Abstract

Shiitake mushrooms were dehydrated by two different drying methods, i.e., microwave-vacuum drying (MVD) and microwave-vacuum combined with infrared drying (MVD + IR). MVD was operated at microwave powers of 56, 143, 209 and 267 W under absolute pressures of 18.66, 29.32, 39.99 and 50.65 kPa, whereas infrared radiation was added in MVD + IR at 100 and 200 W. The effects of microwave power, absolute pressure and infrared power on drying characteristics, qualities and specific energy consumption were investigated. It was found that drying rate increased with lower absolute pressure, higher microwave power and higher infrared power. In particular, the results also indicated that drying undergoing MVD + IR could provide better qualities in terms of color of dried shiitake mushroom, rehydration ratio and texture of rehydrated ones. Furthermore, the drying characteristics were described by fitting data to six different drying models. Based on their coefficient of determination, root mean square error, residual of sum square and chi-square, Modified Page model could accurately predict moisture ratio for all drying conditions. Within the range of this study, the suitable drying condition with respect to the product qualities and energy consumption was MVD + IR drying at 267 W of microwave power, 18.66 kPa of absolute pressure and 200 W of infrared power.

Keywords: Drying, Microwave-vacuum drying, Microwave-vacuum combined with infrared drying, Shiitake mushroom

Introduction

In the past, mushrooms have been consumed as a delicacy because they have a highly desirable taste and aroma and they have been used for medicines in Asia. Generally, mushrooms are rich in dietary fiber, minerals, and vitamins, and also contain various polyphenolic compounds known as an excellent antioxidant. Shiitake mushroom (Lentinus edodes) is one of the most common edible mushrooms and it is the second most cultivated edible mushroom (Chandra et al. 2011). Numerous studies have shown its medicinal attributes including anti-tumor, antimicrobial, liver function improving, cholesterol lowering activity (Choi et al. 2006), lowering blood pressure and strengthening the immune system against diseases including viral ones (Reguła and Siwulski 2007). However, fresh shiitake mushrooms are highly perishable and start deteriorating within a day after harvest, causing difficulties in their distribution and marketing as fresh products. Therefore, fresh shiitake mushrooms are usually dehydrated to extend their shelf life. Moisture removal through drying prevents the growth of spoilage microorganisms, slows the action of enzymes, and minimizes many moisture mediated reactions. Generally, the conventional drying methods are sun drying and convective drying. These methods are easy but time consuming. Especially, hot air drying has some major disadvantages, i.e., time consuming, poor rehydration properties, dark color and hard texture of the products (Hebbar et al. 2004; Therdthai and Zhou 2009).

Microwave drying is an alternative method due to volumetric heating, short drying time, hygienic conditions, energy saving and also providing a good quality of dried products (Kiranoudis et al. 1997; Bal et al. 2010; Hirun et al. 2012). In recent years, microwave-vacuum drying (MVD) has been researched as a potential drying method for high quality dried biological products. Hu et al. (2006) reported that MVD increased the moisture gradient and speeded up the drying rate. Under vacuum, the working temperature can be lower than ordinary microwave drying due to lower boiling point. Therefore, MVD can help to preserve qualities of dried products. Many agricultural products, such as cranberries (Sunjka et al. 2004), tomatoes (Durance and Wang 2002), bananas (Mousa and Farid 2002), apples, kiwis, pears (Kiranoudis et al. 1997), button mushrooms (Giri and Prasad 2006, 2007, 2009), mint leaves (Therdthai and Zhou 2009), bamboo shoots (Bal et al. 2010), sour cherry (Motavali et al. 2011) and turmeric (Hirun et al. 2012) can be successfully dried using MVD.

Microwave-vacuum combined with infrared drying (MVD + IR) is a new technology and it combines the two different heating mechanisms: microwave heating and infrared heating. When microwave energy is applied to foods, heat is generated within the product which increases food temperature rapidly. While, infrared energy induces changes in the vibrational states of atoms and molecules of a product. Infrared lamp is heated and radiation is focused on the food surface which removes surface moisture and prevents sogginess of the dried product (Ruiz Celma et al. 2009; Doymaz 2011; Zhang and Wang 2011). Infrared drying has gained popularity as an alternative method for drying of fruits and vegetables. The main advantages of infrared drying are reduction in drying time, energy saving, high energy efficiency and high product quality, i.e., reduces color change, improves rehydration (Hebbar et al. 2004; Vishwanathan et al. 2010; Doymaz 2011; Zhang and Wang 2011). Food products, such as grapes (Caglar et al. 2009; Ruiz Celma et al. 2009), sweet potatoes (Doymaz 2011) and pineapple (Ponkham et al. 2012) have been dried using infrared dryer. Moreover, agricultural products with high moisture content can be dried using combination drying, as it provides synergistic effect. There are many studies on the application of infrared combined with other drying methods like hot air assisted infrared drying (Vishwanathan et al. 2010; Ponkham et al. 2012) and microwave combined with infrared drying (Sumnu et al. 2005; Wang and Sheng 2006).

In addition, knowledge of the mathematical model is required for a better understanding of controlling the parameters, helping to understand the transport phenomena associated with processing and optimizing the variables of drying process (Wang et al. 2009; Assawarachan and Noomhorm 2011). The drying models of agricultural products can be categorized into three categories, namely theoretical, semi-theoretical and empirical model. The theoretical approach is concerned with diffusion or simultaneous heat and mass transfer equations and takes the internal resistance to moisture transfer into account. While semi-theoretical and empirical approaches consider only the external resistance to moisture transfer between the product and air. The semi-theoretical approach is concerned with approximated theoretical equations. Empirical equations are easily applied to drying simulation as they depend only on experimental data (Akpinar and Bicer 2005; McMinn 2006). In this work, a semi-theoretical models were selected to describe the drying characteristics because they offer a compromise between theory and experimental results, they are commonly used in the literature and easy to use (Shih et al. 2008; Ruiz Celma et al. 2009; Ponkham et al. 2012). A number of semi-theoretical drying models have been widely used to describe the drying process, such as, cyclone drying of eggplants (Akpinar and Bicer 2005), microwave, microwave-convective and microwave vacuum drying of lactose powder (McMinn 2006), sequential infrared radiation and freeze drying for producing crispy strawberries (Shih et al. 2008), microwave drying of bamboo shoot slices (Bal et al. 2010), microwave vacuum drying of sour cherries (Motavali et al. 2011), infrared drying of sweet potato slices (Doymaz 2011), and microwave vacuum concentration of pineapple juice (Assawarachan and Noomhorm 2011).

Bringing all of these into account, it was expected that the use of microwave-vacuum combined with infrared drying could result in an effective drying, i.e., time saving from microwave and fast surface moisture removal by infrared. However, the possibility to dehydrate shiitake mushrooms using microwave-vacuum combined with infrared drying has not been yet explored. Thus, the main objectives of the present study were to study and compare the drying characteristics of shiitake mushrooms undergoing MVD and MVD + IR. Rehydration ratio, hardness, color, microstructure of dried mushrooms and specific energy consumption were also evaluated.

Materials and methods

Material

Fresh shiitake mushrooms (Lentinus edodes) were purchased from a local market and stored at 4-5°C. Prior to drying, mushrooms were cleaned to remove dirt using paper towel and cut the stem out manually. Moisture content of mushrooms was determined in hot air oven at 105°C according to AOAC method (AOAC 2000). Initial moisture content of mushroom was found to be 601.75±1.40 % (dry basis).

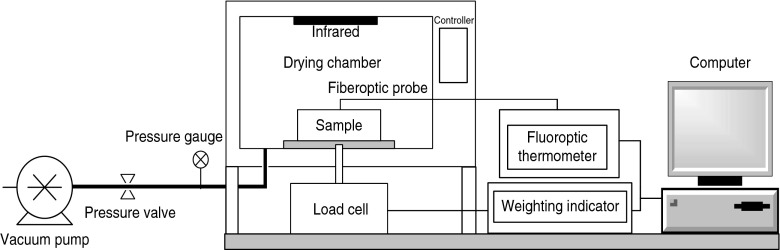

Microwave-vacuum combined with infrared dryer

Microwave-vacuum combined with infrared dryer used in this work was modified from a domestic microwave oven (Samsung, M183GN, Thailand) with the maximum power of 850 W at 2450 MHz. The power of the microwave oven was calibrated using the standard procedure (IMPI 2-L test) (Buffler 1993). To generate vacuum, the chamber was connected to a vacuum pump (BUSCH, Type RC0063 E501, Germany). A pressure valve and a pressure gauge were used to adjust and monitor the pressure inside the chamber. An infrared heater was installed on the top of the chamber. Power output of the infrared heater was varied (0, 100 and 200 W) by connecting to a 220 V AC variac (Matsunaga, 265 M, Japan). Mass and temperature of the samples were monitored using a load cell which was connected to a weighing indicator (A&D, AD-4329, Japan) and a fluoroptic thermometer (Luxtron, M600 OEM, USA) connected to a temperature recorder, respectively. The schematic of the combined microwave-vacuum with infrared dryer is depicted in Fig. 1.

