Abstract

High-quality laboratory space to support basic science, clinical research projects, or health services is often severely lacking in the developing world. Moreover, the construction of suitable facilities using traditional methods is time-consuming, expensive, and challenging to implement. Three real world examples showing how shipping containers can be converted into modern laboratories are highlighted. These include use as an insectary, a molecular laboratory, and a BSL-3 containment laboratory. These modular conversions have a number of advantages over brick and mortar construction and provide a cost-effective and timely solution to offer high-quality, user-friendly laboratory space applicable within the developing world.

Introduction

Public health programs, throughout the world, require high-quality laboratory services to provide, among others, diagnostic testing, quality control/assurance, disease surveillance, basic research, and other essential services. Unfortunately, many public health programs in developing countries face a very real challenge in finding or developing sufficient laboratory space. This can often mean that the services needed to support a program are either of low quality, are performed outside the host country, or are absent all together. In each case, the lack of appropriate space may impede critical development of local capacity. This phenomenon becomes even more marked when time-limited funding is involved. With typical funding cycle timelines of 3–5 years for deployment, implementation, and analysis, the ability to respond rapidly to changing needs becomes crucial. Emergency interventions, e.g., responding to an epidemic or a natural disaster, also require rapid scale-up responses. Some novel solutions have been developed, e.g., “Concrete Canvas” (http://concretecanvas.co.uk/) to provide emergency general use infrastructure, but these are not appropriate for supplying the needs of most public health/disease control programs. When sample analysis, necessary for diagnosis or to inform a treatment regimen or disease control program, occurs either outside the country or far from the point of need, quality of service can be drastically reduced.

Constructing a laboratory from scratch is generally a time-consuming, highly technical, and ultimately expensive exercise. We believe that modular laboratories can solve most if not all of these issues, yet their adoption to date within developing countries has been relatively slow.

A modular laboratory is essentially a structure that is prefabricated at a suitable location, is robust enough to withstand transportation, occupies a minimal footprint when packaged, and requires relatively minimal construction on site. The majority of modular laboratories have used a standard shipping container as the scaffold within which the laboratory is built. Shipping containers have a long history of being converted into offices, homes, and for other uses. They have also been used as laboratories for many decades, though with varying degrees of sophistication. New techniques, materials, designs, and fittings have been repeatedly refined to maximize the space available, improve safety, and generally increase functionality. Other prefabrication construction techniques may be used to construct a modular laboratory and may offer benefits over converting a shipping container. However, our experience has been almost exclusively with converting shipping containers. This work aims to share several possible modular layouts/configurations for different applications and to examine the advantages of containers over more traditional brick and mortar options.

Example layouts/applications.

Limited only by the physical dimensions of a container, there are myriad ways that a container can be configured. It is recommended that users begin with a standardized design and customize it to take into account the local environment, requirements, or specific operational needs. Any number of partition walls, windows, and doors (both internal and external) can be incorporated into a design. With the exception of very large installations, most applications can be accommodated in a standard 40 ft/12 m container; however, multiple containers may be deployed alongside one another or be interconnected, if additional space is required.

Three different conversion design floor plans are shown in Figure 1 , demonstrating some of the applications that containers can be used for. All three designs have been built and are currently in use in sub-Saharan Africa (Figures 2 –4) . They range markedly in price based on the complexity of the design, type of equipment installed (e.g., air filtration systems), or requirement to meet a particular standard (e.g., Biosafety Level [BSL] 2 or 3). A breakdown of the costs and conversion times for the three designs is given in Table 1.

