Abstract

Relaxor-PbTiO3 (PT) based ferroelectric crystals with the perovskite structure have been investigated over the last few decades due to their ultrahigh piezoelectric coefficients (d33 > 1500 pC/N) and electromechanical coupling factors (k33 > 90%), far outperforming state-of-the-art ferroelectric polycrystalline Pb(Zr,Ti)O3 ceramics, and are at the forefront of advanced electroacoustic applications. In this review, the performance merits of relaxor-PT crystals in various electroacoustic devices are presented from a piezoelectric material viewpoint. Opportunities come from not only the ultrahigh properties, specifically coupling and piezoelectric coefficients, but through novel vibration modes and crystallographic/domain engineering. Figure of merits (FOMs) of crystals with various compositions and phases were established for various applications, including medical ultrasonic transducers, underwater transducers, acoustic sensors and tweezers. For each device application, recent developments in relaxor-PT ferroelectric crystals were surveyed and compared with state-of-the-art polycrystalline piezoelectrics, with an emphasis on their strong anisotropic features and crystallographic uniqueness, including engineered domain - property relationships. This review starts with an introduction on electroacoustic transducers and the history of piezoelectric materials. The development of the high performance relaxor-PT single crystals, with a focus on their uniqueness in transducer applications, is then discussed. In the third part, various FOMs of piezoelectric materials for a wide range of ultrasound applications, including diagnostic ultrasound, therapeutic ultrasound, underwater acoustic and passive sensors, tactile sensors and acoustic tweezers, are evaluated to provide a thorough understanding of the materials’ behavior under operational conditions. Structure-property-performance relationships are then established. Finally, the impacts and challenges of relaxor-PT crystals are summarized to guide on-going and future research in the development of relaxor-PT crystals for the next generation electroacoustic transducers.

Keywords: Relaxor-PT, Ferroelectric, Piezoelectric, Crystals, Transducers, Electroacoustic

I. Introduction

1.1 General information on electroacoustic transducers

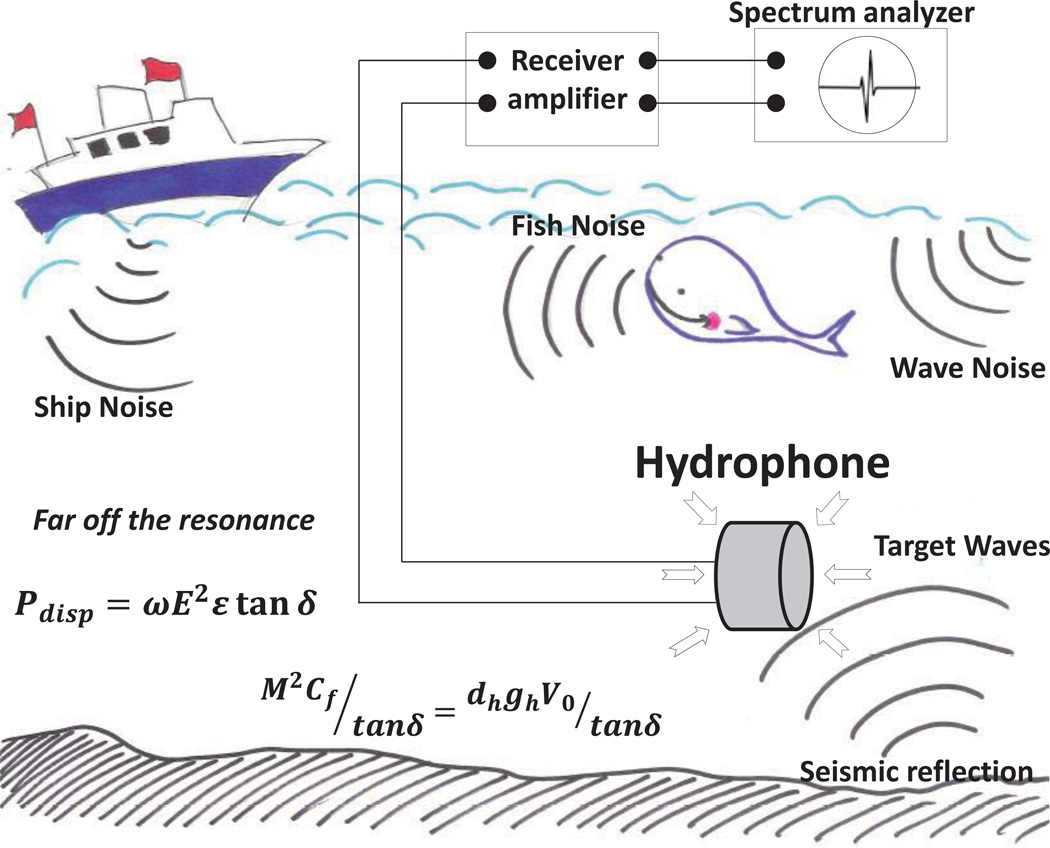

An electroacoustic transducer is a type of device that transforms an electrical signal into acoustic waves or converts an acoustic wave to an electrical signal, or, in many cases, operates in both directions. Electroacoustic transducers are versatile and include magnetostrictive, electrostatic and piezoelectric devices, among which piezoelectric transducers are the most commonly used in a diverse range of applications, such as industrial nondestructive evaluations, underwater acoustics, medical ultrasonics for diagnostics and therapy, ultrasonic cleaning, and material processing, to name a few [1–9]. The operational frequency range varies greatly depending on the applications. For example, common frequencies of 2 to 10 MHz are used in nondestructive testing and evaluation to locate flaws in materials, but lower frequencies can also be used to inspect low density materials. Medical diagnostic transducers generally operate in the frequency range of 2 to 18 MHz, though frequencies up to 50–100 MHz have been used for intravascular, ophthalmic, skin imaging and small animal imaging. The useful spectrum of underwater acoustic extends from sub-audible and audible frequencies allowing for great distances (one to several kilometers) to ultrasonic frequencies (up to > 1 MHz) where echo distances are shorter and increase accuracy of distance measurements is desirable [3,7]. Applications over this wide frequency range require numerous transducer designs. A number of geometries have been demonstrated, resulting in effective underwater acoustic transducers [10]. Each design offers a number of advantages and disadvantages associated with the geometry of the transducer. Common transducer designs include but are not limited to the following: flextensional “cymbal” transducers, where the piezoelectric active material is sandwiched between two mechanical end caps, and the primary axis of mechanical motion is perpendicular to the primary axis of acoustic radiation [10–13]; 1–3 (or 2-2) composite transducers, where a series of piezoelectric pillars (or sheets) are arranged with a predetermined lateral spacing and filled with a mechanically lossy polymer matrix, which operates in an effective longitudinal (or sliver) mode, thus offering greater bandwidth and improved acoustic impedance matching with water or tissue [10,14–20]; and tonpilz transducers (Langevin transducers), where stacked piezoelectric rings are connected with a head and a tail mass resulting in longitudinal operational mode [3,10,21–22]. These underwater acoustic devices are useful in ocean engineering in many ways. For example, the precise location of specific points or objects is often critical when drilling for oil and gas in the deep ocean or laying underwater cables or pipelines, while the combination of underwater and seismic acoustics is needed for finding deposits of oil or gas under the oceans [3].

The first attempt to use ultrasound transducer for medical diagnosis was based on a transmission technique by the Dussik brothers in 1937, working in Austria [8,9]. Research into medical applications of ultrasound is usually said to have started with the work of Wood and Loomis [23], who made a comprehensive study of both the physical and biological effects of ultrasound on biological media. An extensive literature list soon started to develop, particularly after 1954, when the first compound B-scan imaging system was reported. Ultrasonics has since found usage in numerous aspects of medical procedures, including diagnostic (low power), therapeutic (intermediate power), and surgical (high power in several forms, such as heat and mechanical) applications [2]. Ultrasonic wave propagation in body tissue is, in large measure, controlled by the acoustic impedance contrast at boundaries and various scattering mechanisms presented at the different scales within tissue, such as velocity and attenuation factors. These are the basic factors that determine the effectiveness of both diagnostic and therapeutic applications of ultrasound [2].

Recent decades have seen a second revolution in electroacoustic transducers, which benefit from modern electronics as well as with increasing digitization and computer-based data processing, imaging capability to deliver in-situ processing and advanced display/visualization capabilities [2]. These advances have been combined to facilitate new applications at both low and high powers using modern instrumentation and analysis capabilities, leading to major growth and diversification of electroacoustic applications, which in turn drive the developments of new transducer materials [2–4].

1.2 History of piezoelectric materials for transducers

Piezoelectric materials are the heart of piezoelectric transducers and sensors [24–34]. Fig. 1 gives a general milestone map for piezoelectric transducer material development as a function of their respective piezoelectric performance. The piezoelectric effect was first found in 1880 by Pierre and Jacques Curie [35]. They discovered that a stress applied to crystals, such as quartz, produced an electric charge on the surface (direct effect). Conversely, an electric field applied to the surfaces produced a change in the dimensions, and hence an alternating voltage applied to a crystal produced acoustic waves in the surrounding medium. Quartz piezoelectric crystal was used as a transducer material in 1917 by Langevin, who designed the first electroacoustic transducer by sandwiching quartz between steel plates [2,3]. Rochelle salt (sodium potassium tartrate tetrahydrate) crystal was first synthesized in 1655, but its ferroelectricity and subsequent piezoelectric were demonstrated later by Valasek in 1921 [36–38], showing a stronger piezoelectric effect than quartz, and also became available in the form of synthetic crystal to provide an alternate for the electroacoustic transducers [38]. However, Rochelle salt was found to be not stable against dehydration either in vacuum or in dry air. In addition, Rochelle salt is one of few ferroelectric crystals with limited ferroelectric range and two clear Curie points [38–39]. Motivation of exploring new man-made transduction materials lead to the discovery and development of potassium dihydrogen phosphate (KDP) [40] and ammonium dihydrogen phosphate (ADP) [41] crystals in 1935 and the early 1940’s, in which the structural arrangement of phosphate tetrahedral is linked by hydrogen bonding at the corners, showing relatively strong piezoelectric activity. It was generally accepted that ferroelectricity was highly correlated with the hydrogen bonds in the early Rochelle salt and KDP/ADP periods [6,38,42–43]. The ADP crystals were then established as extremely useful for high power acoustic transducers, replacing Rochelle salt [43]. Up to 1945, the principal ultrasonic transducer materials were natural quartz and ADP crystals [3].

