Abstract

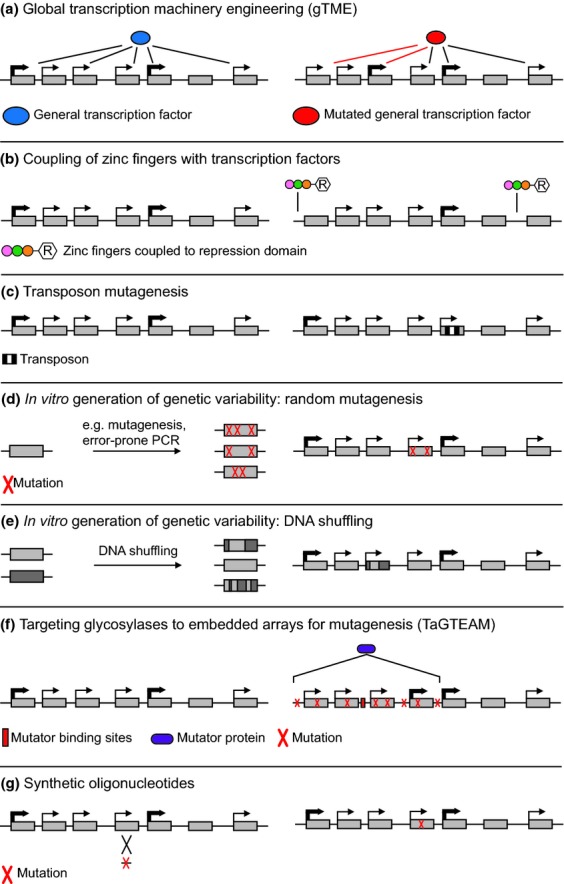

Yeasts have been used for thousands of years to make fermented foods and beverages, such as beer, wine, sake, and bread. However, the choice for a particular yeast strain or species for a specific industrial application is often based on historical, rather than scientific grounds. Moreover, new biotechnological yeast applications, such as the production of second-generation biofuels, confront yeast with environments and challenges that differ from those encountered in traditional food fermentations. Together, this implies that there are interesting opportunities to isolate or generate yeast variants that perform better than the currently used strains. Here, we discuss the different strategies of strain selection and improvement available for both conventional and nonconventional yeasts. Exploiting the existing natural diversity and using techniques such as mutagenesis, protoplast fusion, breeding, genome shuffling and directed evolution to generate artificial diversity, or the use of genetic modification strategies to alter traits in a more targeted way, have led to the selection of superior industrial yeasts. Furthermore, recent technological advances allowed the development of high-throughput techniques, such as ‘global transcription machinery engineering’ (gTME), to induce genetic variation, providing a new source of yeast genetic diversity.

Keywords: genetic engineering, metabolic engineering, Saccharomyces cerevisiae, GMO, non-Saccharomyces, evolutionary engineering

Introduction

Microorganisms, such as yeasts, bacteria, and algae, are key players in numerous industrial processes, ranging from the production of traditional fermented foods and beverages to recombinant proteins and other high-value molecules.

Many of these industrial processes rely heavily on the model yeast Saccharomyces cerevisiae. This yeast is traditionally used in the food industry for the production of alcoholic beverages, such as beer, wine, and sake, as well as for bread fermentation. More recently, S. cerevisiae has also been used in the bioethanol industry and for the production of heterologous compounds, such as human insulin, hepatitis vaccines, and human papillomavirus vaccines (Hou et al., 2012). Notwithstanding the fact that S. cerevisiae remains by far the most widely used industrial yeast species to date, other, so-called nonconventional yeasts, such as Scheffersomyces stipitis, Yarrowia lipolytica, Kluyveromyces lactis, and Dekkera bruxellensis, have also claimed their stake as valuable contributors to industrial fermentation processes.

Despite the intensive use of these and other yeasts in biotechnological applications and industrial fermentations, there is still significant room for improvement: industrial processes are rarely using the most suited or best-performing strain. This is because many industrial strains are currently used because of historical grounds, rather than being carefully selected for a specific application, and are therefore often suboptimal for their purposes. Additionally, demands for increased productivity, wider substrate range utilization, and production of nonconventional compounds in industry, as well as changing consumer preferences, lead to a great interest in further improving the currently used industrial strains and the selection or development of strains with novel properties.

This review aims to give a comprehensive overview of the different strategies that can be used to obtain strains with improved properties. The relevance and importance of these different techniques are illustrated with specific examples from the beer, wine, bread, and biofuel industry. Both the classical approaches of strain improvement and more recent techniques are discussed. In the first section, we discuss natural yeast diversity and the underlying genetic principles and also summarize how the existing natural diversity can be exploited to select strains with a suitable phenotype for a specific industrial application. In the second part, we show how this natural diversity can be further increased by artificially generating variants through mutagenesis, various hybridization methods, and/or directed evolution. Subsequently, the principles of genetic modification are explained, together with specific examples illustrating the applicability of this strategy to food-based fermentations and production of biofuels and high-value chemical compounds. In the final part, we outline several recent advances in genetic modification for the creation of phenotypic variation, illustrating how these cutting-edge techniques combine aspects of traditional technologies with genetic modification and how they could contribute to future improvement strategies for industrial yeasts. Although the major focus of this review is the improvement of the main fermentation workhorse S. cerevisiae and its close relatives, such as Saccharomyces pastorianus, we also highlight the advances that have been made with other, industrially relevant nonconventional yeasts.

Natural and artificial diversity

Introduction

There are multiple strategies developed that aim to provide suitable yeast strains for specific industrial goals. A deceivingly simple, yet very powerful way is to exploit the natural biodiversity by selecting a strain that performs best in a particular industrial process. Indeed, recent (meta)genomics studies indicate that the natural fungal biodiversity is enormous and largely unexplored, with the current industrial strains only representing a small fraction of the natural biodiversity (Liti et al., 2009; Wang et al., 2012b). This implies that nature possibly harbors multiple, as yet unknown species and strains that may prove superior for certain industrial fermentations. Even if many of these strains (for various reasons) turn out to be unsuitable for direct industrial implementation, they may possess certain industrially relevant characteristics. Specific strategies could allow transfer of these properties to industrial strains, thereby creating novel yeasts with extra beneficial features (Fig.1).

Figure 1.

Overview of strategies to obtain superior industrial yeast strains. In order to select novel yeast strains for industrial applications, several strategies can be applied. First, the existing natural diversity can be explored by genotyping and phenotyping isolated feral strains or strains from yeast collections to select the most interesting variants. Apart from investigating naturally occurring yeasts, diversity can also be generated artificially. There are multiple strategies to induce genetic diversity in a single strain or shuffle the genomes of multiple strains. Strains resulting from these strategies are all considered non-genetically modified yeasts, implying that they can be freely used in industrial fermentations. These strategies will be further discussed in the section on ‘Generation of artificial diversity’. Lastly, strategies based on genetic engineering, where a recombinant piece of DNA is transformed in a target strain to confer a specific, industrially relevant phenotype to this strain, can be very efficient. However, this technique genetically modifies yeasts, currently limiting their use in food or beverage fermentations because of consumer concerns.

In addition to exploring naturally occurring yeast variants, several techniques allow researchers to further increase the diversity of yeasts by artificially generating variants, starting from feral or industrial strains. The applicability of these techniques depends on both the targeted phenotype and genetic background. The targeted phenotype is sometimes limited by its selectability (cf. infra), while the complex or understudied genetic background of certain yeasts can sometimes hamper their use in improvement strategies. For example, many industrial S. cerevisiae strains have a much more complex genetic architecture compared to laboratory strains, the latter being carefully bred and selected for sexual reproduction, optimal growth, and easy handling in the laboratory (e.g. no flocculation) (Mortimer & Johnston, 1986), while industrial strains often show aneuploidy and/or polyploidy, poor sporulation efficiency, unstable mating types, etc. Moreover, recent full-genome sequencing and large-scale phenotyping experiments underscore that these ‘tamed’ laboratory strains are not representative for the majority of industrial strains (Liti et al., 2009; Borneman et al., 2011; Warringer et al., 2011). Together, this implies that although most fundamental studies were performed on easy-to-use laboratory strains, such as S288c or EM93, many of these results cannot be simply extrapolated to industrial strains. Therefore, we also address the potential problems accompanying improvement strategies for genetically complex or understudied yeast strains and species. While this section only focuses on so-called non-genetically modified organisms (non-GMO) techniques to create artificial diversity, the last section will further discuss techniques based on recombinant DNA technologies, such as metabolic engineering and synthetic biology, which generate genetically modified (GM) yeasts.

Before we address examples of how natural or artificially generated diversity can provide industrially relevant strains, we first summarize the genetic mechanisms driving the genetic diversity in yeast. Next, different strategies to yield improved yeast strains are described, pros and cons are discussed, and the challenges associated with the selection of optimal strains are given.

Origins of yeast diversity

Yeasts represent a very diverse group of organisms, and even strains that are classified as the same species often show a high level of genetic divergence. The natural diversity of yeasts (between and even within species) has become very clear with the advent of next-generation sequencing technologies that enable in-depth characterization of the genetic variation (Dujon et al., 2004; Liti et al., 2009; Borneman et al., 2011; Wang et al., 2012b; Borneman et al., 2013; see section on ‘Natural yeast diversity and how it can be exploited in industry’).