Fig. 1.

Combined microwave vacuum with infrared oven

Drying processes

20 g of shiitake mushroom was used for each experiment. The mushroom caps were placed in drying chamber at the center of the drying chamber, and then dried to a final moisture content of about 11.11 % (dry basis) according to Thai Community Products Standards (TCPS). As mentioned above, two drying methods were used in this work, i.e., MVD and MVD + IR. Samples were subjected to different microwave power levels (267, 209, 143 and 56 W), absolute pressure levels (50.65, 39.99, 29.32 and 18.66 kPa) and infrared power levels (0, 100 and 200 W). At the end of drying experiment, dehydrated samples were packed in aluminum bags and kept in a desiccator for further quality evaluations.

Selection of drying parameters

The microwave power levels were selected based on the data from literature surveys about the drying of other species of mushroom. Rodríguez et al. (2005) studied the microwave vacuum drying of button mushroom at microwave power levels of 60, 120, 180 and 240 W. In addition, it was also investigated by Giri and Prasad (2007) at the microwave power levels of 115, 150, 200, 250 and 285 W. Therefore, the microwave power levels of 56, 143, 209 and 267 W were selected in accordance with the earlier works mentioned. In addition, the preliminary experiments exhibited that the samples were burned at the microwave power higher than 267 W. This point is almost the same as the drying of button mushroom (study of Giri and Prasad (2006)) which the burning of samples took place above 250 W microwave level. Infrared and infrared-assisted drying were widely used to dry biological products as reported by several investigators. Normally, the infrared power levels were used in the range from 100–500 W to dry products, such as carrots (Sumnu et al. 2005; Kocabiyik and Tezer 2009), red pepper slices (Nasiroglu and Kocabiyik 2009), beetroots (Kowalski and Mierzwa 2009), grapes (Caglar et al. 2009), longans (Nathakaranakule et al. 2010) and sweet potato slices (Doymaz 2011). Regarding the preliminary experiments, the result showed that the application of infrared power higher than 200 W charred the product. Hence, two levels of infrared power at 100 and 200 W were selected in this study. In case of absolute pressure, the lowest level of absolute pressure was set based on the efficiency of the vacuum pump. However, the range of absolute pressure employed in this work covered the range of the microwave vacuum drying of other agricultural products as shown in the works of Giri and Prasad (2006), Sutar and Prasad (2007), Poonnoy et al. (2007) and Motavali et al. (2011).

Drying characteristics

To study the effects of the drying methods and process conditions on drying characteristics, the average moisture ratio, MR, was calculated using Eq. 1:

|

1 |

where M is sample moisture content (dry basis), Me is the equilibrium moisture content which is assumed to be zero due to the vacuum condition, and Mo is the initial moisture content (dry basis).

The experimental results of moisture ratio versus drying time were then fitted to six semi-theoretical models using non-linear regression analysis as listed in Table 1. Coefficient of determination (R2), the root mean square error (RMSE), the residual of sum square (RSS) and the reduced chi-square values (χ2) were used for selecting the best equation to describe the drying data. The higher values of R2 and the lower of χ2, RMSE and RSS were chosen for goodness of fit.

Table 1.

Mathematical models given by various authors for drying curves

| Model | Model equation | Reference |

|---|---|---|

| Newton/Lewis | MR = exp(−kt) | (Doymaz 2011) |

| Page | MR = exp(−ktn) | (Ruiz Celma et al. 2009) |

| Modified Page | MR = exp(−(kt)n) | (Ruiz Celma et al. 2009) |

| Wang and Singh | MR = 1+ a.t + b.t2 | (Bal et al. 2010) |

| Henderson and Pabis | MR = a.exp(−kt) | (Doymaz 2011) |

| Logarithmic | MR = a.exp(−kt) + b | (Doymaz 2011) |

These parameters can be calculated as follows:

|

2 |

|

3 |

|

4 |

where MRpre,i is the ith predicted moisture ratio, MRexp,i is the ith experimental moisture ratio, N is number of observations, and np is the number of constants (Ruiz Celma et al. 2009) .

Quality evaluations

Rehydration ratio

The rehydration ratio was determined by immersing a known amount of dried shiitake mushroom into boiling water for 10 min. The sample was then drained and weighed. All measurements were performed in triplicate and the rehydration ratio of the dried mushroom was calculated as:

|

5 |

Texture measurement (Hardness)

Texture analyzer (Stable Micro Systems, TA.XT.plus, UK) was used to analyze hardness value of rehydrated shiitake mushroom. Texture analysis was adapted from Kotwaliwale et al. (2007) and Giri and Prasad (2009) and carried out under following conditions: pre-test and test speed = 0.8 mm/s; post-test speed = 10 mm/s; strain = 70 % of the sample height; diameter of cylinder stainless steel probe = 6 mm. The measurement was conducted in triplicate and the mean value was reported.

Color measurement

Color of the samples was measured in L*, a*, b* coordinates using a colorimeter (HunterLab, ColorQuest XE, Reston, VA). The instrument was calibrated using standard white tile before the measurements. All samples were measured three times at different positions. The data were reported as average values of these measurements. Color difference between dried and fresh mushrooms (ΔE) was determined by:

|

6 |

|

7 |

where L*, a* and b* present darkness-lightness, greenness-redness and blueness-yellowness, respectively, and subscript o stands for fresh shiitake mushrooms.

Color difference (ΔE) indicates the degree of overall color change of a sample in comparison to color of fresh mushroom. The L*, a* and b*of the fresh mushrooms were found to be 47.93 ± 1.86, 9.73 ± 0.22 and 21.50 ± 1.42, respectively.

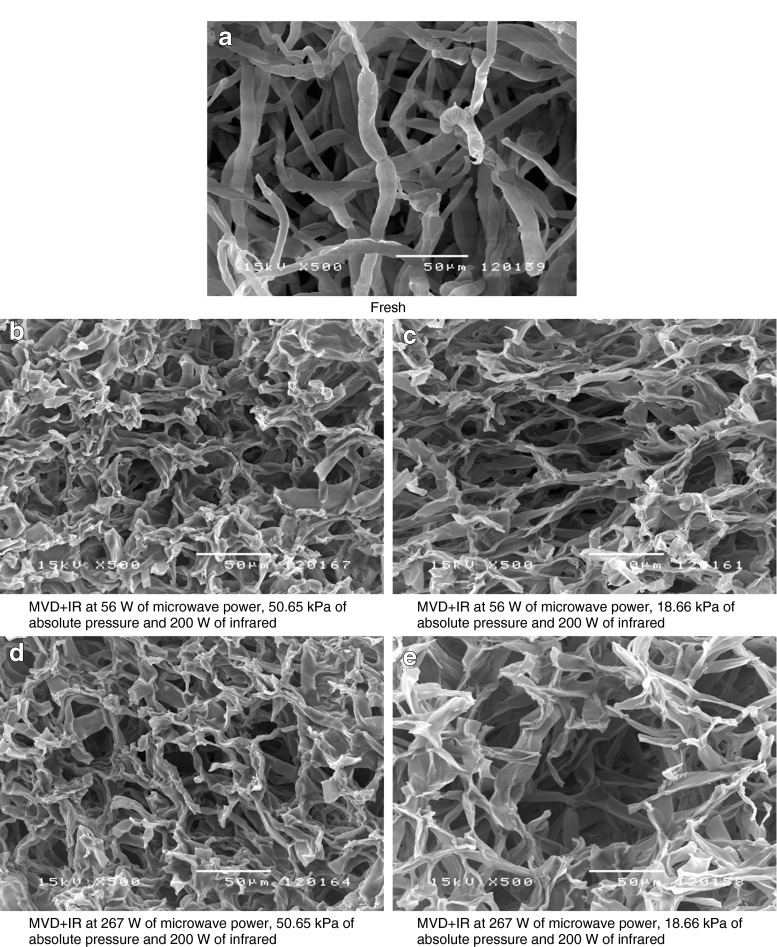

Scanning electron microscopy (SEM)

The Scanning Electron Microscopy was used to analyze the microstructure of mushrooms after drying. Sample microstructure was observed by JEOL model JSM-5410LV, Tokyo, Japan. The specimens for SEM were taken from the center of the cap of dried sample. Small piece of about 4 × 4 × 1 mm was cut from the dried samples and fixed on the SEM stub, which were coated with gold to provide a reflective surface for electron beam. The gold-coated samples were viewed under the microscope and a ×100 magnification was used in all SEM observations.