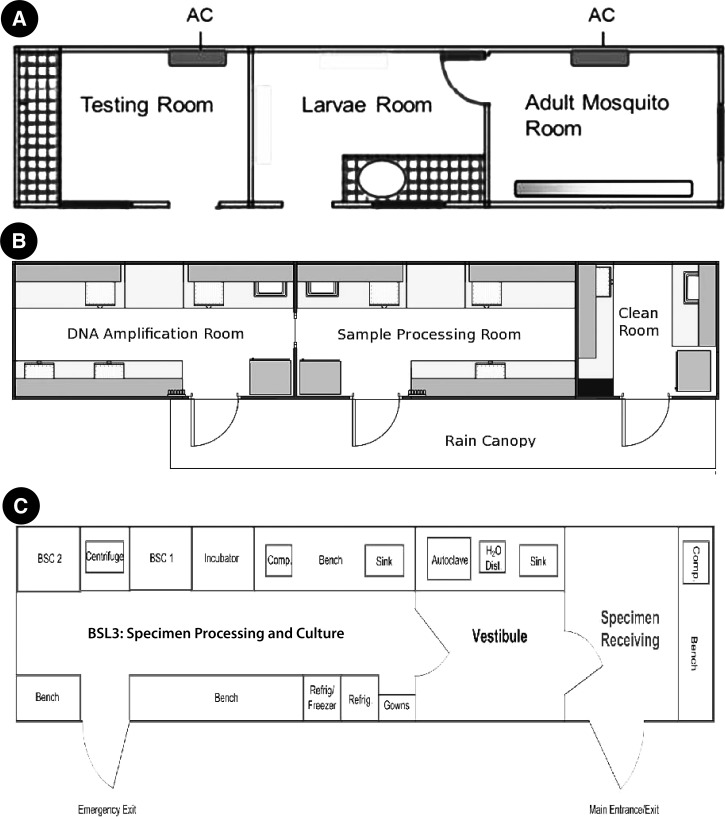

Figure 1.

Floor plans for three different 40 ft/12 m container conversions, consisting of an insectary (A) a molecular laboratory (B), and a BSL 3 containment laboratory (C). The insectary (A) consists of an adult mosquito room, a larvae rearing room, and mosquito identification/insecticide resistance testing room. The modular molecular laboratory (B) consists of a clean room, a sample processing/DNA extraction room, and a DNA amplification room. The BSL 3 containment laboratory (C) consists of a specimen receiving room, a vestibule, and the BSL3 specimen processing and culturing room. AC = air conditioner; BSC = biosafety cabinet; Comp = computer.

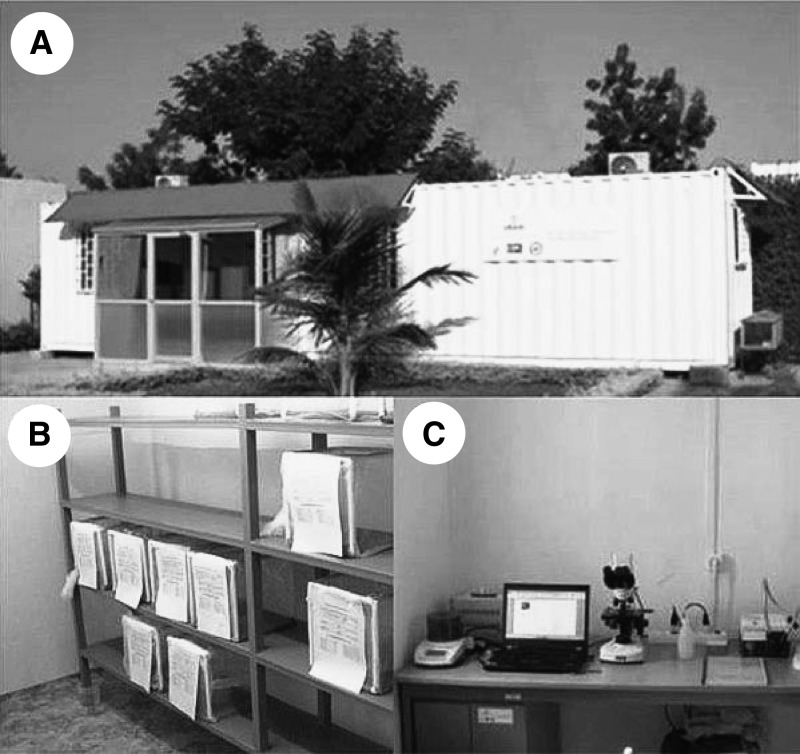

Figure 2.

The President's Malaria Initiative (PMI)-supported insectary in Mali. (A) Exterior (B) Adult room (C) Identification room.

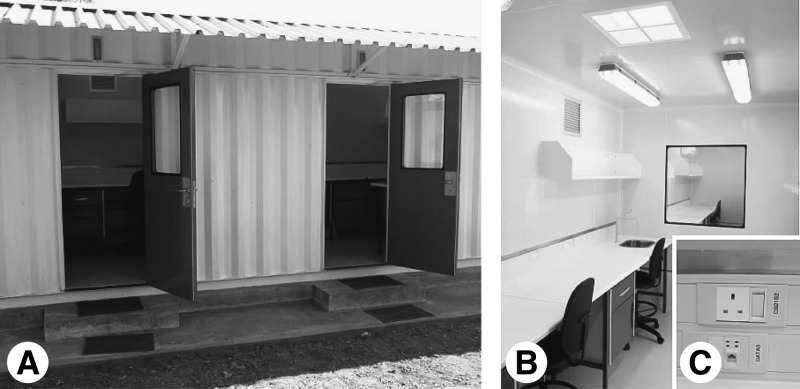

Figure 3.

