Abstract

Geckos, which are capable of walking on walls and hanging from ceilings with the help of micro-/nano-scale hierarchical fibrils (setae) on their toe pads, have become the main prototype in the design and fabrication of fibrillar dry adhesives. As the unique fibrillar feature of the toe pads of geckos allows them to develop an intimate contact with the substrate the animal is walking on or clinging to, it is expected that the toe setae exchange significant numbers of electric charges with the contacted substrate via the contact electrification (CE) phenomenon. Even so, the possibility of the occurrence of CE and the contribution of the resulting electrostatic interactions to the dry adhesion of geckos have been overlooked for several decades. In this study, by measuring the magnitude of the electric charges, together with the adhesion forces, that gecko foot pads develop in contact with different materials, we have clarified for the first time that CE does contribute effectively to gecko adhesion. More importantly, we have demonstrated that it is the CE-driven electrostatic interactions which dictate the strength of gecko adhesion, and not the van der Waals or capillary forces which are conventionally considered as the main source of gecko adhesion.

Keywords: gecko adhesion, contact electrification, electrostatic interactions, electric double layer

1. Introduction

When any two materials, similar or dissimilar, touch each other, electric charges transfer from one to the other, leading to the formation of a net negative charge on one substrate and a net positive one on the other [1–3]. Development of an electrical double layer (EDL) [4] at the contact interface via this contact electrification (CE) phenomenon [1,2] essentially gives rise to the formation of electrostatic interactions between the charged objects [5,6]. Despite the familiarity and importance, the contribution of CE-driven electrostatic interactions in gecko adhesion—which arises from the intimate contact of the fibrillar feature of the gecko toe pads with the substrate the animal is walking on or clinging to [7,8]—has always been overlooked [7–10]. In this study, we have estimated—for the first time—the amount of electric charges and, therefore, the magnitude of electrostatic forces that gecko toe pads develop upon contact. Experiments were conducted on two distinct substrates: on one such substrate geckos adhere strongly, while on the other they do not. Interestingly, simultaneous measurement of electric charges and adhesion forces revealed that CE-driven electrostatic interactions have a decisive contribution to the dry adhesion of geckos over these materials. Better insight into the role of CE-driven electrostatic interactions in gecko adhesion is not only very important for understanding the principles of the supreme adhesion of geckos [8,11], but also is fundamentally very crucial in the design and fabrication of synthetic fibrillar dry adhesives [12–14], which have been recently hypothesized to be largely affected by CE-generated electrostatic interactions [15–17].

2. Results and discussion

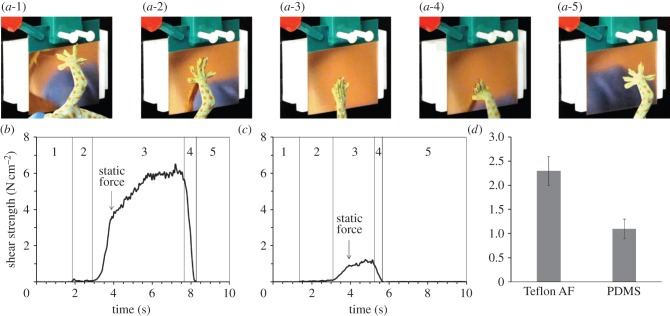

In order to determine the occurrence of CE and the extent of the electrostatic interactions arising from it in gecko adhesion, the magnitude of electric charges—together with the adhesion forces—that build up upon contact of gecko foot pads with two substrates (Teflon AF and polydimethylsiloxane (PDMS)) were measured. Charge and force measurements were performed simultaneously by putting a single foot pad of five live Tokay geckos (Gekko gecko) against a vertically aligned thin film of the polymer, which was coated on a 5 × 5 cm2 ultra-polished (RMS roughness = 13.6 ± 1.6 nm, n = 3), mirror-finished copper sheet. The foot pad was subsequently pulled down the polymer thin film, dragging the toes across the substrate, until the developed shear force on the polymer was saturated. At the end of the course of dragging, the foot pad was pulled upward (perpendicular from the polymer surface), in order to detach the toes from the substrate. The five steps of the adhesion tests are shown in figure 1a, while the characteristic adhesion traces for Teflon AF and PDMS are plotted in figure 1b and c, respectively. The static adhesion strength (i.e. adhesion force per unit pad area) over Teflon AF—which was determined at the point where the toes started to slide—was 2.3 ± 0.3 N cm−2 (n = 10), on average more than twice as large as that of PDMS (1.1 ± 0.2 N cm−2, n = 10) (figure 1d). Following the onset of the sliding on both substrates, however, the shear strength increased. Enhancement of the shear strength during dragging is because of the directionality of the adhesion of gecko toe pads [7,18], considering that they develop a superior contact when the toes get aligned in the direction of dragging (compare figure 1a-2 with a-3). Owing to the familiar stick–slip phenomenon [19,20], on the other hand, the increase of the shear strength throughout the dragging step happened in a fluctuating manner.

