automation Reliability section) may be strong enough to wash out an effect of complacency potential.

Under conditions of constant reliability, and contrary to the expected pattern, high complacency potential individuals had superior detection rates compared to low complacency potential participants (52.4% vs. 18.7%, respectively). However, when the correlation between complacency potential and detection rate was computed within each complacency potential group, the high complacency group had a negative, albeit insignificant, correlation of (r = −.42), and the correlation for the low complacency potential group was essentially null.

Our analysis revealed several possible explanations for the lack of evidence for a relationship between complacency potential and detection rates found by Singh et al. (1993b). First, the CPRS was administered after the first of two experimental sessions. Participants’ experience with the automation in this first session may have influenced their CPRS scores, resulting in an inaccurate representation of their true complacency potential. In addition, the median split used to create the two complacency potential groups was 56, such that the low complacency group contained scores from 47-56, whereas the high complacency group contained scores from 57-70. Considering that the range of possible scores was 16-80, there was not much of a spread in the scores obtained in this sample, perhaps limiting the effect.

Although this initial investigation did not provide much support for a relationship between complacency potential and automation error management, we believe this is likely due to the methodological issues discussed above, as Prinzel et al. (2005) reported data showing an effect of complacency potential. They used the same tasks, automation conditions, and instructions as those used by Singh et al. (1993b); however, they computed perceptual sensitivity (A’) to serve as the measure of automation monitoring performance. They also included 40 participants in their sample, compared to Singh et al.’s 24 participants. Once the CPRS scores were gathered, a median split of 58 was used to divide participants into low and high complacency potential. They found a significant interaction between complacency potential (high or low) and reliability (constant or variable) for automation monitoring performance, such that all groups performed comparably, except for the high complacency-constant reliability group, who performed significantly worse. Their findings demonstrate that complacency potential does influence automation error detection, primarily in situations that are conducive to the formation of complacency (constant automation reliability).

A recent investigation examined how individual differences in working memory and executive function may contribute to a person’s likelihood of exhibiting complacent behaviour. These cognitive components are highly heritable and under dopamingeric control, and the dopamine beta hydroxlase (DBH) gene is thought to regulation dopamine availability in the prefrontal cortex. Therefore, Parasuraman et al. (2012) divided participants into low and high DBH enzyme activity groups (lower DBH activity is associated with more dopamine), and examined their decision making performance when using an imperfect automated aid. They found that when the automation erred, the low DBH group was more likely to verify the automation’s suggestions and had significantly better decision accuracy (i.e., detected more automation errors).

Taken together, these studies suggest that individual differences in complacent behaviour or automation bias may be linked to two sources. Complacency potential, or an individual’s attitude towards automation that reflects a tendency towards complacent behaviour (e.g., not verifying the automation or seeking confirmatory/disconfirmatory evidence), has been shown to predict the likelihood that complacent monitoring behaviour will occur. In addition to attitudinal differences, recent evidence has shown that complacency potential may also have genetic underpinnings in terms of an individual’s working memory and executive function abilities.

4.2.2 Training

Prior to engaging with automation in an operational environment, individuals often partake in some form of training. These training programs can range in duration, fidelity, and content. Consider, for example, the numerous hours commercial pilots must spend in flight simulators before they receive certification, and contrast this to the training (or lack thereof) a consumer might receive after purchasing an automated GPS navigation aid. Although the difference in training is clear, both of these user groups have been found to demonstrate poor automation error management skills. If a portion of training programs was devoted to improving error management, would this result in measurable performance gains?

One study investigated this question by implementing various training programs designed to overcome automation bias, which is the tendency to defer to the automation rather than engage in information seeking behaviour (Mosier et al. 2001). Participants experienced one of three training interventions: (a) general training related to the aircraft systems and how the automation could be verified, (b) training that stressed participants must verify the automation, or (c) training that provided information regarding automation bias, the errors people often make when using automation, and how to avoid these errors. Participants encountered seven automation errors during a simulated flight, including six opportunities for an omission error, and one opportunity for a commission error. Training intervention did not have a significant effect on the likelihood of committing an omission or commission error.

A similar study may shed some light on why there was not an effect in the above study. In this study, the same three training interventions were used and participants worked in a similar simulated flight environment (Skitka et al. 2000b). The critical difference between this and the above study was the increase in opportunities for commission errors. In this study, there were six opportunities for an omission error and six opportunities for a commission error. With this change, Skitka et al. found that training had a significant effect on the number of commission errors committed. Specifically, participants who experienced the training emphasizing automation bias and the possibility of errors made fewer commission errors than the other two training groups. These findings suggest that this form of training may primarily reduce commission errors, but not omission errors. This might explain why Mosier et al. (2001) did not find an effect of training. There was only one opportunity for a commission error, reducing the potential for differences between the training groups.