Specific energy consumption in drying process

Another important consideration for the suitable drying conditions is the cost of energy inputs. The specific energy consumption during dehydration was estimated using Eq. 8:

|

8 |

The total electric power (Etotal) was calculated from:

|

9 |

|

10 |

|

11 |

|

12 |

where EMW is electrical power supplied to the microwave oven, EIR is electrical power supplied to the infrared heater, EVP is electrical power supplied to the vacuum pump, PMW is the microwave power output (kW), PIR is the power of infrared heater (kW), PVP is nominal pump power (kW) and t is drying time (h)(Motavali et al. 2011) .

Statistical analysis

The research was conducted using a full factorial experimental design. The effects of the microwave power (MW), absolute pressure (P) and infrared power (IR) were considered by an analysis of variance (ANOVA) via SPSS® software (Version 13). Duncan’s multiple range tests was used to compare the mean values at a confidence level of 95 %.

Results and discussion

Drying characteristics

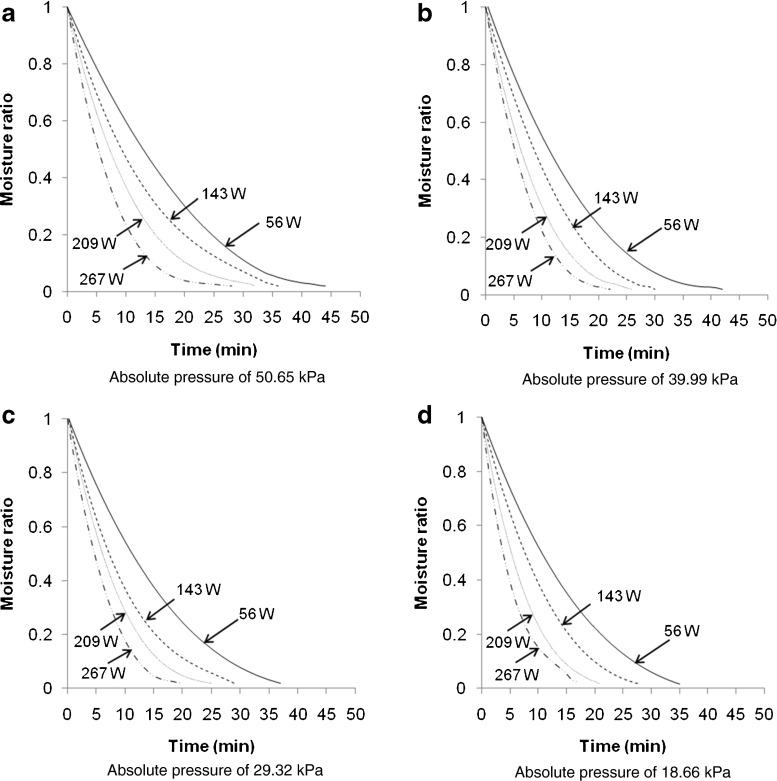

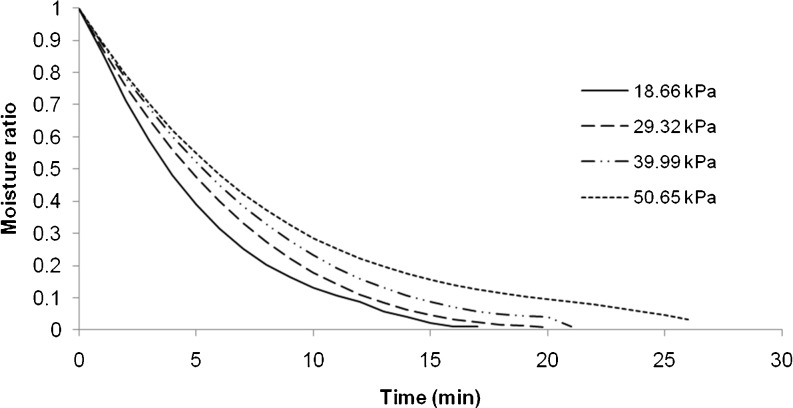

The effects of MW (267, 209, 143 and 56 W) and P (50.65, 39.99, 29.32 and 18.66 kPa) on drying characteristics of shiitake mushrooms were reported in Fig. 2. Under a constant P, the moisture loss of the sample increased as MW level was higher. With higher MW, more heat generated within the sample created a larger vapor pressure difference between the center and the product surface (Wang and Sheng 2006), thus accelerated the interior moisture migration and increased surface water evaporation. In addition, P has significant effect on drying characteristics. The drying time decreased when the lower P was applied at the same MW as shown in Fig. 3. Lower the P decreases the boiling point of water, increases the driving force for mass transfer and speeds up the evaporation of water, thus shortens the drying time (Hu et al. 2006; Han et al. 2010). In conclusion, drying of shiitake mushroom using MVD with higher MW and lower P promotes greater moisture removal and effective dehydration.

Fig. 2.

Effects of microwave power and absolute pressure on moisture ratio of shiitake mushrooms drying undergoing MVD

Fig. 3.

Effect of absolute pressure on drying curve of shiitake mushrooms undergoing MVD at microwave power level of 267 W

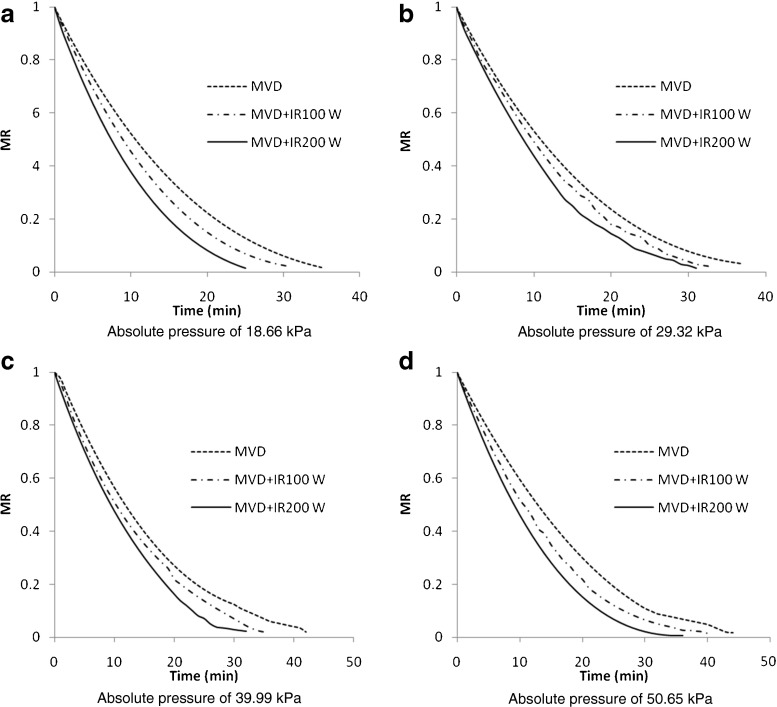

The effects of IR powers, i.e., 100 and 200 W combined with MVD (MW of 56 W at different P) on drying characteristics of shiitake mushrooms are presented in Fig. 4. Similar trends of results were found at MW of 143, 209 and 267 W (data not shown). The results showed that, drying time was decreased when the IR increased from 0 to 100 and 200 W. When the mushroom is exposed to infrared radiation, the water molecule at the surface absorb the infrared, vibrate and then heat is generated simultaneously. The rapid heating of the material increases the rate of moisture movement (Hebbar et al. 2004). As expected, with IR power, mushroom was exposed to more radiative heat and greater mass transfer driving force resulted in faster drying and consequently lower drying time. In addition, the increase in the IR caused higher product surface temperature and more moisture loss which leads to faster drying (Wang and Sheng 2006; Caglar et al. 2009; Nasiroglu and Kocabiyik 2009; Ponkham et al. 2012). This was expected since with the coupled drying mechanism it was possible to reach higher internal temperatures due to microwave heating and higher surface temperatures due to infrared heating. In addition, the drying time also decreased with decrease in the P. This is because the water evaporated at lower temperature when the system was operated at lower absolute pressure.

