Abstract

Background:

Previous studies have reported on mechanical properties of different orthodontic wires. However, there is a paucity of information that comparing the mechanical properties of Blue Elgiloy (BE) when compared to stainless steel and TMA, as finishing wires as received by different companies.

Aims:

The aim of this study was to evaluate the mechanical properties of BE wires compared to stainless steel (SS) and titanium Molybdenum alloy (TMA) also known as β titanium as provided by two companies.

Materials and Methods:

Six 0.016 x 0.022-14mm-samples of each wire were fixed individually to Instron machine and were tested in loading and unloading for three times. The initial load was set for 500 Kg at a speed of 1mm/min and displacement was adjusted for (0.5, 1mm in loading and 0.5 mm unloading at 25°C).

Statistics Analysis:

Variables were compared between groups by ANOVA test using SPSS statistical software.

Results:

BE shows comparable forces to SS when loaded 0.5 and showed decreased forces in 1mm loading compared to SS, and higher than TMA. BE also showed no forces at unloading and high deformation.

Conclusion:

BE from the two companies showed comparable mechanical properties while SS and TMA were different. The deformation of BE and its decreased forces in unloading may limit its clinical use.

Keywords: Blue Elgiloy, mechanical properties, titanium-molybdenum alloy, stainless steel, orthodontic wire

INTRODUCTION

The development in the material science has helped introduction of many alloys to fabricate improved orthodontic wires for better clinical performance.[1,2] Many alloys have been used routinely in orthodontics, and these alloys are classified into four types, namely stainless steel (SS); cobalt-chromium nickel alloy (Elgiloy); titanium-molybdenum alloy (TMA) and nickel-titanium alloy.[3,4,5] SS alloy has been used in orthodontic treatment since 1950, due to its good formability, low cost, and its acceptable clinical performances.[5,6] Cobalt-chromium nickel alloy has been developed since 1950 and called (Elgiloy) that was initially manufactured by the Company (Elgin, USA). Elgiloy has different forms: Blue (soft), yellow (elastic), green (half elastic) and red (flexible). The blue type is the most commonly used by orthodontists because of its formability and the possibility to increase its durability by heat treatment.[5,6] TMA was first introduced by Ormco Company (Ormco, West Collins, USA) and since then is known as TMA wire. It has been used since late eighties to apply less force compared with SS and cobalt chromium alloys.[7,8,9] Nickel-titanium alloy has been used by at the beginning of the nineteen-seventies and it involve using Nitinol alloy that was produced by (3M Unitek, California, USA) refers “Nitinol” to the family of nickel alloys and have had special characteristics in terms of shape memory and high flexibility.[5,6,10,11,12,13]

According to the American Dental Association and Standard No. 32 from the American National Standards Institute, three point bending test is an appropriate mechanical testing of beams, like orthodontic wires, inactivation (loading) and deactivation (unloading).[14] Another study tested three alloys (stainless, beta-titanium and TiMolium) and they used three point bending test to evaluate load deflection rate.[1] They reported that the stainless alloy was the strongest among the tested wires. In contrast, TMA showed the least stiffness, while TiMolium alloy showed intermediate values between stainless and TMA alloys. Three alloys (nickel titanium, beta-titanium and TiMolium) have been tested using three point bending test, and it was reported that there are variations of storage modulus, as measured with the temperature change, between alloys. The lowest value was for the nickel-titanium alloy then beta titanium alloy then SS alloy.[15] In another study, the mechanical properties of three alloys (SS, TMA, new generation titanium Molbydiom called CNA “Connecticut new archwire”) were compared using three point bending test.[16] This study concluded that the SS are the hardest alloy, followed by TMA alloy then CNA alloy. The CNA alloy showed the highest flexibility among the alloys. From the available literature, it can be seen that three-point testing is an acceptable test for mechanical properties of orthodontic wires.