Bahner et al. (2008b) examined the effectiveness of an intervention designed to improve automation error management by exposing participants to errors during training. They reasoned that simply discussing the potential for automation errors may not be enough to effectively change monitoring behavior. The experience group was exposed to two diagnosis errors during training. The information group received only correct diagnoses from the automation during training. The experimental session included a misdiagnosis on the 10th out of 12 faults. If participants followed the misdiagnosis provided by the automation for fault 10, they committed a commission error.

Only five out of the 24 participants committed this commission error, and the distribution of these individuals was not affected by training group (experience group = 2; information group = 3). However, the experience group sampled a significantly higher portion of information relevant to the diagnosis than did the information group. Further, individuals who detected the misdiagnosis sampled significantly more relevant system parameters than those who missed it. Thus, training influenced information sampling behaviour, which in turn predicted whether participants detected the automation error. However, a direct effect of training on error detection was not found.

In another study, using the same simulation, the authors focused on the warning function of the automation rather than the diagnosis component (Bahner et al. 2008a). The experimental manipulation was the same such that one group was exposed to automation errors during training whereas the other group was only told about the potential for errors and warned to double check the automation. The automation errors were misses, that is, the automation failed to detect the presence of a system fault.

In the experimental trials, automation missed faults 10 and 13 (out of 14 total faults). At fault 10 the experience group was significantly less likely to make an omission error than the information group (18.2% vs. 80%). By the next opportunity for an omission error on fault 13, there was no longer a significant difference between the groups (18.2% vs. 22.2%). At fault 14, rather than a miss, the automation misdiagnosed the fault. The majority of participants (74%) failed to catch this misdiagnosis, and there was not a clear effect of training. Those who successfully identified the misdiagnosis had sampled a significantly greater portion of the relevant information up to that point. This finding further highlights the importance of actively monitoring the automation and sampling relevant information as it repeatedly predicts the likelihood of detecting automation errors.

The absence of a group effect for the fault 14 misdiagnosis can be traced back to the specific focus of training. Training for the experience group only included exposure to automation misses, not misdiagnoses. The effect of training was constrained to the type of errors experienced in training, and did not result in a system wide increase in monitoring behaviour, which the authors attribute to individuals having high functional specificity (discussed later in the section on trust). We identified an alternative explanation as to why error detection differed between the two subsystems. Specifically, differences in error detection were related to the consequences of the two types of automation errors. Perhaps the diagnosis component was not as carefully monitored because if a misdiagnosis were acted upon, participants would receive notification that the repair did not work and then would simply have to manually repair the fault. Conversely, if a miss went undetected, the system would enter a critical state, a considerably more serious consequence.

Future research needs to address several issues and open questions. The transferability of error management training to various automated components within a system warrants further investigation, as does the duration of training effects on error management. Further, identifying the specific aspects of training that lead to greater information sampling, and thus greater error detection, will allow training programs to capitalize on the effect. Sarter et al. (1997) proposed that training should focus on encouraging active exploration and knowledge seeking behaviours to help develop refined knowledge structures. The role of knowledge in error management is discussed next.

4.2.3 Knowledge

Users of automation must have knowledge about their role and responsibilities in a given task, knowledge about the automation they are working with, and knowledge about the context in which they are working. This knowledge forms a model of the system and is critical to the process of managing automation errors. For example, consider an automated fault management system designed to detect faults such as a broken pipe. In this scenario, an operator will have some level of knowledge regarding the event the automation is designed to detect (broken pipes happen more often in cold weather due to freezing), and knowledge related to the capabilities of the automation (tends to false alarm rather than miss).

Ideally, operators would integrate these pieces of knowledge into a larger understanding of the system that they are a part of, and use this understanding to improve error management. That is, the hypothetical operator would be more wary of an alert from the automation regarding a broken pipe if it occurred in July compared to if it occurred in January. Unfortunately, the complexity of many modern automated systems makes this knowledge increasingly difficult to acquire and apply. Operators often have gaps or misconceptions in their models of a system that can cause severe disruptions in performance. Further, these inaccuracies may be unbeknownst to the human, resulting in operators who are more confident in their abilities than is warranted.

Such a pattern has been documented in an investigation of the effect of mental model quality on task performance while using an automated navigation aid (Wilkison et al. 2007). Participants were given varying levels of exposure (no exposure, low, and high) to a simulated city map to establish a different mental model quality for each of the three groups. Participants then used a decision aid to navigate the simulated city and could accept or reject the aid’s navigation advice. When using a 70% reliable aid, participants who had a low exposure to the city map during training, and presumably had a weak or vague mental model, were significantly more likely than the no or high exposure groups to reject the advice of the decision aid when it was correct, opting instead to choose their own, less optimal route. Training programs designed to quickly teach learners “the basics” might actually be harmful if they lead individuals to believe they know more than they actually do.

