SUMMARY

Objective.

The project presents a clinical case in which the digital work-flow procedure was applied for a prosthetic rehabilitation in natural teeth and implants.

Materials.

Digital work-flow uses patient’s photo for the aesthetic’s planning, digital smile technology for the simulation of the final restoration and real time scanning to register the two arches. Than the scanning are sent to the laboratory that proceed with CAD-CAM production.

Results.

Digital work-flow offers the opportunities to easily speak with laboratory and patients, gives better clinical results and demonstrated to be a less invasiveness method for the patient.

Conclusion.

Intra-oral scanner, digital smile design, preview using digital wax-up, CAD-CAM production, are new predictable opportunities for prosthetic team. This work-flow, compared with traditional methods, is faster, more precise and predictable.

Keywords: digital smile, digital wax-up, digital scanner, CAD-CAM, digital work-flow

Introduction

Digital work-flow introduce a novel approach for a predictable rehabilitation using patient’s intra and extra oral photo, virtual diagnostic wax-up, intraoral scanner and CAD-CAM production. The first step of a digital work-flow is the virtual diagnostic wax-up build up from the patient’s photos for the aesthetic’s planning using the digital smile’s technology. Digital smile’s method allows a simplified aesthetic diagnosis and makes more effective the communication with patients thanks to the restoration’s preview. Once validated the simulation of the rehabilitation and then validated the preparation, final manufacturing will be create using CAD-CAM technologies. The initial step of the highly precise digital work-flow is an analogue impression (1) so an intra-oral scanner is used to record the two arches. Conventional high precision impression materials offer a well know procedure to transfer the clinical situation into the laboratory (2), however are prone to dimensional changes due to on-going chemical reaction (3) and stone will show expansion due to secondary reaction whilst setting (4). The potential distortion of the impression due to limited suitability for storage, deficient dimensional stability, disinfection in antiseptic solution, partial or extensive separation of the impression material from the tray, transport into the dental laboratory at different climatic conditions and the overall long process chain has to be mentioned (5). Additionally, the choice of the impression technique seems to influence the accuracy of dental impressions, hence the fitting of the resulting restorations (6). Besides, discomfort for the patient like sweating, gagging, pain and partially inconvenient taste is a know issue associated with conventional impression taking. The conventional impression requires many critical steps that can be skipped when using digital impression. This technique can reduce the chair time including the tracks selection, impression, cost setting time, disinfection of the cast and transport to the laboratory (7). This critical steps might be avoided by direct data capturing, which represents a logical direct access to dental CAD-CAM (8). Accurate impressions represent an important prerequisite for precise dental restorations and intraoral digital data capturing seems to be a logical step to prevent the possible errors already at the very beginning of the digital work-flow (9). The accuracy of intra-oral scanner has been determined by several authors (10). This modern technology has progressively been getting more and more attention in the dental field, has it increases the comfort of the patient and minimizes risks of distortions during the impression process (11). Direct acquisitions systems have been constantly improved because this are less invasive, quicker and more precise than the conventional methods (12). Besides the digital image can be easily store for a long time (13). Digital impressions offer benefits to both clinicians and patients. Patients are spared from need for any contact with messy impression material, those with strong gag reflexes may particularly benefit from the digital technology because the scanner do not touch the soft palate. These are used for a briefer interval than impression trays and allows patients to take a break if necessary (14). So the use of intraoral digital scanner has the potential to simplify the task of obtaining impressions (15). After taking the digital impression, clinical can do the web order: scanning are sent, throughout a digital way, to the laboratory. Using the virtual wax-up and the scanning, the laboratory proceeds with computer-aided design/ computer-aided manufacturing (CAD-CAM) production. The application of CAD-CAM restorations provides innovative, state-of-the-art dental service, and its application was increased significantly in the last years. CAD-CAM dentistry utilize a computer design prosthetic structure that will be mechanically milled (CAM). This technology changes from the conventional manual process with higher quality, standardized steps and lower cost. So after the data acquisition, a processing software creates the virtual restoration (virtual mock-up). Once validated the virtual or physical mock-up by the clinical, the laboratory can proceeds with CAM production.

