Abstract

Clostridium botulinum subtype A4 neurotoxin (BoNT/A4) is naturally expressed in the dual-toxin-producing C. botulinum strain 657Ba at 100× lower titers than BoNT/B. In this study, we describe purification of recombinant BoNT/A4 (rBoNT/A4) expressed in a nonsporulating and nontoxigenic C. botulinum expression host strain. The rBoNT/A4 copurified with nontoxic toxin complex components provided in trans by the expression host and was proteolytically cleaved to the active dichain form. Activity of the recombinant BoNT/A4 in mice and in human neuronal cells was about 1,000-fold lower than that of BoNT/A1, and the recombinant BoNT/A4 was effectively neutralized by botulism heptavalent antitoxin. A previous report using recombinant truncated BoNT/A4 light chain (LC) expressed in Escherichia coli has indicated reduced stability and activity of BoNT/A4 LC compared to BoNT/A1 LC, which was surmounted by introduction of a single-amino-acid substitution, I264R. In order to determine whether this mutation would also affect the holotoxin activity of BoNT/A4, a recombinant full-length BoNT/A4 carrying this mutation as well as a second mutation predicted to increase solubility (L260F) was produced in the clostridial expression system. Comparative analyses of the in vitro, cellular, and in vivo activities of rBoNT/A4 and rBoNT/A4-L260F I264R showed 1,000-fold-lower activity than BoNT/A1 in both the mutated and nonmutated BoNT/A4. This indicates that these mutations do not alter the activity of BoNT/A4 holotoxin. In summary, a recombinant BoNT from a dual-toxin-producing strain was expressed and purified in an endogenous clostridial expression system, allowing analysis of this toxin.

INTRODUCTION

Botulinum neurotoxins (BoNTs) are the most poisonous substances known and are produced by certain species of Clostridium (1). There are seven serologically different BoNT serotypes identified, designated A through G (2), and recently the possible existence of a novel 8th serotype, “H,” was described (3, 4). In the past decade, numerous subtypes have also been identified within the serotypes that differ in amino acid sequence by at least 0.9% to as much as 36% (2, 5–7). While these sequence variations have been shown to result in some differences in antibody binding and neutralization (6–8), little is known about the characteristics of BoNT subtypes in vitro and in vivo as only certain of the A subtype neurotoxins have been purified to the 150-kDa neurotoxin form.

BoNTs cause a severe neuroparalytic illness in humans and animals known as botulism, and due to their extraordinary potency and the serious and long-lasting symptoms of botulism, there is concern for their potential deleterious use as bioterrorism agents (9, 10). Despite their extreme toxicity and being a cause of human disease, BoNTs have been widely used as pharmacological agents for treatment of various human neurological disorders (11). Currently, only BoNT/A1 and -B1 isotypes are licensed as pharmaceuticals. With the medical uses of BoNTs expanding and the recognition that botulinum neurotoxins are extremely useful to treat disorders unrelated to musculoskeletal spasticity, such as pain and inflammation (11), it is important to study the distinct characteristics of BoNT subtypes for new drug development. Our laboratory previously reported that BoNT/A2, -A3, -A4, and -A5 subtypes have different properties than the prototype BoNT/A1, including the elicitation of distinctive symptoms in mice (12–16). However, definitive studies of many BoNT subtypes are hindered by the lack of availability of most purified BoNT subtypes other than the primary BoNT for each serotype.

Clostridial strains producing the same serotype or subtype toxin often produce different quantities of BoNTs due to variation in metabolism, nutrient requirements, fermentation conditions, genetic regulation and genomic features (17–20). The quantities of BoNTs detected in Clostridium botulinum strains producing proteolytic type A and B BoNTs, including dual-toxin-producing strains (such as Ab, Ba, Af, and Bf), can vary from 101 to 4 × 106 mouse lethal doses (MLD) per ml of culture (1, 15, 21–25). In the case of BoNT/A4, attempts to isolate the toxin from the native C. botulinum strain 657Ba have been unsuccessful, as this strain is a dual-toxin-producing strain and produces predominantly BoNT/B. In fact, BoNT/A4 toxin production has never been detected directly in this strain, while BoNT neutralization studies with mice have indicated the ratio of BoNT/B to BoNT/A4 antigenic fractions to be at least 10:1 to 100:1 (26). To enable the production of sufficient BoNT/A4 for characterization in vitro and in vivo, expression of recombinant BoNT/A4 (rBoNT/A4) was required. Currently, expression of full-length BoNTs and BoNT peptide fragments and domains in heterologous hosts has been achieved in Escherichia coli (27–29), Pichia pastoris (30), and baculovirus systems (31). BoNTs expressed in these heterologous systems are not processed as in clostridia and require additional in vitro activation steps following purification. Since the natural processing system is not used, these systems could lead to artifacts in subsequent in vitro and in vivo systems. While a few laboratories have been successful in producing BoNTs and their complexes that are proteolytically activated in these systems, the resulting recombinant toxins have not been compared directly to BoNTs produced under native conditions or in an endogenous expression host to the best of our knowledge.

Here, we describe expression and purification of recombinant BoNT/A4 in its endogenous host, Clostridium botulinum. For this purpose, an expression system was created based on a nonsporulating C. botulinum type A strain with the toxin gene inactivated. In this strain, the genes encoding the nontoxic complex proteins remained intact and were expressed, and all natural posttranslational events, such as proteolytic activation and assembly of the BoNT complex, can occur. Previous reports using recombinant truncated BoNT/A4 light chain (LC) produced in E. coli have indicated that the catalytic activity of BoNT/A4 LC was over 100-fold lower than that of BoNT/A1 LC and that this decrease in activity was almost entirely eliminated by introducing a single-amino-acid mutation (I264R) into the A4 light chain (32). A second amino acid mutation, L260F, was also predicted by modeling to improve solubility in this study, but it did not affect the LC activity in in vitro assays. Since the amino acid difference between A1, A4, and A4-I264R light chains did not result in any structural differences, it was suggested that the decreased catalytic activity of A4 compared to those of A1 and A4-I264R is not due solely to improper protein folding but may have a direct effect on catalysis. Here we show that a full-length recombinant BoNT/A4 containing the L260F and I264R mutations (rBoNT/A4-L260F I264R) and produced in the Clostridium expression host had similar in vivo activity, in vitro catalytic activity, and activity in human neurons.

MATERIALS AND METHODS

Biosafety and biosecurity.

Our laboratory and personnel are registered with the CDC Select Agent Program for research involving botulinum neurotoxins and botulinum neurotoxin-producing strains of clostridia. The research program, procedures, occupational health plan, documentation, security, and facilities are closely monitored by the University of Wisconsin—Madison Biosecurity Task Force, University of Wisconsin—Madison Office of Biological Safety, the University of Wisconsin Select Agent Program, and at regular intervals by the CDC and the Animal and Plant Health Inspection Service (APHIS) as part of the University of Wisconsin—Madison Select Agent Program. All personnel have undergone suitability assessments and completed rigorous and continuing biosafety training, including biosafety level 3 (BSL3) and select agent practices before participating in laboratory studies involving botulinum neurotoxins and neurotoxigenic C. botulinum strains. All recombinant DNA protocols for the construction of the recombinant BoNT genes and their expression in C. botulinum strains have been approved by the University of Wisconsin Institutional Biosafety Committee (IBC), and specific experiments were approved by the Division of Select Agents and Toxins at the CDC. A dual use research of concern (DURC) risk mitigation plan has been established and approved by the University of Wisconsin—Madison Select Agent Program and NIAID for these experiments. Preparation of the recombinant BoNT/A4 gene constructs was performed under biosafety level 2, while experiments involving transfer of gene expression vectors into the C. botulinum expression host strain and purification of the recombinant BoNT/A4 were performed in a biosafety level 3 (BSL3) facility, as described in the CDC/NIH documents and in accordance with Select Agent regulations.