The PATH-supported molecular laboratory in Lusaka, Zambia. Outside, an external roof canopy, concrete walkway, and steps (A) have been constructed. Inside, high-quality laboratory benches, cupboards, sinks, skylights, wall-mounted air filters, and shelves are fitted (B). Data and electricity is supplied through ducting that is flush with the interior walls (C).

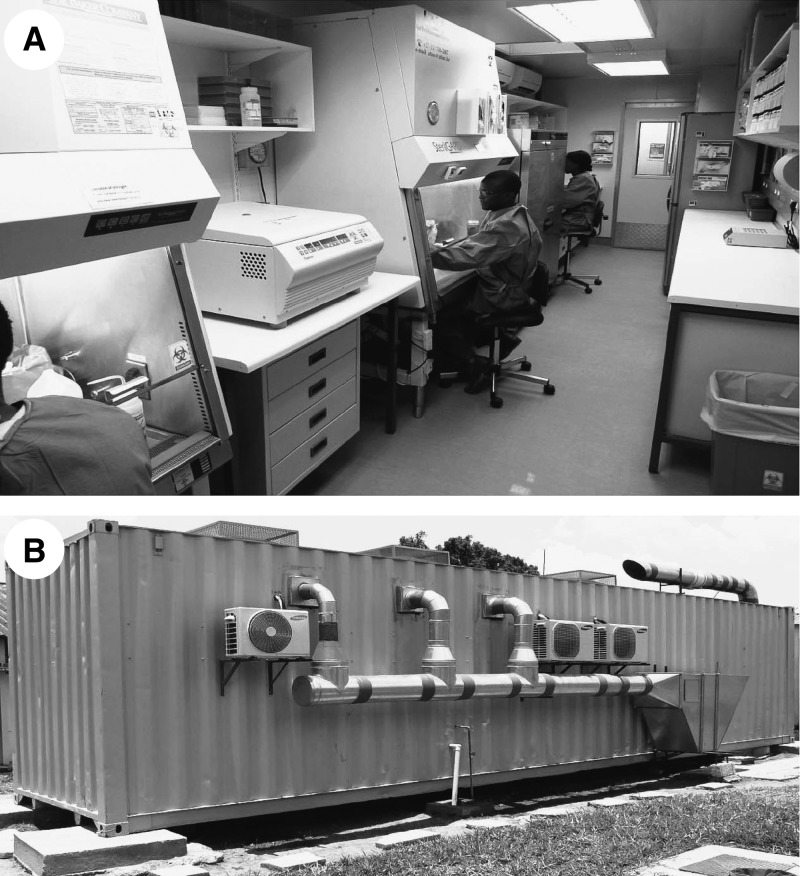

Figure 4.

The Bill and Melinda Gates Foundation supported the BSL3 laboratory in Livingstone, Zambia. With many of the features highlighted in the molecular laboratory, the BSL3 laboratory also contains HEPA-filtered tissue culture hoods (A). Air flow is tightly controlled by an air filtration system, the majority of which is mounted outside, on the rear of the container (B).

Table 1.

Approximate costs and lead times for the three different conversion designs

| Insectary | Molecular laboratory | BSL3 laboratory | |

|---|---|---|---|

| Cost* | $20,000 | $70,000 | $200,000 |

| Lead Time† | 3 weeks | 4 weeks | 12 weeks |

| Maintenance | Air conditioner and humidifier filters changed once per year | Air vent filters cleaned/replaced every 6 months. | Fortnightly changing/washing of primary supply air filters and annual service/certification |

| Container maintenance | Container exterior repainted as required, or every 5 years. | ||

Cost includes the purchase and conversion of the laboratory including all fitted equipment, e.g., air conditioners, benches, etc., but does not include any analytical equipment.

Lead times do not include the time taken to finalize the design or the transit time for delivery from manufacturing site to final destination.

