Abstract

Flow and dynamic rheological properties of hot thickened soups for consumption by the elderly people with swallowing difficulty (dysphagia) were investigated at a serving temperature of 60°C. In this study, sea mustard soup (SMS) and dried pollock soup (DPS), which have been widely known as favorable hot soups provided in a domestic hospitals and nursing homes for dysphagic patients, were thickened with four commercial xanthan gum (XG)-based food thickeners (coded A~D) marketed in Korea. Thickened soups prepared with different thickeners showed high shear-thinning flow behaviors (n=0.15~0.21). Apparent viscosity (ηa,50), consistency index (K), storage modulus (G′), and loss modulus (G″) demonstrated differences in rheological behaviors between the XG-based thickeners. The magnitudes of G′ were much higher than those of G″ over the entire range of frequency (ω) with the high dependence on ω, showing the rheological behavior similar to a weak gel. In general, all rheological parameter values of thickened DPS samples were higher when compared to the thickened SMS samples. These results indicate that flow and dynamic rheological properties of hot thickened soups containing commercial XG-based thickeners are strongly dependent on the type of thickener and soup.

Keywords: food thickener, viscosity, thickened soup, swallowing difficulty, rheological property

INTRODUCTION

It is commonplace for elderly people to experience difficulties in swallowing, a medical condition termed dysphagia, as a result of loss of tooth by aging, neuromuscular disorders, cerebrovascular diseases, and others. Being unable to safely swallow sufficient foods and fluids has influence on health and quality of life (1). The prescription of thickened fluids are often recommended for the clinical treatment of patients with dysphagia which may lead to choking, aspiration, aspiration pneumonia, dehydration, weight loss, and malnutrition (2). Therefore, the thickened fluids prepared with commercial food thickeners have been used to reduce the risk of aspiration because they flow more slowly than regular liquids and also form a slightly more cohesive bolus for swallowing safety (2–4). Recently, the number of elderly people with dysphagia is increasing in Korea because the Korean population is aging more rapidly than that of any other country in the world. In 2014, people over 65 years make up 12.7% of the Korean population, and they are also expected to make up 24.3% of the population by 2030 (5).

In general, commercial instant food thickeners consist of modified starches and gums as their base materials and they are becoming more popular because of low cost, convenience, and easy preparation (6). In the present study, xanthan gum (XG)-based food thickeners were used for preparing hot thickened soups because they are commonly used in thickening fluids for dysphagic patients in Korea due to their palatability and smooth texture when compared to starch-based thickeners (7). Recently, several researchers have studied the rheological properties of various thickened beverages containing commercial XG-based food thickeners at room or refrigeration temperature (8–11). However, no attempt has been made to study the rheological properties of hot thickened soups with commercial XG-based food thickeners at a serving temperature of 60°C. In the present study, sea mustard soup (SMS) and dried pollack soup (DPS) were selected because they have been widely known as favorable hot soups provided in a domestic hospitals and nursing homes and are also preferred by the elderly people in Korea. The main objective of this study was to investigate the effect of thickener type on steady and dynamic rheological properties of thickened hot soups prepared with various XG-based food thickeners marketed in Korea.

MATERIALS AND METHODS

Materials and sample preparation

Four instant XG-based food thickeners were provided from the Korean market: thickener A [composite of xan-than gum (XG), guar gum (GG), and dextrin], thickener B, (composite of XG and dextrin), thickener C (composite of XG, carboxymethyl cellulose, GG, and dextrin), and thickener D (composite of XG and dextrin). In this study, Korean traditional sea mustard soup (SMS) and dried pollock soup (DPS) were used as dispersing media. Commercial instant SMS and DPS were purchased from Ottogi Corp. (Anyang, Korea). Instant soup was prepared based on the manufacturer’s instructions and then passed through a 140 mesh standard sieve (Chunggye, Seoul, Korea) with 106 μm openings to remove their solid ingredients. Subsequently, the clear soups were heated in a water bath to obtain the hot soups. The hot thickened soups were prepared by mixing the food thickener at 3% (dry weight basis) concentration with the clear soups with moderate stirring for 1 min in a 60°C water bath with mild agitation provided by a magnetic stirrer. The amount of thickener used was consistent with clinical practice guidelines (i.e., based on the manufacturer’s recommendations for pudding-like fluids). The thickened soup sample was immediately transferred to the rheometer plate at a serving temperature of 60°C to measure the rheological properties.