Bacterial strains and growth conditions.

C. botulinum strains Hall A-hyper and 657Ba were obtained from our laboratory culture collection (Department of Bacteriology, University of Wisconsin—Madison). During 29 years of working with C. botulinum strain Hall A-hyper, we have never observed spores in this strain. C. botulinum cultures were grown in TYG medium (3% Bacto tryptone, 2% yeast extract, 0.1% sodium thioglycolate [pH 7.3]) for isolation of transconjugant strains; in TPGY medium (5% Trypticase, peptone, 0.5% Bacto peptone, 0.4% glucose, 2% yeast, extract, 0.1% l-cysteine [pH 7.4]) for strain characterization and maintenance, or in type A toxin production medium (TPM: 2% casein hydrolysate [NZ Case TT], 1% yeast extract, 0.5% glucose [pH 7.2]) for expression of the recombinant toxins. E. coli strain DH10B (Life Technologies, Carlsbad, CA) was used for the cloning and maintenance of the recombinant gene constructs. E. coli strain XL-10 Gold (Stratagene, La Jolla, CA) was used for transformation of mutated gene constructs after QuikChange reactions. E. coli strain CA434 (provided by Nigel Minton, University of Nottingham, United Kingdom) served as a donor for conjugal transfer of the recombinant gene expression constructs from E. coli into C. botulinum. Antibiotics were used at the following concentrations: in C. botulinum, cycloserine at 250 μg/ml, thiamphenicol at 15 μg/ml, and erythromycin at 20 μg/ml; in E. coli, ampicillin at 100 μg/ml and chloramphenicol at 25 μg/ml in agar plates and 12.5 μg/ml in broth. NZ Case TT was from Kerry Bio-Science (Beloit, WI); all other bacterial medium components and chemicals were purchased from Becton Dickinson Microbiology Systems (Sparks, MD) and Sigma-Aldrich (St. Louis, MO). Clostridial cultures were maintained under anaerobic conditions, and all bacterial manipulations were performed inside an anaerobic chamber (model 1025; Forma Anaerobic System, Marietta, OH), with an initial gas mixture comprised of 80% N2, 10% CO2, and 10% H2. The chamber's vacuum pump was equipped with an exhaust filter (Balston model CV-0118-30; Parker Hannifin Corp., Haverhill, MA) to prevent release of clostridial spores into the laboratory.

Construction of C. botulinum expression hosts.

Due to biosafety concerns, a nonsporulating C. botulinum expression host strain (Hall A-hyper) was chosen. The botulinum neurotoxin gene in this strain was inactivated using a ClosTron mutagenesis system (33, 34) as previously described (35). The resulting nontoxigenic C. botulinum strain Hall A-hyper/tox− was characterized by PCR and pulsed-field gel electrophoresis (PFGE) or Southern hybridizations to confirm insertion of the intron within the bont/A locus and by Western blotting and mouse bioassay (36) to confirm the absence of any toxin production.

Generation of recombinant BoNT/A4 and BoNT/A4-L260F I264R expression constructs.

bont/A4 (CLJ_0004; GenBank accession no. CP001081) and bont/A4 with a C-terminal six-histidine (His6) tag were amplified by PCR using total genomic DNA isolated from C. botulinum strain 657Ba as a template. After verification of the sequence, both genes were inserted into modular clostridial expression vectors pMTL82152 and pMTL83152 (see reference 37 for GenBank accession numbers). For the L260F I264R mutant, the mutations of Leu260 to Phe (TCT to CTT) and Ile264 to Arg (ATA to AGA) were engineered into the light-chain region of the rBoNT/A4 gene using a QuikChange II XL site-directed mutagenesis kit according to the manufacturer's instructions (Stratagene, La Jolla, CA). The nucleotide sequence of the mutated BoNT genes was verified by DNA sequencing.

Evaluation of rBoNT/A4 expression.

The BoNT/A4 and BoNT/A4-His expression constructs as well as modular vectors without a recombinant toxin gene were transferred into C. botulinum expression host strain Hall A-hyper/tox− by conjugation from E. coli donor strain CA434 as previously described (35).

Three randomly selected C. botulinum clones from each recombinant expression construct were inoculated into 10 ml of TPGY broth supplemented with 15 μg/ml thiamphenicol and grown overnight at 37°C. The cultures were then diluted 1:100 in TPM supplemented with 15 μg/ml thiamphenicol, and the tubes were incubated at 37°C. Aliquots of 450 μl were removed from the culture tubes at 24, 48, 72, 96, and 120 h and mixed with 150 μl of 4× NuPAGE SDS sample buffer (Life Technologies, Carlsbad, CA), and the samples were heated for 5 min at 95°C and then stored at −80°C until analysis. Protein samples were reduced with β-mercaptoethanol (Bio-Rad, Hercules, CA), and 30 μl of the reduced and nonreduced protein samples from each culture was separated by SDS-PAGE using 4 to 12% Bis-Tris NuPAGE Novex gels in MOPS (morpholinepropanesulfonic acid) running buffer (Life Technologies, Carlsbad, CA). Reduced and nonreduced samples of purified subtype A1 botulinum neurotoxin were used as controls. For total protein staining, gels were stained with Coomassie blue. For Western blots, gels were transferred to polyvinylidene difluoride (PVDF) membranes (Millipore Corp., Bedford, MA) by semidry transfer using standard procedures, and BoNT was detected with a polyclonal affinity-purified rabbit IgG specific for the subtype A1 botulinum neurotoxin prepared in our laboratory (38). Membranes containing recombinant toxin samples with a His tag were also incubated with a monoclonal anti-His antibody (Covance, Dedham, MA). The botulinum neurotoxins and rBoNT/A4-His were detected using bovine anti-rabbit and goat anti-mouse secondary antibodies (both from Santa Cruz Biotechnology, Dallas, TX), respectively, and the chemiluminescent Western Breeze kit (Life Technologies, Carlsbad, CA).

Purification of rBoNT/A4.

The recombinant BoNT/A4 and rBoNT/A4-L260F I264R were purified by a method similar to the purification procedure commonly used for BoNT/A1 (21), as detailed below. Freshly prepared TPM (1.75 liters in a 2-liter bottle) supplemented with 15 μg/ml thiamphenicol was inoculated with 1.75 ml of actively growing culture of Hall A-hyper/tox− containing rBoNT/A4 or BoNT/A4-His expression vector (∼16 h). Culture bottles were incubated statically for 120 h at 37°C inside the anaerobic chamber. Then the cultures were chilled for 1 h in an ice-water bath, followed by lowering the pH of the cultures to 3.5 by slow addition of 3 N H2SO4. The formed precipitate was collected by centrifugation at 3,600 × g for 30 min at room temperature in a tabletop Sorvall Legend RT+ centrifuge (Thermo Scientific, Inc., Pittsburgh, PA). The pellet was washed once with distilled water, and the precipitate was collected by centrifugation as described above. The toxin was extracted from the pellet 2 times by suspension in 0.1 M sodium citrate buffer (pH 5.5) with gentle stirring for 2 h at ambient temperature followed by centrifugation (39). The proteins from both extraction steps were precipitated by gradually adding solid ammonium sulfate to 60% saturation (39 g/100 ml), and the suspension was stored at 4°C.