Fig. 4.

Effect of infrared power on drying curve of shiitake mushrooms undergoing MVD and MVD + IR at MW of 56 W

Modeling of drying curves

To get more insight of the drying behaviors of shiitake mushrooms, the moisture ratio data versus drying time at the different drying methods and conditions were fitted to six different mathematical models. In case of Page, Modified Page and Logarithmic, the R2 values of the models were greater than 0.99. In addition, the R2 values of Wang and Singh, and Henderson model were higher than 0.98. The R2 values of Newton model gave the lowest values (>0.97). This indicated a good fit of the experimental drying data to all the test models (data not shown). In addition, low values of RMSE, RSS and χ2 were also confirmed a good fit. The Modified Page model fitted the best with experimental data with the highest R2 and the lowest values of RMSE, RSS and χ2. Thus, Modified Page model was chosen to characterize the drying kinetic of shiitake mushroom. The relative magnitude of the drying rate constant (k) values reflects the drying behavior. For MVD, k tended to increase when the MW increased and P decreased. This was because an increase in MW and a decrease in P resulted in an increase in drying rate. In case of MVD + IR, the k values showed the increasing trend with an increase in IR. When higher IR was used, product surface temperature was elevated thus facilitated evaporation at the surface and enhanced drying rate. In addition, n values in MVD and MVD + IR were found to be higher than 1.0 which indicated that the relationship between moisture ratio and time was not probably a first-order kinetic. This is in accordance with the work of Therdthai and Zhou (2009).

Moreover, the effect of process variables (microwave power (MW), absolute pressure (P) and infrared power (IR)) on k and n values were studied by response surface method after fitting the data to a polynomial. Regression models of k and n were:

|

13 |

|

14 |

All the process variables had significant (p < 0.05) effect on drying rate (k). The process variables were found significant as can be seen from corresponding p-values in Table 2. It is obviously illustrated from Eq. 13 that k was affected mainly by MW followed by P and IR. There was a strong positive correlation between MW and k which was evidenced by the high value of the empirical coefficient since higher MW would enhance the drying rate by generating more heat energy inside the product. This finding is consistent with the results of the study conducted by (Sutar and Prasad 2007). In addition, k increased as IR was increased. This can be attributed to the fact that higher IR resulted in an increased moisture removal rate and product surface temperature (Ponkham et al. 2012). In contrast, k exhibited a decrease with increasing P, supporting the negative value of the empirical coefficient k of Eq. 13. The k increased significantly as P decreased; lowering of P is accompanied by a decrease in water evaporation temperature (McMinn 2006). The effect of process variables (MW, IR and P) on k has been widely studied, for example, Kiranoudis et al. (1997) studied microwave vacuum drying of vegetables, and found that the microwave power and absolute pressure affected the k, in a strongly positive and slightly negative way, respectively. Similar effect of microwave power and absolute pressure on k was found in the work of Pappas et al. (1999) who studied the effect of process conditions on the drying kinetic of microwave vacuum drying of some fruits. In addition, the effect of microwave power and vacuum pressure on k was also investigated in microwave-vacuum concentration of pineapple juice (Assawarachan and Noomhorm 2011). It was found that the effect of microwave on k was stronger than vacuum pressure. Besides, Tireki et al. (2006) studied the infrared assisted microwave drying of bread dough. The results indicated that microwave heating was the dominant mechanism affecting the moisture loss in the infrared assisted microwave drying. Furthermore, the effect of process variables on n values were studied, Eq. 14 shows that n decreased with increase in MW and IR. However, it increased as P increased.

Table 2.

Regression coefficients and p-value of second order polynomial model for process variables of drying rate (k) model

| Term | Coefficient | SE coefficient | p-value |

|---|---|---|---|

| Constant | 0.102435 | 0.002815 | 0.000 |

| MW | 0.049269 | 0.001527 | 0.000 |

| IR | 0.013651 | 0.001395 | 0.000 |

| P | −0.018875 | 0.001528 | 0.000 |

| MW*MW | 0.018835 | 0.002548 | 0.000 |

| IR*IR | 0.00153 | 0.002406 | 0.529 |

| P*P | 0.005125 | 0.002553 | 0.052 |

| MW*IR | 0.006012 | 0.001867 | 0.003 |

| MW*P | −0.015096 | 0.002045 | 0.000 |

| IR*P | −0.004292 | 0.001864 | 0.027 |

Term is significant at p < 0.05

Quality evaluations

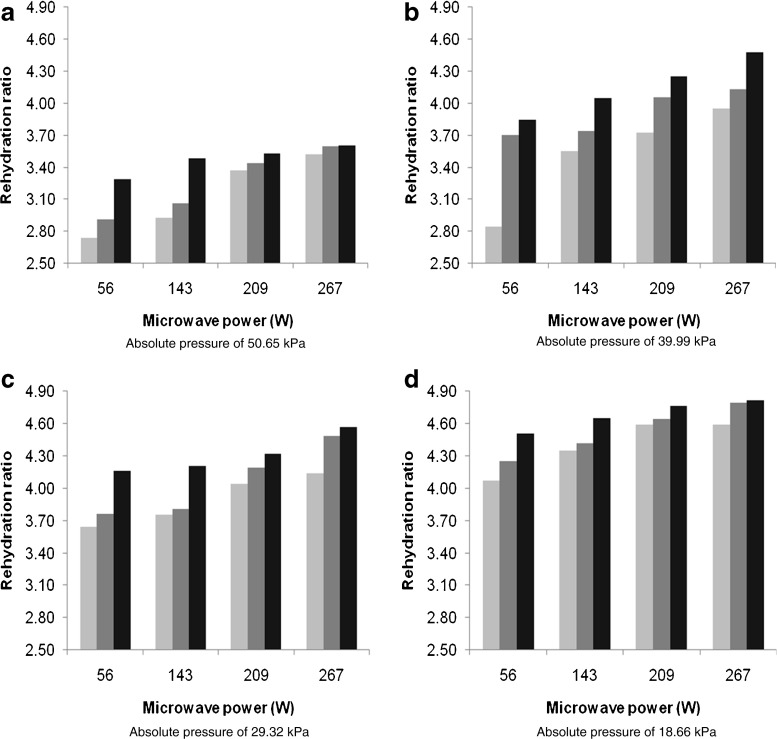

Rehydration ratio

Rehydration characteristics of dried agricultural product are frequently used as an index of structural quality, and they largely depend on the drying conditions employed. The average values of rehydration ratio are given in Fig. 5. MW, P and IR affected the rehydration ratio significantly (p < 0.05). In case of MVD, rehydration ratios were improved by drying under higher MW and lower P. This was due to quick microwave energy absorption causing rapid evaporation of water creating an outward flux of rapidly escaping vapor which helped to prevent the collapse of tissue structure. Moreover, by reducing P, the pressure difference was increased causing puffing characteristics. Hence, better rehydration properties were obtained. The results agreed with the works of Kiranoudis et al. (1997) and Vadivambal and Jayas (2007).

Fig. 5.

Rehydration ratio of dried shiitake mushrooms undergoing different drying conditions. ( ) MVD; (

) MVD; ( ) MVD + IR at 100 W; (

) MVD + IR at 100 W; (  ) MVD + IR at 200 W

) MVD + IR at 200 W

Additionally, the rehydration ratio is also correlated with P. It appears that as P decreases, the rehydration ratio increases. The higher pressure difference between the vacuum chamber and the internal pressure in the product might caused a less dense, more expanded and puff structure then higher capacity to absorb water was obtained (Giri and Prasad 2007). Similar effects of MW and P were reported by Kiranoudis et al. (1997), Durance and Wang (2002), Sunjka et al. (2004), Giri and Prasad (2007) and Therdthai and Zhou (2009).

When infrared heating was applied, rehydration ratio further increased. Higher IR resulted in an increase in rehydration ratio, i.e., increasing 1 to 10 % and 2 to 20 % at IR of 100 W and 200 W, respectively, compared to that dried by MVD. Faster drying with infrared and quicker diffusion of water vapor from the mushroom might help the sample retains its porous structure, increasing its ability to absorb higher amount of water during rehydration (Nasiroglu and Kocabiyik 2009; Vishwanathan et al. 2010). As a result, drying of shiitake mushroom by MVD at 267 W under 18.66 kPa provided a higher rehydration ratio than other MVD conditions. When IR at 200 W was added, the highest rehydration ratio was obtained. Similar effects of MW and IR were previously reported by Sumnu et al. (2005) in the drying of carrots using microwave and halogen lamp-microwave combination ovens.