Rheological measurements

Flow properties of the thickened juices were measured with a Carri-Med CSL2 100 rheometer (TA Instruments, New Castle, DE, USA), using a parallel plate system (4 cm diameter) at a gap of 500 μm. Steady flow data were obtained over a shear rate range of 0.1~100 s−1. Temperature was controlled by a water bath connected to the Peltier system of the bottom plate. Data (shear stress and shear rate) were fitted to the well-known power law model (Eq. 1) to describe the flow properties of the samples.

| (Eq. 1) |

where σ is the shear stress (Pa), γ̇ is the shear rate (s−1), K is the consistency index (Pa·sn), and n is the flow behavior index. The apparent viscosity (ηa,50) at 50 s−1, the reference shear rate for swallowing, was calculated using the magnitudes of K and n.

Dynamic rheological data were obtained from frequency sweeps over the range of 0.63~62.8 rad·s−1 at 2% strain using a small-amplitude oscillatory rheological measurement. Frequency sweep tests were also performed at 60°C. TA Rheometer Data Analysis software (version VI. 1.76) was used to obtain the experimental data and to calculate the storage (or elastic) modulus (G′) and loss (or viscous) modulus (G″). All samples were allowed to rest at 60°C for 5 min to relax the samples before the rheological measurements were taken. The rheological measurements were performed in triplicate.

Statistical analysis

The results are reported as the mean value with a standard deviation of triplicate analyses for each sample. Analysis of variance (ANOVA) and Duncan’s test were used to establish significant differences among the mean values at the 0.05 significance level. Statistical analyses were performed using the Statistical Analysis System program version 9.2 (SAS Institute, Cary, NC, USA).

RESULTS AND DISCUSSION

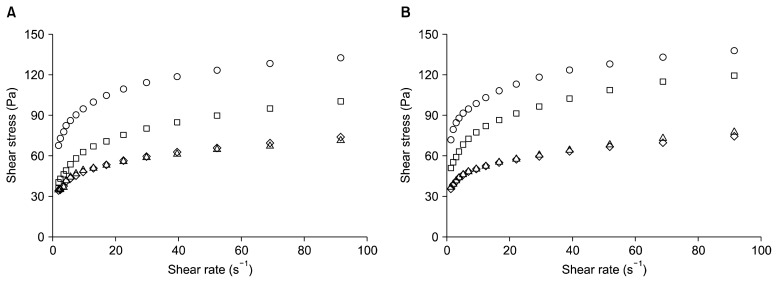

The shear stress (σ) vs. shear rate (γ̇) data for hot thickened soups prepared with different XG-based food thickeners at 60°C are shown in Fig. 1. The experimental re. sults of σ and γ̇ were well fitted to the simple power law model (Eq. 1) with high determination coefficients (R2=0.99) (Table 1). All thickened soups with different XG-based thickeners had high shear-thinning behaviors with low n values (0.15~0.21). This is in agreement with the results of Seo and Yoo (7) and Cho et al. (11), who observed the flow properties of thickened beverages prepared with XG-based thickeners. These low n values could possibly be attributed to the shear-thinning character of XG due to its unique rigid rod-like conformation and high-molecular-weight aggregate (12). Such high degree of shear thinning (low n value) behavior indicates that the thickened soups are less slimy in the mouth (13). Among the XG-based thickeners (thickener A~D) examined, thickener A had lower n values (0.15~ 0.16) in comparison to other thickeners (n=0.16~0.21), indicating that thickener A was less slimy than the other thickeners. However, there were not much differences in n values between the thickened SMS and the thickened DPS.

Fig. 1.

Plots of shear stress versus shear rate for hot thickened soups prepared with different thickeners (coded A~D) at 60°C: (A) sea mustard soup (SMS), (B) dried pollock soup (DPS). ○, thickener A; □, thickener B; △, thickener C; ⋄, thickener D.

