Abstract

The response surface methodology was used to optimize the spray drying process for development of seabuckthorn fruit juice powder. The independent variables were different levels of inlet air temperature and maltodextrin concentration. The responses were moisture, solubility, dispersibility, vitamin C and overall color difference value. Statistical analysis revealed that independent variables significantly affected all the responses. The Inlet air temperature showed maximum influence on moisture and vitamin C content, while the maltodextrin concentration showed similar influence on solubility, dispersibility and overall color difference value. Contour plots for each response were used to generate an optimum area by superimposition. The seabuckthorn fruit juice powder was developed using the derived optimum processing conditions to check the validity of the second order polynomial model. The experimental values were found to be in close agreement to the predicted values and were within the acceptable limits indicating the suitability of the model in predicting quality attributes of seabuckthorn fruit juice powder. The recommended optimum spray drying conditions for drying 100 g fruit juice slurry were inlet air temperature and maltodextrin concentration of 162.5 °C and 25 g, respectively. The spray dried juice powder contains higher amounts of antioxidants viz., vitamin C, vitamin E, total carotenoids, total anthocyanins and total phenols when compared to commercial fruit juice powders and they are also found to be free flowing without any physical alterations such as caking, stickiness, collapse and crystallization by exhibiting greater glass transition temperature.

Keywords: Seabuckthorn, Spray drying, Fruit juice powder, Solubility

Introduction

Drying is an ancient process of preserving foods. It is the most common food preservation process. Hundreds of variants are actually used in the drying of particulate solids, pastes, continuous sheets, slurries or solutions; hence it provides the most diversity among food engineering unit operations. The quality of a food powder is based on a variety of properties depending on the specific application. In general, the final moisture content, solubility, dispersibility and color are of primary importance.

Spray drying is a unit operation, which are widely used in the food industry and it is one of the most practical methods by which the solution of solids in water can be dehydrated to yield a solid final product. Other methods for the removal of water from such solutions e.g. freeze-drying which are usually quite expensive, while liquid-liquid extraction requires the use of solvents, which is often undesirable (Vander-lijn 1976).

Seabuckthorn (Hippophae rhamnoides), a deciduous shrub with yellow or orange berries is attracting considerable attention mainly for its medicinal value and great economic potential (Li and Schroeder 1996; Li and Wang 1998). The juice obtained from berries is found to contain high amount of several constituents like ascorbic acid, carotenoids, phenols and anthocyanins (Chauhan et al. 2001). Therefore, this juice can be effectively utilized for development of nutritive rich fruit juice powder by utilizing spray drying process. The variation of spray drying condition i.e. inlet air temperature and addition of maltodextrin concentration in fruit juice will influence the physico-chemical properties of fruit juice powder. Several variations in physical properties viz., solubility, dispersibility, overall color difference value and chemical properties like moisture and vitamin C content of fruit juice powder can be achieved depending on modification and combination of these different variables. There is, however, not much reports in the literature to explain how inlet air temperature and maltodextrin concentration level addition affect the physico-chemical properties of fruit juice powder. The aim of this study was to find out optimum conditions for spray drying process viz., inlet air temperature and maltodextrin concentration levels for developing seabuckthorn fruit juice powder (SFJP) that should have desirable physico-chemical properties.

Materials and methods

Raw materials

Seabuckthorn fruits (H. rhamnoides) were brought from Field Research Laboratory, Leh, India. Maltodextrin DE 10 and tricalcium phosphate (Food grade) were purchased from HiMedia Laboratories Limited, Mumbai, India. All other chemical reagents were procured from E.Merck and Loba Chemicals Limited, Mumbai, India.

Development of seabuckthorn fruit juice powder

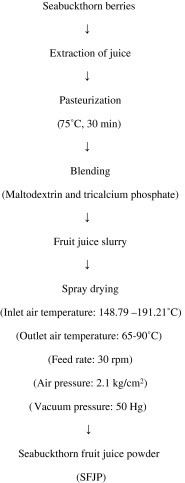

The development of SFJP (Fig. 1) was carried out as per the procedure of Abadio et al. (2004).

Fig. 1.

Process flow chart for development of seabuckthorn fruit juice powder

Preparation of seabuckthorn fruit juice slurry

The seabuckthorn berries were washed thoroughly and crushed in a mixer grinder, squeezed in muslin cloth and sieved through strainer of 30 meshes to get fine juice. The seabuckthorn juice was pasteurized at 75 °C for 30 min in water bath. In order to prevent the formation of lumps during slurry preparation, the maltodextrin was dissolved in small portion of the juice and then added to the rest of the juice for 1 min at low speed and 2 min at high speed in a commercial blender. Tricalcium phosphate was then added to the liquid slurry and then again mixed for 3 min in the blender at high speed to get uniform slurry.