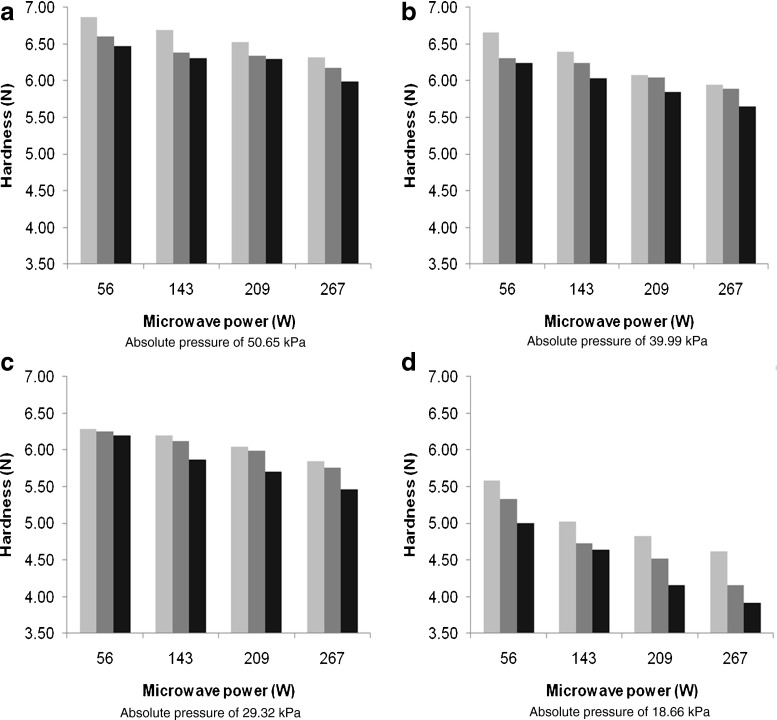

Texture

The results of texture of rehydrated shiitake mushroom in terms of the maximum force (hardness) at various drying conditions are shown in Fig. 6. MW, P and IR significantly affected the hardness (p < 0.05). In case of MVD only, dried samples undergoing lower P and higher MW were softer. During microwave heating, the water absorbed microwave energy and then vaporized within the mushrooms and transferred to the surface, which created a vapor pressure difference. When the P was reduced, the pressure difference was possibly increased and then the outward force was increased. This could cause a puffing characteristic in the mushrooms. In addition, an increased MW could increase the expansion ratio. Therefore, drying under lower P with higher MW led to softer mushrooms. Similar results were reported by Bai-Ngew et al. (2011).

Fig. 6.

Hardness of rehydrated shiitake mushrooms undergoing different drying conditions. ( ) MVD; (

) MVD; ( ) MVD + IR at 100 W; (

) MVD + IR at 100 W; ( ) MVD + IR at 200 W

) MVD + IR at 200 W

When MW and IR increased and P decreased, the hardness of rehydrated mushroom decreased. From the results, among all drying conditions, MVD + IR at 267 W of MW under P at 18.66 kPa combined with 200 W of IR provided the softest texture of rehydrated shiitake mushroom. Similar effects of MW and IR were reported by Uysal et al. (2009) for roasting of hazelnut. In microwave-infrared drying, heat is generated inside the mushroom by microwave while infrared radiation penetrates from the surface into the sample. Consequently, the surface moisture evaporates faster and then sample retains its porous structure. This leads to softening of the texture.

Hardness is one of important properties of rehydrated mushroom that correlates to customer’s satisfaction. In general, the softer rehydrated mushroom might be considered better as it offers more fresh-liked feeling. The results show that hardness of rehydrated samples significantly decreased with an increase in IR under constant MW and P. Variation in hardness of rehydrated mushroom could be correlated to rehydration ratio. An increase in rehydration ratio promoted more water absorption thus resulted in a softer texture of the rehydrated mushroom. This demonstrated another advantage of infrared heating in MVD.

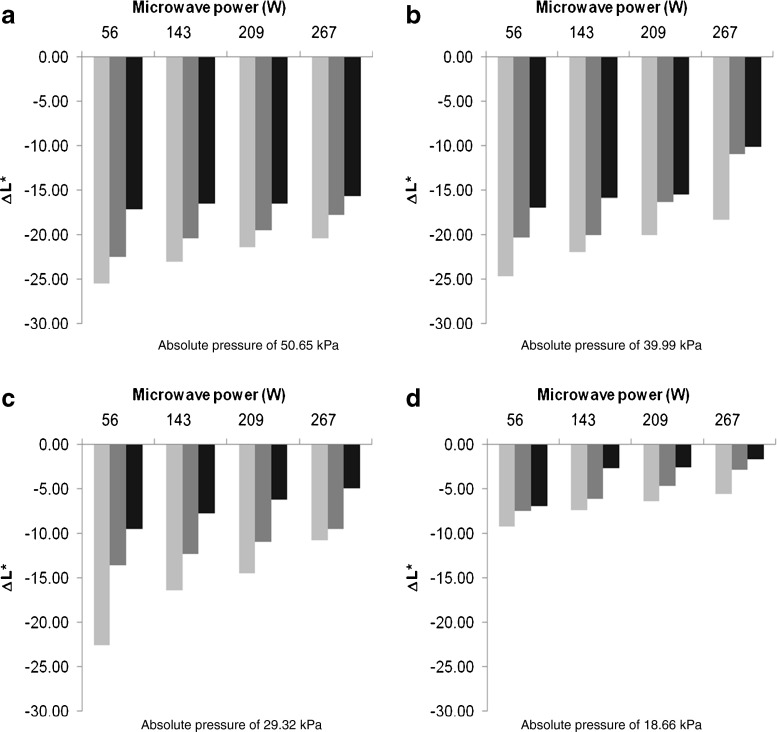

Color

Lightness

Besides texture, color is another important quality parameter that influences consumer acceptance. The highest possible value L* is considered as the bench mark in industry for the color quality of dried mushrooms (Argyropoulos et al. 2008). The ΔL* and color difference (ΔE) of dried mushrooms are presented in Fig. 7. From the results, all drying conditions led to negative ΔL* values. This is because browning reaction took place during drying (Giri and Prasad 2006; Argyropoulos et al. 2008), thus dried mushrooms were generally darker than the fresh ones. At higher MW, lower P and higher IR, the lighter color of dried mushrooms were obtained. Reducing drying time by increasing MW combined with lower drying temperature by reducing P, has resulted in better product color. This finding was consistent with the results of Giri and Prasad (2007).

Fig. 7.

Lightness of dried shiitake mushrooms undergoing different drying conditions. ( ) MVD; (

) MVD; ( ) MVD + IR at 100 W; (

) MVD + IR at 100 W; ( ) MVD + IR at 200 W

) MVD + IR at 200 W

In case of MVD + IR, the lighter color of dried mushrooms was obtained when higher IR was applied. It could be due to an increase in surface temperature which reduces the drying time. Moreover, Zhang and Wang (2011) reported that the browning reaction was inactivated when IR was used to dry fruits and vegetables. Another study also showed that heating apple slices under higher power of IR generally inactivated enzymatic browning much faster than that under low power (Zhu and Pan 2009). This is because of higher IR caused the higher product surface temperature, thus resulted in faster inactivation of enzymes. Therefore, the mushrooms dried by MVD + IR at 200 W were lighter than those dried by MVD + IR at 100 W.

