Abstract

At the Product Quality Research Institute (PQRI) Workshop held last January 14–15, 2014, participants from academia, industry, and governmental agencies involved in the development and regulation of nanomedicines discussed the current state of characterization, formulation development, manufacturing, and nonclinical safety evaluation of nanomaterial-containing drug products for human use. The workshop discussions identified areas where additional understanding of material attributes, absorption, biodistribution, cellular and tissue uptake, and disposition of nanosized particles would continue to inform their safe use in drug products. Analytical techniques and methods used for in vitro characterization and stability testing of formulations containing nanomaterials were discussed, along with their advantages and limitations. Areas where additional regulatory guidance and material characterization standards would help in the development and approval of nanomedicines were explored. Representatives from the US Food and Drug Administration (USFDA), Health Canada, and European Medicines Agency (EMA) presented information about the diversity of nanomaterials in approved and newly developed drug products. USFDA, Health Canada, and EMA regulators discussed the applicability of current regulatory policies in presentations and open discussion. Information contained in several of the recent EMA reflection papers was discussed in detail, along with their scope and intent to enhance scientific understanding about disposition, efficacy, and safety of nanomaterials introduced in vivo and regulatory requirements for testing and market authorization. Opportunities for interaction with regulatory agencies during the lifecycle of nanomedicines were also addressed at the meeting. This is a summary of the workshop presentations and discussions, including considerations for future regulatory guidance on drug products containing nanomaterials.

KEY WORDS: nanomaterials, nanomedicine, nanotechnology, PQRI, risk management, USFDA

INTRODUCTION

The Product Quality Research Institute (PQRI) Workshop for Nanomaterials in Drug Products (1) was designed as a collaborative effort among industry, academia, and the Center for Drug Evaluation and Research (CDER) Nanotechnology Working Group to discuss the current experience and risk management of potential risks from nanomaterials in drug products and to provide direction to future guidance efforts (2). The goals of the workshop were to address key areas for quality, safety, and efficacy of nanomaterial drug products, more specifically to:

Review analytical science and methods for characterizing nanomaterials. Discuss their application to the characterization and quality control of drug products;

Share experience and results using multiple formulation platforms for the same active pharmaceutical ingredient (API): effects on quality, safety, and efficacy of drug products containing nanosize constituents;

Discuss approaches to the management of potential risks of nanomaterials in drug products starting from early drug development and throughout product lifecycle. Implications for maintaining quality, safety, and efficacy were highlighted;

Gather input regarding the considerations for utilizing nanotechnology in pharmaceutical products;

Present experience and perspectives from international regulatory agencies and standard setting organizations on the use of nanotechnology in pharmaceutical products; and

Discuss areas where additional research on the effects of nanosize API on absorption, distribution, metabolism, excretion, and toxicity (ADME and toxicology) may be needed.

The following is a summary of the presentations, ensuing discussions, and key conclusions from the workshop.

SESSION I: NANOMATERIALS IN DRUG PRODUCTS: REGULATORY EXPERIENCE AND STANDARDS PERSPECTIVE

United States Food and Drug Administration’s Approach to Regulation of Nanotechnology Products: R. Nalubola, N. Sadrieh, and C. Cruz

The United States Food and Drug Administration (USFDA) recognizes that nanotechnology is an emerging technology that has the potential to be used across the full spectrum of USFDA-regulated products, including drugs, biological products, and medical devices. Over the past several years, USFDA has taken multiple steps to help ensure the responsible development of nanotechnology products.

In a presentation titled, “USFDA’s Approach to the Regulation of Nanotechnology Products,” Ritu Nalubola, Ph.D., a Senior Policy Advisor in USFDA’s Office of the Commissioner, provided an overview of the Agency’s overarching policy framework, regulatory science activities, and related regulatory cooperation efforts.

In a policy statement articulating its approach (3), USFDA noted that it does not categorically judge all products involving the application of nanotechnology to be either inherently benign or harmful. USFDA continues to regulate nanotechnology products under its existing statutory authorities in accordance with the specific legal standards applicable to each type of product under its jurisdiction. USFDA believes that this regulatory policy allows for tailored approaches that adhere to applicable legal frameworks and that reflect the characteristics of specific products or product classes and the evolving technology and scientific understanding. USFDA intends to ensure transparent and predictable regulatory pathways grounded in the best available science. USFDA’s approach is consistent with the broader US government principles for the regulation and oversight of emerging technologies (4) and nanotechnology (5).

In June 2014, after the PQRI workshop for Nanomaterials in Drug Products, USFDA issued a final guidance for industry, “Considering Whether an USFDA-Regulated Product Involves the Application of Nanotechnology,” to present its current thinking on nanotechnology (6), after taking into account public comment received on the corresponding draft guidance. As noted in that final guidance, USFDA has not adopted a regulatory definition of nanotechnology or related terms. In determining whether an USFDA-regulated product involves the use of nanotechnology, USFDA intends to ask:

-

Whether a material or end product is engineered to have at least one external dimension, or an internal or surface structure, in the nanoscale range (approximately 1 to 100 nm);

In addition, because materials or end products can also exhibit related properties or phenomena attributable to a dimension(s) outside the nanoscale range of approximately 1 to 100 nm that are relevant to evaluations of safety, effectiveness, performance, quality, public health impact, or regulatory status of products, USFDA will also ask:

Whether a material or end product is engineered to exhibit properties or phenomena, including physical or chemical properties or biological effects, that are attributable to its dimension(s), even if these dimensions fall outside the nanoscale range, up to 1 μm (1000 nm).

Table I provides a comparison of USFDA’s points to consider and the definitions proposed by Health Canada and the European Commission. The contents of Table I were updated based on the USFDA final guidance in June 2014, which was published after the PQRI Workshop. In 2014, USFDA also issued additional guidances for the industry to address product-specific technical issues related to the use of nanotechnology in cosmetic products in food substances and in food for animals (7). USFDA also established policies for animal drug submissions and continues to evaluate regulatory gaps for the review of drug products containing nanomaterials in order to formulate future guidance.

Table I.

Comparison of Nanomaterial-Related Descriptions

| USFDA’s points to consider | Health Canada working definition of nanomaterial (9) | European Commission recommendation on the definition of nanomaterial (97) |

|---|---|---|

| 1. Whether a material or end product is engineered to have at least one external dimension, or an internal or surface structure, in the nanoscale range (approximately 1 to 100 nm); and 2. Whether a material or end product is engineered to exhibit properties or phenomena, including physical or chemical properties or biological effects, that are attributable to its dimension(s), even if these dimensions fall outside the nanoscale range, up to 1 μm (1000 nm). |

Any manufactured substance or product and any component material, ingredient, device, or structure if: a. It is at or within the nanoscale in at least one external dimension, or has internal or surface structure at the nanoscale, or; b. It is smaller or larger than the nanoscale in all dimensions and exhibits one or more nanoscale properties/phenomena i. The term “nanoscale” means 1 to 100 nm, inclusive; ii. The term “nanoscale properties/phenomena” means properties which are attributable to size and their effects; these properties are distinguishable from the chemical or physical properties of individual atoms, individual molecules and bulk material; and, iii. The term “manufactured” includes engineering processes and the control of matter. |

A natural, incidental, or manufactured material containing particles, in an unbound state or as an aggregate or as an agglomerate and where, for 50% or more of the particles in the number size distribution, one or more external dimensions is in the size range 1–100 nm. In specific cases and where warranted by concerns for the environment, health, safety, or competitiveness, the number size distribution threshold of 50% may be replaced by a threshold between 1 and 50%. |

Dr. Nakissa Sadrieh, currently a Director in the Office of Cosmetics and Colors at CFSAN, a nanotechnology expert, and the previous CDER lead for nanotechnology, presented a comprehensive view of the types of nanotechnology-based products in CDER. Dr. Sadrieh summarized the technical profile of drug products in CDER based on nanomaterial type, route of administration, indication, and stage in product lifecycle. Overall, the trends show an increasing number of investigational new drugs using nanotechnology such as “nanoparticles” to deliver drugs. Liposomal injections for cancer indications are one of the most common classes of nanotechnology drug products. Nanomaterials can have unique physical or chemical properties that potentially offer great promise, but these same properties may also merit further examination to determine if they affect product safety or other product attributes. USFDA continues to invest in a nanotechnology regulatory science program to help address key scientific gaps in knowledge, methods, and tools necessary for regulatory assessments of nanotechnology products (8). Dr. Sadrieh presented some key topics currently covered under the USFDA research initiatives for nanotechnology-based products.

