Abstract

We have developed a new time calibration method for the DRS4 waveform sampler that enables us to precisely measure the non-uniform sampling interval inherent in the switched-capacitor cells of the DRS4. The method uses the proportionality between the differential amplitude and sampling interval of adjacent switched-capacitor cells responding to a sawtooth-shape pulse. In the experiment, a sawtooth-shape pulse with a 40 ns period generated by a Tektronix AWG7102 is fed to a DRS4 evaluation board for calibrating the sampling intervals of all 1024 cells individually. The electronic time resolution of the DRS4 evaluation board with the new time calibration is measured to be ~2.4 ps RMS by using two simultaneous Gaussian pulses with 2.35 ns full-width at half-maximum and applying a Gaussian fit. The time resolution dependencies on the time difference with the new time calibration are measured and compared to results obtained by another method. The new method could be applicable for other switched-capacitor-array technology-based waveform samplers for precise time calibration.

Keywords: Waveform Sampling, Time Calibration, Switched-Capacitors

1. Introduction

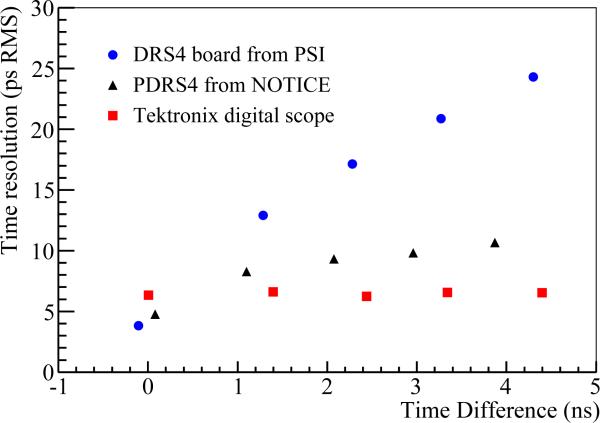

We are developing a high speed waveform sampling-based signal readout using the Domino-Ring-Sampler (DRS4) chip [1] for Time-of-Flight Positron Emission Tomography (TOF PET) [2][3]. In addition to precise time extraction, the use of a waveform sampling readout would result in simplified data acquisition hardware and a unified signal processing chain. Some of our signal readout approaches require a 10~20 ps RMS time resolution [3], and the electronic time resolution needs to be much better than that. It has been found that the DRS4 chip needs careful time calibration for individual capacitor cells in order to achieve precise time measurement within the entire time window it provides [4]. To illustrate this issue, Figure 1 shows the time resolution measurement using three different waveform readout electronics: the Tektronix 6154B digital scope (20 GS/s sampling, 15 GHz analog bandwidth), DRS4 evaluation board [5] (PSI, Switzerland), and PDRS4 [4](NOTICE, Korea and University of Chicago). The DRS4 evaluation board uses the time calibration method provided by PSI, and the PDRS4 uses a different time calibration method that we have previously reported [4]. The DRS4 result clearly shows a significant degradation in time resolution when the time difference increases. While our calibration method reduces such degradation, there is still room for improvement, especially for applications that require precise timing measurement. In contrast, such degradation is not observed with the Tektronix digital scope, which uses flash ADC technology. Comparing the PDRS4 and Tektronix results also suggests that time resolution as precise as achieved by using the high-end commercial digital scopes could be achieved by using the DRS4 chips if their calibration can be performed properly.

Figure 1.

Electronic time resolution as a function of the time difference obtained by using two DRS4-based readout boards and a Tektronix digital oscilloscope. The dependence on the time difference observed in the DRS4-based boards is mainly due to inaccurate time calibration.