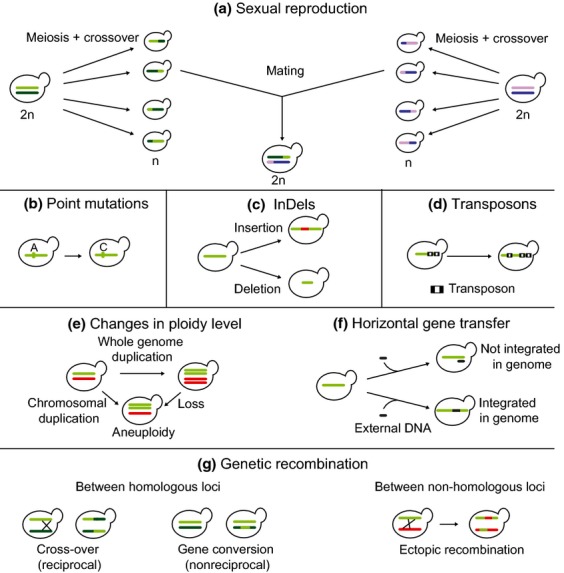

Genetic variability can be generated by several different processes, including sexual reproduction (where the genomes of two parents are mixed and shuffled), changes in the DNA sequence such as point mutations (i.e. changes in single nucleotides), and InDels (i.e. insertion or deletion events of relatively short pieces of DNA), changes in ploidy level (where a whole genome, or large parts, is duplicated or lost), transposons (mobile genetic elements that can cause mutations by insertion in the genome), genetic recombination (where parts of the genome are re-organized; it can act on both homologous and nonhomologous loci), or acquisition of exogenic pieces of DNA by horizontal gene transfer (HGT) (Fig.2). Whereas each of these processes described above has been shown to occur in nature and therefore contribute to genetic diversity, the phenotypic outcome and importance of each of these processes is hard to estimate and often also depends on the exact environmental conditions.

Figure 2.

Origins of genetic variation in yeast. Genetic variation can be caused by several different mechanisms. For sake of simplicity, only one chromosome per yeast cell is displayed (green or purple). Different color shades represent homologous chromosomes. In (e), a second chromosome is represented in red. (a) Sexual reproduction: after sporulation and concomitant meiotic cross-over events in the parental strains (2n), genomes of two haploid (n) segregants can hybridize, a process called mating. (b) Point mutations: changes in single nucleotides. These mutations can be synonymous or nonsynonymous: synonymous mutations do not change the amino acid sequence, while nonsynonymous mutations do. Nonsynonymous mutations are therefore more likely to alter the phenotype. (c) InDels: insertion and deletion events of relatively short pieces of DNA. (d) Transposons: insertion of transposable elements in the genome. (e) Changes in ploidy level: the whole genome, or large parts, is duplicated or lost, which can result in poly- or aneuploidies. (f) Horizontal gene transfer: transfer of genes by means other than regular sexual reproduction. (g) Genetic recombination: reorganization of parts of the genome. It can act on both homologous (cross-over and gene conversion) and nonhomologous loci (ectopic recombination). Homologous recombination such as gene conversion (nonreciprocal transfer of genetic material between highly homologous genes) occurs relatively frequently and can sometimes give rise to novel or modified traits. Ectopic recombination events such as TY-promoted chromosomal translocations are more rare, but can drastically rearrange the genome, and even generate novel genes.

Sexual recombination is the single most important process that generates genetic diversity in higher eukaryotes such as animals and plants. Similarly, in yeasts with a sexual life cycle, such as Saccharomyces spp., sexual reproduction can reshuffle the genomes of different yeast strains, thereby altering their characteristics, and potentially even lead to the evolution of new species. Although sexual recombination is mostly thought of as a ‘natural’ process, mating also occurs between strains or species in industrial settings. A notable example is S. pastorianus, an interspecific hybrid of S. cerevisiae and Saccharomyces eubayanus, which may have originated in the fermentation tank of lager breweries (Libkind et al., 2011). The added advantage of cryotolerance (typical for S. eubayanus) may have led to its observed ability to carry out fermentations better at low temperatures than S. cerevisiae alone (Dunn & Sherlock, 2008).

In contrast to higher eukaryotes, yeasts such as Saccharomyces spp. also have the ability to reproduce asexually. Moreover, this vegetative asexual proliferation is a much more prevalent way of reproduction, with on average only one meiotic cycle for every 1000 mitotic divisions (Ruderfer et al., 2006; Tsai et al., 2008; Zörgö et al., 2012). During these asexual reproductive cycles, spontaneous mutations, such as point mutations, InDels, transposon insertions, and recombination events, can occur. The rate at which spontaneous mutations occur varies across the yeast genome, but has been estimated to be around 3.80 × 10−10 and 6.44 × 10−10/(bp × generation) when measured at two specific loci that allowed for phenotypic detection of mutations (Lang & Murray, 2008). However, spontaneous mutations occur much more frequently in so-called mutation hotspots such as subtelomeric regions and tandem repeats (Ellegren, 2004; Brown et al., 2010; Gemayel et al., 2010; Christiaens et al., 2012), where the mutation rates are often 10–100 000 times higher than average mutation rates in other parts of the genome (Gemayel et al., 2010). One particular category of spontaneous mutations which occurs often in these hotspots is genetic recombination. An interesting example of a gene family that is extremely prone to spontaneous mutations, because they are located subtelomerically and additionally contain tandem repeats, are the genes encoding flocculins (FLO genes). These flocculins are responsible for ‘flocculation’ of yeast cells, a trait of major importance in the wine, beer, and biofuel industry. The instability of the tandem repeats in these genes, which are causing expansion and contraction in the gene size, has allowed for the fast isolation of spontaneous mutants with altered flocculation characteristics (Hammond, 1996; Verstrepen et al., 2005; Ma et al., 2009). Additionally, the available arsenal of flocculins in Saccharomyces yeasts is hugely increased by the generation of chimeric FLO genes by ectopic recombination, which resulted in a huge diversity in the flocculation phenotype of industrial strains (Christiaens et al., 2012).

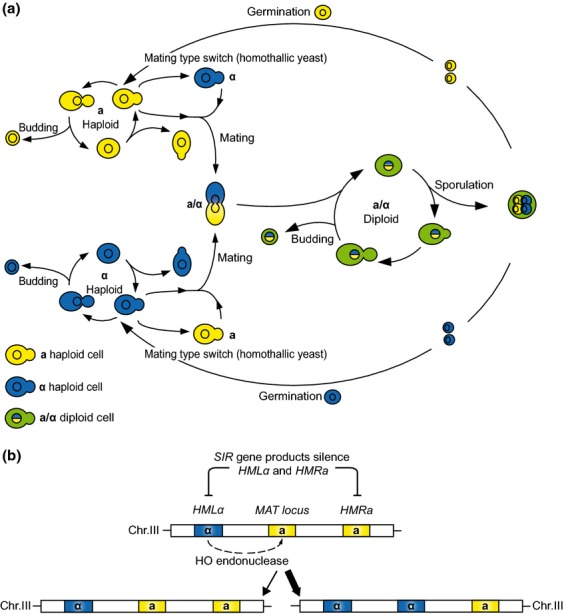

Although spontaneous mutations are one of the main driving forces behind evolution and enable organisms to adapt to specific ecological niches, most mutations are neutral or even deleterious (Drake, 1991). Most yeast species (including S. cerevisiae) generally exist in a diploid stage, which can mask the effect of (heterozygous) deleterious mutations. This can cause these mutations to accumulate during continuous asexual growth, leading to strains with a high mutational load. However, because of its complex sexual life cycle, yeast can filter out these deleterious mutations by a process called ‘genome renewal’ (Mortimer et al., 1994; Mortimer, 2000; Wang et al., 2012b). In essence, genome renewal results in the elimination of cells carrying deleterious recessive mutations from the population, while generating homozygous diploid cells in which these mutations are not present. Genome renewal is mainly described for indigenous Saccharomyces wine yeasts, which often show a high sporulation capacity and are homothallic (see Fig.3), two important prerequisites for genome renewal. Asexually growing cells (with a potentially high mutational load) will undergo meiosis and sporulate. After germinating, viable haploids will start reproducing asexually, and subsequently, mating can occur between neighboring ‘sister’ cells of the opposite mating type (a process called haplo-selfing), yielding a homozygous diploid inbred cell. In this way, the haploid stage filters out lethal recessive mutations and the subsequent haplo-selfing enables recessive, heterozygous mutations to become homozygous and thus influence the phenotype. Intratetrad mating (automixis) after sporulation will have the same effect (Katz Ezov et al., 2010). Together, this can improve cellular fitness and adaptability to the environment (Pretorius, 2000).

Figure 3.

