Abstract

Wheat flour fractioned by sieving into four different particle size fractions namely finer fractions (<75 and 75–118 μm), coarser fractions (118–150 and >150 μm) were analyzed for their chemical, rheological, bread & parotta making characteristics. The finer fractions had lower ash, higher dry gluten, damaged starch and sodium dodecysulphate (SDS)—sedimentation value than the coarser fractions. The flour from finer fractions gave bread with best sensory and textural attributes. The parottas from finer fractions showed significantly higher sensory scores for colour, texture, layers, mouthfeel and overall quality score than the coarser fractions. In the micrograph of finer flour fractions, higher number of loosened single starch granules than the aggregates of starch and protein matrix were seen as compared to coarser fractions. These studies indicate that the flour from the finer fractions produce higher quality bread, parotta owing to the presence of higher damaged starch content, quantity and quality of protein in these fractions than coarser fractions.

Keywords: Wheat flour quality, Particle size, Rheology, Microstructure, Bread, South Indian parotta

Introduction

The process of roller flour milling of wheat involves breaking open of the grain, scraping the endosperm from bran & germ by break rolls and then gradually reducing the chunk of the endosperm into flour by a series of grindings by reduction rolls, with intermediate separation of products by sifters & purifiers (Bass 1988). The quality of the flour depends on number of factors including particle size. The particle size of the flour produced depends on the wheat quality, flow sheet of mill, sifter sieves opening, type and the adjustment of rolls.

Several studies have recognized that the particle size has influence on chemical and physical properties of the flour. The separation of the flour into different fractions varying in physical and chemical properties has both commercial and academic significance. These techniques have provided possibility of production of specialty flours for different end use products.

Earlier some of the studies have shown that medium particle size flours separated by the sieving had better baking quality, where as few studies have shown that fine particle size flours separated by air classification had better baking quality because of higher protein content in these fractions. Gracza and Norris (1961) also opined that the flours with same level of proteins but different particle sizes showed different baking results.

South Indian parotta is a multilayered wheat flour based flat bread of India. Basically parotta is prepared using wheat flour, salt, water and oil while sugar and egg form the optional ingredients (Indrani et al. 2000; Indrani and Venkateswara Rao 2000). More than the 50 % of wheat flour produced by the roller flour mills in south India is utilised for the preparation of parotta. Indrani et al. (2003) reported that speciality flour for parotta could be produced by combining initial reduction streams. With this background, the present study was conducted to observe the nature of starch and protein matrix in different flour fractions through scanning electron microscopy; investigate the effect of particle size of wheat flour on the chemical, rheological and quality characteristics of bread and parotta.

Materials and methods

Raw Material

Commercially available wheat (variety PBW 175) was used for the studies. The roller flour mill had five break rolls and seven reduction rolls with the capacity of 120 t/day. The extraction rate of wheat flour and bran were 76.54 % and 23.46 % respectively.

Physicochemical characterization of raw wheat

The wheat used for milling was analyzed for physical and chemical properties. Hectoliter weight and the thousand-kernel weight were determined by standard procedures (Pomeranz 1988). The moisture, ash, sodiumdodecylsulphate (SDS) sedimentation value and protein content were determined by the AACC methods (AACC 2000)

Flour fractionation based on Particle size

Flour particle size distribution test was determined by sifting 200 g of sample for 5 min in a Lab Sifter (Model KBF 7 SN, Buhler, Switzerland) using the sieves with opening of 180, 150,118 and 75 μm. The flour fractions passing through 180 and 150 μm sieves were named as coarser fractions and throughs of sieves of 118 and 75 μm as finer fractions.

Chemical, rheological and color properties of flours

The flour fractions (coarse and fine) and straight run flour (SRF) samples were analyzed for chemical characteristics such as moisture, ash, gluten, SDS sedimentation value, falling number and damaged starch and rheological characteristics using farinograph and alveograph according to AACC methods (2000). The color value of the flour fractions, SRF and baked products were measured in terms of lightness (L) and color (+ a: red, −a: green, +b: yellow, −b: blue) using the Hunter Lab Color Measuring System (Color measuring Labscan XE system, USA) under illumination C and view angle 10°. The test was done in quadruplicate and the average value was reported.