Fig. 1.

General milestone map for piezoelectric transducer material development. KDP/ADP: KH2PO4/(NH4)H2PO4; BT: BaTiO3; LN: LiNbO3; PZT: Pb(Zr,Ti)O3; PN: PbNb2O6; PMN: Pb(Mg1/3Nb2/3)O3; PMN-PT: Pb(Mg1/3Nb2/3)O3-PbTiO3.

In the early 1940’s, a breakthrough was achieved by the use of ferroelectrics that can be obtained in polycrystalline ceramic form. The first of these ferroelectrics, barium titanate (BaTiO3), with the perovskite structure based upon corner linking of oxygen octahedra, was discovered independently by Von Hippel [44] and Goldman [45]. The first working piezoelectric ceramic transducer can be credited to Gray in 1945, who had the first clear understanding of the importance of electrical poling in establishing a remnant polar domain configuration in the ceramics and corresponding strong piezoelectric response [46]. By the early 1950s, ceramic piezoelectric transducers based on BaTiO3 (BT) were well established in a number of both civil and military applications [38,47]. However, due to the concerns about the stability against depoling - accompanied by multi polymorphic phase transitions (PPTs) in pure BT - and the low field stability (low coercive field EC) [38, 48–50], it was necessary to explore other ferroelectric perovskite compounds with enhanced performance [51–53]. Some of the very early basic work on pure PbTiO3 and PbZrO3-PbTiO3 (PZT) solid solution systems led to the useful outline of its phase diagram [54–56]. The milestone studies, which established the PZT system as exceptionally suitable piezoelectric material formulations, were carried out by Jaffe et al., who discovered that the nearly temperature-independent morphotropic phase boundary (MPB) in PZT was of vital importance for transducer applications, due to the abnormally high piezoelectric and electromechanical properties near the MPB compositions [57–62]. The leading position of PZT compositions was due to their strong piezoelectric effect and relatively high Curie temperature. PZTs also allowed a wide variation in chemical modification to obtain a wide range of operating parameters without serious reduction of the piezoelectric effect, where the chemical dopants included isovalent substitutes of the lead cation by base earth elements and acceptor or donor dopants on the A or B sites [61–62]. Most effects of acceptor or donor doping were attributed to the type of lattice vacancies that arose, where oxygen vacancies induced by acceptor dopants inhibited domain wall motion, while lead vacancies induced by donor dopant made the domain wall motion easier, leading to different “hard” and “soft” characteristics, respectively [63–68]. A series of formulation-labeled PZT (PZT4, PZT5A, PZT5H, PZT8, etc.) have been established to emphasize various properties. Table I summarizes several commercially available PZT ceramics which have been extensively used for more than 60 years [69–71]. It can be seen that different compositions are outstanding with regard to different characteristics and thus beneficial to different applications. The high electromechanical coupling and piezoelectric coefficient of PZT5H have led to its use in medical imaging transducers, while PZT5A is a better choice for sensing applications due to its high piezoelectric voltage coefficient and higher Curie temperature. Meanwhile, the high resistivity of the donor doped PZTs at elevated temperatures allows usage to very low frequencies (the low limit frequency of the materials is inversely proportional to the time constant RC=ε0Kρ, where ε0 is the vacuum permittivity, K, the dielectric constant and ρ, the resistivity). On the contrary, the low mechanical and dielectric losses of PZT4 and PZT8 compositions benefits applications in high power transducers and ultrasonic motors requiring high drive fields. Other formulations, such as PZT6 and PZT7, also found usage in specific applications, where high temperature/time stability and low permittivity are desired, respectively [38, 69–71].

Table I.

Principal properties of various PZT based polycrystalline ceramics, compared to BaTiO3 (BT), PbNb2O6 (PN) ceramics and LiNbO3 (LN) crystals. TC (°C); d (pC/N); s (pm2/N) [70–71]

| TC |

|

|

d33 | d15 | k33 | k15 | kt |

|

|

Qm | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PZT2 | 370 | 450 | 990 | 152 | 440 | 0.63 | 0.70 | 0.51 | 14.8 | 45 | 680 | ||||

| PZT4 | 328 | 1300 | 1475 | 289 | 496 | 0.70 | 0.71 | 0.51 | 15.5 | 39 | 500 | ||||

| PZT5A | 365 | 1700 | 1730 | 374 | 584 | 0.705 | 0.685 | 0.49 | 18.8 | 47.5 | 75 | ||||

| PZT5H | 193 | 3400 | 3130 | 593 | 741 | 0.75 | 0.675 | 0.505 | 20.7 | 43.5 | 65 | ||||

| PZT6B | 350 | 460 | 475 | 71 | 130 | 0.375 | 0.377 | 0.30 | 9.35 | 28.2 | 1300 | ||||

| PZT7A | 350 | 425 | 840 | 150 | 362 | 0.66 | 0.67 | 0.50 | 13.9 | 39.5 | 600 | ||||

| PZT8 | 300 | 1000 | 1290 | 225 | 330 | 0.64 | 0.55 | 0.48 | 13.5 | 31.9 | 1000 | ||||

| BT | 115 | 1700 | 1450 | 190 | 260 | 0.50 | 0.48 | 0.38 | 9.5 | 22.8 | 300 | ||||

| PN | 570 | 225 | / | 85 | / | 0.38 | / | / | 25.4 | / | 15 | ||||

| LN | 1150 | 30 | 84 | 6 | 68 | 0.16 | 0.61 | 0.16 | 5.02 | 17 | 3000 |

Undoubtedly, the PZT family is, by far, the most important and versatile compositional base for piezoelectric elements. In addition to PZTs, other developments in ferroelectric materials are also of major interest. In 1952, studies by Goodman uncovered the interesting and strong ferroelectric properties in lead metaniobate (PbNb2O6: PN) with a tungsten bronze structure [38,72]. It exhibits unusual properties not generally present in other piezoelectric materials and has been the subject of considerable research because of its high hydrostatic sensitivity (due to its large anisotropy, allowing a better response under hydrostatic pressures), low mechanical Qm (being only ≪ 20, benefiting the fabrication of wide bandwidth transducers for high frequency pulse echo measurements that require a short pulse and critical resolution) and negligible aging in a wide temperature range due to its high Curie temperature [38,73–75]. The metaniobate is a problematic ceramic to process, but easily forms solid solution with other end members such as BaNb2O6 with decreased Curie temperature [76], and thus has been specialized for industrial nondestructive evaluation/testing (NDE/NDT) applications. Another development in piezoelectric materials is crystal growth of LiNbO3 (LN) and LiTaO3 (LT) [77–79], which were synthesized for the first time in Bell laboratories and their ferroelectric properties revealed by Matthias and Remeika [80]. Both crystals have an ilmenite structure [81]. The detailed structure and properties were reviewed by Smith et al. [82] and Weis et al.[83]. Both LN and LT are well known for their low acoustic losses and are thus excellent materials for surface acoustic wave (SAW) devices [77–78]. LN, possessing relatively large electromechanical coupling factors and very high Curie temperature of 1150 °C, has been actively studied for high temperature acoustic transducer [84–86]. In addition, it has been studied for high frequency (>20MHz), broad bandwidth single-element transducer applications due to its very high acoustic velocity and low dielectric constant [87–88]. LN possesses a number of useful orientation-controlled crystal cuts, which are now extensively used in transducer applications, including compression 36° rotated y-cut and shear 163° rotated y-cut.

In the 1970s, it was deemed that further improvements in the performance of established piezoelectrics were not forthcoming. Thus, various piezoelectric composites were introduced by Newnham in 1978, through the concept of “engineered biphasic connectivity” [14]. The particular significance of piezoelectric composites is that the structurally and compositionally homogeneous ceramics or single crystals can be combined with a passive polymer material to form composites, increasing material flexibility and improving acoustic impedance matching between the active material and the medium in which the acoustic wave travels. By structurally combining a piezoelectric ceramic and a polymer with certain connectivity, the resulting composite material can successfully integrate the advantages of both materials. Several interesting connectivity patterns were developed, including 0–3, 1–3 and 2-2 structures, and are now being widely employed in transducer applications [13–20,89–110].

Another very important transduction material category is relaxor based ferroelectrics [111–117], with a partially disordered structure and polar nanoregion (PNR), leading to extremely large dielectric constant. One such material is lead magnesium niobate (PMN), first reported in 1961 [118]. The large dielectric constant benefits the electric field induced strain level through the electrostrictive coefficient, with the advantage of very low strain hysteresis, causing PMN to be actively studied for medical and underwater transducer applications [119–125]. Analogous to PZT system, the relaxor components can form solid solutions with classic ferroelectric PT, possessing MPB regions and ultrahigh dielectric and piezoelectric properties [126–136]. Of particular importance is that some of the relaxor-PT ferroelectric solid solutions can be grown into single crystals, such as Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-PT) and Pb(Zn1/3Nb2/3)O3-PT (PZN-PT). The first attempt on the crystal growth started in the early 1980s [137–138], but extensive studies on the relaxor-PT crystals have occurred since the late 1990s. The crystals were found to exhibit high electric field induced strains (~1.7%) and high electromechanical couplings (~0.9) [139–140], demonstrating the potential for improvement over PZT in electroacoustic transducer applications, which are the target piezoelectric materials in this review article.

1.3 Scope of Review

Relaxor-PT single crystals have attracted significant attention and have been actively studied over the last 20 years. Focus on the fundamental understanding of the origin of ultrahigh piezoelectricity and their merits in practical electromechanical applications, showing uniqueness and advantages of the crystals over state-of-the-art polycrystalline ceramics. Several review articles have been written on the crystal growth, property characterizations, piezoelectric mechanisms and related applications [141–154]. However, there have been no review articles surveying the “figure of merits” of relaxor-PT single crystals for various electroacoustic applications, which is very important for the material and device scientists to understand the material behavior under practically operational conditions. This review article provides an understanding of the material structure-property-device performance relationships of relaxor-PT crystals and corresponding applications, which may help the readers to better understand the materials from an application viewpoint and the acoustic devices from a functional material aspect.