Table 1.

Flow properties of hot thickened soups prepared with different thickeners at 60°C

| Soup type | Thickener type | Apparent viscosity ηa,50 (Pa·s) | Power law | ||

|---|---|---|---|---|---|

|

| |||||

| n (−) | K (Pa·sn) | R2 | |||

| SMS | A | 2.39±0.03a1) | 0.16±0.01c | 63.1±1.70a | 0.99 |

| B | 1.99±0.04b | 0.21±0.00a | 42.6±0.59b | 0.99 | |

| C | 1.32±0.01c | 0.17±0.00c | 33.6±0.14c | 0.99 | |

| D | 1.30±0.01c | 0.18±0.00b | 31.4±1.23c | 0.99 | |

| DPS | A | 2.53±0.02a | 0.15±0.00d | 70.8±0.65a | 0.99 |

| B | 2.15±0.04b | 0.20±0.00a | 48.5±0.81b | 0.99 | |

| C | 1.34±0.02c | 0.16±0.01c | 35.4±1.14c | 0.99 | |

| D | 1.37±0.01c | 0.17±0.00b | 34.8±0.15c | 0.99 | |

Values are means±SD. Within each column, values with different letters (a~d) are significantly different (P<0.05).

SMS, sea mustard soup; DPS, dried pollock soup.

Significant differences were found for the flow rheological parameter (ηa,50 and K) values of the thickened soups with different food thickeners (P<0.05) (Table 1). The ηa,50 and K values of all thickened soups significantly increased in the presence of thickeners in the following order: thickener A> B> C> D. This indicates that the ηa,50 and K values in the thickened soup systems are strongly influenced by the type of thickener. In particular, the ηa,50 and K values of thickeners A and B were significantly higher compared to those of the other thickeners (P<0.05). The ηa,50 and K values of thickened DPS samples were higher when compared to the thickened SMS samples, indicating that the flow properties of thickened soups were also influenced by the type of soup. Such difference in flow properties of thickened soups can be due to the different gum compositions in the food thickeners and the different constituents of the soup that interact with the gums in the food thickener. It is also known that the composition of the dispersing medium can influence the flow behaviors of thickened fluids (10). In general, it is well known that thickened fluids are classified into several different “consistency” classes established by the National Dysphagia Diet Task Force (NDDTF). The classes are thin (1~50 mPa·s), nectar or syrup (51~350 mPa·s), honey or custard (351~1,750 mPa·s), and pudding or spoon-thick (>1,750 mPa·s). The ηa,50 values of the thickened SMS and DPS were in the range of 1,300~2,390 mPa·s and 1,340~2,530 mPa·s, respectively. Therefore, the ηa,50 values of all thickened soups were within two of NDDTF “consistency” classes [i.e., honey-like (351~1,750 mPa·s) and pudding-like (>1,750 mPa·s)]. In particular, thickeners A and B, which had much higher ηa,50 values (1,990~2,530 mPa·s) when compared to other thickeners, showed pudding-like consistencies of thickened soups at 3% thickener concentration. Therefore, it was found that the flow properties of thickened soups with XG-based thickeners were dependent on the type of thickener and soup.