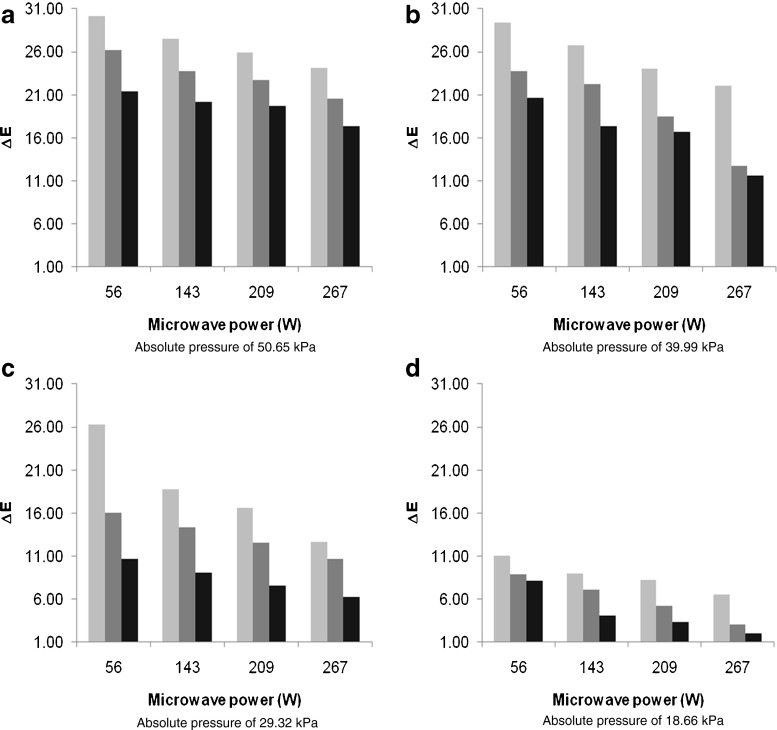

Color difference

Color difference (ΔE) indicates the degree of overall color change of the sample in comparison to color of fresh mushroom. A good quality dehydrated mushrooms should have a minimum ΔE value. The results (Fig. 8) show that lower color differences were obtained when higher MW, lower P and higher IR were applied. Due to the short drying time, the pigments might be less destroyed and color was more preserved (Kotwaliwale et al. 2007). Similarly, Sakai and Mao (2006) suggested that the pigment degradation rate was lower when infrared was applied. This is also an advantage of using infrared as a heat source for vegetable drying. In this study, drying under higher MW, lower P and higher IR is recommended to dry shiitake mushroom because it can preserve the color of the dried shitake mushrooms.

Fig. 8.

Color difference of dried shiitake mushrooms undergoing different drying conditions. ( ) MVD; (

) MVD; ( ) MVD + IR at 100 W; (

) MVD + IR at 100 W; ( ) MVD + IR at 200 W

) MVD + IR at 200 W

The results of color indicated that drying undergoing MVD at 267 W of MW under P at 18.66 kPa combined with infrared drying could be enhanced the color quality of dried mushroom. MVD Drying at 267 W and 18.66 kPa combined with 200 W of IR obviously gave a lighter color and lower color change than that combined with 100 W of IR.

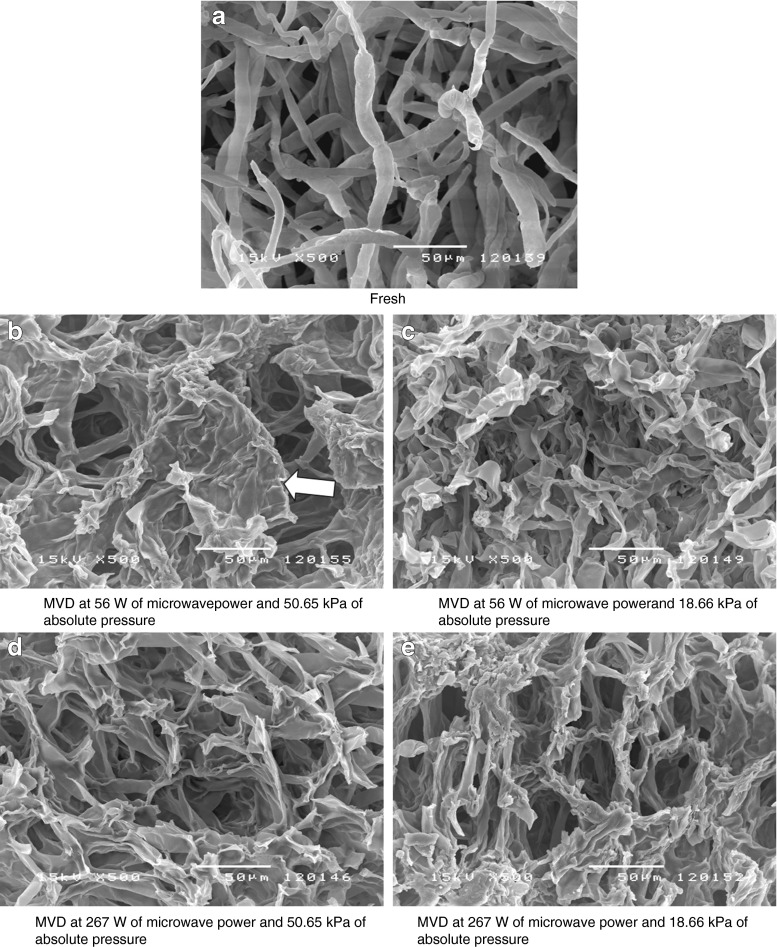

Scanning electron microscopy (SEM)

Effects of different drying methods and conditions on the microstructure of dried mushrooms were observed and compared with the fresh shiitake mushroom as shown in Figs. 9 and 10. In the case of MVD at constant MW (56 W and 267 W) with different P (Fig.9b–e), when P decreased from 50.65 to 18.66 kPa, the microstructure of shiitake mushrooms exhibited larger pore size and less collapsed structure. For example, Fig. 9b clearly shows a collapsed structure, the long drying time during MVD drying at 56 W and 50.65 kPa contributed to the structure collapsed in the sample. In contrast, the structure was less collapsed in sample dried under more vacuum condition (Fig. 9c). This could be explained by the fact that drying at lower temperature under lower P and shorter drying time creates a larger vapor pressure difference between the product and the drying chamber, which allows rapid moisture transfer from the product to the surrounding, thus helping in preventing structure collapse and expansion of tissue. This coincided with the results of Giri and Prasad (2007) and Han et al. (2010). Moreover, in case of constant P, drying at higher MW (from 56 W to 267 W) can maintain product internal structure and provide more porous structure. MVD drying at 267 W and 18.66 kPa (Fig. 9e) provided more porous structure compared with MVD drying at 56 W and 18.66 kPa (Fig. 9c). This could be explained by the fact that increasing MW tends to increase evaporation rate, thus preventing shrinkage and case hardening (Therdthai and Zhou 2009; Bai-Ngew et al. 2011). Therefore, rehydration ratio increased and hardness decreased when higher MW and lower P was applied. The SEM pictures obtained in this part were agreed with the experimental results in Figs. 5 and 6 in terms of rehydration ratio and hardness. In addition, the microstructures of shiitake mushrooms dried by MVD + IR at 200 W at some MW and P are shown in Fig. 10b–e. It was evident that the MVD + IR dried mushroom had more porous and less collapsed structure compared with the MVD alone (Fig. 9b–e). This is because the mushroom is heated rapidly by infrared and water evaporates more quickly resulted in puffing, retains its porous structure and develops large pores within the sample (Shih et al. 2008; Nathakaranakule et al. 2010; Vishwanathan et al. 2010). This helps in increasing its ability to absorb more water during rehydration and thus resulted in a softer texture in agreement with the results shown in Figs. 5 and 6. The same effect of infrared combined with hot air drying was also reported by Vishwanathan et al. (2010) for microstructure of dried carrots. Besides, Shih et al. (2008) reported a sequential infrared and freeze drying for producing crispy strawberries. It was evident that large pores were seen in the strawberry which could be due to water vapor created during infrared drying. Nathakaranakule et al. (2010) studied the drying of longan fruit using infrared in combination with hot air and heat pump dryers. The results showed that infrared helped to create more porous structure of dried longan, and porosity of the samples increased when an IR increased.

Fig. 9.

Scanning electron micrographs of fresh shiitake mushrooms and dried by MVD (white arrow: the collapsed structure)

Fig. 10.