Figure 1.

(a-1) An originally neutral gecko foot pad was brought close to a vertically aligned polymer thin film which was coated on an approximately 5 × 5 cm2, mirror-finished, copper sheet. (a-2) The toe pad was placed on the polymer thin film and the surface charge density was measured. (a-3) The foot was pulled down and the toes were dragged over the polymer thin film for a 2–10 mm distance, depending on the type of the polymer. (a-4) Finally, the foot was pulled up—perpendicular from the thin film—until (a-5) the toes completely detached from the substrate. Characteristic changes in the shear strength (i.e. shear force per unit toe pad area) throughout all five steps of the in situ force/charge measurement tests on (b) Teflon AF and (c) PDMS. (d) Static shear strength values determined from force traces recorded during force/charge measurement tests on both Teflon AF and PDMS. (Online version in colour.)

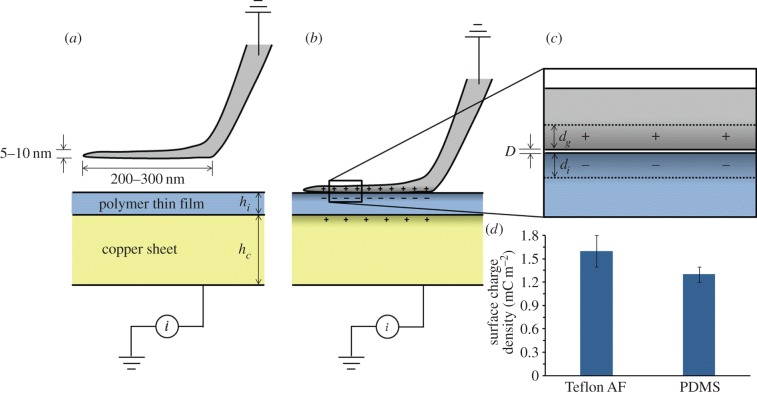

In order to determine the contribution of CE-driven electrostatic interactions in the generated adhesion forces, during the adhesion tests, the magnitude of the electric charges—developed right after contact occurred—was estimated by image charge analysis [4–6]. When an electrically neutral gecko foot pad was brought into contact with the polymer thin film, the toes made contact with the substrate via the nano-scale spatulas (each 200–300 nm wide and 5–10 nm thick) [8,21] at the tip of the keratinous setae [22,23] of each toe on the foot pad (figure 2a). As illustrated in figure 2b and c, the exchange of electric charges between the fibrillar feature of the toe pads and the substrate gave rise to the formation of an EDL at the contact interface. Separation of electric charges at the contact zone induced an image charge, with the density of σimage, in the backing copper sheet. Knowing the magnitude of σimage from the readings of the electrometer connected to the back of the copper sheet, the surface charge density over the polymer (σs), which can practically be considered equal to that on the foot pad [5,6], was determined (see the electronic supplementary material for more details). Charge estimation results revealed that, during almost all contacts, the gecko foot pad became positively charged while the polymer was negatively charged. The absolute values of the surface charge densities immediately after intimate contact with Teflon AF and PDMS were 1.6 ± 0.2 mC m−2 (n = 10) and 1.3 ± 0.1 mC m−2 (n = 10), respectively (figure 2d). In principle, these charge densities (equivalent to approx. 1 elementary charge per 89–134 nm2) are relatively large [2,15], albeit typical for an intimate contact [5,6].

Figure 2.

(a) Before contact of a nano-spatula—at the tip of a seta of a gecko toe pad—with the polymer thin film, both the spatula and the thin film were electrically neutral. (b) As the toe pad came into contact with the polymer thin film, electric charges separated between the nano-spatula and the thin film. The EDL, which was formed at the contact interface, induced certain electric charges in the backing copper sheet, which was grounded through an electrometer. (c) Electric charges that separated upon contact penetrated up to a depth of di and dg into the polymer thin film and the contacted nano-spatula, respectively. D is the actual separation distance (approx. 0.3 nm) [7,21] between the nano-spatula and the thin film. (d) Surface charge densities measured right after contact of gecko toe pads with Teflon AF and PDMS. (Online version in colour.)