Dr. Celia N. Cruz, a Senior Quality Reviewer with the Office of Pharmaceutical Science and current lead of the CDER Nanotechnology Working Group, presented the results from the CDER nanotechnology risk assessment (2). The risk assessment identified the potential risks due to nanomaterials in drug product and any regulatory gaps for the risk management of these drug products, considering routes of administration and stage of the product lifecycle. The risk assessment also addressed the use of nanotechnology-based excipients in drug products. The working group concluded that the current framework for safety, quality, and efficacy assessment is sufficiently robust and flexible to address the potential risks for novel materials, including nanomaterials. Regardless of whether a product contains nanomaterials, USFDA asks relevant questions concerning product safety in order to ensure that the product meets statutory and regulatory requirements for safety. Industry remains responsible for ensuring that its products meet all applicable requirements, and the USFDA continues to offer technical advice and guidance, as needed to help the industry meet its obligations. However, the risk assessment exercise identified that increased reviewer training, targeted research on nanomaterial characterization methods, and the understanding of the impact of nanomaterial attributes on exposure and safety are key areas for continued improvement.

As noted in its draft guidance documents, USFDA encourages the industry to consult with the agency early in the drug development process to address questions related to the safety, effectiveness, or regulatory status of nanotechnology products. These early consultations afford an opportunity to clarify manufacturer’s obligations and discuss methodologies and data needed to meet those obligations.

During the subsequent discussion, USFDA clarified that the points to consider elaborated in the 2011 draft guidance focus on “engineered” substances because USFDA is particularly interested in the deliberate manipulation and control of particle size to produce specific properties. This is distinct from the more familiar use of biological or chemical substances that may naturally exist at small scales, including at the nanoscale, such as microorganisms or proteins. In addition, the points to consider would apply to different types of articles that are regulated by USFDA, including finished products as well as materials that are intended for use in a finished product.

With respect to collaboration with other Federal government agencies, USFDA noted that the Agency continues to collaborate and leverage its resources, as appropriate, with relevant domestic and international counterparts on both regulatory science activities and regulatory policy issues. For example, USFDA actively participates at the US government level in the National Nanotechnology Initiative and its related committees, the Emerging Technologies Interagency Policy Coordination Committee, as well as international regulatory cooperation forums. In addition, USFDA has an ongoing dialogue at the agency level with regulatory partners, including the European Commission, European Medicines Agency, and Health Canada.

Health Canada’s Approach to Regulation of Nanotechnology Products: H. Shahbazian

Hripsime Shahbazian, M. Sc., a Senior Science Advisor in the Office of Sciences and current chair of the Health Products and Food Branch Working Group on Nanotechnology, presented Health Canada’s current perspective on nanotechnology.

Nanomaterials are increasingly being used in the marketplace in a wide range of products and substances that Health Canada is responsible for regulating. It is recognized that nanomaterials exhibit unique physical and chemical properties which can be exploited for improved therapeutic benefits; however, these unique properties may lead to unanticipated behaviors. Health Canada acknowledges that new approaches may be necessary for risk assessment and risk management of nano-based health products to keep pace with advances in this area as there is inadequate information on risks associated with nanomaterials at this time. A number of working groups have been established at Health Canada to raise awareness and address nanotechnology-related issues.

Currently, Health Canada has no specific regulation for nanomaterial-containing regulated products. Health Canada relies on authorities within existing legislative and regulatory frameworks, which require the assessment of potential risks and benefits of products to the health and safety of Canadians before they can be authorized for sale. All health products, including those that contain nanomaterials, are regulated by the Food and Drugs Act and associated regulations. Nanomaterial-containing products are subject to the same rigorous health and safety regulations that apply to conventional health products.

To identify regulated products and substances that may contain nanomaterials and to ensure a consistent approach across diverse regulatory programs, Health Canada developed a general working definition which is described in the Policy Statement on Health Canada’s Working Definition for Nanomaterial (9). The “Working Definition” was adopted on October 6, 2011. It is intended to be used as a tool to help the Department gather safety information about nanomaterials to improve the understanding of nanomaterials in its risk assessment and risk management activities.

New health products can be sold in Canada once they have successfully passed a review process to assess their safety, efficacy, and quality. Responsibility for this review process rests with Health Canada’s Health Products and Food Branch (HPFB). To add visibility and transparency, the HPFB created a nanotechnology webpage entitled Nanotechnology-Based Health Products and Food (10). The webpage outlines applications of nanotechnology and provides general guidance to stakeholders regarding health products containing nanomaterial. The document advises sponsors and other stakeholders to communicate with responsible regulatory areas early in the development process if their products contain or make use of nanomaterial. It provides examples of the type of information that may be required for a nanotechnology-based product’s safety assessment.

To facilitate identification and tracking of nanomaterial-containing drug submissions, Health Canada released a revised Drug Submission Application Form for Human, Veterinary, Disinfectant Drugs and Clinical Trial Application/Attestation (HC/SC 3011) (11). The form asks the sponsor to self-identify when their application concerns a nanomaterial or “nanoproduct.” To capture this information in electronic form, a “Nanomaterial” subclass code was added to the Drug Submission Tracking System (DSTS) to allow queries by subclass code “Nanomaterial.”

Currently, Health Canada does not have any guidance documents specific to nano-based health products. Health Canada believes that, in general, its current risk assessment methodologies are applicable to nanomaterials as they allow for sufficient flexibility. To address unique physical, chemical, and biological properties of nanomaterials, each product is assessed on a case-by-case basis.

The state of science around nanomaterials is evolving. Joint efforts are needed to accelerate the achievements promised by nanotechnology. Strong relations and dialogue with international counterparts are important in achieving program objectives in an increasingly complex regulatory world. Health Canada is involved in various key international initiatives, including:

International Organization for Standardization (ISO) Technical Committee (TC) 229 on Nanotechnologies

Organization for Economic Co-operation and Development (OECD) Working Party on Manufactured Nanomaterials (WPMN)

Canada-US Regulatory Cooperation Council (RCC)

International Cooperation on Cosmetic Regulation (ICCR)

International Regulators Nanotechnology Working Group

European Medicines Agency Regulatory Approach to Nanotechnology Products: S. Haubenreisser

Dr. Sabine Haubenreisser, European Medicines Agency (EMA) liaison official at the USFDA, presented the European Medicines Agency’s perspectives on development of nanomedicines. She gave an overview of nanomedicines reviewed by the EMA and guidance on nanomedicines provided by the EMA to developers, and discussed future challenges.

The EMA has adopted a working definition for “nanomedicines,” as being purposely designed systems for clinical applications, with at least one component at nanoscale, and resulting in definable specific properties and characteristics. These are related to the specific nanotechnology application and intended use and the clinical advantages of the nanoengineering. Also, a nanomedicine needs to meet the definition of a medicinal product according to European legislation (needs to have a pharmacological, immunological, or metabolic mechanism of action or to be a diagnostic in vivo).

To date, the EMA has reviewed some 20 Marketing Authorisation Applications for nanomedicines, covering mainly anti-infectives, antineoplastic, and immunomodulating agents, and various types of nanomedicines systems, including liposomes and nanoparticles. EMA has given scientific advice or protocol assistance in over 50 instances. The Orphan Drug Committee has recommended orphan status for a number of nanomedicines under development.