Sarter and Woods (1994) used a simulated flight scenario to reveal deficiencies in the mental models of experienced pilots interacting with the Flight Management System, considered a core system of flight deck automation. Over 70% of the pilots showed deficiencies related to seven of the 24 scenario probes. A majority of the deficiencies resulted from a lack of knowledge regarding the functional structure of the system. Sarter and Woods also noted that many of the pilots were not aware they had gaps in their knowledge. Future research should use Sarter and Woods’s approach of documenting knowledge gaps in conjunction with performance measures to determine how these gaps influence error management.

One particular subset of knowledge that might influence error management is whether the user has a causal explanation for the errors committed by the automation. Dzindolet et al. (2001) contended that individuals may judge automation to be less reliable if they do not understand why it makes errors, leading them to distrust and disuse an aid that might actually provide a benefit. Dzindolet et al. (2003) examined this hypothesis by providing one group of participants an explanation for automation errors, whereas the other group did not receive this information. Regression analyses revealed that reliance on the aid was greater among participants who were given an explanation for the automation’s errors. It is important to note, however, that the increased reliance on the aid was not always warranted. The error explanation influenced participants’ behaviour, but did not make them better at managing automation errors.

The relationship between knowledge and error management is not clear, due in part to the scarcity of empirical research examining this topic. Certainly, the complexity of knowledge required in many domains may be daunting. There are many open questions to be answered. For instance, does having the requisite knowledge for a particular task guarantee that an individual will access and use it appropriately when needed? Further, although a wealth of knowledge is gained during training, this knowledge base does not remain static. The “on the job” experiences will also alter knowledge. Therefore, providing useful and accurate feedback to operators may help to further refine knowledge.

4.2.4 Summary of person variables

When individuals interact with an automated system, they bring aspects of themselves to bear on how successfully they manage the automation. These factors include their complacency potential, the training they received, and their knowledge of the system. In comparison to the characteristics of the automation, person characteristics have been under-studied. Moreover, factors relating to trust and knowledge may be particularly critical to the explanation, correction, and integration phases of our error management framework, but have primarily been investigated in relation to error detection.

4.3 Task variables

Humans and automation do not work together in a vacuum; rather, they are engaged in performing a task and are part of a larger system. Characteristics of the task can influence the human’s error management skills.

4.3.1 Consequence of automation error

When an automated system errs, it results in the potential for consequences to occur. These consequences can range from minor to severe, and in many systems (e.g., aviation, nuclear power), severe consequences may include the fatalities of many people as well as significant monetary losses. The literature has generally demonstrated that as consequences become more severe, people adjust their behaviour and manage automation errors more effectively.

In a flight simulation study, the data revealed that if an automation error did not affect flight safety, pilots were less likely to detect it than if it did influence flight safety (Palmer and Degani 1991). In fact, the automation errors that would have resulted in a crash were detected by all of the flight crews. Other studies have also found that the failures most harmful to flight safety had higher detection/correction rates (Mosier et al. 1998, Mosier et al. 2001).

An important fact to note regarding the previously discussed studies is that they all occurred in the aviation domain with trained pilots. As discussed by Mosier et al. (2001), these pilots had received extensive training before taking part in the experiment, and part of their training undoubtedly involved prioritization of tasks during flight, with more critical tasks receiving greater priority. From a review of these studies alone, it is not yet clear whether severity of consequences affects error management generally, beyond trained pilots in an aviation context.

To explore how costs influence error management in an unfamiliar context, Ezer et al. (2008) systematically manipulated the consequence of failing to correct an automation error by implementing a point scheme into her experimental task. A significant effect of consequence of error was found, revealing that as the consequence became more severe (more points lost), participants were less likely to rely on the automation. Unfortunately, Ezer et al. did not disclose the performance data related to cost of error, so it is unclear whether the reduced reliance was associated with improved error management. However, in this task, participants’ counting ability was measured and was roughly equal to the reliability of the automation (approximately 70% correct). Therefore, from a strategic point of view, greater reliance on the automation was an effective strategy because performance would be roughly equivalent but less effort would be expended.

Although research on the consequences of automation error is not extensive, there is general agreement among the findings. As consequences of letting the automation err become more severe, the likelihood that the error is managed increases. Interestingly, many empirical investigations in the human-automation literature have used point schemes or other reward/penalty devices to motivate participants to put forth their best effort in the experimental trials. The focus of those studies was not whether consequences influenced behaviour, but their use suggests researchers generally recognize the effect exists.