For purification of rBoNT/A4-His and BoNT/A4-L260F I264R-His, the ammonium sulfate precipitates from both extractions were collected by centrifugation as described above, and the pellet was resuspended in 15 ml of a mixture of 20 mM Tris-HCl (pH 7.9), 0.5 M NaCl, and 5 mM imidazole. The rBoNT/A4-His and BoNT/A4-L260F I264R-His toxin complex was isolated from the protein extract using chromatography on Ni-nitrilotriacetic acid (NTA) resin (Ni-NTA agarose, 5-ml bed volume [Qiagen, Valencia, CA]) following the manufacturer's instructions. The bound proteins were eluted with 10 ml of 20 mM Tris-HCl (pH 7.9), 0.5 M NaCl, and 0.25 M imidazole. For all purifications, chromatography fractions were monitored at an optical density at 278 nm (OD278) and analyzed by SDS-PAGE.

For purification of the rBoNT/A4 lacking the His tag, the ammonium sulfate precipitates from the first and second extractions were collected by centrifugation and resuspended in 5 ml of 50 mM Na citrate buffer (pH 5.5). The suspension was dialyzed for 4 h at room temperature with 3 dialysis changes at 1-h intervals. The dialyzed solution was centrifuged to remove insoluble material, and the supernatant was filtered sequentially through 0.45- and 0.2-μm filters and then loaded onto a 270-ml (2.5-cm by 55-cm) DEAE-Sephadex A-50 column equilibrated with 50 mM Na citrate buffer (pH 5.5) at ambient temperature. The column was washed with 50 mM Na citrate buffer (pH 5.5), and fractions were monitored at OD278 and analyzed by SDS-PAGE. The fractions of the first peak containing the rBoNT/A4 complex were pooled and precipitated with solid ammonium sulfate (39 g/100 ml) and stored at 4°C. The precipitated toxin complex from the DEAE-Sephadex chromatography was collected by centrifugation, resuspended in 10 mM sodium phosphate buffer (pH 7.9), and dialyzed at ambient temperature. The dialyzed solution was loaded on a fast protein liquid chromatography (FPLC) Mono-Q HR 5/5 column (GE Healthcare Life Sciences, Piscataway, NJ) (0.5 ml/min), and a linear NaCl gradient from 0 to 0.35 M was applied to elute the toxin and nontoxin complex proteins. The fractions were monitored at OD278 and analyzed by SDS-PAGE. rBoNT/A4 was recovered in the first peak at ∼130 mM NaCl. The fraction containing the rA4 toxin was concentrated with an Amicon Ultracel YM-30 microconcentrator (Millipore Corp., Bedford, MA) and stored in 10 mM phosphate (pH 7.9), 65 mM NaCl, and 40% glycerol at −20°C. The purity of the toxin was determined by densitometry on a Coomassie blue-stained 4 to 12% SDS-PAGE gel.

Mouse bioassay.

A mouse bioassay was used to detect the presence of active botulinum neurotoxin in C. botulinum cultures and for determination of specific toxicity of purified rBoNT/A4 (36, 40). For toxin detection in C. botulinum cultures, 96-h cultures were centrifuged at 12,000 × g for 10 min to remove cellular debris, and 0.5-ml aliquots of culture supernatants were administered by intraperitoneal (i.p.) injection into two mice per sample. Following injection, animals were observed for signs of botulism. The specific toxicity of the purified 150-kDa rBoNT/A4 and rBoNT/A4 L260F I264R was determined by i.p. injection of the following five toxin amounts in 0.5 ml GelPhos buffer (30 mM sodium phosphate, 0.2% gelatin [pH 6.4]) into groups of four mice (n = 4): 100, 50, 25, 12.5, 6.25, or 3.125 ng/mouse. The injected mice were observed for up to 4 days, and the 50% lethal dose (LD50)/mg of toxin was calculated by the method of Reed and Muench (41).

In vitro BoNT activity assay.

The in vitro enzymatic activity of rBoNT/A4 and the rBoNT/A4-L260F I264R mutant was determined using the BoTest A/E botulinum neurotoxin detection kit (BioSentinel, Madison, WI) according to the manufacturer's instructions, except that 85 mM dithiothreitol was added to ensure complete and rapid reduction of the toxins. BoNT/A1 was added for comparison. The A526/A470 absorbance ratio was determined at 2 h on a BioTek Synergy H1 hybrid reader (BioTek Instruments, Winooski, VT). Three independent dilution series of each toxin were analyzed, and the 50% effective concentration (EC50 [concentration of half-maximal cleavage of the substrate]) was determined using PRISM6 software.

NCB assay.

The relative activities of the rBoNT/A4 and rBoNT/A4-L260F I264R mutant in human neurons were determined by the neuronal cell-based (NCB) assay as previously described (43). Briefly, neurons derived from human induced pluripotent stem cells (hiPSCs) were purchased from Cellular Dynamics International (CDI, Madison, WI) and cultured for 5 days in 96-well thiamine PPi (TPP) tissue culture plates (Midwest Scientific, St. Louis, MO) that were coated with 0.01% poly-l-ornithine (Sigma-Aldrich, St. Louis, MO) and 8.3 μg/cm2 Matrigel (BD Biosciences, San Jose, CA). The cells were exposed to serial dilutions of the toxins in 50 μl of culture medium (supplied with the cells by CDI) for 48 h, and cell lysates were analyzed for SNAP-25 cleavage by Western blotting and densitometry, as described previously (43–45).

Antitoxin neutralization.

Botulism heptavalent antitoxin (Cangene, Winnipeg, Canada) was kindly provided by Susan Maslanka at the CDC. This antitoxin was used to evaluate neutralization of rBoNT/A4. Fifty units of BoNT/A4 was incubated with 0- to 10,000-fold antitoxin and neutralization determined in the mouse bioassay.

RESULTS

Construction of a nontoxigenic C. botulinum expression host strain.