II. The development of Relaxor-PT single crystals

2.1 Background

Single crystal PMN was initially reported in the early 1960s, and it was not until the early 1970s that another relaxor ferroelectric material, lead zinc niobate PZN, was reported. It was found that single crystals in the PZN-PT system could be readily grown from high temperature PbO flux [137–138]. Following studies on PZN-PT single crystals in the early 1990s [155–156], systematic studies on the piezoelectric properties of Relaxor-PT crystals poled along different crystallographic directions were reported in late 1990s and early 2000s. They showed ultrahigh piezoelectric coefficients and electromechanical coupling factors on the order of >1500 pC/N and > 0.9 respectively, far outperforming state-of-the-art ferroelectric PZT ceramics and triggering interest in crystals for various applications [157–237]. Today, relaxor ferroelectric PMN-PT crystals continue to be an exciting research area that promises even further discoveries, and have been commercialized with the help of the mature Bridgman crystal growth method [187,207,210,229,230]. However, issues of PMN-PT crystals include their low Curie temperature and ferroelectric phase transition temperatures, low coercive field and mechanical quality factor (for high power applications). The Curie temperature TC, rhombohedral-to-tetragonal ferroelectric phase transition temperature TRT and coercive field EC determine the temperature and field stabilities, which are major concerns for many electroacoustic applications. In addition, low TC, TRT and low EC bring up the issues of polarization stability under various maintenance storage and driving conditions [141]. Therefore, a dc bias electric field may be required to maintain the polarization and the performance of the devices [18]. Loss in sensitivity, however, occurs when applying a dc bias, which also adds complexity and cost to the driving electronics [171]. Furthermore, though having low dielectric loss (~0.002, similar to hard PZTs), the low mechanical quality factors Qm of PMN-PT crystals, ~100, have been limiting factors in high power transducers and resonance based acoustic devices [166,195,196]. Owing to the above issues observed in PMN-PT crystals, it is desired to develop new single crystal systems with broadened temperature usage range and improved reliability under thermal/electric field, and mechanical stress [141–142].

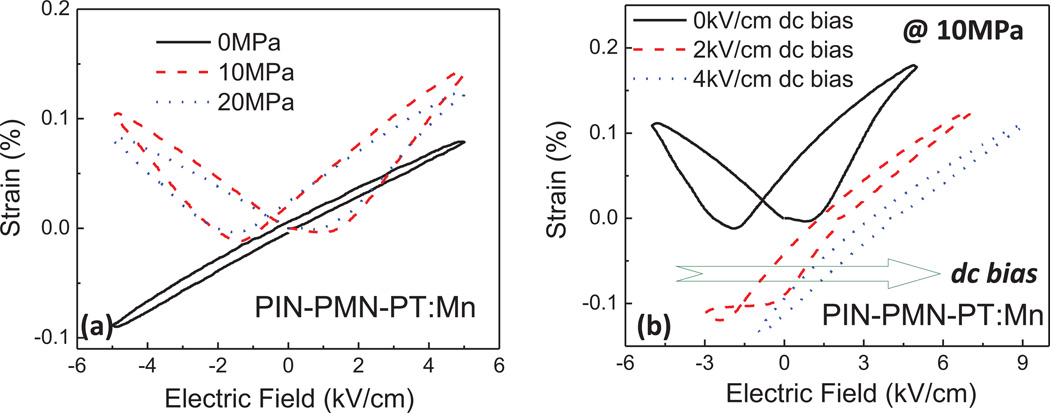

Over the last ten years, extensive effort has been focused on new crystal systems, including binary [238–268] and ternary [269–315] relaxor-PT crystal systems, in which Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3 (PMN-PZT) [269–275] and Pb(In0.5Nb0.5)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 (PIN-PMN-PT) [278–289] have been actively studied due to the potential growth ability of large size and high quality crystals. With new developments in the relaxor-PT single crystals in 2010, the concept of various generation crystals was proposed by Smith [141,316]. The first generation crystals exhibit high electromechanical coupling and piezoelectric coefficients that produce transducers with larger bandwidth (×2) and higher sensitivity (+10 dB) when compared with the state-of-the-art polycrystalline ceramic technology, which already have been commercialized in medical ultrasonic imaging [139–140]. Second generation crystals extend the high electromechanical properties to a broader range of temperature, electric field and mechanical stress, expanding their design envelope by reducing the need for heat shunts and applied dc fields. Crystals with higher ferroelectric phase transition temperatures and higher coercive fields are in this category [141,153,275,278], where the potential commercialization of the ternary PIN-PMN-PT and PMN-PZT is expected. Third generation crystals include the addition of small amount of dopants to tailor the crystal’s electromechanical parameters in order to meet specific device requirements. For example, Mn-doped relaxor-PT crystals have been developed, with greatly increased mechanical quality factors and high piezoelectric properties [273,296,298], which will benefit resonance based devices, such as ultrasonic transducers and motors. The detailed comparison of the three generations of crystal systems are given in Table II [161,273,278,290,304,317]. It was observed that the 2nd and 3rd generation crystals possess comparable piezoelectric and electromechanical properties to those of 1st generation crystals, but with higher ferroelectric phase transition temperatures (~30°C higher) and higher coercive fields (double the value of 1st Gen), allowing for broader temperature usage and higher drive fields /increased signal intensities. In addition, the mechanical quality factor of 3rd generation crystals is about 5–10 times higher than those of 1st and 2nd generation crystals, offering the possibility for high power transducer applications.

Table II.

Property comparison of the three generations relaxor-PT crystals.

| Crystal | TC (°C) |

TRT (°C) |

EC (kV/cm) |

Eint (kV/cm) |

|

d33 (pC/N) |

k33 | Qm | |

|---|---|---|---|---|---|---|---|---|---|

| PMN-PT29 (Gen I) | 135 | 96 | 2.3 | 0 | 5400 | 1700 | 0.91 | 150 | |

| PMN-PT (MPB) (Gen I) | 155 | 65 | 2.8 | 0 | 8200 | 2800 | 0.95 | 100 | |

| PIN-PMN-PT (Gen II) | 191 | 125 | 5.0 | 0 | 4400 | 1500 | 0.92 | 180 | |

| PIN-PMN-PT (MPB) (Gen II) | 197 | 96 | 5.5 | 0 | 7200 | 2700 | 0.95 | 120 | |

| Mn:PIN-PMN-PT (Gen III) | 193 | 119 | 6.0 | 1.0 | 3700 | 1100 | 0.90 | 800 | |

| Mn:PMN-PZT (Gen III) | 203 | 141 | 6.3 | 1.6 | 3400 | 1100 | 0.92 | 1050 |

2.2 General observations of relaxor-PT single crystals: Properties vs TC and TRT

Generally, the Curie temperature and ferroelectric phase transition temperature (polymorphic phase transition: PPT) are important parameters to evaluate the performance of ferroelectric materials, due to the fact that these temperatures not only relate to the material structures, but also determine the temperature usage range and temperature stability of the material properties. In polycrystalline ferroelectric materials, knowledge of the Curie temperature shows a strong relationship of dielectric and piezoelectric properties with TC [157,318]. For relaxor-PT single crystals, however, both TC and PPT (TRT) must be considered, due to the strongly curved MPB. Thus, it is desirable to understand the general relationships, if any, for relaxor-PT single crystal systems.

Fig. 2 shows the room temperature electromechanical coupling factor (k33) and piezoelectric coefficient (d33) of [001]-oriented relaxor-PT-based ferroelectric single crystals as a function of Curie temperature TC and/or rhombohedral–tetragonal phase transition temperature TRT [242,252,279,305,318–328]. Fig. 2(a) depicts the electromechanical coupling k33 as a function of Curie temperature for various crystals with compositions near their respective MPBs, where k33 values were found to be on the order of 0.9 for all [001] domain-engineered rhombohedral relaxor-PT crystals, regardless of their phase transition temperatures (TC or TRT). From Fig. 2(b), however, the levels of piezoelectric coefficients (d33) were found to decrease with increasing TRT, other than TC as observed for polycrystalline ceramics [167]. Thus, relaxor-PT single crystals possessing MPB compositions exhibit higher dielectric and piezoelectric properties, but lower ferroelectric phase transition temperatures and deteriorated thermal stability of the properties when compared to the rhombohedral compositions far away from MPB. The general trend of coercive field of [001]-oriented ferroelectric single crystals as a function of Curie temperature is shown in Fig. 3, where EC was found to increase with increasing TC [163,318]. It is of interest to note that for the same crystal system, tetragonal compositions were found to possess significantly higher coercive fields when compared with their rhombohedral counterparts, not just higher TC. The 90° ferroelastic domain walls and high c/a ratio (c and a are the crystal lattice parameters) make the main contributions to the enhanced coercive field [373].

Fig. 2.

(a) Electromechanical coupling of relaxor-PT crystals as a function of Curie temperature; (b) Piezoelectric coefficient of relaxor-PT crystals as a function of TRT. BSPT: BiScO3-PbTiO3; PYNT: Pb(Yb0.5Nb0.5)O3-PbTiO3. (Reprinted with permission from S. J. Zhang and T. R. Shrout, IEEE Transactions on Ultrasonics Ferroelectrectrics Frequency Control 57, 2138 (2010). Copyright© 2010, IEEE) [318]

Fig. 3.

Coercive field as a function of Curie temperature for perovskite relaxor-PT crystals. (Reprinted with permission from S. J. Zhang and T. R. Shrout, IEEE Transactions on Ultrasonics Ferroelectrectrics Frequency Control 57, 2138 (2010). Copyright© 2010, IEEE) [318].

