Abstract

Controlled combustion experiments were conducted to investigate the influence of fuel charge size, moisture, air ventilation and burning rate on the emission factors (EFs) of carbonaceous particulate matter, parent polycyclic aromatic hydrocarbons (pPAHs) and their derivatives from residential wood combustion in a typical brick cooking stove. Measured EFs were found to be independent of fuel charge size, but increased with increasing fuel moisture. Pollution emissions from a normal burning under an adequate air supply condition were the lowest for most pollutants, while more pollutants were emitted when the oxygen deficient atmosphere was formed in stove chamber during fast burning. The impact of these 4 factors on particulate matter size distribution was also studied. Modified combustion efficiency and the four investigated factors explained 68, 72, and 64% of total variations in EFs of PM, organic carbon, and oxygenated PAHs, respectively, but only 36, 38 and 42% of the total variations in EFs of elemental carbon, pPAHs and nitro-PAHs, respectively.

Keywords: residential wood combustion, influencing factor, carbonaceous particulate matter, polycyclic aromatic hydrocarbons, emission factor

Introduction

Residential wood combustion (RWC) is of wide concern since it generates a large number of pollutants, like CO, PM, organic carbon (OC), elemental carbon (EC), parent polycyclic aromatic hydrocarbons (pPAHs), nitrated PAHs (nPAHs), and oxygenated PAHs (oPAHs) (Cooper, 1980; Li et al., 2007, 2009; Miljevic et al., 2010; Rau et al., 1989; Shen et al., 2012a; Wang et al., 2011; Zhang et al., 2000). It was estimated that in U.S. in 2002, RWC produced about 7% of total national primary PM2.5 (PM with diameter less than 2.5 μm), higher than that from on-road mobile source (Wang et al., 2011). In most developing countries, the contribution of RWC is believed to be much higher because of the larger consumption and relatively lower combustion efficiency. It was estimated that RWC produced about 9.5% and 21%-34% of total black carbon and pPAHs in China (Wang et al., 2012; Xu et al., 2006; Zhang et al., 2008a).

However, it is generally accepted that there are usually high uncertainties and bias in current emission inventories due to lack of sufficient and reliable data, especially for emission factors (EFs). EFs reported in the literature often vary dramatically due to the difference in fuel properties (e.g. moisture and volatile matter content), stove designs (e.g. chamber volume and with chimney or not), fire managements (e.g. air supply amount and fuel-air mixing condition) and even experimental methods (e.g. laboratory chamber, simulated stove/open burning, and field measurement) (Chen et al., 2012; Jenkins et al., 1996; Jetter et al., 2009, 2012; Johnson et al.,2010; McDonald et al., 2000; Simoneit, 2002; Zhang et al., 2007).

It's believed that field measurement can provide realistic EFs for the development of accurate emission inventory. However, it usually requires high labor intensity and cost to cover a wide range of different fuel/stove combination (Chen et al., 2012; Johansson et al., 2008, 2010; Roden et al., 2009). Therefore, in most of current studies, laboratory combustion in chamber or real stoves is often adopted to get EFs for a variety of sources. And laboratory studies can also provide the opportunity to investigate the influence of combustion parameters (Chen et al., 2012; Chomance et al., 2009; Grandesso et al., 2010; Jetter et al., 2012; Korenaga et al., 2001; Lu et al., 2009; Xie et al., 2007). For example, Lu et al., (2009) tested the influence of combustion temperature, fuel moisture and oxygen amount on the emissions of PAHs from crop straw burning in a laboratory chamber. Grandesso et al., (2010) quantified emissions of PCDD/Fs from simulated open biomass burning of under different fuel charge sizes, fuel moisture and chlorine contents. So far controlled burning experiments are mainly conducted in laboratory chambers, rather than in real cooking stoves.

The main objective of this study is to investigate the influence of factors including fuel charge size, moisture, air ventilation, and burning rate, on the pollution emissions from RWC. EFs of PM, OC, EC, pPAHs, nPAHs, and oPAHs (EFPM, EFOC, EFEC, EFpPAHs, EFnPAHs, and EFoPAHs, resepectively) were measured. Their impacts on the size distribution of PM were also discussed.

1. Method

1.1 Fuel, stove and controlled combustions

The stove used in this study was a typical brick cooking stove (Shen et al., 2010, 2012a). In the present controlled combustion study, Poplar (Populus tomentosa Carr.) wood logs of different fuel charge size and moisture were burned under different burning rate, and Paulownia (P.tomentosa Steud.) wood logs were burned to investigate the impact of air ventilation conditions. Since lack of enough poplar wood logs, we changed to use Paulownia logs, which showed similar fuel properties to poplar wood in the ultimate and proximate analysis. (Shen et al., 2012a).

Three levels of fuel moisture, charge size, burning rate, and air ventilation were tested in this study. The burning conditions are listed in Table 1. One additional blower was used to enhance the air ventilation (19.0 m3/h), and a restricted air supply condition was achieved by reducing the air inlet area (Shen et al., 2013a). Wood fuels with different moisture were prepared by sealing the pre-weight wood logs and waters in a vinyl bags (Korenaga et al., 2001; Lu et al., 2009). The bags were stored for about three months to supply enough time for the absorption of water. Wood logs were air-dried to evaporate the surface water. The exact wood moisture contents were measured by weight loss after drying at 105°C in an oven for about 16 h (ASTM). For two groups of wood logs with different moisture, measured contents were 14±3.6 and 27±4.1%, close to designed 15 and 30%, respectively. Triplicate combustion experiments were done. A total number of 30 (=10×3) combustion experiments were conducted.