Scanning electron microscopy (SEM) studies

SEM analysis was carried out using Leo scanning electron microscope model 435VP (Leo Electronic Systems, Cambridge, UK). Preparation and observation of samples under microscope were according to the method described by Prabhasankar et al. (2003).

Bread preparation and evaluation

Bread making characteristics were studied using the following formulation: flour 100 g, compressed yeast: 2.0 g, salt: 1.0 g; sugar: 2.5g, hydrogenated fat: 1.0 g and water: farinograph water absorption. Breads in quadruplicate were prepared according to the method described by Farheen et al. (2012). Bread weight was recorded and bread volume was determined using rapeseed displacement method. Crumb firmness, which is a force at 25 % compression, was measured according to AACC (2000) procedure using texture analyser (Model TA-HDI, Stable Microsystems, Godalming, Surrey, UK). Sensory evaluation of bread was carried out by a panel consisting of baking technologists. The panelists were trained in four sessions involving 2 h of training in each session. Different samples of bread in four replicates were evaluated by each panelist for crust colour for the maximum score of 10; shape (15), symmetry (15), crumb colour (10), grain (20), mouthfeel (20) and taste (10). The overall quality score (100) was taken as the combined score of all the previous attributes.

Parotta preparation and evaluation

Parotta was prepared by mixing wheat flour, salt, sugar and water in a Hobart mixer (Model N-50, New York, Ontario, Canada) to a well developed stage (4 min). The dough was rested for 30 min in a cabinet maintained at the temperature of 30°C and 75 % relative humidity. Dough of 75 g was then rounded and rested in a cabinet for the 10 min. The dough was spread as a thin film with application of oil. The film was folded into multiple layers and then coiled. The coiled dough was rested for 10 min and sheeted again into a circular disc of 15 cm dia-meter and 0.5 cm thickness. The sheeted dough was baked on hotplate at temperature of 180°C for 2 min, it was turned every 30s; about 5 g of oil was applied during baking. The prottas were than cooled under atmospheric conditions by keeping for about 15 min, and then packed it to a polypropylene pouch until further evaluation. The spread ratio of parotta was obtained by dividing the values of diameter by thickness. Objective and sensory evaluation of parotta were as described by Indrani et al. (2000).

Statistical analysis

Data were statically analysed using Duncan’s new multiple range tests with different groups appropriate to the completely randomized design with four replicates each as described by Steel and Torrie (1960). The significant level was established at p ≤ 0.05.

Results and discussion

Physicochemical characterization of raw wheat

The wheat variety PBW 175 used for the milling had the following physico-chemical characteristics: Hectoliter weight-80 Kg/hectoliter, thousand kernel weight-38 g, moisture content 10.2 %, ash −1.6 %, SDS sedimentation value −44 ml and protein −10.5 %. These results indicate that the wheat used for this study is of medium hard type.

Flour fractionation based on Particle size

Four particle size distribution test showed higher percentage of flour of 45.23 % in <75 μm fraction followed by 28.54 % (118–75 μm fraction), 17.78 % (150–118 μm fraction) and 8.45 % (180–150 μm fraction).

Chemical, rheological and color properties of flours

Some chemical characteristics and color values of straight run four (SRF) and fractionated flours are shown in Table 1. The dry gluten content of wheat flour fractions increased with decrease in flour particle size from 8.8 % to 10.4 %. A similar trend was observed for SDS sedimentation value, which increased from 49 to 65 ml with decrease in flour particle size. The dry gluten and SDS sedimentation value of 9.8 % and 61ml were observed for the SRF.

Table 1.