In the DRS4 waveform sampling chip, the sampling interval between two successive capacitor cells is determined by the time delay of the inverters between them. The transistor variations in the chip cause the non-uniform sampling intervals unlike using flash ADC-based waveform sampling. If not properly calibrated, the non-uniform sampling interval results in a time resolution dependence on the time difference as shown in Figure 1: as the time difference increases, more samples are involved and the errors in their time intervals accumulates to degrade the resolution of the time measurement. The current time calibration method implemented in the DRS4 evaluation board Version 4 by its developer [6] uses a 132 MHz clock signal for time calibration (hereafter we refer to it as the DRS4 Eval V4 method).1 This method initially assumes an uniform time interval for all capacitor cells, e.g., 200 ps at 5 GS/s. From the recorded waveform of the 132 MHz clock, zero-crossing points on rising/falling waveforms are calculated, and the time intervals between two adjacent zero-crossing points are compared to the known clock period. The deviations of the calculated time intervals from the clock period are applied as a correction to the capacitor cells within two zero-crossing points. The sampling interval for each capacitor cell is obtained iteratively by repeating the procedure.

However, the non-uniform sampling intervals of the DRS4 are not revealed clearly by the DRS4 Eval V4 method because the time calculation and correction in the method involves multiple capacitor cells (e.g., ~38 cells at 5 GS/s), and the difference between cells could be averaged out as a result. We have developed a new time calibration method to individually measure the sampling interval associated with each capacitor cell of the DRS4. Our method uses a sawtooth-shape pulse as a calibration source, which is linearly increasing/decreasing in amplitude and time coordinate (hereafter we refer to it as the Sawtooth method). Since the slope of the input pulse is kept the same regardless of the sampling instance, the measured amplitude difference between two adjacent sampled points is proportional to the sampling interval between two cells. By using this proportionality, the sampling interval can be determined individually from the differential amplitude for all the capacitor cells. Currently, several high-speed waveform sampling ASICs [7][8][9] based on the switched-capacitor cell technology are available in addition to the DRS4, and several time calibration methods developed for those ASICs have been reported in the literature [9][10][11][12]. Among them, the method [10] by Breton et al. is similar to our approach: the sampling interval is extracted from a segment of a sine wave around a zero-crossing point while assuming linearity of the sine wave in the segment. In our method, such an assumption on the linearity of the calibration source is not necessary, and all of the rising/falling portion of the sawtooth-shape pulse is exploited in calibration.

In this study, the DRS4 evaluation board V4 is used for the experimental tests to compare the results obtained by applying the two different time calibration methods: the DRS4 Eval V4 method and the Sawtooth method. The calibration method, experimental test set-up, and time resolution measurements are presented in the following sections.

2. Method

Figure 2(a) illustrates how a linearly increasing pulse is used for our time calibration method. For simplicity, only three sampled points in amplitude and time coordinate are marked by red circles on the straight line, which is a segment of the input pulse to the DRS4. In the figure, ΔV , the differential amplitude between two adjacent samples, is proportional to Δt, the sampling interval between them. The ratio between ΔV and Δt is the slope of the pulse and is the same for ΔV measurements obtained by all 1024 capacitor cells as shown in Equation 1, where the subscript i is added to ΔV and Δt to refer to the measurements obtained by the ith capacitor cell. In the DRS4, the entire sampling interval of the 1024 capacitor cells is fixed by an on-chip phase-locked loop (PLL) circuit, e.g., 200 ns at 5 GS/s. This constraint, as shown in Equation 2, makes it possible to calculate the single normalization factor, C, from the sum of ΔVi. Equation 3 expresses the sampling interval determined by using the conversion factor and measured differential amplitude for each capacitor cell.

| (1) |

| (2) |

| (3) |

Figure 2.

(a) Sampled waveform on a linearly increasing pulse. The (non-uniform) sampling interval Δti is proportional to the differential amplitude ΔVi. (b) A Sawtooth-shape waveform with 40 ns period generated by the Tektronix AWG7102.