Scanning electron micrographs of fresh shiitake mushrooms and dried by MVD + IR at 200 W

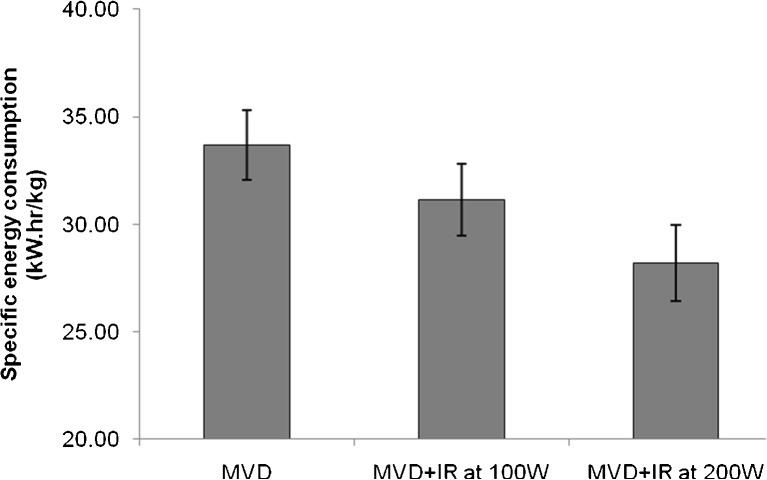

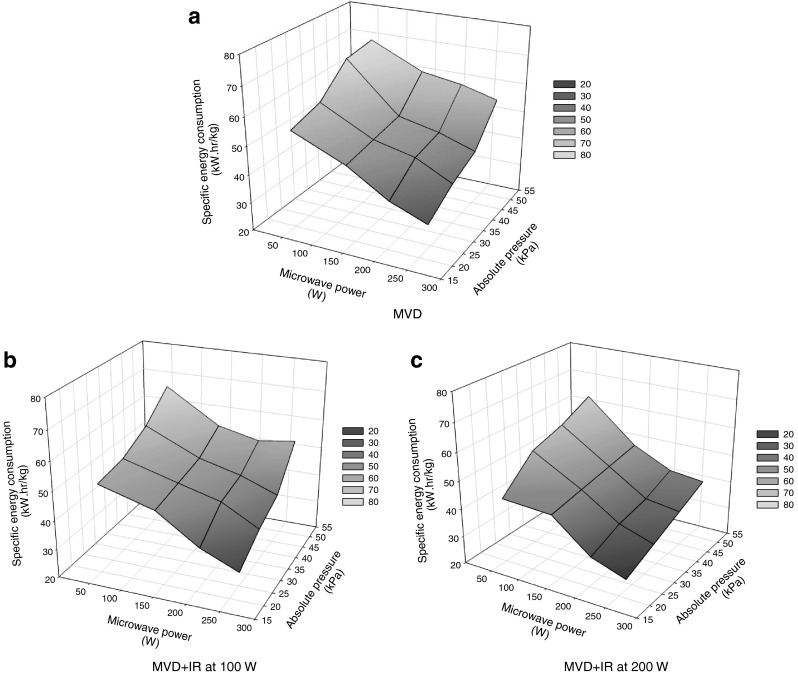

Specific energy consumption

The specific energy consumption during MVD of shiitake mushroom is given in Fig. 11a. The results showed that at each P, specific energy consumption decreases with increasing MW, because drying time is shorter under higher MW. At constant MW, decreased P decreases specific energy consumption. This is due to the fact that drying undergoing lower P resulting in the shorter drying time that decreases the specific energy consumption.

Fig. 11.

Specific energy consumption during MVD and MVD + IR of shiitake mushroom

The specific energy consumptions of the mushroom undergoing MVD + IR at 100 and 200 W are shown in Fig. 11b and c. Considering the effect of IR, the specific energy consumption decreased with the increase in IR because drying time was shorter at higher IR. Similar observations were reported for IR drying of red pepper slices (Nasiroglu and Kocabiyik 2009)

As mentioned above, the quality of dried shiitake mushrooms could be improved by drying using MVD at 267 W of MW at 18.66 kPa combined with IR drying. In addition, effect of infrared power on the specific energy consumption at this condition was compared in Fig. 12. The results show that the minimum energy required for drying was 28.21 kW.h/kg, which occurred at MVD + IR at 200 W. These results suggested that the drying by MVD at 267 W of MW combined with 200 W of IR at 18.66 kPa was considered to be the optimum condition, since this method provided higher rehydration ratio, softer texture, lower color change, shorter drying time and lower energy consumption.

Fig. 12.

Specific energy consumption during MVD and MVD + IR at absolute pressure of 18.66 kPa and microwave power of 267 W

Conclusions

The effects of drying methods, i.e., microwave-vacuum drying (MVD) and microwave-vacuum combined with infrared combination (MVD + IR) on the drying characteristics of shiitake mushroom were investigated. Drying rate increased with lower P, higher MW and higher IR. Modified Page model provided best fit to the drying characteristic of shiitake mushroom, and application of infrared combined with microwave vacuum drying (MVD + IR) significantly improved color of the dried shiitake samples as well as rehydration ratio and texture of rehydrated samples. In addition, increased MW and IR and decreased P resulted in a decrease in drying time and specific energy consumption. Drying undergoing MVD + IR at 267 W of MW combined with 200 W of IR under operating pressure at 18.66 kPa was proposed as the optimum conditions for drying shiitake mushrooms.

Acknowledgements

This work was supported by the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission. Authors also thank the National Research Council of Thailand (NRCT) and the Thailand Research Fund (TRF). Author Kantrong thanks the TRF, through its Royal Golden Jubilee (RGJ) Ph.D. Program, for supporting her doctoral study.

References

- Akpinar EK, Bicer Y. Modelling of the drying of eggplants in thin-layers. Int J Food Sci Technol. 2005;40(3):273–281. doi: 10.1111/j.1365-2621.2004.00886.x. [DOI] [Google Scholar]

- AOAC . Official methods of analysis of the AOAC. Washington: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Argyropoulos D, Heindl A, Müller J (2008) Evaluation of processing parameters for hot-air drying to obtain high quality dried mushrooms in the Mediterranean region. Paper presented at the Conference on International Research on Food Security, Natural Resource Management and Rural Development, Tropentag 2008, University of Hohenheim, October 7–9, 2008

- Assawarachan R, Noomhorm A. Mathematical models for vacuum-microwave concentration behavior of pineapple juice. J Food Process Eng. 2011;34(5):1485–1505. doi: 10.1111/j.1745-4530.2009.00536.x. [DOI] [Google Scholar]

- Bai-Ngew S, Therdthai N, Dhamvithee P. Characterization of microwave vacuum-dried durian chips. J Food Eng. 2011;104(1):114–122. doi: 10.1016/j.jfoodeng.2010.12.003. [DOI] [Google Scholar]

- Bal LM, Kar A, Satya S, Naik SN. Drying kinetics and effective moisture diffusivity of bamboo shoot slices undergoing microwave drying. Int J Food Sci Technol. 2010;45(11):2321–2328. doi: 10.1111/j.1365-2621.2010.02402.x. [DOI] [Google Scholar]

- Buffler CR (1993) Power measurement test procedures In: Microwave Cooking and Processing: Engineering Fundamentals for the Food Scientist. Avi Book, New York

- Caglar A, Togrul I, Togrul H. Moisture and thermal diffusivity of seedless grape under infrared drying. Food Bioprod Process. 2009;87(4):292–300. doi: 10.1016/j.fbp.2009.01.003. [DOI] [Google Scholar]

- Chandra LC, Smith BJ, Clarke SL, Marlow D, D’Offay JM, Kuvibidila SR. Differential effects of shiitake- and white button mushroom-supplemented diets on hepatic steatosis in C57BL/6 mice. Food Chem Toxicol. 2011;49(12):3074–3080. doi: 10.1016/j.fct.2011.09.001. [DOI] [PubMed] [Google Scholar]

- Choi Y, Lee SM, Chun J, Lee HB, Lee J. Influence of heat treatment on the antioxidant activities and polyphenolic compounds of Shiitake (Lentinus edodes) mushroom. Food Chem. 2006;99(2):381–387. doi: 10.1016/j.foodchem.2005.08.004. [DOI] [Google Scholar]

- Doymaz İ (2011) Infrared drying of sweet potato (Ipomoea batatas L.) slices. J Food Sci Technol. doi:10.1007/s13197-010-0217-8:1-7 [DOI] [PMC free article] [PubMed]

- Durance TD, Wang JH. Energy consumption, density, and rehydration rate of vacuum microwave- and hot-air convection- dehydrated tomatoes. J Food Sci. 2002;67(6):2212–2216. doi: 10.1111/j.1365-2621.2002.tb09529.x. [DOI] [Google Scholar]

- Giri SK, Prasad S (2006) Quality and sorption characteristics of microwave-vacuum, air and freeze-dried button mushrooms. Paper presented at the American Society of Agricultural and Biological Engineers, ASAE Annual Meeting, Oregon Convention Center, Portland, Oregon, 9–12 July 2006

- Giri SK, Prasad S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng. 2007;78(2):512–521. doi: 10.1016/j.jfoodeng.2005.10.021. [DOI] [Google Scholar]

- Giri SK, Prasad S. Quality and moisture sorption characteristics of microwave-vacuum, air and freeze-dried button mushroom (Agaricus bisporus) J Food Process Preserv. 2009;33:237–251. doi: 10.1111/j.1745-4549.2008.00338.x. [DOI] [Google Scholar]