Table 1.

Burning conditions of fuel moisture, charge size, air ventilation and burning rates tested in this study. 10 different burning conditions were conducted, and each was done in triplicate.

| No. | Fuel Type | Moisture % | Charge kg | Ventilation m3/h | Burning rate kg/min |

|---|---|---|---|---|---|

| 1 Normal burning | Poplar | 5.3±0.10 | 1.0 | 9.0 | 0.055±0.006 |

| 2 Lower charge size | Poplar | 5.3±0.10 | 0.5 | 9.0 | 0.058±0.007 |

| 3 Higher charge size | Poplar | 5.3±0.10 | 2.0 | 9.0 | 0.059±0.002 |

| 4 Faster burning | Poplar | 5.3±0.10 | 1.0 | 9.0 | 0.091±0.000 |

| 5 Slower burning | Poplar | 5.3±0.10 | 1.0 | 9.0 | 0.032±0.002 |

| 6 Median moisture | Poplar | 14±3.6 | 1.0 | 9.0 | 0.053±0.005 |

| 7 High moisture | Poplar | 27±4.1 | 1.0 | 9.0 | 0.041±0.001 |

| 8 Restricted air | Paulownia | 8.7±1.2 | 1.0 | 4.0 | 0.047±0.005 |

| 9 Normal air supply | Paulownia | 8.7±1.2 | 1.0 | 9.0 | 0.076±0.009 |

| 10 Enhanced air | Paulownia | 8.7±1.2 | 1.0 | 19.0 | 0.069±0.002 |

1.2 Sample collecting and online measurement

The sampling and online measurements were same as previous studies (Shen et al., 2012a, 2012c). The exhaust from the combustion stove entered into a mixing chamber (4.5 m3). A fan was used to cool down the smoke temperature and mix the exhaust well. All sampling works were conducted in the mixing chamber.

Since emission factors in this study were calculated based on the carbon mass balance method (see Method 1.4), the site of sampling probe was flexible (Chen et al., 2012; Zhang et al., 2000). Quartz fiber filters (QFFs, 22 mm in diameter, Pall QAT-UP) were used to collect PM samples, and the analysis of EC, OC and particle-bound organics. Gaseous organics were collected on polyurethane foam plugs (PUFs, 0.024 g/cm3). The flow rate was about 1.5 L/min (XQC-15E, Tianyue, China). The pump was calibrated using a primary flow calibrator (Bios. Defender 510. USA). QFFs and PUFs were packed using clean aluminum foils seperately, and transported back for laboratory analysis.

In addition to the total PM, size segregated PM samples were also collected using a nine stage cascade impactor (FA-3, Kangjie, China) with the flow of 28.3 L/min, and cutoff aerodynamic diameters (Da) were <0.4, 0.4-0.7, 0.7-1.1, 1.1-2.1, 2.1-3.3, 3.3-4.7, 4.7-5.8, 5.8-9.0, and 9.0-10.0 μm, respectively. The sampling covered the whole burning cycle. It was recognized that emission characterization differed during the burning process, like flaming and smoldering phases. In the present study, we mainly focused on the difference in total emissions.

An online analyzer equipped with non-dispersive infrared sensors was used (GXH-3051, Technical Institute, China) to measure CO and CO2. The instrument was calibrated using a span gas and zero checked before each burning experiment. The results were recorded automatically.

1.3 Laboratory analysis and quality control

Laboratory analysis followed the procedure in the previous study (Shen et al., 2012a). Briefly, PM gravimetric measurement was done using a high precision digital balance (0.01 mg). EC and OC concentrations were analyzed using a Sunset EC/OC analyzer (Sunset Lab. USA). The temperature protocol was: increased 600, 840, 550°C in a pure helium atmosphere for OC detection, and then at 550, 650, 870 °C in an oxygen/helium atmosphere for EC detection. Light transmittance correction was used to correct pyrolyzed OC.

For the analysis of organics, PUFs were Soxhlet extracted using 150 mL dichloromethane (8 h), and QFF samples were extracted using a microwave accelerated system (CEM Mars Xpress, USA). The extraction temperature was increased to 110 °C in 10 min and held for another 10 min. The extracts were concentrated to 1 mL, cleaned up using a silica/alumina gel column (70 mL hexane/dichloromethane mixture), and then finally concentrated to 1 mL, spiked with internal standards. pPAHs were analyzed using a GC-MS system in electron ionization mode, and nPAHs and oPAHs were analyzed in negative chemical ionization mode (methane as reagent gas). The oven temperature program for pPAH analysis was 50 °C held for 1 min, increased to 150 °C at a rate of 10 °C/min, to 240 °C at a rate of 3 °C/min, and then to 280 °C held for another 20 min. The oven temperature in nPAH and oPAH analysis was increased from 60 °C to 150 °C at a rate of 15 °C/min, to 300°C at a rate of 5° C/min, and then finally held for 15 min. Target compounds were identified based on the retention time and qualified ions of standards (J&W Chemical, USA) in selected ion mode.