Nanomedicines present scientific challenges, as they are an innovative and evolving scientific field. The EMA has to align with state-of-the-art knowledge and to evolve their methods for evaluation (12,13). From the regulatory standpoint, the EMA is faced with the evaluation of “nanosimilars” and the “next generation of nanomedicines.” Nanosimilars are follow-on nanomedicines as first-generation products come off patent and are claimed to be similar to a reference nanomedicine. In order to demonstrate similarity, in terms of quality, safety, and efficacy, there is a need for stepwise comparability studies. The EMA is also looking at “next-generation” nanomedicines, where recent advances in nanoscience are leading to the creation of even more complex, hybrid structures, paving the way for a wave of new pharmaceuticals, imaging agents, and combination products. Development and evaluation of such products will require special regulatory considerations.

In view of the scientific and regulatory challenges presented by nanomedicines, the EMA has established a pool of expertise for evaluation of both the scientific and regulatory aspects to ensure consistency and collaboration across the European Union (EU). The EMA identified the need for multidisciplinary expertise and, in 2009, established the Expert Group on nanomedicines, bringing together academia and regulators to provide scientific input to Scientific Advice, collate regulatory reflection for evaluation and approval of nanomedicines, monitor the uptake of technical advances in development and evaluation, and formulate guidelines. The EMA also established close cooperation with other EU scientific committees and international cooperation through the International Regulators Expert Group, chaired by the EMA and involving international partners from the USA (USFDA), Japan (Ministry of Health, Labour and Welfare), Canada (Health Canada), and Australia (TGA). Furthermore, the EMA is seeking a transparent dialogue with stakeholders and organized the first International Workshop on Nanomedicines in London in 2010.

The EU has a highly evolved system for the evaluation of the benefit/risk of medicines that has, so far, effectively accommodated new technologies. However, in view of the particular challenges of nanomedicines, EMA has to consider the need for additional guidance, for example, on quality, toxicology, and clinical development and monitoring aspects. In 2011, the Committee for Medicinal Products for Human Use (CHMP) commissioned the multidisciplinary Drafting Group to develop a series of four reflection papers on current scientific and regulatory thinking for nanomedicines. These documents cover the development both of new nanomedicines and of nanosimilars.

The reflection paper on the data requirements for intravenous liposomal products developed with reference to an innovator liposomal product (14)

The draft reflection paper on data requirements for intravenous iron-based nanocolloidal products (15)

The joint EMA/MHLW reflection paper on block copolymer micelle medicinal products (16)

The reflection paper on surface coating (17)

The EMA addresses needs for regulator training. In 2011 and 2012, the EMA held international webinar training sessions on block copolymer micelles and, in 2013, a training session for European regulators on liposomal formulations. An international training session on this topic is planned for this year and further sessions are planned for iron oxide nanoparticles and nanomedicines coating.

The EMA supports developers of nanomedicines in different ways. The Expert Group and Drafting Group on Nanomedicines have been mentioned above. The EMA also offers support through the Innovation Task Force, provides Scientific Advice with option of Parallel Scientific Advice with the USFDA, and has a specialized small- and medium-sized enterprises office (SME).

The Innovation Task Force is a multidisciplinary group that includes scientific, regulatory, and legal competences (18). The Innovation Task Force (ITF) provides a forum for early dialogue with applicants. It holds briefing meetings with applicants on emerging science and technologies with potential regulatory impact. These meetings are free of charge and are intended to facilitate the informal exchange of information and the provision of guidance early in the development process. A dedicated group has been established within ITF, focusing on nanotechnology scientific and regulatory aspects.

The EMA also provides Scientific Advice and protocol assistance to applicants developing nanomedicines (19,20). The Scientific Advice Working Party of the CHMP thus provides an EU view on scientific issues not covered by or deviating from existing guidance. Since experience with nanomedicines is limited, applicants are encouraged to seek early Scientific Advice on the specific data requirements. Applicants can also seek advice on the qualification of biomarkers (21) and can request parallel Scientific Advice from the EMA and USFDA with the aim of streamlining global development plans.

The EMA recognizes the significance of SMEs in the development of nanomedicines, which are often start-up companies or academic spin-offs. The EMA’s SME Office, launched in 2005, is dedicated to addressing the particular needs of smaller companies and aims at promoting innovation and the development of new medicines (22).

In summary, the EMA views nanotechnology as an emerging science which presents new opportunities for medicines in the fields of drug delivery, diagnostics, theranostics, and regenerative medicine and which will yield innovative products contributing to a more proactive paradigm for the diagnosis and therapy of diseases. The focus of the EMA is to facilitate the development of such products. The existing EU regulatory framework does accommodate nanomedicines and adapts constantly to address new challenges. Experience has allowed the EMA to assess the need for development of guidance specific to nanomedicines, which have been addressed so far through the four reflection papers. Applicants are encouraged to contact the EMA at the early stage of development. EMA can provide support through Scientific Advice or through informal briefing meetings with the ITF. Particular regulatory challenges are presented by the evaluation of “nanosimilars” and by advances in nanoscience giving rise to a new generation of complex, hybrid structures.

NANOMATERIALS IN DRUG PRODUCTS—INDUSTRY PERSPECTIVE

Nanomedicines Alliance: F. Malinoski

Dr. Frank Malinoski presented the perspective of the Nanomedicines Alliance on risk assessment and management of nanomedicines. The Nanomedicines Alliance (http://www.nanomedicines-alliance.org/), currently composed of ten pharmaceutical and biotechnology companies, is a unique industry group that promotes and facilitates scientific advancement, regulatory approval, safe use, and public appreciation of nanotechnology-based medicines for the diagnosis, treatment, and prevention of disease. The Alliance provides a forum for member companies to exchange information and discuss emerging issues in nanomedicine development. The Alliance also works with government partners and other stakeholders to define and address priority issues of science, regulation, and policies related to nanomedicine.

Since its formation in 2010, the Alliance has reported on key legislative, regulatory, and scientific developments related to nanomedicines via monthly newsletters. The Alliance has also developed unified industry comments to draft guidances issued by USFDA, National Institute of Occupational Safety and Health, and National Nanotechnology Initiative and established strong working relationships with government entities such as USFDA, National Cancer Institute, National Cancer Institute Alliance for Nanotechnology in Cancer, and Nanotechnology Characterization Laboratory. In 2013, the Alliance sponsored a well-received symposium where government agencies, academics, and industry scientists shared experiences, discussed challenges, and debated best practices in five distinct areas (i.e., design; preclinical pharmacology; toxicology; chemistry, manufacturing, and controls (CMC); and clinical studies) related to nanomedicine development. One white paper highlighting the symposium output was recently published in the AAPS Journal and another will be published soon. In 2014, the Alliance will continue to educate key stakeholders on the promise of nanotechnology for future medicines via publications, sponsorship and organization of conferences and roundtables, and other advocacy efforts.

Nanomedicines have the potential to improve drug targeting and effectiveness, while reducing toxicity and environmental burden. Nanotechnology-based diagnostic tools may be able to diagnose pathological conditions at an earlier stage than conventional diagnostics. There are striking differences (including intended usage, physiochemical properties, human exposure, risk assessment, and regulatory oversight) between nanomedicines and nonmedical nanoparticles, as summarized in Table II. Most importantly, nanomedicines are intended for human exposure and are subject to rigorous regulatory scrutiny before they can be used by patients. Any risk management strategy must weigh risks against benefits for a particular nanomedicinal product, as for other medicines (i.e., a case-by-case approach).

Table II.

Comparison of Nonmedical Nanoparticles and Nanomedicine

| Aspect | Nonmedical nanoparticles | Nanomedicines |

|---|---|---|

| Design goal | Engineering/technical performance | Medical benefit |

| Physicochemical properties | Generally uniform, homogeneous; relatively insoluble | Generally heterogeneous; soluble components |

| Human exposure | Unintended | Intended |

| Risk assessment | Hazard identification; appropriate controls | Safety characterized in development; aim for favorable benefit/risk |

| Regulatory authority oversight (US) | Occupational Health and Safety Administration, Environmental Protection Agency | USFDA |

The Nanomedicines Alliance believes that the current US regulatory framework is sufficiently comprehensive to accommodate nanomedicinal products and that this framework also allows for additional specific considerations on a case-by-case basis. The Alliance will continue to embrace and pragmatically apply, as appropriate, ongoing and emerging advances in bionanotechnology that may stimulate the development of new tools and approaches in the future.