2.3 The uniqueness of relaxor-PT single crystals

Relaxor-PT based ferroelectric single crystals offering high performance with ultra-high electromechanical coupling and piezoelectric coefficient far out-perform state-of-the-art piezoelectric PZTs, attracting extensive attention to these crystal systems in last 20 years. In addition, the crystals exhibit several unique properties inherently associated with the engineered domain configurations, which are not existent in polycrystalline ceramics. In this section, the uniqueness of relaxor-PT crystals, including crystallographic anisotropy, high intrinsic piezoelectric, high cryogenic properties and newly developed shear vibration modes, will be discussed.

2.3.1 Crystallographic Anisotropic Characteristics

Polycrystalline ceramics such as PZT are in ∞∞m symmetry with inversion center in their unpoled status, transfer to ∞m symmetry after poling, exhibiting piezoelectric activity. Contrary to ceramics, relaxor-PT single crystals are in macroscopic 4mm, mm2 and 3m symmetries when poled along their crystallographic [001], [011] and [111] directions respectively, leading to strong anisotropic characteristics in their functionalities. Prior to the discussions of anisotropic behavior exhibited in relaxor-PT single crystals, engineered domain configuration [139,143,145,151,176,180,181], which is a very important concept for ferroelectric crystals, will be introduced first. A domain engineered ferroelectric crystal is one which has been poled by the application of a sufficiently large field along one of the possible polar axes of the crystal other than the zero-field polar axis, creating a set of domains in which the polarization vectors are oriented so that their angles to the poling direction are minimized [331]. In R, O and T phases, different engineered domain configurations and single domain states with different macroscopic symmetries can be achieved by poling along specific crystallographic directions, as listed in Table III.

Table III.

The relationship between the engineered domain configurations and crystal phase/poling directions. The standard coordinate for [111] poled crystals is X:[11̄0]/Y:[112̄]/Z:[111], while they are X:[01̄1]/Y:[100]/Z:[011] and X:[100]/Y:[010]/Z:[001] for [011] and [111] poled crystals (after [176]).

|

Single domain crystals mean that the crystals are poled along the direction parallel to their respective spontaneous polarization directions, where almost all domains are aligned along poling directions, the electromechanical properties of crystals can be treated as that of single domain. It should be noted that ideal single domain state is hard to be achieved in perovskite crystals, since it possesses very high levels of electrical and mechanical energies, and is not stable.

Fig. 4 shows a Relaxor-PT single crystal boule grown by the Bridgman method, which can be separated into three different composition phases, including R phase, O/M (monoclinic) phase and T phase along the growth direction, due to the large segregation coefficient of Ti4+ [153,187,207]. It was observed that the crystals exhibit 4mm macroscopic symmetry when the crystals were poled along [001] directions, with engineered domain configurations 4R and 4O in R and O phase crystals respectively, while single domain state 1T is presented in T phase crystals. Meanwhile, the crystals are in mm2 and 3m symmetries when poled along [011] and [111] directions, corresponding to engineered domain configurations 2R, 2T and 3O, 3T respectively, with single domain states 1O and 1R obtained in O and R crystals owing to their spontaneous polarization directions being along [011] and [111]. In the notations, the numbers ‘1’, ‘2’ and ‘4’ mean that there are one, two and four degenerate polarization directions in the poled crystals. The letters ‘T’, ‘R’ and ‘O’ indicate the crystals are in tetragonal, rhombohedral and orthorhombic ferroelectric phases, respectively.

Fig. 4.

As grown relaxor-PT crystal (middle), domain observation under polarized light for unpoled crystal wafer with R, O and T phases (left), where there is no clear domain wall observed in R crystals, while cloudy and clear domain walls being observed in O and T crystals, respectively. The relevant macroscopic symmetries when poled along different crystallographic directions and the desirable properties corresponding to different domain configurations are listed in the figure (right).

2.3.1.1 Anisotropy in rhombohedral relaxor-PT crystals

About fifty percent of the as-grown PMN-PT crystal boule is in rhombohedral phase, being in 4R, 2R and 1R domain configurations when poled along its crystallographic directions [001], [011] and [111] respectively. The high longitudinal piezoelectric coefficients d33 are obtained in [001] and [011] poled rhombohedral crystals [305], while thickness shear piezoelectric coefficients d15 exhibit superior values in [011] and [111] poled crystals [172,293,297,306].

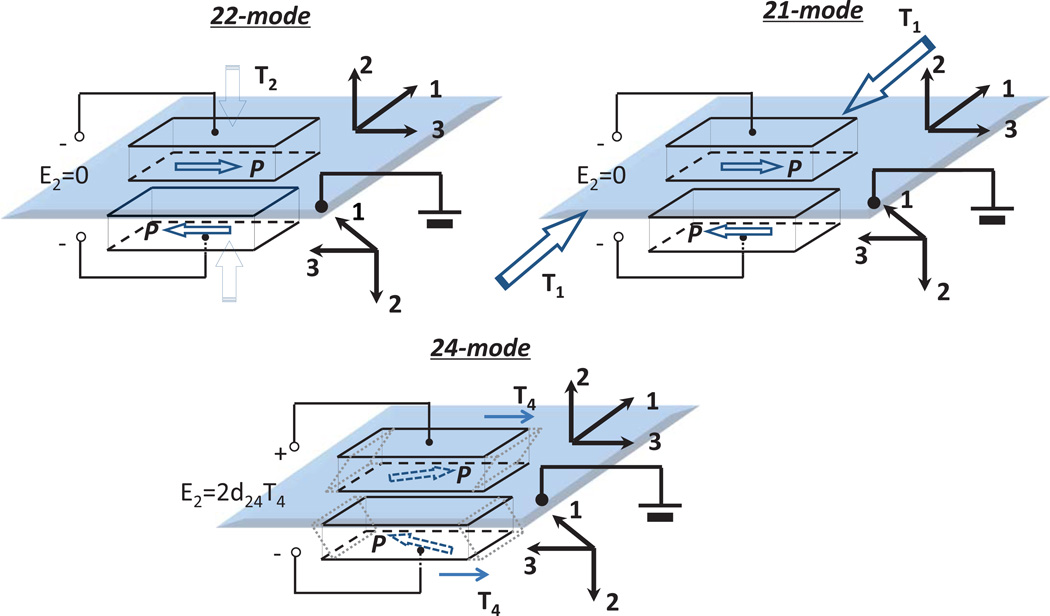

Of particular significance is that the 2R domain configuration, which exists in the [011] poled rhombohedral crystals, exhibits high longitudinal, thickness shear and transverse piezoelectric activities simultaneously [282,300,302]. In 2R domain configuration, there are two independent thickness shear piezoelectric coefficients, d15 and d24, and two transverse piezoelectric coefficients, d31 and d32, where d15 »d24 and –d32 »d31, due to the fact that the contribution of the polarization rotation to the shear deformation S4 and extensional deformation S1 in 71° domains will negate one another [302]. Furthermore, a new face shear (contour shear) vibration mode with high piezoelectric coefficient d36 can also be achieved in rotated 2R crystals (ZXt45° cut) [332–333], leading to a unique feature of relaxor-PT crystals, which will be discussed in 2.3.1.4. In addition to the piezoelectric properties, mechanical quality factor Qm also shows anisotropic behavior, where the longitudinal Q33 for 4R domain configuration is on the order of 100, while the value is above 1000 in single domain state 1R due to the absence of domain wall. Of interest is that both high piezoelectric coefficient d33 and mechanical Q33 were observed in 2R engineered domain configuration due to the fact that only 71° domains remained after polarization [334–335], which will benefit the high power applications at resonance frequency.

In order to clearly demonstrate the anisotropic behavior in R crystals, the principal properties and anisotropic ratios are given in Table IV. It can be observed that single domain rhombohedral PMN-PT crystals possess high anisotropic ratio with ultra-high transverse dielectric, shear elastic and shear piezoelectric constants, contributing to the high longitudinal piezoelectric coefficient in engineered domain configurations. For comparison, the PMN-PT ceramic counterpart was found to possess much lower anisotropic characteristics.

Table IV.

Property anisotropic ratio for rhombohedral PMN-PT crystals with different domain configurations, and compare to PMN-PT ceramic counterpart, dij: pC/N, the values in this table are small due to the fact that the listed compositions are in deep rhombohedral phase. [128,233]

| PMN-PT Crystal | Piezoelectric property | Mechanical Qm | Anisotropic ratio | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Poling direction |

Domain Configuration |

d33/ d33* |

d31 /d31* |

d32/d32* | d15/d15* | d24/d24* | Q33 | Q15 | ε11/ε33 | s55/s33 | d15/d33 |

| [001] | 4R | 1180 | −570 | −570 | 122 | 122 | 140 | 30 | / | / | / |

| [011] | 2R | 860 | 450 | −1150 | 2160 | 160 | 750 | 40 | / | / | / |

| [111] | 1R | 97 | −43 | −43 | 2380 | 2380 | 2000 | 25 | 8.4 | 21.9 | 24.5 |

| PMN-PT ceramic | 800 | −395 | −395 | 1090 | 1090 | 75 | 15 | 0.81 | 2.7 | 1.36 | |

2.3.1.2 Anisotropy in tetragonal and orthorhombic relaxor-PT crystals

In contrast to rhombohedral crystals with 1R single domain state, the [001] poled tetragonal crystals show higher coercive field and higher TC, along with the absence of ferroelectric phase transition TRT/TOT above room temperature and high mechanical Q33, making them potentially useful for high power transducer applications [293,336]. Table V lists the principal properties and the anisotropic ratios for PIN-PMN-PT with single domain states 1O and 1T. Similar to 1R single domain state, large property anisotropic ratios were observed, with very high transverse dielectric and shear piezoelectric constants, leading to high longitudinal piezoelectric properties in engineered domain configurations.

Table V.