The simplest design is for a container insectary (Figure 2). The President's Malaria Initiative (PMI) has installed container insectaries in multiple countries (e.g., Mozambique, Mali, Angola, and Liberia). Container insectaries offer a climate-controlled space to rear both local and susceptible reference mosquito strains for insecticide resistance testing, quality control of long-lasting insecticide-treated nets and indoor residual spraying, and determination of insecticide residual efficacy. The design includes three rooms: an adult mosquito room, a larvae rearing room, and a room in which to conduct mosquito identifications and resistance testing. All rooms were fitted with appropriate equipment including a humidifier, air-conditioner, and options for water and electricity, including battery backup systems for maintenance of a continuous power supply. The insectary entrance was extended outside of the container with a small reception room. This creates double door access thus improving biosafety by limiting the possibility of vectors escaping from the insectary.

The second design is for a molecular laboratory (Figure 3) funded through PATH. This particular installation at the National Malaria Control Center in Lusaka, Zambia, was designed for medium throughput genomic sample analysis consisting of three isolated processes. To minimize cross-contamination, promote separation of each room's equipment and personnel movements, and to maximize space, each of the three rooms' doors deliberately open to the outside. A locally constructed external corridor could be added if additional isolation from the external environment is required. This design, unlike the insectary, uses a fully lined container allowing utilities, e.g., water, electricity, data connections, etc., to be routed through ducting recessed in the lining. Each room is fitted with high-quality scientific benches, cupboards, sinks, shelves, and containment flooring. Air conditioners provide temperature control, while filtered vents in the walls ensure sufficient air circulation without compromising contamination controls.

The most sophisticated design is for a three-room BSL 3 containment laboratory (Figure 4) funded by the Bill and Melinda Gates Foundation. Most of the space is allocated to the main BSL 3 certified room, which is accessed by a single entrance through a specimen reception and then through a vestibule. Laminar (directional) air flow is strictly controlled between rooms to ensure a constant negative pressure in the main laboratory to prevent pathogen escape. Air exhausted from the laboratory passes through HEPA filters in the biological safety cabinets and optional HEPA filters mounted on the outside of the structure.

Advantages and disadvantages of a container.

Quality.

The foundation of any laboratory is the ability to generate reproducible results through controlling all appropriate variables, such as air flow, temperature, light exposure, humidity, etc. In the same way, laboratories often need to act as containment facilities to protect users, the local population, or the environment from biological or chemical exposure. As such, it is important that the physical laboratory is appropriately constructed. For example, air movement between rooms may need to be restricted to prevent cross-contamination or escape of pathogens. A shipping container is immensely strong: a 40 ft/12 m “High Cube” container weighs around 4,000 kg, but is rated to ship with up to 26,000 kg load, and can withstand a stack weight of 192,000 kg. This inherent strength makes them extremely flexible in terms of adding external functions. For example, a tank to supply water to the facility could be placed on the roof. The strength and rigid construction of a shipping container also ensures that they are inherently secure assuming high quality locks, doors, and windows are used.

Containers, although not hermetically sealed, are also essentially weatherproof, and therefore provide an almost perfect starting superstructure within which a laboratory can be constructed. Modifications such as adding additional ventilation, electricity, and insulation between walls and roofs can reduce internal temperature fluctuations and allow the creation of micro-environments within the container. Where high-level containment or isolation from the external environment is required such as with the BSL 3 containment laboratory described previously, a box can be constructed within the container, i.e. a box within a box. By minimizing the number and extent of penetrations (water, electricity, etc.) from the exterior environment to the interior and between compartments, a space can be created that is completely isolated. A pitched roof can also be added on top of the container to help prevent overheating.

With the exception of the relatively simple insectary design, executing the exact needs of a laboratory design involves a number of specialist skills. These skills may either not be available or be of sub-standard quality in many developing countries. It is therefore logical for construction to take place off-site at a location where these skills and materials are more readily available. Ultimately, the conversion of a container laboratory built primarily off-site will likely exceed the quality of a conventional laboratory built in many developing countries.

Mobility.

Unlike brick and mortar buildings that cannot be built offsite and then transported for assembly, container laboratories are inherently portable. Assuming the base container certificate is still valid, containers can travel to any location on the planet accessible by sea, road, or if budgets allow by air. If working in collaboration with a national ministry, air transport may be possible for example through their armed forces.

To reach its final location, smaller 20 ft/6 m containers can be moved by forklift, whereas larger versions would require a crane. If needs change, container laboratories can be moved relatively easily from one location to another as required. Obviously, the more external components, e.g., air ducting and unsecured items, there are in a laboratory, the more involved the moving process will be. It is important that all moveable items before transport are either removed or properly secured inside the container to prevent them causing any damage or being damaged should contents shift in transit.

Permissions.