Spray drying

The slurry was spray dried in a pilot-scale spray dryer (JISL Instruments Private Limited, Mumbai, India) with an inlet air temperature of 148.79–191.21 °C, outlet air temperature of 65–90 °C, constant feed rate of 30 rpm, air pressure of 2.1 kg/cm2 and vacuum of 50 Hg. The spray dried fruit juice powder was collected at the bottom of the cyclone jar. The samples were then transferred to paper foil polyethylene packages of size 15 cm x 20 cm and sealed immediately.

Optimization of spray drying process for development of seabuckthorn fruit juice powder

Response surface methodology (RSM) is a commonly employed tool in analyzing experimental data resulting in the optimization of processes or products (Madamba 1997). The RSM was used to derive the optimum formulation conditions using a five parameter five level Central Composite Rotatable Design (CCRD) which dictated 14 experimental runs. Table 1 shows the real and coded values of the independent variables used to determine the optimum spray drying conditions for developing SFJP. The independent variables affecting the quality of the end product were the different levels of inlet air temperature (X1) and maltodextrin concentration (X2). A total of 14 runs were conducted. Inlet air temperature varied from 148.79 to 191.21 °C and maltodextrin concentration level varied from 20.86 to 49.14 g. Factors such as moisture content (%), solubility (%), dispersibility (%), vitamin C (mg/100 g) and overall color difference value were used as quality attributes of SFJP. The responses were represented as Y1 (moisture content), Y2 (solubility), Y3 (dispersibility), Y4 (vitamin C) and Y5 (overall color difference value). It was assumed that YK (where K = 1, 2, 3, 4, 5) is a function of the two independent variables as shown by Eq. (1).

|

1 |

Table 1.

Real and coded values for the independent variable levels of inlet air temperature (X1) and maltodextrin concentration (X 2) for development of seabuckthorn fruit juice powder

| Experiment no. | Levels of inlet air temperature | Levels of maltodextrin concentration | ||

|---|---|---|---|---|

| Real value (°C)a | Coded value (X1) | Real value (g)a | Coded value (X 2) | |

| 1 | 155 | −1 | 25 | −1 |

| 2 | 185 | +1 | 25 | −1 |

| 3 | 155 | −1 | 45 | +1 |

| 4 | 185 | +1 | 45 | +1 |

| 5 | 148.79 | −1.414 | 35 | 0 |

| 6 | 191.21 | +1.414 | 35 | 0 |

| 7 | 170 | 0 | 20.86 | −1.414 |

| 8 | 170 | 0 | 49.14 | +1.414 |

| 9 | 170 | 0 | 35 | 0 |

| 10 | 170 | 0 | 35 | 0 |

| 11 | 170 | 0 | 35 | 0 |

| 12 | 170 | 0 | 35 | 0 |

| 13 | 170 | 0 | 35 | 0 |

| 14 | 170 | 0 | 35 | 0 |

aFor drying 100 g fruit juice slurry by keeping juice (100 g) and tricalcium phosphate (2 g) as constant variables

The exact mathematical representation of the function (f) is either unknown or extremely complex. However, a second order polynomial of the form of Eq. (2) was assumed to relate the response i.e.

|

2 |

Where, β0, β1, β2, β11, β22 and β12 are regression coefficients and X1 and X2 are the coded levels of independent variables. Based on RSM, this equation was used to evaluate the linear, quadratic and interactive effects of independent variables on the chosen response. The responses for each run (Table 2) were subjected to multiple regression analysis.

Table 2.

The experimental dataa for response surface analysis of the effect of processing conditions on the quality of seabuckthorn fruit juice powder

| Experiment no. | Levels of inlet air temperature (°C) | Levels of maltodextrin concentration (g) | Moisture (%) (Y1) | Solubility (%) (Y2) | Dispersibility (%) (Y3) | Vitamin Cb (mg/100 g) (Y4) | Overall color difference value (∆ EC) (Y5) |

|---|---|---|---|---|---|---|---|

| 1 | 155 | 25 | 4.2 ± 0.02 | 89.2 ± 0.30 | 78.7 ± 0.63 | 396.8 ± 0.74 | 5.8 ± 0.57 |

| 2 | 185 | 25 | 3.6 ± 0.04 | 76.3 ± 0.27 | 63.2 ± 0.50 | 399.7 ± 0.45 | 5.9 ± 0.79 |

| 3 | 155 | 45 | 3.2 ± 0.00 | 92.8 ± 0.34 | 79.6 ± 0.68 | 346.2 ± 0.37 | 7.0 ± 0.66 |

| 4 | 185 | 45 | 2.5 ± 0.03 | 79.9 ± 0.40 | 65.8 ± 0.78 | 349.1 ± 0.52 | 7.1 ± 0.82 |

| 5 | 148.79 | 35 | 3.4 ± 0.00 | 80.1 ± 0.59 | 68.1 ± 0.48 | 406.9 ± 0.82 | 6.3 ± 0.51 |