Life cycle of S. cerevisiae. Yeast cells can exist in both a haploid and diploid state. (a) Diploid cells are heterozygous for the mating type locus (mating type a/α), which makes diploids incapable of mating. Haploid cells have either mating type a or mating type α, making them capable of mating with a cell of the opposite mating type. In nutrient-rich conditions, both haploid and diploid cells can proliferate asexually by budding. When exposed to some nutrient-poor conditions, diploids can undergo sporulation (meiosis followed by spore formation), resulting in the conversion of a diploid cell into four haploid spores, two possessing mating type a and two having mating type α, which can germinate into haploid cells when conditions improve. In homothallic strains, the haploid derivatives can undergo a mating type switch (together with the mother cell), mediated by an endonuclease encoded by the HO gene. In this way, a mating type-switched cell can mate with neighboring sister cells of the opposite mating type, resulting in a homozygous (except for the MAT locus, which determines the mating type) diploid. In heterothallic strains, the HO gene is typically inactive and therefore haploid derivatives cannot switch mating type. (b) Mechanism of the mating type switch of homothallic strains. On chromosome III, the MAT locus is flanked by Hidden MAT Left and Right (HML and HMR, respectively), carrying a silenced copy of MATα and MATa, respectively. Homothallic strains contain the HO gene, a gene coding for an endonuclease that cleaves DNA specifically at the MAT locus. After breakdown of the MAT locus by exonucleases, a gene conversion event occurs, where HML or HMR is used as a template to repair the DNA strand. Because cells prefer to change their mating type, that is, a MATα cell will rather use HMR as a template and vice versa, mating-type switch occurs frequently.

In addition to sexual recombination and spontaneous mutations, the transfer of genetic material through asexual mechanisms, called horizontal gene transfer (HGT), can contribute to genetic diversity. HGT is rare in yeast, and the mechanisms underlying HGT are not yet elucidated, but natural transformation and conjugation have been proposed (Hall et al., 2005). An interesting example of how HGT altered industrially relevant phenotypes in yeast is described for the commonly used wine strain EC1118. Genetic analysis of EC1118 showed strong evidence for the HGT of three DNA regions, encompassing 34 genes involved in key wine fermentation functions (Novo et al., 2009). For example, FSY1, a gene coding for a high-affinity fructose/H+ symporter present in one of the regions, could confer a significant advantage during the wine fermentation process by enabling the yeast to efficiently utilize left-over fructose at the end of the fermentation (Galeote et al., 2010). Interestingly, two of these regions were acquired from non-Saccharomyces species, and Zygosaccharomyces bailii, a typical contaminant of wine fermentations, was identified as the donor of one region; indicating that HGT in yeast can cross genus boundaries.

Lastly, changes in ploidy level also occur and can have profound phenotypic effects. This is best described for the Saccharomyces lineage, which has undergone a whole-genome duplication (WGD) event about 100 million years ago. The most important consequences of this WGD are that an extra copy of the genome allowed a global rewiring of the yeast transcriptional network and gave the duplicated genes a chance to mutate and gain new or adapted functions compared to the original genes (reviewed by Piskur et al., 2006). Additionally, duplication of single genes pre- or post-WGD, such as the duplication of the alcohol dehydrogenase (ADH) gene approx. 80 million years ago, also contributed to the success of Saccharomyces species in the fermentation industry. In the case of ADH, reconstruction of the ancestral gene revealed that the encoding enzyme had a preference to convert acetaldehyde to ethanol and was therefore involved in the generation, and not the consumption, of ethanol (Thomson et al., 2005). Spontaneous duplication of this ancestral gene generated the genes encoding the Adh1 and Adh2 enzymes. These present-day enzymes show a different kinetic behavior, with Adh2 binding ethanol (its substrate) more strongly than Adh1. Duplication of the ancestral ADH gene as well as duplication of several other genes involved in ethanol metabolism, combined with the ability of Saccharomyces spp. to ferment glucose and accumulate ethanol even in the presence of oxygen (a phenomenon known as the Crabtree effect), resulted in the so-called make-accumulate-consume strategy of ethanol production, giving them a competitive advantage over other microorganisms during fermentation processes (Piskur et al., 2006).

Natural yeast diversity and how it can be exploited in industry

Although the basic principles underlying genetic variation are known (cf. supra), the extent of genetic biodiversity in Saccharomyces strains has only recently been elucidated. Two recent seminal papers provided a first comprehensive overview of the genetic architecture of feral (wild) and industrial Saccharomyces strains (Liti et al., 2009; Schacherer et al., 2009). Interestingly, genetic diversity within Saccharomyces paradoxus, a widespread feral species closely related to S. cerevisiae, can almost completely be explained by geographical origin. However, diversity within S. cerevisiae, the main yeast associated with human activity, was at least partly linked to its industrial application (Legras et al., 2007; Dunn & Sherlock, 2008; Liti et al., 2009; Schacherer et al., 2009).

Additionally, despite that it was generally believed that S. cerevisiae was a domesticated species with no truly natural strains existing, it was recently shown that diverged populations of wild S. cerevisiae exist independently of domesticated isolates (Fay & Benavides, 2005; Liti et al., 2009; Sicard & Legras, 2011; Wang et al., 2012b). Moreover, genetic analysis of these feral and industrial strains revealed that the genetic diversity within industrial strains is rather limited compared to the full spectrum of natural biodiversity. For example, while the nucleotide diversity (π, the average number of nucleotide differences per site between any two DNA sequences chosen randomly from the sample population) was calculated to be 0.56 × 10−3 in 14 representative wine yeasts, a more elaborate analysis of 138 strains, including both industrial and feral strains, revealed a sequence diversity that was more than one order of magnitude larger (7.27 × 10−3) (Wang et al., 2012b). It is important to note that this is truly remarkable, because the nucleotide diversity within Homo sapiens is estimated to be ‘only’ 1 × 10−3 (Jorde & Wooding, 2004). Furthermore, even the genetic diversity within geographically isolated feral S. cerevisiae populations can be substantial, illustrated by the fact that isolates from the primeval rainforests in Hainan, a tropical island in southern China, exhibited a magnitude of genetic diversity equivalent to the diversity of the complete human population (Wang et al., 2012b). Together, these observations suggest that the fermentation industry currently relies on only a very small fraction of the available genetic diversity of S. cerevisiae, ignoring a huge pool of unexplored (feral) strains. Although currently used strains have adapted well to the fermentation environment, this largely uncharted yeast pool might contain strains with characteristics potentially valuable for industrial applications.

To exploit this huge natural diversity, several teams have screened diverse feral yeast collections for industrially relevant traits (e.g. Pellegrini et al., 1999; Comitini et al., 2011). Additionally, isolation and analysis of feral or even contaminating yeast strains from niches similar (or identical) to a specific fermentation environment can yield interesting strains for starter cultures. Indeed, continuous evolution and adaptation of indigenous yeast strains to their environment have equipped these strains with phenotypes valuable for industry. For example, several research papers have described the isolation, selection, and incorporation of indigenous wine yeasts as starter cultures in the production of wine (Zagorc et al., 2001; Mannazzu et al., 2002; Lopes et al., 2007; Tosi et al., 2009; Capece et al., 2010; de Ullivarri et al., 2011; Scacco et al., 2012; Tristezza et al., 2012). Similarly, the application of indigenous yeast strains revolutionized the biofuel industry, where the initially used baker's strains were replaced by ‘contaminating’ strains, which were well adapted to the harsh fermentation environment (Basso et al., 1993, 2008; da Silva-Filho et al., 2005). Moreover, two recently isolated S. cerevisiae strains are now responsible for up to 70% of the total Brazilian biofuel production (Basso et al., 2008; Della-Bianca et al., 2012). Likewise, the identification of Dekkera bruxellensis as a contaminating yeast in a Swedish bioethanol production site has raised interest in applying this species as a starter culture, because this strain did not show a compromised fermentation efficiency and exhibited a more energy-efficient metabolism under oxygen limitation than the initially applied S. cerevisiae starter culture (Passoth et al., 2007; Blomqvist et al., 2010).

Generation of artificial diversity

Despite the immense wealth of natural yeast diversity, the extremely selective and specific conditions of industrial fermentations sometimes require (a combination of) phenotypic traits that might not be commonly encountered in nature. While the physiological behavior of feral yeasts is exclusively dedicated to survival and reproduction, most industrial fermentations require maximization of processes and characteristics that may not be beneficial in natural environments. Several techniques have therefore been developed to artificially increase the existing yeast diversity and generate variants that may perform better in industrial settings than the strains that are selected in natural environments.