Figure 2(b) shows the sawtooth-shape pulse used in the calibration. Each portion of the pulse (rising/falling and plateau) has 10 ns duration, yielding a 40 ns period in one cycle. The slope at the rising/falling part of the pulse is fixed to be +100/–100 mV/ns, and the amplitude of the pulse covers the full dynamic input range of the DRS4.

Figure 3 shows a histogram of the measured differential amplitudes at a particular capacitor cell obtained by sending 10,000 (10K) sawtooth-shape pulses to the DRS4 evaluation board. The peaks centered at approximately +16/-16 mV represent when the particular capacitor cell is in the rising/falling portion of the pulse. Similarly, the plateau of the pulse produces the peak at 0 mV. We include the plateau to produce such a center peak in the histogram for verifying whether the measurement procedure works properly. Since this center peak is not used in calibration, the plateau of the pulse can be reduced or removed completely. In addition to the peaks, small tails between peaks are observed. These tails represent when the cell is in the transition regions between the rising/falling portion and the plateau of the pulse. Using this histogram, ΔV measured by a particular capacitor cell for the rising/falling portion of the sawtooth-shape pulse is obtained by averaging the center locations of the positive and negative peaks as determined, as illustrated by Figure 3(b), by Gaussian fitting. From this average ΔV , the sampling time interval Δt associated with the capacitor cell, referred to as the time calibration constant below, is obtained by applying the measured conversion constant C as described above.

Figure 3.

(a) A histogram of the differential amplitude (ΔV ) obtained at a particular capacitor cell obtained by sending 10K sawtooth-shape pulses to the DRS4 evaluation board. (b) Fitting of the positive peak in (a) to a Gaussian function.

3. Experimental Setup

The block diagram of the time calibration set-up is depicted in Figure 4(a). The sawtooth-shape pulse with 40 ns period is generated by using a Tektronix AWG7102 waveform generator [13] and fed to one input channel of the DRS4 evaluation board. The AWG7102 is an arbitrary waveform generator with 10 GS/s sampling and ~1 ps random jitter. For the waveform digitizer, a DRS4 evaluation board (PSI) is used. The DRS4 board, shown in Figure 4(b), provides 4 input channels, each with 1024 capacitor cells. The input dynamic range of the DRS4 chip is 1 V (–0.5 to 0.5 V), and the sampling speed is adjustable from 0.7 to 5 GS/s. Since the DRS4 provides a full sampling range of 200 ns, a 6 cycle-long sawtooth-shape pulse is used in each calibration event, and as mentioned above 10K events are used for the ΔV measurement. Digitized waveforms acquired by the DRS4 board are transferred to a computer for off-line analysis. The evaluation board is equipped with on-board amplitude and time calibration software, and it makes it possible to perform a comparison study between two time calibration methods using the same waveform data set: only the time information is switched while the amplitude of the waveform is kept the same. For measuring the electronic time resolution, two identical Gaussian pulses (σ = 1 ns, 500 mV amplitude) are generated by the AWG7102 and are connected to two input channels of the DRS4 board. The time difference between these two Gaussian pulses is varied by programming the AWG7102.

Figure 4.

(a) A block diagram of experimental setup. Pulses generated by the AWG7102 are sampled by a DRS4 evaluation board, and the waveforms digitized by the DRS4 are transferred to a computer through USB interface. (b) DRS4 evaluation board (PSI).