The inherent mobility and perceived temporary nature of a container installation can be favorable in terms of bypassing many administrative hurdles when securing official authorization for site development. In contrast, brick and mortar buildings often require detailed and time-consuming administrative permissions. Additionally, some organizations limit or do not permit funding of new brick and mortar construction in other countries, which would not be a concern with container laboratories.

Cost.

Designing, identifying a site, planning, building, and commissioning even a modest standard brick and mortar building for clinical/scientific work requires a significant investment in time and money. Using a standardized modular design and construction, end users can adapt a tried and tested container laboratory design to their specific requirements. This option eliminates the need for architects and engineers and any per diems, airfares, and other additional costs associated with site visits. These outlays can have an enormous impact on final cost.

Traditional brick and mortar construction costs vary significantly from country to country. Additionally, most traditional builds are appreciably larger in size. Providing absolute cost comparisons is therefore challenging. Nevertheless, we estimate that modular container laboratories can reduce the price of an installation by 2- to 3-fold. To show this, Table 2 gives a breakdown for the minimum costs associated with transforming a container from a steel shell into a basic laboratory environment. Using traditional construction method costs in Zambia as a comparison, we calculate that a comparable installation would cost between $40,000 and $50,000. Experience has also shown that implementation would be significantly longer, with a total estimated project build time of 6–9 months.

Table 2.

Breakdown of approximate costs associated with converting a shipping container from a steel shell into a basic usable laboratory space*

| Item | Approximate cost (USD) |

|---|---|

| Container | 5,000–10,000 |

| Painting container and treating | 2,000–3,000 |

| Lining container | 900 |

| Cutting door holes (×2) and fitting | 1,500–3,000 |

| Vinyl flooring | 2,000 |

| Electrical distribution board | 1,500 |

| Electrical trunking | 1,300 |

| Light fittings | 1,000–2,000 |

| Sockets and isolators | 500–2,000 |

| TOTAL | 15,700–25,700 |

Note that the final intended use of the container will influence the quality/extent of the work required, hence the range of costs given.

USD = U.S. dollars.

Aside from saving in building the basic structure, specialist equipment can be sourced, fitted, and commissioned by local off-site manufacturers during the conversion process. By constructing close to the various contractors, each can be recalled to solve any problems that may arise. This ensures that different contractors work harmoniously and efficiently to output a complete working installation before it is transported to its final destination. This process drastically reduces logistics planning, time, and total build cost. In comparison, if constructing on-site where specialist skills are flown in, overruns will be costly and may require expensive repeat visits to solve.

Once installed, container laboratories may offer cost-savings in terms of maintenance. For example, the BSL3 laboratory only requires a single annual service, whereas most BSL3 laboratories in developing countries require bi-annual servicing. This is due primarily to using a filtered air supply system, which ensures a cleaner interior environment and reduced burden on expensive HEPA filters. This reduces maintenance costs by at least 50% compared with brick-and-mortar designs (and even other modular laboratories). Additionally, all designs use off-the-shelf technology where possible, e.g., multiple split-type air conditioners provide redundancy versus a single HVAC system. This helps to reduce overall cost and enables local servicing/repairs or replacements.

Finally, it is worth noting that even a fully equipped converted container is still a container. Therefore, additional equipment, such as centrifuges, flow cabinets, and other specialist equipment that may be required for the container laboratory or other facilities can be shipped inside the container. Where bulky items, e.g., −80°C freezers, are required this can offer significant savings on shipping costs.

Design and lead time.

Designing a traditional laboratory, although one of significantly larger dimensions than a container, is likely to take many months and generally starts with a blank canvas. In contrast, the design process is greatly simplified with a smaller space. Combined with generic designs, the process becomes more structured and focused rather than freeform. In many situations, where the ultimate use of the container is well defined, a design can be finalized in a matter of weeks.

Once designed, and depending on the specifications, conversions can take anything from 3 (Insectary) to 14 weeks (BSL3) (Table 1). Once complete, all external and internal fittings can be secured inside the container for transportation to the final site.

Ground work.

Minimal site set-up is required. Containers are designed to bear their load through their four corners. Four 1 m3 (1 × 1 × 1 m) reinforced concrete pillars (20 cm above ground) built in the appropriate locations, and given 7 days to cure are sufficient foundations for the container. Utilities, such as electricity, water, and drains, can be prepared before the containers arrival though they are more commonly added afterward to ensure connections match and to remove any potential obstacles during container offloading. Depending on the local environment, concrete walkways linking entrances and steps may also be added.

Commissioning times.