| 6 | 191.21 | 35 | 2.0 ± 0.03 | 87.5 ± 0.45 | 71.1 ± 0.37 | 336.2 ± 0.59 | 6.6 ± 0.43 |

| 7 | 170 | 20.86 | 3.2 ± 0.06 | 94.7 ± 0.51 | 82.2 ± 0.47 | 369.6 ± 0.30 | 5.5 ± 0.96 |

| 8 | 170 | 49.14 | 2.1 ± 0.02 | 75.1 ± 0.36 | 61.4 ± 0.78 | 374.5 ± 0.94 | 7.2 ± 0.50 |

| 9 | 170 | 35 | 2.7 ± 0.00 | 83.8 ± 0.38 | 69.3 ± 0.53 | 371.0 ± 0.44 | 6.5 ± 0.87 |

| 10 | 170 | 35 | 2.7 ± 0.05 | 84.5 ± 0.44 | 70.2 ± 0.63 | 370.2 ± 0.40 | 6.4 ± 0.82 |

| 11 | 170 | 35 | 2.7 ± 0.02 | 84.5 ± 0.44 | 69.3 ± 0.53 | 372.3 ± 0.37 | 6.5 ± 0.87 |

| 12 | 170 | 35 | 2.7 ± 0.03 | 83.8 ± 0.38 | 70.2 ± 0.63 | 371.0 ± 0.44 | 6.4 ± 0.79 |

| 13 | 170 | 10.0 | 2.7 ± 0.04 | 83.8 ± 0.38 | 69.3 ± 0.53 | 372.3 ± 0.37 | 6.4 ± 0.82 |

| 14 | 170 | 10.0 | 2.7 ± 0.05 | 84.5 ± 0.44 | 69.3 ± 0.53 | 372.3 ± 0.37 | 6.5 ± 0.85 |

aMean ± SD of triplicate analyses

bInitial level of vitamin C in fruit juice slurry before spray drying was 504.0 mg/100 g

Physico-chemical properties of seabuckthorn fruit juice powder

The physico-chemical properties of SFJP like moisture was determined as per the method of AOAC (1984), solubility and dispersibility as per the procedure of IAL (1977) and Pisecky (1985), respectively. Color parameter of fruit juice powders were measured by color difference meter, Chroma Flash (Model 2810, Ashco, India) using 10° standard observer and illuminant D65 and expressed as L*, a*, b*, where L* represents the lightness index; a* and -a* the redness and greenness respectively; b* and –b* the yellowness and blueness respectively.

The powder having different level of total solids were converted into juice after reconstitution with known volume of water at 30 °C. The total color difference (∆Ec) between the seabuckthorn juice used for powder production and the reconstituted powder was calculated by using the Eq. (3).

|

3 |

Where Lo, ao and bo are the L, a and b value of seabuckthorn juice and Lp, ap and bp are corresponding values of the reconstituted powder.

Nutritional properties of seabuckthorn fruit juice powder

The nutritional properties of SFJP like total solids, acidity, total and reducing sugars were determined according to the procedure of Sathe (1999) and AOAC (1970), respectively. Vitamin C was determined by using 2,6-dichlorophenol-indophenol titration method (Ranganna 1986), vitamin E was estimated by using ferric chloride reagent (Desai 1984), spectrophotometrically at 536 nm (UV-Visible Spectrophotometer 1601, Shimadzu, Columbia, MD, USA), total caroteniods, anthocyanins and phenols were determined spectrophotometrically at 450, 535 and 765 nm’s, (Arya et al. 1979; Clydesdale and Francis 1976; Singleton and Rossi 1965), respectively.

Thermal properties of seabuckthorn fruit juice powder

The thermal properties of SFJP i.e. glass transition temperature, which was determined by using Differential Scanning Calorimeter (Model 2010, TA Instruments, Newcastle, USA) with temperature programmer controller. The samples were heated at a rate of 10 °C per min from 0 °C to 20 °C in the pressure cell with the passage of nitrogen gas at a flow rate of 60 mL/min heat flow and temperature calibration was performed using pure indium with a heat of fusion of 28.42 j/g and onset melting temperature of 156.61 °C. The sample (9–11 mg) was immediately transferred into a preweighed aluminium pan and sealed hermetically using encapsulation press and weighed again. The difference between the two weights gave the sample weight. The sample was subjected to DSC analysis within half an hour after the preparation. The experiment was performed in triplicate. Thermograms were analyzed using (Thermal Analysis Version 2000) system software. The glass transition temperature (Tg), amorphous melting temperature(TM), start of the amorphous melting temperature (Ti), span of temperature (ΔT), change in enthalpy of amorphous melting temperature (ΔH), completion temperature (Tc) and thermal degradation of fruit juice powder were recorded.