4. Results

4.1. Time calibration using sawtooth-shape pulse

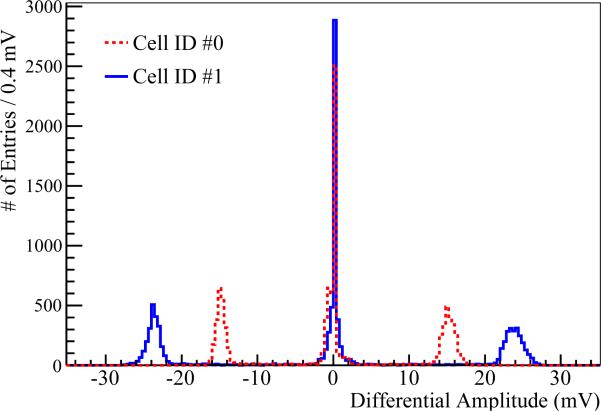

Figure 5 compares the differential amplitude histograms obtained for capacitor cell #0 and #1 by using 10K sawtooth-shape pulses. Following the procedure described in Section 2, the ΔV values are determined to be 15.0 mV and 23.8 mV for cell id#0 and #1, respectively. Such a significant difference in ΔV is observed between the odd- and even-numbers cells of the DRS4.

Figure 5.

Differential amplitude ΔV histogram obtained for the capacitor cell id#0 and 1. Such significant differences in the ΔV measurement are observed between the odd- and even-numbered capacitor cells of the DRS4.

Figure 6(a) shows the histograms of the sampling intervals (the time calibration constants) obtained for the 1024 cells of the DRS4 by using the Sawtooth method and the DRS4 Eval V4 method. With the Sawtooth method, the time calibration constant has two distinct groups, reflecting the difference between the odd- and even-numbered cells. The means (widths) of these two groups are 142.2 ps and 245.8 ps (24.8 ps RMS and 24.8 ps RMS), respectively. The scatter plot in Figure 6(b) reveals a more systematic pattern of the time calibration constants: in addition to the difference in odd- and even-numbered cells, the difference between the first half (#0-511) and second half (#512-1023) can also be observed. These patterns are consistent with the observation recently reported by Shaver et al in which another calibration method is used [14]. Unlike the Sawtooth method, Figure 6(a) also shows that the time calibration constants generated by the DRS4 Eval V4 method are very similar for 1024 capacitor cells: the mean of the distribution is 195.3 ps and the RMS is only 2.4 ps.

Figure 6.

(a) Histograms of the sampling interval (time calibration constant) obtained for the 1024 capacitor cells of the DRS4 by using the DRS4 Eval V4 method and the Sawtooth method. (b) A scatter plot of the sampling intervals obtained by the Sawtooth method.

The resulting time calibration constants are applied to a separately acquired dataset for the sawtooth-shape pulse to evaluate how well the linearity of the rising portion of the pulse is reproduced. Figure 7(a) shows a close-up of the a segment of the rising portion of the sawtooth-shape pulse measured by the DRS4 evaluation board by using the time calibration constants determined by the DRS4 Eval V4 method and Sawtooth method. The samples are fitted with a straight line with a slope of 100 mV/ns, which is the known slope of the segment. It should be noted that the samples of the two methods have the same amplitudes. From the fitting shown in Figure 7(a), it is clearly seen that the samples obtained by the Sawtooth method recover the input pulse better than the samples obtained by the DRS4 Eval V4 method. The straight-line fit is carried out for 10K waveform samples in a -450 mV to 450 mV range, and the normalized χ2 distributions of the fit (degree of freedom in the fit is approximately equal to 47) obtained for the time calibration methods are compared in Figure 7(b). In comparison with the DRS4 Eval V4 method, the χ2 error of the Sawtooth method is much smaller in magnitude and much narrower in distribution.

Figure 7.

(a) A segment of sawtooth-shape waveform using two sets of time calibrations. A straight line fit on the waveform is shown (~0.5 mV error bar is too small to be seen in the figure.) (b) Normalized χ2 of the fit using two sets of time calibrations.