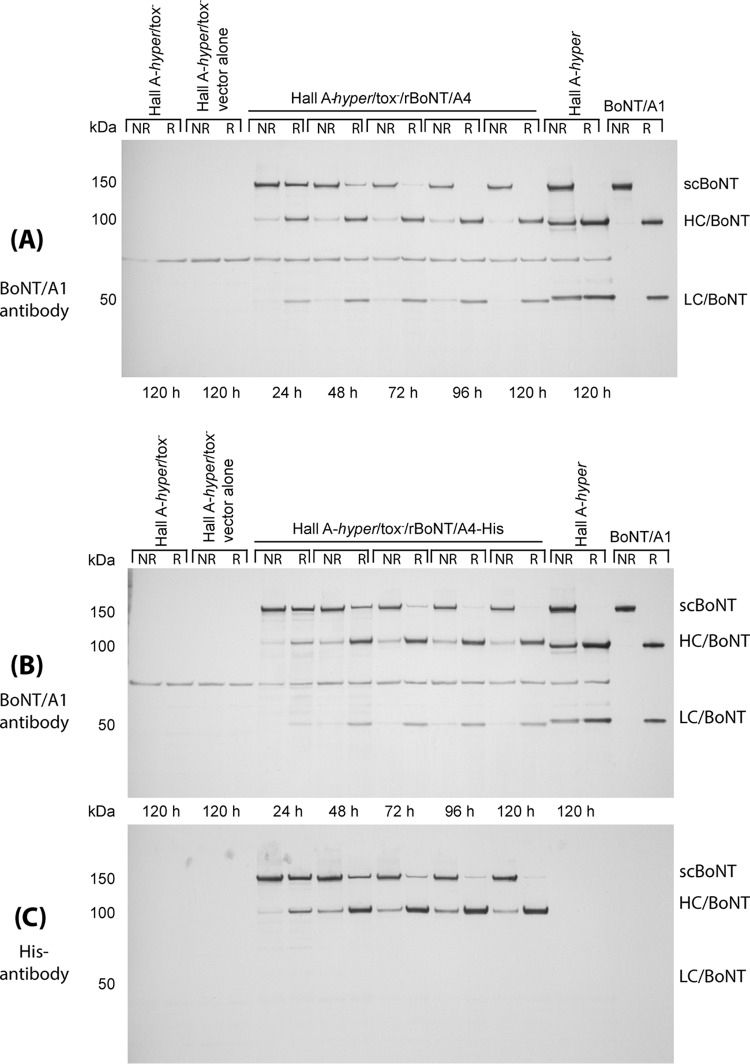

The same ClosTron method for inactivation of the botulinum neurotoxin A1 gene in C. botulinum strain 62A used in earlier studies (35) was used for insertional inactivation of the bont/A1 gene in C. botulinum strain Hall A-hyper. Insertion of a single copy of the group II intron into the toxin gene was confirmed by PCR, PFGE, and Southern hybridization (see Fig. S1 in the supplemental material). Western blot analysis of total culture lysates resulted in an absence of the bands corresponding to the toxin (Fig. 1), and intraperitoneal injection of 2 mice with 0.25 ml of culture supernatant resulted in no detectable toxicity. This indicates complete absence of endogenous BoNT production. The nontoxigenic C. botulinum expression host strain was named Hall A-hyper/tox−.

FIG 1.

Western blot analyses of botulinum neurotoxin expression in C. botulinum wild-type strain Hall A-hyper (BoNT/A1) and in four independent nontoxigenic mutant clones using polyclonal antibodies raised against serotype A1 BoNT. Purified botulinum neurotoxin (reduced and nonreduced) isolated from strain Hall A-hyper was used as a standard; all other samples were reduced. scBoNT, single-chain botulinum neurotoxin; LC/BoNT, botulinum neurotoxin light chain; HC/BoNT, botulinum neurotoxin heavy chain; wt, wild type; tox−, nontoxigenic mutants.

Recombinant BoNT/A4 can be expressed in the C. botulinum strain Hall A-hyper/tox−.

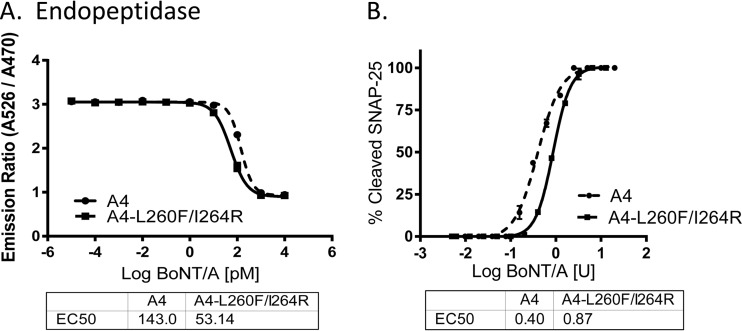

Expression of the recombinant BoNT/A4 with and without a C-terminal histidine tag (His6) in C. botulinum Hall A-hyper/tox− was evaluated by Western blotting of the culture lysates. As shown in Fig. 2, expression of rBoNT/A4 and rBoNT/A4-His was detected as early as 24 h in culture and did not change significantly until 120 h. No protein degradation was observed, and no toxin expression was observed in the expression host strain Hall A-hyper/tox− or in the host strain with a modular vector without the recombinant gene (Fig. 2). Processing of BoNTs in proteolytic C. botulinum strains includes proteolytic cleavage (nicking) of the 150-kDa single chain to the dichain molecule consisting of the 100-kDa heavy chain (HC) and 50-kDa light chain (LC) linked by a disulfide bond. Whether this occurs for the rBoNT/A4 was assessed by examining the protein samples with and without reduction (Fig. 2). At 24 h, most of the rBoNT/A4 was detected as a single 150-kDa band in both reduced and nonreduced samples, indicating that proteolytic cleavage is incomplete at this stage. At 48 h, ∼90% of the rBoNTs was nicked to the 100-kDa heavy chain and the 50-kDa light chain, and by 72 h, the toxin was nearly completely nicked. In order to determine expression levels of the rBoNT/A4 compared to endogenous expression of BoNT/A1 in the parent C. botulinum strain, the intensities of the rA4 bands on the Western blots were compared to those of endogenous BoNT/A1 toxin produced by the wild-type Hall A-hyper strain using densitometry. The intensity of rBoNT/A4 was about ∼20 to 40% compared to BoNT/A1, indicating sufficient production of rBoNT/A4 in this expression host for purification (Fig. 2). Interestingly, the supernatants of the rBoNT/A4 expression cultures were not lethal to mice, supporting our previous data that the specific toxicity of the rBoNT/A4 is very low (about 1,000 times less than that of BoNT/A1) (32).

FIG 2.

rBoNT/A4 (A) and BoNT/A4-His (B and C) expression in C. botulinum strain Hall A-hyper/tox−. Culture aliquots of a representative clone of Hall A-hyper/tox−/rBoNT/A4 and Hall A-hyper/tox−/rBoNT/A4-His were collected at indicated time points during growth, and both reduced (R) and nonreduced (NR) samples of each aliquot were analyzed on a 4 to 12% Bis-Tris gel with MOPS. Total culture lysates and purified botulinum neurotoxin isolated from strain Hall A-hyper were used as standards, and 120-h cultures of the expression host strain with and without the expression vector (no recombinant gene insert) were used as negative controls. For toxin detection, polyclonal antibody raised against BoNT/A1 (A and B) and monoclonal antibody against the His tag (C) were used.

Recombinant BoNT/A4 expressed in C. botulinum Hall A-hyper/tox− was copurified with the nontoxic BoNT/A1 complex proteins.

Two methods for protein purification were analyzed. In the first method, a His6 tag was engineered at the C terminus of the rBoNT/A4, and an Ni-NTA column was used for purification. In the second method, no tag was added to the rBoNT/A4 to ensure expression of a completely native toxin, and standard purification methods were applied based on previous protocols for purification of BoNT/A1 (21). Purification was monitored by SDS-PAGE. For the rBoNT/A4-His purification, the fractions eluted from the Ni-NTA column contained several protein bands ranging in size from 150 to 17 kDa, similar to the band pattern of purified BoNT/A1 complex (data not shown). This indicated that the rBoNT/A4-His copurifies with all of the nontoxic complex protein components that are normally present in the BoNT/A1 complex and that purification by the Ni-NTA column did not separate the complex proteins from the rBoNT. The yields of the rBoNT/A4-His complex from two separate experiments were 1.8 mg/liter and 2.4 mg/liter.