Methods

To present step by step the digital work-flow, a clinical case was chosen that required four implant restoration and four zirconia solidid zir lumnia ez crowns for the replacement of teeth 11-12-21-22, a zirconia solid zir lumnia ez crown for the rehabilitation of 13, and a lithium disilicate veneer for the rehabilitation of 23. The patient is a 55-year-old woman asking for aesthetic improvement of the smile and the closure of the diastema between the maxillary central incisors. At first, a photo of the patient’s smile was taken (Fig. 1). Using the digital smile technology it was possible, from that photo, to obtain a virtual wax-up of the final restoration by making a cutout of the original teeth (Fig. 2). The virtual wax-up offers important advantages to the clinician and to the laboratory and allows an efficient planning of the work. First, it is immediately available and it can be directly used to build up the final dental prosthesis allowing a saving of cost eliminating the manual reproduction of the project by the laboratory. Second, it offers the possibility to the patient to have a personal and extremely realistic view of what would be the resulting smile after rehabilitation. Once the diagnostic project has been accepted by the patient, the insertion of 4 implants in seat 11-12-21-22 and the prosthetic preparation of the 23 and 13 were performed. After four months, a direct digital impression was taken using an intraoral scanner to register the two arches and the right occlusion. To take the impression was used the 3mlavacos intraoral digital scanner and intraoral implant scan bodies, to take the oral scan was also used a powder scan spray to make better the image resolution (Fig. 3). Important to note, it took only 2 minutes without any problems relating to gag’s reflex and it prevents organoleptic’s bothers in the patient. The virtual model (Fig. 4) was sent through a digital way to the laboratory, which proceeded with the CADCAM production. The virtual modeling was performed using 3shape design’s software. The CAD project (Fig. 5) was developed using the virtual wax-up of the final restoration as a model. After validated the laboratory work, it could be possible to proceed with the CAM modeling and the production of the final prosthesis (Figs. 6 a, b). At the third and last appointment took place the finalization of the prosthetic rehabilitation (Figs. 7, 8 a, b). We delivered the finished prosthetic with no need of retouching as assess with the aid of maps of articulation. The modeling software used for the treatment of this clinical case have allowed to obtain a prosthesis extremely precise in the occlusal relationships with the opposing arch, the marginal fitting and in the reproduction of aesthetics simulated with virtual diagnostic wax-up.

Figure 1.

Intraoral patient’s photo.

Figure 2.

Virtual diagnostic wax-up.

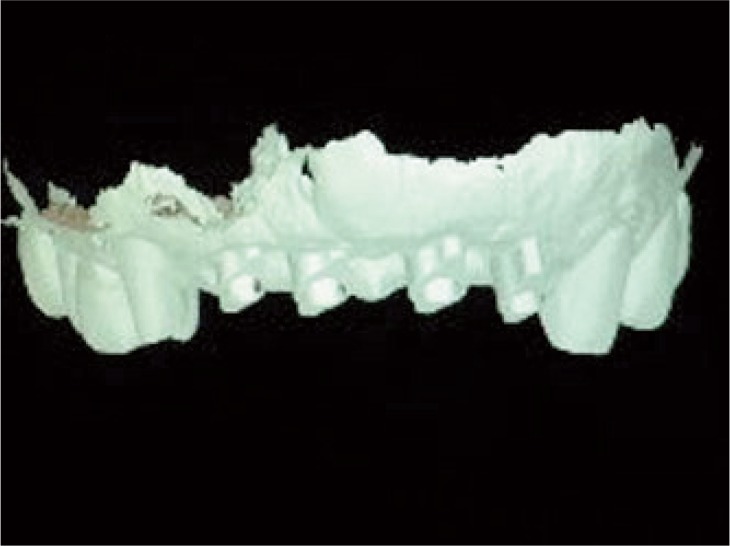

Figure 3.

Digital impression using intraoral implant scan bodies.

Figure 4.

Digital model.