4.2. Electronic time resolution measurement using Gaussian pulses

To evaluate the electronic timing resolution, two identical Gaussian pulses are generated from two channels of the Tektronix AWG7102 waveform generator and sent to two input channels of the DRS4 evaluation board. The time difference between the occurrence of the two Gaussian pulses are varied from 0 ns to 170 ns to investigate the dependence of the time resolution on the time difference. Figure 8(a) shows the samples acquired for the Gaussian pulses with a 5.0 ns time difference. A Gaussian fit is applied to the waveforms recorded, and the center location of the Gaussian fit is taken as the event time. Figure 8(b) shows the time difference measurement using the two Gaussian pulses with 1.0 ns time difference between them. Both the DRS4 Eval V4 method and the Sawtooth method yield a mean value of 0.89 ns; the deviation from the known value of 1.0 ns can be attributed to the slight cable difference. Since the distribution is not Gaussian, the width of the distribution is evaluated by using RMS. The time resolution is measured to be about 2.9 ps RMS with the Sawtooth method and about 8.1 ps RMS with the DRS4 Eval V4 method.

Figure 8.

(a) Sampled waveforms obtained by the DRS4 board for two identical Gaussian pulses with a time difference of 5.0 ns (generated by an AWG7102 waveform generator). (b) Histograms of the measured time difference when the time difference between the Gaussian pulses is 1.0 ns. The time resolution is estimated to be about 2.9 ps RMS and 8.1 ps RMS when using the time calibration constants obtained by the Sawtooth method and the DRS4 Eval V4 method, respectively.

The time resolution dependence on the time difference between the Gaussian pulses is shown in Figure 9(a). Compared to the results using the DRS4

Figure 9.

(a) The electronic time resolution as the time difference varies from 0 to 5 ns. (b) The time resolution with time difference up to 170 ns shows its dependence on the time difference.

Eval V4 method, the time resolution dependence on the time difference is negligible with the Sawtooth method (29.3 ps RMS vs. 3.2 ps RMS at 5.0 ns time difference). The time resolution dependence of the Sawtooth method measured with time difference up to 170 ns is shown in Figure 9(b). The resolution degrades as the time difference increases until it reaches ~120 ns, where the time resolution is ~7.9 ps RMS, and apparently improves as the time difference increases further. This behavior is considered to be the constraint effect of the on-chip PLL and the domino-ring structure of the DRS4.

The linearity of the measured time is shown in Figure 10. Figure 10(a) shows the measured time difference with respect to the known value. The linearity in percentile is calculated by:

| (4) |

Figure 10(b) shows the calculated linearity (%) as a function of the time difference, and the non-linearity is found to be smaller than 0.3% in the range of 0-2 ns time difference, and is smaller than 0.1% above 2 ns to 170 ns (the figure only shows up to 5 ns). The results shown so far are obtained when operating the DRS4 board at 5 GS/s.

Figure 10.

The linearity of the DRS4 time measurement. (a) The measured time difference in DRS4 vs. the time difference at AWG7102 generator. (b) The linearity in percentage as a function of the time difference.

The Sawtooth calibration procedure is also repeated at other DRS4 sampling speeds ranging from 0.7 to 5 GS/s, and the results on the time resolution are shown in Figure 11. The same sawtooth-shape pulse, described in Section 2, is used for the time calibration at the different sampling speeds. However, the width of the Gaussian pulses for measuring the time resolution is scaled in accordance with the sampling speed such that the number of samples obtained for each pulse remains the same: e.g., the width of the Gaussian pulses used for experiments conducted at 1 GS/s is 5 times the width used for the experiments conducted at 5 Gs/s (with a σ equal to 1 ns). The results in Figure 11 show that the time resolution dependencies at all sampling speeds investigated are similar to that at 5 Gs/s, especially in the range of 2-5 GS/s. They also indicate that, as expected, the electronic time resolution is smaller when a higher sampling speed is used, but the differences from 2-5 GS/s are marginal.

Figure 11.

Electronic time resolution as a function of DRS4 sampling speed.