Property anisotropic ratio for orthorhombic and tetragonal PIN-PMN-PT crystals with single domain states, dij: pC/N. [293, 306].

| PIN-PMN-PT Crystal | Piezoelectric property | Mechanical Q | Anisotropic ratio | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Poling direction |

Domain Configuration |

d33 | d31 | d32 | d15 | d24 | Qm33 | Qm15 | ε11/ε33 | s55/s33 | d15/d33 |

| [011] | 1O | 350 | 153 | −346 | 4550 | 4100 | 1500 | 30 | 5.38 | 18.8 | 13.0 |

| [001] | 1T | 530 | −200 | −200 | 2350 | 2350 | 1800 | 30 | 13.8 | 1.34 | 4.43 |

For tetragonal crystals with engineered domain configurations 2T and 3T, on the other hand, high domain wall density can be achieved when the special poling procedure is employed, so-called domain size/wall engineering, leading to high dielectric constant of >10,000 and electromechanical coupling of 0.75~0.78, essential for the electrical impedance matching in high frequency 2D array medical imaging transducers [337–338].

Of particular importance in orthorhombic 1O crystals is the piezoelectric coefficient d24, with high temperature stability and values of ~2000 pC/N due to the vertical R-O phase boundary in the phase diagram [339–340]. Correspondingly, in engineered domain configuration 3O, the longitudinal coefficient d33 is on the order of >800 pC/N with minimal temperature variation (<6 %) due to the fact that the value of d33 in 3O configuration is mainly contributed by the large d24 value in 1O single domain state, taking advantage of the anisotropic piezoelectric properties [139]. This will be discussed in detail in section 3.3.3.1.

2.3.1.3 Orientation dependence of piezoelectric coefficients

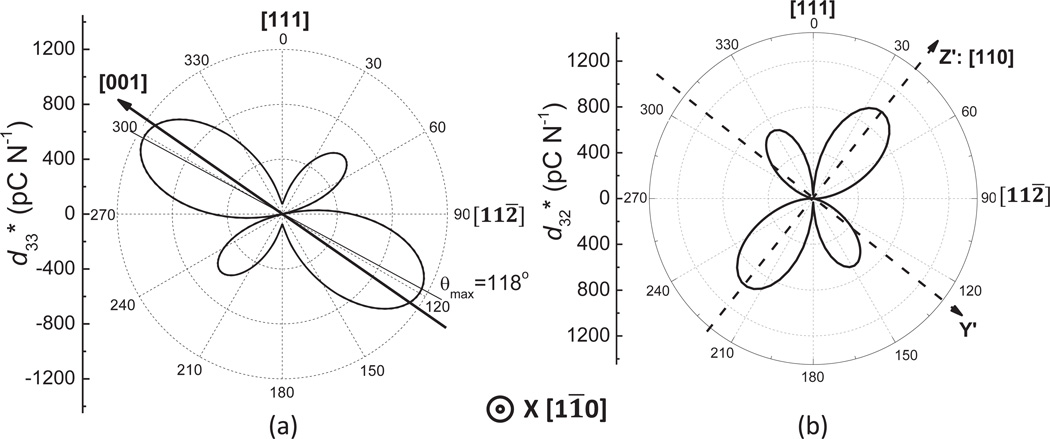

In relaxor-PT crystals, the maximum longitudinal and transverse piezoelectric coefficients do not exist in single domain crystals based on their standard coordinates. As shown in Fig. 5, the highest longitudinal coefficient d33* was observed in the coordinate system with the Z’ axis rotated to the [001] direction, while the highest coefficient d32* was achieved in the coordinate system with Z’, Y’ and X’ axes along [110], [001̄] and [11̄0] directions, respectively. Therefore, in practical applications, rhombohedral relaxor-PT crystals are poled along [001] (4R domain configuration) and [011] directions (2R domain configuration) to obtain optimum piezoelectric coefficient d33* and d32*, respectively. This phenomenon is due to the high level of shear coefficient d15 in the single domain state (d15>>d33) [178,180,206,292,297,327,328]. It should be noted that the data used in Fig. 5 is from the rhombohedral PIN-PMN-PT crystals with a composition away from the MPB [292]. The anisotropic properties of relaxor-PT crystals with MPB compositions are similar to Fig. 5, but with much higher d33* and d32* values being on the order of ~2000 pC/N [290,341].

Fig. 5.

Orientation dependence of the piezoelectric coefficient (left) d33* and (right) d32* for single domain PIN-PMN-PT crystals. For plotting the figures, the X axis is fixed along [11̄0] direction, the Z and Y axis are rotated around X axis. It can be seen from figure (a) and (b) that the maximum piezoelectric coefficients of rhombohedral PIN-PMM-PT crystal are not presented in the standard coordinate system of 3m point group (X, Y, and Z axis are along [11̄0], [11̄2] and [111] direction, respectively). For d33*, the maximum value is observed when the Z’ axis is rotated to [001] direction. For d32*, the maximum value is presented in the coordinate system with Z’ and Y’ axis being along [110] and [001̄] directions, respectively.

2.3.1.4 Origin of the piezoelectric anisotropy

In order to further understand the piezoelectric anisotropy of relaxor-PT ferroelectric crystals [176,179,228,233,342], the dielectric permittivity, spontaneous polarization and electrostrictive coefficients, which contribute to the piezoelectricity of ferroelectric materials, were investigated as a function of orientations. Fig. 6 shows the orientation dependence of the piezoelectric coefficient, dielectric constant (relative dielectric permittivity), polarization and electrostrictive coefficient for tetragonal relaxor-PT crystals. The maximum d33* is achieved along the direction of 48° rotation from the [001] axis [293]. The anisotropy of piezoelectric activity is determined by the orientation dependences of polarization, dielectric constant and electrostrictive coefficient. The maximum polarization is along the polar direction of the single domain crystals and decreases to zero when the direction is perpendicular to the polar axis, as given in Fig. 6(a). For the dielectric constant, on the contrary, the anisotropic characteristic depends on various factors, e.g., temperature, composition, phase transition, etc. For ferroelectric materials, the maximum dielectric constant ε33* is generally along the directions perpendicular to the polar axis when the material is on the proximity of the ferroelectric-ferroelectric phase transition, as revealed in Fig. 6(b). Meanwhile, the maximum ε33* will be along the polar direction if the ferroelectric material approaches the ferroelectric-paraelectric phase transition [178,179,343]. The anisotropy of electrostrictive coefficient Q33* is dominated by the crystal structure. For all perovskite-type materials, the orientation dependence of electrostrictive coefficient Q33* is similar, as given in Fig. 6(c), where the maximum and minimum values are along the <100> and <111> directions, respectively [344,345]. It can be seen that the polarization and electrostrictive coefficient possess stable anisotropic properties in perovskite-ferroelectrics, while the anisotropy of the dielectric constant is very sensitive to the temperature, composition, stress, etc. Thus, differences in piezoelectric anisotropy among different perovskite-ferroelectrics are dominated by the dielectric anisotropy.

Fig. 6.

The orientation dependence of the spontaneous polarization P3*, dielectric permittivity ε33*, electrostrictive coefficient Q33* and piezoelectric coefficient d33* for tetragonal PIN-PMN-PT crystals. Based on the equation d∝PεQ, the orientation dependence of d33* is determined by orientation dependence of spontaneous polarization P3*, dielectric permittivity ε33 and electrostrictive coefficient Q33*. To obtain the coefficient value (Q33*, d33*, or ε33*) of one direction, a line along this direction should be plotted from the origin to surface of 3D figure. An intersection point can be found between the line and surface of 3D figure. The distance between this intersection point and the origin indicates the coefficient value along the direction of this line. (input data from ref. [293])

2.3.2 Intrinsic and Extrinsic Contributions

Another uniqueness of relaxor-PT crystals is that the intrinsic contribution (lattice deformation), which dominates their high longitudinal piezoelectric coefficients, are on the order of ~90–95 % due to the high stability of the engineered domain configurations [133]. As a comparison, the intrinsic contribution of their polycrystalline counterparts was reported to be only 50–75 %, revealing the domain wall extrinsic contribution in ceramics is >25 % [343]. The extrinsic contribution in the ferroelectric materials can be quantitatively evaluated by Rayleigh analysis and high electric field measurements [346–356]. Calculated from the Rayleigh analysis, the ratios of extrinsic contribution to the total piezoelectric response for PMN-PT crystals as a function of composition are given in Fig. 7(a), where the error bars were calculated from three samples for each composition [354]. The error bars were relatively high for compositions near the phase boundaries, demonstrating that the extrinsic contribution for the compositions on the proximity of the MPBs was not stable when compared to that of the compositions far away from the MPB, where the extrinsic contribution ratios for PMN-0.31PT and PMN-0.35PT crystals were found to be on the order of 10 %. The ratio was 7 % for tetragonal PMN-0.37PT crystal, while it was less than 5 % for all other compositions [354]. A similar trend was also observed in PIN-PMN-PT crystals, as given in Fig. 7(b) [305], where the extrinsic contribution is generally less than 5 % for rhombohedral crystals, while the values go up to 12 % for compositions in proximity of the MPB. This phenomenon was also observed in other domain engineered configurations, such as [011] poled PIN-PMN-PT:Mn crystals with 2R domain configuration, where the extrinsic contribution is only on the order of < 2 % [357–358]. This is due to the fact that Mn dopants in the crystals behave as acceptors, inducing oxygen vacancies and forming defect dipoles, clamping the extrinsic domain wall motion [141,334].

Fig. 7.

The level of extrinsic contribution to piezoelectric response at 1kV/cm for (a) (1-x)PMN-xPT crystals with various compositions [Reprinted with permission from F. Li et al., Journal of Applied Physics 108, 034106 (2010). Copyright © 2010, the American Institute of Physics.]; (b) PIN-PMN-PT crystals, where the increase of TC represents the PT content increasing in PIN-PMN-PT crystals. Reprinted with permission from F. Li et al., Journal of Applied Physics 109, 014108 (2011). Copyright © 2011, the American Institute of Physics.

2.3.3 Piezoelectric properties at cryogenic temperatures

As discussed above, the intrinsic contribution dominates the piezoelectricity in relaxor-PT crystals, making them suitable for cryogenic temperature applications [359–368] since the extrinsic domain wall motion is greatly affected by temperature [174,179,197,340,369–372]. For example, the piezoelectric coefficients were reported to be on the order of > 900 pC/N for PIN-PMN-PT crystals at 120 K, much higher than the room temperature piezoelectric activity of polycrystalline ceramics (~750 pC/N for PZT-5H) [363].