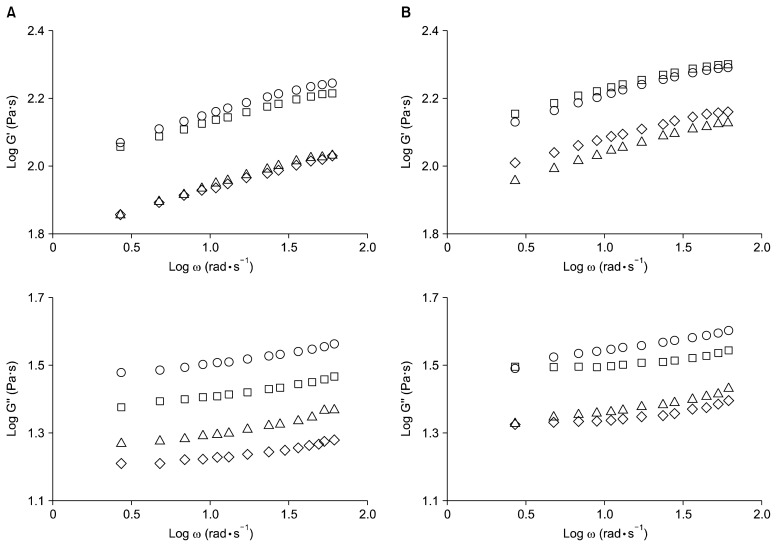

Viscoelastic properties have been proposed as potential relevant for swallowing a food bolus because thickened fluids cannot be adequately described only by a single viscosity value (14). In addition to ηa,50 and K, which are flow rheological parameters for the flow velocity of a food bolus, the dynamic rheological parameters, such as storage modulus (G′) and loss modulus (G″), can be crucial in safe and easy swallowing of bolus (15). Plots of frequency (ω) versus G′ and G″ for the hot soup samples including the different thickeners at a 3% concentration are presented in Fig. 2. The magnitudes of G′ and G″ increased with an increase in ω and G′ was much higher than G″ at all values of ω with frequency dependency, showing a weak gel-like behavior. In general, the thickened soup samples with thickeners A and B showed much higher G′ values than the other samples, indicating that the addition of thickeners A and B among the XG-based thickeners enhanced the elastic properties of thickened soup samples. The G′ and G″ values of thickened SMS and DPS samples significantly increased in the presence of thickeners in the following order: thickener A> B> C> D for G′ of SMS, B> A> D> C for G′ of DPS, and A> B> C> D for G″ of both SMS and DPS (Table 2). There was also a great difference in G′ and G″ values between thickeners B and D, even though they had the same composition (XG and dextrin). This indicates that hot thickened soups have different viscoelastic effects depending on the type of thickener and soup. From these observations, we found that the dependence of rheological parameters on the type of thickener and soup can provide valuable information for preparing hot thickened soup products for the elderly people with swallowing difficulty. In addition, these results can be useful in improving manufacturer’s guidelines specific to hot thickened soups for easy and safe swallowing.

Fig. 2.

Plots of log ω versus log (G′ and G″) for hot thickened soups prepared with different thickeners 60°C: (A) sea mustard soup (SMS), (B) dried pollock soup (DPS). ○, thickener A; □, thickener B; △, thickener C; ⋄, thickener D.

Table 2.

Storage modulus (G′) and loss modulus (G″) alues at 6.28 rad·s−1 of hot thickened soups prepared with different thickeners at 60°C (unit: Pa)

| Soup type | Thickener type | G′ | G″ |

|---|---|---|---|

| SMS | A | 150.0±0.62a1) | 33.87±0.40a |

| B | 125.7±1.45b | 24.13±0.51b | |

| C | 84.6±2.44c | 19.09±0.91c | |

| D | 82.3±0.59c | 16.23±0.27d | |

| DPS | A | 151.4±1.16b | 33.50±0.17a |

| B | 164.8±0.42a | 29.52±0.74b | |

| C | 102.5±2.17d | 21.75±0.46c | |

| D | 118.9±1.67c | 20.71±1.11c |

Values are means±SD. Within each column, values with different letters are significantly different (P<0.05).

SMS, sea mustard soup; DPS, dried pollock soup.

ACKNOWLEDGEMENTS

We thank Rheosfood Inc. for providing the free food thickener A (Visco-up) sample.

Footnotes

AUTHOR DISCLOSURE STATEMENT

The authors declare no conflict of interest.