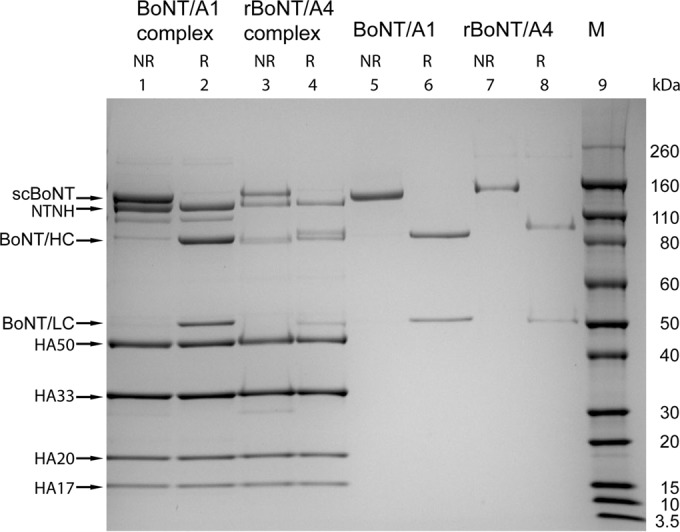

For purification of untagged rBoNT/A4, crude toxin extract was chromatographed on a DEAE-Sephadex A-50 column at pH 5.5. The majority of rBoNT/A4 toxin complex was recovered in the fractions from the first unbound peak. The yields of untagged rBoNT/A4 complex from two separate experiments were 5.5 mg/liter and 4.9 mg/liter. Interestingly, the yields of the rBoNT/A4-L260F I264R toxin complex from 2 separate batches were 13.8 mg/liter and 14.5 mg/liter, or ∼ 3-fold more on average than those of the untagged rBoNT/A4 complex. Densitometry of the toxin complex determined that the toxin accounted for ∼8.5% of all proteins in the complex, compared to ∼22% for toxin in the A1 toxin complex (Table 1). This was similar for the isolated His-tagged rBoNT/A4 complex.

TABLE 1.

Relative composition of BoNTs and nontoxic complexing proteins in toxin complexes from native BoNT/A1 and rBoNT/A4

| Protein | % of total: |

|||

|---|---|---|---|---|

| Unreduced |

Reduceda |

|||

| rBoNT/A4 complex | BoNT/A1 complex | BoNT/A1 toxin | rBoNT/A4 toxin | |

| BoNT | 8.5 | 21.8 | ||

| NTNH | 6.8 | 14.6 | 65.8 (HC) | 66.6 (HC) |

| HA50 | 25.1 | 20.4 | 34.2 (LC) | 33.4 (LC) |

| HA33 | 31.1 | 23.8 | ||

| HA20 | 13.7 | 10.6 | ||

| HA17 | 8.5 | 5.4 | ||

HC, heavy chain; LC, light chain.

The 150-kDa rBoNT/A4 was separated from the other nontoxic protein components by FPLC using a Mono Q HR 5/5 column (42). A >95% pure BoNT/A4 was obtained at an NaCl concentration of ∼130 mM (Fig. 3). The purified 150-kDa toxin was confirmed by SDS-PAGE and mouse bioassay. The yield of toxin from complex after DEAE chromatography was ∼1%; however, after concentration in a C30 microconcentrator, the final recovery was ∼0.5%, which compares to a typical yield of about 10% toxin from complex for BoNT/A1. Similar yields were obtained for the isolation of the mutated rBoNT/A4. rBoNT/A4 was effectively neutralized by botulism heptavalent antitoxin.

FIG 3.

BoNT/A1 and rBoNT/A4 complexes and toxins. Samples of purified BoNT/A1 and rBoNT/A4 before and after separation of the complex proteins were analyzed on a 4 to 12% Bis-Tris gel and Coomassie stained. The holotoxin, BoNT, reduced HC and LC, and complex proteins HA50, HA33, HA20, HA17, and NTNH are indicated. Lane 9, molecular mass markers; lane 1, A1 complex Hall A-hyper strain, unreduced (NR); lane 2, A1 complex Hall A-hyper, reduced (R); lane 3, rBoNT/A4 complex, unreduced; lane 4, rBoNT/A4 complex, reduced; lane 5, purified BoNT/A1; lane 6, purified BoNT/A1, reduced; lane 7, purified rBoNT/A4, unreduced; lane 8, purified rBoNT/A4, reduced.

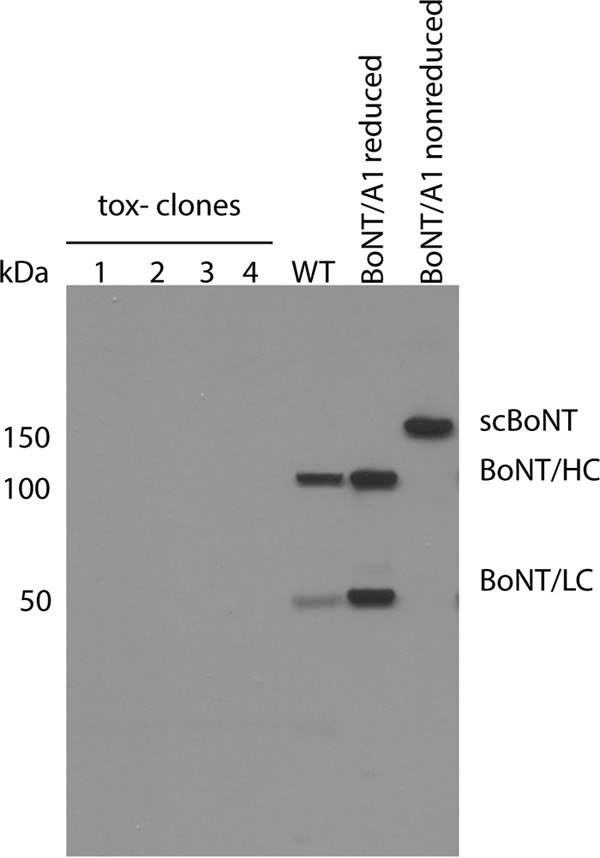

In vivo, in vitro, and cellular toxicities of rBoNT/A4 were not significantly altered by the L260F and I264R mutations.

Previous data analyzing recombinant truncated LCs of BoNT/A subtypes produced in E. coli have indicated that the A4 LC was about 100-fold less enzymatically active than A1. Structural modeling suggested that two mutations, I264R and L260F, would increase activity and solubility of the A4 LC (32). Indeed, an A4 LC containing the I264R mutation increased catalytic activity to levels similar to those of A1 (32). In order to examine the effect of the L260F I264R double mutations on toxicity of the holotoxin, three different assays were employed comparing rBoNT/A4 and rBoNT/A4-L260F I264R in vivo, in vitro, and in cells. First, the in vivo toxicity was determined by mouse bioassay (40). The specific toxicities of two independent preparations of the 150-kDa rBoNT/A4 protein were determined to be ∼1.0 × 105 LD50/mg and 1.3 × 105 LD50/mg, and for a single preparation of rBoNT/A4-L260F I264R, the specific toxicity was 1.1 × 105 LD50/mg (data not shown). This indicates there was no significant difference in in vivo activity and an ∼1,000-fold lower specific toxicity than BoNT/A1, as previously described (12). The in vitro activity determined by a 2-h BoTest resulted in an about 6-fold decrease in activity of rBoNT/A4 compared to A1, similar to a previous report (12), whereas the activity of rBoNT/A4-L260F I264R was reduced about 2-fold compared to that of A1 (Fig. 4A), indicating a slightly increased activity of rBoNT/A4-L260F I264R compared to that of rBoNT/A4. Activity in human neurons was determined by neuronal cell-based (NCB) assay as described previously (43). In this assay, human neurons derived from induced pluripotent stem cells were exposed to serial dilutions of rBoNT/A4 and rBoNT/A4-L260F 264R, and activity was determined by quantifying cleaved and uncleaved SNAP-25 by Western blotting and densitometry. The activity in the NCB assay was determined in relation to mouse LD50 units since it requires fully active holotoxin and was similar to that observed in a previous study for rBoNT/A4 (43). The EC50 value for cleaved SNAP-25 of the rBoNT/A4-L260F I264R was about 2-fold lower than that for rBoNT/A4 (Fig. 4B). This indicates that the L260F and I264R mutations did not increase toxin activity in cultured human neurons. Thus, activity in human neurons mirrored that in mice, with rBoNT/A4 and rBoNT/A4-L260F I264R requiring about 1,000-fold greater toxin concentrations to achieve the same SNAP-25 cleavage as BoNT/A1. Together, these data indicate that the L260F and I264R mutations had no significant effect on toxicity of rBoNT/A4 in cells in vitro and in vivo.