Chemical characteristics and instrument color values of straight run flour (SRF) and different flour fractions.

| Chemical characteristics | SRF | Flour fractions (μm) | |||

|---|---|---|---|---|---|

| 180–150 | 150–118 | 118–75 | <75 | ||

| Moisture (%) | 12.1 ± 0.05b | 12.2 ± 0.04b | 11.8 ± 0.00a | 11.8 ± 0.04a | 12.3 ± 0.03c |

| Ash (%) | 0.58 ± 0.01c | 0.93 ± 0.00e | 0.67 ± 0.01d | 0.56 ± 0.02b | 0.47 ± 0.00a |

| Dry Gluten (%) | 9.8 ± 0.05c | 8.8 ± 0.06a | 9.4 ± 0.08b | 9.8 ± 0.05c | 10.4 ± 0.05d |

| SDS- SDV (ml) | 61 ± 0.03c | 49 ±0.06a | 59 ± 0.07b | 62 ± 0.05c | 65 ± 0.06d |

| Falling Number (Sec) | 536 ± 2.50b | 463 ± 2.02a | 553 ± 3.03c | 558 ± 1.51c | 563 ± 2.00c |

| Damaged Starch (%) | 9.2 ± 0.08c | 6.1 ± 0.07a | 8.4 ± 0.06b | 9.8 ± 0.09d | 10.1 ± 0.10d |

| Color values | |||||

| L | 88.4 ± 0.25c | 83.6 ± 0.20a | 87.6 ± 0.30b | 88.5 ± 0.33c | 89.8 ± 0.26d |

| b | 10.6 ± 0.10b | 13.1 ± 0.12d | 11.6 ± 0.08c | 11.1 ± 0.11c | 9.6 ± 0.15a |

Except moisture, all values are on dry weight basis

SDS-SDV Sodiumdodecylsulphate-sedimentation value; L Lightness value; b yellowness value.

Values in the row with the same letter in superscript are not significantly different from each other at p ≤ 0.05. n = 4

Ash contents of flour fractions decreased from 0.93 % to 0.45 % with decrease in particle size. The damaged starch of flour fractions decreased with increase in flour particle size from 10.06 % to 6.13 %, this is in the agreement with the observation by Wang and Flores (2000). The falling number value increased with decrease in particle size indicating lower alpha amylase activity in finer fraction, which could be due to the presence of bran and aleurone layer (Kruger and Tipples 1980).

The L value, which represents the lightness value, was higher for the finer flours fractions. The L value increased from 83.56 to 89.82 with decrease in the particle size. This could be due to the presence of more bran particles in coarser fractions as shown by the ash values. The yellowness value (+b) ranged in between 9.63 and 13.11 for the flour fractions which could be attributed to the presence of carotenoid pigments. The yellowness value (+b) for the SRF was 10.65.