REFERENCES

- 1.Smith CH, Jebson EM, Hanson B. Thickened fluids: investigation of users’ experiences and perceptions. Clin Nutr. 2014;33:171–174. doi: 10.1016/j.clnu.2013.10.012. [DOI] [PubMed] [Google Scholar]

- 2.Cho HM, Yoo B. Rheological characteristics of cold thickened beverages containing xanthan gum–based food thickeners used for dysphagia diets. J Acad Nutr Diet. 2015 doi: 10.1016/j.jand.2014.08.028. [DOI] [PubMed] [Google Scholar]

- 3.Taniguchi H, Tsukada T, Ootaki S, Yamada Y, Inoue M. Correspondence between food consistency and suprahyoid muscle activity, tongue pressure, and bolus transit times during the oropharyngeal phase of swallowing. J Appl Physiol. 2008;105:791–799. doi: 10.1152/japplphysiol.90485.2008. [DOI] [PubMed] [Google Scholar]

- 4.Bisch EM, Logemann JA, Rademaker AW, Kahrilas PJ, Lazarus CL. Pharyngeal effects of bolus volume, viscosity, and temperature in patients with dysphagia resulting from neurologic impairment and in normal subjects. J Speech Hear Res. 1994;37:1041–1049. doi: 10.1044/jshr.3705.1041. [DOI] [PubMed] [Google Scholar]

- 5.Korean Statistical Information Service. Statistics on the aged. Statistics Korea; Daejeon, Korea: 2014. [Google Scholar]

- 6.Garcia JM, Chambers E, 4th, Matta Z, Clark M. Viscosity measurements of nectar- and honey-thick liquids: product, liquid, and time comparisons. Dysphagia. 2005;20:325–335. doi: 10.1007/s00455-005-0034-9. [DOI] [PubMed] [Google Scholar]

- 7.Seo CW, Yoo B. Steady and dynamic shear rheological properties of gum-based food thickeners used for diet modification of patients with dysphagia: effect of concentration. Dysphagia. 2013;28:205–211. doi: 10.1007/s00455-012-9433-x. [DOI] [PubMed] [Google Scholar]

- 8.Sopade PA, Halley PJ, Cichero JAY, Ward LC. Rheological characterisation of food thickeners marketed in Australia in various media for the management of dysphagia. I: Water and cordial. J Food Eng. 2007;79:69–82. doi: 10.1016/j.jfoodeng.2006.01.045. [DOI] [Google Scholar]

- 9.Sopade PA, Halley PJ, Cichero JAY, Ward LC, Hui LS, Teo KH. Rheological characterisation of food thickeners marketed in Australia in various media for the management of dysphagia. II. Milk as a dispersing medium. J Food Eng. 2008;84:553–562. doi: 10.1016/j.jfoodeng.2007.06.024. [DOI] [Google Scholar]

- 10.Sopade PA, Halley PJ, Cichero JAY, Ward LC, Liu J, Varliveli S. Rheological characterization of food thickeners marketed in Australia in various media for the management of dysphagia. III. Fruit juice as a dispersing medium. J Food Eng. 2008;86:604–615. doi: 10.1016/j.jfoodeng.2007.11.013. [DOI] [Google Scholar]

- 11.Cho HM, Yoo W, Yoo B. Steady and dynamic rheological properties of thickened beverages used for dysphagia diets. Food Sci Biotechnol. 2012;21:1775–1779. doi: 10.1007/s10068-012-0237-4. [DOI] [Google Scholar]

- 12.Urlacher B, Noble O. In: Thickening and gelling agents for food. Imeson A, editor. Chapman & Hall; New York, NY, USA: 1997. pp. 284–311. [DOI] [Google Scholar]

- 13.Szczesniak AS, Farkas E. Objective characterization of the mouthfeel of gum solutions. J Food Sci. 1962;27:381–385. doi: 10.1111/j.1365-2621.1962.tb00112.x. [DOI] [Google Scholar]

- 14.Payne C, Methven L, Fairfield C, Bell A. Consistently inconsistent: commercially available starch-based dysphagia products. Dysphagia. 2011;26:27–33. doi: 10.1007/s00455-009-9263-7. [DOI] [PubMed] [Google Scholar]

- 15.Ishihara S, Nakauma M, Funami T, Odake S, Nishinari K. Swallowing profiles of food polysaccharide gels in relation to bolus rheology. Food Hydrocolloid. 2011;25:1016–1024. doi: 10.1016/j.foodhyd.2010.09.022. [DOI] [Google Scholar]