Statistical analysis

Data and graphical analysis and response optimization were carried out using Statistical Software i.e. Design Expert (Version 6.0.10, Stat-Ease Inc., Minneapolis, MN).

Results and discussion

The experimental data (Table 2) for the responses were fitted into Eq. (2) to estimate the function, f, in Eq. (1). Five response surface models were obtained for the moisture content, solubility, dispersibility, vitamin C content and overall color difference value. Table 3 shows the ANOVA data for response variables and their significance at 95 % confidence level along with correlation coefficients. A high correlation coefficient (R > 0.7478) explained the goodness of fit of the experimental data in the response surface models of moisture content, solubility, dispersibility, vitamin C content and overall color difference value. This function showed that over 74.78 % of the total variation was accounted for or all the five response surface models fitted the data well and were adequately explained.

Table 3.

Analysis of variance (ANOVA) data for the responses in the optimization of processing conditions for developing seabuckthorn fruit juice powder

| Sum of squares | ||||||

|---|---|---|---|---|---|---|

| Source of Variation | df | Moisture | Solubility | Dispersibility | Vitamin C | Overall color difference value |

| Linear | 6 | 4.01 | 10.01 | 680.95 | 17.95 | 0.14a |

| Two factor | 5 | 4.01 | 10.01 | 537.04 | 17.95 | 0.14 |

| Quadratic | 3 | 3.01a | 5.65a | 255.63a | 9.09a | 0.059 |

| Cubic | 1 | 2.85 | 0.33 | 99.18 | 8.06 | 0.019 |

| Pure error | 33 | 0.046 | 7.14 | 15.17 | 19.41 | 15.86 |

| Correlation coefficients (R) | 0.7478 | 0.9894 | 0.7893 | 0.9981 | 0.3478 | |

aSignificant at 95 %

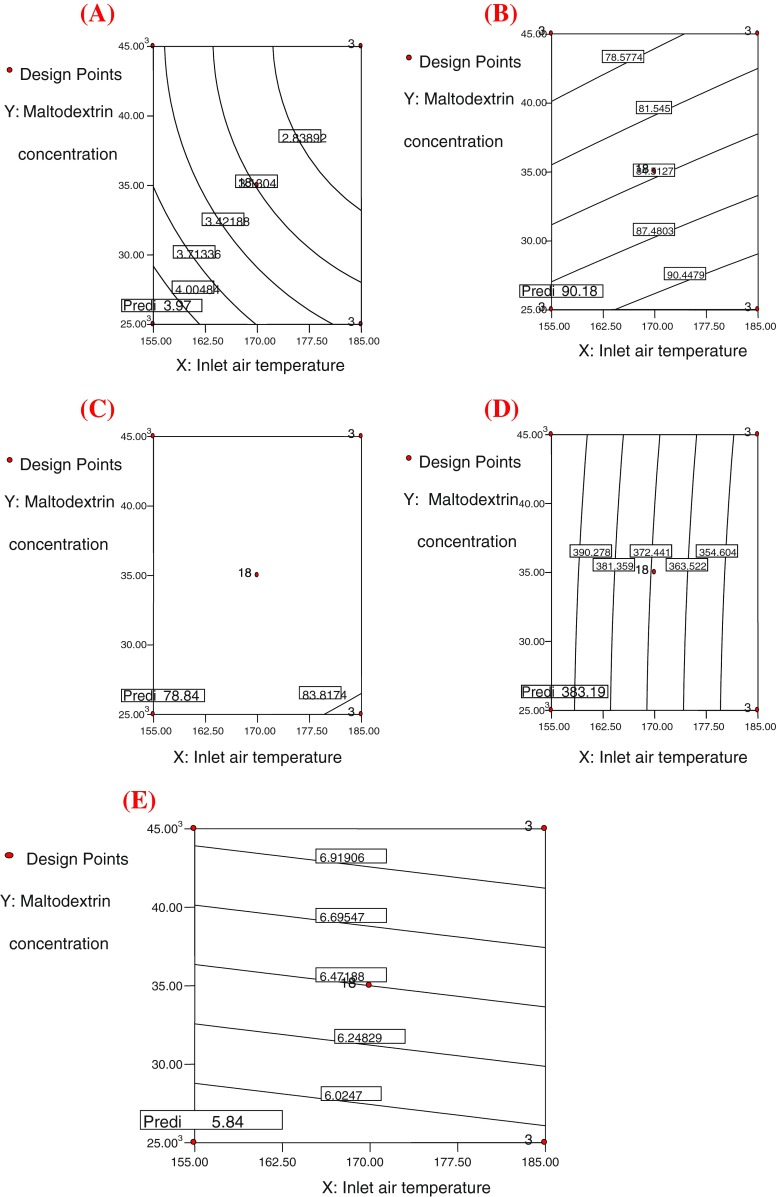

The regression coefficients obtained for the second order polynomials (SOP) of the five responses are shown in Table 4. These coefficients are necessary in developing the multiple regression equations for the responses to coded levels of the variables. The contour plots of five responses were developed as a function of the two independent variables (levels of inlet air temperature and maltodextrin concentration) according to their significance to the response. The contour plot for moisture content, solubility, dispersibility, vitamin C content and overall color difference value as a function of levels of inlet air temperature and maltodextrin concentration is shown in Fig. 2a–e. The optimum area was obtained by superimposing (graphical method) the contour plots from which the optimum formulation was obtained (Madamba 1997).