FIG 4.

Toxicity of rBoNT/A4 and BoNT/A4-L260F I264R mutant. (A) The in vitro catalytic activity of rBoNT/A4 and rBoNT/A4-L260F I264R was determined in a 2-h BoTest in relation to BoNT/A1. (B) Activity in human neurons was determined by an NCB assay. Neurons derived from hiPSCs were exposed to toxin dilutions for 48 h, and cell lysates were analyzed by Western blotting for SNAP-25 cleavage. Uncleaved SNAP-25 and cleaved SNAP-25 were quantified by densitometry, and the averages and standard deviations of triplicate samples were graphed using PRISM6 software.

DISCUSSION

The recognized diversity of botulinum neurotoxins has greatly expanded during recent years primarily as a result of gene sequencing (2, 6, 8). Among the seven well-documented serotypes, A to G, there exist at least 40 subtypes (2) that have been defined as having at least 0.9% amino acid differences. Recently, a new serotype, “H,” has been proposed (3, 4) based on preliminary antibody neutralization and sequence studies. However, this toxin is expressed as the minor toxin in a dual-toxin-producing strain, which has so far hindered a detailed characterization of purified toxin. Such characterization is essential for confirmation of this toxin as a new serotype and for an in depth understanding of the biochemical, toxicological, immunological and other properties. The isolation of purified BoNTs from dual-toxin-producing strains is complicated due to the similar purification schemes for the different BoNTs and especially because one BoNT is usually produced in much larger quantities than the other BoNT. For example, the Af, Bf, Ba, and Ab strains produce two serotypes of BoNTs, where the capital letter indicates the BoNT produced in the larger quantities (46). In fact, the ratio of the two toxin types produced by one culture often differ by 104 to 105 mouse LD50 (22, 47). Thus, the study of distinct characteristics of the toxin produced in smaller quantities can be obscured by the presence of the type produced in a larger quantity. To the best of our knowledge, the only means to cleanly isolate a minor toxin from dual-toxin producers is to express it recombinantly. Expression of recombinant full-length BoNTs has been accomplished in E. coli (27–29), Pichia pastoris (30), and baculovirus (31). Comparisons of endogenously produced BoNTs with BoNTs produced in heterologous expression systems will determine whether the expression host affects toxin folding and activity of any BoNT sero- or subtypes. Here we describe characterization of a recombinant BoNT/A4 expressed in an endogenous Clostridium host. An endogenous expression host provides the natural environment required for the complex events taking place during toxin production, including expression, folding, proteolytic activation, secretion, and solubility, which have posed challenges in nonclostridial systems, such as E. coli and P. pastoris. In addition, expression in a native clostridial expression host avoids other potential problems, such as introduction of protein tags and linkers containing protease cleavage sites, which may leave several additional amino acid residues behind after protease treatment and tag removal. Furthermore, the first methionine in the wild-type BoNTs is cleaved off during the toxin complex formation in native C. botulinum strains (48), and it is unclear whether this occurs in heterologous expression system.

Our laboratory has previously purified subtypes A1, A2, A3, and A5 within the A serotype (15, 21, 25, 49), but the isolation of A4 has been problematic due to the much larger quantity of BoNT/B expressed in the dual-toxin-producing C. botulinum strain 657Ba. Thus, we obtained biological safety clearance for cloning and production of BoNT/A4 in a clostridial host system.

Interestingly, expression of the rBoNT/4 in a host with the chromosomal toxin gene inactivated, while still containing nontoxic genes of the clostridial toxin complexes, such as those coding for hemagglutinins (HAs) and nontoxic nonhemagglutinin (NTNH), resulted in copurification of complex proteins with the toxin. Although some protein complexes are formed as they are translated on the ribosome, the apparent formation of the recombinant BoNT/A4 complex occurred in the cytosol or culture fluid, as has been also observed for protein complexes such as the ribosome. Interestingly, sequencing analyses have shown that C. botulinum strains that produce BoNT/A4 have an orfX toxin gene cluster, and the HA genes are usually not present. Generally these strains produce an NTNH-BoNT complex without HA or other nontoxic components. In this regard, the studies presented here clearly show that the rBoNT/A4 can form a complex also with the HA proteins. Furthermore, in this study, the complexing proteins appeared to be present at higher levels in the rBoNT/A4 complex than in the native BoNT/A1 complex. Specifically, in the rBoNT/A4 complex, the neurotoxin comprised 8.5% of the overall complex, while in BoNT/A1, it comprised 22% of the complex.

The 150-kDa BoNT/A4 isolated in this study was highly pure according to analysis by SDS-PAGE. The specific toxicity of this toxin was 1.0 to 1.3 × 105 LD50/mg as previously reported (12), which is about 1,000-fold lower than that of other BoNT/A subtypes. Previous analysis of a recombinant truncated BoNT/A4 LC (amino acids [aa] 1 to 425) had indicated poor solubility and decreased in vitro activity compared to A1. Of two mutations in the A4 LC, L260F and I264R, which were predicted to increase the solubility, the I264R mutation eliminated the defect in in vitro activity of A4 LC (32). However, introduction of these two mutations into the rBoNT/A4 holotoxin produced in this study did not significantly alter in vivo activity and activity in neuronal cells and only mildly increased in vitro activity (Fig. 4). This indicates that the previously observed improvement in in vitro activity in the A4 LC-I264R is specific to the truncated (aa 1 to 425) A4 LC construct produced in E. coli but is not observed in the BoNT/A4 holotoxin.

The isolation of the purified recombinant BoNT/A4 enabled definitive studies of its specific toxicity, activity in neuronal cell models, and in vitro properties (12, 14). Due to the availability of the purified BoNT/A4, we can now study detailed properties, including immunological features, symptoms elicited in mice, cell entry characteristics, and pharmacological aspects.

In summary, this paper describes the isolation of a minor BoNT originating from a dual-BoNT-producing C. botulinum strain. Isolation of recombinant BoNT/A4 and a mutant BoNT/A4-L260F I264R was accomplished in a native expression host. We also determined that the L260F I264R double mutation, which increased BoNT/A4 recombinant LC activity, did not affect BoNT/A4 holotoxin activity. This study will enable characterization of other BoNTs that occur naturally in very small quantities and in strains that produce more than one serotype of BoNT. These studies will also be valuable in determining the regulation of BoNT expression in dual-toxin producers, for elucidation of the steps in toxin complex formation, and for unequivocal demonstration of new subtypes and serotypes from a protein perspective.