Perhaps the most intuitive way to generate artificial diversity in yeasts is by (human-driven) sexual hybridization (also known as crossing or mating; Tables1 and S1). This practice is very similar to the common ‘selective breeding’ (or ‘artificial selection’) encountered in, for example, agriculture. This technique has been used by humans for thousands of years, for example by farmers who intuitively chose superior plants from their cultivations or animals from their stock to crossbreed in order to obtain crops or livestock with desired traits (Chambers et al., 2009; Steensels et al., 2012). Similarly, the close association of S. cerevisiae with human activities has led to the so-called domestication of this species, resulting in an organism that excels in its industrial task, but performs suboptimal in most other, more ‘natural’ environments (Fay & Benavides, 2005; Liti et al., 2009; Sicard & Legras, 2011). Moreover, human selection may even have given rise to new chimeric species in the Saccharomyces sensu stricto complex in industrial environments, such as the lager yeast S. pastorianus (Libkind et al., 2011). Although these processes occurred naturally (brewers, winemakers, or other craftsmen did not intentionally breed novel yeast strains), recent technological advances and the rapidly increasing knowledge about yeast physiology (e.g. the description of its sexual life cycle) paved the way for more targeted and large-scale approaches of yeast breeding, even beyond species barriers. This targeted breeding of yeast strains can now be used to create novel strains that combine different characteristics of the selected parents, or to optimize a single, often complex, trait, by crossing parents selected for the same phenotype. Using the latter approach, traits can theoretically be improved even beyond the phenotypic boundaries of the parental strains, a phenomenon called heterosis, or hybrid vigor (Lippman & Zamir, 2007). This phenomenon is occasionally encountered for certain traits in breeding experiments (Marullo et al., 2006; Timberlake et al., 2011), but the incidence is generally low (Zörgö et al., 2012). Later in this section, four approaches for strain improvement using sexual hybridization approaches will be discussed: direct mating, rare mating, mass mating, and genome shuffling.

Table 1.

Several key studies using hybridization techniques for the improvement of industrial yeasts. The phenotypes of interest from both parental strains are indicated. For a more extensive list, see Table S1

| Parental strain 1 | Parental strain 2 | Hybridization technique | Industrial application | References | |

|---|---|---|---|---|---|

| Intraspecific hybridization | |||||

| S. cerevisiae | x | S. cerevisiae | Protoplast fusion | Biofuel | Javadekar et al. (1995) |

| Fermentation performance | Flocculation | ||||

| S. cerevisiae | x | S. cerevisiae | Cytoduction | Beer | Hammond & Eckersley (1984) |

| Fermentation performance | Killer phenotype | ||||

| S. cerevisiae | x | S. cerevisiae | Rare mating | Bread | Oda & Ouchi (1990) |

| Fermentation performance | Fermentation performance | ||||

| S. cerevisiae | x | S. cerevisiae | Spore-to-cell mating | Biofuel | Benjaphokee et al. (2012) |

| Temperature tolerance | Ethanol tolerance | ||||

| Interspecific hybridization | |||||

| S. cerevisiae | x | S. cerevisiae (var. diastaticus) | Rare mating | Beer | Tubb et al. (1981) |

| Fermentation performance | Dextrin degradation | ||||

| S. cerevisiae | x | S. mikitae/S. paradoxus/S. kudriavzevii | Rare mating | Wine | Bellon et al. (2011, 2013) |

| Fermentation performance | Flavor profile | ||||

| S. cerevisiae | x | S. bayanus | Protoplast fusion | Biofuel | Choi et al. (2010) |

| Ethanol tolerance | Flocculation | ||||

| S. cerevisiae Fermentation performance | x | S. kudravzevii Low temperature | Spore-to-spore/rare mating/protoplast;fusion | Wine | Perez-Traves et al. (2012) |

| S. cerevisiae | x | S. bayanus | Spore-to-spore mating | Wine | Coloretti et al. (2006) |

| Flocculation | Fermentation performance | ||||

| Intergeneric hybridization | |||||

| S. cerevisiae | x | K. lactis | Protoplast fusion | Biofuel | Taya et al. (1984) |

| Fermentation performance | Lactose utilization | ||||

| S. cerevisiae Fermentation performance/ethanol tolerance | x | Sc. stipitis Xylose utilization | Protoplast fusion and genome shuffling | Biofuel | Zhang & Geng (2012) |

| S. cerevisiae | x | T. delbrueckii | Protoplast fusion | Polyol production/bakery | Lucca et al. (1999, 2002) |

| Fermentation performance | Osmotolerance | ||||

| S. cerevisiae | x | Sc. pombe | Protoplast fusion | Wine | Carrau et al. (1994) |

| Fermentation performance | Malic acid degradation | ||||

| S. cerevisiae (var. diastaticus) | x | Z. rouxii | Protoplast fusion | Bakery | Spencer et al. (1985) |

| Fermentation performance | Osmotolerance | ||||

K. lactis, Kluyveromyces lactis; S. bayanus, Saccharomyces bayanus; S. cerevisiae, Saccharomyces cerevisiae; S. cerevisiae (var. diastaticus), Saccharomyces cerevisiae (var. diastaticus); S. kudravzevii, Saccharomyces kudravzevii; S. mikitae, Saccharomyces mikitae; S. paradoxus, Saccharomyces paradoxus; Sc. pombe, Schizosaccharomyces pombe; Sc. stipitis, Scheffersomyces stipitis; T. delbrueckii, Torulaspora delbrueckii; Z. rouxii, Zygosaccharomyces rouxii.

However, because many industrial strains are, in contrary to most laboratory strains, polyploid or aneuploid and display a low sporulation efficiency and/or low spore viability (Mortimer et al., 1994; Codon et al., 1995), strain improvement by sexual hybridization is not always possible. Still, the unique features of yeast (such as its exceptional life cycle that combines sexual and asexual replication strategies (Fig.3) and their short generation time) facilitate several other strain improvement strategies. For example, a hybridization technique referred to as protoplast (or spheroplast) fusion was designed to hybridize cells asexually, thereby fully precluding the need for sporulation capacity of and sexual compatibility between both parental strains. Additionally, the transfer of non-Mendelian traits, caused by cytoplasmic factors such as dsRNA virus-like particles or prions, without compromising the genome structure of the parental cells, can be accomplished by cytoduction. These techniques, all aiming to combine traits from two parental strains by hybridization, are summarized in Fig.4. Other techniques, such as mutagenesis and directed evolution, use the asexual reproductive cycle of yeast and fully rely on random genetic mutations and strict selection procedures to isolate phenotypically improved variants. This section provides a comprehensive overview of all these techniques, which do not rely on recombinant DNA technology and for which resulting strains are thus considered non-GMO, and discusses their practical applicability, advantages, and limitations. Additionally, specific examples indicating how industrial fermentation processes have benefited from the resulting improved strains are given.

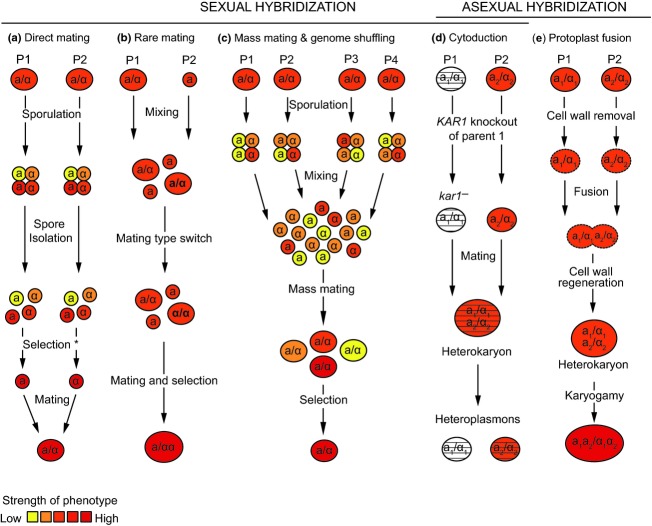

Figure 4.

Overview of different strain improvement techniques using hybridization. Sexual and asexual hybridization is a powerful technique to generate artificial diversity in yeast. Due to the sometimes complex genetics (ploidy, sporulation, …) of yeast, different techniques have been developed. Most techniques start from two parental (P) strains, selected for the target phenotype. The color scheme indicates the strength of the phenotype, for example red = strong ethanol tolerance, yellow = weak ethanol tolerance. In these examples, the parental strains are selected for the same phenotype, but combining different phenotypes of both parents is also possible. (a) In direct mating, two haploid cells or spores of opposite mating types are crossed. When the parental strains are both heterothallic, these haploids can be prescreened and selected, and cell-to-cell mating can be applied. When both or one of the parental strains is homothallic, spore-to-spore or spore-to-cell mating, respectively, can be used. In these latter cases, the selection step (indicated with *) cannot be applied. (b) In rare mating, strains are crossed without a sporulation step. This is possible because diploid yeasts occasionally (but rarely) undergo a homothallic mating-type switch, yielding an a/a or α/α diploid cell. These cells can subsequently hybridize with a haploid cell of the opposite mating type. It is important to note that rare mating is not limited to the development of triploid yeasts. For example, tetraploid hybrids can be obtained if P2 would be an a/a type yeast. (c) In mass mating, multiple parental strains, or a heterogeneous population of the same parental strain, can be used. After mass sporulation and mixing of the resulting spores, mass mating will occur. These rounds of mass sporulation and mass mating can be repeated multiple times, a process which is one way to perform so-called genome shuffling. In genome shuffling, the mass sporulation and mass mating steps can also be replaced by protoplast fusion. (d) Cytoduction can be used to transfer cytoplasmically inherited traits. First, the KAR1 gene of the parental strain containing the targeted cytoplasmic trait is deleted. Next, both parental strains are crossed (or fused by protoplast fusion), but because karyogamy is blocked, the heterokaryon segregates into cells containing a nucleus of only one parent but the cytoplasmic components of both parents (=heteroplasmons). With proper selection, this technique can also yield so-called disomic strains that contain the full chromosome complement of one parent plus one chromosome from the other parent. (e) In protoplast fusion, cells are asexually merged after cell wall removal in osmotically supportive medium. After cell wall regeneration, the formed transient heterokaryons may undergo karyogamy and form hybrids.