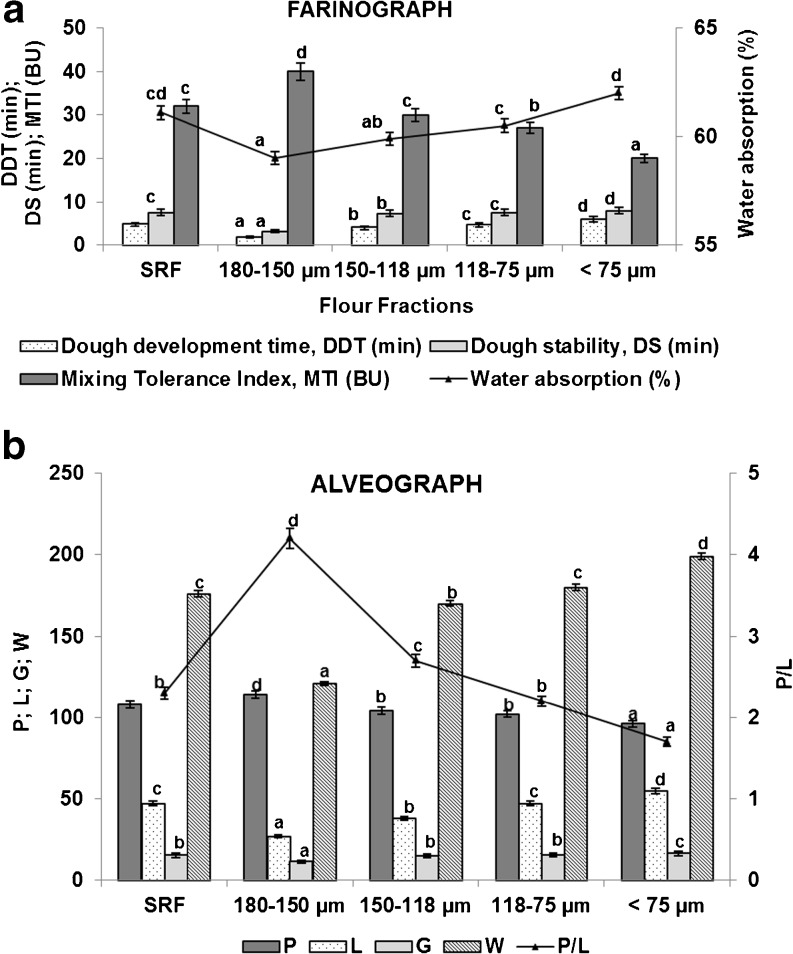

The results the rheological characteristics of the wheat flour fractions are shown in Fig. 1a & b. The water absorption of wheat flour fractions increased with reduction in particle size this is in accordance to Wang and Flores (2000). The dough development time also increased from 1.8 min to 6.0 min and dough stability (3.2 to 8 min) with decrease in the particle size (Fig. 1a). The finest fraction of flour (<75 μm) showed the stronger dough characteristics compared to other coarser fractions, which could be due to the higher protein content present in finest fraction.

Fig. 1.

Rheological characteristics of straight run flour (SRF) and flour fractions. (a) Farinograph characteristics; (b) Alveograph characteristics: P Maximum over pressure, L average abscissa at rupture, G Index of swelling, W deformation energy of dough, P/L curve configuration ratio

The data on alveograph characteristics of flour fractions (Fig. 1b) showed that the maximum over pressure (P), a measure of dough tenacity value decreased from 114 mm to 96 mm with reduction in the particle size. The highest P value of 114 mm was observed for coarse fraction (>150 μm fraction), where as the straight run flour showed P value of 108 mm. The average abscissa at rupture (L), which is a measure of dough extensibility increased from 27 mm to 55 mm with reduction in particle size. The P/L ratio, indicating the ratio of elasticity and extensibility of the dough decreased from 4.2 to 1.7 with decrease in particle size from >150 μm to <75 μm. These results indicate that the coarse flour fractions are more elastic than the fine flour fractions, where as the finer flour fractions are more extensible than coarse flour fractions.

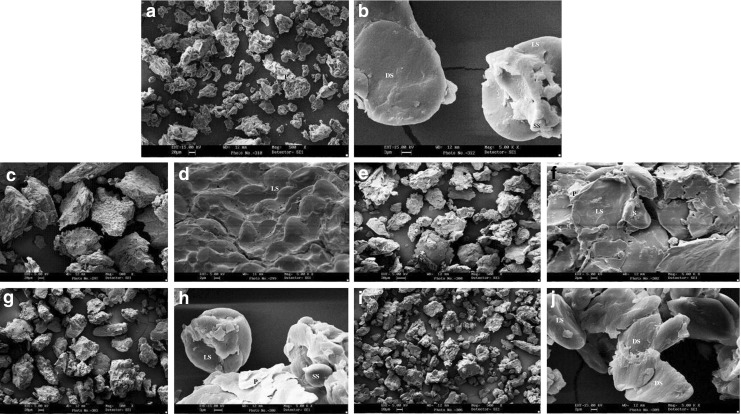

Scanning electron microscopy study

A comparison of images obtained by scanning electron microscope of SRF and flour fractions is shown in the Fig. 2a–j. The micrograph observation of SRF, which is the combination of all the flour fractions, was similar to that of earlier studies of Aranyi and Hawrylewics (1968, 1969) and Rojas et al. (2000).

Fig. 2.