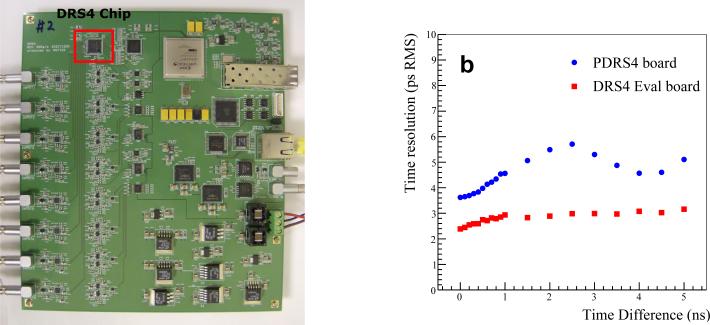

4.3. Results using PDRS4 board

The Sawtooth time calibration method is applied for calibrating the PDRS4 board [4] to check if the method is applicable to other waveform electronics using the DRS4 chip. The PDRS4, shown in Figure 12(a), is a prototype waveform readout board with 8 input channels developed for PET application using the DRS4 chip. Following the same procedure and tests described earlier for the DRS4 evaluation board, the electronic time resolution of the PDRS4 is measured and the result obtained at 5 GS/s is shown in Figure 12(b). Compared to the result using a different calibration method we previously reported [4], shown in Figure 1, the resolution dependence on the time difference is reduced significantly, and the absolute resolution also is improved. In comparison with the time resolution obtained with the DRS4 evaluation aboard using the Sawtooth time-calibration method, the result obtained with the PDRS4 has a worse time resolution and also shows a peak at about 2.5 ns time difference corresponding to its worst resolution within the 0-5 ns time difference range that we have investigated. We attribute the worse time resolution to a signal-to-noise ratio (SNR) difference: the noise level of the PDRS (~1.5 mV RMS) is larger than the DRS4 evaluation board (~0.4 mV RMS) [2][4], and the 1 V input dynamic range is fully used in PDRS4 while only half of it is used in the DRS4 evaluation board. This is consistent with the simplified rule for estimating the time resolution for waveform sampling given in [15]:

| (5) |

where tr is the rise-time of the pulse and Nsamples is the number of samples within tr. The cause of the particular shape of the PDRS4 curve is on the other hand unclear.

Figure 12.

(a) PDRS4 board (b) Electronic time resolution of the PDRS4 measured by applying the new time calibration.

5. Discussion

The voltage linearity of the capacitor cells is an important factor in the proposed time calibration method since the time interval between adjacent capacitor cells is extracted from the differential voltage measurement under the assumption of linear response in voltage. In this study, the voltage calibration was carried out by the PSI software bundled with the DRS4 evaluation board. The voltage calibration uses two DC voltages (0 and 0.4 V) for offset and gain correction for all 1024 capacitor cells, and the voltage output is calculated by assuming linear response in the entire input dynamic range of 1 V. Figure 13(a) shows the voltage linearity of the DRS4 evaluation board to DC input voltages using the PSI voltage calibration. Each point in the figure represents the collective response of the 1024 cells to the applied DC offset voltages. 1000 events were acquired for each DC offset voltage from -475 to 475 mV with a 25 mV step. The voltage non-linearity shown in Figure 13(b) is calculated from the measured voltage output subtracted by the known applied DC voltage. We have tested another voltage calibration method to demonstrate that the non-linearity can be reduced. In the method, 39 different DC offset voltages in a range from -475 to 475 mV are used, and the offset and gain for each cell is determined from the linear fit on the measured responses. The voltage non-linearity measured by applying the new voltage calibration is also shown in Figure 13(b). The variation of non-linearity is reduced from ~4% to ~2% by applying the new voltage calibration. Time resolution results in this study are using the PSI voltage calibration and are expected to be improved with better voltage calibration.

Figure 13.

(a) Voltage linearity of the DRS4 evaluation board. (b) Voltage non-linearity after subtracting the applied DC value.