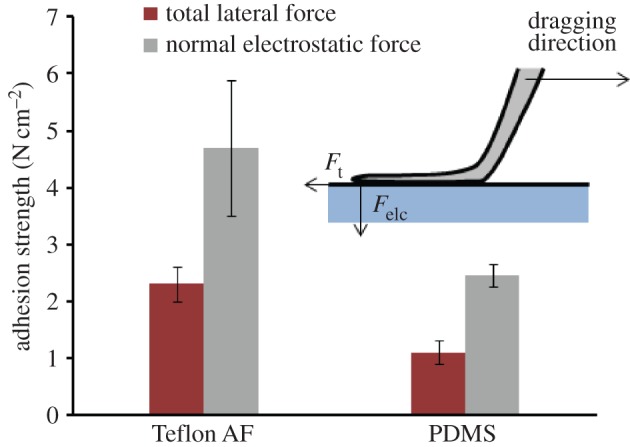

According to the charge estimation results and considering the toe pad–substrate interface as that between two parallel plates, the electrostatic adhesion strengths that gecko foot pads develop with Teflon AF and PDMS—in the normal direction before sliding—are 4.7 ± 1.2 N cm−2 and 2.4 ± 0.4 N cm−2, respectively (see the electronic supplementary material for more details). Interestingly, as illustrated in figure 3, the estimated adhesion strengths are of the same magnitude and also, more or less, of the same proportion (almost, on average, twice larger) as the static lateral shear strengths that were experimentally measured for these substrates.

Figure 3.

Ft, the total lateral adhesion strength (i.e. shear strength), as well Felc, the normal electrostatic adhesion strength (i.e. adhesion force per unit toe pad area), for contact of gecko toe pads with both Teflon AF and PDMS thin films. The schematic shows the contact of a nano-spatula at the tip of a seta of a gecko toe pad with the polymer thin film and the direction of the sliding of the toe pads as well as those of the generated shear and electrostatic forces. Both adhesion strength values were determined right before the initiation of the sliding of the toe pads over the polymer thin films. (Online version in colour.)

Although direct charge measurements clearly demonstrate that the contribution of CE-driven electrostatic interactions in gecko adhesion is dominant, it should be noted that, along with electrostatic forces, van der Waals (vdW) and capillary forces could also contribute to the measured adhesion forces [7,9,24]; vdW interactions naturally exist between two materials in contact [25], whereas capillary interactions become effectual in humid conditions [24,25]. Concerning the latter, however, as all the experiments were carried out at the constant relative humidity of 50 ± 4% (temperature, T = 24 ± 1°C), and as both substrates share an almost similar hydrophobicity (Teflon AF, θ = 108.4 ± 0.6°, n = 6; PDMS, θ = 106.0 ± 0.7°, n = 6), the contribution of capillary interactions in the overall interfacial interactions for both polymers should be essentially identical—while capillary interactions for PDMS could be even slightly more effective [24,26]. With respect to vdW forces, on the other hand, Teflon AF is also expected to generate somewhat smaller vdW forces in comparison with PDMS. In particular, both polymers share a comparable sub-nanometric roughness (Teflon AF, RMS roughness = 0.2 ± 0.2 nm, n = 3; PDMS, RMS roughness = 0.6 ± 0.2 nm, n = 3), and therefore have similar geometry of contact with the gecko foot pad [9,27,28]. Hence, Teflon AF (with a Hamaker constant of 5.1 × 10−20 J) should develop almost 0.8 times smaller vdW forces than PDMS, which has a Hamaker constant of 6.5 × 10−20 J (see the electronic supplementary material for more details). With Teflon AF having a weaker ability than PDMS to generate both vdW and capillary forces, development of the observed enhanced adhesion forces by Teflon AF (figures 1d and 3) again confirms the decisive contribution of CE-driven electrostatic interactions in gecko adhesion.