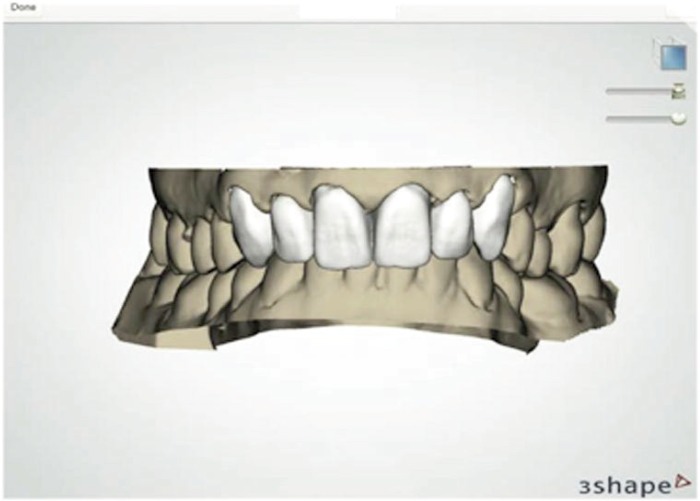

Figure 5.

CAD model.

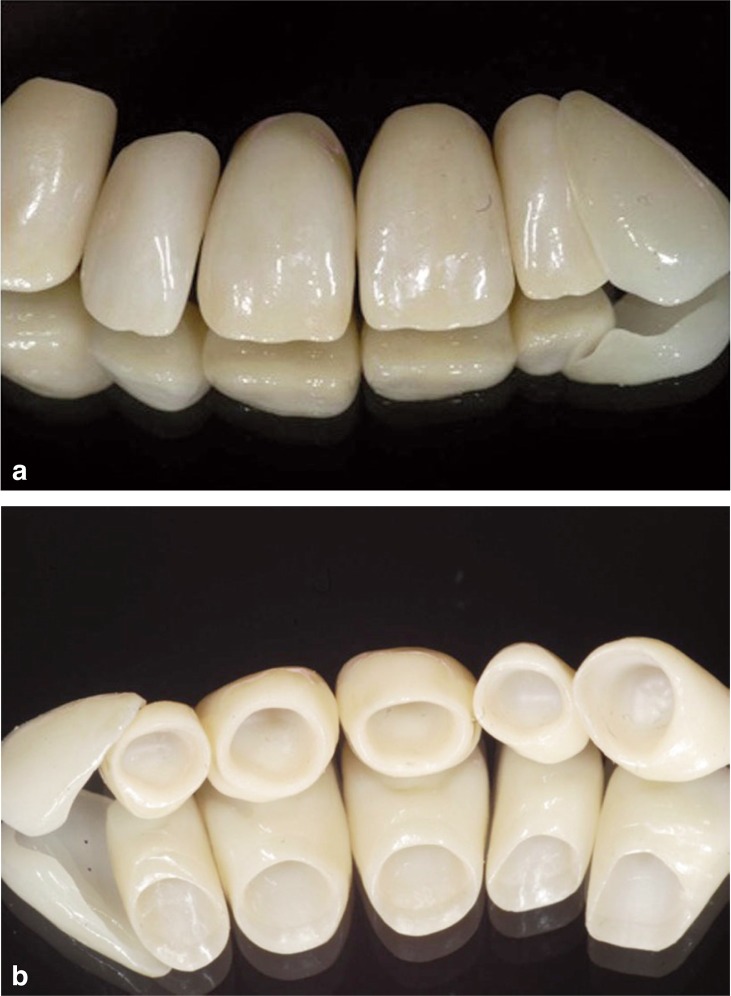

Figure 6 a, b.

CAM prosthesis.

Figure 7.

Definitive rehabilitation: the abutments.

Figure 8 a, b.

Front and lateral view of the final aesthetic.

Results

The digital work-flow, taking advantage of waxup, digital impression, mock-up and CAD-CAM production, facilitates the communication between clinical, patient and laboratory. Diagnostic wax-up are an efficient tool for the prosthetic planning, because they give an immediately preview for the dentist and the patient and because they can also be use directly for the planning of the final restoration. Direct data capturing reduces patient’s discomfort and ensure a better adaptation of the prosthetic by removing disorders associated with gag reflex and issues related to the impression material deformation. CAD-CAM technologies offers the opportunities to visualize three dimensional image of the prosthetic to easily speak with laboratory about clinical cases. More over CAD-CAM enables more rapid production’s times and less production’s cost.

Conclusions

Combining virtual wax-up and digital with CAD-CAM technology enables a dramatic compression of the time required to deliver a final prosthesis. The digital work-flow is a new predictable opportunities for the prosthetic team. Digital work-flow allows a simplify work-flow and a reduction in the number of appointment. In confront of traditional method, the digital work-flow seems to be a more rapid, precise and comfortable solution, with better clinical results.