A total of 28 pPAHs, including naphthalene (NAP), acenaphthylene (ACY), acenaphthene (ACE), fluorene (FLO), phenanthrene (PHE), anthracene (ANT), fluoranthene (FLA), pyrene (PYR), retene (RET), benzo[c]phenanthrene (BcP), cyclopenta[c,d]pyrene(CPP), benzo(a)anthracene (BaA), chrysene (CHR), benzo(b)fluoranthene (BbF), benzo(k)fluoranthene (BkF), benzo(a)pyrene (BaP), benzo(e)pyrene (BeP), perylene (PER),dibenz(a,h)anthracene (DahA), indeno(l,2,3-cd)pyrene (IcdP), benzo(g,h,i)perylene (BghiP), dibenzo[a,c]pyrene (DacP), dibenzo[a,l]pyrene (DalP), dibenzo[a,e]flluoranthene (DaeF), Coronene(COR), dibenzo[a,e]pyrene (DaeP), dibenzo[a,i]pyrene (DaiP), dibenzo[a,h]pyrene (DahP), 4 oPAHs including 9-fluorenone (9FO), anthracene-9,10-dione (ATQ), benzanthrone (BZO), benzo[a]anthracene-7,12-dione (BaAQ), and 6 nPAHs including 1-nitro-naphthalene (1N-NAP), 2-nitro-naphthalene (2N-NAP), 9-nitro-anthracene (9N-ANT), 9-nitro-phenanthrene (9N-PHE), 3-nitro-phenanthrene (3N-PHE), 3-nitro-fluoranthene (3N-FLA), were measured. Instrument detection limit, method detection limit and recoveries of spiked standards were determined (Shen et al., 2012a). Deuterated standards, (NAP-d8, ACE-d10, ANT-d10, CHR-d12, and PER-d12 for pPAHs, and 1N-ANT-d9, 1N-PYR -d9 for PAH derivatives) were used as internal standards in the quantification. All filters were pre-baked at 450 °C for 6 hours and equilibrated in a desiccator for 24 hours prior to weight. PUF was pre-extracted by acetone, dichloromethane and hexane in sequence. All glassware were ultrasonically cleaned and baked at 500°C for at least 10 h prior to use. All solvents were re-distillated. Procedure blanks were also measured and subtracted from the results.

1.4 Data analysis

Emission factors were calculated based on the carbon mass balance method. It followed the assumption that the carbon burned from the fuel combustion was emitted into the atmosphere as the forms of CO2, CO, total gaseous hydrocarbons, and carbonaceous carbon (EC+OC) in PM (Dhammapala et al., 2006; Shen et al., 2010; Zhang et al., 2000). In the present study, we did not measure total gaseous hydrocarbon, which may lead to a small error (Dhammapala et al., 2006; Roden et al., 2006), since most of the carbon was emitted in the forms of CO2 and CO. Stastistica (v5.5, StatSoft) was used in data statistical analysis, and a significance level of 0.05 was adopted.

2. Results and Discussion

2.1 The influence of fuel charge size

EFPM, EFOC, EFEC, EF28pPAHs, EF4oPAHs and EF6nPAHs from the wood burning with different fuel charge size are listed in Table 2 (No. 1, 2, and 3). For all targets, the change in fuel charge size did not affect emission factors significantly (p > 0.05). The overall means and standard deviations (n=9) of EFPM, EFOC, and EFEC were (2.1±0.63), (0.59±0.22), and (1.1±0.42) g/kg, respectively. Size distributions of PM under different burning charge size were similar. The finest fraction (PM0.4, PM with diameter less than 0.4 μm in this study) was the most abundant. On average, PM with diameter less than 2.1 μm (PM2.1, the closest to PM2.5 in the present study) contributed about 77%±8.2% of the total. The ratio of OC to EC (OC/EC) and total carbon fraction in PM were also insignificantly different.

Table 2.

Measured EFs (dry basis) of OC, EC, PM and total parent PAHs, nitro-PAHs, oxygenated PAHs from residential wood combustion under different conditions. Data shown are means and standard derivations from triplicate measurements.

| No. | MCE % | PM g/kg | OC g/kg | EC g/kg | 28 pPAHs mg/kg | 4 oPAHs mg/kg | 6 nPAHs μg/kg |

|---|---|---|---|---|---|---|---|

| 1 | 94.7±0.9 | 1.8±0.25 | 0.67±0.32 | 0.88±0.49 | 13±4.8 | 0.52±0.43 | 5.2±2.1 |

| 2 | 95.1±0.4 | 2.8±0.62 | 0.68±0.04 | 1.4±0.49 | 17±7.2 | 0.92±0.34 | 7.3±2.2 |

| 3 | 95.4±0.7 | 1.8±0.36 | 0.42±0.14 | 0.93±0.12 | 13±6.4 | 0.96±0.36 | 4.9±0.9 |