The temperature-dependent intrinsic and extrinsic contributions of PIN-PMN-PT crystals and PMN-PT ceramics are summarized in Fig. 8(a) [363]. As expected, both intrinsic and extrinsic contributions decreased with decreasing temperature for all compositions. Based on thermodynamic analysis, the shear piezoelectric response (d15) of the rhombohedral/monoclinic single domain state will decrease as temperature moves away from the polymorphic phase transition temperature (PPT) [158,178]. The reduction of shear piezoelectric response corresponds to an effective “hardening” of the polarization rotation process [180], leading to the decrease of intrinsic piezoelectricity. For PMN-PT ceramics, not only intrinsic piezoelectricity, but also the extrinsic contribution α (α is an indicative parameter for extrinsic piezoelectric contribution) drastically decreased from 280 to 40 cm/kV as the temperature decreased from 300 to 120 K, attributed to the clamping of domain wall motion [369–370]. Fig. 8(b) shows the relative variation in piezoelectric response as a function of temperature for PIN-PMN-PT crystals and compared to PMN-PT ceramics. At 120 K, the piezoelectric response was found to decrease by 27 % and 40 % for PIN-PMN-PT crystals with R and MPB compositions, respectively. The PMN-PT ceramic exhibited the largest decrease: ~75 % of the original value.

Fig. 8.

(a) The temperature dependent Rayleigh parameters, (b) Variation of d33 as a function of temperature for [001] poled PIN-PMN-PT crystals and PMN-PT ceramics. (data from ref. [363])

Fig. 9(a) depicts the variation of the d33 coefficient and value of K33Pr versus temperature for PMN-28PT crystals. The two curves exhibit similar variation, in good agreement with the fact that, for piezoelectric material, d33 is proportional to Q33Prεr (εr: relative dielectric permittivity), where Q33 and Pr are electrostrictive coefficient and remnant polarization, respectively. Assuming that Q33Pr is almost temperature independent in the cryogenic temperature range, the d33 curve should present a similar trend with the dielectric behavior. By extrapolation of the curves, the d33 value at 0 K was estimated to be 150 pC/N, similar to that of PZT ceramics. Fig. 9(b) depicts the variation of the electromechanical coupling k33 and elastic constant . To discuss the cryogenic electromechanical properties, Fig. 9 can be divided into three temperature regions: region I (T=10–100 K), region II (T=100–250 K) and region III (T=250–300 K) [372]. In region II, the piezoelectric, dielectric, elastic and electromechanical coupling coefficients were found to exhibit high stability with respect to temperature when compared with regions I and III. In regions I and III, the piezoelectric, dielectric and elastic coefficients were found to drastically decrease with decreasing temperature, while the coupling factor only showed decreasing tendency in region I. In region III, the crystal deviates from the R-T phase transition point, leading to the decrease of d33, ε33 and , while in region I, the degradation of d33, ε33 and cannot be explained by the same mechanism. Based on the thermodynamic analysis, the tangent of d33-T curves will decrease as the crystal deviates from the phase transition point, indicating that the variation of d33 will decrease with the crystal deviating from the phase transition point. However, the tangent of d33-T curves in region I was found to be much higher than that in region III, so the large divergence of d33 in region I cannot be explained based on the thermodynamic theory of traditional ferroelectrics. In addition, no abnormal reduction of piezoelectric coefficients at cryogenic temperature was observed in PZT ceramics [369]. It was proposed that the decreased d33 was related to the influence of temperature on the compositional fluctuation-induced random electric fields, polarization and point defects, which give rise to combinatory pinning effects on the macro domain walls motions [372]. The drastic decrease of d33, ε33 and of relaxor-PT crystals in temperature region I was thought to be associated with the nature of the relaxor: disordered B-site cations and polar nanoregions. With decreasing temperature, the size of polar nanoregions will increase and PNRs will transform to ferroelectric state, thus the thermal fluctuations induced by polar nanoregions (in relaxor state) may die away, leading to a decrease of piezoelectric response [368]. It is worth noting that although the piezoelectric response decreases in both regions I and III, the electromechanical coupling factor only decrease in region I, demonstrating that the phonons associated with the nature of relaxor may dominate the level of electromechanical coupling factor.

Fig. 9.

Temperature dependence of d33 and K33Pr; (b) Temperature dependence of k33 and for PMN-0.28PT crystals. (Reprinted with permission from F. Martin et al., Journal of Applied Physics 111, 104108 (2012). Copyright © 2012, the American Institute of Physics. [365]

2.3.4 The development of new shear vibration modes

2.3.4.1 Thickness shear vibration modes

Table VI summarizes the thickness shear properties for various crystals with different domain configurations and compares them to commercial PZT5 and PZT8 polycrystalline ceramics [374,375]. It is evident that high shear piezoelectric coefficients and elastic compliances can be easily achieved in crystals with single domain states, such as “1R” and “1O” [162,278,292], which will benefit the broad bandwidth transducer applications (high electromechanical coupling) at low operational frequency range (large elastic compliance). In addition, the high shear elastic compliance (low frequency constant) of single crystals results in small parts for the same frequency compared to polycrystalline ceramics, allowing miniaturization of the transducers or sensors [374].

Table VI.

Comparison of the shear vibration modes in various domain configurations, and compared to PZT5 and PZT8 ceramics [340,375]. [hkl]/(hkl)=poling direction/electrode face.

| Poling/ electrode |

Engineered domain |

Crystal |

Ec (kV/cm) |

Eint (kV/cm) |

KT |

d15 (pC/N) |

k15 |

N15 (Hz.m) |

Qm15 |

|---|---|---|---|---|---|---|---|---|---|

| 111/11̄0 | 1R | Pure PIN | 5.0 | 0 | 6000 | 3030 | 0.93 | 470 | 30 |

| 110/1̄10 | 2R | Pure PIN | 5.0 | 0 | 6500 | 2800 | 0.92 | 570 | 20 |

| PIN-Mn | 7.3 | 1.2 | 4600 | 2200 | 0.91 | 520 | 30 | ||

| 110/1̄10 | 1O | Pure PIN | 5.5 | 0 | 5600 | 3400 | 0.95 | 380 | 20 |

| PIN-Mn | 9.0 | 0.6 | 5800 | 3500 | 0.95 | 360 | 25 | ||

| 001/100 | 1T | Pure PIN | 12.0 | 0 | 15000 | 2200 | 0.85 | 850 | 20 |

| PIN-Mn | 11.5 | 1.5 | 8000 | 1200 | 0.77 | 950 | 30 | ||

| PZT5 (Ceramic) | 17 | 0 | 1730 | 584 | 0.685 | 830 | 15 | ||

| PZT8 (Ceramic) | 15 | 8 | 1290 | 330 | 0.55 | 1010 | 150 | ||

However, issues exist for the usage of shear vibration modes, including temperature instability of dielectric and piezoelectric properties, low allowable drive field stability (due to the working direction, i.e. applied electric field, is normal to the poling direction in the thickness shear mode) [375], low mechanical quality factor (which is very important for high power application) and cross-talk effect, etc. [141]. Although large shear properties have been observed in crystals with single domain state, the single domain crystal is subject to cracking from the large electric field induced strain/stress during the poling process [330]. Fig. 10 shows the strain versus electric field curves for rhombohedral PMN-PT crystals along [001] and [111] directions [42], where very high negative strain was observed in [111] poled crystals (this value is about −0.7 % for [001] poled tetragonal crystals [330]). This is due to the fact that the non-180° ferroelastic domains are not equivalent to [111] direction, as shown in Fig. 10(b), thus leading to a very large negative strain during ferroelastic domain switching. The electric field induced strain will lead to cracks during poling, which can be avoided in multi domain state, as shown in Fig. 10(c). The [111] spontaneous strains are equivalent to [001] direction, thus the very low negative strain in crystals with 4R engineered domain configuration is associated with the piezoelectric coefficient other than ferroelastic domain switching. Of particular interest is that large shear d15 and low frequent constant, being on the order of ~2800 pC/N and 570 Hz·m respectively, were also obtained in engineered domain configuration “2R”, with the advantage of no-cracking during the poling process [302], as listed in Table VI.

Fig. 10.

(a) Strain versus electric field curves for PMN-0.29PT crystals measured along [001] and [111] directions at room temperature. (b) Schematic illustration of the domain switching for rhombohedral crystal. (b) [111] oriented crystal. At the coercive, which is antiparallel to the [111] direction, [111] domain could transform to the [1̄11], [11̄1], [1̄1̄1], [111̄], [1̄11̄], and [11̄1] domains, (c) [001] oriented crystal. At the coercive, which is antiparallel to the [001] direction, [111], [1̄11], [11̄1] and [1̄1̄1] domains transform to the [111̄], [1̄11̄], [11̄1̄], and [1̄1̄1̄] domains). Reprinted with permission from L. Jin et al. Journal of the American Ceramics Society 97, 1 (2014) Copyright © 2014, The American Ceramic Society. [42]

2.3.4.2 Face (contour) shear vibration mode

Though thickness shear exhibits ultrahigh piezoelectric coefficients, coupling factors and elastic compliances, the low field stability inherently associated with the 90° polarization rotation angle (the working direction is normal to the poling direction) will restrict their applications at high drive field condition (will be discussed in section 3.3.3.2) [141,374]. Recently, it was reported that [011] poled rhombohedral crystals possessed high face shear properties when the sample was rotated along poling direction of about 45°. That is, Zt±45° cut samples, which incorporate two extensional lateral modes [332–335], exhibit promising properties different from their thickness shear counterparts. Ultralow frequency transducers were projected based on the face shear (or d36) mode in PMN-PT crystals due to their ultralow frequency constant and high piezoelectric coefficients [376,377]. In addition, due to the uniqueness of the face shear vibration in combination with high coupling and high mechanical Q36, face shear crystals have been studied for tactile sensing and ultrasound motor applications [378–382]. In contrast to conventional thickness shear d15, the face shear vibration mode can be repolarized; i.e., the poling electrode is the same as the active electrode [141,340,374]. The ac driving field level and mechanical quality factor Q36 of the face shear mode were reported to be significantly higher compared to thickness shear vibration modes, owing to the fact that the applied electric field in face shear vibration is along polarization direction [141,374].