Table 4.

Regression coefficients of the SOP representing the relationship of the response and independent variables in the optimization of seabuckthorn fruit juice powder processing

| Coefficients | Moisture (Y1) | Solubility (Y2) | Dispersibility (Y3) | Vitamin C (Y4) | Overall color difference value (Y5) |

|---|---|---|---|---|---|

| β0 | 2.77a | 84.21a | 67.05a | 371.56a | 6.47a |

| β 1 | −0.47a | 2.22a | 0.72 | −25.16a | 0.08 |

| β 2 | −0.40a | −6.68a | −4.90a | 1.59a | 0.59a |

| β 1.1 | 0.12 | −0.11 | 1.23a | 0.31 | - |

| β 2.2 | 0.19a | 0.42a | 3.43a | 0.57a | - |

| β1 .2 | 0.00 | 0.00 | −3.46a | −0.00 | - |

aSignificant at 95 % level

Fig. 2.

Contour plots for (a) moisture content, (b) solubility, (c) dispersibility, (d) vitamin C content and (e) overall color difference value as function of levels of inlet air temperature (°C) and maltodextrin concentration (g)

Moisture content

The coefficients of the first order terms for the Eq. (4) (Table 4) with coded variables indicated that the moisture content decreased with the increase in inlet air temperature as well as maltodextrin concentration. Inlet air temperature was found to have maximum influence on moisture content followed by maltodextrin concentration. This may be due to generation of high hot air during drying, which might have trapped the moist air that was found in the fed product and it might have reduced the moisture content to a greater extent (Jaya and Das 2004). It was reported that moisture content was decreased by increasing the inlet air temperature during spray drying of encapsulated pandan extract (Loh et al. 2005).

|

4 |

Solubility and dispersibility

From the regression coefficients of Eqs. (5) and (6), it is clear that a decrease in the maltodextrin concentration level in the fruit juice slurry increased the solubility and dispersibility values of the fruit juice powder. This may be due to presence of less amount of insoluble residue and formation of very few lumps as a result of use of lower amount of additive i.e. maltodextrin (Abadio et al. 2004; Jaya and Das 2004). Increase in solubility and dispersibility values were reported as a result of drastically reducing the additives viz., maltodextrin concentration and tricalcium phosphate during drying of pineapple and mango fruit juices (Abadio et al. 2004; Jaya and Das 2004).

|

5 |

|

6 |

Vitamin C content

The coefficients of the first order terms for the Eq. (7) (Table 4) with coded variables indicated that vitamin C content of the juice powder increased significantly by reducing the spray drying condition i.e. inlet air temperature and food additive i.e. maltodextrin concentration in the fruit juice slurry. Inlet air temperature was found to have maximum influence on vitamin C content followed by maltodextrin concentration. The loss of vitamin C was in the range of 19.5 %–33.3 %, which could be due to use of high temperature during processing. Similar loss in vitamin C content during spray drying of guava puree was reported at such type of varying temperature levels (Muralikrishna et al. 1969).

|

7 |

Overall color difference value

From the regression coefficients of Eq. (8), it is clear that an decrease in maltodextrin concentration level in the fruit juice slurry decreased the overall color difference value of the fruit juice powder, while the reduction in inlet air temperature doesn’t showed any prominent remarkable effect. This may be due to use of maltodextrin concentration at a lower extent, which might have not reduced the intensity of the bright orange color of the fruit juice slurry. Generally for fruit juice powder to be attractive, only lesser overall color difference value is preferred (Jaya and Das 2004) and therefore it can be obtained by using lesser concentration of maltodextrin during drying process. Decrease in overall color difference value was reported due to use of lower maltodextrin concentration levels during drying of mango fruit juice (Jaya and Das 2004).