Direct mating

Direct mating is the most intuitive way of breeding organisms. Similar to selective breeding in agriculture, it consists of the crossing of two carefully selected parents possessing an interesting phenotype. In case of yeast strains, three distinct approaches exist: cell-to-cell, spore-to-cell, and spore-to-spore mating. The applicability of these approaches depends on the sexual cycle of the parental strains.

If both parental strains are heterothallic (Fig.3b), a prescreening of the stable vegetative haploid segregants of both parents can be carried out, after which the best haploid segregants can be selected for the hybridization experiment. This technique dates back to 1943, when it was described in a seminal paper by Lindegren & Lindegren (1943), and is now called ‘cell-to-cell’ mating. By simply mixing cell cultures of the two selected stable haploid parents and subsequent screening for diploid cells, hybrids can be isolated. The major advantage of cell-to-cell over mass and spore-to-spore mating (cf. infra) is that both haploid parents can be fully phenotyped prior to the breeding experiment (Lindegren, 1949), which increases the chance of yielding a superior hybrid. Additionally, no inbreeding can occur, because no cells of the opposite mating type from the same parental strain are present in the same experiment. Furthermore, the same parent can be used many times in a variety of different mating experiments and can theoretically be preserved indefinitely (Lindegren, 1949). Although there are some clear advantages to this approach, it is not used regularly to develop novel yeast hybrids. This is mainly due to the homothallic nature of most industrial and feral yeast strains, making them unsuited for this approach. However, it was recently described that several feral strains show a stable haploid mating type, due to a mutation in the HO endonuclease gene, a gene responsible for mating-type switching (Katz Ezov et al., 2010), making these strains fit for cell-to-cell mating experiments. In principle, also homothallic strains would be amenable to this approach after genetically disrupting the HO endonuclease gene (van Zyl et al., 1993; Walker et al., 2005; Blasco et al., 2011; Fig.3). However, this requires a genetic transformation, which implies that the resulting hybrid is classified as a GMO and is therefore subject to the GMO legislation. In addition, due to the heterozygous nature of many industrial strains, for some complex phenotypes that are difficult to measure, it can be laborious to identify a haploid descendant that exactly recapitulates the parental phenotype.

When one (‘spore-to-cell’ mating) or both (‘spore-to-spore’ mating) parental strains are homothallic, no stable haploid segregants can be obtained, and the additional prescreening step is not feasible. However, direct mating is still possible by placing two single spores of the strains to be hybridized close to one another on an agar surface, monitoring the hybridization event by microscopy, and isolating the developed zygotes (which can be formed if the spores are of the opposite mating type) using a micromanipulator. This approach is preferred when both parental strains are homothallic or when the hybridization efficiency of the two parental strains (outcrossing) is low compared to the hybridization efficiency of cells of the same parent (inbreeding) and no suitable hybrid selection markers are available to specifically isolate outbreds. The latter is, for example, the case in some interspecific crossing experiments, where the (however weak) pre- and postzygotic barriers (such as differences in germination timing or mating preferences) favor inbreeding (Maclean & Greig, 2008; Morales & Dujon, 2012; Murphy & Zeyl, 2012). In this case, spore-to-spore mating (instead of, e.g., mass mating) can be used to promote outcrossing. A major disadvantage of spore-to-spore compared to cell-to-cell mating is that the spores used in the experiment cannot be characterized prior to the mating and therefore might not display the desired phenotype of the parental strain, due to the segregation of causative alleles (Attfield & Bell, 2003). An additional step that can increase the frequency of developing hybrids with the desired phenotype is a phenotypic prescreening of the self-mated homozygous diploids formed after sporulation and tetrad dissection of the homothallic parental strains (Romano et al., 1985; Marullo et al., 2009), or use of a well-designed backcrossing scheme (Marullo et al., 2009).

Although time-consuming, direct mating has proven to be an effective way to obtain hybrids (Sipiczki, 2008); spore-to-spore and spore-to-cell mating are applied regularly to create novel, mainly interspecific hybrids for the fermentation industry (Table1). It has been used successfully to generate wine yeasts with improved cryotolerance, by crossing S. cerevisiae with cryotolerant species such as S. kudriavzevii or S. bayanus (Kishimoto, 1994; Zambonelli et al., 1997; Perez-Traves et al., 2012), or to introduce flocculation in a yeast strain for the production of sparkling wines (Coloretti et al., 2006). Recently, spore-to-cell mating was applied to develop thermotolerant (Marullo et al., 2009) and multistress-tolerant S. cerevisiae strains (Benjaphokee et al., 2012). Also, novel hybrids with improved characteristics developed by cell-to-cell mating have been reported. Hara et al. (1981) used this approach to construct cryotolerant wine yeasts able to produce killer toxins. Russell et al. (1983) described the use of cell-to-cell mating to eliminate the unwanted ‘phenolic off-flavor’ phenotype from brewer's yeast. This approach was also used to construct wine, bread, and beer yeasts with optimal fermentation characteristics (Gjermansen & Sigsgaard, 1981; Eschenbruch et al., 1982; Nakagawa & Ouchi, 1994; Marullo et al., 2006). More recently, it was used to combine specific phenotypes of ale and lager yeasts in order to improve stress resistance and fermentation performance (Garcia Sanchez et al., 2012).

Rare mating

As mentioned above, many natural and industrial yeasts show low sporulation efficiencies and/or low spore viability, hampering their use in direct mating (or mass mating, cf. infra) experiments. In these cases, rare mating can offer a way to obtain hybrids. Rare mating is based on the rare event that some cells in a diploid population can become homozygous for the mating-type locus (resulting in an a/a or α/α cell) and can subsequently be ‘force-mated’ with a cell of the opposite mating type (Gunge & Nakatomi, 1972), see also Figs3 and 4. Typically, in a rare mating experiment, dense cell suspensions of the parental strains are mixed, and subsequently outcrossed hybrids are isolated using a strong selection step. This selection is often achieved by using a respiratory-deficient and an auxotrophic parental strain, making rare hybrids easily selectable by their prototrophy and respiratory proficiency (Pretorius, 2000; Hammond, 2003; see ‘Selection of outcrossed hybrids’).

Although the frequencies of the mating-type switch and subsequent mating are usually very low (Gunge & Nakatomi, 1972; Hammond, 2003), rare mating has been used to study interspecific hybridization events (de Barros Lopes et al., 2002) as well as for the improvement of multiple yeast traits. Saccharomyces cerevisiae and S. cerevisiae (var. diastaticus) were crossed to develop yeasts able to ferment dextrins (low molecular weight carbohydrates, produced by the hydrolysis of starch) in order to produce low-calorie beers (Tubb et al., 1981). It has also been applied to construct cryotolerant wine yeasts (Perez-Traves et al., 2012), dextrin-fermenting and high ethanol-producing yeasts (Kim & Kim, 1996), and yeasts with higher leavening ability in dough fermentations (Oda & Ouchi, 1990). Recently, Bellon and coworkers used rare mating to construct triploid interspecific hybrids of S. cerevisiae and other Saccharomyces sensu stricto species (like Saccharomyces mikatae) to diversify the flavor profile of wines (Bellon et al., 2011, 2013).

Mass mating and genome shuffling

Because yeasts are such small organisms with short life cycles, it is possible to cultivate billions of individual cells and generate many crosses quickly and to execute consecutive rounds of crossing. These more evolved techniques, often referred to as ‘mass mating’ or ‘genome shuffling’, can significantly increase the throughput and thus success rate of the experiment. Mass mating is a technique in which large numbers of haploid yeast cells, often from different parental strains are mixed and allowed to randomly mate. Mass mating is a particularly useful improvement technique for homothallic strains, for strains that show low mating efficiency, or for the creation of interspecific hybrids if strong selective markers for outbreds are available (Kunicka-Styczynska & Rajkowska, 2011).

Mass mating has been used to generate industrial strains with improved characteristics. For instance, Higgins and coworkers used mass mating and selection to combine different properties of two types of bakery strains, namely high osmotolerance, which is typical for strains used in sweet dough, and good maltose utilization, a characteristic of strains used in unsugared dough. First, haploid segregants of seven industrial strains used in sweetened dough were mass-mated followed by selection for osmotolerance, and this procedure was repeated several times. Second, three strains used for unsugared dough fermentations were subjected to repeated cycles of mass mating and selection for growth on maltose. In a final step, the two enriched populations were sporulated and mass-mated, and strains capable of leavening both sweet and unsugared dough were recovered after additional rounds of mass mating and alternating selection for osmotolerance and growth on maltose (Higgins et al., 2001). Mass mating was also used to create new interspecific wine strains by crossing strains of S. cerevisiae and S. bayanus (Sato et al., 2002; Table1).