Scanning electron micrographs of straight run flour (SRF) and flour fractions. S-Starch granules; LS-Large starch granules; SS-Small Starch granules; P-Protein matrix; DS – Deformed starch. A (500X) B (5000X) - straight run flour; C (500X) D (5000X) - 180–150 μm fraction; E (500X) F (5000X) - 150–118 μm fraction; G (500X) H (5000X) - 118–75 μm fraction; I (500X) J (5000X) - 118–75 μm fraction.

SRF showed presence of some intact endosperm structure but the original highly compact packed structure of wheat kernel appeared to be broken up into aggregates of protein matrix embedding groups of cellular components, mainly starch granules (Fig. 2a–b). Two different sizes of starch granules, the large lentil shaped granules and small round shaped starch granules were observed as reported by Hoseney (1994). Some starch granules appeared damaged as a consequence of milling. The micrograph of coarse flour fractions (118–150 and >150 μm) shows the higher aggregates of starch and protein matrix than single starch granules (Fig. 2c–f). The aggregates were found to be of bigger size with intact A- and B- type of starch granules compactly packed in the protein matrix. The micrograph of fine flour fractions (<75 and 75–118 μm) showed higher numbers of loosened single starch granules (Fig. 2g–j) than aggregates of starch and protein matrix as compared to the coarse flour fractions. The higher number of deformed A-type starch granules and intact B-type starch granules were observed in the micrographs of finer flour fractions. The chemical characteristics of flour fractions showed increase in damaged starch with increase in flour particle size from 6.13 to 10.06 % (Table 1). Farinograph water absorption values also increased from 59.0 to 62.0 %.

Baking characteristics

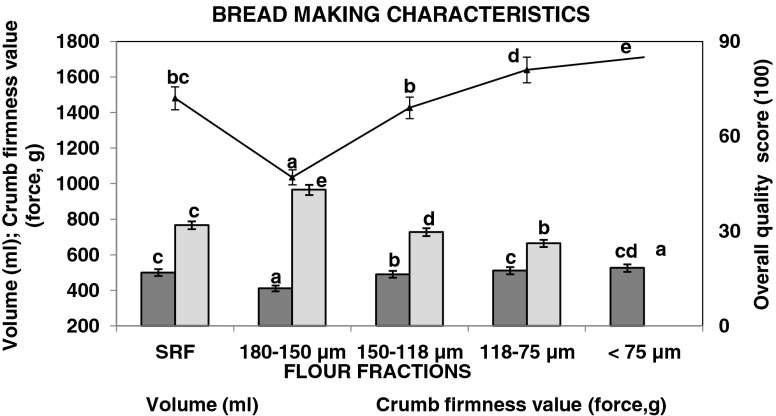

The baking quality of flour fractions (Fig. 3a) showed that the volume increased with reduction in the flour particle size. The highest loaf volume of 525 ml was observed for the <75 μm fraction and lowest volume of 410 ml for >150 μm. The straight run flour showed 500 ml volume. The crumb firmness value, a measure of texture showed that the bread from the finer fractions were softer as indicated by the lower crumb firmness value when compared to the coarser fractions. Sensory evaluation showed that the breads from the finer flour fractions had golden brown crust colour, improved crust shape and symmetry compared to the coarser fractions and straight run flour. The whiteness of the crumb color increased with reduction in particle size. This could be due to the presence of less bran particles in the finer fractions as indicated by decrease in ash content from 0.93 % to 0.45 % (Table 1). The breads from finer fractions showed fine, uniform crumb grain with thin cell walls, where as the coarser fractions showed dense crumb grain with thick cell walls. The breads from finer fractions showed clean mouthfeel while coarser fraction showed slight residual formation during chewing. The quality of bread from finer fractions was better as shown by the overall quality score of 85, 81than coarser fractions (69, 47) and SRF (72).

Fig. 3.

Bread making characteristics of straight run flour (SRF) and flour fractions

Parotta characteristics

The L values representing lightness values for finer fractions were 58.75, 59.25, coarser fractions (48.55.78, 58.78) and SRF (57.77). These results indicate that the white color of parotta increased with reduction in particle size. The b + values representing yellowness value were lower for finer fraction (20.16, 19.56) than coarser fractions (24.06, 20.97) and SRF (21.86). These results indicate that the parottas from coarser fractions and SRF are creamish in color and from finer fractions are less creamish and more whitish in color.