SESSION II: CONSIDERATIONS FOR THE CHARACTERIZATION, DEVELOPMENT, MANUFACTURING, AND POST-COMMERCIALIZATION OF NANOMATERIALS IN DRUG PRODUCTS

Considerations Regarding the Impact of Nanomaterials on Drug Products: K. Tyner

Increased bioavailability, targeted delivery, and increased drug action have all been reported as direct outcomes when incorporating nanotechnology into drug products (23,24). Just as there are multiple reasons to develop a nanodrug, there is a wide diversity of the nanodrugs themselves, with size, shape, material, and route of administration all impacting the overall drug performance (25). Milled nanocrystals, liposomes, and metal colloids are just some of the examples of nanodrugs that are on the market today with even more complex nanodrug formulations on the horizon (26). This diversity provides a nanodrug landscape that is complex from a characterization, manufacturing, and regulatory standpoint. Since regulations and law do not separate nanotechnology products, applicable regulations such as Good Laboratory Practices for Non-Clinical Laboratory Studies (21 CFR 58) and cGMP (21 CFR 210 and 211) apply. However, applying those regulations to nanodrugs may be difficult. For example, fully describing a nanodrug formulation means characterizing it, but there is still much debate on what and how to characterize nanomaterials. In addition, terminology for nanodrugs may be different than for small molecule drugs (e.g., particle stability versus chemical stability). The goal of this session was to introduce the audience to characterization considerations for nanodrugs and to hear from industry representatives on manufacturing considerations for these complex products.

Analytical Considerations for the Characterization of Nanomaterial Drug Products: C. Sayes

The session focusing on the analytical techniques used to characterize nanomaterial drug products began with a platform presentation by Dr. Christie M. Sayes. In the research and development phases of nanomaterial drug product design, there are generally three stages: synthesis and formulation, physical and chemical characterization, and safety/efficacy evaluation. These stages build upon each other to ensure advantageous drug products enabled by nanotechnology. Understanding the biological effects as they relate to the drug’s characteristics enhances the potential for successful implementation of each experimental product, therefore resulting in a more streamlined approach to nanomaterial drug product development (27).

Throughout the R&D phases, choices are made based on tissue target and preferred delivery method. For example, during chemical synthesis, there is a choice between liquid or aerosol phase synthesis that will determine the stability of the product and state of aggregation over time. Other choices may include types of formulation (e.g., emulsification), physiochemical features (e.g., size, amount (weight or number per unit volume), composition (organic, polymeric, metallic), morphology (amorphous or crystalline), and surface functionality (charge, coating, conjugation)).

Synthesis and Formulation

There are two approaches to the synthesis of drug products, the top-down strategy and the bottom-up strategy (28). The top-down method focuses on physical techniques to break down larger particles into nanomaterials, i.e., mechanical techniques such as grinding, milling, or shredding. The bottom-up strategy involves chemical methods to construct nanometer-scale products from molecules (29). Such methods include organic synthesis, chemical reduction, self-assembly, and aerosol growth.

Physical and Chemical Characterization

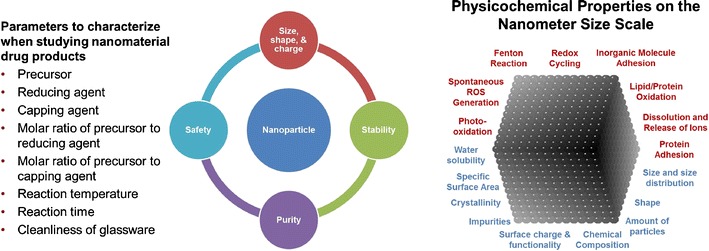

Properties of nanomaterial drug products greatly impact their ability to be used in clinical applications. Such properties (Fig. 1) include size, shape, purity, and stability (28). Factors impacting these properties include the chemical precursors, reducing and capping agents, the molar ratio of precursors to reducing agents or capping agents, reaction temperature, reaction time, and cleanliness of the reactor vessels during synthesis, and separations to remove reagents from the final drug product (30).

Fig. 1.

a Parameters and b physicochemical attributes to consider in the characterization of nanomaterial drug products

When designing nanomaterial drug products, it is important to consider the chemical properties that may impact the material’s interactions and function in a biological system. One such chemical property to consider is redox cycling. Free radical formation has been implicated in the toxicity of a wide range of xenobiotics. Other properties to measure include lipid/protein oxidation, protein adhesion, inorganic molecule adhesion, dissolution and release of ions, Fenton reaction, photo-oxidation, and spontaneous reactive oxygen species generation. Although short-term and long-term cytotoxicity was mentioned, a more elaborate discussion is summarized below in the Effect of Nanosized Excipients on Absorption, Distribution, Metabolism and Excretion (ADME) (31).

Similar to the consideration of chemical properties of nanomaterials engineered as drug products, the physical properties of such nanomaterials must also be designed and characterized carefully. Along with chemical composition, physical properties that impact the interaction of a nanomaterial with a biological system include size and shape, surface charge, and functionality (32–36). These properties can be measured using a variety of techniques including dynamic light scattering (DLS), electron microscopy (EM), nanoparticle tracking analysis (NTA), diffraction patterns, isoelectric point (IEP), water solubility, zeta potential, specific surface area, energy dispersive X-ray spectroscopy (EDS), and atomic emission spectroscopy (AES). The characterization of the nanomaterial in vitro needs to be complemented by its characterization in vivo, since the surface properties and fate of the nanomaterial in vivo are critically dependent on the coatings arising from nanoparticle-serum interactions (37–39).

Product Lifecycle: Transformation of Nanodrugs

There is a need to understand the analytical considerations for characterizing nanomaterial drug products. This need is best accomplished through an integrated product lifecycle approach. A lifecycle approach would include assessment of the pristine, nano-enabled intermediates and products, as well as product end-of-life stages (i.e., shelf life determination and disposal of nanomaterials into the environment). Pristine nanoparticles are generally well-characterized, studied, reported, and understood engineered nanomaterials. Nano-enabled products, however, include pharmaceuticals, devices, and packaging, and their physicochemical properties are not well understood. Product end-of-life scenarios also need additional attention. With this lifecycle approach, pristine and end-of-life particles must be characterized and assessed for safety. As we continue to compare the pristine and end-of-life nanoparticles against the nanomaterial drug product, a more relevant picture of nanotoxicology will be drawn. This enhanced picture will allow for “safer by design” nanomaterial pharmaceuticals.

BREAKOUT SESSION: ANALYTICAL METHODS USED FOR THE CHARACTERIZATION OF NANOMATERIALS: LIMITATIONS AND NEED FOR ADDITIONAL RESEARCH—MODERATORS: N SUBBRAO, K. TYNER, AND C. SAYES

Four major themes arose during the characterization breakout sessions—the first two centered on basic characterization of the drug product and the second two focused on impurities and related quality controls.

Characterization and Measurands

The approval of nanodrugs, like all drug products, is covered under the Code of Federal Regulations (CFR). The requirement to fully characterize a drug product may be found in 21 CFR 314.50(d)(1)(i), which requires a full description of the physical and chemical characteristics for the drug substance, including the identity, strength, and quality. When the product contains a nanomaterial, the tests and metrics that fully describe the drug substance may differ from those of traditional small molecules. There have been multiple groups and organizations that are involved in identifying the minimum requirements to adequately characterize a nanomaterial. These lists range from basic lists of size, shape, and composition to more extensive lists with 20+ measurands identified. In general, an exhaustive list of measurands is not useful to developers and regulators alike, as time and resources will be spent on tests that have no actual bearing on the quality, safety, or efficacy of the end product. As with most aspects of the drug development process, the specific critical quality attributes (CQAs) for a material will be product specific and will most likely include measurands that are both nano- and non-nanospecific. Risk assessment is oftentimes beneficial to determine what attributes need to be examined during development as well as when changes are made to the approved drug product. From a development perspective, standards for how information such as size and size distribution is reported would be beneficial and should be addressed early in the drug review process.