| 4 | 92.9±0.6 | 2.0±0.38 | 0.37±0.10 | 1.4±0.32 | 67±2 | 3.0±0.66 | 13±2.4 |

| 5 | 92.4±1.5 | 2.8±0.67 | 1.2±0.35 | 0.87±0.23 | 23±4 | 1.8±0.52 | 9.8±2.4 |

| 6 | 95.5±0.4 | 3.4±0.21 | 1.7±0.35 | 0.77±0.40 | 13±10 | 1.6±0.01 | 8.4±3.2 |

| 7 | 94.2±0.1 | 4.1±0.65 | 4.3±2.9 | 0.87±0.56 | 22±6.0 | 2.6±0.49 | 11±1.2 |

| 8 | 90.6±0.5 | 8.3±1.2 | 3.2±0.12 | 0.14±0.05 | 30±9.2 | 7.8±3.6 | 13±6.1 |

| 9 | 94.9±0.3 | 1.9±0.21 | 0.39±0.12 | 0.94±0.51 | 7.2±2.1 | 0.64±0.29 | 3.8±0.34 |

| 10 | 90.5±0.5 | 7.2±1.1 | 2.9±1.9 | 0.47±0.31 | 27±12 | 3.0±1.1 | 11±2.7 |

EFs of PAHs and their derivatives under different charge sizes were also not statistically different, and the overall means and standard deviations (n=9) of EF28pPAHs, EF4oPAHs and EF6nPAHs were (14±5.8), (0.80±0.39), and (5.8±1.9×10-3) mg/kg, respectively. The composition profiles and ratios of isomer PAHs were independent of the fuel charge size. NAP, PHE, FLA and PYR were the dominated pPAHs. pPAHs of 2-3 rings (from NAP to FLA) contributed about 77% of the total. 1N-NAP (35%) and 2N-NAP (34%) were the dominant nPAHs, and among the 4 oPAHs detected, 9FO was the most abundant (67%) with EF mean and standard deviation of 0.52±0.26 mg/kg (n=9).

It was reported that emissions of PM and PCDD/Fs from simulated open burning of forest biomass were independent of the fuel charge size, and also no significant differences found in the PCDD/Fs isomer patterns and homologue distributions (Grandesso et al., 2011). Our previous study also showed that emissions of PM and PAHs from indoor corn straw burning were insignificantly different among the combustion with varied fuel charge size (Shen et al., 2013a, 2013b).

2.2 The influence of fuel moisture

For the emissions for wood with different moistures (Table 2-No. 1, 6, and 7), measured EFs of PM, OC, pPAHs, nPAHs and oPAHs, except EC, increased with increasing wood moisture. The correlations were statistically significant with the correction coefficients of 0.910-0.992 (p < 0.05). It was thought that in the burning of high moisture fuel, extra energy was required to vaporize water, which usually resulted in reduced fuel combustion efficiency and increased emissions of incomplete combustion pollutants (Rogge et al., 1998; Simoneit, 2002). Insignificant difference in EFEC might be partly explained by the relatively low temperature formed in the high moisture fuel burning that was not favorable for the formation of EC. Also, relatively large variations in the EF measurements could be also another reason of the statistical insignificance.

Different dependence of emission on fuel moisture was reported in the literature (Chen et al., 2010; Grandesso et al., 2011; Hays et al., 2003; Korenaga et al., 2001; Lu et al., 2009). For example, Bignal et al., (2008) reported that EFs of CO and PAHs for high moisture fuel were about 2 and 5 times of those measured for low moisture wood logs. Chomanee et al., (2009) also observed an increase on PM and PAH emission with the increase of wood moisture. In our previous study on the EF measurements for different types of wood fuels (also varying in moisture), positive correlation between fuel moisture and EFs of incomplete pollutants was revealed (Shen et al., 2012a, 2012b). But, in a controlled burning experiment, Grandesso et al., (2011) did not find significant impact of wood moisture on the emissions of PCDD/Fs. In a field measurement, Roden et al., (2006) also reported a statistically insignificant dependence of PM emission on fuel moisture, probably due to the interacted influence of other factors. Complicated influence of fuel moisture was also reported for crop straw, beside wood. Lu et al., (2009) reported that EFPAHs decreased with the increase of crop straw moisture, mainly because of the decreased combustion temperature. Similar results were also revealed in an indoor crop straw burning study (Shen et al., 2010, 2011). In addition to affect temperature, an oxygen deficient atmosphere formed in the burning of low moisture fuel, which usually had a fast burning rate, could also result in the yield higher pollutant emissions. However, Korenaga et al., (2001) reported that emission of PAHs was the highest for dry crop straw, and the lowest value was found for crop straw with moisture of 15%, after which (moisture from 20%-30%), PAH emissions increased. From the studies in the literature so far, it is difficult to reach a conclusion of either positive or negative impacts of fuel moisture, also impossible to get an accurate boundary of moisture.