Conceptually related to mass mating, genome shuffling is one of the most recent techniques to improve complex phenotypes in microorganisms in a fast and relatively easy manner (see Gong et al., 2009). In a heterogeneous population, a cell displaying a specific phenotype might harbor beneficial mutations that differ from those present in another, phenotypically similar cell within this population. By applying repeated rounds of genetic recombination (either by protoplast fusion or by mass mating) and selection to this population, genome shuffling aims to combine many of these different beneficial mutations in the same cell, leading to additive or synergistic effects on the phenotype under study (Santos & Stephanopoulos, 2008).

Compared to other improvement techniques, genome shuffling has the advantage of exploiting the full genetic diversity in a population and makes it possible to combine useful mutations from many different individuals, while other hybridization methods, such as direct mating, typically involve only a limited number of haploid cells (Fig.4). Additionally, while classical methods of strain improvement often only select the best-performing mutant for the next round, genome shuffling exploits a much larger proportion of the diversity present in the population. The first convincing example of genome shuffling showed rapid improvement of tylosin production in the bacterium Streptomyces fradiae (Zhang et al., 2002). While it initially took 20 rounds of mutagenesis and selection to improve the tylosin titer ninefold, the same result was obtained by applying only two rounds of genome shuffling on a mutagenized population of the same starting strain, demonstrating the potential of this technique to take much larger leaps in the fitness landscape, enabling rapid improvement of a phenotype.

Most studies applying genome shuffling to yeast have focused on enhancing the tolerance to an industrially relevant stress factor and overall fermentation performance. To this end, variation is typically induced by mutagenizing a single strain. Mutants are then screened for the phenotype of interest, and cells showing phenotypic improvement are used as a starting population for multiple rounds of genome shuffling. After each round of genome shuffling, the severity of the stress is (usually) increased. In this way, both laboratory and industrial strains of S. cerevisiae have been improved for phenotypes such as ethanol tolerance, thermotolerance, acetic acid tolerance, and fermentation performance (Table2). Some recent studies also combine metabolic engineering with genome shuffling (Wang & Hou, 2010; Jingping et al., 2012; Tao et al., 2012; Wang et al., 2012a; Demeke et al., 2013). These approaches are promising to optimize strains for second-generation bioethanol production. Although the production of inferior, so-called crippled strains (cf. infra) is a potential disadvantage of genome shuffling because the prevalence of deleterious alleles may result in a majority of variants that perform better at the task they are selected for, but not other important traits, the first proof-of-principle use of a genome-shuffled S. cerevisiae strain in an industrial fermentation environment was recently published (Zheng et al., 2011a, b).

Table 2.

Studies using genome shuffling for the improvement of industrial yeasts. The phenotypes of interest from the parental strain(s) are indicated. The technique used to generate genetic variation and used for recombination is indicated

| Strain(s) | Phenotype | Technique variation | Recombination technique | Industrial application | Reference |

|---|---|---|---|---|---|

| S. cerevisiae (industrial haploid) | Ethanol tolerance, thermotolerance | UV mutagenesis | Protoplast fusion | Biofuel | Shi et al. (2009) |

| S. cerevisiae (laboratory diploid) | Ethanol tolerance | EMS mutagenesis | Mass mating | Biofuel | Hou (2009) |

| S. cerevisiae (industrial diploid) | VHG fermentation capacity | EMS mutagenesis | Mass mating | Biofuel/beer | Hou (2010) |

| S. cerevisiae (industrial diploid ale) | Wort and ethanol tolerance | EMS and UV mutagenesis | Mass mating | Beer | Wang & Hou (2010) |

| S. cerevisiae (industrial diploid biofuel) | Acetic acid tolerance | UV mutagenesis | Mass mating | Biofuel | Zheng et al. (2011a) |

| S. cerevisiae (industrial strains) | Multistress tolerance | Use of two strains | Mass mating | Biofuel | Zheng et al. (2011b) |

| S. cerevisiae (laboratory diploid) | VHG fermentation capacity | EMS mutagenesis | Mass mating | Biofuel/beer | Liu et al. (2011) |

| S. cerevisiae (industrial haploid strains) | Spent sulfite liquor tolerance | UV mutagenesis | Mass mating | Biofuel | Pinel et al. (2011) |

| S. cerevisiae (diploid soil isolate + GMO) | Ethanol production | Use of multiple strains | Protoplast fusion | Biofuel | Jingping et al. (2012) |

| S. cerevisiae (industrial strain) | Heat, acetic acid, and furfural tolerance | DES mutagenesis | Protoplast fusion | Biofuel | Lu et al. (2012) |

| S. cerevisiae (industrial strain) | VHG fermentation capacity | GMO strain | Mass mating | Biofuel | Tao et al. (2012) |

| S. cerevisiae (industrial strain) | VHG fermentation capacity | GMO strain and EMS/UV mutagenesis | Mass mating | Biofuel | Wang et al. (2012a) |

| S. cerevisiae (industrial near triploid) | VHG fermentation capacity | MCB mutagenesis | Mass mating | Biofuel | Zheng et al. (2013a) |

| S. cerevisiae (industrial near triploid) | VHG fermentation capacity and dessication tolerance | MCB mutagenesis | Mass mating | Biofuel | Zheng et al. (2013b) |

| S. cerevisiae (industrial strain) | Xylose fermentation | GMO strain and EMS mutagenesis | Mass mating | Biofuel | Demeke et al. (2013) |

| Z. rouxii (wild-type strain) | Salt tolerance | EMS mutagenesis | Protoplast fusion | Soy sauce | Cao et al. (2009) |

| H. anomala (wild-type strain) | Salt tolerance | EMS and UV mutagenesis | Protoplast fusion | Soy sauce | Cao et al. (2012) |

| Sc. stipitis (wild-type strain) | Spent sulfite liquor tolerance | UV mutagenesis | Mass mating | Biofuel | Bajwa et al. (2010) |

| C. krusei | Acetic acid tolerance | UV mutagenesis | Protoplast fusion | Biofuel | Wei et al. (2008) |

C. krusei, Candida krusei; H. anomala, Hansenula anomala; S. cerevisiae, Saccharomyces cerevisiae; Sc. stipitis, Scheffersomyces stipitis; Z. rouxii, Zygosaccharomyces rouxii; DES, diethylsulfate; EMS, ethyl methane sulfonate; GMO, genetically modified organism; UV, ultraviolet; MCB, methyl benzimidazole-2-yl-carbamate; VHG, very high gravity.

Genome shuffling has been applied to non-Saccharomyces yeasts as well. In high-salt soy sauce fermentations, salt-tolerant yeast strains are added for improved flavor. Cao et al. (2009) enhanced salt stress resistance and flavor formation of Zygosaccharomyces rouxii using three rounds of genome shuffling. In a similar approach, Cao et al. (2012) could increase the salt stress tolerance and soy sauce fermentation performance of Hansenula anomala. Bajwa et al. (2010) exploited the sexual cycle of the pentose-fermenting yeast Sc. stipitis to improve its tolerance to hardwood spent sulfite liquor. Lastly, the acetic acid tolerance of Candida krusei was improved using a protoplast fusion-based genome shuffling strategy (Wei et al., 2008).

Protoplast fusion

Although the rationale for protoplast fusion (often referred to as spheroplast fusion) is very similar to sexual hybridization (they both strive to combine positive traits of multiple parents in one hybrid strain), this technique can be used for strains that do not meet the requirements for sexual hybridization. This means that this technique is useful for strains that cannot sporulate, yield inviable spores, show unstable mating type or for strains that are incapable to mate with each other (Pretorius, 2000; Attfield & Bell, 2003), see also Fig.4. In this way, interspecific or even intergeneric crosses can be obtained. Because meiosis is not required, protoplast fusion can also be used to increase the ploidy of strains, which in some cases can increase cell productivity (Attfield & Bell, 2003).

In practice, protoplast fusion generally consists of three major steps: yeast cell wall degradation (generation of protoplasts), induction of hybridization, and cell wall regeneration. After hybridization, the parental nuclei temporarily coexist within a shared cytoplasm before (potentially) proceeding to karyogamy (Kavanagh & Whittaker, 1996). The success rate of the hybrid formation mainly depends on the taxonomic proximity of the strains and applied fusion protocol (Peberdy, 1980; Pina et al., 1986; Kavanagh & Whittaker, 1996; Attfield & Bell, 2003). Intraspecific fusion frequencies usually vary from 10−3 to 10−4, while for intergeneric fusions, it can be as low as 10−6 to 10−7 (Pina et al., 1986; Urano et al., 1993). Consequently, development of an optimal hybrid selection procedure is a crucial step in order to maximize the chance of achieving the desired genetic combination (further discussed in ‘Selection of outcrossed hybrids’).

An important disadvantage of using protoplast fusion as a strain improvement strategy is that many of the hybrids are mitotically unstable and chromosomal loss (resulting in aneuploidy) or dissociation into the parental strains often occurs (Pina et al., 1986; Attfield & Bell, 2003). Distantly related species are more prone to show this effect than closely related species (Morgan, 1983). Generally, protoplast fusion experiments result in hybrids containing the full genome of one parent, with a (few) extra chromosome(s) of the second parent (Yamazaki & Nonomura, 1994; Kavanagh & Whittaker, 1996). As a consequence, the phenotype and genotype of the resulting fused strain are very difficult to predict. The ratio at which both genomes are present in the hybrid might be a result of the fusion protocol employed, or the selection procedure used to isolate the hybrids (Kavanagh & Whittaker, 1996). Additionally, strains obtained by protoplast fusion are in some regions considered GMOs.