References

- 1.Güth JF, Keul C, Stimmelmayr M, Beuer F, Edelhoff D. Accuracy of digital models obtained by direct and indirect data capturing. Clin Oral Investig. 2013 May;17(4):1201–8. doi: 10.1007/s00784-012-0795-0. Epub 2012 Jul 31. [DOI] [PubMed] [Google Scholar]

- 2.Rubel BS. Impression materials: a comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am. 2007 Jul;51(3):629–42. vi. doi: 10.1016/j.cden.2007.03.006. Review. [DOI] [PubMed] [Google Scholar]

- 3.Johnson GH, Craig RG. Accuracy of four types of rubber impression materials compared with time of pour and a repeat pour of models. J Prosthet Dent. 1985 Apr;53(4):484–90. doi: 10.1016/0022-3913(85)90630-4. [DOI] [PubMed] [Google Scholar]

- 4.Millstein PL. Determining the accuracy of gypsum casts made from type IV dental stone. Source J Oral Rehabil. 1992 May;19(3):239–43. doi: 10.1111/j.1365-2842.1992.tb01098.x. Department of Biomaterials, Boston University, Goldman School of Graduate Dentistry, Massachusetts 02118. [DOI] [PubMed] [Google Scholar]

- 5.Christensen GJ. The challenge to conventional impressions. J Am Dent Assoc. 2008 Mar;139(3):347–9. doi: 10.14219/jada.archive.2008.0165. No abstract available. [DOI] [PubMed] [Google Scholar]

- 6.Al-Bakri IA, Hussey D, Al-Omari WM. The dimensional accuracy of four impression techniques with the use of addition silicone impression materials. J Clin Dent. 2007;18(2):29–33. [PubMed] [Google Scholar]

- 7.Glassman S. Digital impressions for the fabrication of aesthetic ceramic restorations: a case report. Pract Proced Aesthet Dent. 2009 Jan-Feb;21(1):60–4. [PubMed] [Google Scholar]

- 8.Luthardt RG, Loos R, Quaas S. Accuracy of intraoral data acquisition in comparison to the conventional impression. [Article in English, German] Int J Comput Dent. 2005 Oct;8(4):283–94. [PubMed] [Google Scholar]

- 9.Mehl A, Ender A, Mörmann W, Attin T. Accuracy testing of a new intraoral 3D camera. [Article in English, German] Int J Comput Dent. 2009;12(1):11–28. [PubMed] [Google Scholar]

- 10.Ender A, Mehl A. Full arch scans: conventional versus digital impressions—an in-vitro study. [Article in English, German] Int J Comput Dent. 2011;14(1):11–21. [PubMed] [Google Scholar]

- 11.Galhano GÁ, Pellizzer EP, Mazaro JV. Optical impression systems for CAD-CAM restorations. J Craniofac Surg. 2012 Nov;23(6):e575–9. doi: 10.1097/SCS.0b013e31826b8043.. [DOI] [PubMed] [Google Scholar]

- 12.Birnbaum NS, Aaronson HB. Dental impressions using 3D digital scanners: virtual becomes reality. Compend Contin Educ Dent. 2008 Oct;29(8):494–496. 498–505. [PubMed] [Google Scholar]

- 13.Ramsey CD, Ritter RG. Utilization of digital technologies for fabrication of definitive implant-supported restorations. J Esthet Restor Dent. 2012 Oct;24(5):299–308. doi: 10.1111/j.1708-8240.201100481.x. Epub 2011 Oct 25. [DOI] [PubMed] [Google Scholar]

- 14.Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009 Jan;28(1):44–56. doi: 10.4012/dmj.28.44. Review. [DOI] [PubMed] [Google Scholar]

- 15.Bottino Marco Antonio, Valandro Luiz Felipe, Faria Renata, Scotti R, Caldari M, Galhano G, et al., editors. Percepcao-estetica em pròteses livres de metal em dentes naturais e implantes. Vol. 1. Sao Paulo: Artes Medicas; 2008. Sistemas Cam e CAD-CAM em protese odontologica; pp. 543–632. [Google Scholar]