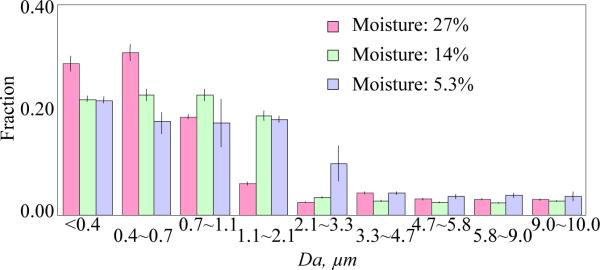

Though measured EFs varied significantly, the ratios of OC/EC, the composition profiles of pPAHs and their derivatives, and isomer ratios, were not statistically different. This might be partly because of the relatively large variations in the measurements. And, also the simultaneous change in these co-emitted pollutants was another possible reason. Figure 1 compares the size distributions of PM emitted from the wood combustions with different fuel moisture. Though the overall total mass percents of fine PM2.1 were not significantly different (p > 0.05), it seems there was an increase of fine PM with the increase of burned fuel moisture. The normalized mass fraction of PM with diameter between 0.4-1.1 μm was higher in the combustion of fuel with moisture at 14% than that in low moisture wood burning. The fraction of PM0.4 and PM0.4-0.7 (PM with diameter between 0.4-0.7 μm) were higher in the emissions from the burning of high moisture wood (27%), compared to those from the burnings of low and median moisture wood fuels. The statistical analysis was not significant, which might be due to a large variation in measurement and a small sample size. It was reported that fuel moisture could influence the PM size distribution through the change in combustion temperature, relative humidity of exhaust, limitation of the partitioning of organics, and other reasons (Hays et al., 2003; Purvis et al., 2000; Shen et al., 2010). More studies in future are needed to confirm that the results observed in this study.

Fig. 1.

Size distributions of PM emitted from residential firewood (polar) combustions of different moistures.

2.3 The influence of burning rate

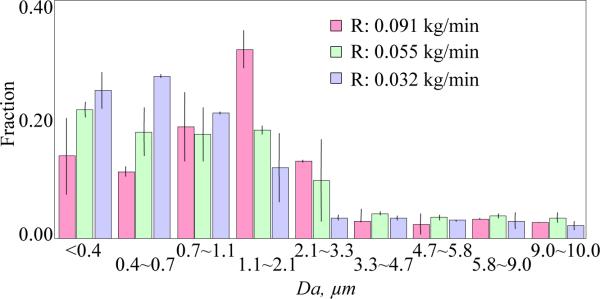

Measured EFPM, EFOC, and EFEC were not significantly different among the wood combustions at different burning rates (Table 2-No. 1, 4, and 5). Also, the calculated OC/EC ratio and carbon fraction in PM were not significantly different. Though measured EFPM was not found to be different among the three tested burning rate, the size distribution of PM was slightly different, as shown in Fig. 2. The mass percentage of fine particles decreased generally with the increase of burning rate. For example, the fractions of PM0.4 were (35±0.4), (25±3.6), and (10±6.5) % for wood burned at burning rates of 0.020, 0.045 and 0.119 kg/min, respectively. This might be partly explained by the distinct oxygen conditions formed in the combustion chamber. It was thought that relatively high oxygen could sustain the flaming condition that can yield high amounts of small particles (Hays et al., 2003). As a result, a fast burning rate may result in an oxygen deficient atmosphere in the stove chamber that was not favorable for the formation of fine particles.

Fig. 2.

Size distributions of PM emitted from residential firewood (polar) combustions at different burning rate.

The emissions of pPAHs, oPAHs and nPAHs were much higher (2-4 times) in the fast burning, but not significantly different between the low and median burning. It is believed that a fast burning could result in an oxygen deficient atmosphere leading to a higher emission. However, other factors, like the air-fuel mixing status, can affect the burning process as well, and also large variations in measurements could result in an insignificant result. The composition profiles were not obviously different among the combustions of different rates. Again, NAP, PHE, FLA and PYR, 1N-NAP and 2N-NAP, and 9FO were the dominated pPAHs, nPAHs and oPAHs, respectively.

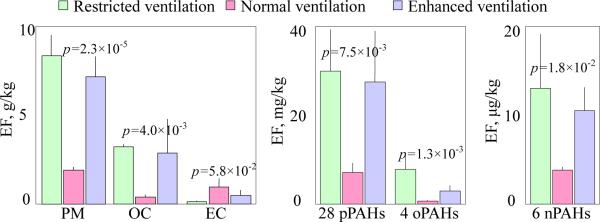

2.4 The influence of air ventilation

Figure 3 compared measured EFs under different air ventilation conditions (Table 2-No. 8, 9, and 10). It's obvious that under both restricted and enhanced air ventilation conditions, measured EFs were higher in comparison with those in normal air ventilation burning. One exception was EC, which was not significantly different among these three distinct ventilation conditions (p=0.058). The result based on a multiple comparison showed that EFEC from the burning in restricted air ventilation condition was significantly lower than that in a normal ventilation burning, but EFEC in the enhanced air ventilation burning was insignificant different from that in a normal ventilation burning. It was reported that high oxygen contents may sustain the intense flaming combustion (Hays et al., 2003) which is favorable for the formation of light absorption carbon (Li et al., 2009). However, due to limited data in the present study, it's difficult to well explain the phenomenon currently. Moreover, the statistically insignificance may be also attributed to the relative high variations in the measurements. More studies are needed in future. Again, the calculated ratios and profiles were similar in three air ventilation conditions.

Fig. 3.

Emission factors of PM, OC, EC, pPAHs, oPAHs and nPAHs measured under different air ventilation conditions.