4.3.2 Cost of verification

A critical step in managing automation errors is verifying or checking the automation. This verification procedure is often the step that leads a user to detect that an error is present, and/or determine the appropriate course of action for overcoming the error. As discussed by Cohen et al. (1998), verification may include several activities, such as:

… checking the aid’s reasoning, examining the aid’s conclusion against evidence known to the user but not to the aid… or attempting to find (or create) a better alternative. Verification is not usually a once-and-for-all decision. More typically, it is an iterative process…The process should end when the uncertainty is resolved, the priority of the issue decreases, or the cost of delay grows unacceptable. (p. 19)

Ezer et al. (2008) allowed participants to verify an automated suggestion by choosing to view relevant stimuli. They manipulated the cost associated with this verification process such that the cost of verification was either high (loss of one point for every 2 seconds of verifying), or low (no loss of points for verification). Task performance was superior in the low cost of verification condition, relative to the high cost condition.

The current research examining how the cost of verifying automation influences error management is minimal. Future research should investigate the various forms that cost can take, such as time, resources, and performance, to determine if certain costs are more influential than others. It is likely that minimizing verification costs would support error management performance. This is easier said than done, and research is needed to understand how to successfully accomplish this.

4.3.3 Accountability

In human teams, responsibility for successful task completion is often dispersed among all team members. In a human-automation team, the automation cannot be expected to detect its own errors in the same way that humans are capable of detecting when they themselves have erred, so this task must fall to the human. If diffusion of responsibility occurs between a human and an automated system, it may lead the operator to accept automated directives without any form of double-checking (Mosier and Skitka 1996).

Mosier et al. (1998) conducted one of the first endeavours in understanding the role of accountability in the context of human-automation interaction. Pilots were placed in either an accountable or a non-accountable group. Those in the accountable group were informed that their performance would be monitored, collected, and evaluated with respect to how they used the automation, and they would have to justify their performance in a post-simulation interview. Pilots in the non-accountable group were told that performance data could not be collected due to a computer issue, and that their contribution would primarily be subjective responses to a questionnaire. No mention of justification was included.

The likelihood of detecting automation errors did not vary significantly with the accountability manipulation. However, pilots who missed none or only one automation error, when asked to rate their perceptions of accountability, reported a higher sense of being evaluated on their performance and strategies, and reported a stronger need to justify how they interacted with the automation. Although the experimental manipulation of accountability did not affect error management, individuals who reported feeling less accountable were more likely to miss automation errors than those who reported feeling accountable.

In a following investigation, Skitka et al. (2000a) adjusted their experimental manipulation of accountability and examined the effect of general versus specific accountability instructions on performance. Participants were given either non-accountable instructions, or one of four types of accountable instructions. The accountable groups were informed that their goal was to maximize either overall performance, accuracy, response time, or tracking performance.

Forms of accountability had a significant effect on the number of omission and commission errors committed by participants. Omission errors (failing to detect automation misses) occurred less frequently in the accountability groups focused on overall performance, accuracy, and response time. Further, commission errors (failing to detect automation false alarms) occurred less frequently in the accountability groups focused on overall performance and accuracy. An examination of participants’ verification behaviour revealed that the two groups with the best error management performance, those accountable for overall performance and accuracy, verified the automation more than the other three groups.

4.3.4 Summary of task variables

Aspects of the task that the human and automation are engaged in play a role in how well the human manages automation errors. As the cost of failing to correct automation errors increases, the likelihood of detecting those errors also increases. It is important to note that minor consequences are still consequences, and if these types of errors are largely ignored, the sum of their impact may create opportunities for serious accidents. In addition to consequences, the costs (both to performance and operators’ cognitive load) associated with verifying the automation, and the form of accountability imposed on the operator regarding task success influence how likely operators are to detect automation errors.

4.4 Emergent variables

Several of the most widely researched variables in the human-automation literature cannot be ascribed solely to the automation, human, or task. These variables result from the interaction of all three components. For example, individuals’ trust in automation is determined by previous experiences with automation, by the capabilities and design of the current automation, and by the task being worked on. Oftentimes, these emergent variables are examined as outcome variables, but there is evidence that they also predict the extent to which operators will successfully manage automation errors.

4.4.1 Trust in automation

Lee and See (2004) defined trust as “the attitude that an agent will help achieve an individual’s goal in a situation characterized by uncertainty and vulnerability” (p. 51). Generally, individuals’ trust in automation positively relates to their dependence on automation (Muir 1994, Muir and Moray 1996, Parasuraman and Riley 1997, Dzindolet et al. 2003). However, because dependence is not always warranted, as is the case when automation errs, a critical aspect of trust is calibration. Calibration is the match between capabilities of the automation and an individual’s trust in the automation (Lee and See 2004). Dependent upon this match, individuals may have calibrated trust (trust matches automation capabilities), overtrust (trust exceed automation capabilities), or distrust (trust falls short of automation capabilities).