Although protoplast fusion is sometimes used in biotechnology to increase productivity of a strain by increasing the ploidy, it is mostly applied to combine characteristics from two parental strains. These parental strains can be from the same species, but often a Saccharomyces strain is combined with a nonconventional yeast displaying a specific trait, such as lactose utilization (Taya et al., 1984; Farahnak et al., 1986; Krishnamoorthy et al., 2010; Guo et al., 2012), temperature tolerance (Sakanaka et al., 1996), osmotolerance (Spencer et al., 1985; Loray et al., 1995; Lucca et al., 2002), starch degradation (Kishida et al., 1996), killer activity (Gunge & Sakaguchi, 1981), malic acid degradation (Carrau et al., 1994), or (hemi)cellulose hydrolysate utilization (Pina et al., 1986; Heluane et al., 1993; Table1).

Interestingly, protoplast fusion rarely yields nuclear hybrids (Chambers et al., 2009). While most research addressing protoplast fusion focuses on traits embedded in the genomic DNA, mitochondrial transfer without karyogamy occurs at a much higher frequency. Much like the strains resulting from cytoduction experiments (cf. infra), ‘cybrids’ can be defined as fusion products in which the cytoplasmic contents of the fusing protoplasts merge, without the concomitant fusion of, or exchange of genetic information between, the nuclei (Kavanagh & Whittaker, 1996). This phenomenon has been successfully used for the transfer of cytoplasmically inherited traits like the killer phenotype (Seki et al., 1985), respiratory competence (Richard et al., 1987; Kavanagh & Whittaker, 1996), or resistance to oligomycin (Matsuoka et al., 1982).

Cytoduction

Some factors underlying industrially relevant phenotypes are not embedded in the nuclear DNA, but are located in the mitochondrial DNA (e.g. several respiration-related genes) or present in the cytoplasm (e.g. killer plasmids). To selectively transfer these non-Mendelian traits from a donor to a recipient strain without disrupting the nuclear integrity of the recipient strain, a technique called cytoduction can be applied (Pretorius, 2000).

In cytoduction procedures, the donor strain (which contains the cytoplasmically transferable factor) carries a dysfunctional KAR1 gene. A kar1 mutant is defective in karyogamy (=nuclear fusion) after hybridization (Conde & Fink, 1976; Georgieva & Rothstein, 2002). As a consequence, through mating or protoplast fusion of donor and recipient strain, a zygote-like transient heterokaryon is formed which by subsequent mitotic divisions can bud off haploid heteroplasmons, containing only one genome but mixed cytoplasmic factors (Conde & Fink, 1976; Fig.4). These heteroplasmons, which still contain the full, undisrupted genome of the recipient strain but are supplemented with the (desired) cytoplasmic factors of the donor strain, have the desired combined phenotype. Occasionally, one or a few chromosomes of the second parent are transferred to the other nucleus, a process called ‘single-chromosome transfer’ (Nilsson-Tillgren et al., 1980; Dutcher, 1981). This results in ‘exceptional’ cytoductants that are sometimes used to examine individual chromosomes of industrial yeast strains in detail, for example chromosome III of lager yeasts (Nilsson-Tillgren et al., 1981; Kielland-Brandt et al., 1995).

Cytoduction is frequently used to obtain industrial strains with a positive killer phenotype, a trait encoded by a dsRNA virus-like particle (Ouchi et al., 1979; Young, 1983; Hammond & Eckersley, 1984; Seki et al., 1985; Yoshiuchi et al., 2000). Alternatively, it can be used to transfer flocculation characteristics (Barre et al., 1993), factors influencing carbon source utilization (Spencer et al., 1992) or yeast artificial chromosomes (YACs; Spencer et al., 1994). Cytoduction is also applied in fundamental research when studying amyloids (e.g. prions) in yeast (Saifitdinova et al., 2010; Wickner et al., 2012).

It is important to note that development of kar1 mutants does require genetic modification, which could hamper the use of this technique for industrial applications.

Mutagenesis

The in vivo induction of random mutations by chemical or physical mutagens and subsequent selection of phenotypically improved cells is one of the most widely used techniques to generate optimized microorganisms. One of the most impressive examples is the enormous increase, estimated to be more than three orders of magnitude, in penicillin production by Penicillium chrysogenum, which was achieved over a period of 60 years using multiple mutagenesis procedures (Demain, 2010). Over the last decades, mutagenesis has been applied to improve both monogenic and polygenic traits in a wide range of microorganisms (Giudici et al., 2005). Strain improvement using mutagens consists of two key steps: mutagenesis and screening. The screening is very similar to the screening procedures used in other procedures and will therefore be discussed in a separate paragraph (see section on ‘Selection of phenotypically improved cells’).

A typical mutagenesis experiment consists of overnight growth of the strain under study followed by the actual mutagenic treatment and a recovery step. Both the type of mutagen (different mutagens induce different types of mutations, see Table3) and the dose should be carefully selected or determined (see detailed reviews by Rowlands, 1984; Crook & Alper, 2012). However, it is often hard to predict which type of genetic alteration is required to improve a certain phenotype and hence which mutagen should be used. Therefore, it is advised to change the type of mutagen in a mutagenesis program consisting of multiple rounds, in order to sample as many different types of genetic changes as possible (Rowlands, 1984).

Table 3.

Mutagens often used in mutagenesis programs in yeast. Indicated are the mode of action of the mutagen and the resulting genetic alterations that it can induce. See for more information: Rowlands (1984) & Rubio-Texeira et al. (2010)

| Mutagen | Mode of action | Genetic alterations | |

|---|---|---|---|

| Physical | UV | Mitotic crossing over; mitotic gene conversion; pyrimidine dimers; hydroxylated bases; cross-linking DNA strands; reverse mutations | Frameshift mutations, base pair substitutions, transversions |

| Ionizing radiation | Single- and double-strand breaks in DNA; deamination and dehydroxylated bases | Point mutations | |

| Chemical | EMS | Alkylation | GC-AT transitions |

| MNNG | Alkylation, acts close to replication points | Transitions, transversions; clustered mutations |

EMS, ethyl methanesulfonate; MNNG, methylnitronitrosoguanidine; UV, ultraviolet.

As important as the type of mutagen is the mutagenic dose and exposure time. In general, a very low dose will yield a low proportion of mutants, making improved mutants hard to identify. Moreover, most mutants may only carry one or a few mutations, which reduces the chance to find improvements for which combinations of different mutations are needed. On the other hand, a high dose generates mutants that carry multiple mutations, of which many may be deleterious, leading to a large fraction of inferior or even unviable cells. Consequently, the optimal dose is the one that gives the largest proportion of beneficial mutants out of all cells that manage to survive; something which largely depends on the nature of the phenotype. Simple phenotypes that depend on one or a few mutations, like auxotrophy, typically show a monotonic dose–response curve, meaning that the fraction of desired mutants per survivor increases with increasing dose and reaches saturation at some point, after which the number of superior mutants may decline again because of the increasing proportion of individuals with deleterious mutations (Crook & Alper, 2012). For complex phenotypes, like the production of a compound/metabolite in a high concentration, that are influenced by many different genes, the ideal dose and the dose–response curve are harder to predict. Although a high dose will usually lead to fast phenotypic improvement, researchers usually prefer to use a low dosage. In this way, they avoid the accumulation of deleterious mutations and only increase the mutation rate when low killing rates do not yield improved mutants (Rowlands, 1983).

In both the wine and brewing industry, early studies applied random mutagenesis to generate mutants with improved industrial characteristics. In wine strain improvement, mutagenesis is often used to purge undesired monogenic traits (Giudici et al., 2005). Industrial yeast strains are (at least) diploid, implying that only dominant mutations can alter the phenotype directly. Therefore, haploid derivatives are preferred for mutagenesis programs (Pretorius, 2000). However, these yeasts are often homothallic, so no stable haploid cell cultures can be maintained for these strains. To circumvent this issue, mutagenesis can be applied to spores (instead of vegetative haploid cells) derived from such homothallic strains (Romano et al., 1983; Rous et al., 1983). After autodiploidization, these recessive mutations become homozygous and potentially influence the phenotype. However, it is not essential to use haploid strains or spores in a mutagenesis program. Mutagenesis of polyploid brewing yeasts yielded strains producing lower amount of the off-flavors diacetyl and H2S (Molzahn, 1977). In a recent study, the commercial diploid wine strain PDM was mutagenized directly using EMS, and mutants with reduced H2S production were obtained (Cordente et al., 2009). Also, sake strains in their natural ploidy were successfully mutagenized to obtain auxotrophic mutants (Hashimoto et al., 2005), which can be of great value in breeding and metabolic engineering strategies (Crook & Alper, 2012). Auxotrophic mutants were also developed by applying EMS mutagenesis to a haploid derivative of a commercial wine strain, in order to decrease higher alcohol production (Rous et al., 1983). Mobini-Dehkordi et al. (2008) used EMS mutagenesis to develop mutants with increased ethanol production. In a different study, EMS was used to develop mutants with increased dough fermentation capacity (Angelov et al., 1996).