It seems from the current literature that the study of the mechanical properties of these alloys used in orthodontics is necessary for optimum clinical utilization. Normally, the components of these alloys are not available from the manufacturers mainly because of trade secrets. The possible difference in alloy structure between companies can change their mechanical properties and consequently their clinical performances. However, there is a paucity of information that comparing the mechanical properties of Blue Elgiloy (BE) when compared with SS and TMA, as finishing wires as received by different companies. It is worthwhile studying the mechanical properties of these materials produced by different companies to facilitate decision making in choosing the appropriate type of the alloy for specific treatment/application. Therefore, the objectives of this study were to evaluate the mechanical properties of three orthodontic alloys, namely SS, TMA and BE that are produced by two companies that produce the wires using three-point bending test in order to help clinicians with decision making when considering choosing any of these wires companies in clinical orthodontics.

MATERIALS AND METHODS

Mechanical properties have been studied of three orthodontic alloys for two companies (company 1 [Rocky Mountain Orthodontics, Denver, CO, USA] and company 2 [Dentaurum, Pforzheim, Germany]). The tested wires were SS, TMA and BE, and all have diameter of 0.016″ × 0.022″. The sample size was calculated to be six samples per group based on sample size calculation method using the standard error and the level of confidence (95%) and the amount of allowable error (1% based on the standard error reported by several previous studies).[6,7,8] The experiment was performed using Universal Testing Machine (Instron, model no. 350 M, Testometric, England) Figure 1a.

Figure 1.

(a) Instron machine set up used in this experiment, (b) Specially designed fixture. Two brackets were soldered and the length of each wire was fixed at 14 mm to simulate the clinical inter-bracket distance

In addition, components of each wire were performed using High Speed Micro ED X-ray Spectrometer (Bruker AXS GmbH Oestliche, Rheinbrueckenstr. 49 76187 Karlsruhe, Germany) Table 1.

Table 1.

Chemical composition of the used wires as evaluated by XRF

A full-scale load of 5 kN with sensitivity of 0.01 N was used at a speed of 1 mm/min. A specially designed fixture [Figure 1b] was used (where two brackets were soldered to the fixture, and the length of each wire is spanning the two brackets was fixed at 14 mm to simulate the average clinical inter-bracket distance).

The wires were fixed on the brackets with using 0.012-inch elastomeric ligatures to simulate the routine clinical use of these wires.

The specimens from each group were evaluated at 25°C in 0.5 mm and 1 mm loading, and unloading 0.5 mm (from the 1 mm loading) then back to original position (zero position). Each test was repeated 3 times in using the same wire (A, B, C) to evaluate mechanical performance in unloading and possible wire deformation.

Statistical Analysis

Measured variables were forces as measured by the Instrone machine in loading and unloading. All the variables were calculated and compared between groups by ANOVA test using SPSS (version 17, SPSS, Chicago, IL, USA).

RESULTS

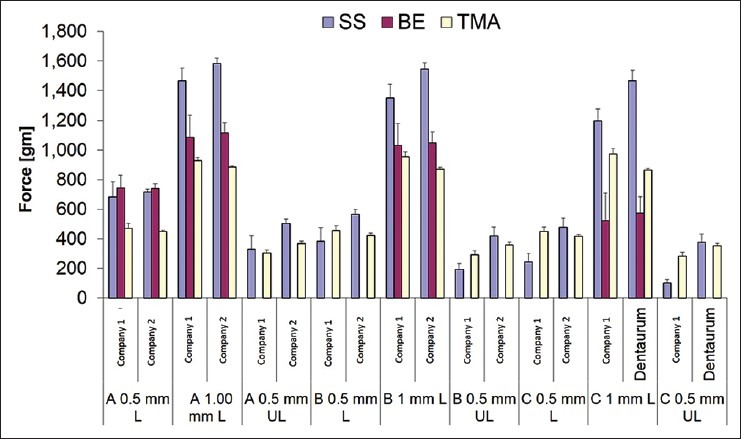

Comparisons of three-point bending forces in loading and unloading in the three deflections, A, B and C between alloys from the two companies are outlined in Tables 1, 2 and Figure 2. Company 1 SS wires showed lower forces than company 2 SS wires in loading while showing higher forces in unloading tests. Furthermore, company 1 SS wires deformed more than company 2 SS wires, especially after second (B deflection) or third (C deflection) tests [Figure 2]. There was no significant difference between the force levels when testing BE wires of the two companies both in loading and unloading [Figure 3]. However, company 2 BE wires showed high deformation after third test compared with company 1 BE wires [Figure 2]. Also, there was no statistical significant difference of the force levels in loading TMA wires between the two companies in bending 0.5 mm (loading). In contrast, there was statistically significant differences in force levels of TMA wires in the rest of the tests both loading and unloading [Tables 2 and 3]. With regard to wire deformation of BE and TMA, there was no significant difference between the wires of the two companies in the second deflection, while company 2 TMA showed more deformation than company 1 TMA wires [Figure 2].