The principal properties related to the face shear vibration mode for relaxor-PT crystals are reported in Table VII and compared to conventional thickness shear properties [300,333,383]. The dielectric constant for the studied crystals was found to be in the range from 4500 to 5200, while the dielectric loss was in the range of 0.1–0.2%. The elastic compliance and piezoelectric coefficient d36 were found to be on the order of 160–200 pm2/N and 2000–2500 pC/N respectively, with electromechanical coupling factor k36 being 0.80–0.83. It should be noted that the property variations observed in all shear vibration modes are closely related to the crystal composition, following the general trend of relaxor-PT crystals [318]. The value of ~500 Hz∙m for the ultra-low face shear frequency constant N36 was obtained, which is similar to the values of thickness shear modes, ~350–600 Hz·m [333]. Fig. 11 shows the comparison of the piezoelectric deformation of thickness shear and face shear vibrations. For the case of face shear mode, the frequency constant refers to the large dimension (length) of the samples, allowing for design of ultralow frequency and broad bandwidth transducers with minimized dimension [374,383]. In addition, it is important to note that the mechanical quality factor Q36 obtained for the face shear crystals are on the order of 150–180 (higher Q36 >350 was observed for 3rd generation relaxor-PT crystals), significantly higher than those of the thickness shear modes, ~20–30. The low mechanical Q15 is believed to relate to the ease of polarization rotation in corresponding thickness shear cuts, while the enhanced Q36 in face shear is due to the polarization rotation angle of 35.5° in [011] poled rhombohedral crystals [141,357]. Meanwhile, the field stability ratio of the face shear vibration mode, on the order of 100% of its respective coercive field, greatly expands the usage range for high power application, which is due to the fact that the working direction is along the poling direction in face shear vibration [335]. Above the coercive field, the crystals will be depolarized due to the micro cracks induced by the large anisotropy of the transverse strains [298].

Table VII.

The comparison of thickness shear and face shear in [011] poled rhombohedral PIN-PMN-PT and PIN-PMN-PT:Mn crystals with “2R” engineered domain configuration. [300,333,383] Nr: Resonance frequency constant, where N15 is not necessarily related to the , while [333]

| Crystal | Vibration mode | KT | tanδ |

deff (pC/N) |

keff |

sE (pm2/N) |

Nr (Hz·m) |

Qm | Drive stability ratio |

|---|---|---|---|---|---|---|---|---|---|

| PIN | Face shear | 4500 | 0.004 | 2000 | 0.81 | 170 | 550 | 180 | 100% |

| PIN:Mn | Face shear | 3790 | 0.002 | 1800 | 0.80 | 170 | 550 | 350 | 100% |

| PIN | Thickness shear | 6500 | 0.015 | 2800 | 0.92 | 161 | 570 | 20 | 40% |

Fig. 11.

(a) Schematic figure of thickness shear piezoelectric deformation, (b) Schematic figure of face shear piezoelectric deformation. P is the poling direction. It should be noted that the resonance frequency is controlled by the thickness of the piezoelectric element in thickness shear deformation, while it is controlled by the edge length of the element in face shear deformation. Reprinted with permission S.J. Zhang et al. IEEE Transactions on Ultrasonics Ferroelectrectrics Frequency Control 60, 1572 (2013) Copyright © 2013, IEEE. [374]

Other uniqueness of the relaxor-PT single crystals include high coupling and low mechanical loss, leading to high figure of merit (FOM) of k2Qm for high power transducer applications [318], and simultaneous high piezoelectric and low strain hysteresis for high precision actuator applications [139]. These will be discussed in the following section III.

III. Figure of merits (FOM) of piezoelectric materials for various electroacoustic applications

A figure of merit is a number employed to characterize the performance or efficiency/effectiveness of a device or material, albeit the definition of FOM is difficult. It is extremely valuable to the device design process because it compels the designer to think critically about what parameters are the most meaningful to a successful design outcome.

3.1 Medical Diagnostic Ultrasound

3.1.1 Piezoelectric materials for ultrasound imaging (diagnostic)

There are many different medical imaging modalities, such as radiography, magnetic resonance imaging (MRI), computed tomography (CT), elastography, photoacoustic imaging, and ultrasound, to name a few. Among these, medical ultrasound uses high frequency broadband transducers, with advantages of real time monitoring of moving structures and no ionizing radiation, etc. [384]. Ultrasonic transducers convert electrical energy into mechanical form when generating an acoustic wave (transmitter) and convert mechanical energy into an electrical signal when detecting the echo (receiver) [2]. In general, broadband transducers should be used for medical ultrasonic imaging. The broad bandwidth response corresponds to a short pulse length, resulting in a better axial resolution which is dominated by the high electromechanical coupling factor, acoustic impedance and electrical impedance matching [385]. Fig. 12 gives a schematic view of the obstetric ultrasound imaging for a developing fetus, with a three-port network ultrasonic imaging transducer and the operational mechanism. The transducer consists of two mechanical components including the matching and backing layers, and one electrical component, the piezoelectric element, which is the heart of the transducer. It can be seen from the figure that both transmission efficiency and reception sensitivity parameters (TP and RP, respectively) are closely associated with the thickness electromechanical coupling kt, clamped dielectric constant and elastic stiffness of the piezoelectric element [385]. Meanwhile, the bandwidth (e.g. −6dB fractional bandwidth) is also related to the coupling factor, where broad bandwidth can be achieved in materials possessing high coupling factor. Since the acoustic impedance of the piezoelectric materials is about ~30–37 MRayl, much higher than those of water or human tissues (~1.5–5 MRayl), a substantial part of the emitted acoustic energy will be lost, leading to a poor resolution and sensitivity. Thus single or multi matching layer(s) with lower acoustic impedance(s) are required to further improve the front acoustic matching of the transducer. The backing material is added to the rear of the transducer in order to damp the acoustic backwave and to reduce the pulse duration [385]. In addition, the electrical impedance of the transducer needs to be matched to the resistance of the coaxial cable and electrical circuit, which is generally 50 Ohm. The electrical impedance is inversely associated with the capacitance of the transducer, thus determined by the clamped dielectric constant and dimension of the piezoelectric element [24].

Fig. 12.

Schematic view of the medical imaging system and the operational mechanism. The equations are from references [3,385]. k: coupling; : clamped dielectric, : elastic stiffness, ρ: density, v: sound velocity, R: electrical impedance, C: capacitance, Z: acoustic impedance.

Based on the above discussion, the figure of merit (FOM) of the piezoelectric element for imaging transducers is the electromechanical coupling, which accounts for the high resolution, high power efficiency and broad bandwidth [385]. The thickness coupling factor for piezoelectric materials, including the relaxor-PT single crystals and PZT ceramics, is generally on the order of 0.5–0.6 [70–71]. In order to take advantage of the ultrahigh longitudinal coupling of relaxor-PT crystals, 1–3 and 2-2 crystal/epoxy composites have been extensively studied and commercialized in various transducer applications [11–20, 386–387]. Fig. 13 gives the geometries of monolithic samples, 2-2 and 1–3 composites, with their corresponding coupling factors, which are thickness mode, sliver mode and longitudinal mode, respectively. The coupling factors of longitudinal k33 and sliver k33’ modes are found to be >0.9 and ~0.8 respectively, both much higher than that of thickness mode kt ~0.6, greatly benefitting transducer applications [374,388]. Furthermore, the composites are found to possess the advantage of lower acoustic impedance associated with the passive epoxy phase, about 12–20 MRayl, much smaller than those of single crystals (~30–37 MRayl), thus improving acoustic matching of transducers to the human body [2,385]. Table VIII lists the principal properties of relaxor-PT single crystals as compared to the state-of-the-art PZT-5H polycrystalline ceramics. The relaxor-PT crystals are found to exhibit higher electromechanical coupling factors, higher piezoelectric coefficients and higher elastic compliance when compared to PZT5H ceramics, which will benefit greater bandwidth, higher sensitivity and reduced device dimension for ultrasound transducer applications. Meanwhile, the lower dielectric loss will suppress internal heat generation, thus reducing the operating temperature rise. It should be noted that the clamped dielectric constants of relaxor-PT crystals are lower than those of ceramics, alberit their high free dielectric constants, this will impair the electrical impedance matching for array transducer applications. In addition, the lower coercive field of crystals will deteriorate the drive stability.

Fig. 13.

The comparison of various vibration modes of relaxor-PT crystals and their corresponding electromechanical coupling values.

Table VIII.

Comparison of 1st generation crystals and PZT5H ceramics for medical imaging transducers. T: °C; EC: kV/cm; d: pC/N; s: pm2/N.

| TC | TRT | EC | tanδ | k33 | d33 | kt | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PMNT | 135 | 96 | 2.2 | 5400 | 0.004 | 910 | 0.91 | 1540 | 0.82 | 0.60 | 60.0 | ||||

| PZT5H | 193 | / | 7.0 | 3400 | 0.02 | 1470 | 0.75 | 593 | 0.67 | 0.505 | 20.7 |

3.1.2 High frequency ultrasonic imaging and the challenges of piezoelectric crystals

The medical community has increasingly looked to other ultrasonic capabilities for the potential insights that can be given to biomedical systems through improving current diagnostic ultrasonic frequency ranges, e.g. the 2–10 MHz range, and in some cases up to about 20 MHz [2]. High-frequency imaging beyond 30 MHz was reviewed by Lockwood et al. [389], including the ophthalmic ultrasound at 60 MHz, intravascular and intra-articular imaging up to 60MHz, skin imaging at 100 MHz, and some early works at 40–60 MHz investigating mouse embryonic development. Other studies used the acoustic microscope as a tool to determine tissue properties, such as those in fresh tissue at 100 MHz, which were measured by Scherba et al. [390]. Fig. 14 lists transducer operational frequencies and the corresponding imaging human tissues, with the frequency ranges from 2.5 MHz to 100 MHz [2]. Generally, higher operational frequency gives rise to higher resolution (smaller wavelength), but with less penetration. For a piezoelectric transducer, the frequency is closely related to the elastic constant (sound velocity or frequency constant) and the thickness of the piezoelectric materials, where a smaller thickness usually corresponds to a higher frequency for the same material [391–392]. Lithium niobate single crystals have been studied for high frequency transducer applications by employing 36° rotated Y-cut sample with coupling factor kt of 0.48, clamped dielectric constant of ~40 and high elastic stiffness (high sound velocity of 7340 m/s), which makes the high frequency piezoelectric element easier [87–88, 393]. However, the coupling factor is far inferior to that of relaxor-PT crystals.