|

8 |

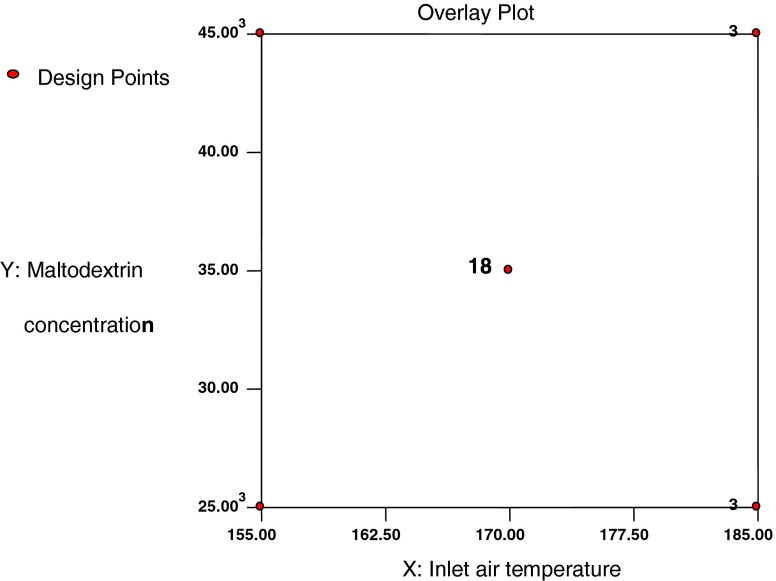

Optimization of fruit juice powder processing

Numeric and graphic optimizations were carried out for the process parameters of` the seabuckthorn fruit juice powder. The desired goals for each variable and response were chosen as summarized in Table 5a. The limit for each variable was narrowed down to obtain an optimal region. Each goal was chosen to be is: to minimize and also is to maximize based on the moisture content, solubility, dispersibility, vitamin C content and overall color difference value of the developed product, because at this desired level only the free flowing characteristics of the fruit juice powder can be obtained i.e. by using low moisture content levels; improved instantanisation properties can be achieved by maximizing the levels of solubility and dispersibility; enhanced nutritive value can be obtained with higher vitamin C content and finally the improved aesthetic appearance i.e. color can be achieved by minimizing the levels of overall color difference value. Table 5b shows that the software generated one optimum conditions of independent variables with the predicted values of responses, in the inlet air temperature is at minimum level = 162.5 °C and maltodextrin concentration is also at minimum level = 25 g/100 g for achieving the minimum moisture content = 3.97 %, maximum solubility = 90.18 %, maximum dispersibility = 78.84 %, maximum vitamin C content = 383.19 mg/100 g and minimum overall color difference value = 5.84.

Table 5.

Criteria (a) and outputs (b) of the numerical optimization of the responses for seabuckthorn fruit juice powder processing

| (a) | |||||||

| Constraints | Goal | Limit | |||||

| X1: Inlet air temperature (°C) | Is to minimize | 155–185 | |||||

| X 2: Maltodextrin concentration (g) | Is to minimize | 25–45 | |||||

| Y1: Moisture (%) | Is to minimize | 2.02–4.31 | |||||

| Y2: Solubility (%) | Is to maximize | 74.84–95.19 | |||||

| Y3: Dispersibility (%) | Is to maximize | 60.84–82.76 | |||||

| Y4: Vitamin C (mg/100 g) | Is to maximize | 335.58–407.65 | |||||

| Y5: Overall color difference value | Is to minimize | 4.39–7.91 | |||||

| (b) | |||||||

| No. | X1 | X 2 | Y1 | Y2 | Y3 | Y4 | Y5 |

| 1. | 162.5 | 25.0 | 3.97 | 90.18 | 78.84 | 383.19 | 5.84 |

From the set of constraints and outputs given in Table 5a and b, contour plots of relevant and statistically significant responses were generated, and the overlaying of those plots is displayed in Fig. 3. The shaded area in Fig. 3 represents the X1-X2 domain satisfying the imposed criteria. Thus, optimum processing conditions can be drawn from this shaded area to achieve a specific goal. For example, shaded area in Fig. 3 determines the following criteria and goals: inlet air temperature = 162.5 °C, maltodextrin concentration =25 g/100 g, moisture content = 3.97 %, solubility = 90.18 %, dispersibility = 78.84 %, vitamin C content = 383.19 mg/100 g and overall color difference value = 5.84.

Fig. 3.

Superimposed contour plot for significant responses viz., moisture content, solubility, dispersibility, vitamin C content and overall color difference value as affected by levels of inlet air temperature (°C) and maltodextrin concentration (g)

Verification of second order polynomial model

The SFJP was developed using the derived optimum processing conditions to check the validity of the SOP model. The experimental values for moisture, solubility, dispersibility, vitamin C and overall color difference value were determined and compared with the predicted values of the SOP model (Table 6). The experimental values (mean of three trials) were found to be in close agreement to the predicted values and were within the acceptable limits indicating the suitability of the model in predicting quality attributes of SFJP.

Table 6.