A Tektronix AWG7102 waveform generator is used to generate the sawtooth-shape pulse for time calibration in this study. The reasons for using the AWG7102 are to produce a highly linear rising/falling pulse and measure the electronic time resolution precisely, avoiding any possible effects from inaccurate generators. To demonstrate that the method works well with other lower-end pulse generators, we have also repeated the calibration by using a Rigol DG4162 (160 MHz frequency) waveform generator [16]. In the test, the rise time of the sawtooth-shape pulse was varied from 10 ns to 80 ns to see any possible effects on the time resolution, and the sampling speed of the DRS4 was fixed at 5 GS/s. The Gaussian pulse data set generated by the AWG7102 is used here also for comparing the results. Table 1 summarizes the time resolution obtained by using the time calibration constants obtained from the sawtooth-shape pulses having rise time ranging from 10 - 80 ns for three time differences: 1 ns, 5 ns, and 10 ns. The results show that the time resolution is not much affected by the rise time of the calibration pulse in the 20 - 80 ns range. The worse time resolution obtained with 10 ns rise-time is considered to be an instrumental effect of the DG4162 generator.

Table 1.

Time resolutions (σ) obtained by using the time calibration constants obtained from the sawtooth-shape pulses with various rise time generated by the DG4162 for three time differences (Δt.)

| Pulse rise time | σ (Δt = 1 ns) | σ (Δt = 5 ns) | σ (Δt = 10 ns) |

|---|---|---|---|

| 10 ns | 2.8 ps | 6.6 ps | 7.9 ps |

| 20 ns | 3.0 ps | 3.7 ps | 4.5 ps |

| 40 ns | 2.9 ps | 3.3 ps | 4.3 ps |

| 60 ns | 2.9 ps | 3.4 ps | 4.6 ps |

| 80 ns | 2.9 ps | 3.4 ps | 4.0 ps |

In this study, 10K events of the sawtooth-shape pulse are used for the time calibration. Because of the plateau part of the pulse, the effective number of calibration events is reduced by half to 5K, and the time calibration was carried out by using the ΔV histogram with ~5K entries for each capacitor cell. We have also checked how quickly the proposed Sawtooth method converges with the number of events used in calibration: the time calibration constants are calculated from the subset of the original 10K events, 250, 500, 750, 1K, 2.5K, 5K and 7.5K, and the newly obtained calibrations are applied to measure the time resolution at time differences of 1, 5 and 10 ns, following the procedure described in Section 4.2. The DRS4 sampling speed is set to 5 GS/s. Figure 14 shows the measured time resolution as a function of the number of calibration events. The results indicate that the time resolution starts degrading when the number of calibration events is below 1K.

Figure 14.

Time resolution as a function of the number of calibration events. Each point represents the time resolution measured by applying the time calibration constants obtained by using a subset of the original 10K events.

According to the DRS4 chip specification [17], offset and gain errors due to temperature drift are reported to be 75 μV/°C and 25 ppm/°C in 25 to 50°C, respectively. We tested the stability of the time resolution of the DRS4 at three different temperatures: 28, 33 and 44°C. The temperature drift during data acquisition, monitored by the on-board temperature sensor (MAX6662, MaximIntegrated) on the DRS4 evaluation board, was kept within 1°C. The time calibration constants obtained at these temperatures were applied to the same Gaussian pulse samples for time resolution measurement. The results, summarized in Table 2, show that the time resolution is stable to temperature changes in the range of 28 to 44°C. It is noted that in this experiment the sawtooth-shape pulses having a 10 ns rise-time for calibration were generated by using a Tektronix AFG3102 (100 MHz); the measured time resolutions are again similar to the results obtained by using the time calibration constants obtained with the AWG7102.

Table 2.