Table 2.

Comparison of the mechanical properties of different wires between company 1 and company 2 for all alloys in A: First time test; B: Second retesting; C: Third retesting; B deflection: Refers to the amount of deformation of the wire (mm) after the retesting for the second time

Figure 2.

Comparison deformation of the 0.016" × 0.022" wires alloys between the two companies after second (B deflection) and third (C deflection)

Figure 3.

Comparison of force levels in loading and unloading for 0.016” × 0.022” wires alloys between the two companies

Table 3.

Differences between alloys for company 1 wires, diameter 0.016”×0.022” with ANOVA test

DISCUSSION

The wide variety of available orthodontic wires by different companies may have some misperception about which wires would be the best choice for different clinical situations. Thus, understanding the possible mechanical properties of similar wires provided by different companies may help the clinicians in their decision making about which wire would be optimum for their clinical use. Although BE wires were introduced to orthodontics long time ago, evaluation of their mechanical testing, especially comparing those of different companies is not available in the literature.

The decreased force levels in loading and unloading by TMA wires of both companies than SS wires in our study [Table 4] is in agreement with previous studies.[1,2,6,7,8,15,16] The decreased force levels of TMA wires in loading and unloading for both companies than SS wires is in agreement with previous studies [Figure 2]. This is consistent with other studies[2,16] that confirmed the high stiffness for SS alloy and high resilience for TMA alloy. However, those two studies did not test BE alloy. The increased deformation of company 2 TMA than company 1 TMA wires after third loading/unloading suggests that company 2 wires can be only bent once for an adjustment while company 1 TMA wires may provide more than one bending without severe deformation. This difference in mechanical properties between different wires and companies also could be due to the difference in chemical composition [Table 1]. Furthermore, the decreased deformation of company 1 BE after the third loading/unloading may indicate that its shape memory is better than company 2 BE wire that shows more formability than company 1 BE wires [Figures 2 and 3]. It is to be noted that all the tested BE wires were not heat treated, with heat treatment these values may be different. This may warrant future studies to evaluate the behavior of these wires after heat treatment. The clinical relevance of the decreased force levels of BE in unloading may be important clinically in that BE might be a preferred wire selection for clinicians who prefer lighter forces. However, the almost zero force level in unloading may question its clinical efficacy in delivering any forces for orthodontic tooth movement.

Table 4.

Differences between alloys for company 2 wires, diameter 0.016”×0.022” with ANOVA test

The present study showed some differences in forces in loading and unloading that may be clinically considered when choosing special wire dimension/alloy from different companies. A possible compensation for the differences in wires forces in loading and unloading could be achieved by changing wire dimension, however this warrant further investigation. BE in its as received state, although is still been used by many clinicians in finishing the stage, its deformation and decreased forces in unloading may limit its use to perform special types of tooth movement. Future research may be conducted to test BE mechanical properties after heat treatment.

CONCLUSIONS/IMPLICATIONS

BE without heat treatment shows comparable forces to SS when loaded 0.5 and showed decreased forces in 1 mm loading over the three tests compared to SS, and higher than TMA in the first two 1 mm loading experiments. However in the third 1 mm loading, BE showed lowest forces

TMA alloy showed the lowest forces in loading and unloading and the least deformation compared to BE or SS alloys

There were insignificant differences in loading and unloading forces between SS and BE alloys

After repeating the tests, wire deformation was the highest for BE then SS then TMA alloy

SS and TMA wires showed differences in forces to deformation and resilience between companies. However, there were no differences in BE mechanical properties between companies

Increased deformation of BE after loading may limit its clinical use.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