Characterization Tools

In addition to specific CQAs that emerge with the incorporation of nanomaterials, the tools and methods used to characterize these attributes may also be different from those used with small molecules. Techniques for the characterization of many aspects of nanodrugs are available, with more being developed to address specific attributes unique to nanomaterials. As with the identification of CQAs of the nanomaterial in the drug product, the techniques chosen to measure the attribute should be appropriate and validated. For example, if a particle size is supposed to be less than 100 nm, the instrument used for measuring the particle size should be validated to analyze at dimensions less than 100 nm. It is widely known that different instruments may provide different results when measuring nanomaterial attributes (such as size). To address this variability, it is generally recommended throughout the field that orthogonal/complementary methods be used when measuring the CQAs. Finally, the tests and tools used for development may not be the same as the ones used for release testing or additional quality checks. Knowledge sharing to keep the USFDA informed about technology used for measuring nano-attributes is recommended, especially when instrumentation and technology are new.

Impurities

In addition to the general considerations for impurities and impurity controls used for small molecules, nanodrugs may have additional impurity considerations. It has been reported previously how the size, shape, and structure of a nanomaterial may all be related to the function of a nanodrug. However, size and shape are rarely homogenous in a nanomaterial preparation and may itself be a source of drug performance variability. The extent and effect of observed variability should be studied and appropriately controlled. For example, a different shape or size of a nanomaterial could be considered an impurity if it is impacting the quality, safety, or efficacy of the product, even if it is the same composition. In addition, as with small molecule drugs, impurities may be introduced externally from processing conditions (e.g., milling media appearing in the final formulation), or internally (e.g., agglomeration occurring during processing, packaging, or storage). Using risk assessment and understanding if and when a change may be impactful to the quality, safety, and efficacy of the product will be critical in evaluating these impurities. Additional guidance exists for determining chemical impurity testing levels (40).

Quality Controls

The previous three sections highlight the need to understand the CQAs of a material and to choose the correct methods and tools to track these attributes throughout the lifecycle of the product. There is a general need to understand what type of testing is needed initially in the development of the drug versus release and quality testing later in the lifecycle of the product. Understanding the CQA will help determine the tolerable levels of heterogeneity lot to lot and process to process for the drug product. As with any drug, sponsors will need to demonstrate and justify what attributes are relevant and that the instruments used to characterize those attributes are robust enough to provide those data. In general, it is the outcome of the quality, safety, and efficacy of the product that will dictate the required tests.

INDUSTRIAL EXAMPLES OF NANOMATERIALS

Milled Nanomaterial Drug Intermediates and Products: M. Brewster

The pharmaceutical preparation of nanomaterial-based dosage forms is encouraged by a number of API, pharmaceutical, and biopharmaceutical drivers. For compounds whose water solubility or dissolution rate limits their oral bioavailability (e.g., BCS class II or IV materials), size reduction into the nanodomain can, via the Noyes-Whitney/Nernst-Bruner relationship, increase in vivo dissolution rate and fraction absorbed (41–44). These principles have led to a number of marketed products wherein a nanosuspension is either prepared as a liquid formulation (i.e., Megace ES®, megesterol acetate (Par, 2005)) or converted into a tablet or capsule (e.g., Rapamune®, sirolimus (Wyeth, 1999), Tricor®, fenofibrate (Abbott, 2004), Triglide®, fenofibrate (SkyPharma, 2005)) (45–48). Furthermore, nanosizing can also be of use in the design of parenteral dosage forms wherein poorly soluble APIs are milled to a specified size and size range resulting in not only useful bioavailability but also sustained release features (49). The antischizophrenic agent, Invega® Sustenna®, paliperidone palmitate (Janssen, 2009) provides 1 month of drug coverage after a single intramuscular injection, with a 3 month dosing interval project being developed along similar design. Other areas attracting interest include nano-aggregated inhalation platforms.

The development of nanosized formulations generally involved top-down approaches in which the API is milled or otherwise subjected to particle reduction strategies in an aqueous environment in the presence of a stabilizer or a set of stabilizers (50). Top-down strategies were considered more controllable and more robust as a function of process and design space for this type of manipulation. If the API is milled, it is often attrited under high energy in the presence of a milling media like highly reticulated polystyrene or zirconium milling beads. In some cases, piston gap high pressure homogenization can be used to generate the desired nanosuspension (51). Milling is generally monitored by an appropriate particle sizing technique and design and process spaces defined by milling curves first at small scale and then at production scale.

The production scale development of nanosized formulations when completed using ball milling usually involves high-energy mills which can recirculate the material, remilling it until a consistent product is generated (52,53). As suggested, the milling media can also abrade under the conditions of milling, and care should be taken that significant contamination of the nanosuspension by the milling media does not occur. The principle of high-energy milling can be carried across scales from 1 mL to more than 1000 L, and while scaling is a function of the product and the equipment, useful results are often obtained (45,54). Sterile nanosuspensions are also possible using high-energy ball mills by implementing isolator technology and other sterility-assuring components. Likewise, large-scale production using homogenizers is possible and this equipment type can offer advantages under various situations. Finally, several approaches allow for the conversion of the liquid nanosuspensions to be converted into resuspendable solid dosage forms (46,47).

Liposomes: D. Cabral-Lilly

Liposomes are perhaps the most established of carrier nanomedicines with several available on the commercial market and many more in clinical and preclinical development. A liposome carrier is used to increase a drug substance’s therapeutic index, often by multiple mechanisms including (1) favorably changing drug biodistribution and pharmacokinetics, (2) increasing drug substance stability in plasma, (3) decreasing drug toxicity, and/or (4) to deliver optimal ratios of drug combinations to the site of action with the goal of markedly increasing efficacy.

Considerations for manufacturing are similar for all liposome technologies, for example, microfluidization, ethanol injection, emulsion/extrusion, and remote loading. First, the manufacturing process must be reproducible and scalable from a few milliliters at the proof of principle stage to more than 200 L for commercial supplies. The process should minimize hazardous conditions where possible through choice of solvent mixture, equipment rating, and methods for isolating operators from the hazards. It is recommended to develop a scalable manufacturing process early to minimize the number of modifications that are required as the batch size is increased or product dosage form is changed. To date, liposome nanomedicines have been administered by routes that require the product to be sterile (inhalation, intravenous, intrathecal, intramuscular). For products with a relatively large mean particle size (>400 nm), manufacturing must be done as an aseptic process. Sterile filtration can be used for products with a mean particle size of approximately 100 nm or less, making compounding in class B or class C suites possible. This option is much more amenable to technology transfer to contract manufacturing sites, minimizes difficulties for the operator(s), and reduces costs significantly.

Characterization is an important component of the development and manufacturing of liposome nanomedicines. A set of core physicochemical attributes apply to all liposomal products: membrane phase transition temperature, morphology and lamellarity, trapped volume, and zeta potential. Product-specific characterization focuses on drug-excipient interaction, drug loading mechanisms, drug-drug interactions, and physical disposition of the drug in the carrier. An example was presented where data from two characterization techniques were used to help determine the final drug product formulation (48). CPX-1 (irinotecan/floxuridine) liposome injection is a clinical stage liposomal nanomedicine intended for the treatment of advanced colorectal cancer. The manufacturing process co-encapsulates irinotecan HCl and floxuridine at a 1:1 molar ratio into preformed liposomes. The aromatic region of the 1H NMR spectrum of the drug product shows three peaks from irinotecan. When the buffer inside the liposomes was sodium gluconate-triethanolamine (NaGluc-TEA), the 1H peaks are quite broad. When this entrapped buffer was copper gluconate-triethanolamine (CuGluc-TEA), the 1H peaks were much sharper suggesting an interaction between irinotecan and copper. Correspondingly, the drug release profiles from an in vitro release (IVR) assay also showed a difference. In the liposomes with NaGluc-TEA, the floxuridine and irinotecan were released from the liposomes at different rates, whereas with CuGlu-TEA as the entrapped buffer, the two drug substances released from the liposomes at the same rate under the conditions of the IVR assay.