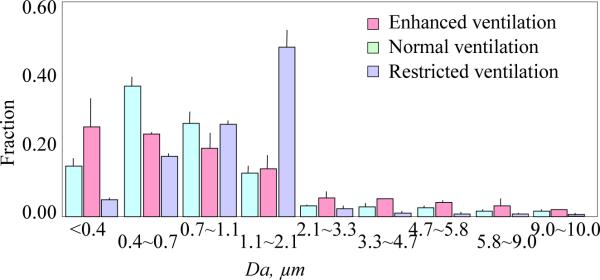

Size distributions of PM emitted for wood under normal, restricted and enhanced air ventilation conditions are shown and compared in Fig. 4. When air supply was restricted, the fractions of PM with diameter between 0.7-1.1 and 1.1-2.1μm were higher, meanwhile the mass percentages of PM0.4 and PM0.4-0.7 decreased. This may be explained by the favorable formation of finer particles in high oxygen amounts and intense flaming burning. Whereas, in comparison with emissions from the burning under normal air supply, the fractions of PM0.4-0.7 (37% vs 23%) and PM0.7-1.1(26% vs 19%) in PM emitted from enhanced air supply burning were higher, but the mass percent of PM0.4 was lower (14% vs 25%), which might be due to the decreased combustion temperature under increased air ventilation condition (Johansson et al., 2003; Shen et al., 2012c).

Fig. 4.

Size distributions of PM emitted from residential firewood (polar) combustions under varied air ventilation conditions

2.5 EF prediction

Modified combustion efficiency (MCE), defined as CO2/(CO2+CO), was calculated to characterize the combustion. In the present controlled burning experiments, MCE ranged from 90% to 95%. There was no significant correlation between MCE and influencing factors. A linear regression model was used to predict EFs using four tested factors (fuel charge size, burning rate, moisture, and air ventilation) and calculated MCE as independent variables. EFPM (g/kg), EFOC (g/kg), EFEC (g/kg), EF28pPAHs (mg/kg), EF4oPAHs (mg/kg) and EF6nPAHs (mg/kg) could be predicted based on the following equations:

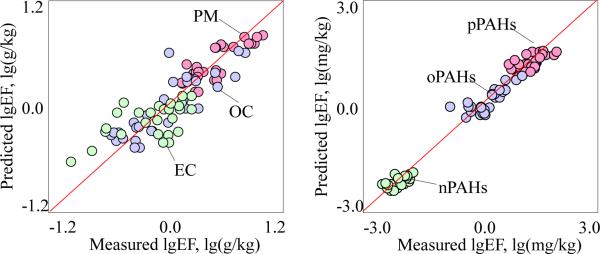

where C, MCE, R, M, and V are the fuel charge size (g), modified combustion efficiency (%), burning rate (kg/min), moisture (%) and air ventilation (m3/h), respectively. Figure 5 compares predicted and measured EFs. These five parameters explained the variations in EFs of PM, OC and oPAHs better (68, 72, and 64% of the total variations), but only explained 36, 38, and 42% of the total variations in EFEC, EF28pPAHs, and EF6nPAHs, respectively. The results from stepwise regression analysis showed that MCE was the most significant factor (p < 0.05) identified for all pollutants measured. The second significant factor was fuel moisture for PM, OC, oPAHs and nPAHs, but burning rate for EC and pPAHs. MCE alone could explain about 49, 21, 23, 29, 46, and 30% of the total variations in EFPM, EFOC, EFEC, EF28pPAHs, EF4oPAHs and EF6nPAHs, respectively.

Fig. 5.

Comparison of predicted EFs based on the five factors including fuel charge size, burning rate, air ventilation, moisture and MCE and measured EFs in this study. A 1:1 line is also shown.

It is recognized that there are lots of other factors that affected emissions of incomplete pollutants from RWC, and the influence of a specific factor may differ for different compounds.

3. Conclusion

In this study, the impacts of fuel charge size, moisture, air ventilation and burning rate on the emission factors of carbonaceous particulate matter and PAHs were investigated. Measured EFs were similar in the burning with distinct fuel charge size, and positively correlated with fuel moisture. Under different burning rates, EFPM, EFOC and EFEC were not statistically different, but EFs of PAHs and their derivatives were found to be much higher in the fast burning. In comparison with emissions in the normal air supply condition, both restricted and enhanced air ventilations resulted in increased emissions of most pollutants. About 68, 72, 36, 38, 64 and 42% of total variations in EFPM, EFOC, EFEC, EFpPAHs, EFoPAHs, and EFnPAHs can be explained by these four tested factors, together with calculated MCE. More future studies are needed to better understand the influence of combustion parameters on emission performance, and in regard of this, controlled combustion experiments are usually preferable.

Acknowledge

This work was supported by the National Natural Science Foundation of China (No. 41130754, 41001343, and 41001343), Beijing Municipal Government (No. YB20101000101), Ministry of Environmental Protection (No. 201209018) and NIEHS (No. P42 ES016465).