Predicted and actual values of the responses at optimum processing conditions of seabuckthorn fruit juice powder

| Response variables | Predicted values | Experimental valuesa |

|---|---|---|

| Moisture (%) | 3.97 | 4.01 ± 0.04 |

| Solubility (%) | 90.18 | 90.1 ± 0.80 |

| Dispersibility (%) | 78.84 | 78.9 ± 0.6 |

| Vitamin C (mg/100 g) | 383.19 | 384.2 ± 0.6 |

| Overall color difference value | 5.84 | 5.81 ± 0.52 |

aMean ± SD of triplicate analysis

Nutritional properties of SFJP

The nutritional properties of SFJP sample in comparison with other commercial fruit juice powders were given in Table 7. The result shows that the spray dried juice powder contains higher amounts of antioxidants viz., vitamin C, vitamin E, total carotenoids, total anthocyanins and total phenols. This may be due to presence of above antioxidants in enormous amount in fruit juice, from which the fruit juice powder was being developed. In particular the concentration of total phenols, vitamin C, E was found to be higher when compared to other two antioxidants i.e. carotenoids and anthocyanins. The commercial pineapple fruit juice powder exhibited non detectable vitamin E content, this may be because of absence of vitamin E content in that fruit pulp.

Table 7.

Nutritional properties of seabuckthorn fruit juice powder in comparison with other commercial fruit juice powders

| Parameters | Seabuckthorn fruit juice powder | Pineapple fruit juice powder | Grape fruit juice powder |

|---|---|---|---|

| Total solids (%) | 95.9 ± 0.21 | 95.6 ± 0.17 | 95.5 ± 0.23 |

| Acidity (%) | 5.5 ± 0.04 | 3.0 ± 0.06 | 3.3 ± 0.05 |

| Total sugars (%) | 14.2 ± 0.80 | 22.8 ± 0.70 | 27.5 ± 0.50 |

| Reducing sugars (%) | 2.2 ± 0.70 | 11.4 ± 0.60 | 19.6 ± 0.80 |

| Vitamin C (mg/100 g) | 384.2 ± 0.60 | 15.2 ± 0.40 | 12.8 ± 0.80 |

| Vitamin E (mg/100 g) | 152.4 ±1.70 | ND | 40.1 ± 1.30 |

| Total carotenoids (mg/100 g) | 5.4 ± 0.60 | 0.2 ± 0.10 | 0.1 ± 0.00 |

| Total anthocyanins (mg/100 g) | 1.1 ± 0.38 | 0.11 ± 0.06 | 0.19 ± 0.08 |

| Total phenols (mg/100 g) | 453.6 ± 1.00 | 40.5 ± 1.80 | 46.9 ± 1.30 |

ND: not detectable

Thermal properties of SFJP

Agglomeration and caking of food powders are deleterious phenomena that limit the use of powders. The main cause of caking and agglomeration is water—induced plasticization of the particle surface. These physical changes were successfully explained and predicted by the glass transition concept on the basis of glass transition temperature (Tg) as a reference temperature (Chuy and Labuza 1994). Such physical transformations have been observed to occur above Tg (Aguilera et al. 1995; Champion et al. 2000).

Table 8 show’s the thermal behaviour of SFJP. The juice powder showed a higher glass transition temperature i.e. 43.36 °C (Tg) when compared to acerola fruit juice powder that are already reported in literature (Righetto and Netto 2005). This might be due to use of high molecular weight amorphous polymers such as maltodextrin, which had increased the glass transition temperature to a greater extent (Righetto and Netto 2005). At this temperature the juice powder was found to be free flowing without any physical alterations such as caking, stickiness, collapse and crystallization. The charring or thermal degradation of powder occurred at a temperature of 164.92 °C.

Table 8.

Thermal properties of seabuckthorn fruit juice powder developed by using optimized processing conditions

| Parameters | Valuesa | |

|---|---|---|

| Glass transition temperature (Tg) °C | - | 43.3 ± 0.64 |

| Amorphous melting temperature (TM) °C | - | 76.0 ± 0.29 |

| Start of the amorphous melting (Ti) °C | - | 50.9 ± 0.58 |

| Span of temperature (ΔT) °C | - | 40.2 ± 0.34 |

| Change in enthalpy of amorphous melting temperature (ΔH) mj | - | 134.7 ± 0.27 |

| Completion temperature (Tc) °C | - | 91.1 ± 0.41 |

| Thermal degradation of powder °C | - | 164.9 ± 0.30 |

aMean ± SD of triplicate analysis

Conclusion

Fourteen different runs according to the CCRD were used to study the quality parameters of SFJP at various levels of inlet air temperature and maltodextrin concentration. The response surface methodology was used to optimize the processing conditions using moisture content, solubility, dispersibility, vitamin C content and overall color difference value as responses. The SOP models for moisture content, solubility, dispersibility, vitamin C content and overall color difference value were statistically significant. By superimposing the contour plots, an optimum spray drying process i.e. inlet air temperature level of 162.5 °C and maltodextrin concentration level of 25 g for drying 100 g of fruit juice slurry was recommended with predicted responses close to experimental values. The SFJP sample developed using the optimized spray drying process compared well with the commercial fruit juice powder sample in terms of nutritional properties.