Fig. 14.

Medical imaging transducer operational frequency and the corresponding imaging human tissues. The equations are from [391]. C: capacitance; A: sample area; t: sample thickness; fa: antiresonance frequency; cD: elastic stiffness; v: sound velocity; λ: wavelength; f: frequency.

As given in Fig. 14, it should be noted that the capacitance of the piezoelectric element is inversely proportional to its thickness; in order to match the electrical impedance, it is desirable to use low dielectric constant monolithic crystals for high frequency applications. It was reported that the tetragonal monolithic PMN-PT single crystals, with coupling factors kt of 0.6 and clamped dielectric constant of ~200–300, showed promising properties for single element transducers with operational frequency range of >40 MHz [394–395]. As discussed in section 3.1.1, the FOM for medical imaging is the coupling factor. Thus, in order to further increase the electromechanical coupling factor, 1–3 crystal/epoxy composites have been actively studied, taking advantage of the high longitudinal coupling k33 of relaxor-PT crystals (as shown in Fig. 13). Traditionally, the dice-and-fill method is employed to develop low- frequency (<10 MHz) 1–3 composite transducers. However, due to the physical limitation of blade and brittleness of the active materials, the traditional method cannot be used to develop high- frequency (>30 MHz) composite transducers [90–93]. With the increasing demand of high-frequency ultrasonic applications, etch-and-fill technique and facile method have been developed recently [396–397]. Using the ICP (Inductively Coupled Plasma) -RIE (Reactive Ion Etching) dry etching technique, PMN-PT single crystals can be etched to a periodic pillar pattern with a sidewall angle of >85° [398–404]. However, recent experimental data for PMNT crystal/epoxy 1–3 composites (piezoelectric composite- micromachined ultrasound transducer PC-MUT) operating at high frequencies >20 MHz exhibited a relatively large decrease in electromechanical coupling, with values being less than 0.75, showing a strong scaling effect and leading to the question of the origin of property degradation at high frequencies [141,374,405–406].

Fig. 15 shows the electromechanical properties of relaxor-PT crystal/epoxy 1–3 composites as a function of sample thickness. For comparison, the longitudinal coupling factors (k33) of the monolithic relaxor-PT crystals were calculated by the equation and plotted as a function of sample thickness. Note that the corresponding resonance frequencies on the top X-axis of Fig. 15 were calculated from the frequency constants by assuming ~1000 Hz·m for both monolithic and 1–3 composites samples. As shown in Fig. 15, the monolithic PMN-PT crystals were found to exhibit a decrease trend in coupling (k33) with decreasing the thickness of crystal, due to the degradation of the free dielectric constant [405–406]. The 20 MHz PIN-PMN-PT/epoxy 1–3 composites were found to maintain higher electromechanical coupling factors on the order of 0.80, compared to 20 MHz PMN-PT composites with coupling of only 0.74. It should be noted that all 1–3 composites have the same volume fraction and ratio of post height to width. The observed scaling effect is reported to be associated with the ferroelectric domain size, where the large domains will be clamped by the surface boundary when the physical size of samples becomes of the same order as the domain size, inhibiting the domain wall motion and restricting the polarization rotation. This can be confirmed by the domain observations, where the domain size of PMN-PT crystals was found to be on the order of 10–20 µm, while it is only about 1 µm for PIN-PMN-PT crystals, showing the advantage of the ternary system [405–406]. Similar phenomena were also reported for BT and KT single crystals, where fine domain size accounted for the enhanced piezoelectric properties [407–409]. Furthermore, in polycrystalline PMN-PT ceramics, the fine grain ceramics were found to possess improved properties [121] and scaling effect when compared to their coarse grain size counterparts, due to their smaller domain size (domain size is proportional to ) [410–412]. Admittedly, the surface damage layer induced by the dicing process and the stiffness of the epoxy filler also contribute to the coupling degradation; these can be alleviated by RIE dry etching and employing soft epoxy.

Fig. 15.

Electromechanical coupling factor for monolithic and crystal/epoxy 1–3 composites as a function of sample thickness and corresponding ultrasound frequency. Reprinted with permission from H. J. Lee et al., Journal of Applied Physics 107, 124107 (2010). Copyright © 2010, the American Institute of Physics. [405]

In order to confirm the role of domain size on the piezoelectric properties in ultrathin samples, a field-cool poling approach was applied to PMN-PT crystals with 100 µm thicknesses, where significantly smaller domain sizes on the order of ~5 µm were achieved [198]. Consequently, the piezoelectric coefficient was greatly improved from 1300 pm/V (coarse domain sample ~20 µm) to 2200 pm/V, as shown in Fig. 16(a), due to the fact that the domain size of field-cool poled crystals is much smaller than the thickness of the samples, leading to less impact on the polarization rotation and domain wall motion from the boundary clamping [198]. The stability of the engineered domain wall was further investigated by domain observation and strain behavior measurement as a function of pulse-field and number of cycles on the thin PMN-PT crystals. With increasing the pulse electric field magnitude and cycling number, the piezoelectric coefficients were found to decrease from 2000 pm/V to 1300 pm/V, as given in Fig. 16 (b), corresponding to the enlarged domain size from 5 µm to 30 µm with applied field from 3 kV/cm to 6 kV/cm (~3EC) after 1.5×106 pulses, demonstrating the inferior field stability of the finer domains [198].

Fig. 16.

Left: Unipolar strain as a function of electric field for room temperature poled (a) and field cooling poled (b) [001] oriented PMN-PT crystals (with thickness of 100 µm); Right: the unipolar strain behavior after pulse tests (a) 3 kV/cm, 7 × 105 cycles, (b) 3 kV/cm, 7 × 107 cycles, (c) 6 kV/cm, 7 × 105 cycles, (d) 6 kV/cm, 1.5 × 106 cycles. Reprinted with permission from D. B. Lin et al. Scripta Materialia 64, 1149 (2011), Copyright © 2011, Acta Materialia Inc. [198]

3.2 Therapeutic and Surgical Ultrasound

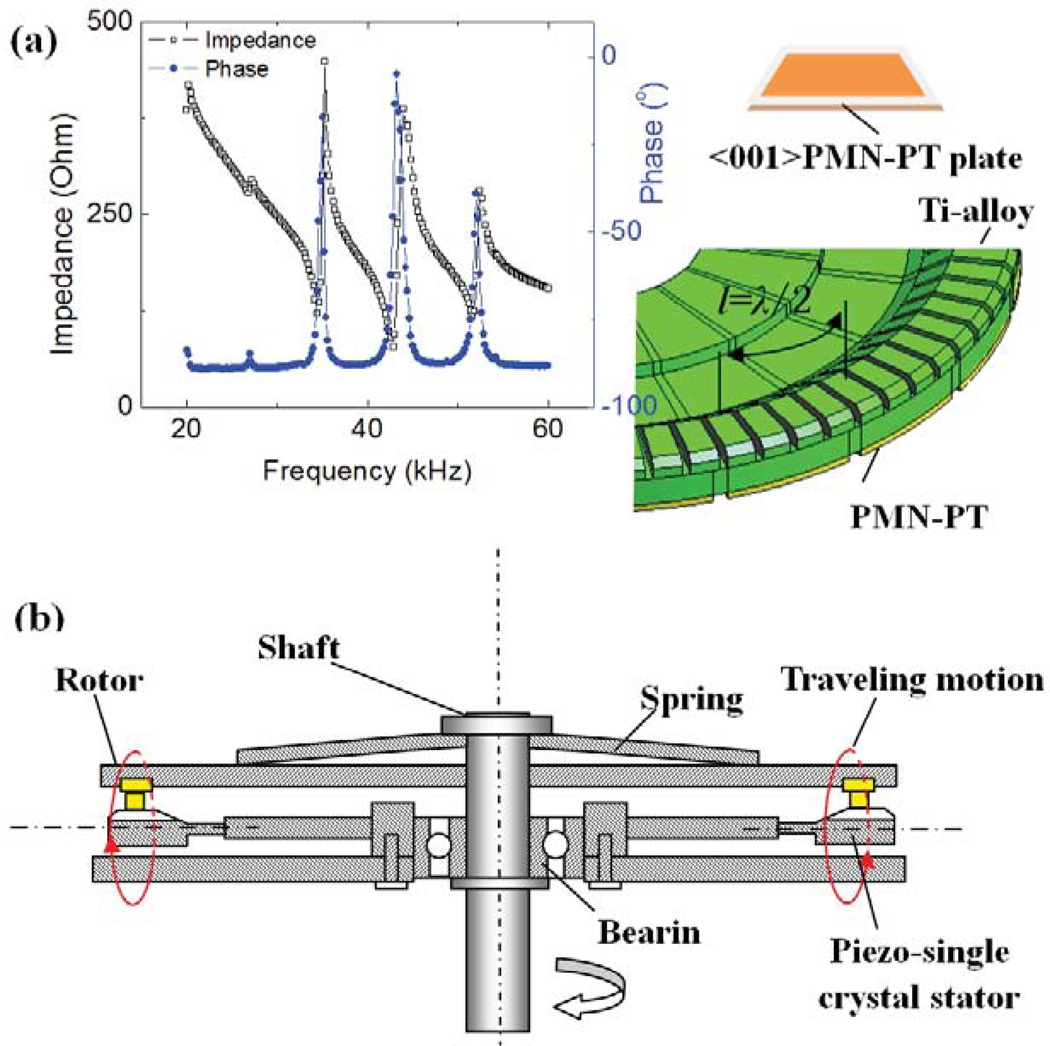

3.2.1 Piezoelectric materials for therapeutic ultrasound and surgical applications