As illustrated, what makes the difference between geckos sticking strongly to one substrate and not to the other is the extent of the contribution of CE-driven electrostatic interactions for each substrate. Even so, during the last 80 years of research on gecko adhesion, the role of electrostatic interactions in gecko adhesion was always passed over [7–10] by referring to the experiments conducted by Dellit [29], in which adhesion of a gecko (12 g Tarentola mauritanica) was tested against a vertically aligned chromed metal surface. After bombardment with ionized air, supposedly eliminating electrostatic interactions, and observing that the adhesion between the gecko and the metal surface did not change, Dellit concluded that the electrostatic interactions did not contribute to the adhesion of geckos [29]. The control sample used by Dellit was small pieces of paper that were brought to adhere to a glass rod, which was charged by rubbing in advance [29]. In regard to Dellit's experiments, it should be noted that air ionization can only be employed to eliminate electrostatic interactions from non-tight contacts but not those from intimate contacts—like the CE-driven electrostatic interactions of gecko foot pads. Put otherwise, during ionization of air by radioactive materials or X-ray radiation, as employed by Dellit [29], elementary air ions (typically approx. 0.4 nm in size), within a fraction of a second after their creation, attract 8–15 (mostly water) molecules to themselves and form positive and negative molecular clusters, known as ‘air ions’ [30]. As a matter of fact, owing to their relatively massive size, air ions can only be employed to eliminate electric charges from an electrostatic contact—like that of the paper–glass with typical micro-scale roughness—where air ions can reach the contact interface to dissipate surface charges. In the intimate contact of seta-substrate, with an atomic separation distance of approximately 0.3 nm [7,21], however, eliminating CE-generated electrostatic forces by air ionization is not physically practical, simply because air ions cannot penetrate between the contact interface in order to dissipate surface charges.

Supplementary Material

References

- 1.Harper WR. 1967. Contact and frictional electrification. Morgan Hill, CA: Laplacian Press. [Google Scholar]

- 2.Lowell J, Rose-Innes A. 1980. Contact electrification. Adv. Phys. 29, 947–1023. ( 10.1080/00018738000101466) [DOI] [Google Scholar]

- 3.Apodaca MM, Wesson PJ, Bishop KJ, Ratner MA, Grzybowski BA. 2010. Contact electrification between identical materials. Angew. Chem. Int. Ed. 122, 958–961. ( 10.1002/ange.200905281) [DOI] [PubMed] [Google Scholar]

- 4.Ireland PM. 2009. Contact charge accumulation and separation discharge. J. Electrostat. 67, 462–467. ( 10.1016/j.elstat.2009.01.014) [DOI] [Google Scholar]

- 5.Horn RG, Smith DT. 1992. Contact electrification and adhesion between dissimilar materials. Science 256, 362–364. ( 10.1126/science.256.5055.362) [DOI] [PubMed] [Google Scholar]

- 6.Horn RG, Smith DT, Grabbe A. 1993. Contact electrification induced by monolayer modification of a surface and relation to acid–base interactions. Nature 366, 442–443. ( 10.1038/366442a0) [DOI] [Google Scholar]

- 7.Autumn K, Liang YA, Hsieh ST, Zesch W, Chan WP, Kenny TW, Fearing R. 2000. Adhesive force of a single gecko foot-hair. Nature 405, 681–685. ( 10.1038/35015073) [DOI] [PubMed] [Google Scholar]

- 8.Autumn K. 2006. Properties, principles, and parameters of the gecko adhesive system. In Biological adhesives (eds Smith A, Callow J.), pp. 225–256. New York, NY: Springer. [Google Scholar]

- 9.Autumn K, et al. 2002. Evidence for van der Waals adhesion in gecko setae. Proc. Natl Acad. Sci. USA 99, 12 252–12 256. ( 10.1073/pnas.192252799) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Hiller U. 1968. Untersuchungen zum feinbau und zur funktion der haftborsten von reptilien. Z. Morphol. Tiere 62, 307–362. ( 10.1007/BF00401561) [DOI] [Google Scholar]

- 11.Autumn K, Gravish N. 2008. Gecko adhesion: evolutionary nanotechnology. Phil. Trans. R. Soc. A. 366, 1575–1590. ( 10.1098/rsta.2007.2173) [DOI] [PubMed] [Google Scholar]

- 12.Boesel LF, Greiner C, Arzt E, del Campo A. 2010. Gecko-inspired surfaces: a path to strong and reversible dry adhesives. Adv. Mater. 22, 2125–2137. ( 10.1002/adma.200903200) [DOI] [PubMed] [Google Scholar]