- Han Q-H, Yin L-J, Li S-J, Yang B-N, Ma J-W. Optimization of process parameters for microwave vacuum drying of apple slices using response surface method. Dry Technol. 2010;28(4):523–532. doi: 10.1080/07373931003618790. [DOI] [Google Scholar]

- Hebbar HU, Vishwanathan KH, Ramesh MN. Development of combined infrared and hot air dryer for vegetables. J Food Eng. 2004;65(4):557–563. doi: 10.1016/j.jfoodeng.2004.02.020. [DOI] [Google Scholar]

- Hirun S, Utama-ang N, Roach P (2012) Turmeric (Curcuma longa L.) drying: an optimization approach using microwave-vacuum drying. J Food Sci Technol. doi:10.1007/s13197-012-0709-9:1-7 [DOI] [PMC free article] [PubMed]

- Hu Q-g, Zhang M, Mujumdar AS, G-n X, Jin-cai S. Drying of edamames by hot air and vacuum microwave combination. J Food Eng. 2006;77(4):977–982. doi: 10.1016/j.jfoodeng.2005.08.025. [DOI] [Google Scholar]

- Kiranoudis CT, Tsami E, Maroulis ZB. Microwave vacuum drying kinetics of some fruits. Dry Technol. 1997;15(10):2421–2440. doi: 10.1080/07373939708917368. [DOI] [Google Scholar]

- Kocabiyik H, Tezer D. Drying of carrot slices using infrared radiation. Int J Food Sci Technol. 2009;44(5):953–959. doi: 10.1111/j.1365-2621.2008.01767.x. [DOI] [Google Scholar]

- Kotwaliwale N, Bakane P, Verma A. Changes in textural and optical properties of oyster mushroom during hot air drying. J Food Eng. 2007;78(4):1207–1211. doi: 10.1016/j.jfoodeng.2005.12.033. [DOI] [Google Scholar]

- Kowalski SJ, Mierzwa D. Convective drying in combination with microwave and IR drying for biological materials. Dry Technol. 2009;27(12):1292–1301. doi: 10.1080/07373930903207712. [DOI] [Google Scholar]

- McMinn WAM. Thin-layer modelling of the convective, microwave, microwave-convective and microwave-vacuum drying of lactose powder. J Food Eng. 2006;72(2):113–123. doi: 10.1016/j.jfoodeng.2004.11.025. [DOI] [Google Scholar]

- Motavali A, Najafi G, Abbasi S, Minaei S, Ghaderi A (2011) Microwave–vacuum drying of sour cherry: comparison of mathematical models and artificial neural networks. J Food Sci Technol. doi:10.1007/s13197-011-0393-1:1-9 [DOI] [PMC free article] [PubMed]

- Mousa N, Farid M. Microwave vacuum drying of banana slices. Dry Technol. 2002;20(10):2055–2066. doi: 10.1081/DRT-120015584. [DOI] [Google Scholar]

- Nasiroglu S, Kocabiyik H. Thin-layer infrared radiation drying of red pepper slices. J Food Process Eng. 2009;32(1):1–16. doi: 10.1111/j.1745-4530.2007.00195.x. [DOI] [Google Scholar]

- Nathakaranakule A, Jaiboon P, Soponronnarit S. Far-infrared radiation assisted drying of longan fruit. J Food Eng. 2010;100(4):662–668. doi: 10.1016/j.jfoodeng.2010.05.016. [DOI] [Google Scholar]

- Pappas C, Tsami E, Marinos-Kouris D. The effect of process conditions on the drying kinetics and rehydration characteristics of some mw-vacuum dehydrated fruits. Dry Technol. 1999;17(1–2):158–174. doi: 10.1080/07373939908917523. [DOI] [Google Scholar]

- Ponkham K, Meeso N, Soponronnarit S, Siriamornpun S. Modeling of combined far-infrared radiation and air drying of a ring shaped-pineapple with/without shrinkage. Food Bioprod Process. 2012;90(2):155–164. doi: 10.1016/j.fbp.2011.02.008. [DOI] [Google Scholar]

- Poonnoy P, Tansakul A, Chinnan M (2007) Estimation of moisture ratio of a mushroom undergoing microwave-vacuum drying using artificial neural network and regression models. Chemical Prod and Process Modeling 2(3): Article 25:1–13

- Reguła J, Siwulski M. Dried shiitake (Lentinulla edodes) and oyster (Pleurotus ostreatus) mushrooms as a good source of nutrient. Acta Sci Pol, Technol Aliment. 2007;6(4):1644–0730. [Google Scholar]

- Rodríguez R, Lombraña JI, Kamel M, de Elvira C. Kinetic and quality study of mushroom drying under microwave and vacuum. Dry Technol. 2005;23(9–11):2197–2213. doi: 10.1080/07373930500212685. [DOI] [Google Scholar]

- Ruiz Celma A, Cuadros F, López-Rodríguez F. Characterisation of industrial tomato by-products from infrared drying process. Food Bioprod Process. 2009;87(4):282–291. doi: 10.1016/j.fbp.2008.12.003. [DOI] [Google Scholar]

- Sakai N, Mao W. Infrared heating. In: Sun D-W, editor. Thermal food processing: new technologies and quality issues. Florida: CRC; 2006. pp. 493–525. [Google Scholar]

- Shih C, Pan Z, McHugh T, Wood D, Hirschberg E. Sequential infrared radiation and freeze-drying method for producing crispy strawberries. ASABE. 2008;51(1):205–216. doi: 10.13031/2013.24205. [DOI] [Google Scholar]

- Sumnu G, Turabi E, Oztop M. Drying of carrots in microwave and halogen lamp–microwave combination ovens. LWT-Food Sci Technol. 2005;38(5):549–553. doi: 10.1016/j.lwt.2004.07.006. [DOI] [Google Scholar]

- Sunjka PS, Rennie TJ, Beaudry C, Raghavan GSV. Microwave-convective and microwave-vacuum drying of cranberries: a comparative study. Dry Technol. 2004;22(5):1217–1231. doi: 10.1081/DRT-120038588. [DOI] [Google Scholar]

- Sutar PP, Prasad S. Modeling microwave vacuum drying kinetics and moisture diffusivity of carrot slices. Dry Technol. 2007;25(10):1695–1702. doi: 10.1080/07373930701590947. [DOI] [Google Scholar]

- Therdthai N, Zhou W. Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen) J Food Eng. 2009;91(3):482–489. doi: 10.1016/j.jfoodeng.2008.09.031. [DOI] [Google Scholar]

- Tireki S, Sumnu G, Esin A. Effect of microwave, infrared and infrared-assisted microwave heating on the drying rate of bread dough. Am J Food Technol. 2006;1(2):82–93. doi: 10.3923/ajft.2006.82.93. [DOI] [Google Scholar]

- Uysal N, Sumnu G, Sahin S. Optimization of microwave–infrared roasting of hazelnut. J Food Eng. 2009;90(2):255–261. doi: 10.1016/j.jfoodeng.2008.06.029. [DOI] [Google Scholar]

- Vadivambal R, Jayas DS. Changes in quality of microwave-treated agricultural products—a review. Biosystems Eng. 2007;98(1):1–16. doi: 10.1016/j.biosystemseng.2007.06.006. [DOI] [Google Scholar]

- Vishwanathan KH, Hebbar HU, Raghavarao KSMS. Hot air assisted infrared drying of vegetables and its quality. Food Sci Technol Res. 2010;16(5):381–388. doi: 10.3136/fstr.16.381. [DOI] [Google Scholar]

- Wang J, Sheng K. Far-infrared and microwave drying of peach. LWT-Food Sci Technol. 2006;39(3):247–255. doi: 10.1016/j.lwt.2005.02.001. [DOI] [Google Scholar]

- Wang Z-F, Fang S-Z, Hu X-S. Effective diffusivities and energy consumption of whole fruit chinese jujube (Zizyphus jujuba Miller) in microwave drying. Dry Technol. 2009;27(10):1097–1104. doi: 10.1080/07373930903221200. [DOI] [Google Scholar]

- Zhang L, Wang X (2011) Progress of internal, external structure and quality change of fruits and vegetables during infrared drying process. Paper presented at the New Technology of Agricultural Engineering (ICAE), 2011 International Conference, 27–29 May 2011

- Zhu Y, Pan Z. Processing and quality characteristics of apple slices under simultaneous infrared dry-blanching and dehydration with continuous heating. J Food Eng. 2009;90(4):441–452. doi: 10.1016/j.jfoodeng.2008.07.015. [DOI] [Google Scholar]