Time resolutions (σ) measured for various time differences (Δt) by using the time calibration constants obtained when the DRS4 evaluation board is operated at three different temperatures.

| Temperature (°C) | σ (Δt = 1 ns) | σ (Δt = 5 ns) | σ (Δt = 10 ns) |

|---|---|---|---|

| 28 | 2.9 ps | 3.4 ps | 3.9 ps |

| 33 | 3.0 ps | 3.5 ps | 3.9 ps |

| 44 | 2.9 ps | 3.4 ps | 3.8 ps |

6. Summary

We report a new time calibration method for DRS4-based waveform sampling electronics. Based on the linearity of the sawtooth-shape pulse, the method can calibrate the individual sampling intervals associated with the 1024 capacitor cells of the DRS4 from differential-voltage measurements. After applying this method, the large variation in the sampling interval of the DRS4 chip is clearly revealed. The dependence of the time resolution on the time difference of two pulses, which has been observed by using other time calibration methods, is significantly reduced after applying the proposed calibration method, and we are able to achieve 2.4 - 3.2 ps RMS time resolution for the time difference in the 0-5 ns range. The proposed time calibration method was applied to two different readout boards using the DRS4 chip and could be applicable to other waveform sampling electronics based on switched-capacitor-array technology.

Acknowledgment

This work was supported in part by the NIH grant R01EB016104, R01EB006085, T32EB002103, the University of Chicago and Fermilab strategic collaboration seed grants, and the University of Chicago Institute for Translational Medicine awards.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

After submitting the manuscript, the next version (V5) of the DRS4 evaluation board was announced, and improved performances relative to the V4 including time resolution are claimed in the DRS4 web page.

References

- 1.Ritt S, Dinapoli R, Hartmann U. Nucl. Instr. and Meth. 2010;623:486. [Google Scholar]

- 2.Kim H, Chen C-T, Frisch H, Tang F, Kao C-M. Nucl. Instr. and Meth. 2012;662:26. doi: 10.1016/j.nima.2011.09.059. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Kim H, et al. IEEE NSS/MIC Conference Record. 2012:2466. [Google Scholar]

- 4.Kim H, Kao C-M, Kim S, Chen C-T. IEEE NSS/MIC Conference Record. 2011:2393. [Google Scholar]

- 5.DRS4 Chip Home Page. http://www.psi.ch/drs/

- 6.DRS4 evaluation board software (verstion 4.0.1) http://www.psi.ch/drs/software-download.

- 7.Delagnes E, Degerli Y, Goret P, Nayman P, Toussenel F, Vincent P. Nucl. Instr. and Meth. 2006;567:21. [Google Scholar]

- 8.Varner G, Ruckman L, Wong A. Nucl. Instr. and Meth. 2008;591:534. [Google Scholar]

- 9.Oberla E, Genat J-F, Grabas H, Frisch H, Nishimura K, Varner G. Nucl. Instr. and Meth. 2014;735:452. [Google Scholar]

- 10.Breton D, Delagnes E, Maalmi J. Proceedings of the Topical Workshop on Electronics for Particle Physics (TWEPP-09) Paris:France. 2009 http://hal.in2p3.fr/in2p3-00421366.

- 11.Breton D, Delagnes E, Maalmi J, Nishimura K, Ruckman LL, Varner G, Va'vra J. Nucl. Instr. and Meth. 2011;629:123. [Google Scholar]

- 12.Nishimura K, Romero-Wolf A. Physics Procedia. 2012;37:1707. [Google Scholar]

- 13.AWG7102 data sheet. http://www.tek.com/sites/tek.com/files/media/media/.../76W_19779_3.pdf.

- 14.Shaver DS. presentation at IEEE NSS/MIC 2012 and private communication.

- 15.Ritt S. DRS chip developments, Workshop on electronics and DAQ for timing electronics in medical and particle physics, Clemont-Ferrand; France. January 2010; http://www.psi.ch/drs/DocumentationEN/clermont_jan10.ppt. [Google Scholar]

- 16.Rigol DG4162 Waveform generator. http://www.rigolna.com/products/waveform-generators/dg4162/

- 17.DRS4 chip specification sheet. http://www.psi.ch/drs/DocumentationEN/DRS4_rev09.pdf.