References

- American Society for Testing and Materials Standard method for moisture analysis of particulate wood fuels. 1998:E871–82. [Google Scholar]

- Bignal K, Langridge S, Zhou J. Release of polycyclic aromatic hydrocarbons, carbon monoxide and particulate matter form biomass combustion in a wood-fired boiler under varying boiler conditions. Atmospheric Environment. 2008;42(39):8863–-8871. [Google Scholar]

- Chen L, Verburg P, Shackeelford A, Zhu D, Susfalk R, Chow J. Moisture effects on carbon and nitrogen emission from burning of wild land biomass. Atmospheric Chemistry and Physics. 2010;10(14):6617–-6625. [Google Scholar]

- Chen Y, Roden C, Bond T. Characterizing biofuel combustion with patterns of real-time emission data (PaRTED). Environmental Science & Technology. 2012;46(11):6110–-6117. doi: 10.1021/es3003348. [DOI] [PubMed] [Google Scholar]

- Chomanee J, Tekasakul S, Tekasakul P, Furuuchi M, Otani Y. Effects of moisture content and burning period on concentration of smoke particles and particle-bound polycyclic aromatic hydrocarbons from rubber wood combustion. Aerosol and Air Quality Research. 2009;9:404–-411. [Google Scholar]

- Cooper J. Environmental impact of residential wood combustion emissions and its implications. Journal of the Air Pollution Control Association. 1980;30(8):855–-861. [Google Scholar]

- Dhammapala R, Claiborn C, Corkill J, Gullett B. Particulate emissions from wheat and Kentucky bluegrass stubble burning in eastern Washington and northern Idaho. Atmospheric Environment. 2006;40(6):1007–-1015. [Google Scholar]

- Grandesso E, Gullet B, Touati A, Tabor D. Effect of moisture, charge size, and chlorine concentration on PCDD/F emissions from simulated open burning of forest biomass. Environmental Science & Technology. 2011;45(9):3887–-3894. doi: 10.1021/es103686t. [DOI] [PubMed] [Google Scholar]

- Hays M, Smith N, Kinsey J, Dong Y, Kariher P. Polycyclic aromatic hydrocarbon size distributions in aerosols from appliances of residential wood combustion as determined by direct thermal desorption-GC/MS. Journal of Aerosol Science. 2003;34(8):1061–-1084. [Google Scholar]

- Jenkins B, Jones A, Turn S, Williams R. Emission factors for polycyclic aromatic hydrocarbons from biomass burning. Environmental Science & Technology. 1996;30(8):2462–-2469. [Google Scholar]

- Jetter J, Kariher P. Solid-fuel household cook stoves: characterization of performance and emissions. Biomass & Bioenergy. 2009;33(2):294–-305. [Google Scholar]

- Jetter J, Zhao Y, Smith K, Khan B, Yelverton T, DeCarlo P, et al. Pollutant emissions and energy efficiency under controlled conditions for household biomass cookstoves and implications for metrics useful in setting international test standards. Environmental Science & Technology. 2012;46(19):10827–-10834. doi: 10.1021/es301693f. [DOI] [PubMed] [Google Scholar]

- Johansson L, Tullin C, Leckner B, Sjovall P. Particle emissions from biomass combustion in small combustors. Biomass and Bioenergy. 2003;25(4):435–-446. [Google Scholar]

- Johnson M, Edwards R, Frenk C, Masera O. In field greenhouse gas emissions from cookstoves in rural Mexican households. Atmospheric Environment. 2008;42(6):1206–-1222. [Google Scholar]

- Johnson M, Edwards R, Berrueta V, Masera O. New approaches to performance testing of improved cookstoves. Environmental Science & Technology. 2010;44(1):368–-374. doi: 10.1021/es9013294. [DOI] [PubMed] [Google Scholar]

- Korenaga T, Liu X, Huang Z. The influence of moisture content on polycyclic aromatic hydrocarbons emission during rice straw burning. Chemosphere. 2001;3(1):117–-122. [Google Scholar]

- Li X, Duan L, Wang S, Duan J, Guo X, Yi H, et al. Emission characteristics of particulate matter from rural household biofuel combustion in China. Energy & Fuel. 2007;21(2):845–-851. [Google Scholar]

- Li X, Wang S, Duan L, Hao J, Nie Y. Carbonaceous aerosol emissions from household biofuel combustion in China. Environmental Science & Technology. 2009;43(15):6076–-6081. doi: 10.1021/es803330j. [DOI] [PubMed] [Google Scholar]

- Lu H, Zhu L, Zhu N. Polycyclic aromatic hydrocarbon emission from straw burning and the influence of combustion parameters. Atmospheric Environment. 2009;43(4):978–-983. [Google Scholar]

- McDonald J, Zielinska B, Fujita E, Sagebiel J, Chow J, Watson J. Fine particle and gaseous emission rates from residential wood combustion. Environmental Science & Technology. 2000;34(11):2080–-2091. [Google Scholar]

- Rau J. Composition and size distribution of residential wood smoke particles. Aerosol Science Technology. 1989;10(1):181–-192. [Google Scholar]

- Miljevic B, Heringa M, Keller A, Meyer N, Good J, Fairfull-smith K, et al. Oxidative potential of logwood and pellet burning particles assessed by a novel profluorescent nitroxide probe. Environmental Science & Technology. 2010;44(17):6601–-6607. doi: 10.1021/es100963y. [DOI] [PubMed] [Google Scholar]