- 13.Hu S, Xia Z. 2012. Rational design and nanofabrication of gecko-inspired fibrillar adhesives. Small 8, 2464–2468. ( 10.1002/smll.201200413) [DOI] [PubMed] [Google Scholar]

- 14.Kwak MK, Pang C, Jeong H, Kim H, Yoon H, Jung H, Suh K. 2011. Towards the next level of bioinspired dry adhesives: new designs and applications. Adv. Funct. Mater. 21, 3606–3616. ( 10.1002/adfm.201100982) [DOI] [Google Scholar]

- 15.Izadi H, Penlidis A. 2013. Polymeric bio-inspired dry adhesives: van der Waals or electrostatic interactions? Macromol. React. Eng. 7, 588–608. ( 10.1002/mren.201300146) [DOI] [Google Scholar]

- 16.Izadi H, Golmakani M, Penlidis A. 2013. Enhanced adhesion and friction by electrostatic interactions of double-level Teflon nanopillars. Soft Matter 9, 1985–1996. ( 10.1039/c2sm27329b) [DOI] [Google Scholar]

- 17.Izadi H, Sarikhani K, Penlidis A. 2013. Instabilities of Teflon AF thin films in alumina nanochannels and adhesion of bi-level Teflon AF nanopillars. Nanotechnology 24, 505306 ( 10.1088/0957-4484/24/50/505306) [DOI] [PubMed] [Google Scholar]

- 18.Autumn K, Dittmore A, Santos D, Spenko M, Cutkosky M. 2006. Frictional adhesion: a new angle on gecko attachment. J. Exp. Biol. 209, 3569–3579. ( 10.1242/jeb.02486) [DOI] [PubMed] [Google Scholar]

- 19.Persson B, Popov V. 2000. On the origin of the transition from slip to stick. Solid State Commun. 114, 261–266. ( 10.1016/S0038-1098(00)00045-4) [DOI] [Google Scholar]

- 20.McGuiggan PM. 2008. Stick slip contact mechanics between dissimilar materials: effect of charging and large friction. Langmuir 24, 3970–3976. ( 10.1021/la703882h) [DOI] [PubMed] [Google Scholar]

- 21.Tian Y, Pesika N, Zeng H, Rosenberg K, Zhao B, McGuiggan P, Autumn K, Israelachvili J. 2006. Adhesion and friction in gecko toe attachment and detachment. Proc. Natl Acad. Sci. USA 103, 19 320–19 325. ( 10.1073/pnas.0608841103) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Maderson P. 1964. Keratinized epidermal derivatives as an aid to climbing in gekkonid lizards. Nature 203, 780–781. ( 10.1038/203780a0) [DOI] [Google Scholar]

- 23.Alibardi L. 2009. Cell biology of adhesive setae in gecko lizards. Zoology 112, 403–424. ( 10.1016/j.zool.2009.03.005) [DOI] [PubMed] [Google Scholar]

- 24.Huber G, Mantz H, Spolenak R, Mecke K, Jacobs K, Gorb SN, Arzt E. 2005. Evidence for capillarity contributions to gecko adhesion from single spatula nanomechanical measurements. Proc. Natl Acad. Sci. USA 102, 16 293–16 296. ( 10.1073/pnas.0506328102) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Israelachvili JN. 2011. Intermolecular and surface forces, 3rd edn New York, NY: Academic Press. [Google Scholar]

- 26.Stark AY, Badge I, Wucinich NA, Sullivan TW, Niewiarowski PH, Dhinojwala A. 2013. Surface wettability plays a significant role in gecko adhesion underwater. Proc. Natl Acad. Sci. USA 110, 6340–6345. ( 10.1073/pnas.1219317110) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Huber G, Gorb SN, Hosoda N, Spolenak R, Arzt E. 2007. Influence of surface roughness on gecko adhesion. Acta Biomater. 3, 607–610. ( 10.1016/j.actbio.2007.01.007) [DOI] [PubMed] [Google Scholar]

- 28.Persson B, Gorb S. 2003. The effect of surface roughness on the adhesion of elastic plates with application to biological systems. J. Chem. Phys. 119, 11437 ( 10.1063/1.1621854) [DOI] [Google Scholar]

- 29.Dellit W. 1934. Zur anatomie und physiologie der Geckozehe. Jena Z. Naturw 68, 613–656. [Google Scholar]

- 30.Jonassen N. 2002. Electrostatics. New York, NY: Springer. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.