Supplementary Material

ACKNOWLEDGMENTS

This work was sponsored by the NIH/NIAID Regional Center of Excellence for Biodefense and Emerging Infectious Diseases Research (RCE) Program. We wish to acknowledge membership within and support from the Region V “Great Lakes” RCE (NIH award U54-AI-057153) and from the Pacific Southwest RCE (NIH award U54-AI-065359). This work was also partially funded by the Wisconsin Alumni Research Foundation and NIH grant 1R01AI095274.

We thank the University of Wisconsin—Madison Select Agent Program, and in particular Rebecca Moritz, for the immense task of ensuring that all research and publication thereof was within select agent regulations. We thank Nigel Minton (University of Nottingham, United Kingdom) for providing the ClosTron mutagenesis system, modular clostridial vectors, and E. coli strain CA434. We thank Christina Pier for managing biosafety issues and day-to-day operations in our laboratory, and Guangyun Lin and Jacob Scherf for helpful discussions and technical assistance. An aliquot of the botulism heptavalent antitoxin was kindly provided by Susan Maslanka (CDC). We also appreciate the expert advice of Susan Maslanka and Brian Raphael for the antitoxin neutralization experiments.

Footnotes

Published ahead of print 19 September 2014

Supplemental material for this article may be found at http://dx.doi.org/10.1128/AEM.01795-14.

REFERENCES

- 1.Schantz EJ, Johnson EA. 1992. Properties and use of botulinum toxin and other microbial neurotoxins in medicine. Microbiol. Rev. 56:80–99. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Rossetto O, Pirazzini M, Montecucco C. 2014. Botulinum neurotoxins: genetic, structural and mechanistic insights. Nat. Rev. Microbiol. 12:535–549. 10.1038/nrmicro3295. [DOI] [PubMed] [Google Scholar]

- 3.Barash JR, Arnon SS. 2014. A novel strain of Clostridium botulinum that produces type B and type H botulinum toxins. J. Infect. Dis. 209:183–191. 10.1093/infdis/jit449. [DOI] [PubMed] [Google Scholar]

- 4.Dover N, Barash JR, Hill KK, Xie G, Arnon SS. 2014. Molecular characterization of a novel botulinum neurotoxin type H gene. J. Infect. Dis. 209:192–202. 10.1093/infdis/jit450. [DOI] [PubMed] [Google Scholar]

- 5.Hill KK, Smith TJ, Helma CH, Ticknor LO, Foley BT, Svensson RT, Brown JL, Johnson EA, Smith LA, Okinaka RT, Jackson PJ, Marks JD. 2007. Genetic diversity among botulinum neurotoxin-producing clostridial strains. J. Bacteriol. 189:818–832. 10.1128/JB.01180-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Hill KK, Smith TJ. 2013. Genetic diversity within Clostridium botulinum serotypes, botulinum neurotoxin gene clusters and toxin subtypes. Curr. Top. Microbiol. Immunol. 364:1–20. 10.1007/978-3-642-33570-9_1. [DOI] [PubMed] [Google Scholar]

- 7.Smith TJ, Lou J, Geren IN, Forsyth CM, Tsai R, Laporte SL, Tepp WH, Bradshaw M, Johnson EA, Smith LA, Marks JD. 2005. Sequence variation within botulinum neurotoxin serotypes impacts antibody binding and neutralization. Infect. Immun. 73:5450–5457. 10.1128/IAI.73.9.5450-5457.2005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Popoff MR, Bouvet P. 2013. Genetic characteristics of toxigenic clostridia and toxin gene evolution. Toxicon 75:63–89. 10.1016/j.toxicon.2013.05.003. [DOI] [PubMed] [Google Scholar]

- 9.US Government Printing Office. 18 March 2005. Electronic Code of Federal Regulations (e-CFR). Title 42: public health, part 73—select agents and toxins. http://www.ecfr.gov/cgi-bin/retrieveECFR?gp=&SID=8a4be60456973b5ec6bef5dfeaffd49a&r=PART&n=42y1.0.1.6.61.

- 10.National Institutes of Health. 29 March 2012. United States Government policy for oversight of life sciences dual use research of concern. http://osp.od.nih.gov/office-biotechnology-activities/biosecurity/dual-use-research-concern.

- 11.Dressler D. 2012. Clinical applications of botulinum toxin. Curr. Opin. Microbiol. 15:325–336. 10.1016/j.mib.2012.05.012. [DOI] [PubMed] [Google Scholar]

- 12.Whitemarsh RC, Tepp WH, Bradshaw M, Lin G, Pier CL, Scherf JM, Johnson EA, Pellett S. 2013. Characterization of botulinum neurotoxin A subtypes 1 through 5 by investigation of activities in mice, in neuronal cell cultures, and in vitro. Infect. Immun. 81:3894–3902. 10.1128/IAI.00536-13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Whitemarsh RC, Tepp WH, Johnson EA, Pellett S. 2014. Persistence of botulinum neurotoxin A subtypes 1–5 in primary rat spinal cord cells. PLoS One 9:e90252. 10.1371/journal.pone.0090252. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Wang D, Krilich J, Pellett S, Baudys J, Tepp WH, Barr JR, Johnson EA, Kalb SR. 2013. Comparison of the catalytic properties of the botulinum neurotoxin subtypes A1 and A5. Biochim. Biophys. Acta 1834:2722–2728. 10.1016/j.bbapap.2013.09.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Tepp WH, Lin G, Johnson EA. 2012. Purification and characterization of a novel subtype A3 botulinum neurotoxin. Appl. Environ. Microbiol. 78:3108–3113. 10.1128/AEM.07967-11. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Pier CL, Chen C, Tepp WH, Lin G, Janda KD, Barbieri JT, Pellett S, Johnson EA. 2011. Botulinum neurotoxin subtype A2 enters neuronal cells faster than subtype A1. FEBS Lett. 585:199–206. 10.1016/j.febslet.2010.11.045. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Johnson EA, Bradshaw M. 2001. Clostridium botulinum and its neurotoxins: a metabolic and cellular perspective. Toxicon 39:1703–1722. 10.1016/S0041-0101(01)00157-X. [DOI] [PubMed] [Google Scholar]

- 18.Bonventre PF, Kempe LL. 1960. Physiology of toxin production by Clostridium botulinum types A and B. I. Growth, autolysis, and toxin production. J. Bacteriol. 79:18–23. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Bonventre PF, Kempe LL. 1960. Physiology of toxin production by Clostridium botulinum types A and B. IV. Activation of the toxin. J. Bacteriol. 79:24–32. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Peck MW. 2009. Biology and genomic analysis of Clostridium botulinum. Adv. Microb. Physiol. 55:183–320. 10.1016/S0065-2911(09)05503-9. [DOI] [PubMed] [Google Scholar]

- 21.Malizio CJ, Goodnough MC, Johnson EA. 2000. Purification of Clostridium botulinum type A neurotoxin. Methods Mol. Biol. 145:27–39. [DOI] [PubMed] [Google Scholar]

- 22.Gimenez DF. 1984. Clostridium botulinum subtype Ba. Zentralbl. Bakteriol. Mikrobiol. Hyg. A 257:68–72. [PubMed] [Google Scholar]