Acknowledgments

The authors are thankful to Defence Research and Development Organization for providing grant to carry out this research work.

References

- Abadio FDB, Domingues AM, Borges SV, Oliveira VM. Physical properties of powdered pineapple (Ananas comosus) juice—effect of maltodextrin concentration and atomization speed. J Food Eng. 2004;64:285–287. doi: 10.1016/j.jfoodeng.2003.10.010. [DOI] [Google Scholar]

- Aguilera JM, Levi G, Karel M. Effect of water content on the glass transition and caking of fish protein hydrolysates. Biotech Prog. 1995;9:651–654. doi: 10.1021/bp00024a013. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. Washington: AOAC; 1970. [Google Scholar]

- AOAC . Official methods of analysis,14 th edn. Washington: AOAC; 1984. [Google Scholar]

- Arya SS, Natesan V, Parihar DB, Vijayaraghavan PK. Stability of carotenoids in dehydrated carrots. J Food Tech. 1979;14:579–586. doi: 10.1111/j.1365-2621.1979.tb00904.x. [DOI] [Google Scholar]

- Champion D, Le Meste M, Simatos D. Towards an improved understanding of glass transition and relaxation in foods: molecular mobility in the glass transition range. Trends Food Sci Technol. 2000;11:41–55. doi: 10.1016/S0924-2244(00)00047-9. [DOI] [Google Scholar]

- Chauhan AS, Rekha MN, Ramteke RS, Eiperson WE. Preparation and quality evaluation of processed products from seabuckthorn (Hippophae rhamnoides Lin.) berries. Beverage and Food World. 2001;27:31–34. [Google Scholar]

- Chuy LE, Labuza TP. Caking and stickiness of dairy – based food powders as related to glass transition. J Food Sci. 1994;59:43–46. doi: 10.1111/j.1365-2621.1994.tb06893.x. [DOI] [Google Scholar]

- Clydesdale FM, Francis FJ. Pigments. In: Fennema OR, editor. Food chemistry. New York: Marcel Dekker; 1976. pp. 385–426. [Google Scholar]

- Desai ID. Improved spectrophotometric assay for vitamin E: Oxygen radicals in biological systems. In: Packer L, editor. Methods in enzymology. Orlando, USA: Academic; 1984. pp. 142–144. [Google Scholar]

- IAL . Normas analiticas: metodos fisicos y quimicos para analise de alimentos. Sao Paulo, Brazil: IAL; 1977. [Google Scholar]

- Jaya S, Das H. Effect of maltodextrin, glycerol monostearate and tricalcium phosphate on vacuum dried mango powder properties. J Food Eng. 2004;63:125–134. doi: 10.1016/S0260-8774(03)00135-3. [DOI] [Google Scholar]

- Li TSC, Schroeder WR. Seabuckthorn (Hippophae rhamnoides Lin.): A multipurpose plant. Hort Technology. 1996;6:370–380. [Google Scholar]

- Li TSC, Wang LCH. Physiological components and health effects of ginseng, echinacea and seabuckthorn. In: Mazza G, editor. Functional foods, biochemical and processing aspects. Lancaster: Technomic Publishing; 1998. pp. 329–356. [Google Scholar]

- Loh SK, Cheman YB, Tan CP, Osman A, Hami NS. Process optimization of encapsulated pandan (Pandanus amaryllifolius) powder using spray drying method. J Sci Food Agric. 2005;85:1999–2004. doi: 10.1002/jsfa.2169. [DOI] [Google Scholar]

- Madamba PS. Optimization of the drying process: An application to the drying of garlic. Dry Technol. 1997;15(1):117–136. doi: 10.1080/07373939708917221. [DOI] [Google Scholar]

- Muralikrishna M, Nanjundaswamy AM, Siddappa GS. Guava powder preparation, packaging and storage studies. J Food Sci Technol. 1969;6:93–98. [Google Scholar]

- Pisecky J. Standards, specifications and test methods for dry milk products: Concentration and drying of foods. Delhi, India: Elsevier Science Publishing Co; 1985. [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. Delhi, India: Tata McGraw-Hill; 1986. [Google Scholar]

- Righetto AM, Netto FM. Effect of encapsulating materials on water sorption, glass transition and stability of juice from immature acerola. Intl J Food Properties. 2005;8:337–346. doi: 10.1081/JFP-200060262. [DOI] [Google Scholar]

- Sathe AY. A first course in food analysis. In: Whistler RL, Be Miller JN, editors. Carbohydrate chemistry. New York: Academic; 1999. [Google Scholar]

- Singleton VL, Rossi JA. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Eno Viti. 1965;16:144–158. [Google Scholar]

- Vander-lijn J. Simulation of heat and mass transfer in spray drying. Wageningen: Centre for Agricultural Publishing and Documentation; 1976. [Google Scholar]