The numerous components of liposome products (multiple membrane lipids, additional excipients, possibly multiple active agents), as well as the multistep/day manufacturing process pose challenges to performing development and validation studies using the standard quality by design (QbD) approach; the design space would be extremely complex. It should be possible, however, to obtain a good understanding by studying each step in the manufacturing campaign separately using science-based and process-based protocol designs. The CQAs of the product would be assured by determining the critical process parameters for liposome preparation, drug substance encapsulation, lyophilization, and the feasibility of reworking. An example was presented of a phase 3 clinical stage product, CPX-351 (cytarabine/daunorubicin) liposome injection, being developed for acute myelogenous leukemia (55). Here the two drug substances are encapsulated sequentially into preformed liposomes to achieve a 5:1 molar ratio in the final product. The batch size started at 0.5 L, progressed to 14, 21, and then to 200 L using a manufacturing process for the bulk product that is essentially unchanged. The drug product for phase 1 and 2 trials was a liposome suspension stored frozen at −20°C due to instability at refrigerated temperatures. The drug product was converted to a lyophilized form for phase 3 and comparability to the frozen product demonstrated using in vitro physicochemical characterization that included core parameters, product-specific characteristics, and in vitro release. Upon reconstitution with water, more than 95% of both cytarabine and daunorubicin remain encapsulated. The lyophilized product is stable for at least 3 years when stored refrigerated and for at least 2 years when stored at room temperature.

Gold Particles: L. Tamarkin

To be considered as a potential pharmaceutical product ready for the marketplace, nanomedicine manufacturing processes need to be robust, reproducible, and cost-effective. CytImmune has developed a simple method for manufacturing a family of anticancer nanomedicines that harness the therapeutic potential of the naturally occurring, anticancer hormone, tumor necrosis factor alpha (TNF) and are readily characterized (56).

Colloidal gold is the core of CytImmune’s proprietary nanotechnology. The mean size of the gold nanoparticles used as the core of CytImmune’s nanomedicine is 27 nm, where 95% of the particles range in size from 15 to 35 nm. The quality of the resultant gold sol is then confirmed by transmission electron microscopy and the quantity of gold is measured by inductively coupled plasma-atomic emissions spectroscopy (ICP-AES).

The next step in manufacturing is to independently bind two molecules to the gold nanoparticles, TNF and an analog of polyethylene glycol (PEG), using thiol binding to form dative covalent bonds with the gold nanoparticles. Each molecule serves a different purpose. TNF serves two functions, one as the tumor-targeting entity and a second as the API. The PEG analog, on the other hand, shields the gold particles from immune detection.

To ensure that both TNF and PEG-thiol bind to individual gold nanoparticles, the binding needs to occur in a small volume. This is accomplished by simultaneously drawing the colloidal gold sol and a mixture of TNF and PEG-thiol into a Y-connector using a single peristaltic pump. This dilute form of the final drug product is ultrafiltered and then vialed and lyophilized. To date, this lyophilized product has been shown to be stable for 3 years, and the process is scalable.

This nanomedicine, termed CYT-6091 (57,58), has a number of unique features that facilitate its characterization. First, TNF is bound to the surface of the nanocarrier, so that the API on the final drug product may be interrogated without destroying the final drug product. Second, the reagents bound to the gold nanoparticles may be stripped off the gold nanoparticles using a strong reducing agent, such as dithiothreitol or β-mercaptoethanol. And third, the gold nanoparticles may be centrifuged, enabling a simple process for separating gold-bound reagents from unbound (or free) reagents.

By measuring bound versus free TNF, the product specifications were established wherein 80% or more of the initial amount of TNF is in the final drug product that contains less than 5% free TNF. The range of APIs that this nanomedicine platform may carry is not limited to biologic molecules. CytImmune has developed thiolated linkers that release parent small molecule therapeutics either through hydrolysis or self-immolation (58). Now, using the same manufacturing process described above, CytImmune is able to bind a biologic (TNF), an analog of a small molecule therapeutic (e.g., paclitaxel) and PEG-thiol simultaneously to individual gold nanoparticles. Thus, this nanomedicine platform has the versatility to deliver multiple agents to tumors, each of which acts independently and potentially synergistically to target and destroy both the tumor vasculature and its cancer cells.

BREAKOUT SESSION: CURRENT AND EMERGING TECHNOLOGIES FOR MANUFACTURING STABLE NANOMATERIAL-CONTAINING DRUG PRODUCTS: MODERATORS: J. BARTLETT AND W.M. EICKHOFF

The breakout sessions stimulated a lot of very good discussion about the challenges and opportunities around nanomaterial-containing drug products. The following is an account of the major conclusions from the discussion during the breakout session. Some common themes that emerged from the different breakout sessions are summarized below.

Why Are There Not More Nanomaterial-Containing Drug Products on the Market?

From presentations given earlier in the day, it was shown that a major part of approved nanomedicines may be classified as the more “mature” technologies, for example, oral nanocrystals and liposomes. This topic of “why not more nanomedicines” was discussed and a few themes emerged. It is perceived that the development of a nanomedicine comes at a higher regulatory and technical risk. The perception that nanomedicines would require “enhanced drug development” which translates to greater costs and longer development timelines was also noted. This added development barrier comes at a cost to the innovator; therefore, a clear definition by the innovator companies around the medical benefit of the nanomedicine approach is key. For example, if a nanomedicine is being used to advance a candidate which displays poor aqueous solubility intended for oral delivery, the question should be addressed as to what advantage is the nanomedicine bringing compared with alternative oral solubilization approaches? There were a number of examples given over the course of the meeting where nanomedicines have the potential to offer significant medical benefits. Parenteral drug delivery employing nanomedicines was seen as the emerging technology where the greatest medical benefits may be observed. Oral nanomedicines were seen as more mature technologies, primarily employed to overcome poor dissolution and solubility of drug candidates.

Balance of a Deeper Understanding of the Technology Versus Development Timeline

Several points were captured around the perception that developing nanomedicines, particularly for the parenteral route of administration, will require a deeper understanding of the critical attributes of the formulation on efficacy and safety. There was discussion around the need to develop more and/or better in vitro or preclinical in vivo models that can accurately evaluate key performance endpoints (i.e., safety and efficacy) of the novel nanomedicines. For example, when a nanosystem is being used to increase the dissolution rate/bioavailability of a compound, predictive in vitro dissolution screens have been developed to assess the performance of the nanocrystals systems. It was noted that the challenges to developing these tests should not be underestimated. One of the key challenges in the development of more predictive models is that you need to know what to measure (biologically or in vitro) that is relevant to a clinical endpoint (i.e., safety and efficacy). Advancements are being made in this area, and several examples were presented with regard to the development of ADME screens to look at uptake/distribution of different nanomaterials. In some cases, several prototype nanomaterial-containing formulations are put directly into exploratory human clinical trials in order to explore the impact of nanoproperties, for example particle size distribution or surface properties, on pharmacokinetics (PK) or pharmacodynamics (PD) responses very early in the development program. From these results, correlations can be developed which can be used to develop predictive in vitro/in vivo models and to optimize future formulation efforts.

What Are the Major Barriers for Entry of Novel Nanomaterial-Containing Medicines: Technical, Regulatory, Funding?