Once in place, commissioning the container, i.e., setting up all of the preinstalled systems/internal equipment, etc., will generally take anywhere from 1 to 10 days depending on the complexity of the design. Pre-shipment commissioning or completion of installation at the “factory” can ensure that this is kept to a minimum both to decrease cost and ensure quality. With standardized designs and negligible risk of damage occurring during transit commissioning after the container is on site can be pared down to the minimum.

Potential lifetime and maintenance.

Containers are built to be extremely durable. Most damage to a shipping container occurs during loading and off-loading or when exposed to corrosive elements, e.g., seawater. Even under these harsh conditions a container has an expected working lifespan of at least 10 to 15 years traveling the world. Assuming a new or nearly new container is used for the conversion, and if the container is not frequently moved or placed in a harsh environment, this lifespan may be considerably extended. We expect that the container structure could easily last more than a couple of decades. This makes them at least comparable to an average quality conventional brick and mortar building, but probably superior to a low-quality build. In many cases it is the latter that predominates in the developing world. Of course the various components of a laboratory, e.g., flooring, may need to be intermittently replaced, but this is unlikely to be any different from a traditional laboratory.

Location.

A container laboratory can be placed where a conventional laboratory either cannot be built or where it is not cost-effective. Container laboratories can therefore be placed on steep slopes, marshes, ships, trucks, etc. As long as it has a firm foundation at each corner, a container can go just about anywhere.

Standardization.

Once a successful design has been implemented, it is possible to recreate as many copies as required. Subsequent replicas will be cheaper to build as the majority of the design phase will have been removed. They will also be standardized to ensure that safety and comparability between laboratories is maximized. We recommend learning from the experiences and mistakes of others rather than reinventing the wheel each time.

Appeal.

The external appearance of a container is rarely considered visually pleasing. Unfortunately, this often translates into a reticence to commit to using a container format. Similarly, the galley-like layout of a container laboratory often constricts people's thoughts to images of cramped dark spaces and dingy benches. In reality, the latest container laboratories are bright, airy, and remarkably spacious (Figures 2–4). In our experience, almost all users become “converts” once they step inside a completed laboratory. Failing that, it is always possible to enclose the container laboratory either completely within a building or to build a front hallway/entrance that screens the structure from view. Obviously, both options are likely to have a significant impact on the overall cost and future mobility of the container installation.

Summary

Extending and improving healthcare services in the developing world is going to increasingly require state-of-the-art purpose-built laboratories. The conversion of standard shipping containers into fully functioning laboratories provides a scalable, rapidly implementable, and highly affordable solution to any programs or institutes requiring such a facility. Many designs have already been built and refined, providing new users with a wealth of options to choose from.

Footnotes

Financial support: We thank the various funding agencies, i.e., PMI (Insectary Lab in Mali), PATH (Molecular lab in Zambia) and the Bill and Melinda Gates Foundation (BSL3 Lab in Zambia) for enabling these designs to become a reality.

Disclosure: Since the initial submission of this manuscript the author B. Kosloff has become a paid scientific advisor to Air Filter Maintenance Services (AFMS) and Biocontainment Infrastructure Solutions (BIS), both of Johannesburg, South Africa, suppliers of modular BSL3 infectious disease laboratories and BSL2 molecular laboratories, respectively. Although this manuscript compares modular versus brick-and-mortar laboratories, the authors do not endorse any specific manufacturers or products.

Authors' addresses: Daniel J. Bridges and Anna M. Winters, Akros, Cresta Golfview Grounds, Lusaka, Zambia, E-mails: dbridges@akros.com and awinters@akros.com. James Colborn, President's Malaria Initiative, U.S. Centers for Disease Control and Prevention, Mozambique, E-mail: jcolborn@cdc.gov. Adeline S. T. Chan, Entomology Branch, Centers for Global Health, U.S. Centers for Disease Control and Prevention, Atlanta, GA, E-mail: asc8@cdc.gov. Dereje Dengala, Abt Associates Inc., Bethesda, MD, E-mail: Dereje_Dengela@abtassoc.com. Christen M. Fornadel, President’s Malaria Initiative, U.S. Agency for International Development, Washington, DC, E-mail: cfornadel@usaid.gov. Barry Kosloff, London School of Hygiene and Tropical Medicine, Faculty of Tropical Infectious Diseases, Department of Clinical Research, London, UK, and ZAMBART Project, University of Zambia School of Medicine, Lusaka, Zambia, E-mail: bkosloff@zambart.org.zm.