- Purvis C, McCrillis R, Kariher P. Fine particulate matter (PM) and organic speciation of fireplace emissions. Environmental Science & Technology. 2000;34(9):1653–-1658. [Google Scholar]

- Roden C, Bond T, Conway S, Pinel A. Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves. Environmental Science & Technology. 2006;40(21):6750–-6757. doi: 10.1021/es052080i. [DOI] [PubMed] [Google Scholar]

- Rogge W, Hildemann L, Mazurek M, Cass G, Simoneit B. Sources of fine organic aerosol. 9. pine, oak, and synthetic log combustion in residential fireplaces. Environmental Sciences & Technology. 1998;32(1):13–-32. [Google Scholar]

- Shen G, Yang Y, Wang W, Tao S, Zhu C, Min Y, et al. Emission factors of particulate matter and elemental carbon for crop residues and coals burned in typical household stoves in China. Environmental Science & Technology. 2010;44(18):7157–7162. doi: 10.1021/es101313y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen G, Wang W, Yang Y, Ding J, Xue M, Min Y, et al. Emissions of PAHs from indoor crop residue burning in a typical rural stove: emission factors, size distribution, and gas-particle partitioning. Environmental Science & Technology. 2011;45(4):1206–-1212. doi: 10.1021/es102151w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen G, Tao S, Wei S, Zhang Y, Wang R, Wang B, et al. Emissions of parent, nitro, and oxygenated polycyclic aromatic hydrocarbons form residential wood combustion in rural China. Environmental Science & Technology. 2012a;46(15):8123–-8130. doi: 10.1021/es301146v. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen G, Wei S, Wei W, Zhang Y, Min Y, Wang B. Emission factors, size distributions, and emission inventories of carbonaceous particulate matter from residential wood combustion in rural China. Environmental Science & Technology. 2012b;46(7):4207–-4214. doi: 10.1021/es203957u. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen G, Tao S, Wei S, Zhang Y, Wang R, Wang B, et al. Reductions in emissions of carbonaceous particulate matter and polycyclic aromatic hydrocarbons from combustion of biomass pellets in comparison with raw fuel burning. Environmental Science & Technology. 2012c;46(11):6409–-6416. doi: 10.1021/es300369d. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen G, Xue M, Wei S, Chen Y, Wang B, Wang R, et al. The influence of fuel mass load, oxygen supply and burning rate on emission factor and size distribution of carbonaceous particulate matter from indoor corn straw burning. Journal of Environmental Science-China. 2013a doi: 10.1016/s1001-0742(12)60191-0. DOI: 10.1016/S1001-0742(12)60191-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shen G, Xue M, Wei S, Chen Y, Wang B, Wang R, et al. Emissions of parent, nitrated, and oxygenated polycyclic aromatic hydrocarbons from indoor corn straw burning in normal and controlled combustion conditions. Journal of Environmental Science-China. 2013b doi: 10.1016/s1001-0742(12)60249-6. DOI: 10.1016/S1001-0742(12)60249-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Simoneit B. Biomass burning- a review of organic tracers for smoke from incomplete combustion. Applied Geochemistry. 2002;17(3):129–-162. [Google Scholar]

- Wang Y, Hopke P, Rattigan O, Xia X, Chalupa D, Utell M. Characterization of residential wood combustion particles using the two-wavelength Aethalometer. Environmental Science & Technology. 2011;45(17):7387–-7393. doi: 10.1021/es2013984. [DOI] [PubMed] [Google Scholar]

- Wang R, Tao S, Wang W, Liu J, Shen H, Shen G, et al. Black carbon emissions in China from 1949 to 2050. Environmental Science & Technology. 2012;46(14):7593–-7603. doi: 10.1021/es3003684. [DOI] [PubMed] [Google Scholar]

- Xie J, Yang X, Zhang L, Ding T, Song W, Lin W. Emissions of SO2, NO and N2O in a circulating fluidized bed combustor during co-firing coal and biomass. Journal of Environmental Sciences-China. 2007;19(1):109–-116. doi: 10.1016/s1001-0742(07)60018-7. [DOI] [PubMed] [Google Scholar]

- Xu S, Liu W, Tao S. Emission of polycyclic aromatic hydrocarbons in China. Environmental Science & Technology. 2006;40(3):702–-708. doi: 10.1021/es0517062. [DOI] [PubMed] [Google Scholar]

- Zhang J, Smith K, Ma Y, Ye S, Jiang F, Qi W, et al. Greenhouse gases and other airborne pollutants from household stoves in China: a database for emission factors. Atmospheric Environment. 2000;34(26):4537–-4549. [Google Scholar]

- Zhang Y, Shao M, Zhang Y, Zeng L, He L, Zhu B, Wei Y, Zhu X. Source profiles of particulate organic matters emitted from cereal straw burnings. Journal of Environmental Sciences-China. 2007;19:167–-175. doi: 10.1016/s1001-0742(07)60027-8. [DOI] [PubMed] [Google Scholar]

- Zhang Y, Dou H, Chang B, Wei Z, Qiu W, Liu S, et al. Emission of polycyclic aromatic hydrocarbons from indoor straw burning and emission inventory updating in China. Annals of the New York Academy of Sciences. 2008;1140:218–-227. doi: 10.1196/annals.1454.006. [DOI] [PubMed] [Google Scholar]