This question was discussed at some length with varying opinions because “one size does not fit all.” There are multiple different nanomaterial-containing nanomedicine approaches (e.g., top-down versus bottom-up approaches) and multiple routes of administration (e.g., oral versus parenteral), and therefore, broadly defining the major barriers to entry for nanomedicines is a challenging topic. There was some discussion around classifying the different nanomedicines based on various attributes to help assign different levels of risk and provide more focused regulatory guidance, for example, attributes such as particle size, route of administration, longevity of the particles in the body, whether the particles are water soluble or water insoluble, extent of distribution within the body, etc. It was noted that there have been efforts in the literature regarding this approach (59) and by the EMA through the publication of focused reflection papers on the development of different nanomedicines (14–17).

There was a general understanding that if the medical benefit is clearly defined, and a market driver identified, technical hurdles with regard to the science, development, and manufacturing would be overcome. There was a general concern around the lack of regulatory guidance and acceptable level of manufacturing changes that may occur during the development of a new medicine. There was consensus that a specific SUPAC-like guidance for each type of nanomaterial was not practical and that a Quality Risk Management based on principles outlined in International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) Q9 and ICH Q10 (40) would be more appropriate.1 The question was rooted in a concern that the development of a novel nanomaterial-containing drug product may carry additional development costs, timeline, and a higher level of regulatory risk that upon commercialization additional preclinical/clinical studies may be requested. To reduce this risk, it was noted that a more enhanced drug development program may be needed much earlier in a product development which comes at an added cost. Since many novel nanomedicines are being developed by small companies, the additional development costs could be a barrier. By more clearly defining what the key barriers to entry of new nanomedicines are, solutions could be identified to help overcome the obstacles.

SESSION III: SAFETY AND ADME CASE STUDIES OF NANOTECHNOLOGY-DERIVED DRUG PRODUCTS

Introduction: Safety and Toxicological Effects: A. Jacobs

Nanosize: What can we learn about nonclinical evaluations of nanomaterial drug products? There is an interplay between characterization of the nanomaterial and its toxicology. It is important to know that the material can be made reproducibly and is representative of what humans will be exposed to. There are many questions asked about nanomaterial drugs/formulations/carriers. For insoluble nanomaterials, it would be helpful to know to which part of the size range should any biologic effects be attributed, and which changes in which properties could affect biologic properties? This is not a simple task, but the developer should understand the critical variables.

There are two general types of regulatory submissions for nanomaterials. In one case, the product and active ingredient are completely de novo, and the standard ADME and toxicology studies used to evaluate non-nanomaterials during product development would apply. In other cases, there is a previously approved active pharmaceutical ingredient, which has been milled into the nanorange for better oral bioavailability. In this case, a bridging toxicity study and ADME study should generally suffice. However, there may be route-specific issues for nonoral routes of administration that may warrant evaluation.

Which in vitro tests are appropriate and in vivo safety concerns depend on whether the nanoparticle or carrier is not water soluble or biodegradable. If the product is biodegradable and water soluble then in vitro assays can have utility. These statements include some generalizations, but the final decision on what is needed will be based on a case-by-case approach.

Case Study: Safety and ADME and Toxicology of Nanotechnology in Parenteral Drug Products: W. Zamboni

Nanoparticle Anticancer Agents

Major advances in the use of carrier vehicles delivering pharmacologic agents to sites of disease, such as tumors, have occurred in the past 15 years (60,61). The primary types of carrier-mediated anticancer agents are liposomes, nanoparticles (NPs), and conjugated agents. Liposomes can be subdivided into stabilized (e.g., PEGylated) and nonstabilized (non-PEGylated) liposomes (62,63). The theoretical advantages of carrier-mediated drugs include increased solubility, prolonged duration of exposure, selective delivery of entrapped drug to the tumor, and improved therapeutic index (60). PEGylated liposomal doxorubicin (Doxil®, Lipodox®, PEGylated liposomal doxorubicin (PLD)), liposomal daunorubicin (DaunoXome®), liposomal vincristine (Marqibo®), and paclitaxel albumin-bound particles (Abraxane®) are the only USFDA-approved members of this relatively new class of drugs (61). However, there are hundreds of NP anticancer agents in development that may be improved based on the results and methods in this study. Thus, our proposed studies may have a far-reaching impact.

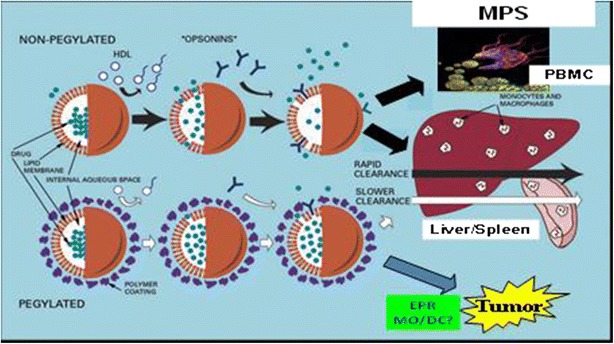

Pharmacokinetics and Pharmacodynamics of Nanoparticle Agents

NP and liposomal agents are cleared via the mononuclear phagocyte system (MPS), also called the reticuloendothelial system (RES), which is located primarily in the liver, spleen, and blood, as well as in the lung and bone marrow (64) (Fig. 2). Non-PEGylated or nonstabilized NPs are cleared relatively quickly via the MPS. PEGylated or stabilized NPs are also cleared via the MPS but at a much slower rate than nonstabilized carriers. We have reported that the slower clearance of PEGylated liposomal agents is associated with greater interpatient PK variability than non-PEGylated liposomal agents (65). The factors affecting the PK and PD variability of NPs remain unclear but most likely include the MPS (64). NPs can alter both the tissue distribution and the clearance of drugs because the drug takes on the PK characteristics of the carrier. Compared to small molecule formulations, the primary sites of accumulation of NPs are the tumor, liver and spleen. The delivery of NP agents to the tumor may also be affected by the MPS (66). Elucidating the mechanism(s) of interaction between NPs and the MPS and understanding the factors that alter MPS function are fundamental to the optimal clinical development of NPs.

Fig. 2.

The clearance (CL) of non-PEGylated and PEGylated liposomal nanoparticle (NP) (e.g., liposomes) agents via the mononuclear phagocyte system (MPS) in the blood, liver, and spleen. NP are taken up and cleared via MPS cells (e.g., monocytes, macrophages, dendritic cells) in the blood, liver, and spleen. The MPS has been shown to be involved in the PK and PD of a wide variety of NP agents

The PK of liposomes and NPs are dependent upon the carrier and not the encapsulated drug until the drug is released from the carrier (64). The drug that remains encapsulated within liposomes or NPs is an inactive prodrug; thus, the drug must be released from the carrier to be active. After the drug is released from the carrier, the PK of the drug will be the same as if one administered the noncarrier form of the drug; however, the overall exposure of released drug is dependent on the variable clearance of the carrier (67). The PK of NPs is complex, and thus, detailed studies must be performed to evaluate the disposition of the NP encapsulated and the released forms.

PK and PD variability of NPs and liposomal anticancer agents administered intravenously (IV) is several-fold higher than small molecule drugs administered IV or oral (65). A meta-analysis comparing the interpatient PK variability of liposomal and small molecule formulations of the same anticancer agents (n = 9) reported significantly higher PK variability of the liposomal agents (65,68). The PK variability depicted as the area under the curve (AUC) CV% (P < 0.001) and ratio of max AUC to min AUC (P = 0.04) was significantly higher for the liposomal agents compared to the small molecule agents. In a phase I study of PEGylated liposomal CKD-602 (S-CKD602), the interpatient variability in the exposure of encapsulated and released CKD-602 ranged from 20- to 100-fold (69). Significant interpatient variability in PK and PD of PLD and other liposomal agents has also been observed.