- 23.Hatheway CL, McCroskey LM, Lombard GL, Dowell VR., Jr 1981. Atypical toxin variant of Clostridium botulinum type B associated with infant botulism. J. Clin. Microbiol. 14:607–611. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Bradshaw M, Dineen SS, Maks ND, Johnson EA. 2004. Regulation of neurotoxin complex expression in Clostridium botulinum strains 62A, Hall A-hyper, and NCTC 2916. Anaerobe 10:321–333. 10.1016/j.anaerobe.2004.07.001. [DOI] [PubMed] [Google Scholar]

- 25.Lin G, Tepp WH, Pier CL, Jacobson MJ, Johnson EA. 2010. Expression of the Clostridium botulinum A2 neurotoxin gene cluster proteins and characterization of the A2 complex. Appl. Environ. Microbiol. 76:40–47. 10.1128/AEM.01882-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Gimenez DF, Gimenez JA. 1983. Identification of strain B 657 of Clostridium botulinum. Rev. Argent. Microbiol. 15:51–55. [PubMed] [Google Scholar]

- 27.Dolly JO, Wang J, Zurawski TH, Meng J. 2011. Novel therapeutics based on recombinant botulinum neurotoxins to normalize the release of transmitters and pain mediators. FEBS J. 278:4454–4466. 10.1111/j.1742-4658.2011.08205.x. [DOI] [PubMed] [Google Scholar]

- 28.Rummel A, Mahrhold S, Bigalke H, Binz T. 2011. Exchange of the H(CC) domain mediating double receptor recognition improves the pharmacodynamic properties of botulinum neurotoxin. FEBS J. 278:4506–4515. 10.1111/j.1742-4658.2011.08196.x. [DOI] [PubMed] [Google Scholar]

- 29.Gu S, Rumpel S, Zhou J, Strotmeier J, Bigalke H, Perry K, Shoemaker CB, Rummel A, Jin R. 2012. Botulinum neurotoxin is shielded by NTNHA in an interlocked complex. Science 335:977–981. 10.1126/science.1214270. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Webb RP, Smith TJ, Wright P, Brown J, Smith LA. 2009. Production of catalytically inactive BoNT/A1 holoprotein and comparison with BoNT/A1 subunit vaccines against toxin subtypes A1, A2, and A3. Vaccine 27:4490–4497. 10.1016/j.vaccine.2009.05.030. [DOI] [PubMed] [Google Scholar]

- 31.Band PA, Blais S, Neubert TA, Cardozo TJ, Ichtchenko K. 2010. Recombinant derivatives of botulinum neurotoxin A engineered for trafficking studies and neuronal delivery. Protein Expr. Purif. 71:62–73. 10.1016/j.pep.2009.12.013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Henkel JS, Jacobson M, Tepp W, Pier C, Johnson EA, Barbieri JT. 2009. Catalytic properties of botulinum neurotoxin subtypes A3 and A4. Biochemistry 48:2522–2528. 10.1021/bi801686b. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Heap JT, Pennington OJ, Cartman ST, Carter GP, Minton NP. 2007. The ClosTron: a universal gene knock-out system for the genus Clostridium. J. Microbiol. Methods 70:452–464. 10.1016/j.mimet.2007.05.021. [DOI] [PubMed] [Google Scholar]

- 34.Heap JT, Kuehne SA, Ehsaan M, Cartman ST, Cooksley CM, Scott JC, Minton NP. 2010. The ClosTron: mutagenesis in Clostridium refined and streamlined. J. Microbiol. Methods 80:49–55. 10.1016/j.mimet.2009.10.018. [DOI] [PubMed] [Google Scholar]

- 35.Bradshaw M, Marshall KM, Heap JT, Tepp WH, Minton NP, Johnson EA. 2010. Construction of a nontoxigenic Clostridium botulinum strain for food challenge studies. Appl. Environ. Microbiol. 76:387–393. 10.1128/AEM.02005-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Hatheway CL, Ferreira JL. 1996. Detection and identification of Clostridium botulinum neurotoxins. Adv. Exp. Med. Biol. 391:481–498. 10.1007/978-1-4613-0361-9_39. [DOI] [PubMed] [Google Scholar]

- 37.Heap JT, Pennington OJ, Cartman ST, Minton NP. 2009. A modular system for Clostridium shuttle plasmids. J. Microbiol. Methods 78:79–85. 10.1016/j.mimet.2009.05.004. [DOI] [PubMed] [Google Scholar]

- 38.Goodnough MC, Hammer B, Sugiyama H, Johnson EA. 1993. Colony immunoblot assay of botulinal toxin. Appl. Environ. Microbiol. 59:2339–2342. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Gimenez JA, Sugiyama H. 1987. Simplified purification method for Clostridium botulinum type E toxin. Appl. Environ. Microbiol. 53:2827–2830. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Schantz EJ, Kautter DA. 1978. Standardized assay for Clostridium botulinum toxins. J. Assoc. Off. Anal. Chem. 61:96–99. [Google Scholar]

- 41.Reed LJ, Muench H. 1938. A simple method of estimating fifty percent endpoints. Am. J. Hyg. (Lond.) 27:493–497. [Google Scholar]

- 42.Woody MA, DasGupta BR. 1988. Fast protein liquid chromatography of botulinum neurotoxin types A, B and E. J. Chromatogr. 430:279–289. 10.1016/S0378-4347(00)83163-1. [DOI] [PubMed] [Google Scholar]

- 43.Whitemarsh RC, Strathman MJ, Chase LG, Stankewicz C, Tepp WH, Johnson EA, Pellett S. 2012. Novel application of human neurons derived from induced pluripotent stem cells for highly sensitive botulinum neurotoxin detection. Toxicol. Sci. 126:426–435. 10.1093/toxsci/kfr354. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Pellett S, Tepp WH, Clancy CM, Borodic GE, Johnson EA. 2007. A neuronal cell-based botulinum neurotoxin assay for highly sensitive and specific detection of neutralizing serum antibodies. FEBS Lett. 581:4803–4808. 10.1016/j.febslet.2007.08.078. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Pellett S, Tepp WH, Toth SI, Johnson EA. 2010. Comparison of the primary rat spinal cord cell (RSC) assay and the mouse bioassay for botulinum neurotoxin type A potency determination. J. Pharmacol. Toxicol. Methods 61:304–310. 10.1016/j.vascn.2010.01.003. [DOI] [PubMed] [Google Scholar]

- 46.Gimenez DF, Gimenez JA. 1993. Serological subtypes of botulinum of botulinal neurotoxins, p 421–431 In Dasgupta BR. (ed), Botulism and tetanus neurotoxins: neurotransmission and biomedical aspects. Plenum Press, New York, NY. [Google Scholar]

- 47.Gimenez DF, Ciccarelli AS. 1970. Studies on strain 84 of Clostridium botulinum. Zentralbl. Bakteriol. Orig. 215:212–220. [PubMed] [Google Scholar]

- 48.Schmidt JJ, Sathyamoorthy V, DasGupta BR. 1984. Partial amino acid sequence of the heavy and light chains of botulinum neurotoxin type A. Biochem. Biophys. Res. Commun. 119:900–904. 10.1016/0006-291X(84)90858-1. [DOI] [PubMed] [Google Scholar]

- 49.Jacobson MJ, Lin G, Tepp W, Dupuy J, Stenmark P, Stevens RC, Johnson EA. 2011. Purification, modeling, and analysis of botulinum neurotoxin subtype A5 (BoNT/A5) from Clostridium botulinum strain A661222. Appl. Environ. Microbiol. 77:4217–4222. 10.1128/AEM.00201-11. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.