Parotta making characteristics of SRF and different fractions are shown in the Table 2. The spread ratio value increased from 28.3 to 34.8 with decrease in particle size. The sensory evaluation showed that the color of parrotas was creamish white with uniformly distributed light brown spots on the surface for finer flour fractions. The parottas from coarser fractions had brownish white color with non uniform dark brown spots on the surface. The hand-feel of parottas was softer for finer fractions than the coarser fractions. The <75 fraction showed higher scores for the texture and layers than the other fractions. The parotta was soft and slightly chewy with distinct layers for <75 μm fraction. The >150 μm fraction parotta was chewy with less distinct layers. The >150 μm fraction parotta was doughy and showed slight residue formation in mouth. There was no significant difference in the oiliness in all the parotta samples. The taste and aroma of parottas made from <75, 75–118, 118–150 μm fractions and straight run flour were similar. The overall quality score increased from 59 to 87 with reduction in particle size from >150 to <75 μm fraction. The overall quality score for the straight run flour was 73. The higher overall quality score of parotta for the finer fractions could be due to higher dry gluten content and SDS-sedimentation value, showing good quality and quantity of protein this is in agreement with Indrani et al. (2000).

Table 2.

Parotta making characteristics of straight run flour (SRF) and different flour fractions

| Sensory characteristics | Score (max) | SRF | Flour fractions (μm) | |||

|---|---|---|---|---|---|---|

| 180–150 | 150–118 | 118–75 | <75 | |||

| Spread ratio | -- | 31 ± 0.05c | 28.3 ± 0.03a | 29.2 ± 0.44a | 32.9 ± 0.32d | 34.8 ± 0.25e |

| Color | 10 | 7 ± 0.11b | 4 ± 0.01a | 6 ± 0.02b | 8 ± 0.01c | 9 ± 0.03c |

| Nature of spots | 10 | 8 ± 0.05b | 7 ± 0.02a | 8 ± 0.01b | 8.5 ± 0.02bc | 8.5 ± 0.21bc |

| Shape | 10 | 7 ± 0.01a | 7 ± 0.01a | 8 ± 0.11b | 8.5 ± 0.05b | 8.5 ± 0.22b |

| Hand feel | 10 | 7.5 ± 0.01b | 6 ± 0.02a | 8 ± 0.12b | 8.5 ± 0.12bc | 9 ± 0.35c |

| Texture | 15 | 10 ± 0.05b | 8 ± 0.02a | 11 ± 0.25b | 12 ± 0.15bc | 13.5 ± 0.33d |

| Layers | 15 | 10.5 ± 0.06b | 8 ± 0.11a | 11.5 ± 0.03b | 12.5 ± 0.26c | 13.5 ± 0.41d |

| Oiliness | 10 | 8 ± 0.04a | 7 ± 0.12a | 8 ± 0.32a | 8 ± 0.33a | 8 ± 0.40a |

| Mouth feel | 10 | 7 ± 0.02b | 5 ± 0.22a | 8 ± 0.25b | 9 ± 0.25c | 9 ± 0.22c |

| Taste and aroma | 10 | 8 ± 0.02b | 7 ± 0.32a | 8 ± 0.21b | 8 ± 0.18b | 8 ± 0.26b |

| Overall quality score | 100 | 73 ± 0.35b | 59 ± 0.55a | 76.5 ± 0.51bc | 83 ± 0.45d | 87 ± 0.65e |

Values in the row with the same letter in superscript are not significantly different from each other at p ≤ 0.05. n = 4

Conclusion

Flour fractionated on particle sizes showed variation in dry gluten, SDS sedimentation value, damaged starch, falling number and ash content. The dry gluten, SDS sedimentation value, damaged starch and falling number increased with reduction in particle size, whereas ash content decreased with decrease in particle size of flour fractions. The finest fractions (<75 μm) of flour showed stronger quality gluten and dough exhibited better balance of elasticity and extensibility compared to other coarser fractions with higher dough development time and dough stability. The flour fractions showed significant differences in bread and parotta quality. The finer fractions produced bread and parotta with soft texture and improved sensory characteristics.