In addition to the high interpatient variability in the PK of NPs, there also may be high intrapatient variability in the PK of NPs. Gabizon and colleagues reported that the clearance of sum total (encapsulated + released doxorubicin) decreased by approximately 25 to 50% from cycles 1 to 3 in patients with ovarian cancer (70). In addition, La and colleagues reported that this reduction in clearance of Doxil from cycle 1 to cycle 3 was associated with a reduction in precycle monocyte count (71). These studies suggest that there is a reduction in the clearance of liposomes over time that is associated with a reduction in MPS function. Thus, dose reductions may be needed in subsequent cycles to minimize the risk of toxicity. These results and prior results reporting a relationship between the reduction in monocyte counts in blood and the clearance of PEGylated liposomal agents in patients where greater monocyte reductions were associated with greater clearance of the liposomal agents suggest that there is a bidirectional interaction between NPs and the MPS, where the MPS cells take up NPs and the NPs have pharmacologic and/or toxicologic effects on the MPS cells (72,73). Interestingly, repeat dose studies of PEGylated liposomal doxorubicin in mice and rats did not report accumulation of drug in plasma suggesting that these preclinical models may not accurately reflect the disposition of PEGylated liposomal agents after repeated dosing (74,75). Thus, there is a need to develop better preclinical animal models for pharmacology and toxicology studies of liposomal and nanoparticle agents.

The PK variability contributes in part to variability in a drug’s PD effects, making it difficult to predict how a particular patient will respond in terms of efficacy and/or toxicity (64). This issue raises concern about the translational development and clinical utility of NP agents due to the high interpatient PK variability of NPs. Thus, there is a need to identify the factors associated with the PK and PD variability of NPs as methods to improve response and reduce toxicity.

MPS Effects on NP PK and PD

A fundamental and highly referenced principle of NP PK is the predominant effect of the MPS on the distribution and clearance of a wide variety, if not all, NP agents (64,66). New publications by Khanbeigi et al., Shah et al., Skoczen et al., Moghimi et al., Andersen et al., Crist et al. from NCI’s Nanotechnology Characterization Lab, and many others highlight the interaction of the MPS with a wide variety of NP agents (65,76,77). Specifically, studies by Shah et al. and Khanbeigi et al. reported that NPs with various surface properties (e.g., PEG and ligands) and sizes (i.e., 50 to 1000 nm), respectively, are all identified and taken up by the MPS. Our prior studies in animal models and in patients have reported that the MPS is highly involved in the clearance of liposomal agents, such as PLD (67). Moreover, there are no publications suggesting the MPS is not a predominant factor involved in the PK of NP agents, especially NP agents >50 nm.

Our previous studies suggest that the significantly high and clinically relevant variability in the PK and PD of liposomal and other NP anticancer agents is related to variability in the function of the MPS, which serves as the clearance pathway for NP agents (68). The patient factors that affect MPS function and NP PK and PD variability include age, gender, body habitus, sex hormone levels, and chemokines (78–80). However, these patient-related factors do not account for all of the PK and PD variability, and thus, the development of phenotypic probes of the MPS that incorporates or accounts for all of these factors may be a more appropriate approach to predicting the PK and PD of NP in animal models and in patients (Fig. 3). These probes could also be used to individualize the dose of NPs on cycle 1 and subsequent cycles as there is high inter- and intrapatient variability in MPS function and NP PK. Studies in preclinical animal models and in patients using phenotypic probes of MPS function to predict the clearance of PEGylated liposomal agents support this plan (67).

Fig. 3.

Summary of the process to use a phenotypic probe of MPS function in blood to measure MPS function in patients which would predict NP PK, efficacy, and toxicity. This type of probe could be used as a test that could retrospectively be used to explain patients with highly variable PK and PD. This type of probe could also be used as a method to individualize the dose of NPs as needed

Case Study: Safety and ADME Aspects of Nanotechnology in Topical Products (Sun Screens/Wound Healing/Topical/Ophthalmic Products): S. Ciotti and S. Gracon

Dr. Susan Ciotti and Dr. Stephen Gracon from NanoBio Corporation presented a case study of “soft nanoparticle” nanoemulsion-based therapies. A nanoemulsion is a high-energy emulsification of an aqueous phase, oil phase, nonionic surfactant, and a cationic surfactant. The nanoemulsion particles presented the range between approximately 180 and 500 nm. This “soft nanoparticle” formulation allows for permeation of the nanoemulsion (with drug) into the skin and mucosal surfaces.

Nanoemulsion droplets function in opposition to other soft formulations such as detergent micelles; nanoemulsions do not cross tight junctions or epithelial tissues, whereas detergent micelles can cross the tight junctions and disrupt cells and tissues, which may ultimately lead to irritation. This versatile platform allows for a broad spectrum of products, including ones incorporating antiviral and antimicrobial activity. The presented nanoemulsions are being probed for intranasal vaccines. A seasonal influenza vaccine based on these nanoemulsions is currently in phase I clinical trials.

BREAKOUT SESSION: THE SAFETY AND ADME EFFECTS OF NANOTECHNOLOGY ON DRUG PRODUCTS—MODERATORS: A. JACOBS AND E. MOREFIELD

In this breakout session, the following topics were discussed: the need to agree on specific terminology in the nanoscience and technology field, such as defining a “particle” or a “colloid”; addressing the gaps in current safety assessments and identifying testing needs specific for nanomaterial drug products; developing methods to characterize a nanodrug product and include tests for characterizing the stability of the product over time; develop methods for manufacturing reproducible products; understand the limitations of animal models when testing efficacy and safety; gain an appreciation of the physicochemical properties that are most important in efficacy and safety testing, such as crystal structure, formulations, and surface coatings; and develop methods for testing safety for dermal routes of exposures. The importance of only asking for studies that are “need to know” versus “nice to know” was emphasized. Equally important is understanding the minimum requisite analytical tools needed.

The following points were made during this breakout session:

Nanomaterial drug products are currently evaluated on a case-by-case basis. There is a desire to have some generally applicable tests to help minimize differences arising from a case-by-case approach. A suggestion was made to make a general nanochapter in the USP.

Another suggestion to the USFDA was that the training developed for agency reviewers be shared with nanoproduct developers.

- Other topics for a potential guidance were discussed and included:

- Whether there are enough nanorelated items to write a guidance.

- Whether a database should be developed to gather information on nanoproducts.

- Whether any potential guidance should be safety guidance or a quality guidance?

- How much variability is allowed for the physicochemical specifications and how variability should be addressed?

- If PK/distribution does not change with a change in physicochemical properties of a nanoproduct, what if any, analyses of the product or toxicology studies need to be repeated.

- Whether any change in a nanoproduct means that many analyses or toxicology tests need to be repeated.

- Guidance could include blinded examples of what changes in nanoproperties were acceptable, and what data were required for such changes.

Effect of Nanosized Excipients on Absorption, Distribution, Metabolism, and Excretion: R. David

Dr. R. David presented on the effect of nanosized excipient on ADME. Excipients can modify the bioavailability of the active ingredient by enhancing absorption and distribution or by decreasing metabolism and excretion. Nanomaterials as excipients also act to improve bioavailability. Understanding the properties of nanomaterials can aid in the development of new nanoexcipients. Liposomes have been used for many years and the history of liposomes as successful carriers can provide insight into how to craft new drug carrier excipients.

Any active ingredient has biological barriers to overcome to be effective. In their review, Alexis and coworkers (36) list those barriers as absorption, i.e., getting into the blood (assuming a nonparenteral route of administration); distribution limitations, i.e., getting to the target tissue and target cell; and avoiding metabolism and excretion mostly via scavenging into the reticuloendothelial system or filtration in the kidneys. Alexis et al. identify properties such as size (smaller particles are more easily absorbed into cells than are larger ones) and surface charge (negatively charged or neutral particles are retained in the circulation longer than are positively charged ones) as two properties of importance. Maeda and coworkers (81) agree with the biological barriers, but add that there are practical ones: will the active ingredient be efficacious; what are the regulatory and safety issues for the excipient; and what will be the cost/benefit of the new formulation? Indeed, the USFDA has already provided some guidance on the regulatory and safety issues (3) with encouragement to applicants for engaging in a presubmission consultation that will outline the specific issues for each new material or formulation.