Mutagenesis approaches are not limited to Saccharomyces yeasts. For instance, EMS mutagenesis has been used to increase astaxanthin production in Xanthophyllomyces dendrorhous (Phaffia rhodozyma; Brehm-Stecher & Johnson, 2012). Recently, EMS mutagenesis was successfully applied to improve the secretion of a heterologous protein in Ashbya gossypii (Ribeiro et al., 2013). Induced mutants of Sc. stipitis for improved lignocellulose fermentation were generated in various studies (Watanabe et al., 2010; Hughes et al., 2011), whereas multiple rounds of mutagenesis boosted the ethanol production of Kluyveromyces marxianus (Pang et al., 2010).

In recent studies, mutagenesis is often the first step to generate genetic variation in a population, after which genome shuffling of the best-performing mutants is applied to combine multiple beneficial mutations in the same cell, or the mutant population is subjected to directed evolution (cf. infra). Alternatively, strains obtained by genetic modification or breeding can also be further improved using random mutagenesis. For instance, Kumari & Pramanik (2012) subjected a hybrid between S. cerevisiae and Pachysolen tannophilus to multiple rounds of mutagenesis in order to increase its tolerance to high temperature, ethanol, and toxic compounds.

Directed evolution

Strain improvement through evolutionary engineering, a term first coined by Butler et al. (1996) and later also often referred to as adaptive, directed, or experimental evolution, relies on the basic principles of (natural and/or induced) genetic variation and subsequent selection acting on this variation. In general, a population of cells is grown under continuous selection for the phenotype of interest for many generations (cell divisions). Over time, random mutants will arise in this population. Directed evolution can also be combined with the use of mutagens and/or sexual hybridization within the evolving population(s) in order to increase the genetic and phenotypic variability that selection can act on. If a specific mutation (or mutations) endows a cell with a fitness advantage, this variant will be selected and enriched for in the population. Because of the short generation time and easy manipulation and cultivation of microorganisms in the laboratory, evolutionary engineering is a feasible route to generate yeast strains with improved phenotypes in a relatively fast fashion (Elena & Lenski, 2003; Buckling et al., 2009).

Different experimental setups can be used for growing cells under the desired selective conditions: batch culture, with serial passaging of cells, or a continuous culture system such as a chemostat or a turbidostat. In a chemostat, cells are kept at physiological steady state, and growth occurs at a constant rate. This constant growth rate is maintained by the continuous influx of a growth-limiting substrate, setting a fixed dilution rate (Dykhuizen & Hartl, 1983). In a turbidostat, there is continuous feedback between the inflow of the medium and the cell density of an exponentially growing culture, measured through, for example, an optical sensor (Bryson & Szybalski, 1952). In principle, it is also possible to evolve populations directly in the industrial setting where they are to be employed. It is important that the selection conditions match the industrial parameters as closely as possible in order to avoid ‘crippled’ strains that show improvement for the selected trait, but are inferior to the parent for other relevant traits (cf. infra). In fact, in applications where yeasts are continuously used for longer time periods, for example serial repitching of brewer's yeast in beer fermentations (Gibson et al., 2007), these populations are (unintentionally) being subjected to directed evolution, yielding strains with (sometimes positively) adjusted phenotypes. For example, at the end of the beer fermentation process, yeast cells sediment to the bottom of the fermentation tank. It has been shown that re-using cells from specific layers (near the top or bottom) of this pack of sedimented cells can influence the sedimentation behavior (including flocculation) in later fermentation rounds (Powell et al., 2004).

Directed evolution has proven to be a valuable tool to create yeast strains with specific, improved characteristics (Sauer, 2001). Examples of industrially relevant phenotypes improved through this strategy can be found in Table4. Several studies have investigated how yeast cells adapt to specific nutrient limitations, for example glucose, phosphate, or sulfate limitation (Paquin & Adams, 1983a, b; Dunham et al., 2002; Gresham et al., 2008). Because the main focus of these studies was to determine the exact genetic underpinnings of how cells adapt to a specific stress and also how reproducible the adaptation was, this research was performed with standard laboratory yeast strains that have only limited industrial relevance. However, several more applied studies have started from strains commonly used in the wine, beer, biofuel, and baking industry. The phenotypes targeted include resistance to individual stresses, such as high levels of acetate (Aarnio et al., 1991) or ethanol (Brown & Oliver, 1982; Dinh et al., 2008), osmotic stress (Ekberg et al., 2013), and high concentrations of metal ions such as copper (Adamo et al., 2012) and cobalt (Cakar et al., 2009), as well as (improved) utilization of alternative carbon sources such as xylose and arabinose (starting from metabolically engineered strains, see also below; Sonderegger & Sauer, 2003; Wisselink et al., 2009; Scalcinati et al., 2012; Demeke et al., 2013). However, in industrial settings, cells are often faced with a combination of different stresses: during brewing fermentations for example, cells encounter osmotic stress, high levels of ethanol, and nutrient deprivation (Gibson et al., 2007). By performing the selection steps under conditions resembling this harsh environment, researchers have succeeded to isolate multistress-tolerant lager strains with improved fermentation capacity in high-gravity wort (Blieck et al., 2007; Huuskonen et al., 2010). Using long-term batch culturing on gluconate, a carbon source poorly assimilated by S. cerevisiae, Cadière et al. evolved a commercially used wine strain with increased flux through the pentose phosphate pathway (Cadière et al., 2011). Evolved strains showed higher fermentation rates and increased aroma production compared to the parental strain in laboratory-scale fermentations. Interestingly, similar phenotypic improvements were observed when this evolved strain was used in pilot-scale fermentation trials (Cadière et al., 2012). Most evolutionary engineering studies have been performed using the model organism S. cerevisiae, but other yeast species have been subjected to evolutionary engineering as well. Examples include lager strains (S. pastorianus), subjected to sequential selection for tolerance to high ethanol levels and rapid growth at high osmolarity, to obtain strains with enhanced fermentation capacity under industrially used brewing conditions (Ekberg et al., 2013).

Table 4.

Studies using directed evolution for the improvement of industrial yeasts. The targeted phenotype, target species, and technique used to generate variation in the starting population are indicated

| Improved phenotype | Species | Starting population | Reference |

|---|---|---|---|

| Ethanol tolerance | S. uvarum | EMS-mutagenized and nonmutagenized | Brown & Oliver (1982) |

| S. cerevisiae | EMS-mutagenized and nonmutagenized | Dinh et al. (2008) | |

| S. cerevisiae | EMS-mutagenized and nonmutagenized | Stanley et al. (2010) | |

| Acetic acid tolerance | S. cerevisiae | Nonmodified | Aarnio et al. (1991) |

| Thermotolerance | S. cerevisiae | UV and EMS-mutagenized | Balakumar et al. (2001) |

| Copper resistance | S. cerevisiae | Nonmodified | Adamo et al. (2012) |

| C. humilis | Nonmodified | ||

| Cobalt resistance | S. cerevisiae | EMS mutagenized | Cakar et al. (2009) |

| Tolerance to inhibitors in lignocellulosic hydrolysates | S. cerevisiae | Nonmodified | Almario et al. (2013) |

| Freeze tolerance | S. cerevisiae | UV mutagenized | Teunissen et al. (2002) |

| Glycerol production | S. cerevisiae | Nonmodified | Kutyna et al. (2012) |

| Wine fermentation properties | S. cerevisiae | Metabolic engineered and EMS mutagenized | Cadière et al. (2011) |

| Flux through pentose phosphate pathway | S. cerevisiae | Metabolic engineered and EMS mutagenized | Cadière et al. (2011) |

| Fermentation under high-gravity conditions | S. pastorianus | EMS mutagenized | Huuskonen et al. (2010) |

| S. pastorianus | UV mutagenized | Blieck et al. (2007) | |

| Ethanol tolerance, growth, and high osmotic stress | S. pastorianus | EMS mutagenized | Ekberg et al. (2013) |

| Oxidative, freeze–thawing, high temperature, and ethanol stress | S. cerevisiae | EMS mutagenized | Cakar et al. (2005) |

| Utilization of glucose, xylose, and arabinose mix | S. cerevisiae | Metabolic engineered and EMS mutagenized | Wisselink et al. (2009) |

| Anaerobic growth on xylose | S. cerevisiae | Metabolic engineered and EMS mutagenized | Sonderegger & Sauer (2003) |

| Xylose fermentation | S. cerevisiae | Metabolic engineered | Shen et al. (2012) |

| S. cerevisiae | Metabolic engineered, EMS mutagenized, and genome shuffled | Demeke et al. (2013) |

C. humilis, Candida humilis; S. cerevisiae, Saccharomyces cerevisiae; S. pastorianus, Saccharomyces pastorianus; S. uvarum, Saccharomyces uvarum; EMS, ethyl methane sulfonate; UV, ultraviolet.