REFERENCES

- 1.Krishnan V, Kumar KJ. Mechanical properties and surface characteristics of three archwire alloys. Angle Orthod. 2004;74:825–31. doi: 10.1043/0003-3219(2004)074<0825:MPASCO>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 2.Verstrynge A, Van Humbeeck J, Willems G. In-vitro evaluation of the material characteristics of stainless steel and beta-titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 2006;130:460–70. doi: 10.1016/j.ajodo.2004.12.030. [DOI] [PubMed] [Google Scholar]

- 3.Kapila S, Sachdeva R. Mechanical properties and clinical applications of orthodontic wires. Am J Orthod Dentofacial Orthop. 1989;96:100–9. doi: 10.1016/0889-5406(89)90251-5. [DOI] [PubMed] [Google Scholar]

- 4.Kusy RP. A review of contemporary archwires: Their properties and characteristics. Angle Orthod. 1997;67:197–207. doi: 10.1043/0003-3219(1997)067<0197:AROCAT>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 5.Brantley WA. Structures and properties of orthodontics material. In: Brantley WA, Eliades T, editors. Orthodontics Material. Stutgart NY: Thieme; 2001. pp. 1–25. [Google Scholar]

- 6.Kusy RP, Mims L, Whitley JQ. Mechanical characteristics of various tempers of as-received cobalt-chromium archwires. Am J Orthod Dentofacial Orthop. 2001;119:274–91. doi: 10.1067/mod.2001.111554. [DOI] [PubMed] [Google Scholar]

- 7.Burstone CJ. Welding of TMA wire. Clinical applications. J Clin Orthod. 1987;21:609–15. [PubMed] [Google Scholar]

- 8.Nelson KR, Burstone CJ, Goldberg AJ. Optimal welding of beta titanium orthodontic wires. Am J Orthod Dentofacial Orthop. 1987;92:213–9. doi: 10.1016/0889-5406(87)90414-8. [DOI] [PubMed] [Google Scholar]

- 9.Vijayalakshmi RD, Nagachandran KS, Kummi P, Jayakumar P. A comparative evaluation of metallurgical properties of stainless steel and TMA archwires with timolium and titanium niobium archwires - an in vitro study. Indian J Dent Res. 2009;20:448–52. doi: 10.4103/0970-9290.59450. [DOI] [PubMed] [Google Scholar]

- 10.Proffit WR, Fields HW. Mechanical principles in orthodontic force control. In: Rudolph P, editor. Contemporary Orthodontics. 4th ed. St. Louis, USA: Mosby; 2007. p. 361. [Google Scholar]

- 11.Segal N, Hell J, Berzins DW. Influence of stress and phase on corrosion of a superelastic nickel-titanium orthodontic wire. Am J Orthod Dentofacial Orthop. 2009;135:764–70. doi: 10.1016/j.ajodo.2007.04.042. [DOI] [PubMed] [Google Scholar]

- 12.Liaw YC, Su YY, Lai YL, Lee SY. Stiffness and frictional resistance of a superelastic nickel-titanium orthodontic wire with low-stress hysteresis. Am J Orthod Dentofacial Orthop. 2007;131:578.e12–8. doi: 10.1016/j.ajodo.2006.08.015. [DOI] [PubMed] [Google Scholar]

- 13.Graber T, Burstone C. Application of Bioengineering to Clinical Orthodontics. 3rd ed. St. Louis, USA: Mosby; 2000. p. 259. [Google Scholar]

- 14.NSI/ADA, Council on Dental Material and Devices. Specification (1977) No. 32 for Orthodontics Wires [Google Scholar]

- 15.Kusy RP, Whitley JQ. Thermal and mechanical characteristics of stainless steel, titanium-molybdenum, and nickel-titanium archwires. Am J Orthod Dentofacial Orthop. 2007;131:229–37. doi: 10.1016/j.ajodo.2005.05.054. [DOI] [PubMed] [Google Scholar]

- 16.Juvvadi SR, Kailasam V, Padmanabhan S, Chitharanjan AB. Physical, mechanical, and flexural properties of 3 orthodontic wires: An in-vitro study. Am J Orthod Dentofacial Orthop. 2010;138:623–30. doi: 10.1016/j.ajodo.2009.01.032. [DOI] [PubMed] [Google Scholar]