It can be concluded from the present study that the particle size flour has significant influence on the quality of parotta. The technique of flour fractionation into different particle size by sieving can be used in the commercial flour mill for the production of specialty flour for parotta.

References

- AACC . American Association of Cereal Chemists. St. Paul, MN: AACC; 2000. [Google Scholar]

- Aranyi C, Hawrylewics EJ. A note on scanning electron microscope of flour and doughs. Cereal Chem. 1968;45:500–502. [Google Scholar]

- Aranyi C, Hawrylewics EJ. Application of scanning electron microscopy to cereal specimens. Cereal Sci Today. 1969;14(230–233):253. [Google Scholar]

- Bass EJ. Wheat flour milling. In: Pomeranz Y, editor. Wheat: chemistry and technology, vol. 2. 3. St Paul: American Association of Cereal Chemists; 1988. pp. l–68. [Google Scholar]

- Farheen D, Jyothi Lakshmi A, Prakash J, Indrani D. Effect of ingredients on rheological, nutritional and quality characteristics of high protein, high fibre and low carbohydrate bread. Food Bioprocess Tech. 2012;5:2998–3006. doi: 10.1007/s11947-011-0752-y. [DOI] [Google Scholar]

- Gracza R, Norris CG. Flour strength and particle size. Bakers Dig. 1961;35:56–62. [Google Scholar]

- Hoseney RC. In: Principles of Cereal Science and Technology. AACC Inc: MN, USA; 1994. [Google Scholar]

- Indrani D, Jyotsna Rao S, Udaya Sankar K, Venkateswara Rao G. Changes in the physical—chemical and organoleptic characteristics of parotta during storage. Food Res Int. 2000;33:323–329. doi: 10.1016/S0963-9969(00)00025-9. [DOI] [Google Scholar]

- Indrani D, Venkateswara Rao G. Effect of chemical composition of wheat flour and functional properties of dough on the quality of south Indian parotta. Food Res Int. 2000;33:875–881. doi: 10.1016/S0963-9969(00)00117-4. [DOI] [Google Scholar]

- Indrani D, Rajiv J, Prabhasankar P, Venkateswara Rao G. Chemical, rheological and parotta making characteristics of flourmill streams. Eur Food Res Technol. 2003;217:219–223. doi: 10.1007/s00217-003-0741-0. [DOI] [Google Scholar]

- Kruger JE, Tipples KH. Relationship between falling number, amylograph viscosity and alpha amylase activity in Canadian wheat. Cereal Res Commun. 1980;8:97–105. [Google Scholar]

- Prabhasankar P, Indrani D, Jyotsna R, Venkateswara Rao G. Scanning electron microscopic and electrophoretic studies of the baking process of south Indian parotta—An unleavened flat bread. Food Chem. 2003;82:603–609. doi: 10.1016/S0308-8146(03)00017-7. [DOI] [Google Scholar]

- Pomeranz (1988) In: Wheat chemistry and technology Vol. 1 (pp. 17–21). St. Paul, MN, USA: American of Association of Cereal Chemists.

- Rojas JA, Rosell CM, Benedito de Barber C, Perez-Munuera I, Lluch MA. The baking process of wheat rolls followed by cryo scanning electron microscopy. Eur Food Res Technol. 2000;212:57–63. doi: 10.1007/s002170000209. [DOI] [Google Scholar]

- Steel RGD, Torrie JH. Principles and Procedures of Statistics. New York, NY: McGraw-Hill; 1960. [Google Scholar]

- Wang L, Flores RA. Effect of flour particle size on the textural properties of flour tortillas. J Cereal Sci. 2000;31(3):263–272. doi: 10.1006/jcrs.2000.0302. [DOI] [Google Scholar]